UBS Axcera 840A User Manual

10-kW UHF Transmitter with Chapter 5, Detailed Alignment Procedures

Feedforward Drive

Chapter 5

Detaile d Alignment Procedures

This transmitter was aligned at the

factory and should not require additional

alignments to achieve normal operation.

Before beginning the alignment

procedures, check that the RF output at

J2 of (A18) the output coupler assembly

of the transmitter is terminated into a

dummy load or is co nnect ed to the

antenna. While performing a ny

alignments, refer to the Test Data Sheet

for the transmitter and compare the final

readings from the factory with the

readings on each of the trays. They

should be very similar. If a reading is off

by a substantial amount, the problem is

lik e ly t o be in th a t t ra y.

5.1 (A1-A4) UHF Exciter Tray

(1063301; Appendix A)

If the (o p tional) 4. 5-MHz com p o s ite in p u t

kit has been purchased, the UHF exciter

tray is capable of operating using either

the 4.5-MH z comp os ite input or the

baseband audio and video inputs. The kit

adds (A24) the composite 4.5-MHz filter

board and (A25) the 4.5-MHz bandpass

filter board to the UHF exciter. The 4.5

MHz generated by the aural IF

synthesizer board is not used when the

4.5-MHz composite input kit has selected

the 4.5-MHz intercarrier signal generated

by the 4.5-MHz composite input. The

composite 4.5-MHz filter board and the

4.5-MHz bandpass filter board are not

used when the 4.5-MHz composite input

kit uses the 4.5-MHz intercarrier signal

generated by the baseband video and

audio inputs with baseband select.

The exciter tray has been factory tuned

and should not need to be aligned to

achieve normal operation. To align the

UHF exciter for 4.5-MHz composite input,

apply the 4.5-MHz composite input, with

the test signals used as needed, to video

input jack J1 on the rear of the tray.

Select the 4.5-MHz composite input by

removing the baseband select from J7-6

and J7- 7 on the rea r of the tray, if

applied.

To align the UHF exciter using baseband

video and audio inputs, connect the

baseband video, with the test signals

used as needed, to video input jack J2 on

the remote interface panel. For balanced

audio input, connect the baseband audio

to TB1-1(+), TB1-2(-), and TB1-3 (GND)

on the remote inte rface panel. Fo r

composite/stereo audio, connect the

stereo source to J6 on the remote

interface panel.

5.1.1 (A6) (Optional) Delay Equalizer

Board (1227-1204; Appendix B)

This board has been factory tuned and

should not be retuned without the proper

equipme nt. If it is neces sar y to tune the

board:

1. Select a sinX/X test signal as the

video source to the delay equalizer

board.

2. Monitor the video output of the

board at video sample jack J2 with

a video meas uring set (VM700) that

has been adjusted to meas ure

group delay.

3. Tune the four stages of the board

using the variable inductors (L1-L4)

and potentiometers (R7, R12, R17,

and R22) unti l the signa l attai ns the

FCC group delay curve. The stages

are arranged in order of increasing

frequency. Adjust R29 as needed to

attain the same level coming out of

the board as is going into the

board.

840A, Rev. 0 5-1

10-kW UHF Transmitter with Chapter 5, Detailed Alignment Procedures

Feedforward Drive

5.1.2 (A24) (Optional) Composite

4.5-MHz Filter Board (1227-1244;

Appendix B)

The (A24 ) (optional) composite 4.5-MHz

filter board will only function properly

with a 4.5-MHz composite input signal

and with the 4.5-MHz composite input

selected.

Connect the test signal from an envelope

delay measurement set to the video

input of the tray at J1 or J2.

Connect an oscilloscope to jack J7, video

out, between the J7 center pin and pin 1

or 3 ground. Adjust C 21, frequency

response, if needed, for the best

frequency response. Adjust R32, v ideo

gain, for a signal level of 1 Vpk-pk on the

oscilloscope.

The output at J6 and J7 of the board

should be video only with no 4.5-MHz

aural subcarrier.

5.1.4 (A7) IF Carrier Oscillator Board

(1191-1404; Appendix B)

To align (A7) the IF carrier oscillator

board:

1. While monitoring J3 with a

spectrum analyzer, observe the

45.75-MHz visual IF (typical +5

dBm).

2. Connect a frequency counter to J3

and adjust C17 for 45.750000 MHz.

3. Connect a frequency counter to J1

and check for 50 kHz; th is is the

aur al p h as e lo c k lo op (P LL)

reference.

5.1.5 (A5) Sync Tip Clamp/

Modul ator Board (1265-1302;

Appendix B)

To align (A5) the sync tip clamp/

modulator board:

5.1.3 (A25) (Optional) 4.5-MHz

Bandpass Filter Board (1265-1307;

Appendix B)

The (A25) (optional) 4.5-MHz bandpass

filter board will only function properly

with a 4.5-MHz composite input signal

and with the 4.5-MHz composite input

selected.

Adjust the filter with L2, C3, L4, and C7

for a frequency resp onse of no greater

than ±.3 dB from 4.4 to 4.6 MHz.

Adjust C19 for an overall peak-to-peak

variation of less t han ±.3 dB from 4.4

MHz to 4.6 MHz.

Recheck the frequency response; it may

have changed with the adjustment of the

envelope delay. If necessary, retune the

board.

1. Determine if jumper W4 on jack J3

is present. Jumper W4 terminates

the video input into 75Ω. Remove

jumper W4 if the video loopthrough is required on the rear

chassis at jacks J1 and J2.

2. Se t the controls R20, the white clip,

R24, the sync clip, and R45, the

sync stretch cut-in, to their fully

counter-clockwise (CCW) position.

Set R48, the sync magnitude, fully

clockwise (CW).

3. Place the jumper W7 on jack J4 to

the clamp off, disable, position.

4. Connect a 5-step staircase video

test signal to the input of the

transmitter.

5. Monitor TP2 with an oscilloscope.

Adjust R12, the video gain pot, for

1 Vpk-pk.

840A, Rev. 0 5-2

6. Change the video input test signal

to a multib urst test pattern. While

10-kW UHF Transmitter with Chapter 5, Detailed Alignment Procedures

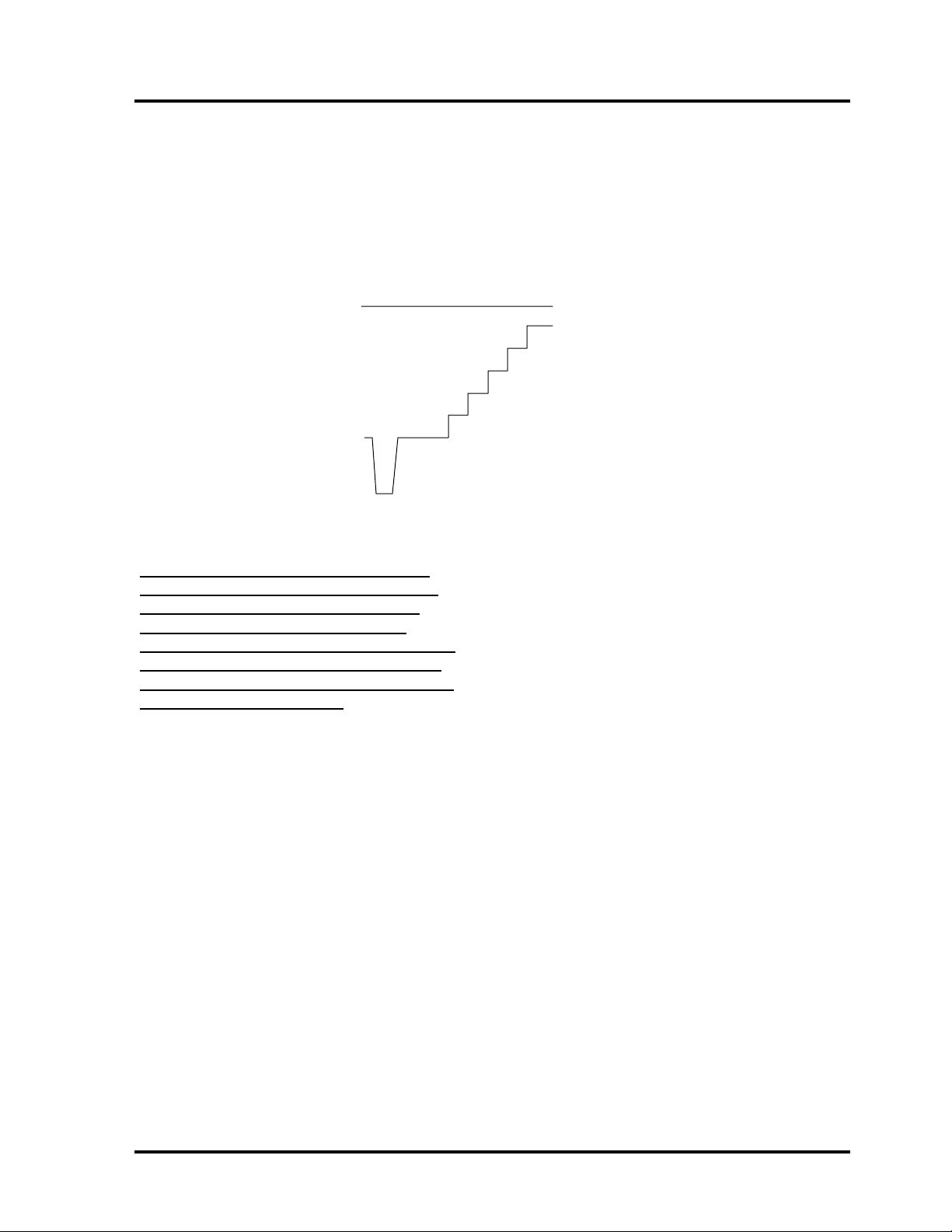

0 Volt

Feedforward Drive

monitoring TP2, adjust C8 and R32

for a flat-f req u e nc y res p onse.

Change the input video test signal

back to the 5-step staircase.

7. Monitor TP2 with an oscilloscope.

Adjust the pot R41, manual offset,

Figure 5-1. Waveform at TP2.

Note: The waveform in Figure 5-1

repres ent s the theoretical level for

proper modulation depth. Step 9

below describes how to set the

modulation d epth through the use of

a television demodulator or a zerospanned sp ectrum analyzer t uned to

the vis ual IF frequenc y .

8. The following test setup is for the

adjustment of the depth of

modulation and ICPM at IF:

A. Remove the cable that is now

on J18. Connect the double

sideband 45.75-MHz visual IF

signal from J18 to a 10-dB

splitter/coupler. Connect the

coupled port of the splitter/

coupler to the RF inp ut of a

television demodulator.

Connect the direct port to a

spectrum analyzer.

B. Connect the 75-Ω video output

of the demodulator to the video

input of a waveform monitor.

For incidental carrier phase

modulation (ICPM)

for a blanking level of -0.8 VDC.

The waveform in Figure 5-1 should

be observed at this point. Move

jumper W2 on J4 to the clamp

enable position. Adjust pot R152,

depth of modulation, for a blanking

level of -0.8 VDC.

s

.1 Volts

measurements, also connect

the q uadrature output of the

demodulator to the horizontal

input of the waveform monitor

using a 250-kHz low-pass filter.

(An oscilloscope can be used in

pla ce of a waveform monitor).

C. Set the controls of the

demodulator as follows:

• Detector Mode: Cont

• Sound Trap: In

• Zero Carrier: On

• Auto: Sync

• Audio Source: Split

• De-Emphasis: In

9. Move jumper W7 on J4 to the clamp

disable position. Readjust pot R41,

manual off set, for the correct depth

of modulation by observing the

demodulated waveform on the

waveform monitor or on the

spectrum analyzer set to zero span.

10. Check the demodulated video for

the proper sync-to-video ratio (sync

is 28.6% of the total white video

840A, Rev. 0 5-3

10-kW UHF Transmitter with Chapter 5, Detailed Alignment Procedures

Feedforward Drive

signal). If sync stretch is needed,

adjust R45, sync stretch cut-in,

until sync stretch occurs. Adjust

R48, sync stretc h magnitude, for

the proper amount of stretch.

Readjust R41, manual offset, if

necessary, for the correct depth of

modulation.

11. Move jumper W7 on J4 to the clamp

enable position. Readjust pot R152,

the depth of modulation, for the

correct depth of modulation.

12. Set the wavefo rm monitor to

display ICPM. Preset R53 fully CCW,

adjust C78 for the greatest effect at

white on the ICPM display, and

adjust R53 for minimum ICPM.

13. Recheck the depth of modulation

and, if necessary, adjust R152,

depth of modulation.

14. Adjust pot R70 for a level of

approximately -10 dBm on the

spectrum analyzer at J18.

15. Remove the video input. Place the

front panel meter in the video

pos ition and, while monitoring the

meter, adjust pot R144, zero

adjust, for a reading of zero.

16. Replace the video inp ut test

signal (the 5-step staircase).

Turn the front panel meter to

the Video position and adjust

R20 on the transmitter control

board for a reading of 100 (10

on the 0-to-10 scale). This

board does not have sync

metering.

17. Reconnect the plug to J18 and

move the spectrum analyzer test

cable to 41.25 IF output jack J16.

Tune C59 and L17-L20 to maximize

the 41.25-MHz aural IF signal and

minimize the out-of-band products.

Adjust pot R97 for -20 dBm at J16.

18. Reconnect the plug to J16 and

move the spectrum analyzer test

cable to IF output jack J20. Preset

R62, the visual IF gain pot, to the

middle. Insert a multiburst test

signal into the transmitter and

observe the visual frequency

response with the spectrum

analyzer set at 1 dB/division. Tune

R63 and C 30, th e IF freq ue nc y

response adjustments, for a flatfrequency response (±0.5 dB).

19. While still monitoring J20 with a

spectrum analyzer, readjust R62,

visual IF gain, for a visual output

level of 0 dBm. Adjust R85, A/V

ratio, for a -10 dB aural-to-visual

ratio or to the needed A/V ratio.

Reconnect the plug to J20.

20.

Using an input video test signal (the

5-step staircase) with a 100 IRE

white level, monitor TP2 with an

oscilloscope. Set the control R24,

the sync clip, just below the point

where sync clipping begins to occur.

Also, set R20, the white clip, to the

point just below where the white

video begins to clip.

Note: This procedure should be

performed after the system setup or

if linearity problems occur.

5.1.6 (A26) Diacrode VSBF Bypass

Board (1293-1230; Appendix B)

The (A26) diacrode VSBF bypass board is

used to bypass the clamp board saw filter

when S1 and S2 are in the enable

position. This double sideband signal can

be used to sweep the tube cavity with a

double sideband and no aural present. C2

is us ed to flatten the double sideband

response. S1 and S2 are normally in the

bypass position.

840A, Rev. 0 5-4

10-kW UHF Transmitter with Chapter 5, Detailed Alignment Procedures

Feedforward Drive

5.1.7 (A4) Aural IF Synthesizer

Board, 4.5 MHz (1265-1303,

Appendix B)

1. The test equipment setup f or (A4)

the aural IF synthesizer board, 4.5

MHz, is as follows:

A. Connect a 600-Ω balanced

audio output from an audio

oscillator to the balanced audio

input te rminals of the tray at

TB1-1 (+), TB1-2 (-), a nd TB13 (ground) on the rear chassis.

B. Connect the combined IF

output at J21, the IF sample on

the clamp modulator board, to

the input of a n IF splitter.

Connect one output of the

split ter to the video

demodulator and the other

output to the spectrum

analyze r.

C. Connect a short cable at the

front of the demodulator from

the RF-out jack to the IF-in

jack.

D. Connect a cable from the 600-

Ω audio output jack of the

demodulator to the input of an

audio distortion analyzer.

2. Set the output frequency of the

audio oscillator to 400 Hz and the

output level to +10 dBm.

3. Center the aural carrier on the

spectrum analyzer with the

spectrum analyzer set to the

following:

• Frequency/ Division: 10 kHz

• Resolution Bandwidth: 3 kHz

• Time/Division: 50 msec

• Trig g e r: Fr ee run

B. The green LED DS1 should be

illuminated, indicating a locked

condition. If not, retune L5 for

a locked condition.

4. Adjust R13, balanced audio gain, on

the aural IF synthesizer board for

±25 kHz deviation.

5. Check the distortion on the aural

distortion analyzer (< 0.5%).

6. Disconne ct t he 600-Ω balanced

audio input to the tra y. Conn ect a

75-Ω stereo audio input (400 Hz at

1 Vpk-pk) to composite audio input

jack J3 on the rear of the tray.

Follow the procedure in the stereo

generator instruction manual for

matching the level of the generator

to the exciter. R17 is used to adjust

the composite audio gain.

7. Check the distortion level on the

distortion analyzer (< 0.5%).

5.1.8 (A8) ALC Board (1265-1305;

Appendix B) (Part 1 of 2)

The following details the meaning of each

LED of (A8) the ALC board when it is

illuminated:

• DS1 - Red LED: Indicates that an

ab norm ally lo w IF sign a l le v e l is

present at IF input connector J1

• DS2 - Red LED: Indicates that the

ALC circuit is unable to maintain the

signal level requested by the ALC

reference; this is usually due to

excessive attenuation in the linearity

or the IF phase corrector signal path,

or becaus e the jumper W3 on J6 is in

manual gain

• DS3 - Red LED: Indicates a video loss

fault

A. Adjust L5 for approximately

+3.5 VDC at TP2.

840A, Rev. 0 5-5

• DS4 - Red LED: Indicates that a Mute

command is present (not used in this

configuration)

10-kW UHF Transmitter with Chapter 5, Detailed Alignment Procedures

Feedforward Drive

• DS5 - Green LED: Indicates that the

outpu t from the modulator is selected

as the input to the ALC board

1. To align the ALC board, preset the

following controls in the UHF exciter

tray:

• ALC board – Move jumper W1 on J4

to disable, between pins 2 and 3 (to

disable linearity correctors); move

jumper W3 on J6 to manual, between

pins 2 and 3 (for manual gain

control); adjust R87, the manual gain

pot, to mid-rang e

• IF phase corrector board – Move

jumper W2 on J9 to the phase

correction enable position; move the

jumper W3 on J10 to the amplitude

correction disable position.

2. The combined IF output of the sync

tip clamp modulator board is cabled

to jack J32 of the ALC board.

Remove J32 from the board and

check to see that DS1, Input Fault,

is illuminated. Reconnect J32 and

check to see that DS1 is

extinguished.

3. Jumper W3 on J6 should be in the

manual position; monit or jack J3

with a spectrum analyzer.

into the board should be approximately

the same as the output of the board.

The IF input jack of the IF phase

corrector board is fed from J3, the IF

output jack of (A8) the ALC board.

The IF output jack of the IF phase

corrector board is fed to J7, the IF input

jack of (A8) the ALC board.

5.1.10 (A8) ALC Board, NTSC (12651305; Appendix B) (Part 2 of 2)

Input a multiburst video test signal at the

baseband video input. Connect a

spectrum analyzer to J11. Tune C63 for a

flat-frequency response of ±0.5 dB.

Move the Operate/Standby switch on the

front panel of the transmitter to the

Operate posi tion.

Place jumper W3 on jack J6 in the

Manual mode and adjust R87 for 0.8

volts at TP 4.

Place jumper W3 on J6 in the Auto mode

and adjust the front panel power adjust

control A20 fully CW. If the optional

rem ote power raise/lower kit is present,

adjust switch S1 on the board to

maximum voltage at TP4. Adjust R74,

the range adjust, for 1 volt at TP4.

4. With a multiburst video signal

present, tune C4 for a flatfrequency resp onse of ±0.5 dB.

5. Before proceeding with part 2 of the

ALC board alignment (described in

section 5.1.10), check the IF phase

corrector board to make sure that it

is functioning properly.

5.1.9 (A9) IF Phase Corrector Board

(1227-1250; Appendix B)

Refer to the system alignme nt

procedures at the end of this chapter for

the set up of (A9) the IF phase corrector

board in the exciter tray. The signal level

840A, Rev. 0 5-6

Adjust the front panel power adjust

cont rol (A20) for 0.8 VDC at TP4. If the

optional remote power raise/lower kit is

present, adjust switch S1 on the board to

the mid-range of its travel and then

adjust the front panel Power Adjust

cont rol (A20) for 0.8 VDC at TP4.

Dis connect the plug that is now on J12

(IF ou tput) and monitor the output with a

spectrum analyzer. The output should be

approximately 0 dBm. Adjust R99, if

necessary, to increase the output level. If

a smaller o utput level is needed, move

the jumpers J27 and J28 to pins 2 and 3

and adjust R99 as needed. Reconnect

J12.

10-kW UHF Transmitter with Chapter 5, Detailed Alignment Procedures

Feedforward Drive

Move W2 on J5 to the cutback enable

position. Remove the input video signal

and verify that the output of the

transmitter drops to 25%. Adjust R71,

the cutback level, if necessary. Restore

the video input signal.

Note: This step affects the response

of the entire transmitter. Connect a

video sweep signal to the input of

the tray. Monitor the output of the

system with a spectrum analyzer.

Adjus t C71 with R103 and C72 with

R106, as needed, to flatten the

response. C71 and C72 can b e

adjusted for the frequency of the

correction notch being applied to the

visual response of the tran smitte r.

R103 and R106 are used to adjust

the depth and width of the correction

notch.

Controls R13, R18, and R23, the

magnitude controls, should be set fully

CW. Controls R34, R37, and R40 are the

linearity cut-in adjustments.

5.1.11 (A11) UHF Upconverter Board

(1265-1310; Appendix B)

To alig n (A11) the UHF upconverter

board, place W1 on J10 in the Manual

position. R10 is a gain control that is

adjusted to give an output of

approximately +17 dBm at J5 of the

board with an input of 0 dBm of IF.

5.1.12 (A14-A1) Channel Oscillato r

Board (1145-1201; Appendix B)

The (A14 -A1) channel oscillator board is

mounted in (A14) the channel oscillator

assembly. To align this board:

1. Connect J1, the main output of the

channe l oscillator, to a spectrum

analyzer tuned to the crystal

frequency. Peak the tuning

capacitors C6 and C18 for

maximum output. Tune L2 and L4

for maximum output. The output

level should be about +5 dBm. The

channel oscillator should maintain

an oven temperature of 50° C.

If a sp ectrum analyzer is not

available, connect a digital

voltmeter (DVM) to TP1 on the x8

multiplier board. Tune capacitors C6

and C18 for maximum voltage and

tune L2 and L4 for maximum

voltage output at TP1.

2. Connect J2, the sample output of

the channel oscillator, to a suit able

counter and tune C11, coarse

adjust, to the crystal frequency.

Tune C9 for the fine-frequency

adjustment.

Caution: Do not repeak C6, C18, L2,

or L4. This can change the output

level.

Note: While adjusting C9 an d C11 to

the crystal frequency, the peak

vol t age monitored at TP1 of the x8

multiplier board should not decrease.

If a decr ease does oc cur, there may

be a problem with the crystal.

Contact the ADC Field Service

Department for further instructio ns.

Note: If the channel oscillator in the

channel oscillator assembly is used,

the C9 fine-frequency adjust is not

on the channel oscillator board. It

can be found on the FSK

w/EEPROM board by using R9.

3. Reconnect J1, the main output of

the channel oscillator, to J1, the

input of the x8 multiplier.

5.1.13 (A15-A 1) x8 Multiplier Board

(1227-1002; Appendix B)

The (A15 -A1) x8 multiplier board is

mounted in an x8 multiplier enclosure

assembly. During no rmal operation, the

green LED DS1, which can be seen

through the access hole in the enclosure

assembly, will be lit to indicate that the

LO is present at the output of the x8

multiplier boa r d.

840A, Rev. 0 5-7

10-kW UHF Transmitter with Chapter 5, Detailed Alignment Procedures

Feedforward Drive

Connect a spectrum analyzer to

output jack J2 of the board.

Tune C4, C6, C10, C12, C18, and C20 for

maximum output.

Readjust all of the capacitors to minimize

the seventh and the ninth harmonics of

the channel oscillator frequency. They

should be at least -30 dB down without

affecting the x8 multiplier output.

If a spectrum analyzer is not available, a

DC voltmeter can be used. When a

voltmeter is used, the harmonic

frequencies must be minimized to

prevent interference with other channels.

While monitoring each test point with a

DC voltmeter, maximize each test point

by tuning the broadband multipliers in

the following sequence:

• Monitor TP1 with a DVM and tune C4

for maximum (typical 0.6 VDC).

• Monitor TP2 and tune C6 and C10 for

maximum (typical 1.2 VDC).

• Monitor TP3 and tune C12 and C18

for maximum (typical 2.0 VDC).

• Monitor TP4 and tune C20 for

maximum.

• Repeak C12 and C10 while

monitoring TP4 (typical 3.5 VDC).

• The typical output level is +15 dBm.

5.1.14 (A19) Visual/Aural Metering

Board (1265-1309; Appendix B)

5.1.15 (A3) +12 VDC (4A)/-12 VDC

(1A) Power Supply Board (12651312; Appendix B)

There are no adjustments that need to

be made to (A3) the +12 VDC (4A)/-12

VDC (1A) power supply board. DS1 will

be lit if a +12 VDC output is c onnected to

J6. DS2 will be lit if a +12 VDC output is

connected to J3. DS3 will be lit if a +12

VDC output is connected to J4. DS4 will

be lit if a +12 VDC output is c onnected to

J5. DS5 will be lit if a -12 VDC output is

connected to J7 and J8.

5.1.16 Transmitter Control Board

(1293-1221; Appendix B)

To align the VSWR cutback, adjust the 3watt amplifier tray for a 12.5% Visual

Power reading on the metering control

panel. Reverse the J6 and J3 cables on

(A2-A2) the coupler on the output of the

diacrode cavity. Adjust R22 unto the

VSWR light sta rts to ill umi nate on the

exciter front panel. Place the J3 and J6

cables back in their original positions.

To align the video metering, insert a

composite or some other 100-IRE test

signal into the exciter tray. Adjust R20

for a full-scale reading (1 volt) on the

bottom scale of the front panel meter of

the exciter tray in the video metering

position.

To align the audio meter ing, adjust the

audio input level for a ±25 kHz deviation

using a spectrum analyzer. Adjust R19 on

the board for a 25-kHz reading on the

bottom scale of the front panel meter of

the excite r tray.

The (A19) visual/aural metering board is

adjusted to give a peak-detected output

indication to the front panel meter for the

visual output and aural output of the

driver cabinet. The board should not

need to be adjusted to achieve normal

operation.

840A, Rev. 0 5-8

This completes the detailed alignment

procedures for the UHF exciter tray.

10-kW UHF Transmitter with Chapter 5, Detailed Alignment Procedures

Feedforward Drive

5.2 (A9) 3-Watt Amplifier Tray

(1068203; Appendix A)

The 3-watt amplif ier tray has been

aligned at the factory and should not

require any further adjustments. If an

alignment is nece ssary, terminate the 3 watt tray into a dummy load before

performing any adjustments.

5.2.1 (A1) UHF Filter (1007-1101;

Appendix B)

The (A1) UHF filter (1007-1101) has

been factory swept and should not be

tuned without the proper equipment. The

filtered output is sent to (A2) the AGC

board input jack J1.

5.2.2 (A2) AGC Board (1007-1201;

Appendix B)

Perform the following steps to align (A2)

the AGC board (1007-1201):

1. With S1 on the AGC board in the

Manual position, adjust R32 for about

a -2 dBm output at J2.

2. The RF output of the AGC board is fed

to (A27) the UHF phase shifter board

input jack J1.

5.2.4 (A3) UHF Amplifier/Regulato r

Board (1007-1204; Appendix B)

The (A3) UHF amplifier/regulator board

(10 07- 12 04) ha s no tun i ng ad just ments

and has a gain of about +17 dB. The

outpu t is fed to (A5) the 3-watt amplifi er

board #1 input jack J1.

5.2.5 (A5) 3-Watt Amplifier # 1

(1007-1211; Appendix B)

The (A5) 3-watt amplifier #1 (1007-

1211) has a gain of about 9 dB and is

tuned with C2, C4, and C8 for maximum

output.

The operating current, static current with

no drive applied, of the amplifier is set to

800 milliamps with R7 on (A6) the optobias board. The current is determined by

measuring the voltage drop across R3,

the 3.3-ohm resistor in the collector

circuit of Q1 on the amplifier board, and

adjusting R7 for a voltage drop of 2.64

volts.

The RF output is fed to (A7) the 3-watt

amplifier board #2.

5.2.6 (A7) 3-Watt Amplifier # 2

(1007-1211; Appendix B)

5.2.3 (A27) UHF Phase Shifter Board

(1142-1315; Appendix B)

The (A27) UHF phase shifter board

(1142-1315) adjusts the phase of the

signal to produce the maximum output of

the transmitter when the two parallel

amplifiers are added together.

Adjust R7 on the front panel of the tray

for maximum output power. Monitor the

com bined % Output power on the front

panel meter of the transmitter.

The phase-corrected RF output is fed to

(A3) the UHF amplifier/regulator board

input jack J1.

840A, Rev. 0 5-9

The (A7) 3-watt amplifier #2 (1007-

1211) has a gain of about 9 dB and is

tuned with C2, C4, and C8 for maximum

output.

The op erating current of the amplif ier is

set to 850 mA with R7 on (A 8) the optobias board. The current is determined by

measuring the voltage drop across R3,

the 3.3-ohm resistor in the collector

circuit of Q1 on the amplifier board, and

adjusting R7 for a voltage drop of 2.8

volts.

The output of the amplifier is fed through

(A9) the UHF dual coupler assembly to

RF output jack J2 of the tray. A forward

and reflected power sample is taken from

the UHF dual coupler assembly and fed to

(A10) the dual peak detector board.

Loading...

Loading...