UBS Axcera 835-3 User Manual

3-kW UHF Transmitter Chapter 4, Detailed Alignment Procedures

Chapter 4

Detailed Alignment Procedures

Before beginning the alignment procedures, make sure that the RF output at J2 of (A11)

the output coupler assembly of the transmitter is terminated into a dummy load of at

least 3000 watts. While performing the alignment, refer t o the test data sheet for the

transmitter and compare the final readings from the factory with the readings on each

of the trays. The readings should be very similar. If one of the readings is off by a

significant degr ee, the pro blem is likely to be in that tray.

Switch on the UHF exciter tray circuit breaker on the AC distribution panel in the UHF

exciter cabinet and the circuit breaker on the rear of the UHF exciter tray for the 3-kW

transmitter. Also switch on the main and the individual amplifier circuit breakers on the

AC distribution panel in the amplifier array cabinet.

4.1 (A1) UHF Exci t er Tray (1227-1200; Append ix A)

The (A1) UHF exciter tray has been factory tuned and should need no alignment to

achieve normal operation. Apply the baseband video and audio inputs of the test signals,

as needed, to the A/V input and remote interface panel on the rear of the transmitter.

4.1.1 (Opti onal) (A6) Delay Equalizer Board (1227-1204; Appendix B)

This board may not be present in the tray.

This board has been factory tuned and should not be re-tuned without the proper

equipment. To align this board:

•

Connect a sinX/X test signal into jack J1-2 on the delay equalizer board.

•

Monitor the video output of the board at video sample jack J2 with a video

mea suring set VM700 adjusted to measure group delay.

•

Tune the four stages of the board using the variable inductors (L1-L4) and

potentiometers (R7, R12, R17, and R22) until the signal attains the FCC group delay

curve. The stages are arranged in order of increasing frequency. Adjust R29, if

needed, for the desired video gain.

4.1.2 (A7) IF Carrier Oven Oscillator Board (1191-1404; Appendi x B)

While monitoring J3 with a spectrum analyzer, observe the 45.75 MHz visual IF (+5

dBm).

Connect a frequency counter to J3 and adjust C17 for 45.750000 MHz.

Connect a frequency counter to J1 and check for 50 kHz; this is the aural phase lock

loop reference.

4.1.3 (A5) Cl amp /Modul ator Board (1227-1208; Appendix B)

Determine if jumper W1 on jack J3 is present. Jumper W1 terminates the video input

into 75 ohms. Remove jumper W1 if video loop-through is required on the rear chassis

jacks J1 and J2.

835-3, Rev. 0 4-1

3-kW UHF Transmitter Chapter 4, Detailed Alignment Procedures

Set the controls R28, the white clip; R31, the sync clip; and R43, the sync stretch, to

their fully counter-clockwise (CCW) position.

Note: On Revision 6 or later boards, controls R43, sync stretch cut-in, and

R176, sync stretch magnitude, should be set fully CCW .

Place jumper W5 on jack J11 to the clamp disable position (towards the top of the

board) and jumper W2 on jack J4 to the AGC disable (out) position.

Connect a 5-step staircase video test signal to the input of the transmitter.

Monitor TP5 (on Revis ion 1 or later boards) with an oscilloscope. Adjust R15, the vide o

gain pot, for 1 Vpk-pk. Alternately, pin 2 on video sample jack J7 can be monitored for 1

Vpk-pk when terminated into 75 ohms (2 Vpk-pk when unterminated).

Change the video input test sig nal to a multiburst test pattern. While monitoring TP5 or

video sample jack J7, pin 2, adjust C8 and R35 for a flat-frequency response. Change

the input video test signal back to the 5-step staircase.

Decrease the amplitude of the input video test signal (the 5-step staircase) to 0.5 Vpkpk. (Do uble terminat ing the input will accomplish the required level redu ction or R15

can be adjusted as needed.) Monitor pin 2 of IC U8B (or TP6 on Revision 1 or later

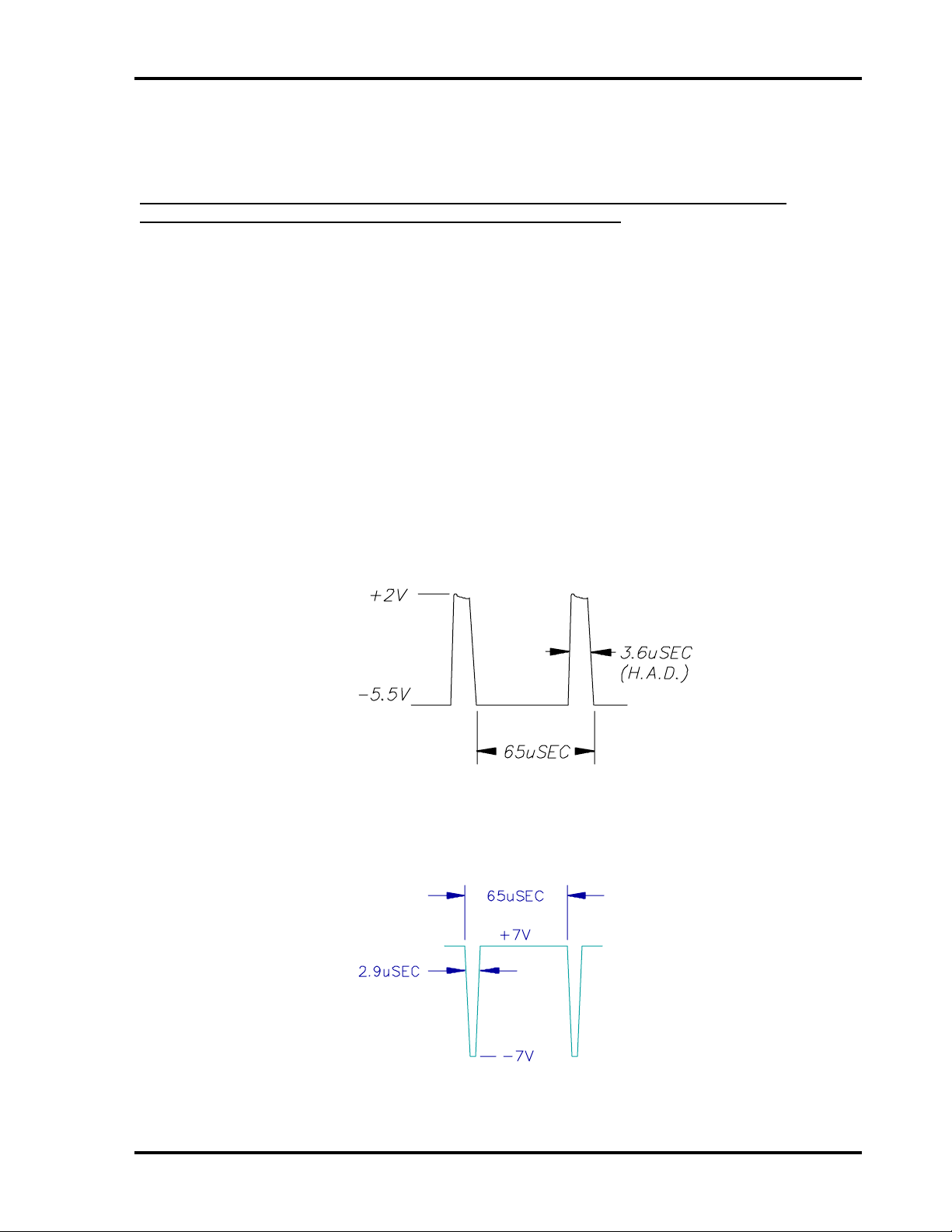

boards) with an oscilloscope. Adjust R76, the sync separator, to obtain a steady

waveform as shown in Figure 4-1.

Figure 4-1. Steady Waveform Obtained When R76 is Adjusted

Monitor pin 9 of IC U9 with an oscilloscope. The waveform show n in Figure 4-2 should

be observed.

Figure 4-2. Waveform Observed When Pin 9 of IC U9 is Monitored

835-3, Rev. 0 4-2

3-kW UHF Transmitter Chapter 4, Detailed Alignment Procedures

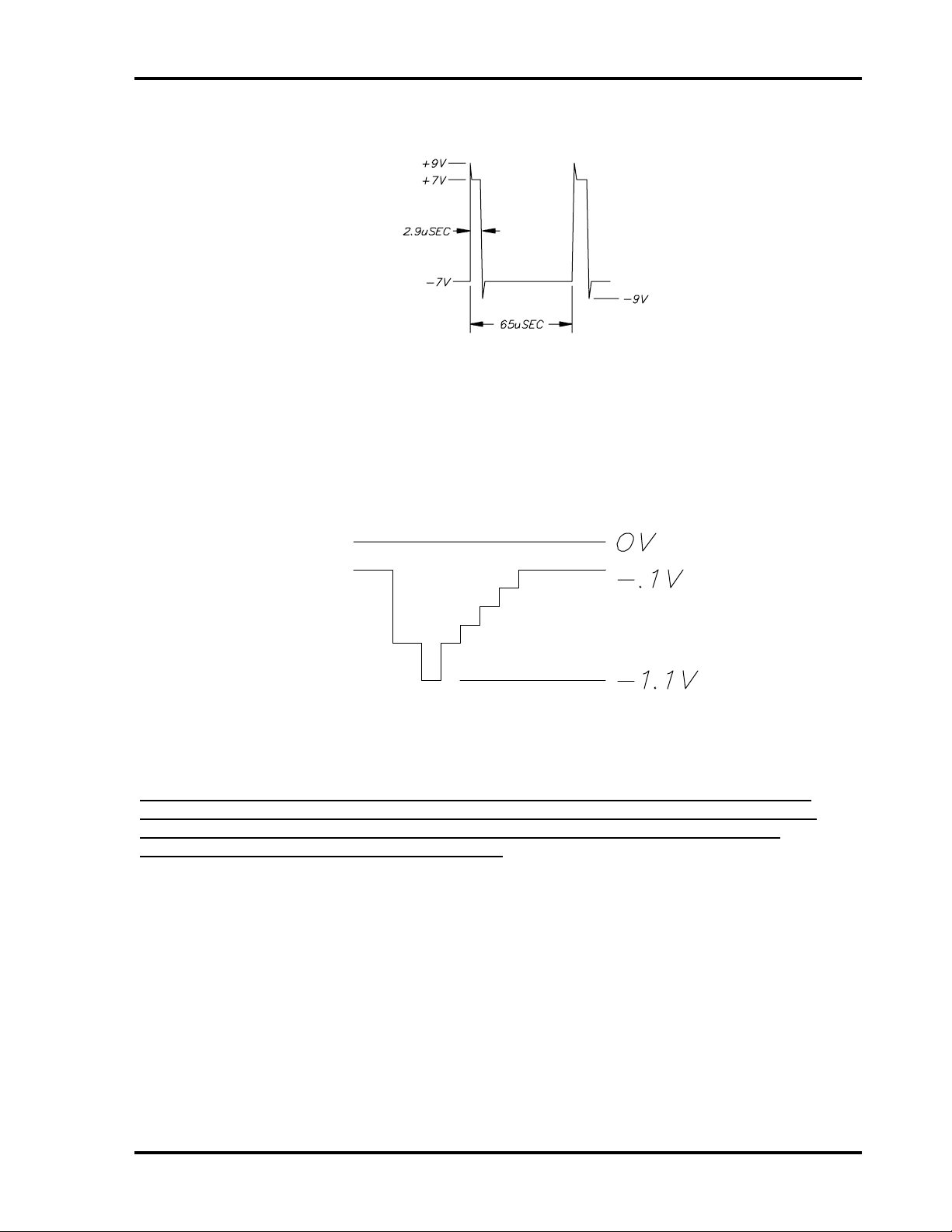

Monitor pin 13 o f IC U6 (or TP7 on Revision 1 or later boards) with an oscilloscope. Th e

waveform shown in Figure 4-3 should be observed.

Figure 4-3. Waveform Observed When Pin 13 of IC U6 is Monitored

Restore the input video level to 1 Vpk-pk.

Monitor TP5 (on Revision 1 or later boards) or pin 2 of J7 (terminated into 75 ohms)

with an o scilloscope. Adjust pot R105, manual bias, for a blanking level of -0.8 VDC. The

waveform shown in Figure 4-4 should be observed. Move jumper W5 on J11 to the

clamp enable position (towards the bottom of the board). Adjust pot R95, clamp bias, for

a blanking level of -0.8 VDC. Again, the waveform in Figure 4-4 should be observed.

Figure 4-4. Waveform Observed When An Adjustment is Made

for a Blanking Level of –0.8 VDC

Note: The waveform in Figure 4-4 represents the theoretical level for proper

modulation depth. The second step below explains how to set the modulation

depth by the use of a television demodulator or a zero-spanned spectrum

analyzer t uned t o the vis ual IF frequenc y.

Connect the oscilloscope to the lead of L4 that is closest to C32 and adjust the color

notch subcarrier trap, C32, until the 3.58-MHz colo r burst is nulled.

Check the ratio o f sync to video (0.286 volts of sync for a 1 Vpk-pk total video signal). If

necessary, adjust R43, the sync stretch cut-in (on Revision 6 or later boards, also adjust

R176, the sync stretch m agnitude) for the proper sync ratio. Re-adjust R15, the video

gain pot, as described above, to maintain a 1 Vpk-pk video signal.

To construct the test setup for the adjustment of the depth of modulation and ICPM at

IF:

•

Remove the cable on J18 and connect the double sideband 45.75-MHz visual IF

signal from J18 to a 10-dB splitter/coupler. Connect the coupled port of the

835-3, Rev. 0 4-3

3-kW UHF Transmitter Chapter 4, Detailed Alignment Procedures

splitter/coupler to the RF input of a television demodulator. Connect the direct port

to a spectrum analyzer.

•

Connect the 75-ohm video output of the demodulator to the video input of a

waveform monitor. For ICPM measurements, also connect the quadrature output of

the demodulator to the horizontal input of the waveform monitor using a 250-kHz

low pass filter (an osc illoscope can be used in place of a waveform monitor).

•

Set the controls of the demodulator to the following:

Detector mode – Cont

Sound Trap – In

Zero Carrier – On

Auto – Sync

Audio Source – Split

De-emphasis – In

Move jumper W5 on J11 to the clamp disable p osition. Re-adjust pot R105, manual bias,

for the correct depth of modulation by observing the demodulated waveform on the

waveform monitor or on the spectrum a nalyzer set to zero span.

Move jumper W5 on J11 to the clamp enable position. Re-adjust pot R95, the clamp

bias, for the correct depth of modulation.

Set the wavefo rm monitor to display ICPM. Preset R143 fully clockwise (CW) and adjust

C65 for the greate st effect at white on the ICPM disp lay. Adjust R 143 for minimum

ICPM.

Recheck the depth of modulation and adjust R95, clamp bias, if necessary.

Remove the video input signal. Alternately, turn the front panel meter switch between

the video and sync positions and adjust blanking pot R49 for a reading of zero on both

pos itions on the front panel meter.

Replace the input video test signal (the 5-step staircase). While monitoring the front

panel meter in the sync position, adjust R19 on the transmitter control board (1227-

1209) for a reading of 40 (4 on the 0 to 10 sca le). Turn the front panel meter to the

video position and adjust R20 on the transmitter control board for a reading of 100 (10

on the 0 to 10 scale).

Place jumper W2 on jack J4 to the AGC enable position. Adjust R60, the sync level, for

the proper depth of modulation in the AGC mode. Return jumper W2 on jack J4 to the

AGC disable position.

Note: Use the AGC mode only if the incoming program video level cannot be

properly maintained.

Reconnect the plug to J18 and move the spectrum analyzer test cable to 41.25 IF output

jack J16. Tune C56 and L10 to L13 to maximize the 41.25-MHz aura l IF signal and

minimize the out-of-band products.

Reconnect the plug to J16 and move the s pectrum analyzer test cable to IF output jack

J20. P reset R150, the visual IF gain po t, to the middle of the range. Insert a multiburst

test signal into the transmitter and observe the visual frequency response with the

835-3, Rev. 0 4-4

Loading...

Loading...