Page 1

Fieldbus Independent

I/O Modules

Bluetooth

750-644

®

RF Transceiver

Manual

Version 1.0.1

Page 2

2 • General

Copyright © 2008 by WAGO Kontakttechnik GmbH & Co. KG

All rights reserved.

WAGO Kontakttechnik GmbH & Co. KG

Hansastraße 27

D-32423 Minden

Phone: +49 (0) 571/8 87 – 0

Fax: +49 (0) 571/8 87 – 1 69

E-Mail: info@wago.com

Web:

http://www.wago.com

Technical Support

Phone: +49 (0) 571/8 87 – 5 55

Fax: +49 (0) 571/8 87 – 85 55

E-Mail:

support@wago.com

Every conceivable measure has been taken to ensure the correctness and completeness of this documentation. However, as errors can never be fully excluded, we would appreciate any information or ideas at any time.

E-Mail: documentation@wago.com

We wish to point out that the software and hardware terms as well as the

trademarks of companies used and/or mentioned in the present manual are

generally trademark or patent protected.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 3

Important Comments • 3

Legal Principles

Content

1 Important Comments ................................................................................. 7

1.1 Legal Principles........................................................................................7

1.1.1 Copyright............................................................................................. 7

1.1.2 Personnel Qualification .......................................................................

1.1.3 Intended Use........................................................................................

1.2 Symbols....................................................................................................8

1.3 Number Notation......................................................................................8

1.4 Safety Notes ............................................................................................. 9

1.5 Scope ........................................................................................................7

2 I/O Modules ...............................................................................................10

2.1 Special Modules ..................................................................................... 10

2.1.1 750-644 [Bluetooth® RF Transceiver]...............................................10

2.1.1.1 View..............................................................................................10

2.1.1.2 Description....................................................................................10

2.1.1.3 Indicators.......................................................................................13

2.1.1.4 Schematic Diagram.......................................................................15

2.1.1.5 Technical Data ..............................................................................15

2.1.1.6 Function Description..................................................................... 17

2.1.1.7 Operating Modes........................................................................... 21

2.1.1.8 Process Image ...............................................................................31

7

7

3 Configuration of a Bluetooth® Piconet ....................................................58

4 Tools for Configuring and Operating .....................................................60

4.1 Configuring and Operating with WAGO-I/O-CHECK..........................61

4.1.1 User Interface ....................................................................................

4.1.1.1 Title Bar ........................................................................................

4.1.1.2 Symbol Bar ...................................................................................

61

62

62

4.1.1.3 Navigation.....................................................................................63

4.1.1.4 Mode Assignment .........................................................................

4.1.1.5 Parameterization Area...................................................................

4.1.1.6 Status Display ...............................................................................

®

4.2 Configuring the Bluetooth

4.2.1 Setting the Bluetooth

Module 750-644 ........................................78

®

Process Data and Mailbox Size..................... 78

64

65

77

4.2.2 Setting the Mode................................................................................ 78

4.2.3 Role Assignment (Master/Slave).......................................................79

4.2.4 Search for and Display Devices within Range .................................. 79

4.2.5 Bind new Devices.............................................................................. 79

4.2.5.1 Entering Bluetooth® Devices manually ........................................79

®

4.2.5.2 Bind Bluetooth

4.2.6 Assigning Slave Process Data to Slots in the Master........................

Devices from Network Search........................... 80

81

4.2.7 Diagnostics ........................................................................................81

WAGO-I/O-SYSTEM 750

I/O Modules

Page 4

4 • Important Comments

Legal Principles

5 Fieldbus-specific Additions ......................................................................82

5.1 CANopen................................................................................................82

5.1.1 Process Image Access........................................................................ 82

5.1.1.1 Example ........................................................................................83

5.2 DeviceNet............................................................................................... 86

5.2.1 Process Image Access........................................................................ 86

5.2.1.1 Example ........................................................................................86

5.3 ETHERNET ........................................................................................... 88

5.3.1 Process Image Access........................................................................ 88

5.3.1.1 MODBUS Protocol....................................................................... 88

5.3.1.2 EtherNet/IP Protocol..................................................................... 90

5.4 PROFIBUS-DP.......................................................................................92

5.4.1 Process Image Access........................................................................

5.4.1.1 Example ........................................................................................

5.5 LON........................................................................................................95

92

92

6 Appendix ....................................................................................................

6.1 Mailbox Commands ...............................................................................

96

96

6.1.1 Overview Sorted According to Groups and Opcodes .......................96

6.1.2 Overview Sorted According to Mailbox Commands ........................99

6.2 Return Values of Mailbox Commands................................................. 101

6.3 Mailbox Command References............................................................102

6.3.1 General Commands .........................................................................104

6.3.1.1 No Task (IDLE, 0x00) ................................................................104

6.3.2 Block Transfer .................................................................................105

6.3.2.1 Download Start of a Block (DLD_START, 0x01) .....................105

6.3.2.2 Continuation of a Block Download or Upload (DLD_CONT,

0x02) ...........................................................................................107

6.3.2.3 End a Block Download or Upload (DLD_END, 0x03) .............. 109

6.3.3 Maintenance and Firmware .............................................................

111

6.3.3.1 Warm Start of the Bluetooth® Subsystem (RebootHost, 0x10) ..111

6.3.3.2 Saving the Configuration with Subsequent Warm Start

(FlashRebootHost, 0x11) ............................................................ 112

6.3.3.3 Read Host Firmware Version (GetHostFwVersion, 0x12).........

113

6.3.3.4 Read Version of Baseband Controller Firmware

(GetBbFwVersion, 0x13)............................................................ 115

6.3.4 Process Image ..................................................................................116

6.3.4.1 Determine the Size of a Slot for Data Transfer in the Master

Process Image (SetRemotePiSize, 0x32).................................... 116

6.3.4.2 Query the Remote Process Image Parameters within the Master

Process Image (GetRemotePiMapping, 0x33)............................ 118

6.3.5 Device Configuration.......................................................................120

6.3.5.1 Read the Local Device Name(GetLocalDeviceName, 0x40) ..... 120

6.3.5.2 Write the Local Device Name (SetLocalDeviceName, 0x41).... 121

6.3.5.3 Read Local MAC ID (GetLocalMacID, 0x42) ...........................123

6.3.5.4 Read Local IP Address (GetLocalIPAddress, 0x43) ..................124

WAGO-I/O-SYSTEM 750

I/O Modules

Page 5

Important Comments • 5

Legal Principles

6.3.5.5 Set Local IP Address (SetLocalIPAddress, 0x44) ......................125

6.3.5.6 Read Local Subnet Mask (GetLocalSubnetMask, 0x45)............126

6.3.5.7 Set Local Subnet Mask (SetLocalSubnetMask, 0x46) ...............127

6.3.5.8 Read Local WAGO Device Class (GetLocalDeviceClass,0x47)128

6.3.5.9 Write Local Device Class (SetLocalDeviceClass, 0x48) ...........129

6.3.5.10 Read Local Operation Mode (GetLocalOperationMode, 0x49). 130

6.3.5.11 Set Local Operation Mode (SetLocalOperationMode, 0x4A)....131

6.3.5.12 Read Local Encryption Mode (GetLocalEncryptionMode, 0x4D) ..

.....................................................................................................133

6.3.5.13 Set Local Encryption Mode (SetLocalEncryptionMode, 0x4E). 134

6.3.5.14 Read Local Authentication Mode (GetLocalAuthenticationMode,

0x4F)...........................................................................................135

6.3.5.15 Set Local Authentication Mode (SetLocalAuthenticationMode,

0x50) ...........................................................................................136

6.3.5.16 Read Local Bluetooth® Password (GetLocalPassphrase, 0x51) . 138

6.3.5.17 Write Local Bluetooth® Password (SetLocalPassphrase, 0x52). 139

6.3.5.18 Delete Locally Saved Authorization (EraseLocalAuthentication,

0x53) ...........................................................................................141

6.3.5.19 Read Length of the Flash Configuration

(GetLocalDeviceConfigLen, 0x54) ............................................142

6.3.5.20 Read Role of the Local Device (GetLocalDeviceRole, 0x55).... 143

6.3.5.21 Set Role of the Local Device (SetLocalDeviceRole, 0x56) .......144

6.3.5.22 Restore Factory Settings (SetFactorySettings, 0x57) ................. 145

6.3.5.23 Search for Remote Bluetooth® Device in the Wireless Network

(ScanRemoteDevices, 0x80).......................................................146

6.3.5.24 Read MAC-ID of a Remote Bluetooth® Device

(GetRemoteDeviceMacID, 0x81)............................................... 148

6.3.5.25 Read Device Name of a Remote Bluetooth® Device

(GetRemoteDeviceName, 0x82).................................................150

6.3.5.26 Enter External Device in the Table of Authorized Devices

(AllowRemoteDevice, 0x83) ...................................................... 152

6.3.5.27 Read Back External Device from the Table of Authorized Devices

(GetAllowedRemoteDevices, 0x84)........................................... 154

6.3.5.28 Grant Access Authorization for a Device (BindRemoteDevice,

0x85) ...........................................................................................

156

6.3.5.29 Delete Access Authorization for a Device (UnbindRemoteDevice,

0x86) ...........................................................................................

157

6.3.5.30 Read Access Authorization for Remote Devices

(GetBoundRemoteDevices, 0x87) .............................................. 159

6.3.5.31 Read Back the QoS Settings (GetConnectionQoS, 0x88) .......... 160

6.3.5.32 Set the QoS Settings (SetConnectionQoS, 0x89) ....................... 161

6.3.5.33 Read Back Time Settings - Between Two Attempts to Establish a

Connection (GetReconnectionTimePeriod, 0x8A)..................... 163

6.3.5.34 Set Time Settings - Between Two Attempts to Establish a

Connection (SetReconnectionTimePeriod, 0x8B)...................... 164

6.3.5.35 Read the User-Friendly Name of an Authorized Device

(GetUserfriendlyName, 0x8C).................................................... 166

WAGO-I/O-SYSTEM 750

I/O Modules

Page 6

6 • Important Comments

Legal Principles

6.3.5.36 Write the User-Friendly Name of an Authorized Device

(SetUserfriendlyName, 0x8D) .................................................... 168

6.3.6 Diagnostics ......................................................................................170

6.3.6.1 Read Status of the Local Bus Module (GetLocalDeviceStatus,

0xD0) ..........................................................................................170

6.3.6.2 Read Status of the Wireless Network (GetNetworkStatus, 0xD1) ...

.....................................................................................................172

6.3.6.3 Read Diagnostic Information (GetStatusMessage, 0xD2).......... 174

6.3.6.4 Read Connection Quality (GetLinkQuality, 0xD5) .................... 179

6.3.6.5 Read Signal Strength for a Connection (GetLinkSignalStrength,

0xD7) ..........................................................................................181

6.3.6.6 Read Available Hopping Channels (GetAvailableChannelMap,

0xD8) ..........................................................................................183

6.3.6.7 Set an LED (SetLED, 0xD9) ...................................................... 185

6.3.6.8 Mirror Mailbox for Test Purposes (MirrorMailboxCommand,

0xDA) .........................................................................................187

6.3.6.9 Read the Operating Time of the Module (GetLocalUpTime,

0xDB)................................................................................................

.....................................................................................................188

6.4 Extended Register Structure (Configuration Block) ............................ 190

6.5 Example Configurations using WAGO-I/O-CHECK .......................... 193

6.5.1 Startup with the Bluetooth® Parameterization Dialog .....................193

6.5.1.1 Network Structure....................................................................... 193

6.5.1.2 Starting up the Bluetooth® Modules ...........................................194

6.5.1.3 Testing the Process Data Exchange ............................................202

6.5.2 Startup using Mailbox Commands in the Process Data Dialog.......203

6.5.2.1 Network Structure....................................................................... 203

6.5.2.2 Starting up the Bluetooth® Modules ...........................................203

6.5.2.3 Testing the Process Data Exchange ............................................210

Glossary ........................................................................................................

211

WAGO-I/O-SYSTEM 750

I/O Modules

Page 7

Important Comments • 7

Legal Principles

1 Important Comments

To ensure fast installation and start-up of the units described in this manual,

we strongly recommend that the following information and explanations are

read carefully and followed.

1.1 Legal Principles

1.1.1 Copyright

This manual is copyrighted, together with all figures and illustrations contained therein. Any use of this manual which infringes the copyright provisions stipulated herein, is not permitted. Reproduction, translation and electronic and photo-technical archiving and amendments require the written consent of WAGO Kontakttechnik GmbH & Co. KG. Non-observance will entail

the right of claims for damages.

WAGO Kontakttechnik GmbH & Co. KG reserves the right to perform modifications allowed by technical progress. In case of grant of a patent or legal

protection of utility patents all rights are reserved by WAGO Kontakttechnik

GmbH & Co. KG. Products of other manufacturers are always named without

referring to patent rights. The existence of such rights can therefore not be

ruled out.

1.1.2 Personnel Qualification

The use of the product detailed in this manual is exclusively geared to specialists having qualifications in PLC programming, electrical specialists or persons instructed by electrical specialists who are also familiar with the valid

standards. WAGO Kontakttechnik GmbH & Co. KG declines all liability resulting from improper action and damage to WAGO products and third party

products due to non-observance of the information contained in this manual.

1.1.3 Intended Use

For each individual application, the components supplied are to work with a

dedicated hardware and software configuration. Modifications are only permitted within the framework of the possibilities documented in the manuals.

All other changes to the hardware and/or software and the non-conforming use

of the components entail the exclusion of liability on part of WAGO Kontakttechnik GmbH & Co. KG.

Please direct any requirements pertaining to a modified and/or new hardware

or software configuration directly to WAGO Kontakttechnik GmbH & Co.

KG.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 8

8 • Important Comments

Symbols

1.2 Symbols

Danger

Always abide by this information to protect persons from injury.

Warning

Always abide by this information to prevent damage to the device.

Attention

Marginal conditions must always be observed to ensure smooth operation.

ESD (Electrostatic Discharge)

Warning of damage to the components by electrostatic discharge. Observe

precautionary measures for handling components at risk.

Note

Routines or advice for efficient use of the device and software optimization.

Additional Information

References for additional literature, manuals, data sheets and web pages.

1.3 Number Notation

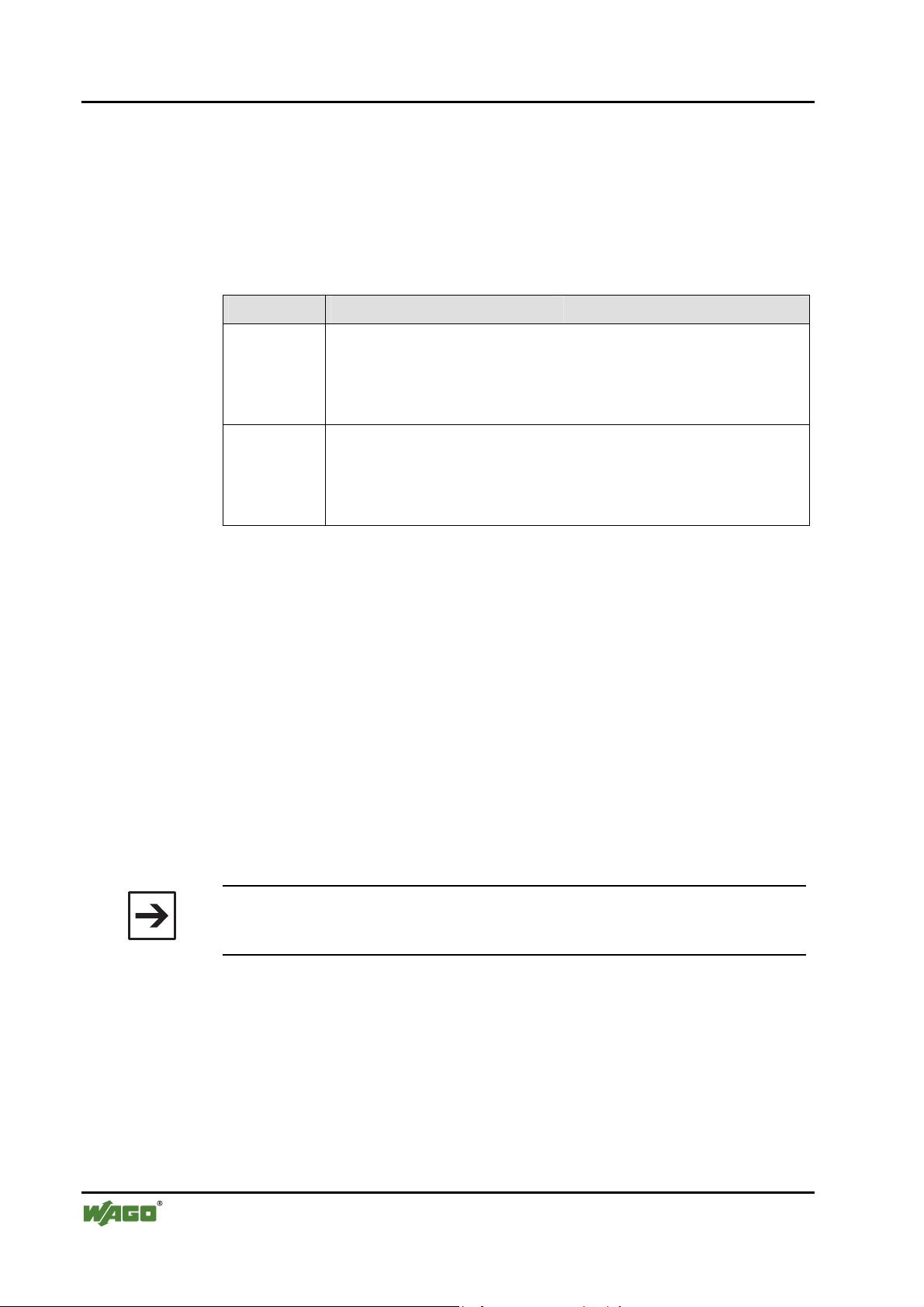

Number Code Example Note

Decimal 100 normal notation

Hexadecimal 0x64 C notation

Binary '100'

'0110.0100'

within inverted commas,

nibble separated with dots

WAGO-I/O-SYSTEM 750

I/O Modules

Page 9

Important Comments • 9

Safety Notes

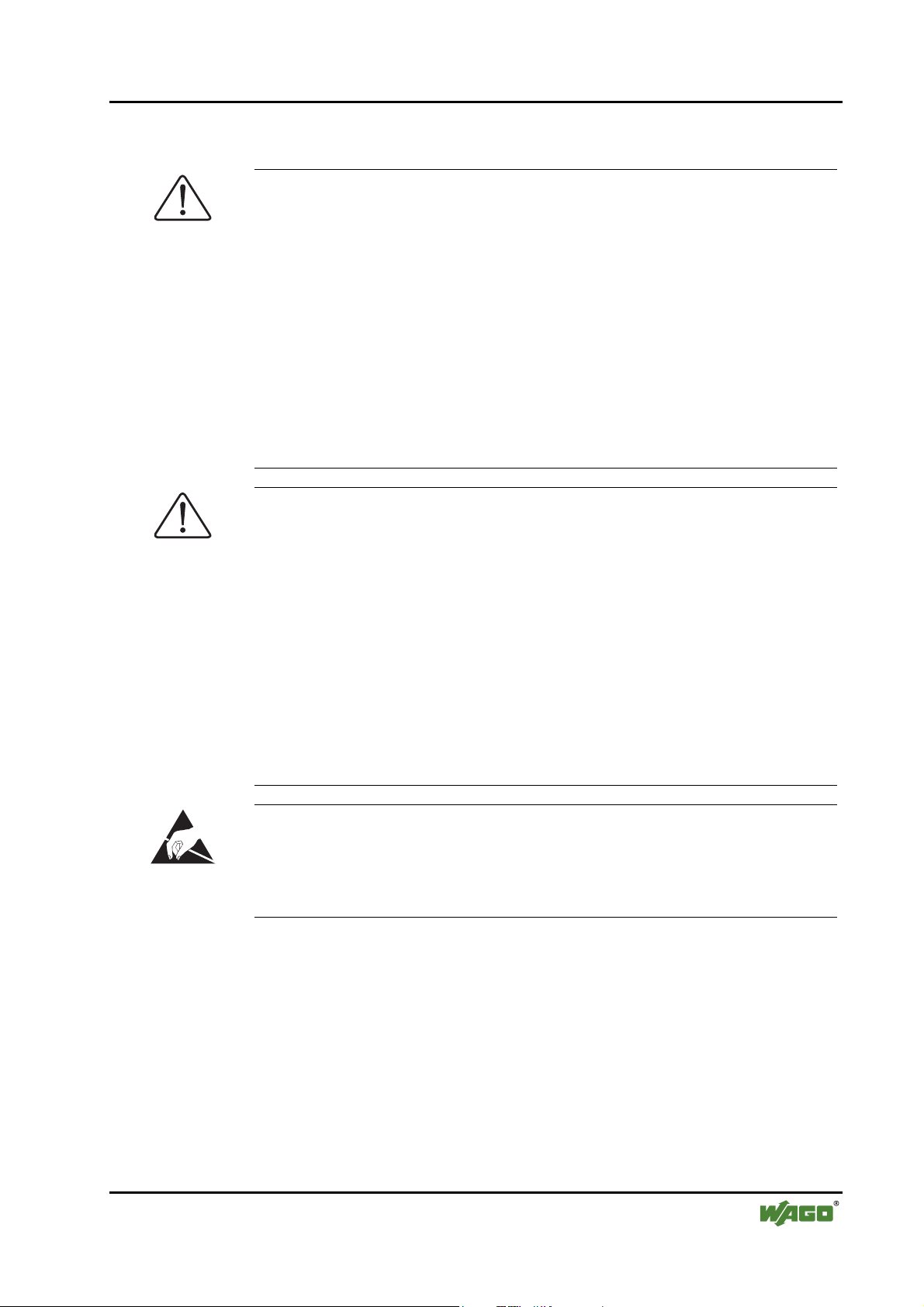

1.4 Safety Notes

Warning

Switch-off the system prior to working on bus modules!

In the event of deformed contacts, the module in question is to be replaced, as

its functionality can no longer be ensured on a long-term basis.

The components are not resistant against materials having seeping and insulating properties. Members of this group include: aerosols, silicones, triglycerides (found in some hand creams).

If it cannot determined that these materials appear in the component environment, then additional measures must be taken:

- install of the components in an appropriate enclosure

- handle components only with clean tools and materials.

Attention

Soiled contacts may only be cleaned with ethyl alcohol and leather cloths.

This helps ensure compliance with ESD information.

1.5 Scope

Do not use any contact spray. The spray may impair the functioning of the

contact area.

The WAGO-I/O-SYSTEM 750 and its components are an open system. As

such, the system and its components must be installed in appropriate housings, cabinets, enclosures or in electrical operation rooms. Access must only

be provided via key or tool to authorized, qualified personnel.

The relevant valid and applicable standards and guidelines concerning the

installation of switch boxes are to be observed.

ESD (Electrostatic Discharge)

The modules are equipped with electronic components that may be destroyed

by electrostatic discharge. When handling the modules, ensure that the environment (persons, workplace and packing) is well grounded. Avoid touching

conductive components; e.g., gold contacts.

This manual describes the Bluetooth® RF Transceiver 750-644 from the

WAGO-I/O-SYSTEM 750. Handling, assembly and startup are described in

the manual for the fieldbus coupler/controller. This documentation is therefore

only valid in connection with the appropriate manuals.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 10

10 • I/O Modules

Special Modules

2 I/O Modules

2.1 Special Modules

2.1.1 750-644 [Bluetooth® RF Transceiver]

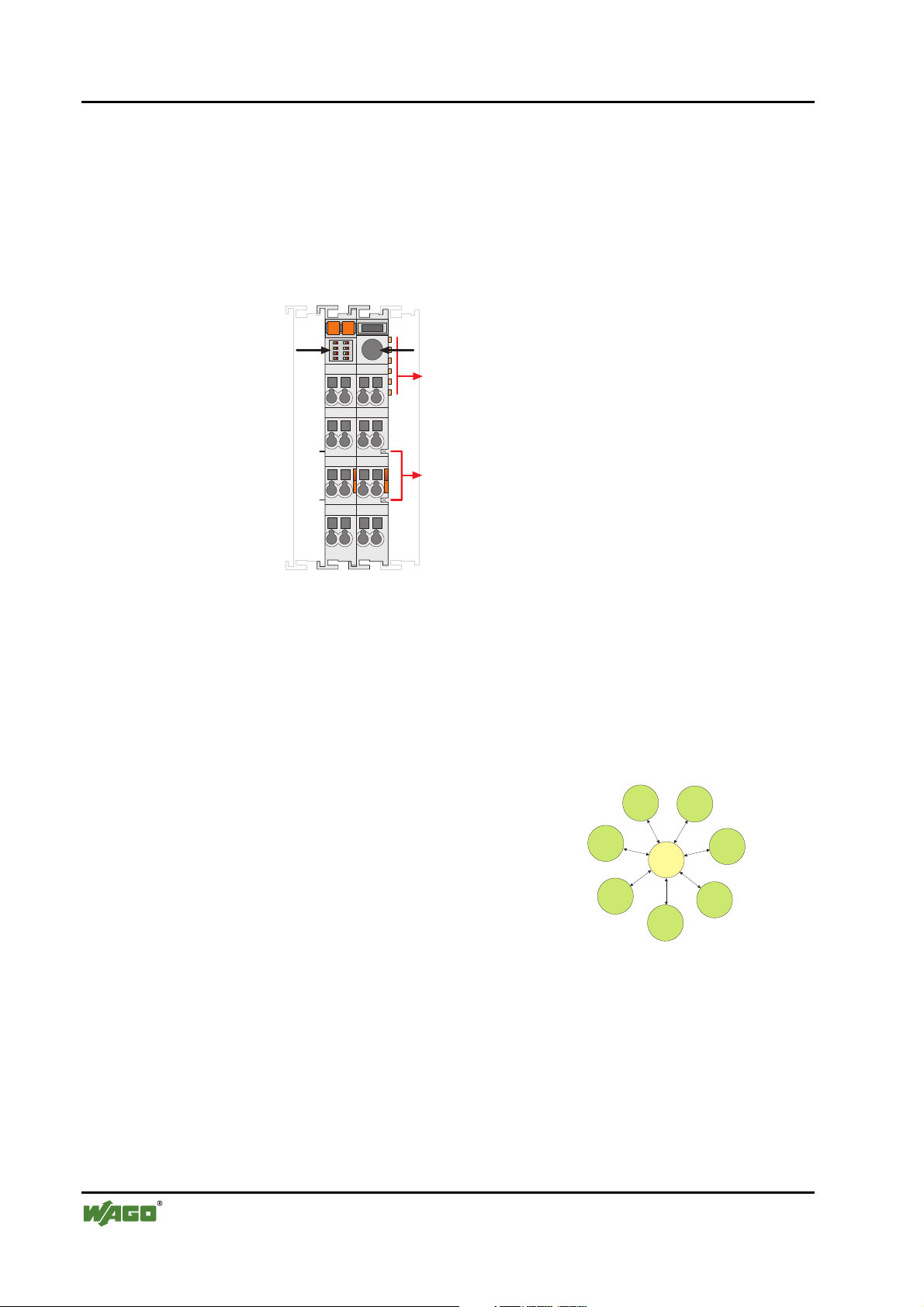

2.1.1.1 View

13 14

Operational and

connection

status

Antenna socket

SMA

Data contacts

Power jumper

contacts

Figure 1: View g064400e

2.1.1.2 Description

The Bluetooth® RF Transceiver 750-644 (referred to in the following as "Bluetooth® module") integrates a Bluetooth® network (piconet) into the WAGO-

I/O-SYSTEM 750. This means that Bluetooth® modules will be installed and

used jointly with the WAGO-I/O-SYSTEM 750 modules in different fieldbus

systems.

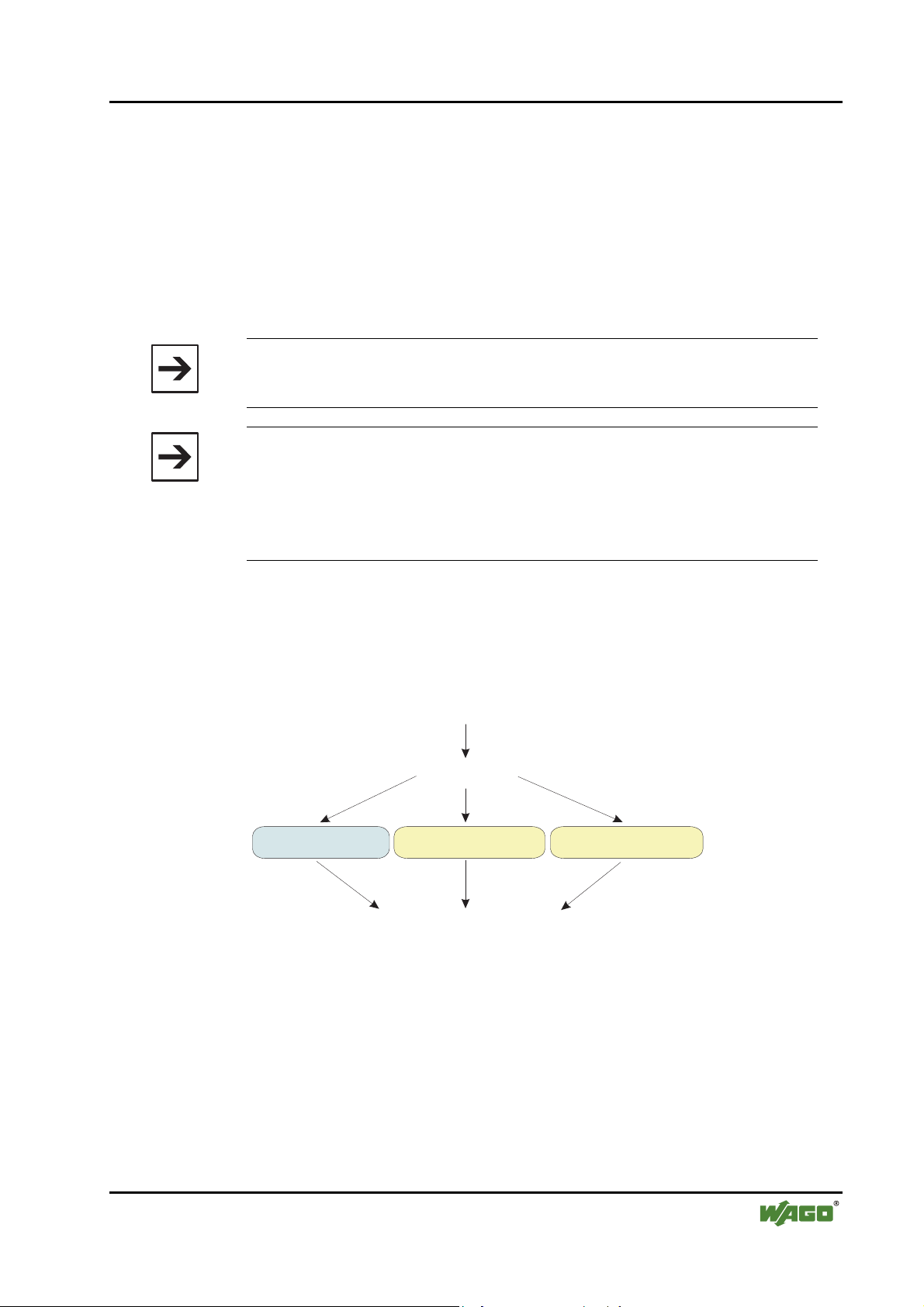

The Bluetooth® module facilitates wireless

data exchange within the Bluetooth

It can function as the coordinator (referred to

in the following as the "master") or as the

terminal (referred to in the following as the

"slave") depending on the configuration. A

maximum of seven slaves may communicate

with one master (see

The module's configuration (network configuration/process image mapping) is

determined locally via WAGO-I/O-CHECK software.

750-644

Figure 2).

®

piconet.

Slave

7

Slave

Figure

Slave

1

6

Master

Slave

5

Slave

2

Slave

4

Slave

3

2: Piconet g064403x

The current status of the module is displayed by LEDs. While the LEDs associated with the function of "slave" signal the quality of the connection, the

LEDs associated with the "master" function show the connection status to

each individually connected slave.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 11

I/O Modules • 11

Special Modules

The Bluetooth® module is operated in the public domain ISM 2.4 GHz band

and enables wireless data transfer over large distances. If using the WAGO

Antenna 758-912, ranges of up to 1000 meters can be achieved.

The Bluetooth® module 750-644 can be used with the following couplers/controllers of the WAGO-I/O-SYSTEM 750:

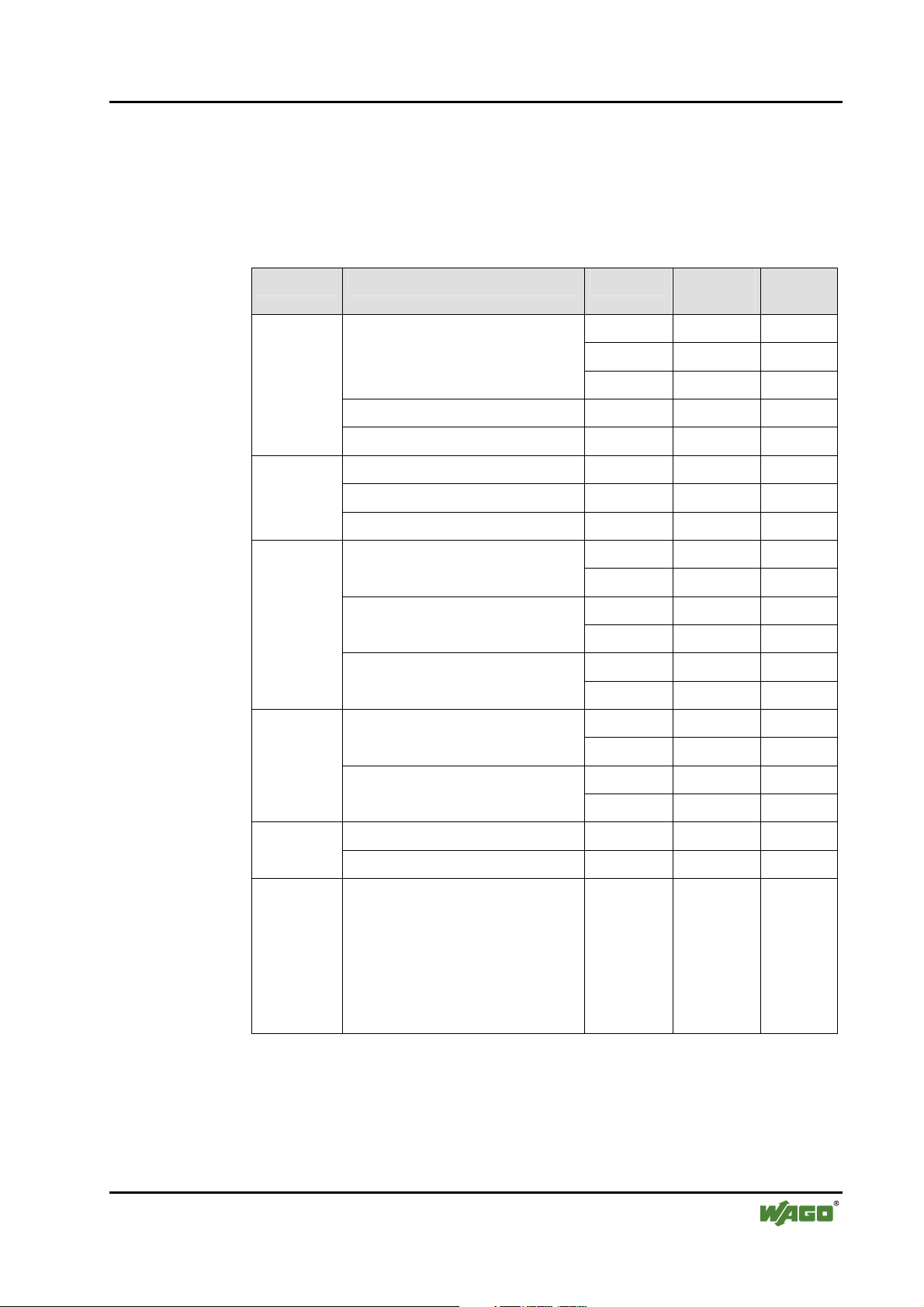

Bus System Coupler/Controller Item No. Hardware

version

PROFIBUS

DeviceNet

CANopen

ETHERNET

Fieldbus coupler

ECO fieldbus coupler 750-343 03 from 06

Programmable fieldbus controllers 750-833 12 from 07

Fieldbus coupler 750-306 11 4I

ECO fieldbus coupler 750-346 02 07

Programmable fieldbus controllers 750-806 02 07

Programmable fieldbus controllers

750-301 01 07

750-303 01 07

750-333 12 from 07

750-337 09 10 Fieldbus coupler

750-338 01 14

750-347 01 04 ECO fieldbus coupler

750-348 01 04

750-837 06 11

750-838 01 11

750-341 03 03 Fieldbus coupler

Software

version

750-342 04 14

Programmable fieldbus controllers

Fieldbus coupler 750-319 07 05 LON

Programmable fieldbus controllers 750-819 08 07

IPC WAGO-IPC 750-870 02 IPC firm-

Other couplers/controllers upon request.

750-841 03 07

750-842 04 12

ware

02.04.

18/0200

Kbus

firmware

01.02.

03(06)

WAGO-I/O-SYSTEM 750

I/O Modules

Page 12

12 • I/O Modules

Special Modules

The version information is contained in the serial number or in the update matrix; both are printed on the right side of the coupler/controller. The serial

number is constructed as follows:

WWYYSWHWFL-Bm1m2m3

Abbreviation

WW Week of manufacture

YY Year of manufacture

SW Software version of the bus coupler

HW Hardware version of the bus coupler

FL Software version of the firmware loader

- Empty space, no additional meaning

B Designation of the soldered bus connector

m1 Manufacturer of the interface card

m2 Manufacturer of the CPU card

m3 Manufacturer of the power supply card

The m3 designation is not included for bus couplers of the ECO family.

Description

The update matrix is constructed as follows:

NO Work Order Number

DS Date Stamp

SW Software version of the bus coupler

HW Hardware version of the bus coupler

FWL Software version of the firmware

loader

WAGO-I/O-SYSTEM 750

I/O Modules

Page 13

I/O Modules • 13

Special Modules

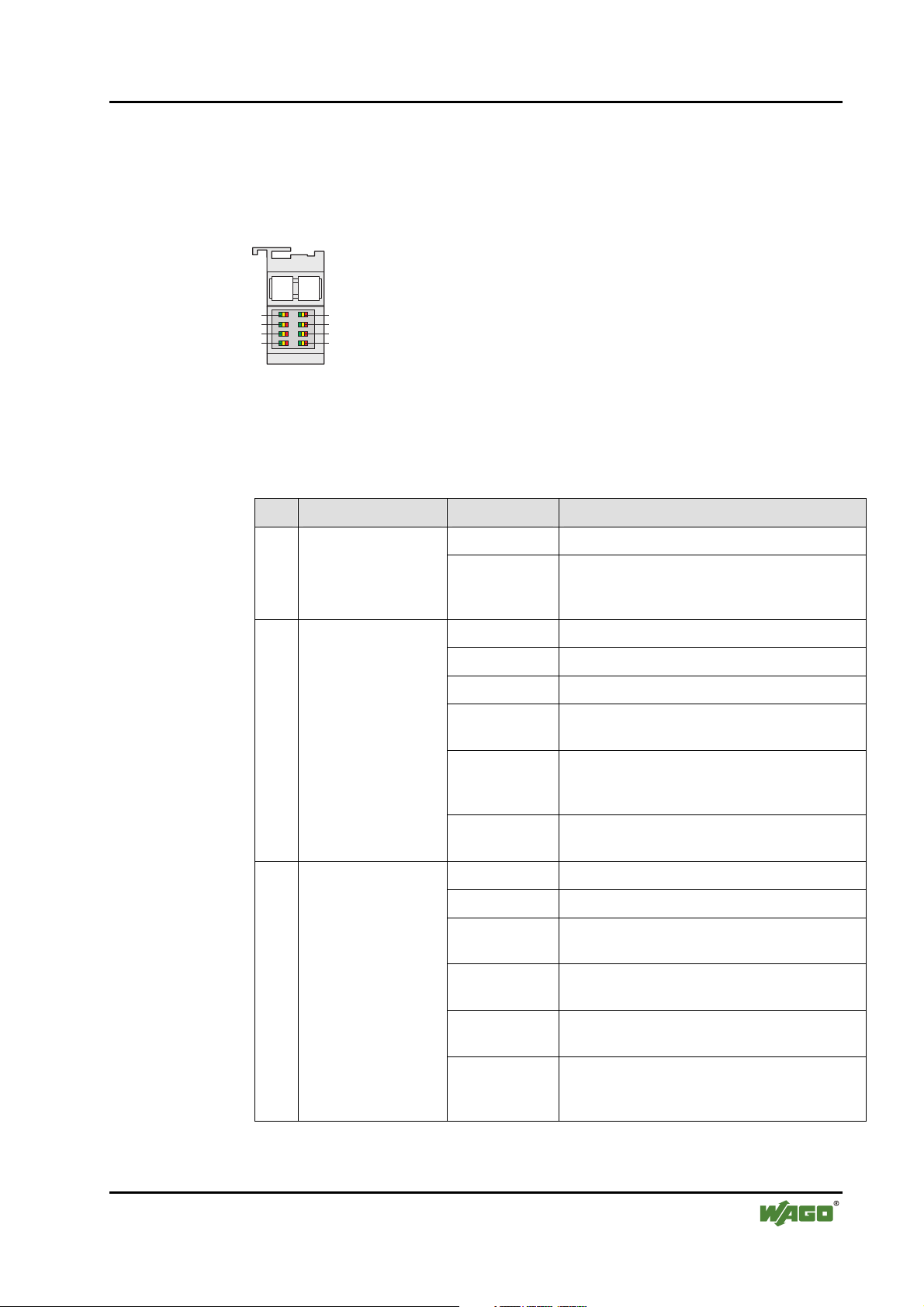

2.1.1.3 Indicators

The LED display must be interpreted differently depending on whether the

Bluetooth® module functions as a master or as a slave (see Sections 2.1.1.3.1

and 2.1.1.3.2).

13 14

1

3

5

7

2

4

6

8

Figure 3: Display Elements g064402x

2.1.1.3.1 Master

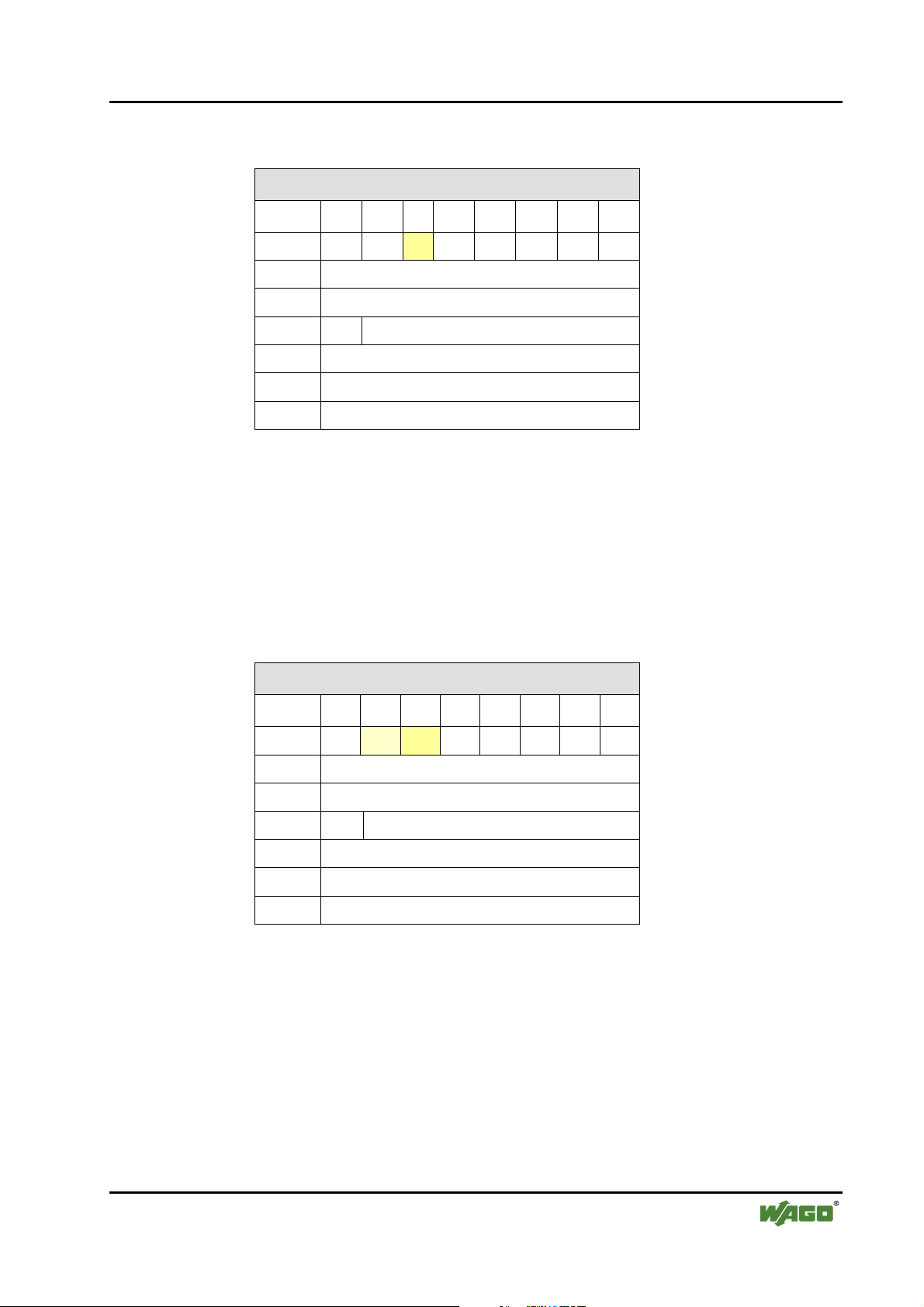

Table 1: LED Master Signals

LED Designation Status: Function

Operation status

1

indicator

Connection display of

the first WAGO slot

(communication

2

mode) and signaling

in the configuration

mode

Connection display

for WAGO slots j (j =

3…8

2…7) (in communication mode only)

green Normal operation

red Disruption of the local internal bus connection,

the field voltage or the internal communication

(circuit board)

green Connection to slave(s) established

green flashing Data transfer

off No slave is configured for this slot

yellow flashing Connection to the first slave is being estab-

lished (in communication mode only)

yellow System is configured (in configuration mode

only) or connection to the first slave could not

be established (in communication mode only)

red Connection interrupted by error (in communi-

cation mode only)

green Connection to slave(s) established

green flashing Data transfer

yellow Unsuccessful connection configuration to slot j

(in communication mode only)

yellow flashing Connection to Slot j is being established

(in communication mode only)

red Connection interrupted by error (in communi-

cation mode only)

WAGO-I/O-SYSTEM 750

I/O Modules

off No slave is configured for this slot (in commu-

nication mode only) or the system is in configuration mode.

Page 14

14 • I/O Modules

Special Modules

2.1.1.3.2 Slave

Table 2: LED Slave Signals

LED Designation Status: Function

green Operating status OK (independent of radio

1

Operation status indicator

red Disruption of the local internal data bus

green Connection to master established

green flashing Data transfer

off No master is configured for this slot.

communication)

connection, the field voltage or the internal

communication (circuit board)

2

3, 4

5, 6

Connection display for

connected master

RSSI

Over- or undermodulation of the

Bluetooth

®

receiver

Connection quality

according to bit error

rate

yellow flashing

Connection to the master is being established (in communication mode only)

yellow System is being configured (in configura-

tion mode only) or connection to the master could not be established (in communication mode only)

red Connection interrupted by error (in com-

munication mode only)

green Signal strength of the received signal good

yellow Signal strength of the received signal very

strong (solution: increase distance of the

device)

Red Signal strength of the received signal weak

(solution: reduce distance of the device).

off There is still no information on the signal

strength of the received signal (there is no

connection or there is a connection only

after a few seconds)

green low bit error rate <10-3

yellow bit error rate 10-2 to 10-3

red high bit error rate > 10

-2

(bad transmission line)

off no active connection (similar RSSI)

green > 53 lines free (no or negligible third-party

activity in the frequency range)

activity in the frequency range)

7, 8

Interference display

Number of busy lines

in the 2.4 GHz frequency range

yellow 39…53 free lines

red < 39 marked as free (massive third-party

off no active connection (similar RSSI)

WAGO-I/O-SYSTEM 750

I/O Modules

Page 15

I/O Modules • 15

Special Modules

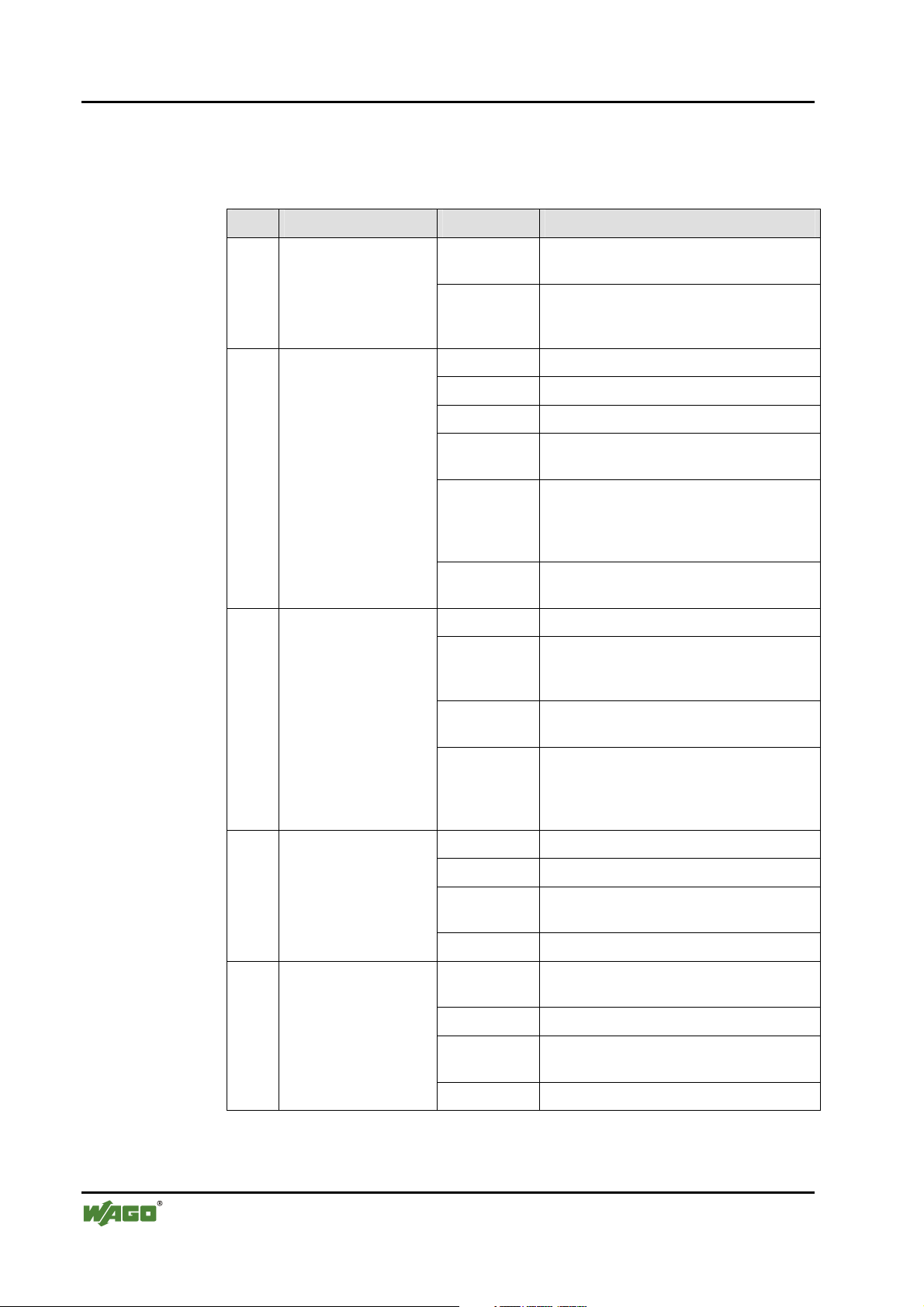

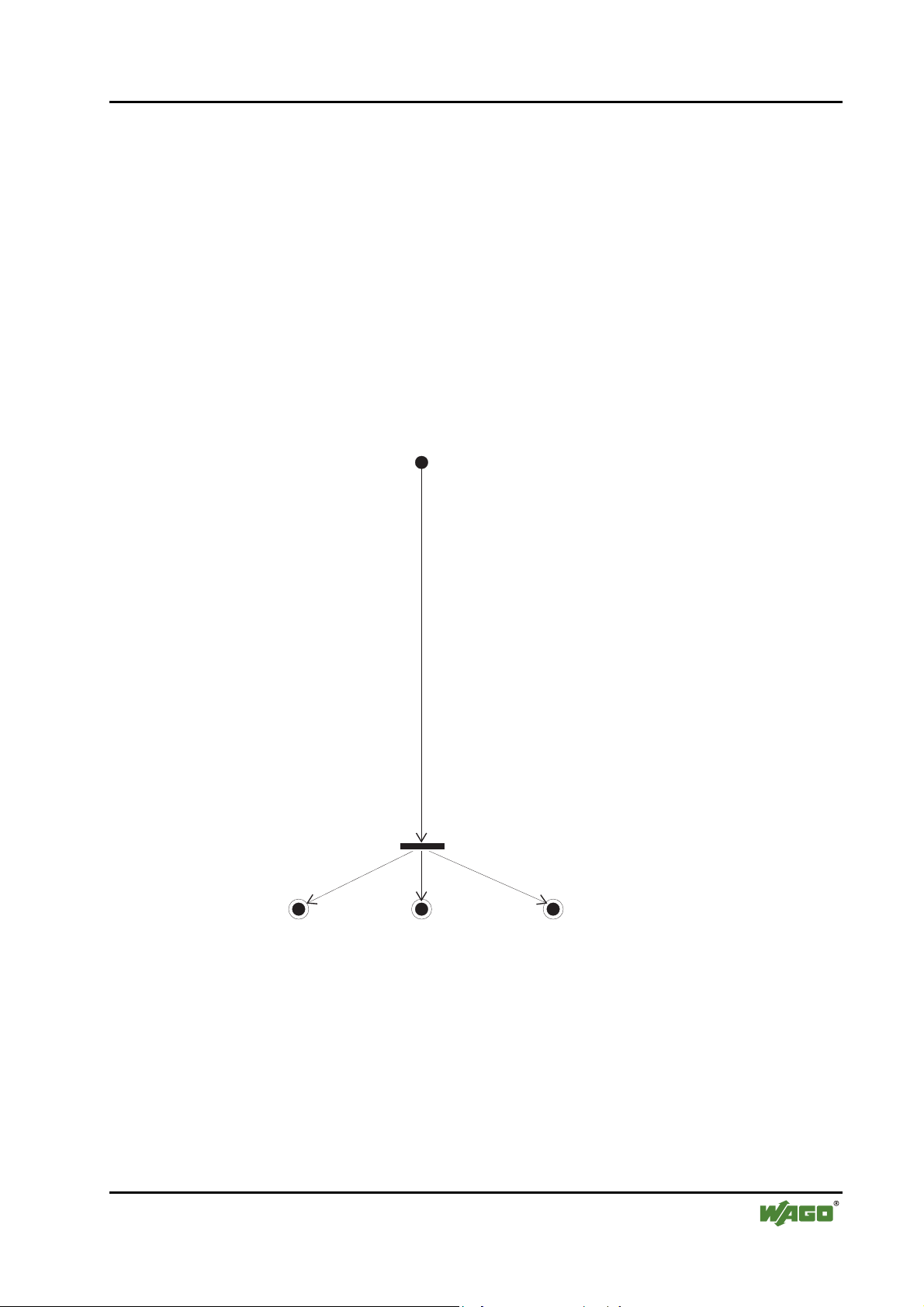

2.1.1.4 Schematic Diagram

Antenna socket

SMA

1

5

1

5

Antenna

24 V

2

6

2

+24 V

0V

3

4

750-644

6

BTModule

7

3

7

8

4

8

0V

OS

SPI

SPI

Logic

8-segment

LED

display

Figure 4: Schematic Diagram g064401e

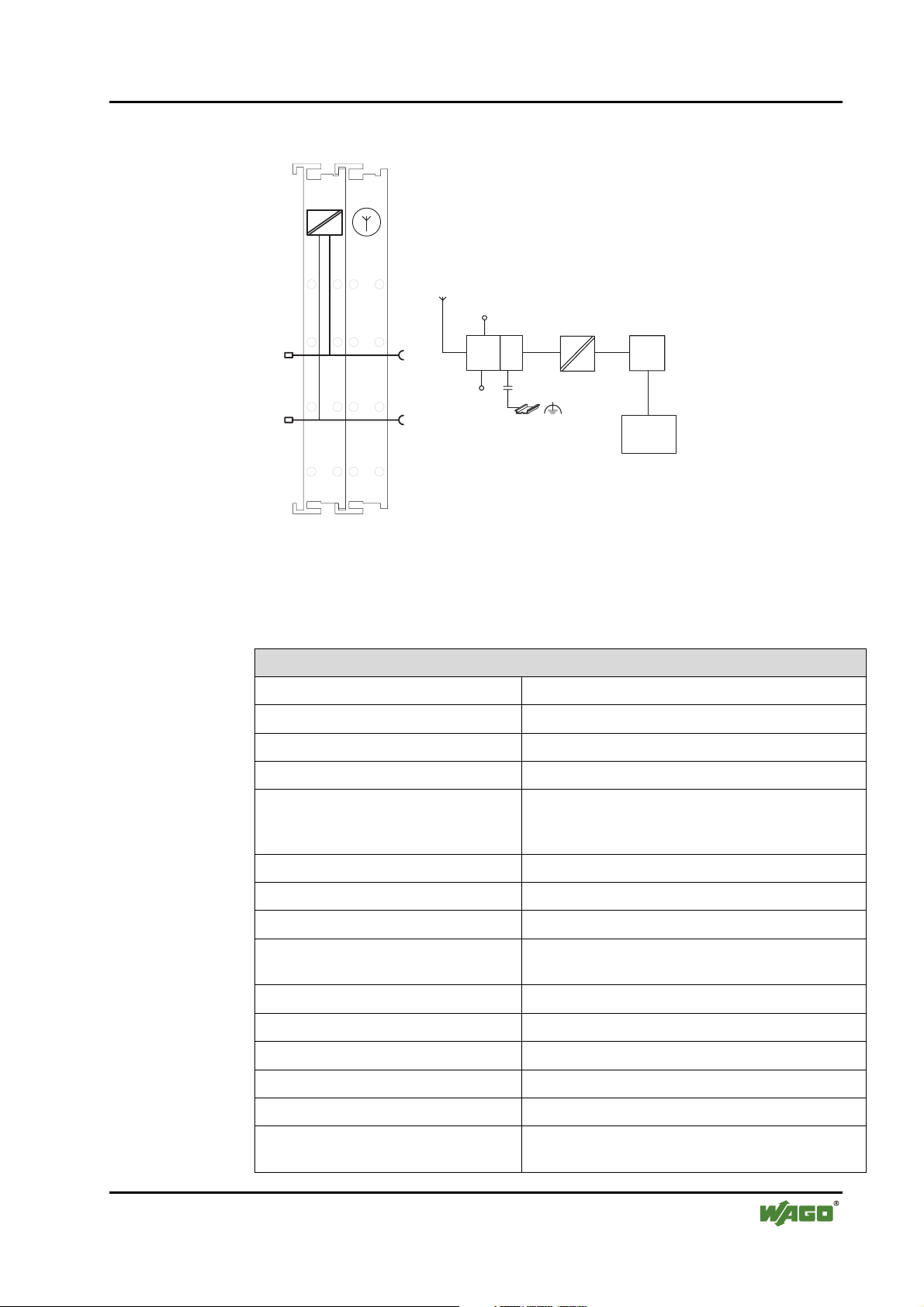

2.1.1.5 Technical Data

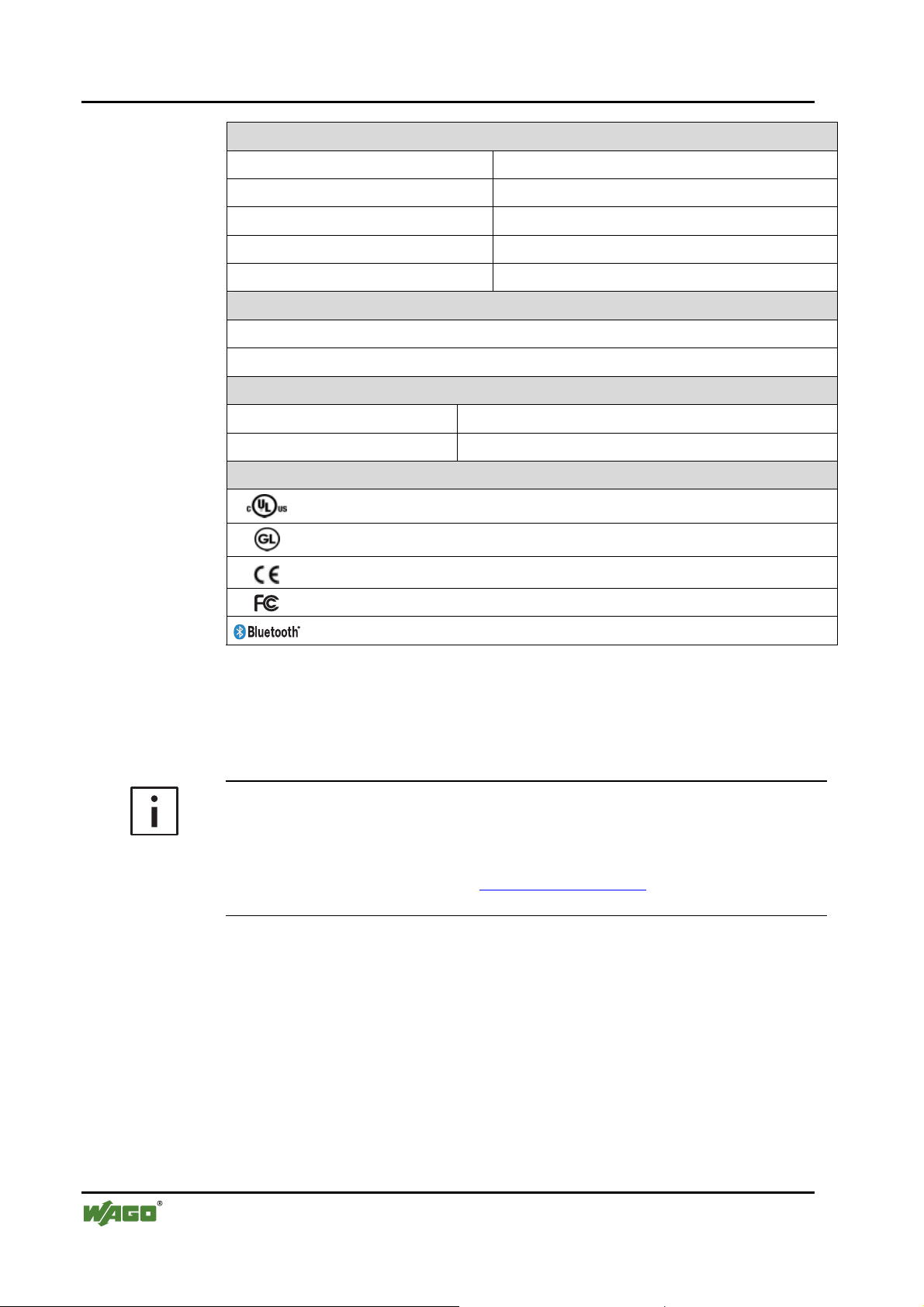

Table 3: Technical Data for Bluetooth® Module 750-644

Module-Specific Data

Radio technology Bluetooth® 2.0 + EDR

Topology Piconet (1 master, maximum of 7 slaves)

Coexistence AFH and adaptive transmitting power

Profiles SPP, PAN

Operating modes Communication mode with ad hoc profile for high

Frequency band public domain, ISM band, 2402…2480 MHz

Transmitting power up to 20 dBm (Bluetooth® Class 1)

Receiver sensitivity -94 dBm

Range (maximum) 1000 m in open air, 100 m in buildings (if using an

Voltage supply (Bluetooth®) through field supply DC 24 V

connectivity and real-time profile for time-critical

applications and configuration mode

external WAGO antenna, item no. 758-912)

Voltage supply (internal) via system voltage DC/DC

Current consumption (Bluetooth®) approx. 8 mA, maximum 35 mA

Current consumption (internal) approx. 20 mA

Isolation 500 V (antenna/system)

Data width, internal Configurable to 12, 24, 48 bytes, including 1 con-

WAGO-I/O-SYSTEM 750

I/O Modules

trol/status byte

Page 16

16 • I/O Modules

Special Modules

Module-Specific Data

Diagnosis (through optical display) Device status, connection status

Diagnosis (through process image) Device status, connection status

[1]

[1]

, time monitoring

Configuration WAGO-I/O-CHECK and WAGO-I/O-PRO CAA

Dimensions (mm) W x H x L 24 x 64

[2]

x 100

Weight approx. 85 g

Accessories

Miniature WSB Quick marking system

External WAGO antenna, SMA, with magnet base (item no. 758-912)

Standards and directives (see Section 2.2 in manual on coupler/controller)

EMC CE Immunity to interference according to EN 61000-6-2 (2005), EN 61131-2 (2003)

EMC CE Emission of interference according to EN 61000-6-3 (2007), EN 61131-2 (2003)

Approvals (see Section 2.2 in manual on coupler/controller)

(UL508) (patent pending)

CULUS

GL (Germanischer Lloyd) (patent pending)

Conformity marking

FCC approval

Bluetooth

[1]

Quality of the radio link, signal strength, interference

[2]

plus approx. 6.5 mm excess length of the SMA socket

[3]

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation.

[3]

®

approval

Additional Information

Please refer to the "Overview on WAGO-I/O-SYSTEM 750 approvals" documentation for detailed information on approvals.

You will find this on the CD ROM "AUTOMATION Tools and Docs"

(item no. 0888-0412) or online at http://www.wago.com under documentation

! WAGO-I/O-SYSTEM 750 ! System Description

WAGO-I/O-SYSTEM 750

I/O Modules

Page 17

I/O Modules • 17

Special Modules

2.1.1.6 Function Description

Bluetooth® technology defines piconet as a topology consisting of a master

and up to seven slaves. Data can be exchanged between each slave and the

master wirelessly and bidirectionally. Data transfer from slave to slave is possible indirectly through the master.

The Bluetooth® module implements Bluetooth® Protocol 2.0+EDR and can be

configured as either master or slave. The configuration and activation of special functions is done through the mailbox interface described in Appendix

6.1. This is used by the startup tool WAGO-I/O-CHECK and function blocks

of WAGO-I/O-PRO CAA in order to provide the user with simple softwaresupported access to the module's full range of functions.

The following networks can be configured with Bluetooth

®

modules:

• Bluetooth® module as master, up to 7 Bluetooth® modules as slaves (real-

time profile). This real-time scenario is distinguished by an especially low

latency and cycle time.

• Bluetooth® module as master and up to 6 active slaves. In this configura-

tion, Bluetooth® modules configured as slaves and other Bluetooth® devices (e.g. Bluetooth® notebooks or PDAs) can be combined (ad hoc profile). This scenario offers flexible connection possibilities and interoperability.

A Bluetooth® module configured as a master can use up to 46 bytes of data

width for bidirectional data exchange with the slaves. In this case, which process data is assigned to which slave can be flexibly configured – the available

data width can be assigned exclusively to one individual slave or be distributed with freely configurable portions among several slaves.

®

With Bluetooth

modules, ranges of up to 1000 m can be achieved with intervisibility. Good reception is also possible inside buildings, even with the distribution of network participants in different rooms or floors of the building.

For maximum security, data exchange can be encrypted. Another security feature of the network is that a piconet configured with Bluetooth® modules allows no penetration by non-authorized devices.

Radio transmission with Bluetooth

outside influences. Thanks to frequency hopping procedures and adaptive

transmitting power, co-existence with other ISM radio technologies (e.g.

WLAN according to IEEE 802.11) is problem-free.

Potential-disturbing influences can be recognized early by the Bluetooth®

module – even before they have a negative effect on communication. Cyclic

and acyclic retrievable diagnostic information that provide information on the

quality of the wireless connection and fulfillment of real-time conditions (in

WAGO-I/O-SYSTEM 750

I/O Modules

®

is robust, particularly when faced with

Page 18

18 • I/O Modules

Special Modules

the real-time profile) are offered for this purpose. The most important diagnostic information is also displayed on the device via LEDs, so that the status can

also be directly monitored without additional components at the installation

site.

Additional Information

The Bluetooth® module starts either with the startup tool WAGO-I/OCHECK or function blocks of the WAGO-I/O-PRO CAA. The function

blocks for configuration are contained in the library

WAGO_Bluetooth_xx.lib, which you can download from the website

http://www.wago.com under Documentation ! WAGO Software 759 !

WAGO-I/O-PRO ! 759-333 ! Additional Information ! Libraries.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 19

I/O Modules • 19

Special Modules

2.1.1.6.1 Bluetooth® Class of Device (CoD)

The Class-of-Device (CoD) is a 24-bit field specifying the capabilities of a

Bluetooth® device that is sent with the packet "Frequency Hop Synchroniza-

tion" (FHS) during the device search. According to the Bluetooth® Standard,

the CoD describes the capabilities of the device, thus supporting the search for

devices with certain functionalities.

The CoD enables a rapid assignment of remote devices to different device

categories such as network, audio, telephony. It is divided into the Major Service Class (bit 23…13), Major Device Class (bit 12…8) and Minor Device

Class (bit 7…2).

Internal device (sub)classes have been specified for the WAGO module. The

device class for the WAGO-I/O-SYSTEM 750 is represented by bit values 1,

1, 1, in bits 7, 6, 5. It is represented by the bit string 110 for bits 4, 3, 2 (see

Table 4).

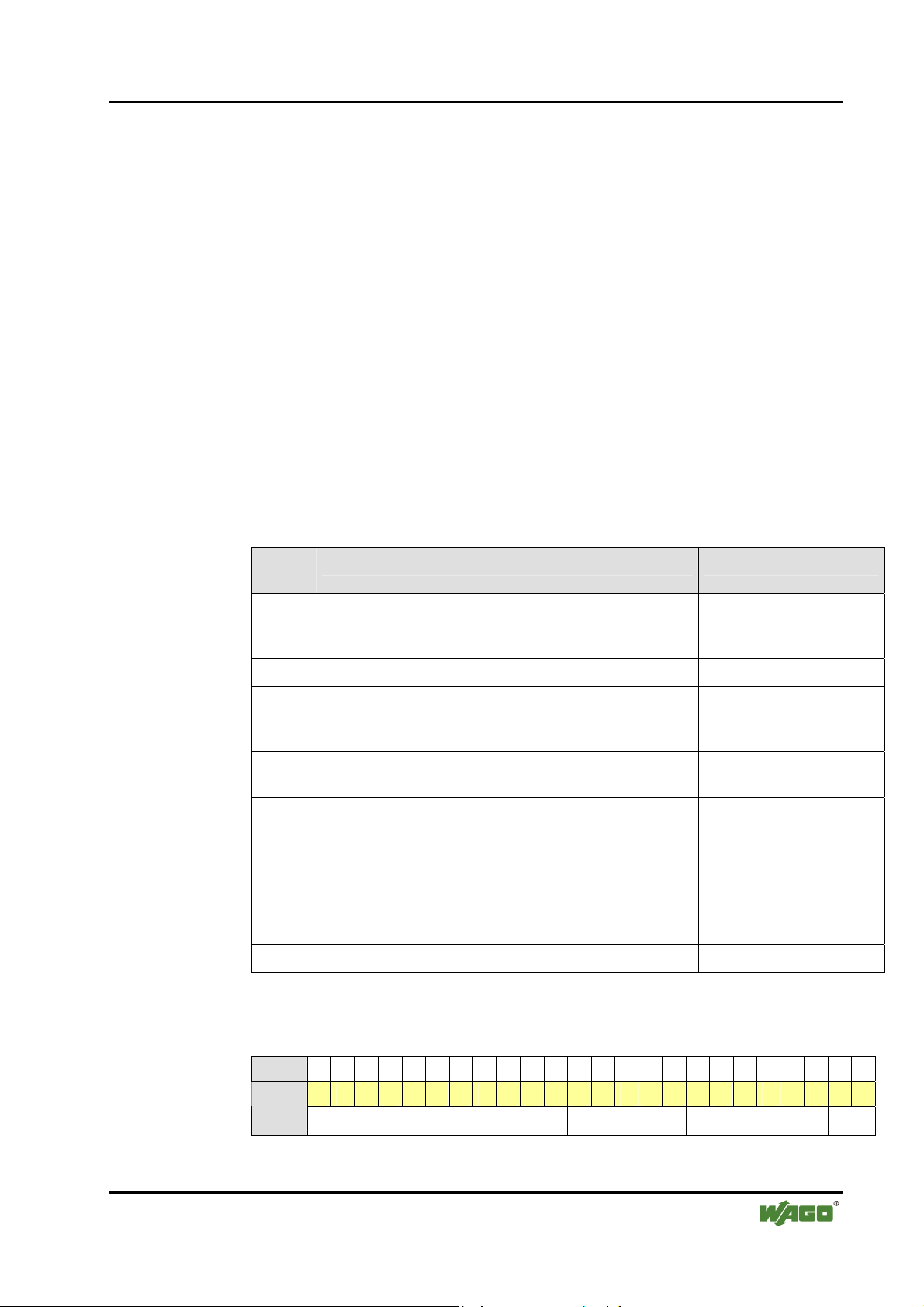

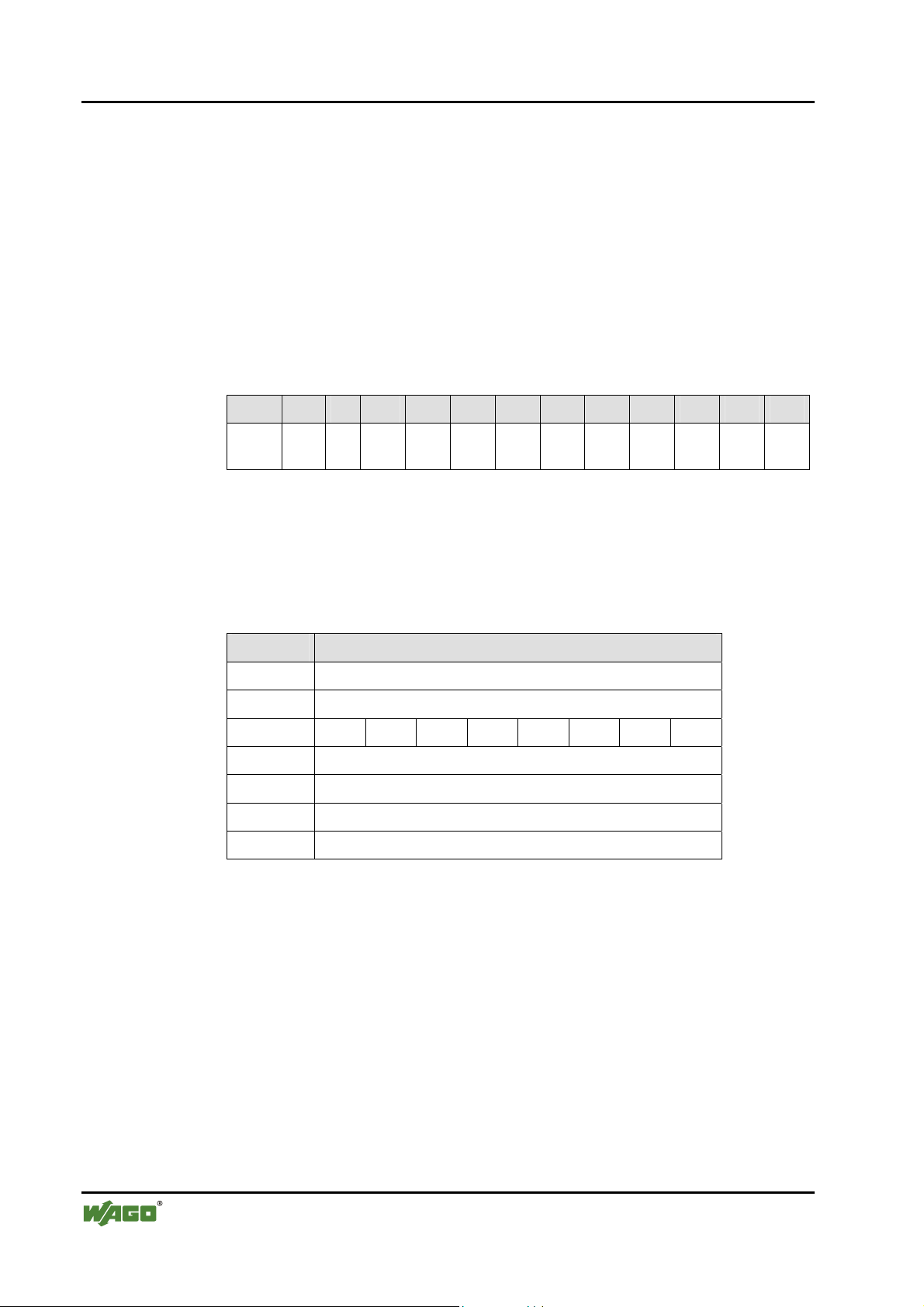

Table 4: Configuration of the CoD

Bit

position

23-16

15, 14 Reserved 00

13

12…8

7…2

1, 0 Reserved, format type 00

Description Suggested values

Major Service Class

Not given, in accordance with the Bluetooth

since there is no service that can be uniquely assigned

Limited Discoverable Mode

According to the Bluetooth

also support the non-discoverable mode

Major Device Class

According to the BT specification, set as "Miscellaneous"

Minor Device Class (can be used WAGO-specific) According to the Bluetooth

Device Class is "Miscellaneous"

WAGO-specific use: use of a bit pattern with the following

two-part device class; e.g., to identify the WAGO-I/OSYSTEM device subclass; e.g., to identify different products in the device class

®

specification, the device must

®

specification: open since the

®

specification,

00000000

1

00000

111

(= WAGO-I/O-System

750)

bit 7,6,5 device class

110

(= bus module 750-644)

bit 4,3,2 device subclass

The complete CoD for the bus module 750-644 is 0x0020F8

000000000010000011111000

Bit

WAGODevice

Class

WAGO-I/O-SYSTEM 750

I/O Modules

or

hex

(see following diagram).

bin

23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 1 1 1 1 1 0 0 0

Major Service Class Major Device Class Minor Device Class Type

Page 20

20 • I/O Modules

Special Modules

Note

The device subclass can be set by mailbox commands (see Appendix 6.3.5.9).

The CoD can only be influenced by the device (sub)class. Changes in the

Major Service Class or Major Device Class are not possible.

When loading the factory settings, the device class is set to value 7 and the

device subclass to value 6. This results in a CoD of 0x0020F8 for the Blue-

tooth® inquiry.

Many stacks handle devices according to their CoD. Therefore, the set device

(sub)class can influence the function (indirectly through the CoD) in external

devices..

WAGO-I/O-SYSTEM 750

I/O Modules

Page 21

I/O Modules • 21

Special Modules

2.1.1.7 Operating Modes

The Bluetooth® module has two different modes available. Each mode fulfills

a certain function:

• Configuration mode

• Communication mode

• in real-time profile

• in ad hoc profile

Note

The Bluetooth® module is in configuration mode when the customer receives it.

Note

If a Bluetooth® master is operated in the real-time profile, up to 7 Bluetooth® slaves can be connected to the master. If the Bluetooth® master is

operated in the ad hoc profile, 6 slaves can be connected. The profile of the

Bluetooth® slaves is irrelevant here. Modes and profiles are a master prop-

erty.

The operating mode is changed (see Figure 5) using WAGO-I/O-CHECK or

function blocks in the WAGO-I/O-PRO CAA and is controlled by mailbox

commands. After the operating mode is changed, the Bluetooth® subsystem is

automatically reset.

Restart

Saved Operation Mode

Configuration Mode

After changing the saved operation mode via mailbox command,

a restart will be performed automatically.

Figure 5: Operating modes g064404e

Communication Mode

Ad-Hoc Profile

Communication Mode

Real-Time Profile

WAGO-I/O-SYSTEM 750

I/O Modules

Page 22

22 • I/O Modules

Special Modules

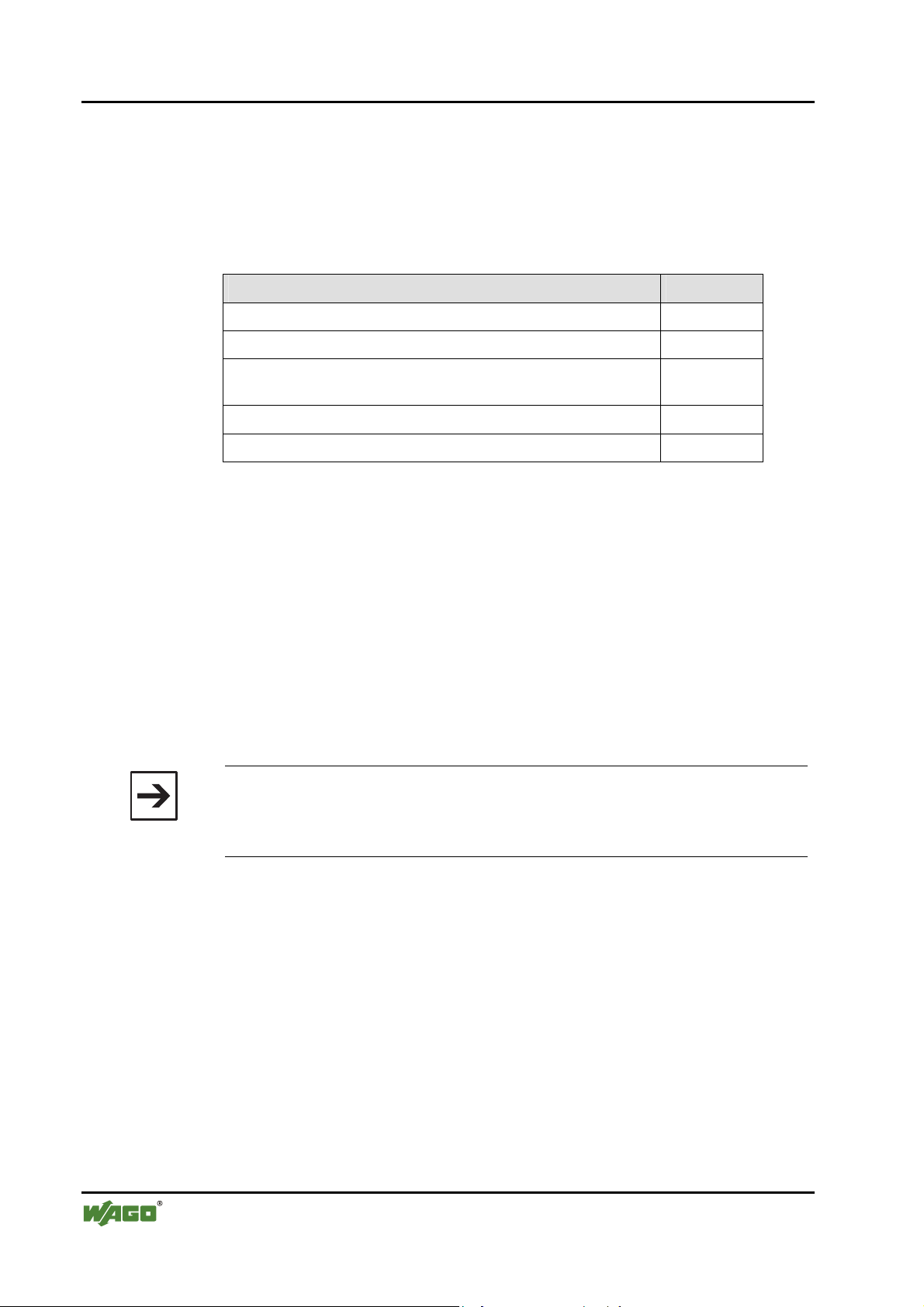

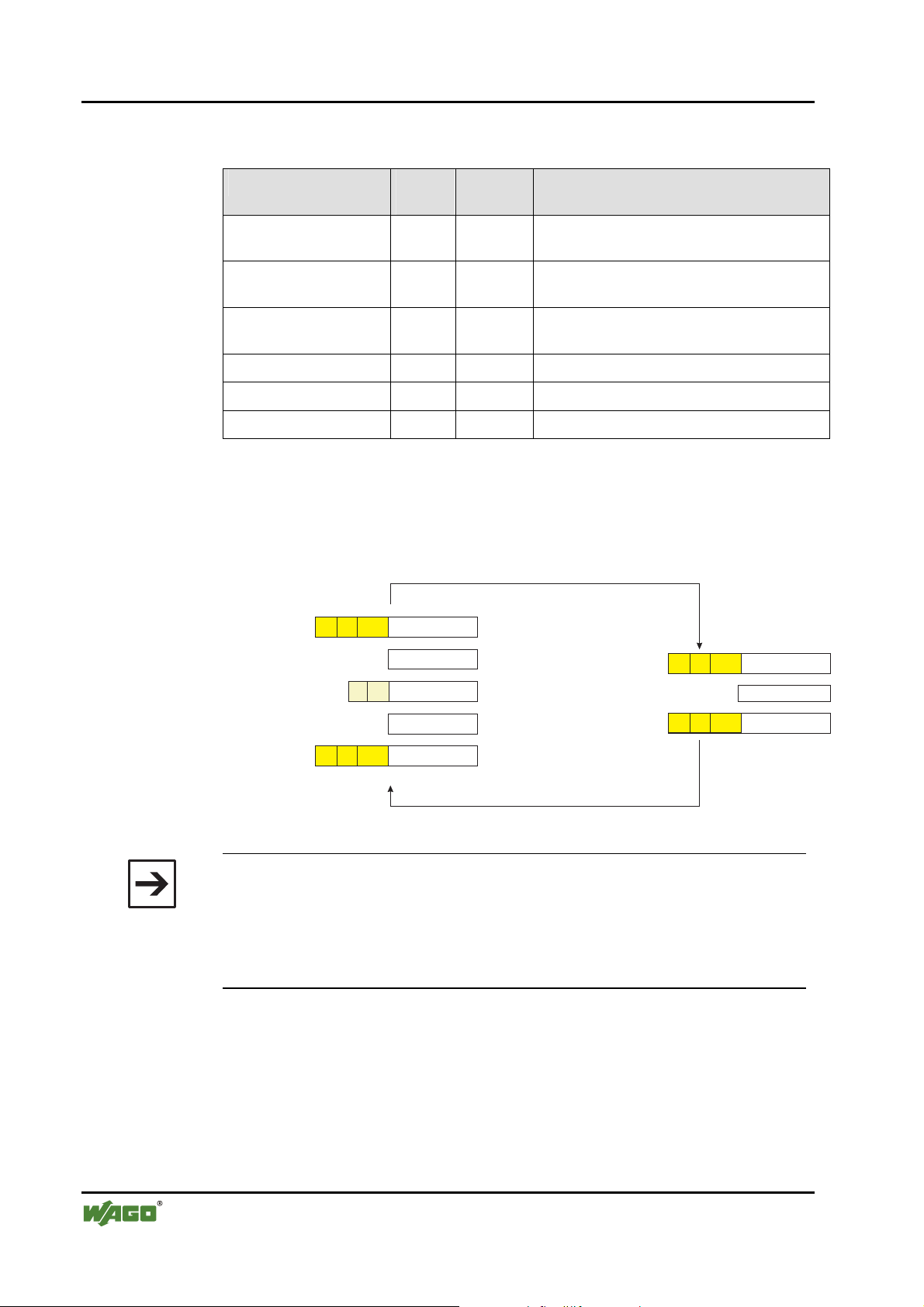

2.1.1.7.1 Time Required for Initialization

Waiting times occur during the initialization of the module

(see Table 5):

Table 5: Waiting times during normal operation of the module

Waiting times for Seconds

2-3

[1]

[2]

[3]

Connecting to the first slave ~ 5

Establishment of connection to a ready-to-receive slave 2-3

Successful establishment of connection by the master to another

slave

Unsuccessful attempt to connect to another slave 3-5

Inquiry up to 10.3

[1] if the slave is ready-to-receive at the conclusion of the master's boot process

[2] the master does not achieve a connection to the slave when attempted

[3] shorter in more than 15 found devices

2.1.1.7.2 Configuration and Communication Mode

The Bluetooth® module operates automatically in configuration mode during

the first operation. If the communication mode with the real-time or ad hoc

profile has already been selected via WAGO-I/O-CHECK, the module's mode

will be changed to the respective profile.

During startup of the module, the last configuration is the one loaded. If this is

not correct; e.g., in the case of an invalid memory structure, the configuration

is overwritten with the factory settings.

Note

The factory settings can also be reset using the mailbox command "SetFactorySettings". The individual values for the factory settings can be found in

Table 6.

During initialization, the general error bit 26 is set in the status byte. This

means that no mode has been received and there is no valid process data available. LED 1 lights up red during initialization (duration approx. 5s).

Once initialization is complete, the module takes on the last configured operating mode, and LED 1 changes to green. During first operation (factory setting), the module will be in configuration mode following initialization.

In configuration mode, the settings of the module can be configured according

to the desired function, for example by using WAGO-I/O-CHECK. In this

mode, the module can search for other Bluetooth

®

devices within reception

range and is visible for queries.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 23

I/O Modules • 23

Special Modules

However, no data exchange takes place. As there is no cyclic process data, the

general error bit continues to be set.

With suitable settings, or immediately after initialization (if already set beforehand), the module can change to communication mode.

If the module is started in communication mode, profiles are first loaded and

quality-of-service procedures are prepared. Finally, the connection to preconfigured devices is configured. Display LED 1 lights up green. The display of

the remaining LEDs depends on the configuration and the communication profile that has been set (see Sections 2.1.1.3.1 and 2.1.1.3.2).

Before the master and slaves exchange process data, they are synchronized to

a common process data size. This is then used from then on for data exchange.

Bootl Loader

Load Operation Mode

Perform Bluetooth module's initialization

Load non-volatile configuration

If configuration is invalid, then load factory settings

Compare non-volatile configuration with factory settings

Correct settings

Initialize Bluetooth stack

Set AccessibleMode ("Not connected") to "Not accessible"

Set Class-of-Device

Set LED (LED 0 green, LED 1-7 off)

Prepare connection establishment

Initialize mailbox

Save process image into module

Set general error bit 2 in status byte to 1

6

Configuration Mode

Figure 6: Initialization of the configuration and communication mode g064405e

WAGO-I/O-SYSTEM 750

I/O Modules

Communication Mode

Real-Time Profile

Communication Mode

Ad-Hoc Profile

Page 24

24 • I/O Modules

Special Modules

2.1.1.7.2.1 Configuration Mode

Mailbox commands are used in configuration mode to configure the Bluetooth® module for use. The commands are passed to the Bluetooth® module

and carried out, for example, with WAGO-I/O-CHECK or by using function

blocks of the WAGO-I/O-PRO CAA.

Additional Information

The mailbox commands for configuring the Bluetooth® module can be found

in Appendix 6.1. In Section 3 and Appendix 6.5, the configuration is described using WAGO-I/O-CHECK. The Bluetooth®-specific function blocks

of the WAGO-I/O-PRO CAA for configuring the module are contained in the

document "WAGO_Bluetooth_03.lib", is available online at

http://www.wago.com under Documentation ! WAGO Software 759 !

WAGO-I/O-PRO ! 759-333 ! Additional Information ! Libraries.

Table 6 below contains the factory settings. These can be restored and saved

in case of altered configuration by using the mailbox commands "SetFactorySettings" (except for Bluetooth

®

device name). A device name is overwritten

by the assigned mailbox command.

Table 6: Factory settings for the Bluetooth® module

Parameter Setting

Bluetooth® device name WAGO-750-644

IP 192.168.0.2

Subnet Mask 255.255.255.0

Gateway 192.168.0.1

Device role slave

Operating mode configuration mode

Mailbox cascade

Encryption active

Authentication with password

Standard password 0000

Quality of Service (QoS) disabled

Class of Device 0x0020F8

Time for reconfiguration of connection 30 seconds

Authorized devices none (all lists are initialized with "0")

Linked devices none (all lists are initialized with "0")

Process image sizes of the up to 7 slaves in the

master

10,0,0,0,0,0,0 bytes (used when changing

the device role to "master")

WAGO-I/O-SYSTEM 750

I/O Modules

Page 25

I/O Modules • 25

Special Modules

2.1.1.7.2.2 Block Transfer

The module parameters can be individually read and written using mailbox

commands (see Appendix 6.1). It is also possible, as an alternative, to upload

or download the complete configuration in 512-byte blocks. For example, a

created or read out configuration block can be used to set up and configure all

additional slaves.

512-byte blocks are sent. The transfer is opened each time by the group

DLD_START described in Appendix 6.3.2.1 and closed with DLD_END.

With each DLD_CONT command, one element of the block is transferred. After transferring one 512-byte block, the module verifies the checksum.

After the copying process has been successfully completed, the module confirms the DLD_END command by sending the calculated checksum and the

return 0x00 (OK).

The format of the configuration block transferred by means of the DLD commands is described in 6.4.

Table 7: Block transfer process using DLD commands

DLD commands Explanations

Procedure

DLD_START Configuration of the block transfer

n x DLD_CONT Transfer of the 512-byte blocks in n* consecutive elements

(* depends on the mailbox size, see Appendix

DLD_END End of the block transfer, testing of the checksum

The exact mode of operation of the commands "DLD_START",

"DLD_CONT" and "DLD_END" can be found in Appendix 6.3.2.

2.1.1.7.2.3 Communication Mode – Real-Time Profile

In the real-time profile, signals can be monitored in real-time. The cycle and

error message time is assured making this profile especially suited for timecritical applications such as system monitoring. In case of an error, the system

can be stopped immediately. The real-time network is invisible to Bluetooth

networks. Real-time capable masters only exchange data with directly connected slaves.

6.3.2.2)

®

Within the module, time intervals between different, repeating events are

monitored by Watchdog and other monitoring mechanisms. In case of disturbances, warnings/errors are signaled, depending on the type of disturbance, or

the module is automatically restarted.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 26

26 • I/O Modules

Special Modules

If there is an existing connection between WAGO devices, the time between

the received packets is measured. If there is a significant timeout, warnings or

error messages are sent (see Table 8). The typical time response is significantly more high performance than the upper limits given here for warnings

and errors.

Table 8: Time responses for Bluetooth® module

Name Value

BTCOM_

WARNTIME

BTCOM_

ERRORTIME

master, 1 slave linked:

master, 2…5 slaves linked:

master, 6 slaves linked:

master, 7 slaves linked:

slave:

master, 1 slave linked:

master, 2…5 slaves linked:

master, 6 slaves linked:

master, 7 slaves linked:

slave:

40 ms

20 ms * (number of end devices + 1)

240 ms

280 ms

280 ms

80 ms

40 ms * (number of end devices + 1)

480 ms

560 ms

560 ms

If the time limits cannot be adhered to, warnings or error messages are issued

via acyclic diagnosis functions (LED displays, see Section 2.1.1.3) or cyclically through the status byte of the process image (see Section 2.1.1.8.1.1).

For optimal time response, a valid piconet configuration must exist. If the

master cannot establish a connection to all slaves, the attempt to reintegrate

these devices leads to interruptions in data communication (see also "SetReconnectionTimePeriod", Appendix 6.3.5.34). To prevent this, you can temporarily remove defective devices from the piconet. No change in configuration

is required for removing the devices; simply set the affected devices to "not

linked" in the "real-time" communication profile. The master then no longer

integrates these devices during this time.

With the next change in operating mode or restart, the master will again try to

connect to all devices.

Note

Only connections to WAGO devices can be configured in the real-time profile.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 27

I/O Modules • 27

Special Modules

2.1.1.7.2.4 Communication Mode – Ad Hoc Profile

"Ad hoc communication" is the "spontaneous" connection of devices. The

main feature is the problem-free connection of very different types of devices.

Therefore, the requirements for partner devices are less strict, making realtime communication impossible when using this profile.

Note

In the ad hoc profile, you can connect up to 6 slaves with one master (up to 7

slaves in the real-time profile).

Note

Adherence to time limits (see Section 2.1.1.7.2.3) is not monitored in the ad

hoc profile, making this profile ideal for less time-critical applications.

WAGO devices can be connected with each other and with third-party Blue-

tooth® devices in the ad hoc profile. The Bluetooth® protocols SPP & PAN are

available for this purpose (see Table 14).

2.1.1.7.2.4.1 Connecting WAGO Devices with External Devices

The Bluetooth® module from WAGO can be connected with other WAGO

Bluetooth® modules via L2CAP. These connections are especially fast and are

subject to various reliability and reaction speed requirements. Slaves that support this form of connection are referred to as WAGO devices in this document.

By using PAN and SPP, devices that do not fulfill these requirements can also

be used. These devices, which actually control the exchange of the process

image, but not the real-time requirements, are called "external devices".

When configuring the wireless connection of an external Bluetooth® device

(e.g., PDA) to a WAGO Bluetooth® device, note that external devices must

have a valid protocol header embedded in their Bluetooth® packets. This must

be configured according to the following pattern (see Table 9):

WAGO-I/O-SYSTEM 750

I/O Modules

Page 28

28 • I/O Modules

Special Modules

Table 9: Configuration of the Bluetooth® Packet

Channel name Length

Value Description

in bytes

CHANNEL_SELECT 1 0000 0001

Virtual channel selection, always 0x01

(0x01)

STATUS_FLAGS 1 0000 0000

Status bits, always 0x00 for external devices

(0x00)

STATUS_DATA_SIZE 1 xxxx xxxx Data length in bytes, according to "cutoff"

(see Section

2.1.1.8.1.2)

DATA[1] 1 xxxx xxxx 1st byte of process data

... ... xxxx xxxx ...

DATA[n] (=cutoff) 1 xxxx xxxx nth (last) byte of process data

This header is automatically added in WAGO (see Figure 7).

WAGO Device

Header is added and removed automatically

Header is added

automatically

Control/status byte

are not transmitted

Local data

Control/status byte

are added

Header is removed

automatically

Bluetooth

®

Cutoff

01 00 Data

length

C/S int Data

Cutoff

01 00 Data

length

Data

Data

External Device

Header must be added and removed from the device

Radio transmission

Header is removed

from the device

Local data

Header must be

created from the device

Bluetooth

01 00 Data

01 00 Data

®

Cutoff

length

Cutoff

length

Data

Radio transmission

Figure 7: Adding the header in data packets of external devices g064406e

Note

Missing data in the protocol header may lead to termination of the connection. Therefore, prepend the 3-byte channel information (0x01 and 0x00 and

field length) to the data to be transferred if you would like to send from an

external device to a WAGO device.

WAGO devices add the header automatically.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 29

I/O Modules • 29

Special Modules

2.1.1.7.2.5 Configuration of the Wireless Connection

End devices are passive during configuration of the connection. Masters are

also passive if the connection is configured through SPP or PAN by external

devices. During the configuration of a connection, the status of a remote node

(if it is authorized and entered on the external devices list) is tested. Connections are actively configured only if the Bluetooth® module is operating as a

master in the real-time or ad hoc profile. The module can be connected

through the PAN profile using port 3501.

2.1.1.7.2.6 Net Forming

"Net forming" is the configuration of Bluetooth® modules for the purpose of

defining a Bluetooth® network.

The role of the Bluetooth® module - master or slave - is established in the configuration mode (see Section 2.1.1.7.2.1). The devices that are to be included

in the list of permitted devices is also established by entering the respective

device MAD IDs in WAGO-I/O-CHECK. A search can serve as an additional

aid here. Then, out of all the entered MAD IDs, those devices to which a connection is actually to be configured are marked as "linked". The prerequisite

for a successful configuration is a bilateral authorization, both from the master

for the slaves and from each slave for the master. Then the new settings are

downloaded into the module.

If you select "real-time" or "ad hoc" in the communication profile (see Section

2.1.1.7.2.3 to 2.1.1.7.2.4), a search for already configured Bluetooth® devices

will be performed first. The list of all authorized slaves is processed. The

module attempts to actively connect (master) with connected devices or to accept connections from them (slave). If a device is not marked as "linked" in

the list, connection attempts are refused by the device (slave) or no attempt to

connect to this device is made (master). Even if one or more devices are not

connected, data exchange with the remaining participants begins immediately

after the connection attempt.

The module attempts to configure the complete network at regular intervals.

Devices that cannot be reached temporarily are also reconnected as soon as the

connection is re-established. It is irrelevant whether a connection has never

been configured or whether it failed due to power failure at the site of the remote node, for example (can be set using "SetReconnectionTimePeriod").

WAGO-I/O-SYSTEM 750

I/O Modules

Page 30

30 • I/O Modules

Special Modules

Note

Wireless packets are only accepted and forwarded to the slave if a bilaterally

authorized wireless connection exists; i.e., the Bluetooth® MAC address of

the communication partner is entered in the table of permitted devices and the

table entry has been activated for the creation of a connection (linked) in the

master and slave. Since a maximum of seven remote devices can be linked,

the entry of authorized MAC addresses is independent of the process of linking/delinking.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 31

I/O Modules • 31

Special Modules

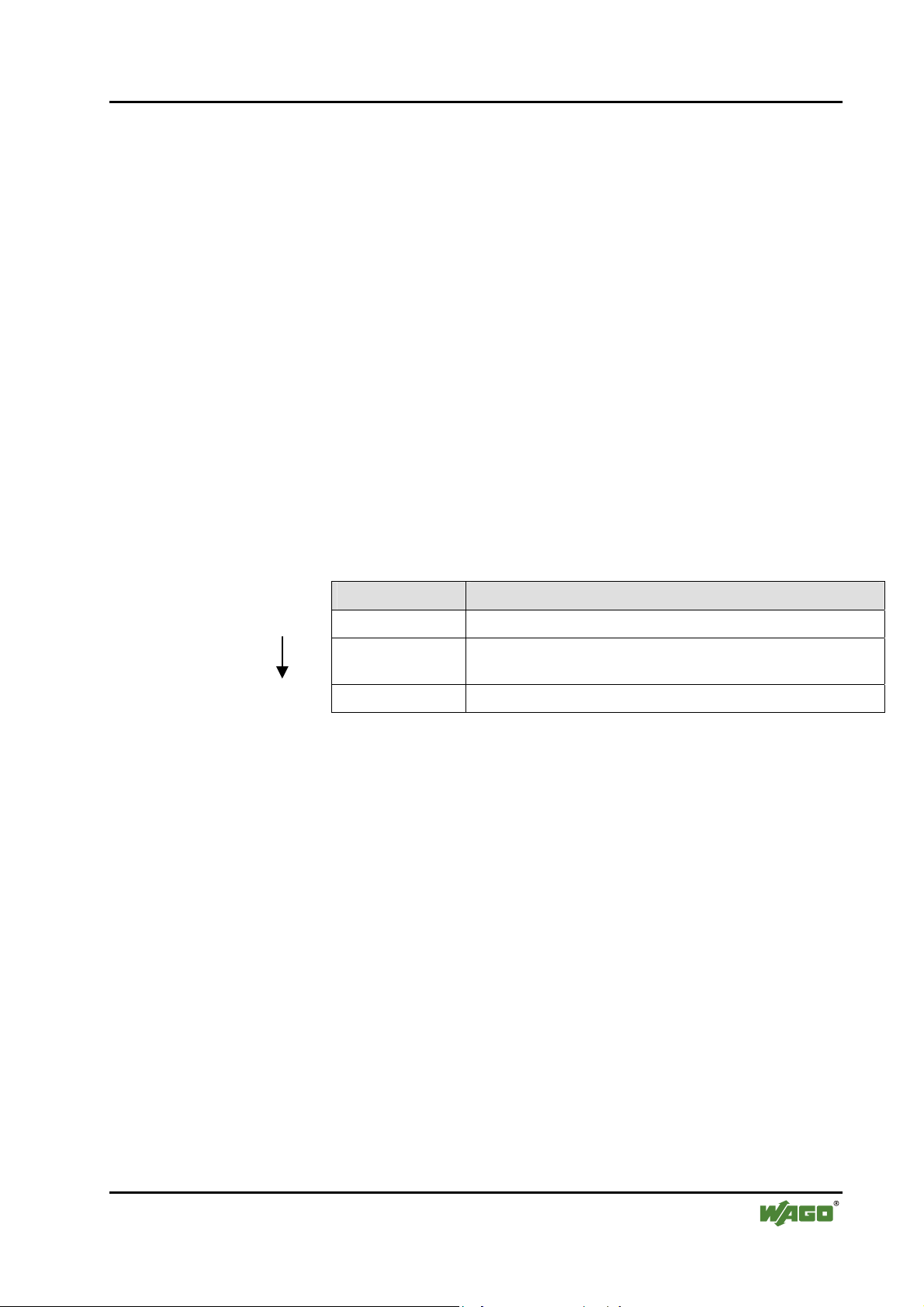

2.1.1.8 Process Image

Process data communication using the Bluetooth® protocol is cyclic. Data is

requested, processed in a fixed sequence and exchanged between master and

slaves.

For configuration, diagnosis and register communication, data is transmitted

acyclically between modules and locally connected applications - but not

wirelessly (see Figure 8).

Both the cyclic and acyclic communication share a transmission channel - the

process image.

Fieldbus

WAGO-I/O-CHECK

WAGO-I/O- CAAPRO

Configuration,

Diagnostics

(acyclic)

Figure 8: Cyclic and acyclic communication g064407e

Bluetooth

Module

Process image

Process data exchange

®

Radio Channel

(cyclic)

Bluetooth

Module

®

Configuration,

Diagnostics

(acyclic)

Process image

Fieldbus

WAGO-I/O-CHECK

WAGO-I/O- CAAPRO

The size of the process image for the Bluetooth® module can be set as a fixed

size, 12, 24 or 48 bytes. The process image contains 2 bytes of control information consisting of a control / status byte and an internally used byte.

The mailbox is superimposed in a size of 6, 12 or 18 bytes on the Bluetooth

process data as long as the control bit (0x20) is set.

Mailbox and process image sizes are set either via startup tool WAGO-I/OCHECK or by using WAGO-I/O-PRO CAA over the address 0 in the parameter channel.

Table 10 explains the breakdown of the data in process data and register communication.

WAGO-I/O-SYSTEM 750

I/O Modules

®

Page 32

32 • I/O Modules

Special Modules

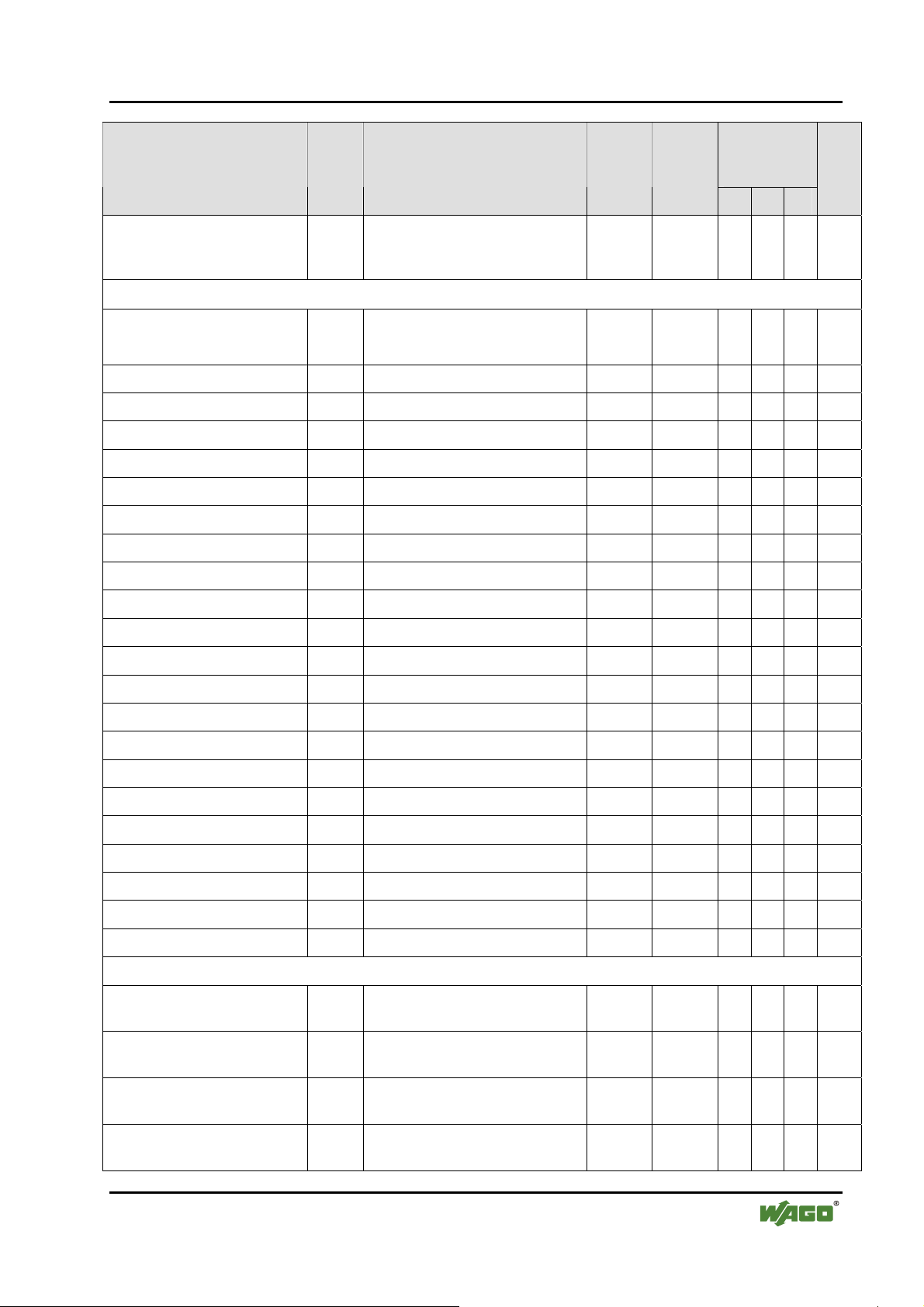

Table 10: Process data and register communication

Process data communication

Register Communication

Mailbox switched on Mailbox switched off

Control /status

(1 byte long, from byte 0)

Used internally

(1 byte long, from byte 1)

Mailbox

(Acyclical data,

Control /status

(1 byte long, from byte 0)

Used internally

(1 byte long, from byte 1)

Control /status

(1 byte long, from byte 0)

Used internally

(1 byte long, from byte 1)

Register data

(2 bytes long, from byte 2 to 3)

6…18 bytes long,

from byte 2 to n)

Process data

(Cyclical data,

0…32 bytes long,

Process data

(Cyclical data,

0…32 bytes long,

from byte 2 to m)

Invalid data

(from byte 4 to m)

from byte n + 1 to m)

(Pay attention to the valid-

ity of the data!)

The possible settings with regard to the overall process image and mailbox

size are explained in the following graphic.

Control/status byte

Reserved

Process data length

12 byte

Process data length

24 byte

Process data length

48 byte

Figure 9: Superimposition of the mailbox and register data on the process data g064408e

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

0

1

2

3

4

5

6

7

8

9

Process data 12-46 byte Control/status = 0x00

Register data 2 byte Control/status = 0x80

Mailbox

6 byte

= 0x20Control/status

Mailbox

12 byte

= 0x20Control/status

Mailbox

18 byte

= 0x20Control/status

WAGO-I/O-SYSTEM 750

I/O Modules

Page 33

I/O Modules • 33

Special Modules

If the mailbox bit (bit 25 in the control byte) is set to masked mailbox (see

Table 10), the mailbox is masked by the cyclical data field. The masked field

is then no longer valid; however, the non-masked field continues to be updated and may be used. If the mailbox flag is not set, the mailbox is masked

and the cyclical data field is valid. The desired setting is confirmed by mirroring in bit 25 of the status byte.

Note

Consider the validity of the data areas in your application program

(WAGO-I/O-PRO CAA).

To activate register communication (see Table 10), bit 27 in the control byte

is set. Resetting this bit switches the register communication off again. The selected setting is mirrored in bit 27 of the status byte. The register data is covered with an offset and a size of 2 bytes by the respective cyclic or acyclic

(covered by the mailbox) memory area.

Attention

During register communication, the mailbox and process data are invalid!

In the following Sections 2.1.1.8.1 and 2.1.1.8.3, the different types of communication between Bluetooth® modules are described. You can find an overview in Table 11.

Table 11: Overview of types of communication

Type of communication Configuration of the control / status byte

Process data communication

without mailbox

Process data communication

with mailbox

Register Communication

Control byte

Status byte

Control byte

Status byte

Control byte

Status byte

no bit set (0x00)

no bit set (0x00)

(contains additional diagnostic information, see Section

5

Bit 2

set (0x20)

5

and 26 set (0x60)

Bit 2

(contains additional diagnostic information, see Section

7

Bit 2

set (0x80)

7

set (0x80)

Bit 2

(contains additional information, e.g. the

register number, see Section

2.1.1.8.1.1)

2.1.1.8.1.1)

2.1.1.8.3.1)

WAGO-I/O-SYSTEM 750

I/O Modules

Page 34

34 • I/O Modules

Special Modules

2.1.1.8.1 Process Data Communication

During active process data communication, cyclic process data is exchanged

between master and slaves.

2.1.1.8.1.1 Configuration of the Control and Status Bytes

In process data communication, the control byte is configured as follows:

Table 12: Configuration of the control byte

Control byte

Bit

27 2

6

2

5

2

4

2

3

2

2

2

1

2

0

Value/

Description

Bit Value Description

20 0 Reserved (always 0)

21 0 Reserved (always 0)

22 0 Reserved (always 0)

23 0 Reserved (always 0)

24 0 Reserved (always 0)

0 Mailbox masked 25

1 Mailbox unmasked

26 0 Reserved (always 0)

27 0 During process data communication, always 0

0 0 Mailbox 0 0 0 0 0

(switch between process data communication and register communication)

In the status byte, messages, warnings and errors are signaled as follows:

Table 13: Configuration of the status byte

Status byte

Bit

Value/

Description

Bit Value Description

20 0 Reserved (always 0)

0 No warning

21

1

WAGO-I/O-SYSTEM 750

I/O Modules

27 26 2

Gen-

0

eral

error

Warning of obsolete process data. Indicates that no packet has been received

from the other party for a connection within the time defined as the error limit

(for times, see table from 2.1.1.7.2.3)

5

24 2

Mailbox 0

3

2

General.

warning

2

2

Mailbox

(remote)

Monitoring of

time behavior

1

2

0

0

Page 35

I/O Modules • 35

Special Modules

Bit Value Description

22

23

24 0 Reserved (always 0)

25

26

27 0

0 Mailbox of the connected device covered

1 Mailbox of the connected device uncovered (warning of obsolete data)

0 No warning

Warning; e.g., if after the expiration of a defined time limit for warning mes-

1

sages, no packet has been received from the other party

0 Mailbox masked (confirmation of the bus module)

1 Mailbox unmasked (confirmation of the bus module)

0 Wireless connection is established

Warning of non-existence of process data or invalid process data, for example in

1

configuration mode, during a restart or in the case of an interrupted wireless connection

During process data communication, always 0 (confirmation of the bus module)

(switch between process data communication and register communication)

2.1.1.8.1.1.1 Connecting WAGO Devices and External Devices

Slaves are divided into two groups: WAGO devices and external devices. The

WAGO devices use the real-time profile and the connection over L2CAP. External devices can be connected with the master using the ad hoc profile by

SPP profile or through PAN. Both groups are therefore administered in separate tables, even if they must be considered together with regard to simultaneous connections. The table for WAGO devices can accept up to seven entries.

Up to six devices are administered for external devices. A maximum of seven

simultaneous connections can exist at the same time, independently of how

many devices are listed in the tables of authorized devices using their MAC

addresses (see Table 14 and Table 15).

Table 14: Differences between WAGO devices and external devices

Table

Protocols

Profile of the master for a

connection

Maximum number of

slaves/slots per master

Process image

Module bus (in bytes)

Data width of wireless transmission

Initiator of the connection

WAGO-I/O-SYSTEM 750

I/O Modules

WAGO devices External devices

WAGO_DEVICE (0x20) EXTERNAL_DEVICE (0x10)

L2CAP SPP, PAN

Real-time, ad hoc Ad hoc

7 (6 in the ad hoc profile) 6

10, 22, 46

(Process image – 2)

per slot, according to the

"cutoff"

Master Slave

device-specific

per slot, according to the "cutoff"

Page 36

36 • I/O Modules

Special Modules

If WAGO and external devices in different modes are connected with a

WAGO master, the following guidelines apply for communication with each

other (see Table 15):

Table 15: Possible connection of a master with WAGO or external slaves

Slave

Master

Real-time profile

Ad hoc profile

WAGO BT module

Real-time profile

up to 7 devices - -

up to 6 devices up to 6 devices

In the ad hoc profile, a maximum of 7 devices can be active at the

same time, but there are always 13 slots available for configuration.

WAGO BT module

Ad hoc profile

External device

In the master, slots 1 through 7 correspond to the entries in the table of

WAGO devices. In the ad hoc profile, slots 8 through 13 are added with the

table entries for external devices.

In the ad hoc profile, connections to a maximum of seven slaves are established. Of these, a maximum of six can be (see Table 15) WAGO slaves and a

maximum of six can be external devices. By using up the tables for external

and WAGO devices, process image areas can be configured for up to 13 slots

in the master.

Note

When changing to the ad hoc profile, care must be taken that the real-time

device is not connected to slot 7. If a device with a "cutoff" greater than zero

is configured, slot 7 is filled with zeros in the process image.

In the slave, the process image always contains only one slot in which the configured master is unmasked. The width of a slot is determined by the "cutoff"

of this slot.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 37

I/O Modules • 37

Special Modules

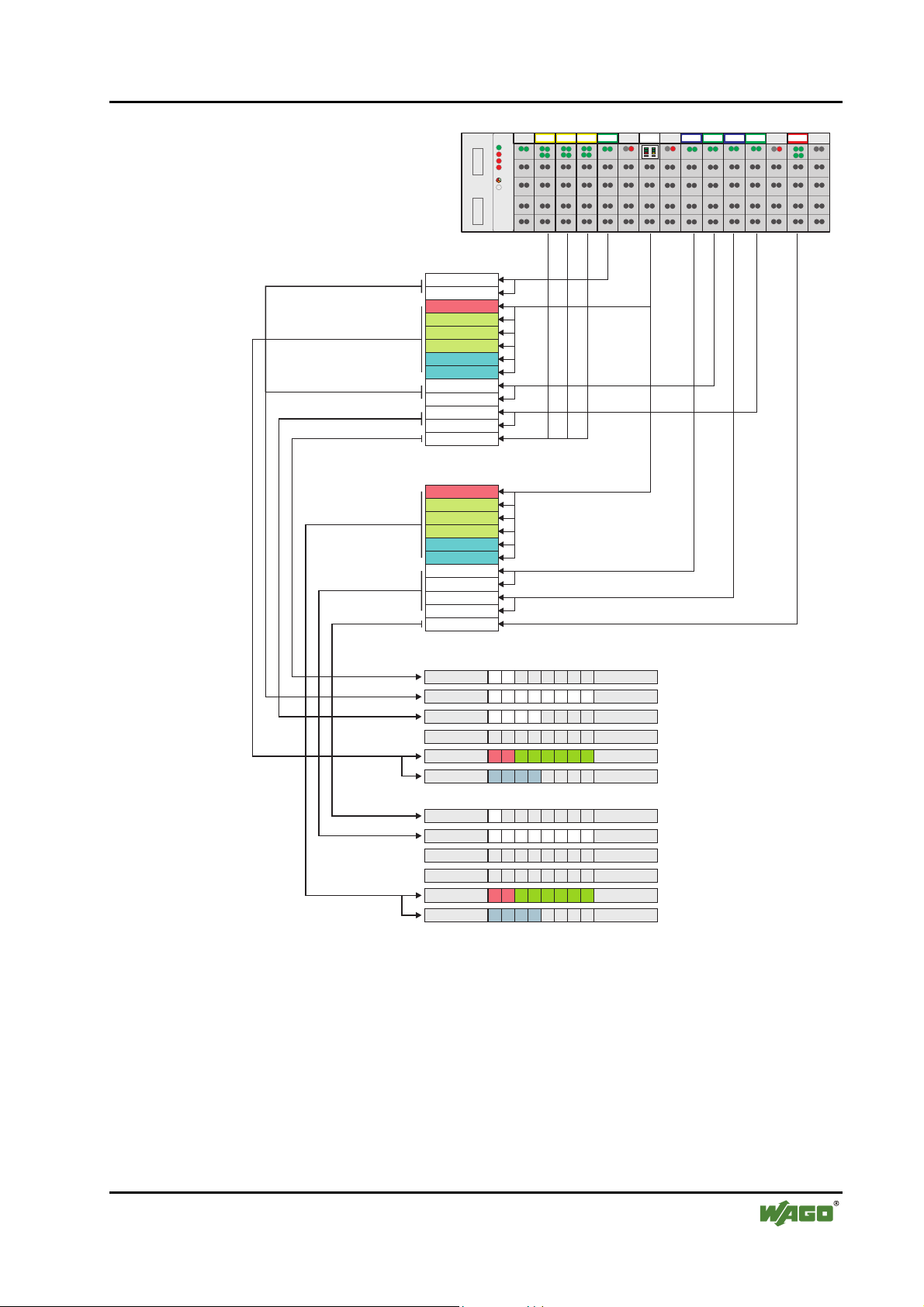

2.1.1.8.1.2 Process Image Mapping of the Master

Up to seven slaves can be connected to one master. The process images of

these slaves are mapped in the process image of the master.

The process image consists of a fixed number of virtual plug-ins for the Blue-

tooth® master and slaves, designated as slots. Each slot is assigned a defined

share of the process image by means of the process image mapping. One slave

can be configured for each slot, to which data can be transmitted in the area

assigned to this slot. A maximum of 6 or 7 devices can be active at one time.

The slots can occupy a length of up to 46 bytes in the master (see

Figure 10).

If only one slave is connected to the master, this slave can take advantage of

the entire available size of the master.

In WAGO-I/O-CHECK (configuration mode), the user determines which and

how much data the individual slaves currently occupy in the process image of

the master.

The local process image is constructed similar to that in

Figure 9. For data ex-

change between devices, the available area after byte 2 is further divided.

Figure 10: Mapping of the slaves in the master process image g064409e

Note

The size of the slave process images in the process image of the master can

be changed, not only by WAGO-I/O-CHECK, but also of the command "SetRemoteSize". The operation is symmetrical for the data stream entering or

exiting the master.

After changing to communication mode, the data exchange between master

and slaves begins. The master requests data that the slave sends back over the

Bluetooth

WAGO-I/O-SYSTEM 750

I/O Modules

®

network.

Page 38

38 • I/O Modules

Special Modules

In doing so, the slaves only send "excerpts" of their process data to the master.

The size of these "excerpts" is determined by "cutoff" in the configuration

mode. The command "cutoff" is symmetrical for the data stream entering and

exiting the master. The current data to be read and written, which are assigned

slots in the master's process image, remain (see Figure 11).

Slave A Slave B Slave C

...

...

Slave X

Process image

...

Radio transmission

(without control/status byte )

Data Direction Slave Master

Data Direction Master Slave

Master

Cut off by cutoff, is not transmitted

Figure 11: Process image mapping between master and slaves g064410e

Slot1 Slot 2 Slot 3 Slot 4 Slot 5 Slot 6

The following example (see Table 16) shows that both slots in the process image not occupied by slaves (see slot 1 and 4) as well as slots that are not visible due to a "cutoff" of 0 (see slot 4) can be visible. A "cutoff" of 0 is independent of whether a device has been set up for the slot or not.

Table 16: Example of a slot configuration

Slot Slave Cutoff Offset

...

1 - 4 0

2 "Pump" 6 4

3 "Valve" 10 10

4 - 0 20

WAGO-I/O-SYSTEM 750

I/O Modules

Page 39

I/O Modules • 39

Special Modules

In an additional example, we describe how the slot configurations behave in

conjunction with a configuration of the master (process image size = 48

bytes):

WAGO Table External Table

W1 permitted cutoff = 6 E1 linked cutoff = 6

W2 linked cutoff = 6 E2 linked cutoff = 6

W3 free cutoff = 0 E3 linked cutoff = 6

W4 linked cutoff = 4 E4 free cutoff = 0

W5 linked cutoff = 6 E5 free cutoff = 0

W6 free cutoff = 0 E6 free cutoff = 0

W7 linked cutoff = 6

Resulting process image in the master (ad hoc profile)

• 13 available slots, 5 of these with a width of 0 (W3, W6, E4, E5, E6)

• Since no connection is established with W7, the slot remains filled with ze-

ros

W1 W2 W4 W5 W7 E1 E2 E3

0 48

Resulting process image in the master (real-time profile)

• 7 available slots, 2 of these with a width of 0 (W3, W6)

W1 W2 W4 W5 W7 free

0 48

E1 has been removed in the configuration mode (ad hoc profile)

• "AllowRemoteDevice" with external Table E1 and MAD-ID: 0:0:0:0:0:0

• After removing E1, the slot is filled with zeros. No data are transmitted to

this slot

W1 W2 W4 W5 W7 00000... E2 E3

0 48

WAGO-I/O-SYSTEM 750

I/O Modules

Page 40

40 • I/O Modules

Special Modules

W6 has been processed in the configuration mode (ad hoc profile)

• "AllowRemoteDevice" with MAC address of W6

• "Cutoff" for slot 6 raised from 0 to 6

W1 W2 W4 W5 W6 W7 E2 E3

0 48

Connection to E2 is disconnected (ad hoc profile)

• UnbindRemoteDevice or end device discontinues the connection

• Slot assignments are not changed

• The last data is retained until the next reboot

W1 W2 W4 W5 W7 E1 E2 (Data

obsolete)

0 48

Control/status byte and internally used byte

The complete process image is first transmitted from the slave to the master. If

the slave has received a process image of the master, it sends only those bytes

that are still visible after the "cutoff" from this point on. It is always the visible

portion of the process image only, which is not truncated by "cutoff", that is

transmitted from the master to the slave.

Note

Missing data in the protocol header may lead to termination of the connection. Therefore, prepend the 3-byte channel information (0x01 and 0x00 and

field length) to the data to be transferred if sending from an external device to

a WAGO device. WAGO devices add the header automatically (see Section

2.1.1.7.2.4.1).

E3

WAGO-I/O-SYSTEM 750

I/O Modules

Page 41

I/O Modules • 41

Special Modules

Slave's process image

12, 24, 48 Byte

Usable process data (local)

Control/status byte

Byte used internally

10, 22, 46 Byte

Cutoff

will be transmitted

Master's process image

12, 24, 48 Byte

Slave

Radio transmission

Master

Importing of individual

information (cutoff)

Cutoff size entry

into header

Bluetooth®

protocol header

Bluetooth® protocoll

Bluetooth®

protocol header

Assignment of slave process image

to a slot within the master process image

Control/status byte

Byte used internally

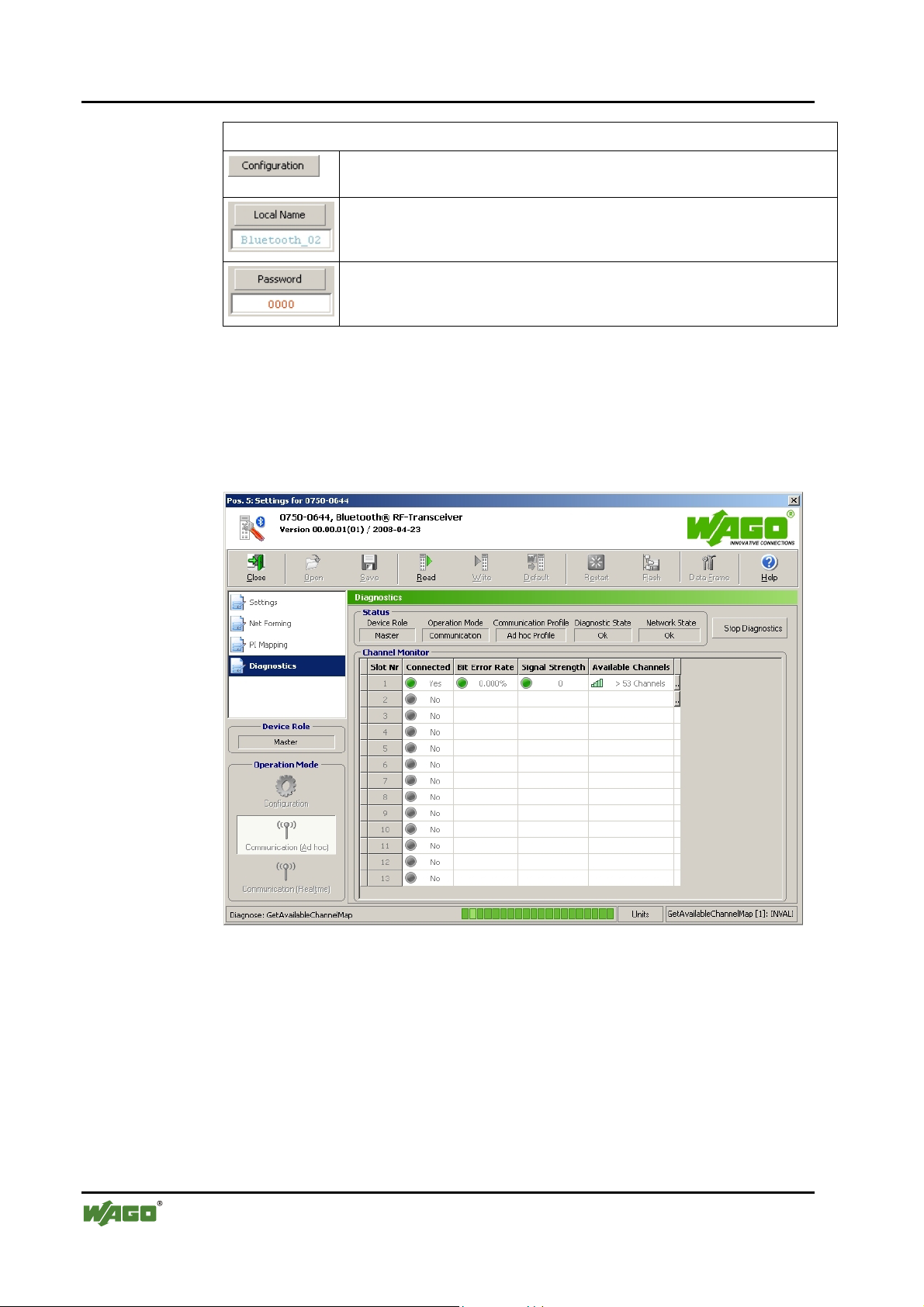

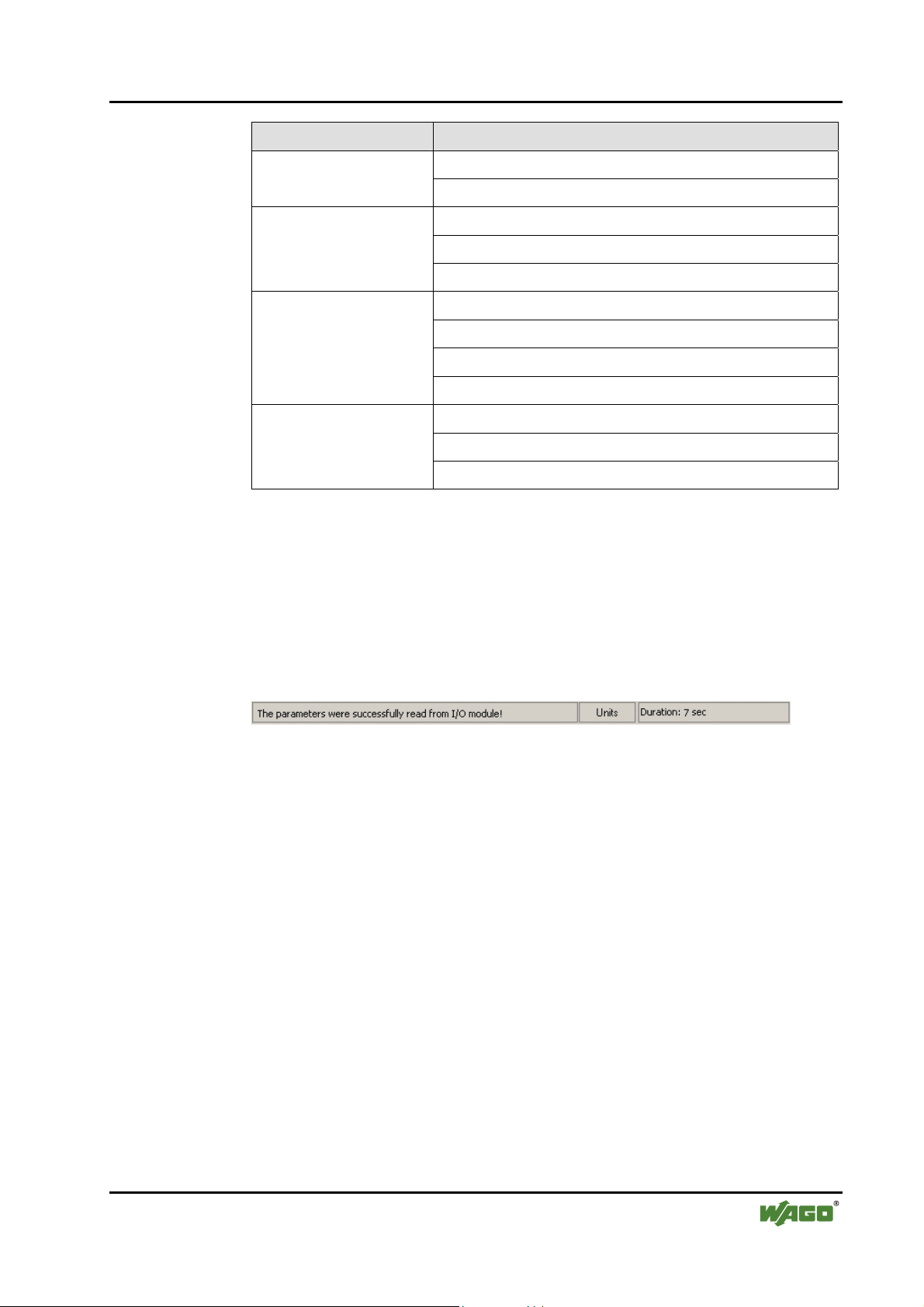

Slot1 Slot 2 Slot 3 Slot 4