Page 1

INSTRUCTION MANUAL

836A

2000 WATT UHF

TRANSLATOR

AXCERA, LLC

103 FREEDOM DRIVE P.O. BOX 525 LAWRENCE, PA 15055-0525 USA

(724) 873-8100 • FAX (724) 873-8105

www.axcera.com • info@axcera.com

Page 2

836A 2 kW UHF Television Translator, Internally Diplexed Table of Contents

1. Introduction:

2. System - 836A:

A. System Description

B. Specifications

C. Site Considerations

D. Unpacking and Installation Procedures

E. Translator Set Up and Operation Procedure

F. Meters, Switches and Indicators

G. Translator Detaile d Alignment Procedure

H. Remote Control Interface Connections

I. Drawings:

1. 2 kW Translator Block Diagram..................................................... 1276-3000

2. 2 kW Translator Interconnect ...................................................... 1276-8000

3. Remote Interface Assembly w/Moseley Interconnect ........................ 1276-8011

3. AC Distribution Assembly, Narrow

A. Drawings:

1. Interconnect ............................................................................ 1276-8200

4. UHF Exciter

A. Drawings:

1. Block Diagram........................................................................... 1265-3300

2. Interconnect ............................................................................ 1265-8300

5. VHF/UHF Receiver Tray

A. Drawings

1. Block Diagram........................................................................... 1265-3100

2. Interconnect ............................................................................ 1265-8100

6. UHF Amplifier Tray

A. Drawings:

1. Block Diagram........................................................................... 1281-3100

2. Interconnect ............................................................................ 1281-8100

7. Subassemblies:

Refer to the Subassembly Section of the Instruction Manual for the Schematics, of the

Boards and Modules that make up the 836A. A Subassembly Drawing List, which is a list of

the drawings in the order they appear in the Section, is located in the front of the

Subassembly Section.

- Page 1 of 2 -

Page 3

836A 2 kW UHF Television Translator, Internally Diplexed Table of Contents

8. Maintenance:

This section contains information on the operation and maintenance of the 836A. This

section contains information on the Plugs, Jacks, Sockets and Pins that make up the

Harness and Cable Assemblies in the 836A.

- Page 2 of 2 -

Page 4

FF WARNING!!!

×× HIGH VOLTAGE ØØ

DO NOT ATTEMPT TO REPAIR OR TROUBLESHOOT THIS EQUIPMENT

UNLESS YOU ARE FAMILIAR WITH ITS OPERATION AND EXPERIENCED

IN SERVICING HIGH VOLTAGE EQUIPMENT. LETHAL VOLTAGES ARE

PRESENT WHEN POWER IS APPLIED TO THIS SYSTEM. IF POSSIBLE,

TURN OFF POWER BEFORE MAKING ADJUSTMENTS TO THE SYSTEM.

«« RADIO FREQUENCY RADIATION HAZARD ««

MICROWAVE AMPLIFIERS AND TUBES GENERATE HAZARDOUS RF

RADIATION WHICH CAN CAUSE SEVERE INJURY INCLUDING

CATARACTS, WHICH CAN RESULT IN BLINDNESS. SOME CARDIAC

PACEMAKERS MAY BE AFFECTED BY THE RF ENERGY EMITTED BY

MICROWAVE AMPLIFIERS. NEVER OPERATE A MICROWAVE SYSTEM

WITHOUT A PROPERLY MATCHED RF ENERGY ABSORBING LOAD

ATTACHED. KEEP PERSONNEL AWAY FROM OPEN WAVEGUIDES AND

ANTENNAS. NEVER LOOK INTO AN OPEN WAVEGUIDE OR ANTENNA.

MONITOR ALL PARTS OF THE RF SYSTEM FOR RADIATION LEAKAGE

AT REGULAR INTERVALS.

Page 5

EMERGENCY FIRST AID INSTRUCTIONS

Personnel engaged in the installation, operation, or maintenance of this equipment are urged to become

familiar with the following rules both in theory and practice. It is the duty of all operating personnel to be

prepared to give adequate Emergency First Aid and thereby prevent avoidable loss of life.

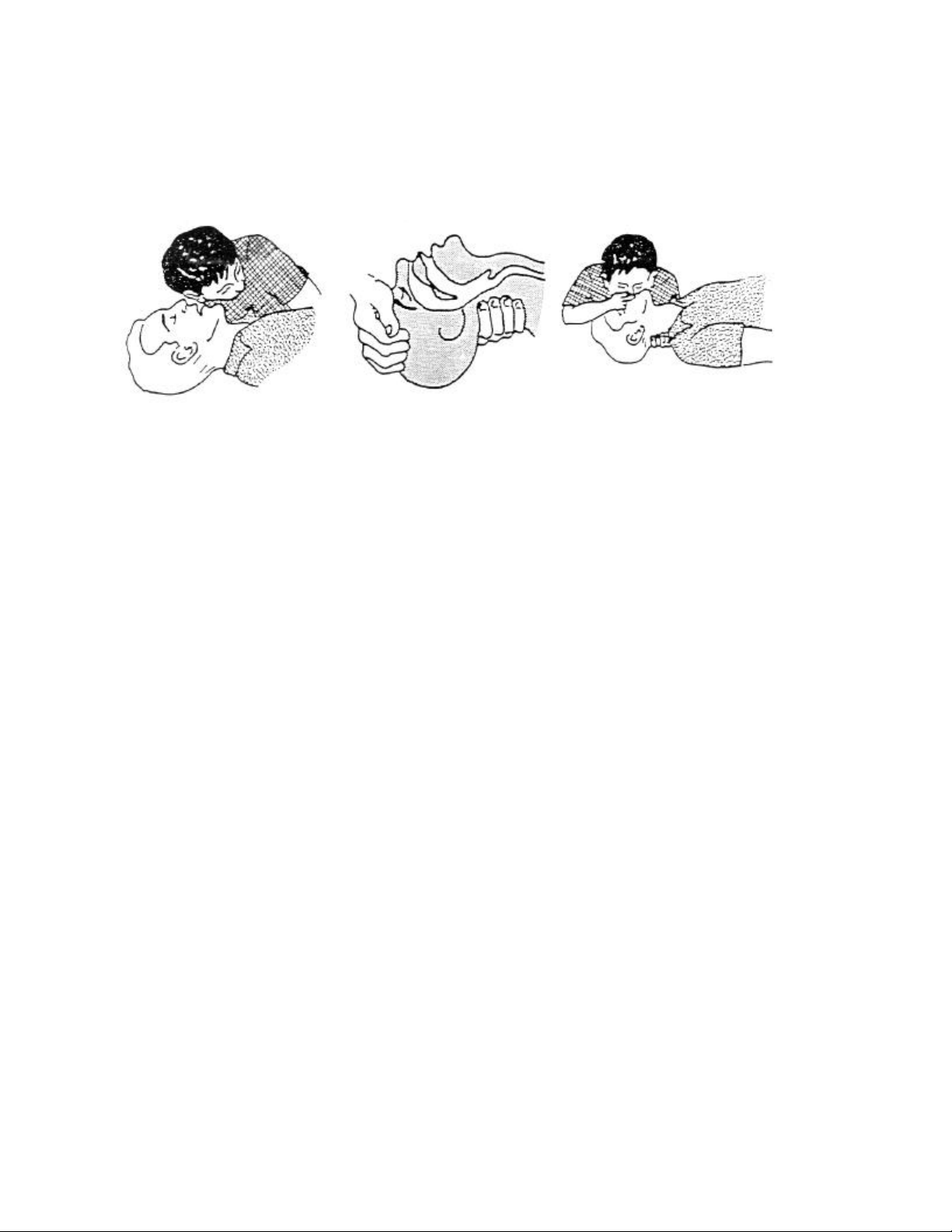

RESCUE BREATHING

1. Find out if the person is

breathing.

You must find out if the person

has stopped breathing. If you

think he is not breathing , place

him flat on his back. Put your

ear close to his mouth and look

at his chest. If he is breathing

you can feel the air on your

cheek. You can see his chest

move up and down. If you do

not feel the air or see the chest

move, he is not breathing.

SKIN REDDENED: Apply ice cold water to burned

area to prevent burn from going deeper into skin

tissue. Cover area with clean sheet or cloth to

keep away air. Consult a physician.

SKIN BLISTERED OR FLESH CHARRED: Apply ice

cold water to burned area to prevent burn from

going deeper into skin

2. If he is not, open the airway

by tilting his head backwards.

Lift up his neck with one hand

and push down on his forehead

with the other. This opens the

airway. Sometimes doing this

will let the person breathe

again by himself. If is does not,

begin rescue breathing.

3. If he is still not breathing,

begin rescue breathing.

-Keep his head tilted backward.

Pinch nose shut.

-Put your mouth tightly over his

mouth.

-Blow into his mouth once

every five seconds

-DO NOT stop rescue breathing

breathing until help comes.

LOOSEN CLOTHING - KEEP

WARM

Do this when the victim is

breathing by himself or help is

available. Keep him as quiet as

possible and from becoming

chilled. Otherwise treat him for

shock.

BURNS

tissue. Cover area with clean sheet or cloth to

keep away air. Treat victim for shock and take

to hospital.

EXTENSIVE BURN - SKIN BROKEN: Cover area

with clean sheet or cloth to keep away air. Treat

victim for shock and take to hospital.

Page 6

LIMITED WARRANTY

ONE YEAR

Seller warrants each new product manufactured and sold by Seller against

defects in material and workmanship under normal use and service, for a

period of one (1) year from the date of shipment from Seller's plant, when

operated in accordance with Seller's operating instructions. This warranty

shall not apply to tubes, fuses, batteries, or bulbs.

Warranties are valid only when and if (a) Seller receives prompt written

notice of breach within the period of warranty, (b) the defective product is

properly packed and returned by the Buyer (transportation and insurance

prepaid), and (c) Seller determines, in its sole judgment, that the product is

defective and not subject to any misuse, neglect, improper installation,

negligence, accident, or (unless authorized in writing by Seller) repair or

alteration. Seller's exclusive liability for any personal and/or property damage

(including direct, consequential or incidental) caused by the breach of any or

all warranties, shall be limited to the following: (a) repairing or replacing (in

Seller's sole discretion) any defective parts free of charge (F.O.B. Seller's

plant), and/or (b) crediting (in Seller's sole discretion) all or a portion of the

purchase price to the Buyer.

Equipment furnished by Seller, but not bearing its trade name, shall bear no

warranties other than the special hours-of-use or other warranties extended

by or enforceable against the manufacturer at the time of delivery to the

buyer. NO WARRANTIES, WHETHER STATUTORY, EXPRESSED OR

IMPLIED, AND NO WARRANTIES OF MERCHANTABILITY, FITNESS FOR

ANY PARTICULAR PURPOSE, OR FREEDOM FROM INFRINGEMENT, OR THE

LIKE, OTHER THAN AS SPECIFIED IN PATENT LIABILITY ARTICLES, AND

IN THIS ARTICLE, SHALL APPLY TO THE EQUIPMENT FURNISHED

HEREUNDER.

Page 7

))MATERIAL RETURN PROCEDURE

In order to efficiently handle equipment or components returned for repair or sent out on loan,

Axcera requests that each returned item be accompanied by a Material Return Authorization

Number (MRA#).

To obtain an MRA follow the procedures below:

pp Call Axcera Customer Service at (724)-873-8100

or FAX (724) 873-8105

pp A Service Engineer will provide you with an MRA#

pp Write the MRA# on the packing list or in the case of repairs, a

note describing the reason for return. Also, be sure to include contact

information.

pp Send ALL MRA items to the following address

Axcera, LLC

103 Freedom Drive P.O. Box 525

Lawrence, PA 15055-0525

%% TELEPHONE TECHNICAL SUPPORT

Axcera currently provides free telephone technical support. When calling, be prepared to

provide the following information:

pp Transmitter model # AND Serial #

pp Status of front panel LED’s (are any red LED’s on ?)

pp Have a copy of your operation manual ready prior to calling

From 8:00 AM - 5:00 PM EST call (724) 873-8100 for technical support

Page 8

..PROPER PACKING OF MATERIALS

When returning materials to Axcera, it is extremely important to pack them properly. Due to the

delicate nature of components contained within the equipment, major damage can occur without

proper packing. Please adhere to the following guidelines when returning materials.

oo Save the boxes that the transmitter is shipped in. Each tray is sent

double boxed and enclosed in foam padding. Use the same packing

method when returning materials.

Failure to properly pack any returned materials may result in damage to the

equipment. Axcera is not responsible for damaged equipment under these

circumstances. Many freight companies will not compensate for damages when items

are not packed properly. Please pack items properly!

Page 9

dBm, dBw, dBmV, dBµµV, AND VOLTAGE EXPRESSED IN WATTS

50 ohm system

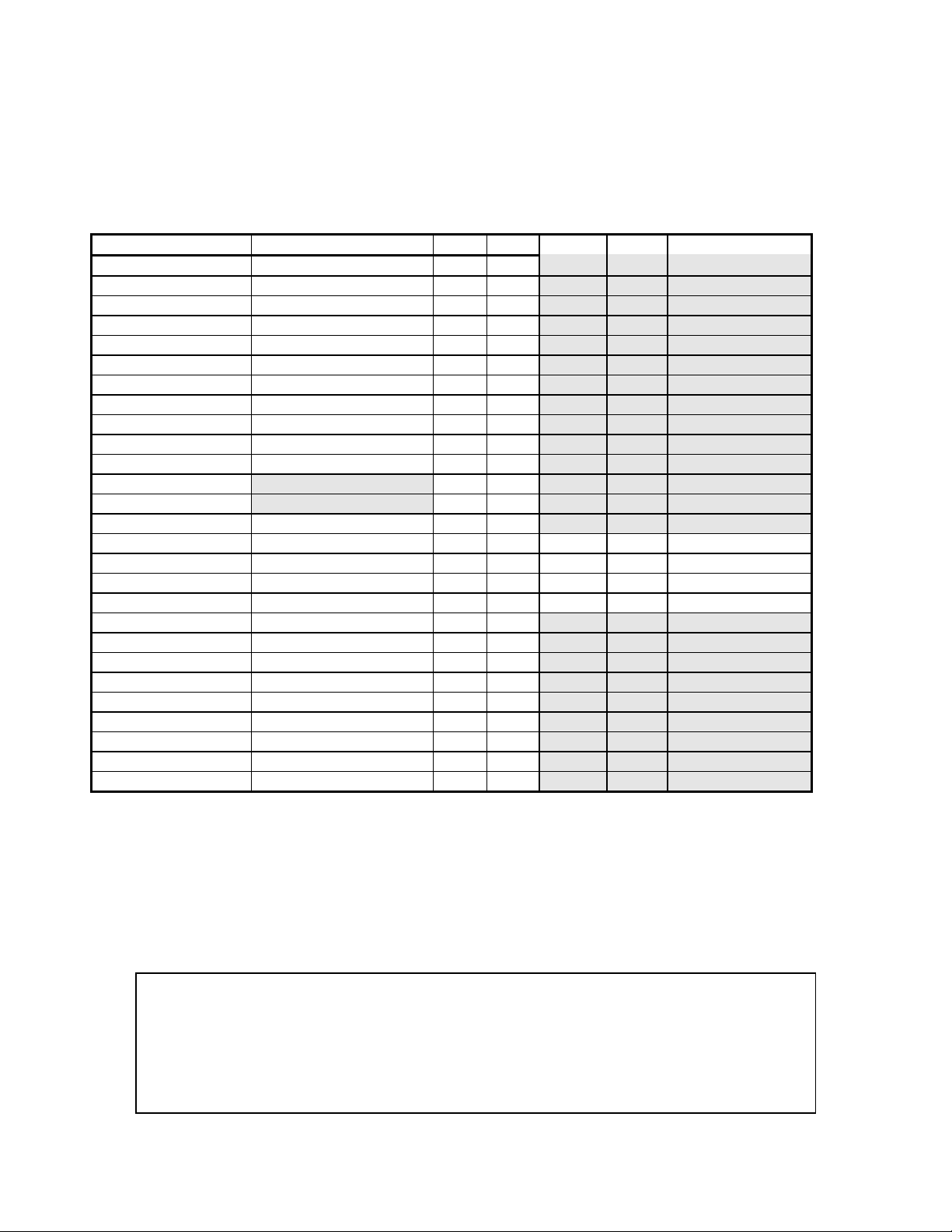

WATTS PREFIX dBm dBw dBmV dBµV VOLTAGE

1,000,000,000,000 1 TERAWATT +150 +120

100,000,000,000 100 GIGAWATTS +140 +110

10,000,000,000 10 GIGAWATTS +130 +100

1,000,000,000 1 GIGAWATT +120 + 99

100,000,000 100 MEGAWATTS +110 + 80

10,000,000 10 MEGAWATTS +100 + 70

1,000,000 1 MEGAWATT + 90 + 60

100,000 100 KILOWATTS + 80 + 50

10,000 10 KILOWATTS + 70 + 40

1,000 1 KILOWATT + 60 + 30

100 1 HECTROWATT + 50 + 20

50 + 47 + 17

20 + 43 + 13

10 1 DECAWATT + 40 + 10

1 1 WATT + 30 0 + 77 +137 7.07V

0.1 1 DECIWATT + 20 - 10 + 67 +127 2.24V

0.01 1 CENTIWATT + 10 - 20 + 57 +117 0.707V

0.001 1 MILLIWATT 0 - 30 + 47 +107 224mV

0.0001 100 MICROWATTS - 10 - 40

0.00001 10 MICROWATTS - 20 - 50

0.000001 1 MICROWATT - 30 - 60

0.0000001 100 NANOWATTS - 40 - 70

0.00000001 10 NANOWATTS - 50 - 80

0.000000001 1 NANOWATT - 60 - 90

0.0000000001 100 PICOWATTS - 70 -100

0.00000000001 10 PICOWATTS - 80 -110

0.000000000001 1 PICOWATT - 90 -120

TEMPERATURE CONVERSION

°°F = 32 + [(9/5) °°C]

°°C = [(5/9) (°°F - 32)]

Page 10

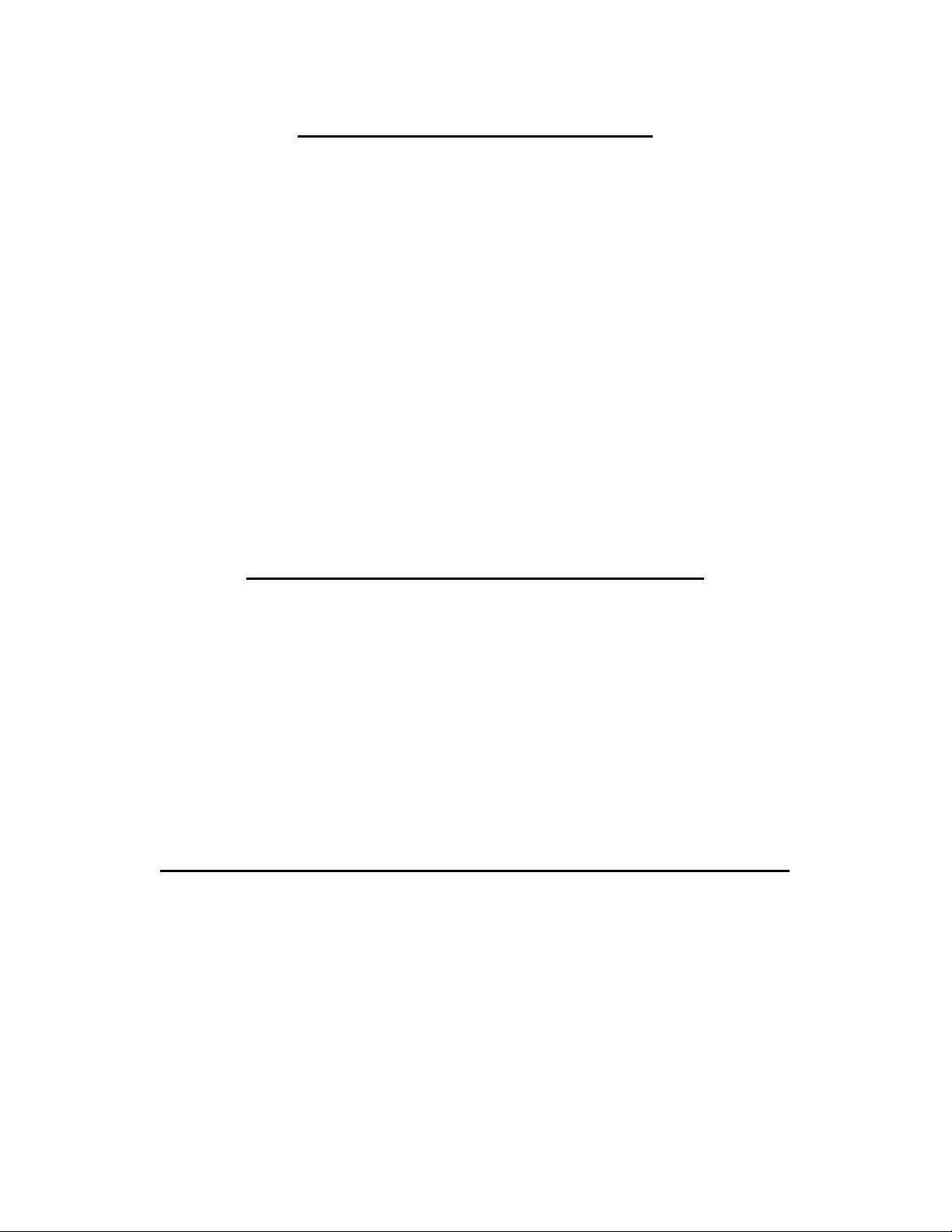

USEFUL CONVERSION FACTORS

TO CONVERT FROM TO MULTIPLY BY

mile (US statute) kilometer (km) 1.609347

inch (in) millimeter (mm) 25.4

inch (in) centimeter (cm) 2.54

inch (in) meter (m) 0.0254

foot (ft) meter (m) 0.3048

yard (yd) meter (m) 0.9144

mile per hour (mph) kilometer per hour(km/hr) 1.60934

mile per hour (mph) meter per second (m/s) 0.44704

pound (lb) kilogram (kg) 0.4535924

gallon (gal) liter 3.7854118

U.S. liquid

(One U.S. gallon equals 0.8327 Canadian gallon)

fluid ounce (fl oz) milliliters (ml) 29.57353

British Thermal Unit watt (W) 0.2930711

per hour (Btu/hr)

horsepower (hp) watt (W) 746

NOMENCLATURE OF FREQUENCY BANDS

FREQUENCY RANGE DESIGNATION

3 to 30 kHz VLF - Very Low Frequency

30 to 300 kHz LF - Low Frequency

300 to 3000 kHz MF - Medium Frequency

3 to 30 MHz HF - High Frequency

30 to 300 MHz VHF - Very High Frequency

300 to 3000 MHz UHF - Ultrahigh Frequency

3 to 30 GHz SHF - Superhigh Frequency

30 to 300 GHz EHF - Extremely High Frequency

LETTER DESIGNATIONS FOR UPPER FREQUENCY BANDS

LETTER FREQ. BAND

L 1000 - 2000 MHz

S 2000 - 4000 MHz

C 4000 - 8000 MHz

X 8000 - 12000 MHz

Ku 12 - 18 GHz

K 18 - 27 GHz

Ka 27 - 40 GHz

V 40 - 75 GHz

W 75 - 110 GHz

Page 11

ABBREVIATIONS/ACRONYMS

AC Alternating Current

AFC Automatic Frequency Control

ALC Automatic Level Control

AM Amplitude modulation

AGC Automatic Gain Control

AWG American wire gauge

BER Bit Error Rate

BW Bandwidth

DC Direct Current

D/A Digital to analog

dB Decibel

dBm Decibel referenced to 1 milliwatt

dBmV Decibel referenced to 1 millivolt

PCB Printed circuit board

QAM Quadrature Amplitude Modulation

dBw Decibel referenced to 1 watt

FEC Forward Error Correction

FM Frequency modulation

Hz Hertz

ICPM Incidental Carrier Phase Modulation

I/P Input

IF Intermediate Frequency

LED Light emitting diode

LSB Lower Sideband

MPEG Motion Pictures Expert Group

O/P Output

PLL Phase Locked Loop

Page 12

R

E

T

U

R

N

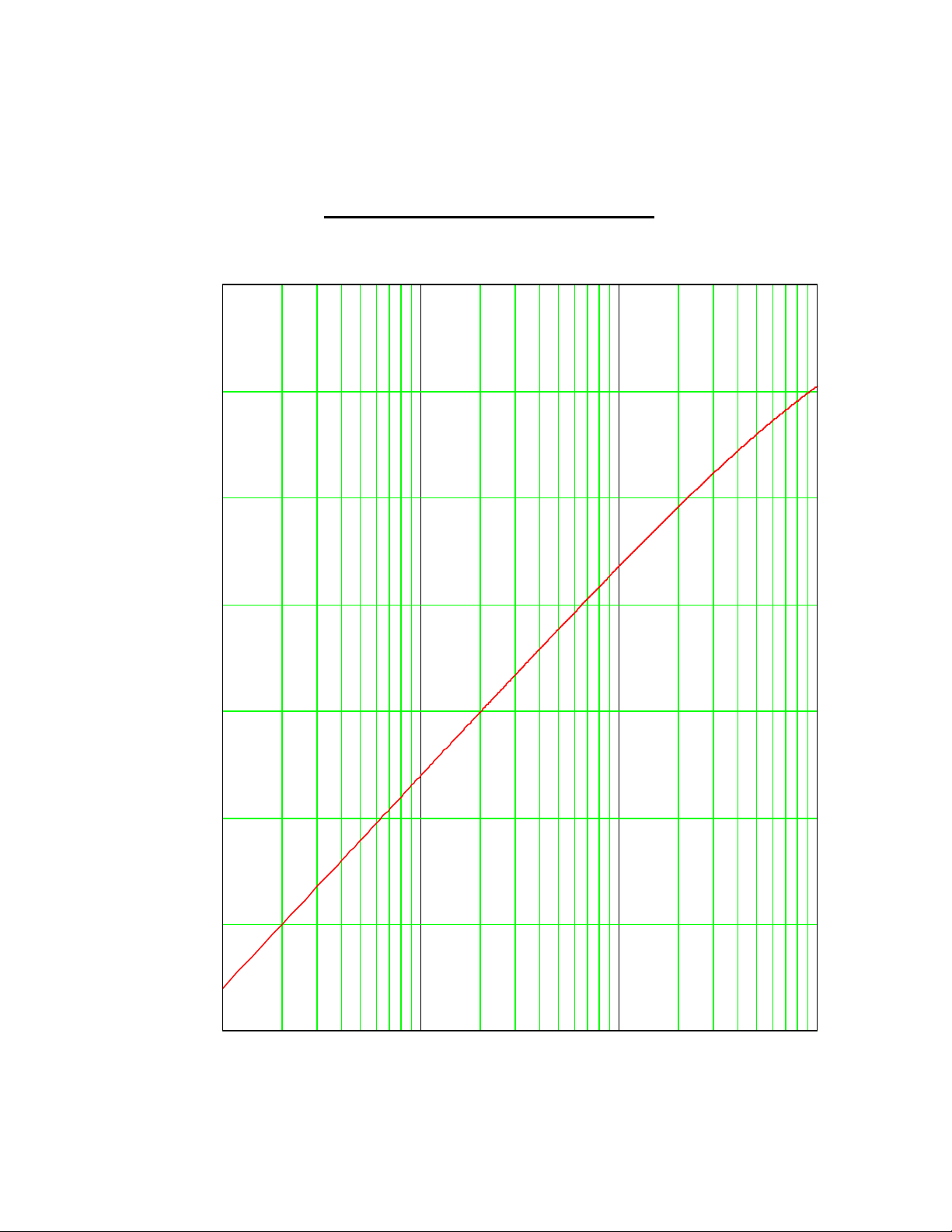

RETURN LOSS VS. VSWR

0

-10

-20

-30

dB

L

O

S

-40

-50

-60

-70

1.001 1.01 1.1 2.0

VSWR

Page 13

836A 2 kW UHF Translator, Internally Diplexed System Description

The 836A is a complete 2 kW UHF Solid State Internally Diplexed Television Translator which

operates at a nominal Visual Output Power of 2000 Watts Peak of Sync and with an Average Aural

Output Power of 200 Watts at an A/V Ratio of 10 dB, 10 % Sound. The Translator uses the

combined IF Output of the Receiver Tray as the input to the UHF Exciter Tray.

The 836A (1078476) is functionally comprised of (A4) the UHF Exciter (1300-1020), (A3) the

VHF/UHF Receiver Tray (1265-1100), (A5) the 4 Way Splitter Assembly, (A6, A7, A8 & A9) four

UHF Amplifier Trays (1294-1112, 1294-1113 or 1294-1114), (A10 & A11) two UHF Tee Assemblies,

(A12) a Hybrid Combiner , (A13) a Bandpass Filter, (A14) an (Optional) UHF Trap Filter, (A16) a

Coupler Assembly, (A2) an AC Distribution Assembly (1276-1200) and (A17) an (Optional) A/V

Input & Remote Interface Assembly (1276-1008) or a Remote Interface Assembly w/Moseley

(1314-1008).

The (A3) VHF/UHF Receiver Tray (1265-1100) takes the On Channel RF Input, which connects to

J5 for 75Ω or J1 for 50Ω on the rear of the Tray and generates a Modulated Diplexed IF Output.

The Combined IF from J4 connects to the J6 on the (A4) UHF Exciter Tray (1265-1300) which

upconverts the signal to the On Channel Frequency Visual + Aural RF Output. The RF Output of

the UHF Exciter at J15 is split four ways by (A5) the Four Way Splitter Assembly (ZFSC-4-1SMA).

The outputs of the Splitter feed to J1 on the four (A6, A7, A8 & A9) UHF Amplifier Trays. The RF

outputs of the (A8 & A9) UHF Amplifier Trays are combined in the (A11) UHF Tee Assembly and the

outputs of the (A6 & A7) UHF Amplifier Trays are combined in the (A10) UHF Tee Assembly. The

Combined Outputs of each UHF Tee are combined in (A12) a Hybrid Combiner. A 500 Watt Dummy

Load (A18) is connected to the Hybrid Combiner and provides Transmitter protection, using the

Thermal Switch (A18-A1), in case of misalignment in the combining or a malfunction in the UHF

Amplifier Trays which causes overtemperature. The RF output of the Hybrid Combiner is connected

to (A13) a Bandpass Filter, and then either directly to (A16) an Output Coupler Assembly or

through (A14) an (Optional) One Section or Two Section UHF Trap Filter. The 7/8” RF Output at

J2 of the Coupler is the output of the Translator. The (A16) 7/8" Coupler Assembly supplies a

Forward Power Sample and a Reflected Power Sample to the Visual/Aural Metering Board located in

the UHF Exciter. The Samples are peak detected and wired to the Transmitter Control Board which

connects the Visual, Aural and Reflected Power Output Samples to the front panel Meter on the

Exciter for monitoring.

The Combined Visual IF + Aural IF Input (0 dBm Typical) from the Receiver Tray connects to J6 on

the UHF Exciter Tray. The Combined IF is cabled to the (A8) ALC Board (1265-1305) which gives

the operator control over the output power level of the Translator by adjusting the level of the

combined IF Signal. The IF Signal is fed out of the ALC Board to (A9) an IF Phase Corrector Board

(1227-1250) that is adjusted for best signal and then back to the ALC Board.

Upconverter Section

The output of the ALC Board (0 dBm) connects to (A11) the UHF Upconverter Board (1265-1310),

located in the Upconverter Section, which takes the L.O. and heterodynes it with the Combined IF,

that is then filtered to produce the RF On Channel Output. The crystal frequency needed to

generate the L.O. is produced by (A14-A1) the Channel Oscillator Board (1145-1201) located in

(A14) the Channel Oscillator Assembly (1145-1202) or if the Optional FSK Identifier Kit is

purchased, by the VCXO Channel Oscillator Board (1145-1204) located in the VCXO Channel

Oscillator Assembly (1145-1206). The Crystal Frequency (+5 dBm) is multiplied 8 times by (A15A1) the x8 Multiplier Board (1227-1002), located in (A15) the x8 Multiplier Enclosure (1265-1347),

which produces the L.O. Signal at the proper frequency (+16 dBm) needed in the upconversion

process that takes place on the UHF Upconverter Board. The L.O. is filtered by (A16) a UHF Filter

(1007-1101) before it is applied to the UHF Upconverter Board. The L.O. is mixed with the IF to

produce an On Channel RF Output that is filtered by (A12) a UHF Filter (1007-1101) and connected

back to the Upconverter Board. The RF is connected through an AGC circuit and is amplified

before it is attached to the output of the board.

- Page 1 of 3 -

Page 14

836A 2 kW UHF Translator, Internally Diplexed System Description

Output RF Section

The RF Output of the UHF Exciter is split four ways in (A5) the 4 Way Power Splitter Assembly

(ZFSC-4-1SMA). The outputs of the Splitter feed the four (A6, A7, A8 & A9) UHF Amplifier Trays

which amplify the RF signals to approximately 600 Watts each. A Forward Power Sample from the

4 Way Combiner Board inside the Tray is connected to the Dual Peak Detector Board which

provides a peak detected forward sample to the Amplifier Control Board that supplies the sample to

the front panel meter of the UHF Amplifier Tray. Before exiting each UHF Amplifier Tray the RF is

fed through a Circulator for protection of the Tray from high VSWR conditions. The Reject Port of

the Circulator provides a Reject Sample to the 4 Way Combiner Board, which supplies the Reflected

Sample to the Dual Peak Detector Board. The peak detected Reflected Sample connects to the

Amplifier Control Board that provides the sample to the front panel meter of the Tray. The outputs

of the two (A6 & A7) UHF Amplifier Trays are then combined in (A10) a UHF Tee Assembly (12271017 L.B., 1227-1018 M.B. or 1227-1019 H.B.) that provides approximately 1100 Watts Peak of

Sync Output. The outputs of the other two (A8 & A9) UHF Amplifier Trays are then combined in

(A11) a UHF Tee Assembly (1227-1017 L.B., 1227-1018 M.B. or 1227-1019 H.B.) that provides

approximately 1100 Watts Peak of Sync Output. The two 1100 Watts Outputs then combined in

(A12) a Hybrid Combiner that provides approximately 2200 Watts Peak of Sync Output. The

combined output is connected to (A13) a Bandpass Filter, then either through (A14) an (Optional)

One Section or Two Section Trap Filter or directly to (A16) the Output Coupler Assembly to the

output of the System. The Bandpass Filter and Trap Filter are tuned to provide high out of band

rejection of unwanted products. The (A16) 7/8" Coupler Assembly provides a Forward Power

Sample and a Reflected Power Sample. The Forward and Reflected Samples are cabled to the

Visual/Aural Metering Board located in the UHF Exciter. The Forward and Reflected Samples are

processed to provide peak detected Visual and an Aural Power Output Samples to the Transmitter

Control Board. The Transmitter Control Boards connect the Visual, Aural and Reflected Power

Output Samples to the front panel Meter for monitoring.

Control and Status

The Meter and the LED indicators located on the front panel of the UHF Exciter provide the Control

and the Status Indications of the Translator. The switches and LED indicators are part of the

Transmitter Control Board (1265-1311) which is mounted so that the switches and the LEDs are

operated or viewed from the front Panel of the UHF Exciter. Switch (S1) is an Operate/Standby

Switch that controls the output of the Translator by providing the Enables, when in Operate,

needed to turn on the Switching Power Supplies in the four UHF Amplifier Trays. In Operate the

Green LED (DS2) is On and when in Standby the Amber LED (DS1) is On. If the Translator does

not switch to Operate, when S1 is switched to Operate, check that a Dummy Jumper Plug, with a

Jumper between Pins 23 & 24 is connected to J11 on the rear of the UHF Exciter Tray or with a

jumper between Pins 21 & 22 on Jack J9 on (A17) the (Optional) A/V Input & Remote Interface

Panel. This Jumper provides the Interlock needed for the Translator to operate. If the Interlock is

present the Green LED (DS5), located on the Transmitter Control Board, should be lit.

Switch (S2) is an Automatic/Manual Switch that controls the operation of the Translator by the

presence of the Input Signal. When the switch is in Automatic the Green LED (DS3) is lit and if the

Input Signal to the Translator is lost, the Translator will automatically switch to Standby. When

the Input Signal returns the Translator will automatically switch back to Operate. In Manual,

Amber LED (DS4) lit, the Operation of the Translator is controlled by the front panel switches.

During Normal operation of the Translator Switch S2 should be in the Auto position. The front

panel of the UHF Exciter also has LEDs that indicate a Video Fault (Loss), Red LED (DS9) and a

VSWR Cutback, Amber LED (DS7).

- Page 2 of 3 -

Page 15

836A 2 kW UHF Translator, Internally Diplexed System Description

Operation of the Translator

The Translator needs an AC input of 220 VAC at 80 Amps connected to it in order to operate. The

220 VAC Input connects to the Terminal Block (TB1), located in the upper right rear of the

Cabinet, that is part of (A2) the AC Distribution Panel (1276-1200). The AC Distribution Panel

contains Six Circuit Breakers that supply the AC to the rest of the Translator.

The Input AC from TB1 is connected to (CB1) the Main AC Circuit Breaker (80 Amps) which

distributes the 220 VAC to the Terminal Block (TB2). TB2 has three MOVs, mounted to the

Terminal Block, one connected from each leg of the Input AC to ground and one across the two

legs. The Input AC is wired from TB2 through five Circuit Breakers, CB2, CB3, CB4, CB5 & CB6 to

the rest of the Translator. CB2 (10 Amps) supplies the AC voltage to the IEC Outlet Strip (A1)

into which the UHF Exciter, the Optional Receiver Tray and any other Optional Accessories are

connected. CB3 (20 Amps) supplies AC through J5 to the (A6) UHF Amplifier Tray. CB4 (20 Amps)

supplies AC through J6 to the (A7) UHF Amplifier Tray. CB5 (20 Amps) supplies AC through J7 to

the (A8) UHF Amplifier Tray. CB6 (20 Amps) supplies AC through J8 to the (A9) UHF Amplifier Tray.

When the UHF Exciter circuit breaker is switched On, +12 VDC is supplied to the UHF Amplifier

Trays for operation of the LED Status Indicators in the Tray.

Input and Remote Connections

The On Channel RF Input from the Antenna connects to J5 for 75Ω or J1 for 50Ω located on the

rear of the VHF/UHF Receiver Tray. Jacks J10 and J11 on the rear of the UHF Exciter provides

connections for Remote Monitoring and Operation of the Translator. Jack (J11) should have a

dummy plug connected to it which has a jumper between Pins 23 & 24 that provides the Interlock

needed to operate the Translator. If remote connections are made to the Translator they should

be made through the plug in J10 or J11 in the positions noted on the Interconnect Drawing (1276-

8000).

The (Optional) Remote Interface Assembly, if present, provides connections for Remote Monitoring

and Operation of the Translator at Jack (J9 & J10). Jack (J9) should have a dummy plug

connected to it which has a jumper between Pins 21 & 22 that provides the Interlock needed to

operate the Translator. If remote connections are made to the Translator they should be made

through the plug in J9 or J10 in the positions noted on the Interconnect Drawing (1276-8000).

Instruction Manual Description

The Instruction Manual is divided into sections that are labeled as to their contents. The first

main section is the System Section that contains the Parameters and Specifications of the 836A

along with the Site Preparation, Installation, System Set Up, Alignment and Operation Procedures.

The Block Diagram and Interconnect for the Translator are also found in the System Section.

The Manual is further divided into Tray and Assembly Sections. Each Tray or Assembly Section of

the Manual contains the Block Diagrams, Control Location Drawings and Interconnects of that

Assembly or Tray. Each of the Sections also contains the Circuit Descriptions and Detailed

Alignment Procedures for that Tray or Assembly.

The Schematics, Parts Location Drawings and the Replacement Parts Lists for the individual boards

that make up the Trays and Assemblies in the Translator are located in the Subassembly Section

of the Manual. There is a Drawing List at the beginning of the Subassembly Section that lists the

drawings in the order they appear in the section.

- Page 3 of 3 -

Page 16

UHF Solid State Transmitter / Translator

825A / 827A - 500W

830A / 832A - 1kW

834A / 836A - 2kW

These products represent the state of the art in

solid state UHF transmitters. High performance,

redundancy, and simplicity are combined in a

very compact unit. Multiplexed aural/visual

amplification is achieved with very good

intermodulation performance, thanks to highly

linear amplifiers and extensive correction

capability.

Front panel samples, status, and metering, most

of which are remote controllable, allow for

convenient system monitoring. As with all

Axcera products, servicing is made easy with

slide out assemblies that require no extender

cards. This allows the circuits to be accessed for

maintenance or adjustments even while on the

air.

Page 17

UHF Solid State Transmitter / Translator

Exciter

The exciter, designed and

built by Axcera, contains the

circuitry to convert the input

video and audio signals to a

combined, modulated RF

signal which drives the

power amplifiers. In the

translator version, a receiver

replaces the modulator

circuits to accept an off air

RF input and convert it to IF.

An optional Frequency

Correcting Receiver (FCR) is

available, which uses a

phase locked loop to correct

frequency errors from the

incoming signal. This option

is especially useful in

multiple hop translator

systems.

Video/Visual Modulation

The video signal is processed

in several ways prior to

modulation. Sync tip

clamping is provided to

UHF Solid State Transmitter / Translator

restore proper DC level.

Sync and white clipping are

also included to limit video

transient faults. Back porch

clamping is also available for

some scrambling systems.

The video signal is then

applied to a double balanced

diode modulator, providing

modulation capability to 1%

at standard intermediate

frequency (IF). A SAW filter

is employed for precise

sideband filtering with

minimal group delay error.

Audio/Aural Modulation

The audio signal is applied to

a very wideband, linear FM

modulator which operates at

intercarrier frequency (4.5

MHz for system M). The

high performance modulator

readily accepts the full range

of multichannel sound

signals. Standard aural IF is

achieved by heterodyne

conversion of the modulated

intercarrier signal with the

visual IF.

IF Processing

The visual and aural

modulated IF signals are

combined and applied to IF

processing stages. These

stages provide outstanding

signal precorrection to yield a

very linear transmitter

output. Amplitude linearity,

incidental carrier phase

modulation (ICPM), and

frequency response

correction are all adjustable.

Upconversion

The IF signal is upconverted

to final channel frequency

through heterodyning with a

very stable local oscillator.

The oscillator is crystal

controlled, and embedded in

two ovens for tight stability.

The exciter is controlled with

an Automatic Level Control

(ALC) loop which ensures

stable signal levels. After

upconversion the signal is

amplified to provide the

exciter output.

Power Amplifiers

The 600 watt power

amplifiers are high gain units

producing 45 to 50dB of

gain. Operating in parallel in

the 1 and 2kW versions,

these trays provide

redundant paths from the

exciter output to the

bandpass filter. Redundancy

is enhanced with

independent power supplies

and cooling for each

amplifier assembly.

Furthermore, the output

stage of each amplifier tray

employs eight transistors in

parallel for added

redundancy.

A high degree of protection

is provided with each

amplifier. Individual

circulators, overdrive

protection, VSWR cutback,

and overtemperature

protection are all included.

AGC around each amplifier

ensures that the transmitter

output remains stable.

An integrated output

bandpass and trap filter is

included to provide superior

out of band rejection. This

network also adds lightning

protection through the

quarter wave stub of the trap

filter (DC and lightning short)

and the DC short circuit of

the band pass filter.

www.axcera.com • 724-873 -1500

Page 18

UHF Solid State Transmitter / Translator

■ Utilizes 100% solid state circuitry for high reliability

and low maintenance costs

■ 1kW and 2kW configured with parallel high gain

amplifiers, separate power supplies and cooling

for excellent redundancy, including driver stages

UHF Solid State Transmitter / Translator

■ Packaged in a compact design, completely

contained in a single rack - including output

filters!

■ Provides standard ±1 kHz frequency stability for

stations with an offset frequency

■ Configured with broadcast quality exciter

that includes full BTSC sound capability

■ Provides output circulator amplifier protection

for high VSWR conditions

■ Experienced field service/support team is ready to

help you 24 hours a day, 7 days a week.

Standard with all Axcera products is 24 hour/day, 7 day/week

customer support. This service operates as a direct telephone

line during business hours, and on a pager system at all other

times. Since all our products are designed and built at our

facility just south of Pittsburgh, Pennsylvania, we are able to

offer quick turnaround on most replacement modules, and

timely shipping from the Pittsburgh International Airport.

www.axcera.com • 724-873 -1500

Page 19

UHF Solid State Transmitter / Translator

Visual Performance

Power Output (Peak) 500, 1000, 2000 W

Output Impedance 50 ohms

Output Connector 7/8" EIA

Frequency Range* 470 to 806 MHz

Carrier Stability (Transmitters) ±1 kHz (standard)

±350 Hz (optional)

Frequency Translation Stability ±1 kHz (standard)

(Translators) ±350 Hz (optional)

Regulation of RF Output Power 3%

Output Variation (over 1 frame) 2%

Sideband Response (System M/N-others on request)

-1.25 MHz and below -20 dB

-0.75 to -0.5 MHz +0.5 dB, -2 dB

-0.5 to +3.58 MHz ±0.5 dB

+3.58 MHz to +4.18 MHz +0.5 dB, -1 dB

Freq Response vs. Brightness ±0.5 dB

Visual Modulation Capability 1%

(Transmitters)

Differential Gain 5%

Incidental Phase Modulation ±3°

Linearity (Low Frequency) 5%

Differential Phase ±3°

Signal-to-Noise Ratio 55 dB

2t K-Factor 2%

Noise Figure (Translators) 5 dB (max.)

w/input Preamp 3 dB (max.)

Input Dynamic Range -60 dBm to -15 dBm

(Translators)

w/input Preamp -75 dBm to -30 dBm

Env. Delay (Transmitters) Per CCIR or FCC

Standard

Env. Delay .02 to 4.18 MHz ±40 ns

(Translators)

Video Input (Transmitters) 75 ohms

(loop through)

Harmonics -60 dB or better

Intermodulation Products -52 dB or better

Spurious -60 dB or better

(>3 MHz from channel edge)

Aural Performance

Power Output (Average) 50, 100, 200 W

Frequency Deviation Capability ±75 kHz

(Transmitters)

Distortion 0.5%

FM Noise -60 dB

AM Noise -50 dB

Aural to Visual Separation 4.5 MHz, ±100 Hz

Composite Audio Input (multi-channel sound)

(Transmitters)

Input Level 1V peak, nominal

Input Impedance 75 ohms, unbalanced

Frequency Range

±0.1 dB response 50 Hz to 50 kHz

±0.5 dB response 30 Hz to 120 kHz

Monaural Audio Input (Transmitters)

Input Level 0 to +10 dBm

Input 600 ohms, balanced

Freq Range (±0.5 dB resp) 30 Hz to 15 kHz

Pre-emphasis 75µs

Subcarrier Input (Transmitters)

Input Level 1V peak, nominal

Input Impedance 75 ohms, unbalanced

Freq Range (±0.5 dB resp) 20 kHz to 120 kHz

General

Operational Temperature Range -30°C to +50°C

Operational Humidity Range 0% to 95%

Altitude* 8,500 feet

825A/827A

Size (H x W x D) 55" x 22" x 34"

Weight 320 lbs

Power Consumption 1800 watts (50% APL)

830A/832A

Size (H x W x D) 55" x 22" x 34"

Weight 400 lbs

Power Consumption 3500 watts (50% APL)

834A/836A

Size (H x W x D) 76" x 22" x 34"

Weight 750 lbs

Power Consumption 7000 watts (50% APL)

Line Voltage* 230V ±10%, 1 phase,

50/60 Hz

B0007 1101R1-E

*Consult factory for other frequencies, altitudes and line voltages

Page 20

836A 2 kW UHF Translator, Internally Diplexed Site Considerations

There are special considerations that need to be made before installing the 836A and this section

will help you plan ahead.

The Translator requires an AC Input Line of 220 VAC with a rating of 80 Amps. Check that the site

has the voltage requirement needed.

836A is designed and built to provide long life with a minimum of maintenance. The environment in

which it is placed is important and certain precautions must be taken. The three greatest dangers

to your Translator are heat, dirt and moisture. Heat is usually the greatest problem, followed by

dirt and then moisture. Over-temperature can cause heat related problems such as thermal

runaway and component failure. Each Amplifier Tray in the Translator contains a Thermal Interlock

Protection Circuit that will shut down that Tray until the temperature drops to an acceptable level.

To begin to design a suitable environment for your new Translator it is imperative that you

understand what an "Ideal Environment" is and how it can enhance the overall performance and

reliability of your Translator, thereby maximizing revenues by minimizing down time. A properly

designed facility will have an adequate supply of cool clean air, free of airborne particulates of any

kind, and without excessive humidity. An Ideal Environment will require temperature in the range

of 40 degrees F to 70 degrees F year round, reasonably low humidity and a dust free room. It

should be noted that this is rarely if ever attainable in the real world. However, the closer your

environment is to the Ideal Environment the greater the operational elevation. A heat related

problem may not surface for many months if the installation is completed during cool weather, but

may suddenly appear during the heat of summer.

The fans and blowers designed and built into your Translator will remove the heat from within the

cabinet but additional means is required for removing this heat from the building. In doing this a

few considerations should be noted. The first step is to determine the amount of heat to be

removed. There are generally three sources of heat that must be considered. The first and most

obvious is the heat from the 2 kW Translator itself. This can readily be determined by subtracting

the Average Power to the Antenna (1290 Watts) from the AC Input Power (8000 W). These

numbers will be different for the 5 kW and 10 kW Translator but can be found by referring to the

published literature or directly from Axcera. This number in Watts (6710) is then multiplied by 3.41

which gives (22881.1) the BTU's to be removed every hour. 12,000 BTU's per hour equals one ton,

so a two-ton air conditioner will cool a 2 kW Translator. The second source of heat is other

equipment in the same room. Calculate this number as you did above. The third source of heat is

equally obvious but not as simple to calculate. This is the heat coming through the walls, roof and

windows on a hot summer day. Unless the underside is exposed, the floor is usually not a problem.

Determining this number is usually best left up to a qualified HVAC Technician. There are far too

many variables to even estimate this number without detailed drawings of the site showing all

construction details. The sum of these three sources is the total amount of heat that must be

removed. There may be other sources of heat, such as personnel, and all should be taken into

account.

Now that you know the amount of heat that must be removed we will consider how this can be

accomplished. Your options are air conditioning, ventilation or a combination of the two. Air

conditioning is always the preferred method and is the only way to approach the Ideal

Environment.

Ventilation will work quite well if the ambient air temperature will be below 100 degrees F or about

38 degrees C and the humidity should be at a reasonable level. In addition, the air stream must be

adequately filtered to ensure that no airborne particulate of any kind will be carried into the

Translator. The combination of air conditioning for summer and ventilation during the cooler

months is acceptable when the proper cooling cannot be obtained through the use of ventilation

alone and air conditioning year round is not feasible for whatever reason. However, operation of

air conditioning and ventilation simultaneously is not recommended because this can cause

- Page 1 of 3 -

Page 21

836A 2 kW UHF Translator, Internally Diplexed Site Considerations

condensation in Translators. For tube type Translators this can be especially serious if the

condensation forms in the tube cavity and creates damaging arcs.

A few cautions should be observed concerning an air conditioning system.

1. Air conditioners have an ARI nominal cooling capacity rating. In selecting your air

conditioner do not assume you can equate this number to your requirements. Make certain

that your contractor uses the actual conditions you wish to maintain in determining the size

of the unit. With desired conditioned room temperature under 80 degrees F the unit must be

derated, possibly by a substantial amount.

2. Do not have the air conditioner blowing directly onto the Translator. Condensation may

occur on, or worse, in the Translator under certain conditions.

3. Do not isolate the front of the Translator from the back with the thought of air conditioning

the front only. Cooling air is drawn in the front of all Translators and in the front and back

of others. Any attempt to isolate the front from the rear will adversely affect the cooling

air flow.

4. Interlocking the Translator with the air conditioner is recommended to preclude operation of

the Translator without the necessary cooling.

5. The periodic cleaning of all filters is a must.

When using ventilation alone, the following general statements apply.

1. The Blower with attendant filters should be on the inlet, thereby pressurizing the room

which prevents the ingress of dirt.

2. The inlet and outlet should be on the same side of the building, preferably the leeward side.

The pressure differential created by wind will be minimized. Only the outlet may be through

the roof.

3. The inlet and outlet should be screened with 1/8" hardware cloth (preferred), galvanized

hardware cloth (acceptable).

4. Cooling air should enter the room as low as practical but in no case higher than four feet

above the floor. The inlet must be located where dirt, leaves, snow, etc. will not be carried

in with the cooling air.

5. The exhaust should be located as high as possible. Some ducting is usually required to

insure complete flushing of heated air with no stagnant areas.

6. The filter area must be adequate to insure a maximum air velocity of 300 feet per minute

through the filter. This is not a conservative number but a never exceed number. In a

dusty or remote location, this number should be reduced to 150 CFM.

7. The inlet and outlet(s) must have automatic dampers that close any time the ventilation

blower is Off.

8. Where Translators are regularly Off for a portion of each day a temperature differential

sensor controlling a small heater must be installed. This sensor will monitor inside and

outside temperatures simultaneously. If the inside temperature falls to within 5 degrees F of

the outside temperature the heater will come On. This will prevent condensation when the

ventilation blower comes On and applies even in the summer.

- Page 2 of 3 -

Page 22

836A 2 kW UHF Translator, Internally Diplexed Site Considerations

9. A controlled air bypass system must be installed to prevent the temperature in the room

from falling below 40 degrees F during Translator operation.

10. The blower should have two speeds, which are thermostatically controlled, and interlocked

with the Translator.

11. The blower on high speed must be capable of moving the required volume of air into a half

inch of water pressure at the required elevation. The free air delivery method must not be

used.

12. Regular maintenance of the filters can not be overemphasized.

13. Tube Translators should not rely on the internal blower for exhausting tube cooling air at

elevations above 4000 feet. For external venting, the air vent on the cabinet top must be

increased to 8" diameter for a 1 kW Translator and to 10" for 5 kW & 10 kW Translators. An

equivalent rectangular duct may be used but in all cases the outlet must be increased in

area by 50 % through the outlet screen.

14. It is recommended that a site plan be submitted to Axcera for comment before installation

commences.

In calculating the blower requirements, filter size and exhaust size, use the following guide. If the

total load is known in Watts, you will need 2000 CFM into 1/2" of water for each 5000 Watts. If

the load is known in BTU's you will need 2000 CFM into 1/2" of water for each 17,000 BTU's. The

inlet filter must be seven square feet minimum, larger for dusty and remote locations, for each

5000 Watts or 17,000 BTU's. The exhaust must be at least four square feet at the exhaust screen

for each 5000 Watts or 17,000 BTU's. The above is a general guide and may need modified for

unusually severe conditions.

A combination of air conditioning and ventilation installation should not be difficult to design using

the above information. System interlocking and thermostat settings should be reviewed with

Axcera. As with any equipment installation it is always good practice to consult the manufacturer

when questions arise. Axcera may be contacted at (724) 873-8100.

See the drawing that follows for more information.

- Page 3 of 3 -

Page 23

836A 2 kW UHF Translator, Internally Diplexed Unpacking and Installation

Air conditioning and any related heat exhaust ducts should be in place before continuing with the

installation of the Translator.

Please inspect the Cabinet and all other material thoroughly upon arrival. Axcera certifies that

upon leaving our facility the equipment was undamaged and in proper working order. The shipping

containers should be inspected for obvious damage that is indicative of rough handling. Check for

dents, scratches, broken switches, meters or connectors. Any claims against in-transit damage

should be directed to the Carrier. Also please inform Axcera as to the extent of the damage.

Remove the Cabinet with Trays, UHF Tee Assembly, Bandpass Filter, (Optional) Trap Filter,

Directional Coupler and Installation Material that make up the 836A from the crates and boxes.

Remove the straps which hold the Cabinet to the shipping skid and slide the Cabinet from the skid.

Remove the plastic wrap and foam protection from around the Cabinet. Do not remove any

labeling or tags from any cables or connectors, for these are for identification markers which make

reassembly of the Translator as easy as possible.

Remove the four L-brackets, mounted on the front panel rails, which hold the Trays in place during

shipment. The Trays are mounted in the cabinet using Chassis Trak cabinet slides. The Tray

Slides are on the Top and Bottom of the UHF Amplifier Trays and on the sides of the UHF Exciter

Tray and the VHF/UHF Receiver Tray. Inspect for any loose hardware or connectors, tightening

where needed. Open the rear door, the key to the lock, if present, is found in a tan envelope

taped to the door, and inspect the interior for packing material. Carefully remove any packing

material that is found. Slowly slide each Tray in and out to verify that they do not rub against

each other and have no restriction to free movement. Caution: Each UHF Amplifier Tray has a

hardline coaxial cable connected to the rear panel and will not slide out without first

removing this connection. To pull the tray out for test purposes, use the extender coaxial

cable included in the installation material kit for connection from the tray to the output

cable.

Adjustments to the position of the Trays may be necessary, and are accomplished by loosening

the cabinet slide mounting bolts that hold the front of the slide to the mounting frame of the

Cabinet and moving the Tray up or down as needed to correct for the rubbing.

The air intake to the 2 kW Translator is intended for room air only. The cabinet should be

positioned with consideration taken for adequate air intake and exhaust, the opening of the rear

door, access to the Trays including sliding them out for testing, the Main AC Hook-Up and the

installation of the Output Transmission Line. The Cabinet should be Grounded using copper

strapping material also should be permanently mounted to the floor of the Site using the holes in

the bottom of the Cabinet.

Once the Cabinet is in place and the Trays are checked for damage, the Main AC Hook-Up is ready

to be made. Before connecting the 230 VAC, make certain that all of the circuit breakers

associated with the Translator are switched Off. The Main AC Input circuit to the 2 kW Translator

should be an 80 Amp, 230 VAC line, using AWG 6 wire, inside of 1-1/4" conduit.

The 230 VAC Input connections are made to the Terminal Block TB1, which is part of (A2) the AC

Distribution Panel, located facing the rear door of the Translator. Terminals 1 & 2 (230 VAC) and

Terminal 3 (Chassis Ground). Line 2 is the Neutral for International Systems using 220 VAC Hot

and Neutral.

The RF Output at J2 of (A16) the Coupler Assembly, or the (Optional) Trap Filter (A14), which is

7/8" Rigid Coax, should connect to the Transmission Line that is connected to your Antenna

System.

The On Channel RF Input connects to the rear of the (A3) VHF/UHF Receiver Tray at the “F”

connector J5 for 75Ω or the “N” connector J1 for 50Ω or to the (Optional) (A17) A/V Input &

- Page 1 of 2 -

Page 24

836A 2 kW UHF Translator, Internally Diplexed Unpacking and Installation

- Page 2 of 2 -

Remote Interface Panel mounted on the Rear Top of the Translator. A plug is connected to Jack

(J11), with Pins 23 & 24 jumpered together on the UHF Exciter or to Jack (J9),with Pins 21 & 22

jumpered together on the (Optional) Remote Interface Assembly, which are 37 Position "D"

Connectors that provide the Interlock for the Translator. Jacks J10 and J11 on the UHF Exciter

and Jacks J9 and J10 on the (Optional) Remote Interface Assembly, are used to connect the

Remote Control functions to the Translator.

This completes the Unpacking and Installation of the 836A 2 kW UHF Solid State Translator. Refer

to the Set Up and Operation Procedure that follows before applying power to the Translator.

Page 25

836A 2 kW UHF Translator, Internally Diplexed Set Up and Operation Procedure

Initially the Translator should be turned on with the RF Output at (A11) the Coupler Assembly

terminated into a dummy load of at least 2000 Watts. If a load is not available, check that the

Output of the Coupler Assembly is connected to the Antenna for your System.

Connect the Antenna output to the “F” connector J5 for 75Ω or to the “N” connector J1 for 50Ω,

located on the rear of the VHF/UHF Receiver Tray..

Switch On the Main AC, UHF Exciter, Amplifier #1, Amplifier #2, Amplifier #3 and Amplifier #4 Circuit

Breakers located on the AC Distribution Panel facing the rear of the Cabinet mounted behind the

rear door. On the UHF Exciter Tray, switch the Operate/Standby Switch to Standby and the

Auto/Manual Switch to Manual. Normal operation of the Translator is in Automatic. Automatic

operation uses the Video Input to the UHF Exciter as an Operate/Standby Switch. In Auto, if the

Input Video is lost for approximately 7 seconds, the Translator will automatically revert to Standby

and when the Video Signal is restored, the Translator will quickly return to Operate.

Move the Operate/Standby Switch, located on the UHF Exciter Tray, to Operate. Note the power

supply reading, +26.5 VDC, on the front panel of the UHF Amplifier Trays. Note: If the Translator

does not switch to Operate, when the Operate/Standby Switch is switched to Operate, check that

an External Interlock Plug, with a Jumper wired from Pins 23 to 24, is connected to Jack (J11)

located on the rear of the UHF Exciter or if (A17) the Optional A/V Input & Remote Interface

Assembly is present in your System, the External Interlock Plug, with a Jumper wired from Pins 21

to 22, is connected to Jack (J9) on the Assembly. Observe the front panel Meter reading in the

% Visual Power position on the UHF Exciter Tray, it should read 100%. If needed, readjust the

screwdriver adjust Power pot located on the front panel of the UHF Exciter for 100%. As you are

checking the Power Level, check the Meter Reading in the % Reflected Power Position. If the %

Reflected Power is very high, above 50%, a problem with the Output Coaxial Lines is present and

needs to be checked. A center bullet missing from the 7/8" Rigid Coax Lines or loose bolts on the

connections can cause this problem. Return the Operate/Standby Switch to Standby.

The Gain and Phase controls located on the front panels of the individual UHF Amplifier Trays were

adjusted at the factory to attain 100% Output of the Translator and should not need readjusted.

The front panel readings on the individual UHF Amplifier Trays may not be the same. Refer to the

Test Data Sheet for your Translator to compare the final readings from the Factory with the

readings on each of the Trays after the Set Up. They should be very close to the same. If a

reading is way off, refer to the Phasing and Power Adjustment Procedure for the UHF Amplifier

Trays in the Detailed Alignment Procedure before trying to adjust.

If a dummy load is connected to the Translator, switch the Translator to Standby and switch the

Main AC Circuit Breaker Off. Remove the dummy load and make all connections needed to connect

the Translator to the Antenna for your System. Switch the Main AC Circuit Breaker On and the

Operate/Standby Switch to Operate. Adjust the Output Power screwdriver pot to attain 100%

Output.

If the Translator is already connected to the Antenna, check that the Output is 100%. If needed

adjust the Power screwdriver pot.

If a problem occurred during the Set-Up and Operation Procedure refer to the Detailed Alignment

Procedure of the Translator, which follows, for more information.

This completes the Translator Set-Up and Operation Procedure for the 836A UHF Solid State

Translator. The Translator can now be operated normally.

- Page 1 of 1 -

Page 26

836A 2 kW UHF Translator, Internally Diplexed Typical Operational Readings

UHF Exciter

ALC = .8 VDC.

% Exciter = The level is as needed to attain 100% output power from the Transmitter.

% Reflected = < 5 %

% Visual Power = 100 %

% Aural Power = 100 %

UHF Amplifier Trays

(A6) (A7)

AGC Voltage = 1 to 2 VDC. AGC Voltage = 1 to 2 VDC.

% Reflected = < 5 % with both Trays operating. % Reflected = < 5 % with both Trays operating.

< 50 % with one Tray operating. < 50 % with one Tray operating.

% Output Forward = The level is as needed % Output Forward = The Level is as needed

to attain 100% Output Power from the Transmitter to attain 100% Output Power from the Transmitter.

Power Supply = +26.5 VDC. Power Supply = +26.5 VDC.

(A8) (A9)

AGC Voltage = 1 to 2 VDC. AGC Voltage = 1 to 2 VDC.

% Reflected = < 5 % with all Trays operating. % Reflected = < 5 % with all Trays

operating.

< 25 % with one Tray operating. < 25 % with one Tray

operating.

% Output Forward = The level is as needed to % Output Forward = The Level is as

needed to attain 100% Output Power from the transmitter to attain 100% Output

Power from the Transmitter.

Transmitter.

Power Supply = +26.5 VDC. Power Supply = +26.5 VDC.

- Page 1 of 1 -

Page 27

836A 2 kW UHF Translator, Internally Diplexed Meters, Switches, Indicators and Samples

UHF Exciter Tray:

Name Function

“Metering”

Meter (A4-A18) Reads power in terms of a percentage of the calibrated Output

Power level on the upper scale. The Voltage Level is read on

one of the bottom two scales. A full scale reading on the top

scale is 100%, which is equivalent to the full rated 2000 Watts

Peak of Sync Visual. Also reads % Aural Power, % Exciter

Power, % Reflected Power and ALC reading.

Switch (S3), Meter Selects the desired ALC Voltage reading, % Exciter Power, %

Reflected Power, % Visual Power or % Aural Power.

ALC Reads the ALC Voltage Level, .8 VDC, on the 0-10 scale.

(0-10 V)

% Exciter Reads the % Exciter Output Power Level needed to attain

100% Output of the

(0-100) Transmitter on the top scale.

% Aural Power Reads the % Aural Output Power of the Transmitter, 100% =

(0-100) 10 dB A/V Ratio, on the top scale.

% Visual Power Reads the % Visual Output Power of the Transmitter, 100% =

(0-100) Pk Sync, on the top scale.

% Reflected Reads the % Reflected Output Power, <5%, on the top scale.

(0-100)

“Control”

Switches

Transmitter (S1) The momentary switch (S1) applies a ground to K1, a latching

Operate/Standby Operate/Standby relay, located on the Transmitter Control

200 Watts @

2000 Watts

Board. K1 will switch either to Operate or to Standby

depending on which direction S1 is pushed. When switched to

Operate, the low, Enable Commands, are applied to the four

UHF Amplifier Trays. These Enables will turn on the UHF

Amplifier Trays. The opposite occurs when switched to

Standby.

Mode Select (S2) The momentary switch (S2) applies a ground to K2, a latching

Auto/Manual relay, located on the Transmitter Control Board. K2 will switch

the Transmitter to Automatic or Manual depending on which

direction S2 is pushed. In Automatic, the Video Fault Command

from the ALC Board will control the Operation of the

Transmitter. The Transmitter will switch to Standby, after a

slight delay, if the input video is lost and will switch back to

Operate, quickly, when the Video is restored. In Manual, the

- Page 1 of 4 -

Page 28

836A 2 kW UHF Translator, Internally Diplexed Meters, Switches, Indicators and Samples

Transmitter is controlled by the Operator using the front panel

Operate/Standby Switch or by remote control.

Power Adjust (R1) The 5 kΩ Pot A20 sets the ALC Level on the ALC Board which

sets the output power of the Transmitter.

UHF Exciter Tray:

Name Function

“Status”

Fault Indicators

Video Loss (DS9 RED) Indicates that the Input Video has been lost to the Translator.

The Fault is generated on the ALC Board located in the UHF

Exciter Tray.

VSWR Cutback (DS7 Amber) Indicates that Reflected Power Level of the Translator has

increased above 20 % which will automatically cutback the

Output Power Level to 20 %. The Fault is generated on the

Transmitter Control Board located in the UHF Exciter Tray.

“Samples”

f(s) A Sample of the Channel Oscillator Output taken from

Exciter O/P An Output Power Sample of the Exciter taken from the UHF

Translator O/P A Forward Power Sample of the Translator taken form the

VHF/UHF Receiver Tray

“Samples”

f(IF) Output A Sample of the IF Output taken from the IF Filter/ALC Board.

F(s) Oscillator A Sample of the Channel Oscillator Output taken from the

UHF Amplifier Trays:

the Sample Jack of the Channel Oscillator Assembly.

Upconverter Board.

Visual/Aural Metering

Board.

Sample Jack of the Channel Oscillator Assembly.

“Metering”

Meter (A6, A7, A8 & A9 - A9) Reads power in terms of a percent of the calibrated power

output value. A full scale reading is 100% which is equivalent

to the full rated 600 Watts Peak of Sync Visual + Aural Output

- Page 2 of 4 -

Page 29

836A 2 kW UHF Translator, Internally Diplexed Meters, Switches, Indicators and Samples

Power. Also reads % Reflected Power, Power Supply Voltage

Levels and AGC Voltage Levels.

Switch (S2), Meter Selects the desired % Power or the Voltage reading.

% Output Pwr Reads the % Output Power of the Tray, 100% = 600 Watts

Peak of Sync Visual + Aural, on top scale.

% Refl (Reflected) Reads the % Reflected Output Power of the Tray, <20% with

all Amplifier Trays operating A6, A7, A8 & A9, as measured on

top scale.

Power Supply Reads the Power Supply Voltage, +26.5 VDC, on the middle

scale.

UHF Amplifier Trays:

Name Function

“Metering” - Continued

AGC Voltage Reads the AGC Voltage Level, +1 VDC to +3 VDC, on bottom

scale.

“Status”

Indicators

Enable (DS4 Green) Indicates that an Enable, Operate Command, is applied to the

UHF Amplifier Tray from the selected UHF Exciter Tray.

Overdrive (DS2 Red) Indicates that the level of the drive is too high. The protection

circuit will limit the drive to the set threshold. The Fault is

generated on the Amplifier Control Board.

VSWR Cutback (DS1 Red) Indicates that Reflected Power Level of the Tray has increased

above 50% which will automatically cutback the Output Power

Level to 20 %. The Fault is generated on the Amplifier Control

Board.

Overtemp (DS3 Red) Indicates that the temperature of (A5-A6-A3 & A5-A6-A4) one

or both of two Thermal Switches mounted on the heatsink

assembly for the output amplifiers is above 175 degrees F.

When this Fault occurs the Enable to the Switching Power

Supply in the effected Amplifier Tray is removed immediately

and it will shut down.

Input Fault (DS5 Red) Indicates that the Input RF Level to the Amplifier Trays

dropped below the 0 dBm Range.

- Page 3 of 4 -

Page 30

836A 2 kW UHF Translator, Internally Diplexed Meters, Switches, Indicators and Samples

“Control”

Adjustments

Phase (A10-R5) Adjusts the Phase of the RF Output approximately 70°.

Gain (A11-R6) Adjust the gain of the RF Output when the Amplifier control

Board is in the AGC Mode.

“Sample”

Module O/P (0 dBm) A Sample of the Combined Output of the four Dual Stage

Amplifier Boards taken from the Dual Peak Detector Board.

- Page 4 of 4 -

Page 31

836A 2 kW UHF Translator, Internally Diplexed Detailed Alignment Procedure

This Translator was aligned at the factory and should require no additional alignment to achieve

normal operation.

Check that the RF Output at J2 of (A16) the Coupler of the Translator is terminated into a dummy

load of at least 2000 Watts. Refer to the Test Data Sheet for your Translator and compare the

final readings from the Factory with the readings on each of the Trays while doing the alignment.

They should be very close to the same. If a reading is way off, the problem is likely to be in that

Tray.

Switch On the Main AC and the UHF Exciter Circuit Breakers located on the AC Distribution Panel

mounted behind the rear Cabinet door.

(A3) VHF/UHF Receiver Tray (1265-1100)

Connect a UHF Input (-61 dBm to -16 dBm), with a Multiburst Test signal applied, that is at the On

Channel Frequency to Jack J5, "F" type connector for 75Ω or Jack J1, "N" type connector for 50Ω

located on the Receiver Tray. Check that the On/Off Circuit Breaker, located on the rear of the

Receiver Tray, is On. If the Optional Remote Preamplifier is purchased, the Fuse F1 located in the

Receiver Tray must be removed to eliminate the +12 VDC from the input to the Receiver Tray to

prevent damage to the Test equipment. Check the Front Panel Sample Jack (J6) with a Frequency

Counter. The signal should be at the needed frequency, check the top of the Channel Oscillator

Assembly for the actual frequency, to produce the IF Outputs.

(A4) UHF Exciter Tray (1300-1020)

The IF Section of the UHF Exciter Tray includes adjustments for automatic level control (ALC),

linearity (amplitude predistortion) and phase (phase change vs. level) predistortion for correction

of the nonlinearities of the RF Amplifier Trays. The Upconverter Section also includes adjustments

of the local oscillator chain tuning and also the local oscillator center frequency tuning. Both of

these were completed at the factory and should not require adjustment at this time.

Move the Operate/Standby Switch located on the UHF Exciter Tray to Standby. The set up of the

RF Output, includes adjustment of the drive level to the four UHF Amplifier Trays, the adjustment

of the Linearity and Phase Predistortion which compensate for any nonlinear response of the

Amplifier Trays and also the gain and phasing adjustments of the four UHF Amplifier Trays.

Verify that all Red LEDs located on the ALC Board are extinguished. The following list details the

meaning of each LED when illuminated.

DS1 (Input Fault) Indicates abnormally low or no IF is present at the Input of the ALC Board.

DS2 (ALC Fault) Indicates that the ALC circuit is unable to maintain the signal level requested by

the ALC reference. Normally this is due to excessive attenuation in the linearity signal path, the IF

Phase corrector signal path or that Jumper W3 on J6 is in the Manual ALC Gain position.

DS3 (Video Loss) Indicates a loss of Video at the Input of the ALC Board.

DS4 (Mute) Indicates a Visual Mute Command is present. Not used in this configuration.

DS5 (Modulator Enable) Indicates Modulator IF Output is selected. Will be Off if the output of the

Receiver Tray is selected.

The ALC is Muted when the Translator is in Standby. To monitor the ALC, turn Off the front panel

On/Off circuit breaker located on the Amplifier Trays and switch the Translator to Operate. Adjust

- Page 1 of 7 -

Page 32

836A 2 kW UHF Translator, Internally Diplexed Detailed Alignment Procedure

the Power Adjust Gain Pot, located on the Front Panel of the UHF Exciter Tray, to obtain +0.8 VDC

on the Front Panel Meter in the ALC Position. On the ALC Board (1265-1305), move the Jumper

W3 on J6 to the Manual Position, between Pins 2 & 3, and adjust R87 on the ALC Board for +0.8

VDC on the Front Panel Meter in the ALC Position. Move the Jumper W3 back to Auto, between

Pins 1 & 2, which is the normal operating position. The detected IF signal level at J19-2 of the

ALC Board is connected to the Transmitter Control Board that distributes the level to the Four UHF

Amplifier Trays where it is used as a reference for the automatic gain control (AGC) in each

Amplifier Tray.

(A6, A7, A8 & A9) UHF Amplifier Trays (1294-1112 Low Band, 1294-1113 Mid Band, or

1294-1114 High Band)

Check that the output power of the Translator is 100 %, if it is not, adjust the Power screwdriver

Adjust Pot located on the front panel of the UHF Exciter Tray as needed to achieve 100%.

When testing one of the UHF Amplifier Trays the other circuit breakers, located on the AC

Distribution Panel, should be turned Off. The Amplifier 1 Circuit Breaker applies power to the Top

left UHF Amplifier Tray, the Amplifier 2 Circuit Breaker applies power to the bottom left UHF

Amplifier Tray, the Amplifier 3 Circuit Breaker applies power to the bottom left UHF Amplifier Tray

and the Amplifier 4 Circuit Breaker applies power to the bottom right UHF Amplifier Tray. The UHF

Amplifier Trays should be turned on into a dummy load of at least 600 Watts to verify that the

Tray is functioning. Preset the AGC Switch on (A8) the Amplifier Control Board (1265-1414) to the

AGC On position. The four UHF Amplifier Trays are set up in pairs, the top two A6 with A7 and the

bottom two A8 with A9. Switch On the Amplifier 1 Circuit Breaker, located on the AC Distribution

Panel. Switch to Operate the Translator Operate/Standby Switch, located on the UHF Exciter, and

observe the power supply metering position on the UHF Amplifier Tray. It should read +26.5 VDC

when the Tray is switch On and the Translator is in Operate.

Switch the Tray to the % Output Power Meter Position and adjust the front panel Gain pot located

on that Amplifier Tray to 100% on the Meter, then back off the Gain Pot to the reading as written

on the Test Data Sheet for your Translator. Repeat for the Amplifier 2 Tray of the pair. Switch

the Translator to Standby and reconnect the UHF Amplifier Trays to the (A10) UHF Tee Assembly.

Repeat the above procedure for Amplifier 3 and Amplifier 4. After the setup of all four Amplifier

Trays, switch the Translator to Operate and adjust the Phase Controls on each of the Amplifier

Trays to give maximum Output Power on the Front Panel of the UHF Exciter. The Output Power

reading on the front panel of the UHF Exciter should be 100%, if it is not, adjust the Power

screwdriver Adjust Pot located on the front panel of the UHF Exciter Tray as needed to achieve

the 100% Output.

Switch the Input Test source to select a NTSC 3.58 MHz Modulated Staircase or Ramp Test

waveform and set up the station demodulator and monitoring equipment to monitor the differential

gain and differential phase of the RF Output signal.

If a synchronous demodulator having a quadrature video output is available, it can be used with an

X-Y Oscilloscope to display incidental carrier phase modulation (ICPM). As shipped, the Exciter

was preset to include linearity (gain vs. level) and incidental phase (carrier phase vs. level)

predistortion. The predistortion was adjusted to approximately compensate the corresponding

non-linear distortions of the Amplifier which is driven to place the Sync Level near saturation.

Move the Jumper W1 on J4 on the ALC Board to the Enable Position. Refer to the Test Data Sheet

for your Translator for the final test readings on each Amplifier Tray. Adjust the Phase Pot located

on each UHF Amplifier Tray to obtain maximum % Visual Output Power. Adjust each of the Gain

Pots, on the UHF Amplifier Trays, equally, as needed to obtain 100% Visual Output Power on the

Front Panel Meter of the UHF Exciter.

- Page 2 of 7 -

Page 33

836A 2 kW UHF Translator, Internally Diplexed Detailed Alignment Procedure

Linearity Corrector Adjustment

The IF linearity correction function consists of three non-linear cascaded stages, each having

adjustable magnitude and threshold or cut-in points located on the ALC Board. The threshold

adjustment determines at what IF signal level the corresponding corrector stage begins to increase

gain. The magnitude adjustment determines the amount of gain change for the part of the signal

which exceeds the corresponding threshold point. Refer to the UHF Exciter Tray Assembly Drawing

(1265-5300), or the Assembly Drawing for (A8) ALC Board (1265-5305), to locate the adjustments

for the first through third linearity corrector stages. Because the stages are cascaded, the order

of correction is important. The first stage should cut -in near white level, with the cut -in point of

the next stage toward black and with the last stage primarily stretching sync.

To adjust the linearity correctors from scratch. Ensure that the Translator is operating at full

power with the desired A/V Ratio. Check that the Jumper W1 on J4 on the ALC Board is Enabled,

between Pins 1 & 2. Check that the ALC Voltage is set to +0.8 VDC as monitored on the Front

Panel Meter in the ALC Position.

Insert a modulated ramp video test signal into the Translator. Demodulate the output signal of the

Translator and observe the waveform on a Waveform Monitor while also looking at the signal on a

Spectrum Analyzer. On the IF ALC Board (1265-1306), preset the Pots R34, R37 & R40 (Threshold)

full CCW, and the Magnitude Adjustments R13, R18 & R23 full CW. On the IF Phase Corrector

Board (1227-1250), preset the Pots R7, R15, R23 & R35 full CW, and R3, R11, R19 & R31 full CCW.

Linearity Corrector Adjustment - Continued

Set the Waveform Monitor to Differential Step Filter and the Volts/Division scale to .1V. Center

the display around Blanking.

Gradually adjust pots R3, R11 and R19 Clockwise on the IF Phase Corrector Board as needed to

minimize the observed thickness of the intermod as seen on the display.

Adjust the pots R34, R37 and R40 Clockwise on the IF ALC Board needed to give correction at

Sync or at low luminance levels, which are viewed at the rightmost edge of the Waveform Monitor.

The intermod beat products between the Color Burst and the Aural Carrier at 920 kHz above Visual

Carrier should also be observed on the Spectrum Analyzer while performing the preceding

adjustments. The frequency will vary for PAL Systems. When the adjustments are performed

properly, the intermod products on the Spectrum Analyzer should be at least -52 dB down, with a

Red Field input, from peak visual carrier and the Intermod Distortion as displayed on the Waveform

Monitor should be no more than 1 IRE. The pot R31 on the IF Phase Corrector Board is used for

any extra Intermod correction that may be needed.

It should be noted that any adjustment of the above pots affects other visual parameters and

some slight adjustments of all the pots may be needed to meet all specifications simultaneously.

If the Translator is being driven very hard, it may not be possible to get enough Sync Stretch

while maintaining a flat differential gain. In this case, some Video Sync Stretch may be used from

the Sync Tip Clamp/Modulator Board. The Sync Stretch adjustment is R48 located on the Sync

Tip Clamp/Modulator Board. Switch the Translator to Standby.

Phase and Gain Adjustment of the UHF Amplifier Trays

- Page 3 of 7 -

Page 34

836A 2 kW UHF Translator, Internally Diplexed Detailed Alignment Procedure

The following procedure was completed at the factory and should only be followed if one of the

UHF Amplifier Trays is replaced.

Preset the Phase and Gain potentiometer located on each UHF Amplifier Tray Full CCW. Switch the

Translator to Operate and adjust the Gain Pot on each Tray for 25% Output Power. Adjust the

Phase Control CW on the Left UHF Amplifier Tray. If the % Visual Output Power goes UP, continue

to adjust until either the Peak is reached or the End of Travel is reached. If the % Output Power

goes Down, Reset the Phase Control on the UHF Amplifier Tray Fully CCW and repeat the above

procedure with the Phase Control of the other Amplifier Tray.

If the End of Travel is reached on the Phase Adjust, Reset the Phase Control CCW and add a 2"

length of Cable to the output of the (A5) Splitter Module which connects to the effected UHF

Amplifier Tray at J1. Readjust the Phase of that Tray until a Peak is reached or until End of Travel

is achieved. If End of Travel is reached, repeat the above procedure replacing the 2" length cable

with a 4" length of cable. Once a Peak is reached, move the Phase Control, that is Full CCW, Up 2

Turns and re-peak using the Phase Control located on the other Tray. This allows both Trays to

have some range of adjustment.

Adjust the Gain of both UHF Amplifier Trays for 90% Tray Output Power. Readjust each Phase

Control to Peak the Combined Output, the Phase should only have been effected slightly. There

should be a definite Peak that is achieved while adjusting the Phase of each Tray though it may

take a few Turns to notice a change. Raise or Lower the Output Power of each Tray to achieve

100% Output Power. The Output Power of each Tray should be 90% - 100%.

Calibration of the Forward Output Power Level of the Translator

Note: - Perform the following only if the power calibration is suspect.

Switch the Translator to Standby and preset R51, Aural Null pot, located on the Visual/Aural

Metering Board (1265-1309), full CCW. Adjust R48, the Null Offset pot, located on the Visual/Aural

Metering Board, for 0% Visual Output. Do the following adjustments with no Aural present, by

removing the Aural from the RF Input Test Signal. Connect a Sync and Black Test Signal to the

Input of the UHF Exciter Tray. Switch the Translator to Operate.

Calibration of the Forward Output Power Level of the Translator .- Continued

Next Set the Translator up for the appropriate Average Output Power Level. (Sync + Black 0 IRE

Setup Wattmeter = 1190 Watts). (Sync + Black 7.5 IRE Setup Wattmeter = 1090 Watts).

Note: Must have 40 IRE Units of Sync. Adjust R28, Visual Calibration, located on (A19) the

Visual/Aural Metering Board (1265-1309) for 100% on the front panel meter in the % Visual Output

Position.

With the Spectrum Analyzer set to Zero Span Mode, obtain a peak reference on the screen.

Reinsert the Aural to the RF input test Signal. While in the Visual Output Power position, adjust L3

for minimum visual power reading. Turn the power adjust pot on the front panel until the original

peak reference level is attained. Peak L1 and C8 for maximum Aural Power reading, then adjust

R20 also for 100% Aural Power reading. Then switch to Visual Output Power position and adjust

R51 for 100% Visual Power.

Calibration of the Reflected Output Level of the Translator

Turn the Power Adjust Pot to 20% on the Meter in the Visual Power position, check that the