UBX-16010572 - R14

C1-Public www.u-blox.com

TOBY-R2 series

Multi-mode LTE Cat 1 modules with 2G/3G fallback

System integration manual

Abstract

This document describes the features and the system integration of TOBY-R2 series multi-mode

cellular modules. These modules are a complete, cost efficient and performance optimized LTE

Cat 1 / 3G / 2G multi-mode solution covering up to four LTE bands, up to four 3G UMTS/HSPA bands

and up to four 2G GSM/EGPRS bands in the compact TOBY LGA form factor.

TOBY-R2 series - System integration manual

UBX-16010572 - R14 Document information Page 2 of 151

C1-Public

Document information

Title

TOBY-R2 series

Subtitle

Multi-mode LTE Cat 1 modules with 2G/3G fallback

Document type

System integration manual

Document number

UBX-16010572

Revision and date

R14

30-Mar-2021

Disclosure restriction

C1-Public

Product status

Corresponding content status

Functional sample

Draft

For functional testing. Revised and supplementary data will be published later.

In development /

Prototype

Objective specification

Target values. Revised and supplementary data will be published later.

Engineering sample

Advance information

Data based on early testing. Revised and supplementary data will be published later.

Initial production

Early production information

Data from product verification. Revised and supplementary data may be published later.

Mass production /

End of life

Production information

Document contains the final product specification.

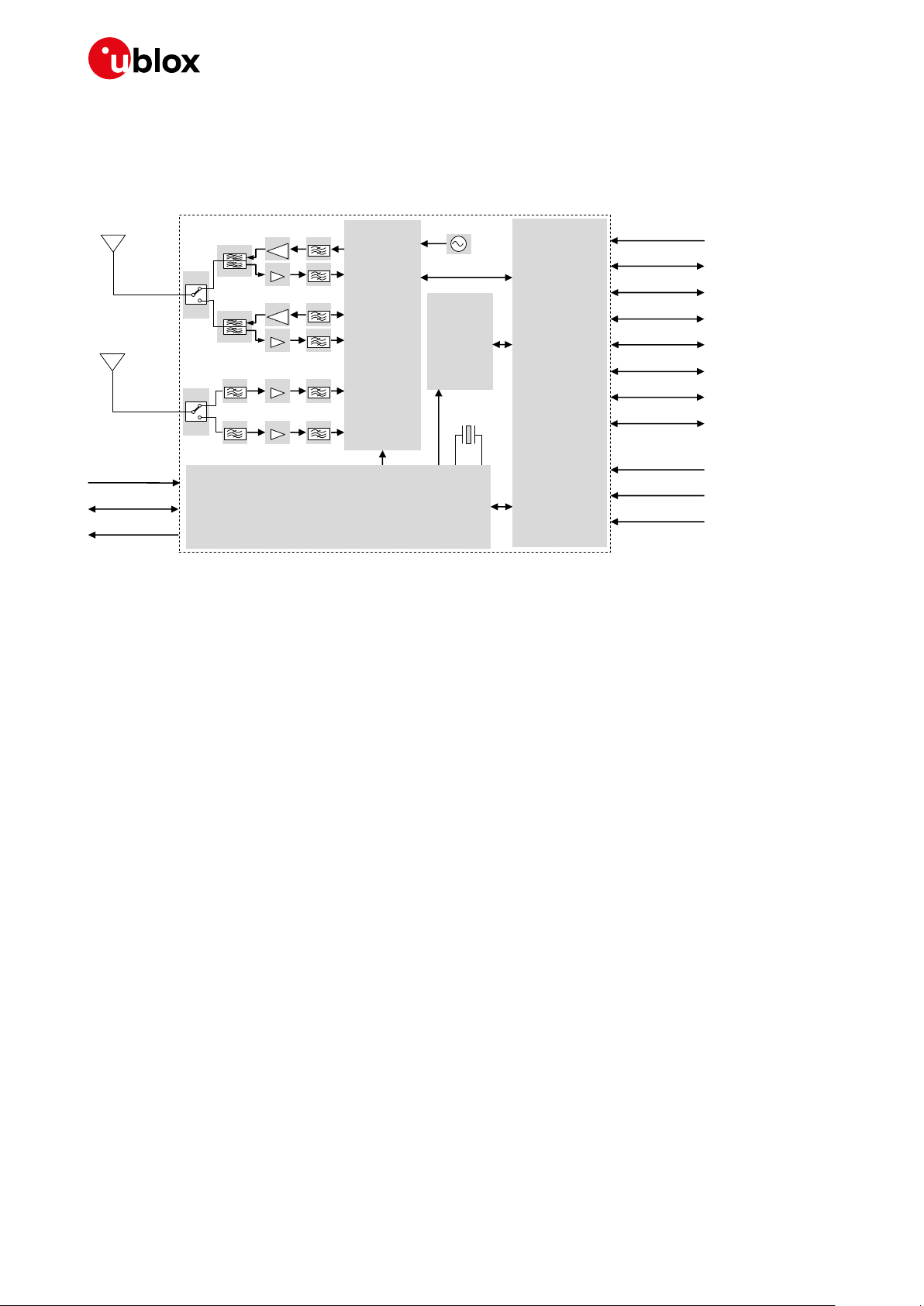

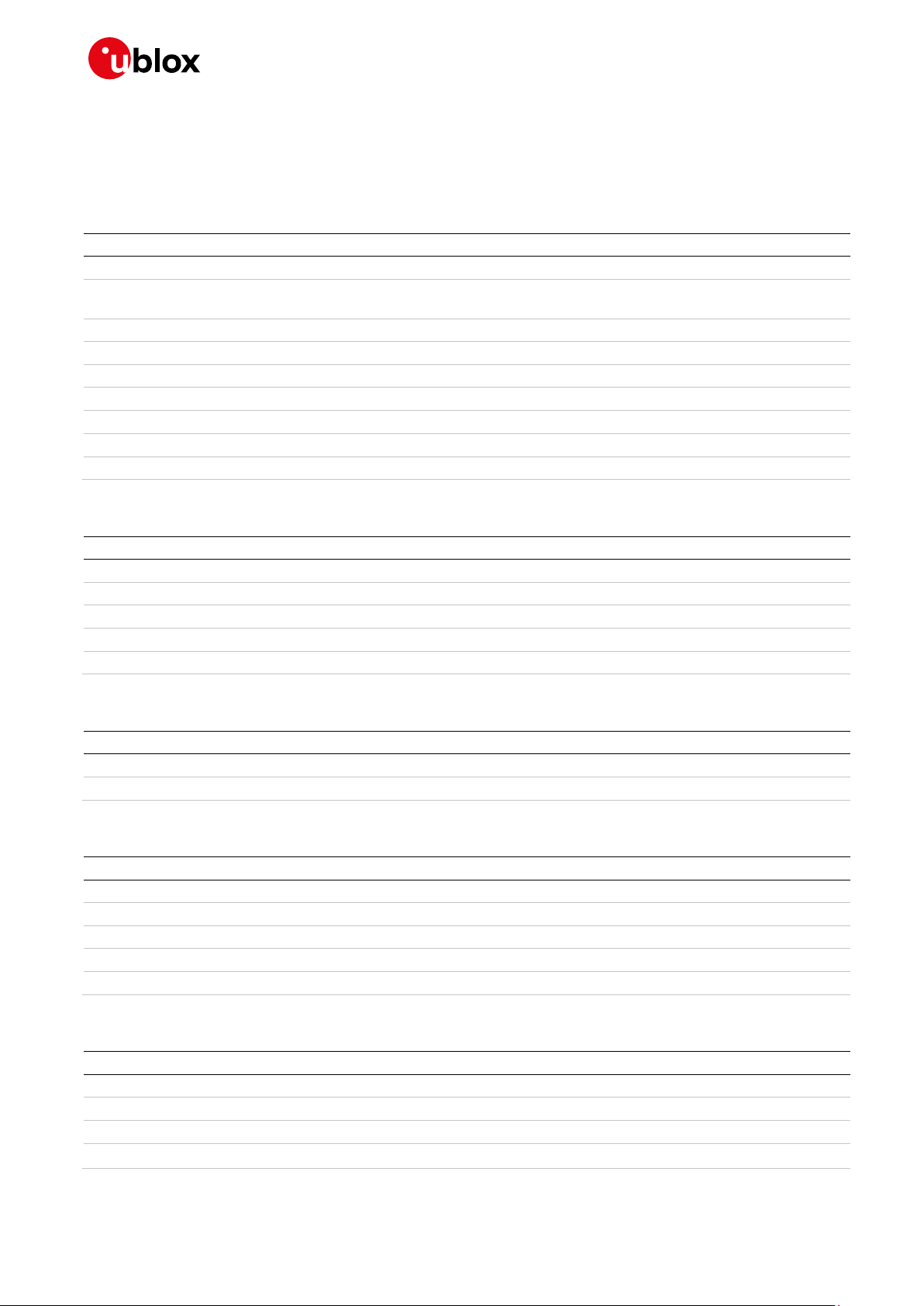

This document applies to the following products:

Product name

Type number

Modem version

Application version

PCN reference

Product status

TOBY-R200

TOBY-R200-02B-00

30.31

A01.01

UBX-17006265

Obsolete

TOBY-R200-02B-01

30.31

A02.00

UBX-17048314

Obsolete

TOBY-R200-02B-02

30.31

A02.01

UBX-18018067

Obsolete

TOBY-R200-02B-03

30.31

A02.02

UBX-18057549

Obsolete

TOBY-R200-02B-04

30.33

A02.02

UBX-19011731

Mass production

TOBY-R200-42B-00

30.53

A01.02

UBX-19045985

Mass production

TOBY-R200-82B-00

30.53

A01.03

UBX-19043497

Mass production

TOBY-R200-03B-00

30.55

A01.00

UBX-20027523

Mass production

TOBY-R202

TOBY-R202-02B-00

30.31

A01.01

UBX-17006265

Obsolete

TOBY-R202-02B-01

30.31

A02.00

UBX-17048314

Obsolete

TOBY-R202-02B-02

30.31

A02.01

UBX-18018067

Obsolete

TOBY-R202-02B-03

30.31

A02.02

UBX-18057549

Obsolete

TOBY-R202-02B-04

30.33

A02.02

UBX-19011731

Mass production

TOBY-R202-02B-34

30.33

A02.04

UBX-19039777

Obsolete

u-blox or third parties may hold intellectual property rights in the products, names, logos and designs included in this

document. Copying, reproduction, modification or disclosure to third parties of this document or any part thereof is only

permitted with the express written permission of u-blox.

The information contained herein is provided “as is” and u-blox assumes no liability for its use. No warranty, either express or

implied, is given, including but not limited to, with respect to the accuracy, correctness, reliability and fitness for a particular

purpose of the information. This document may be revised by u-blox at any time without notice. For the most recent

documents, visit www.u-blox.com.

Copyright © u-blox AG.

TOBY-R2 series - System integration manual

UBX-16010572 - R14 Contents Page 3 of 151

C1-Public

Contents

Document information ................................................................................................................................ 2

Contents .......................................................................................................................................................... 3

1 System description ............................................................................................................................... 7

1.1 Overview ........................................................................................................................................................ 7

1.2 Architecture ................................................................................................................................................. 9

1.3 Pin-out .........................................................................................................................................................10

1.4 Operating modes .......................................................................................................................................14

1.5 Supply interfaces ......................................................................................................................................16

1.5.1 Module supply input (VCC) .........................................................................................................16

1.5.2 RTC supply input/output (V_BCKP) ..........................................................................................24

1.5.3 Generic digital interfaces supply output (V_INT) ...................................................................25

1.6 System function interfaces ....................................................................................................................26

1.6.1 Module power-on ...........................................................................................................................26

1.6.2 Module power-off ..........................................................................................................................28

1.6.3 Module reset ..................................................................................................................................31

1.6.4 Module / host configuration selection ......................................................................................31

1.7 Antenna interface .....................................................................................................................................32

1.7.1 Antenna RF interfaces (ANT1 / ANT2) .....................................................................................32

1.7.2 Antenna detection interface (ANT_DET) .................................................................................34

1.8 SIM interface ..............................................................................................................................................34

1.8.1 SIM interface .................................................................................................................................34

1.8.2 SIM detection interface ...............................................................................................................34

1.9 Data communication interfaces ............................................................................................................35

1.9.1 UART interface ..............................................................................................................................35

1.9.2 USB interface .................................................................................................................................46

1.9.3 DDC (I2C) interface .......................................................................................................................49

1.9.4 SDIO interface ...............................................................................................................................51

1.10 Audio ............................................................................................................................................................52

1.10.1 Digital audio over I2S interface ..................................................................................................52

1.11 Clock output ...............................................................................................................................................53

1.12 General Purpose Input/Output ...............................................................................................................53

1.13 Reserved pins (RSVD) ..............................................................................................................................53

1.14 System features ........................................................................................................................................54

1.14.1 Network indication ........................................................................................................................54

1.14.2 Antenna supervisor ......................................................................................................................54

1.14.3 Jamming detection ......................................................................................................................54

1.14.4 Dual stack IPv4/IPv6 .....................................................................................................................54

1.14.5 TCP/IP and UDP/IP ........................................................................................................................55

1.14.6 FTP ...................................................................................................................................................55

1.14.7 HTTP ................................................................................................................................................55

TOBY-R2 series - System integration manual

UBX-16010572 - R14 Contents Page 4 of 151

C1-Public

1.14.8 SSL / TLS ........................................................................................................................................55

1.14.9 Bearer Independent Protocol ......................................................................................................57

1.14.10 AssistNow clients and GNSS integration ................................................................................57

1.14.11 Hybrid positioning and CellLocate® ...........................................................................................58

1.14.12 Wi-Fi integration ...........................................................................................................................60

1.14.13 Firmware update Over AT (FOAT) .............................................................................................60

1.14.14 Firmware update Over The Air (FOTA) .....................................................................................60

1.14.15 Smart temperature management ............................................................................................61

1.14.16 Power saving ..................................................................................................................................63

2 Design-in ................................................................................................................................................ 64

2.1 Overview ......................................................................................................................................................64

2.2 Supply interfaces ......................................................................................................................................65

2.2.1 Module supply (VCC) ....................................................................................................................65

2.2.2 RTC supply output (V_BCKP) .....................................................................................................79

2.2.3 Generic digital interfaces supply output (V_INT) ...................................................................80

2.3 System functions interfaces ..................................................................................................................82

2.3.1 Module power-on (PWR_ON) ......................................................................................................82

2.3.2 Module reset (RESET_N) .............................................................................................................83

2.3.3 Module / host configuration selection ......................................................................................84

2.4 Antenna interface .....................................................................................................................................85

2.4.1 Antenna RF interfaces (ANT1 / ANT2) .....................................................................................85

2.4.2 Antenna detection interface (ANT_DET) .................................................................................92

2.5 SIM interface ..............................................................................................................................................94

2.5.1 Guidelines for SIM circuit design ...............................................................................................94

2.5.2 Guidelines for SIM layout design ...............................................................................................99

2.6 Data communication interfaces ......................................................................................................... 100

2.6.1 UART interface ........................................................................................................................... 100

2.6.2 USB interface .............................................................................................................................. 105

2.6.3 DDC (I2C) interface .................................................................................................................... 107

2.6.4 SDIO interface ............................................................................................................................ 111

2.7 Audio interface ....................................................................................................................................... 112

2.7.1 Digital audio interface ............................................................................................................... 112

2.8 General Purpose Input/Output ............................................................................................................ 116

2.9 Reserved pins (RSVD) ........................................................................................................................... 117

2.10 Module placement ................................................................................................................................. 117

2.11 Module footprint and paste mask ...................................................................................................... 118

2.12 Thermal guidelines ................................................................................................................................ 119

2.13 ESD guidelines ........................................................................................................................................ 120

2.13.1 ESD immunity test overview ................................................................................................... 120

2.13.2 ESD immunity test of TOBY-R2 series reference designs ................................................ 121

2.13.3 ESD application circuits ........................................................................................................... 121

2.14 Schematic for TOBY-R2 series module integration........................................................................ 123

2.14.1 Schematic for TOBY-R2 series module “x2” product version ........................................... 123

TOBY-R2 series - System integration manual

UBX-16010572 - R14 Contents Page 5 of 151

C1-Public

2.15 Design-in checklist ................................................................................................................................. 124

2.15.1 Schematic checklist .................................................................................................................. 124

2.15.2 Layout checklist ......................................................................................................................... 125

2.15.3 Antenna checklist ...................................................................................................................... 125

3 Handling and soldering ................................................................................................................... 126

3.1 Packaging, shipping, storage and moisture preconditioning ....................................................... 126

3.2 Handling ................................................................................................................................................... 126

3.3 Soldering .................................................................................................................................................. 127

3.3.1 Soldering paste .......................................................................................................................... 127

3.3.2 Reflow soldering ......................................................................................................................... 127

3.3.3 Optical inspection ...................................................................................................................... 128

3.3.4 Cleaning ....................................................................................................................................... 128

3.3.5 Repeated reflow soldering ....................................................................................................... 129

3.3.6 Wave soldering ........................................................................................................................... 129

3.3.7 Hand soldering ............................................................................................................................ 129

3.3.8 Rework .......................................................................................................................................... 129

3.3.9 Conformal coating ..................................................................................................................... 129

3.3.10 Casting ......................................................................................................................................... 129

3.3.11 Grounding metal covers............................................................................................................ 130

3.3.12 Use of ultrasonic processes ..................................................................................................... 130

4 Approvals ............................................................................................................................................. 131

4.1 Product certification approval overview ............................................................................................ 131

4.2 US Federal Communications Commission notice ........................................................................... 132

4.2.1 Safety warnings review the structure ................................................................................... 132

4.2.2 Declaration of Conformity ........................................................................................................ 132

4.2.3 Modifications .............................................................................................................................. 133

4.3 Innovation, Science, Economic Development Canada notice ....................................................... 133

4.3.1 Declaration of Conformity ........................................................................................................ 133

4.3.2 Modifications .............................................................................................................................. 134

4.4 European Conformance CE mark ....................................................................................................... 136

4.5 ANATEL Brazil ........................................................................................................................................ 136

5 Product testing ................................................................................................................................. 137

5.1 u-blox in-series production test .......................................................................................................... 137

5.2 Test parameters for OEM manufacturer .......................................................................................... 138

5.2.1 “Go/No go” tests for integrated devices ............................................................................... 138

5.2.2 RF functional tests .................................................................................................................... 138

Appendix ..................................................................................................................................................... 140

A Migration between TOBY-L2 and TOBY-R2 ............................................................................ 140

A.1 Overview ................................................................................................................................................... 140

A.2 Pin-out comparison between TOBY-L2 and TOBY-R2 ................................................................... 142

A.3 Schematic for TOBY-L2 and TOBY-R2 integration ........................................................................ 145

B Glossary ............................................................................................................................................... 146

TOBY-R2 series - System integration manual

UBX-16010572 - R14 Contents Page 6 of 151

C1-Public

Related documentation ......................................................................................................................... 149

Revision history ........................................................................................................................................ 150

Contact ........................................................................................................................................................ 151

TOBY-R2 series - System integration manual

UBX-16010572 - R14 System description Page 7 of 151

C1-Public

1 System description

1.1 Overview

The TOBY-R2 series comprises LTE Cat 1 / 3G / 2G multi-mode modules supporting up to six LTE

bands, up to four 3G UMTS/HSPA bands and up to four 2G GSM/(E)GPRS bands for voice and/or data

transmission in the small TOBY LGA form-factor (35.6 x 24.8 mm, 152-pin), easy to integrate in

compact designs:

• TOBY-R200 are designed for worldwide operation on LTE, 3G and 2G networks, and primarily in

North America

• TOBY-R202 are designed primarily for operation in North America, on LTE and 3G networks

TOBY-R2 series modules are form-factor compatible with u-blox SARA, LISA and LARA cellular

module families and are pin-to-pin compatible with u-blox TOBY-L cellular module families: this

facilitates easy migration from the u-blox GSM/GPRS, CDMA, UMTS/HSPA, and LTE high data rate

modules, maximizes the investments of customers, simplifies logistics, and enables very short

time-to-market.

The modules are ideal for applications that are transitioning to LTE from 2G and 3G, due to the long

term availability and scalability of LTE networks.

With a range of interface options and an integrated IP stack, the modules are designed to support a

wide range of data-centric applications. The unique combination of performance and flexibility make

these modules ideally suited for medium speed M2M applications, such as smart energy gateways,

remote access video cameras, digital signage, telehealth and telematics.

TOBY-R2 series modules include product versions supporting Voice over LTE (VoLTE) and voice over

3G / 2G (CSFB) for applications that require voice, such as security and surveillance systems.

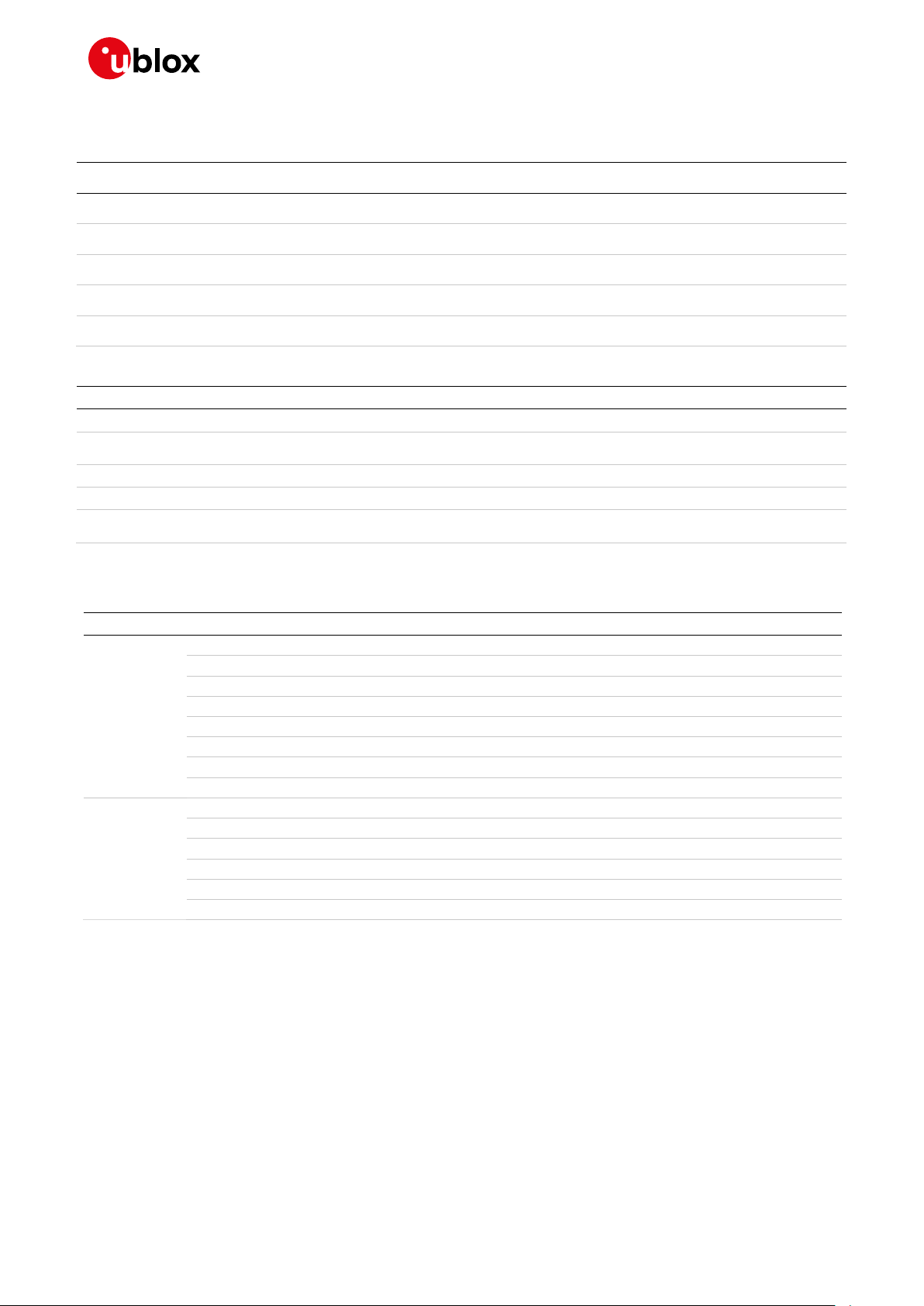

Table 1 summarizes the main features and interfaces of TOBY-R2 series modules.

Model

Region

Radio Access

Technology

Positioning

Interfaces

Audio

Features

Grade

LTE bands

1

UMTS bands GSM bands GNSS via mo

dem

AssistNow Software CellLocate® UART

USB 2.0

SDIO * DDC (I2C) GPIOs Analog audio Digital audio Network indication VoLTE Antenna

supervisor

Rx Diversity Embedded TCP/UDP stack Embedded HTTP, FTP, SSL FOTA

Dual stack IPv4 / IPv6 Standard Professional Automotive

TOBY-R200-02B

North

America

2,4

5,12

850,900

1900,2100

Quad

■ ■ ■

1 1 1 1 9

●

●

●2

● ● ● ● ●

● ●

TOBY-R200-03B

Global

1,2,4

5,8,12

850,900

1900,2100

Quad

■ ■ ■

1 1 1 1 9

●

●

●

2

● ● ● ● ●

● ●

TOBY-R200-42B

Global

1,2,4

5,8,12

850,900

1900,2100

Quad

● ● ●

1 1 1 1 9

● ● ● ● ● ● ● ● ● ●

TOBY-R200-82B

Global

1,2,4

5,8,12

850,900

1900,2100

Quad

● ● ●

1 1 1 1 9

●

●

●

2

● ● ● ● ●

● ●

TOBY-R202-02B

North

America

2,4

5,12

850,1900

■ ■ ■

1 1 1 1 9

●

●

●2

● ● ● ● ●

● ●

● = Supported by all FW version ■ = Supported by "TOBY-R2xx-02B-01" FW version onwards * = HW ready

Table 1: TOBY-R2 series main features summary

1

LTE band 12 is a superset including band 17: LTE band 12 is supported along with Multi-Frequency Band Indicator feature

2

AT&T certified

TOBY-R2 series - System integration manual

UBX-16010572 - R14 System description Page 8 of 151

C1-Public

Table 2 summarizes cellular radio access technology characteristics and features of the modules.

4G LTE

3G UMTS/HSDPA/HSUPA

2G GSM/GPRS/EDGE

3GPP Release 9

Long Term Evolution (LTE)

Evolved UTRA (E-UTRA)

Frequency Division Duplex (FDD)

DL Rx Diversity

3GPP Release 9

High Speed Packet Access (HSPA)

UMTS Terrestrial Radio Access (UTRA)

Frequency Division Duplex (FDD)

DL Rx diversity

3GPP Release 9

Enhanced Data rate GSM Evolution (EDGE)

GSM EGPRS Radio Access (GERA)

Time Division Multiple Access (TDMA)

DL Advanced Rx Performance Phase 1

Band support3:

• TOBY-R200-02B:

o Band 12 (700 MHz)4

o Band 5 (850 MHz)

o Band 4 (1700 MHz)

o Band 2 (1900 MHz)

• TOBY-R200-03B, TOBY-R200-42B,

TOBY-R200-82B:

o Band 12 (700 MHz)4

o Band 5 (850 MHz)

o Band 8 (900 MHz)

o Band 4 (1700 MHz)

o Band 2 (1900 MHz)

o Band 1 (2100 MHz)

• TOBY-R202:

o Band 12 (700 MHz)4

o Band 5 (850 MHz)

o Band 4 (1700 MHz)

o Band 2 (1900 MHz)

Band support:

• TOBY-R200-02B:

o Band 5 (850 MHz)

o Band 8 (900 MHz)

o Band 2 (1900 MHz)

o Band 1 (2100 MHz)

• TOBY-R200-03B, TOBY-R200-42B,

TOBY-R200-82B:

o Band 5 (850 MHz)

o Band 8 (900 MHz)

o Band 2 (1900 MHz)

o Band 1 (2100 MHz)

• TOBY-R202:

o Band 5 (850 MHz)

o Band 2 (1900 MHz)

Band support:

• TOBY-R200-02B:

o GSM 850 MHz

o E-GSM 900 MHz

o DCS 1800 MHz

o PCS 1900 MHz

• TOBY-R200-03B, TOBY-R200-42B,

TOBY-R200-82B:

o GSM 850 MHz

o E-GSM 900 MHz

o DCS 1800 MHz

o PCS 1900 MHz

LTE Power Class

• Class 3 (23 dBm)

UMTS/HSDPA/HSUPA Power Class

• Class 3 (24 dBm)

GSM/GPRS (GMSK) Power Class

• Class 4 (33 dBm) for GSM/E-GSM band

• Class 1 (30 dBm) for DCS/PCS band

EDGE (8-PSK) Power Class

• Class E2 (27 dBm) for GSM/E-GSM

band

• Class E2 (26 dBm) for DCS/PCS band

Data rate

• LTE category 1:

up to 10.3 Mb/s DL, 5.2 Mb/s UL

Data rate

• HSDPA category 8:

up to 7.2 Mb/s DL

• HSUPA category 6:

up to 5.76 Mb/s UL

Data rate5

• GPRS multi-slot class 336, CS1-CS4,

up to 107 kb/s DL, up to 85.6 kb/s UL

• EDGE multi-slot class 336, MCS1-MCS9,

up to 296 kb/s DL, up to 236.8 kb/s UL

Table 2: TOBY-R2 series LTE, 3G and 2G characteristics summary

TOBY-R2 series modules provide Voice over LTE (VoLTE) as well as Circuit-Switched-Fall-Back (CSFB)

audio capability.

3

TOBY-R2 modules support all the E-UTRA channel bandwidths for each operating band according to 3GPP TS 36.521-1 [25]:

• Band 12: 1.4 MHz, 3 MHz, 5 MHz, 10 MHz

• Band 5: 1.4 MHz, 3 MHz, 5 MHz, 10 MHz

• Band 4: 1.4 MHz, 3 MHz, 5 MHz, 10 MHz, 15 MHz, 20 MHz

• Band 2: 1.4 MHz, 3 MHz, 5 MHz, 10 MHz, 15 MHz, 20 MHz

4

LTE band 12 is a superset that includes band 17

5

GPRS/EDGE multi-slot class determines the number of timeslots available for upload and download and thus the speed at

which data can be transmitted and received, with higher classes typically allowing faster data transfer rates.

6

GPRS/EDGE multi-slot class 33 implies a maximum of 5 slots in DL (Rx) and 4 slots in UL (Tx) with 6 slots in total.

TOBY-R2 series - System integration manual

UBX-16010572 - R14 System description Page 9 of 151

C1-Public

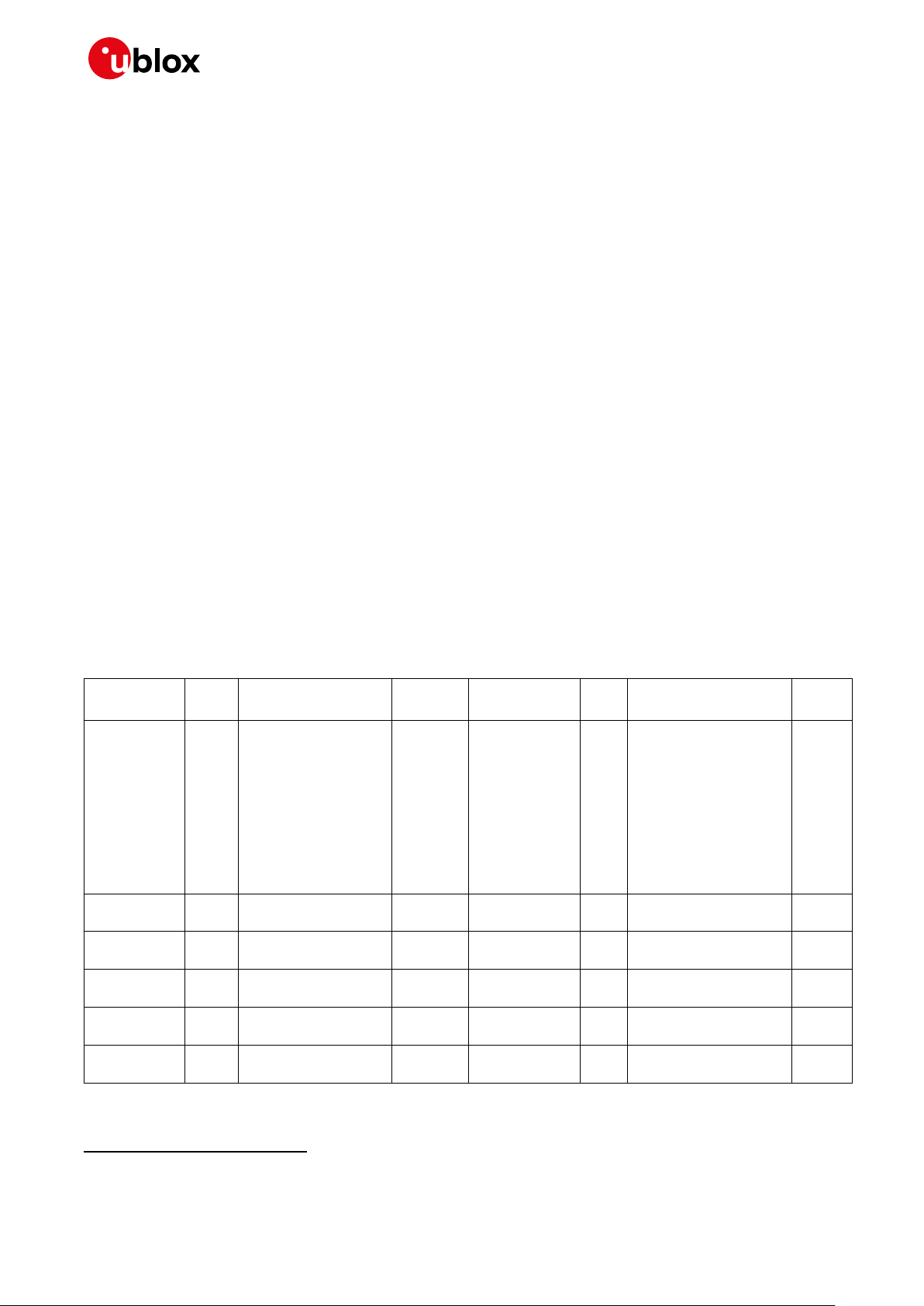

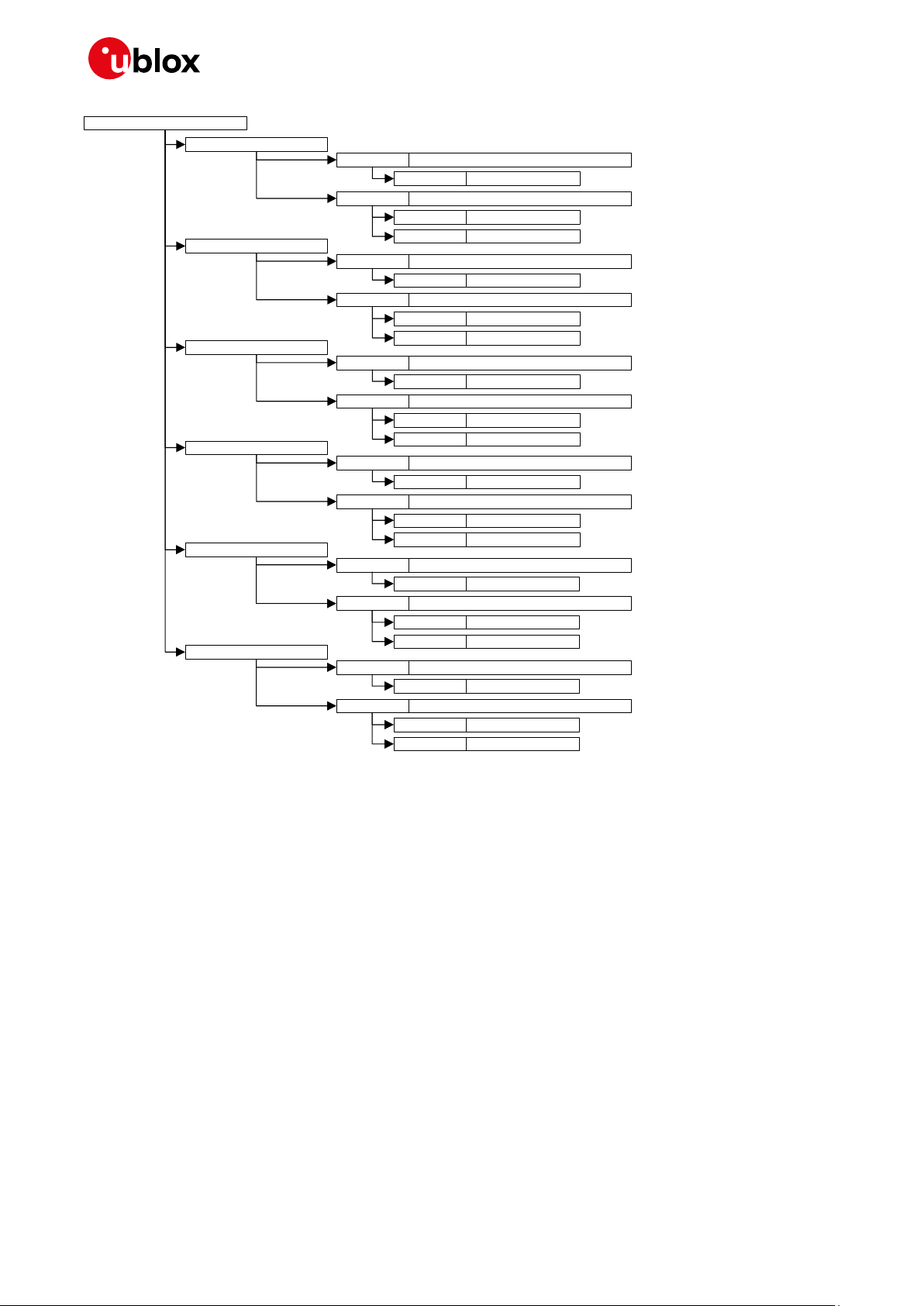

1.2 Architecture

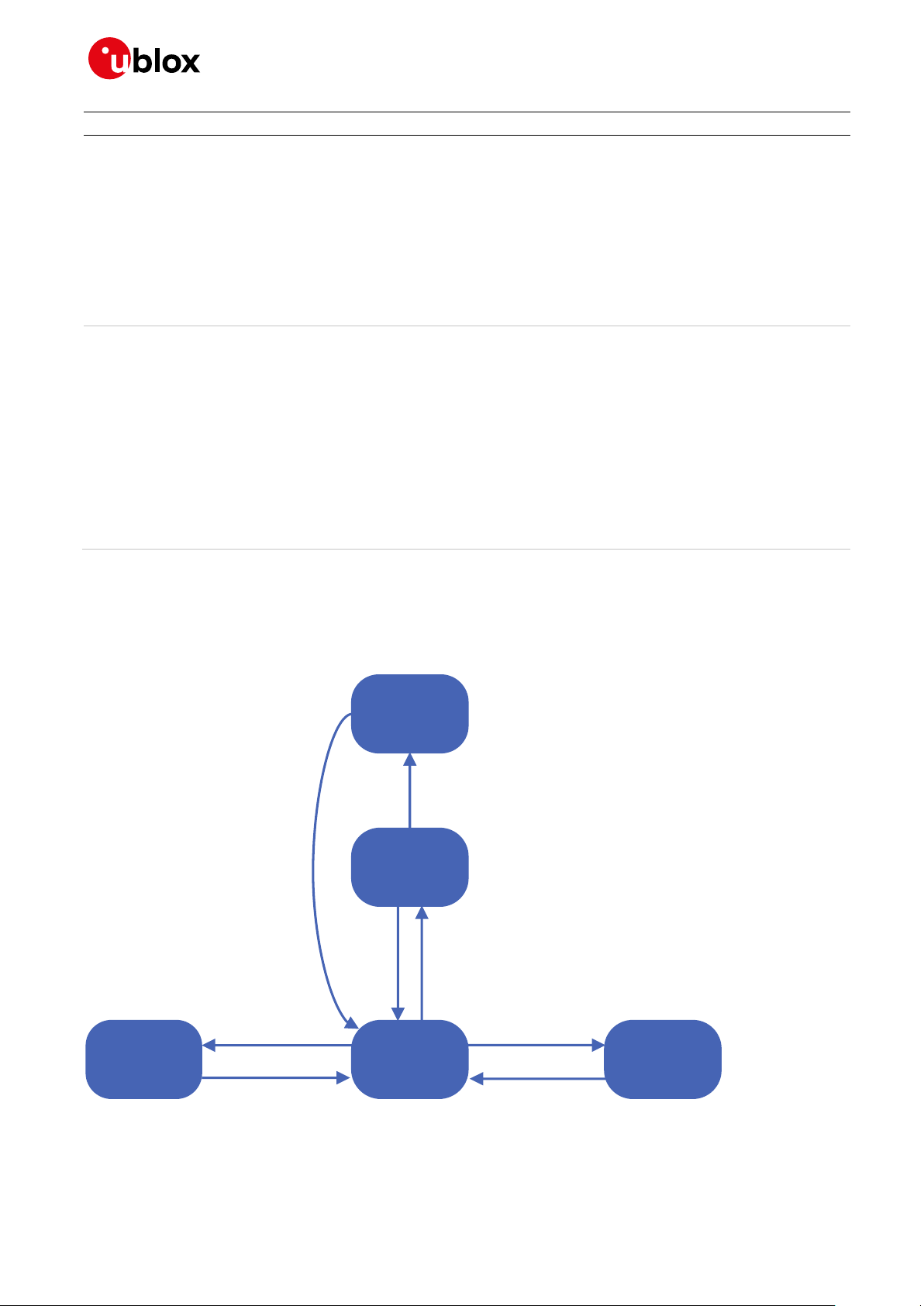

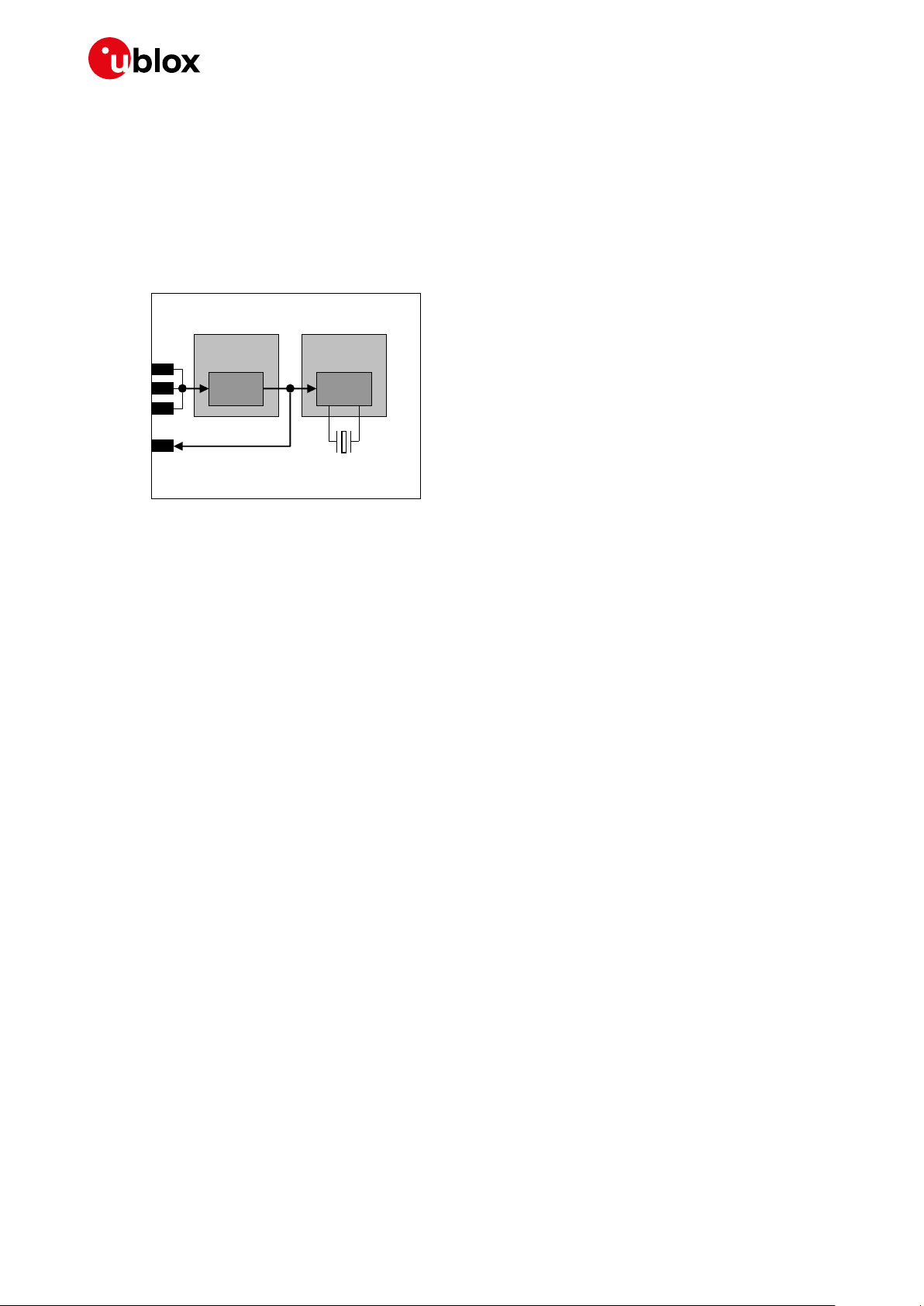

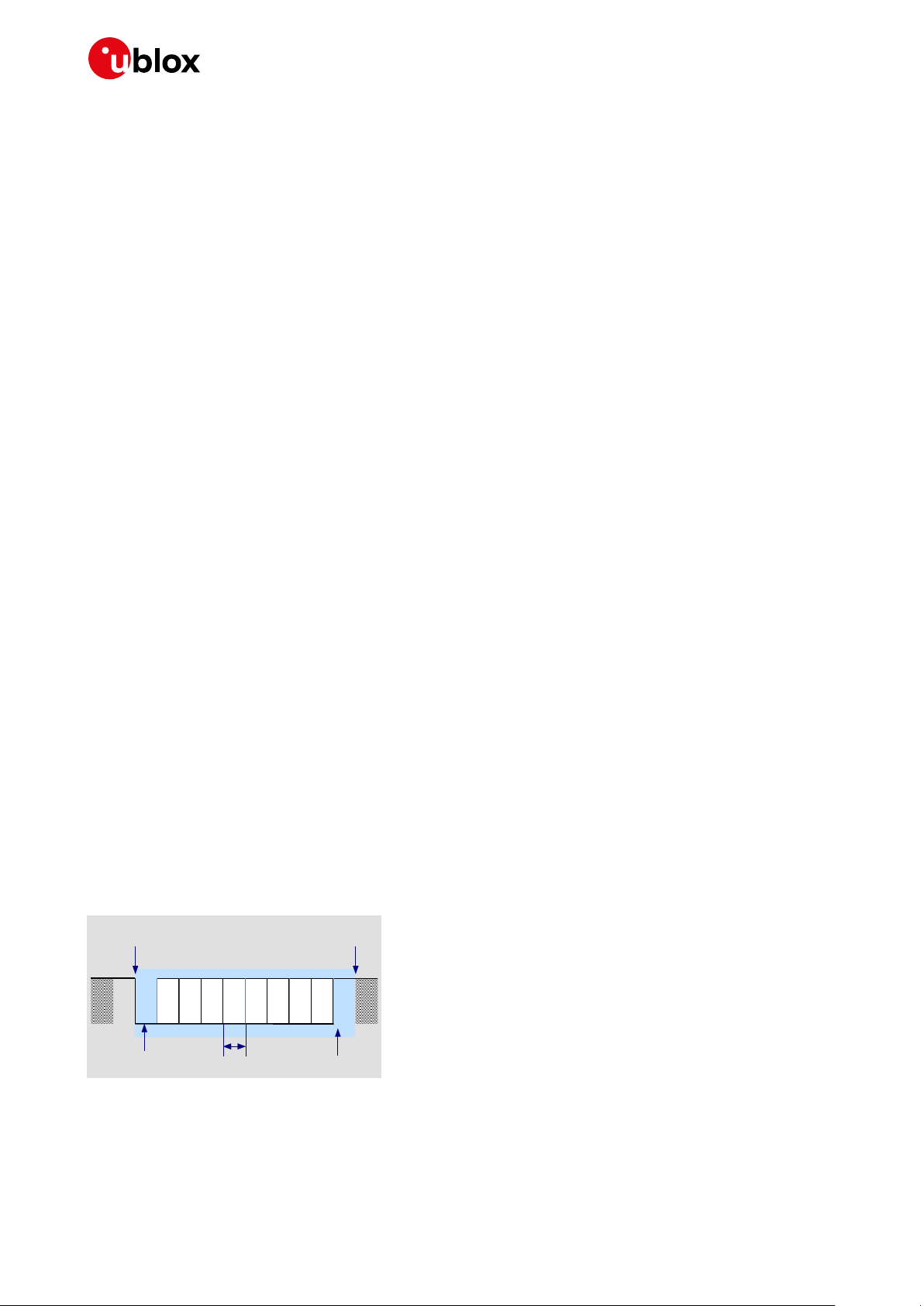

Figure 1 summarizes the internal architecture of TOBY-R2 series modules.

Cellular

Base-band

Processor

Memory

Power Management Unit

26 MHz

32.768 kHz

ANT1

RF

Transceiver

ANT2

V_INT (I/O)

V_BCKP (RTC)

VCC (Supply)

SIM

USB

GPIO

Power On

External Reset

PAs

LNAsFilters

Filter

s

Duplexer

Filters

PAs

LNAsFilter

s

Filter

s

Duplexer

Filters

LNAsFilter

s

Filters

LNAsFiltersFilter

s

Switch

Switch

DDC(I2C)

SDIO

UART

Digital audio (I2S)

ANT_DET

Host Select

Figure 1: TOBY-R2 series modules simplified block diagram

TOBY-R2 series modules internally consists of the RF, Baseband and Power Management sections

here described with more details than the simplified block diagrams of Figure 1.

RF section

The RF section is composed of RF transceiver, PAs, LNAs, crystal oscillator, filters, duplexers and RF

switches.

Tx signal is pre-amplified by RF transceiver, then output to the primary antenna input/output port

(ANT1) of the module via power amplifier (PA), SAW band pass filters band, specific duplexer and

antenna switch.

Dual receiving paths are implemented according to LTE Receiver Diversity radio technology supported

by the modules as LTE category 1 User Equipment: incoming signal is received through the primary

(ANT1) and the secondary (ANT2) antenna input ports which are connected to the RF transceiver via

specific antenna switch, diplexer, duplexer, LNA, SAW band pass filters.

• RF transceiver performs modulation, up-conversion of the baseband I/Q signals for Tx,

down-conversion and demodulation of the dual RF signals for Rx. The RF transceiver contains:

o Single chain high linearity receivers with integrated LNAs for multi band multi-mode operation,

o Highly linear RF demodulator / modulator capable GMSK, 8-PSK, QPSK, 16-QAM,

o RF synthesizer,

o VCO.

• Power Amplifiers (PA) amplify the Tx signal modulated by the RF transceiver

• RF switches connect primary (ANT1) and secondary (ANT2) antenna ports to the suitable Tx / Rx

path

• SAW duplexers and band pass filters separate the Tx and Rx signal paths and provide RF filtering

• 26 MHz voltage-controlled temperature-controlled crystal oscillator generates the clock reference

in active-mode or connected-mode.

TOBY-R2 series - System integration manual

UBX-16010572 - R14 System description Page 10 of 151

C1-Public

Baseband and power management section

The Baseband and Power Management section is composed of the following main elements:

• A mixed signal ASIC, which integrates

o Microprocessor for control functions

o DSP core for cellular Layer 1 and digital processing of Rx and Tx signal paths

o Memory interface controller

o Dedicated peripheral blocks for control of the USB, SIM and generic digital interfaces

o Interfaces to RF transceiver ASIC

• Memory system, which includes NAND flash and LPDDR2 RAM

• Voltage regulators to derive all the subsystem supply voltages from the module supply input VCC

• Voltage sources for external use: V_BCKP and V_INT

• Hardware power on

• Hardware reset

• Low power idle-mode support

• 32.768 kHz crystal oscillator to provide the clock reference in the low power idle-mode, which can

be set by enable power saving configuration using the AT+UPSV command.

1.3 Pin-out

Table 3 lists the pin-out of the TOBY-R2 series modules, with pins grouped by function.

Function

Pin Name

Pin No

I/O

Description

Remarks

Power

VCC

70,71,72

I

Module supply input

VCC supply circuit affects the RF performance and

compliance of the device integrating the module with

applicable required certification schemes.

See section 1.5.1 for functional description / requirements.

See section 2.2.1 for external circuit design-in.

GND

2, 30, 32,

44, 46, 69,

73, 74, 76,

78, 79, 80,

82, 83, 85,

86, 88-90,

92-152

N/A

Ground

GND pins are internally connected each other.

External ground connection affects the RF and thermal

performance of the device.

See section 1.5.1 for functional description.

See section 2.2.1 for external circuit design-in.

V_BCKP

3

I/O

RTC supply

input/output

V_BCKP = 1.8 V (typical) generated by internal regulator

when valid VCC supply is present.

See section 1.5.2 for functional description.

See section 2.2.2 for external circuit design-in.

V_INT

5

O

Generic digital

interfaces supply

output

V_INT = 1.8 V (typical) generated by internal DC/DC

regulator when the module is switched on.

Test-Point for diagnostic access is recommended.

See section 1.5.3 for functional description.

See section 2.2.3 for external circuit design-in.

System

PWR_ON

20 I Power-on input

Internal 10 k pull-up resistor to V_BCKP.

See section 1.6.1 for functional description.

See section 2.3.1 for external circuit design-in.

RESET_N

23 I External reset input

Internal 10 k pull-up resistor to V_BCKP.

Test-Point for diagnostic access is recommended.

See section 1.6.3 for functional description.

See section 2.3.2 for external circuit design-in.

HOST_SELECT0

26

I/O

Selection of module/

host configuration

Not supported.

See section 1.6.4 for functional description.

See section 2.3.3 for external circuit design-in.

TOBY-R2 series - System integration manual

UBX-16010572 - R14 System description Page 11 of 151

C1-Public

Function

Pin Name

Pin No

I/O

Description

Remarks

HOST_SELECT1

62

I/O

Selection of module/

host configuration

Not supported.

See section 1.6.4 for functional description.

See section 2.3.3 for external circuit design-in.

Antennas

ANT1

81

I/O

Primary antenna

Main Tx / Rx antenna interface.

50 nominal characteristic impedance.

Antenna circuit affects RF performance and end-device

compliance with required certification schemes.

See section 1.7 for functional description / requirements.

See section 2.4 for external circuit design-in.

ANT2

87 I Secondary antenna

Rx only for Rx diversity.

50 nominal characteristic impedance.

Antenna circuit affects RF performance and end-device

compliance with required certification schemes.

See section 1.7 for functional description / requirements.

See section 2.4 for external circuit design-in.

ANT_DET

75 I Antenna detection

ADC for antenna presence detection function

See section 1.7.2 for functional description.

See section 2.4.2 for external circuit design-in.

SIM

VSIM

59 O SIM supply output

VSIM = 1.8 V / 3 V output as per connected SIM type.

See section 1.8 for functional description.

See section 2.5 for external circuit design-in.

SIM_IO

57

I/O

SIM data

Data input/output for 1.8 V / 3 V SIM

Internal 4.7 k pull-up to VSIM.

See section 1.8 for functional description.

See section 2.5 for external circuit design-in.

SIM_CLK

56 O SIM clock

3.25 MHz clock output for 1.8 V / 3 V SIM

See section 1.8 for functional description.

See section 2.5 for external circuit design-in.

SIM_RST

58 O SIM reset

Reset output for 1.8 V / 3 V SIM

See section 1.8 for functional description.

See section 2.5 for external circuit design-in.

UART

RXD

17 O UART data output

1.8 V output, Circuit 104 (RXD) in ITU-T V.24,

for AT commands, data communication, FOAT, FW

update by u-blox EasyFlash tool and diagnostic.

Test-Point and series 0 for diagnostic recommended.

See section 1.9.1 for functional description.

See section 2.6.1 for external circuit design-in.

TXD

16 I UART data input

1.8 V input, Circuit 103 (TXD) in ITU-T V.24,

for AT commands, data communication, FOAT, FW

update by u-blox EasyFlash tool and diagnostic.

Internal active pull-up to V_INT.

Test-Point and series 0 for diagnostic recommended.

See section 1.9.1 for functional description.

See section 2.6.1 for external circuit design-in.

CTS

15

O

UART clear to send

output

1.8 V output, Circuit 106 (CTS) in ITU-T V.24.

See section 1.9.1 for functional description.

See section 2.6.1 for external circuit design-in.

RTS

14

I

UART ready to send

input

1.8 V input, Circuit 105 (RTS) in ITU-T V.24.

Internal active pull-up to V_INT.

See section 1.9.1 for functional description.

See section 2.6.1 for external circuit design-in.

DSR

10

O

UART data set ready

output

1.8 V, Circuit 107 in ITU-T V.24.

See section 1.9.1 for functional description.

See section 2.6.1 for external circuit design-in.

TOBY-R2 series - System integration manual

UBX-16010572 - R14 System description Page 12 of 151

C1-Public

Function

Pin Name

Pin No

I/O

Description

Remarks

RI

11

O

UART ring indicator

output

1.8 V, Circuit 125 in ITU-T V.24.

See section 1.9.1 for functional description.

See section 2.6.1 for external circuit design-in.

DTR

13

I

UART data terminal

ready input

1.8 V, Circuit 108/2 in ITU-T V.24.

Internal active pull-up to V_INT.

Test-Point and series 0 for diagnostic recommended.

See section 1.9.1 for functional description.

See section 2.6.1 for external circuit design-in.

DCD

12

O

UART data carrier

detect output

1.8 V, Circuit 109 in ITU-T V.24.

Test-Point and series 0 for diagnostic recommended.

See section 1.9.1 for functional description.

See section 2.6.1 for external circuit design-in.

USB

VUSB_DET

4 I USB detect input

VBUS (5 V typical) USB supply generated by the host must

be connected to this input pin to enable the USB interface.

If the USB interface is not used by the Host Processor,

Test-Point for diagnostic / FW update is recommended.

See section 1.9.2 for functional description.

See section 2.6.2 for external circuit design-in.

USB_D-

27

I/O

USB Data Line D-

USB interface for AT commands, data communication,

FOAT, FW update by u-blox EasyFlash tool and diagnostic.

90 nominal differential impedance (Z0)

30 nominal common mode impedance (ZCM)

Pull-up or pull-down resistors and external series resistors

as required by the USB 2.0 specifications [13] are part of

the USB pin driver and need not be provided externally.

If the USB interface is not used by the Host Processor,

Test-Point for diagnostic / FW update is recommended.

See section 1.9.2 for functional description.

See section 2.6.2 for external circuit design-in.

USB_D+

28

I/O

USB Data Line D+

USB interface for AT commands, data communication,

FOAT, FW update by u-blox EasyFlash tool and diagnostic.

90 nominal differential impedance (Z0)

30 nominal common mode impedance (ZCM)

Pull-up or pull-down resistors and external series resistors

as required by the USB 2.0 specifications [13] are part of

the USB pin driver and need not be provided externally.

If the USB interface is not used by the Host Processor,

Test-Point for diagnostic / FW update is recommended.

See section 1.9.2 for functional description.

See section 2.6.2 for external circuit design-in.

DDC

SCL

54 O I2C bus clock line

1.8 V open drain, for communication with I2C-local devices

No internal pull-up.

See section 1.9.3 for functional description.

See section 2.6.3 for external circuit design-in.

SDA

55

I/O

I2C bus data line

1.8 V open drain, for communication with I2C-local devices

No internal pull-up.

See section 1.9.3 for functional description.

See section 2.6.3 for external circuit design-in.

SDIO

SDIO_D0

66

I/O

SDIO serial data [0]

Not supported by ‘02B’, ‘42B’, ‘82B’, ‘03B’ product versions.

See section 1.9.4 for functional description.

See section 2.6.4 for external circuit design-in.

SDIO_D1

68

I/O

SDIO serial data [1]

Not supported by ‘02B’, ‘42B’, ‘82B’, ‘03B’ product versions.

See section 1.9.4 for functional description.

See section 2.6.4 for external circuit design-in.

SDIO_D2

63

I/O

SDIO serial data [2]

Not supported by ‘02B’, ‘42B’, ‘82B’, ‘03B’ product versions.

See section 1.9.4 for functional description.

See section 2.6.4 for external circuit design-in.

TOBY-R2 series - System integration manual

UBX-16010572 - R14 System description Page 13 of 151

C1-Public

Function

Pin Name

Pin No

I/O

Description

Remarks

SDIO_D3

67

I/O

SDIO serial data [3]

Not supported by ‘02B’, ‘42B’, ‘82B’, ‘03B’ product versions.

See section 1.9.4 for functional description.

See section 2.6.4 for external circuit design-in.

SDIO_CLK

64 O SDIO serial clock

Not supported by ‘02B’, ‘42B’, ‘82B’, ‘03B’ product versions.

See section 1.9.4 for functional description.

See section 2.6.4 for external circuit design-in.

SDIO_CMD

65

I/O

SDIO command

Not supported by ‘02B’, ‘42B’, ‘82B’, ‘03B’ product versions.

See section 1.9.4 for functional description.

See section 2.6.4 for external circuit design-in.

Audio

I2S_TXD

51

O /

I/O

I2S transmit data /

GPIO

I2S transmit data output, alternatively settable as GPIO.

See sections 1.10 and 1.12 for functional description.

See sections 2.7 and 2.8 for external circuit design-in.

I2S_RXD

53

I /

I/O

I2S receive data /

GPIO

I2S receive data input, alternatively configurable as GPIO.

See sections 1.10 and 1.12 for functional description.

See sections 2.7 and 2.8 for external circuit design-in.

I2S_CLK

52

I/O /

I/O

I2S clock /

GPIO

I2S serial clock, alternatively configurable as GPIO.

See sections 1.10 and 1.12 for functional description.

See sections 2.7 and 2.8 for external circuit design-in.

I2S_WA

50

I/O /

I/O

I2S word alignment /

GPIO

I2S word alignment, alternatively configurable as GPIO.

See sections 1.10 and 1.12 for functional description.

See sections 2.7 and 2.8 for external circuit design-in.

Clock

output

GPIO6

61 O Clock output

1.8 V configurable clock output.

See section 1.11 for functional description.

See section 2.7 for external circuit design-in.

GPIO

GPIO1

21

I/O

GPIO

1.8 V GPIO with alternatively configurable functions.

See section 1.12 for functional description.

See section 2.8 for external circuit design-in.

GPIO2

22

I/O

GPIO

1.8 V GPIO with alternatively configurable functions.

See section 1.12 for functional description.

See section 2.8 for external circuit design-in.

GPIO3

24

I/O

GPIO

1.8 V GPIO with alternatively configurable functions.

See section 1.12 for functional description.

See section 2.8 for external circuit design-in.

GPIO4

25

I/O

GPIO

1.8 V GPIO with alternatively configurable functions.

See section 1.12 for functional description.

See section 2.8 for external circuit design-in.

GPIO5

60

I/O

GPIO

1.8 V GPIO with alternatively configurable functions.

See section 1.12 for functional description.

See section 2.8 for external circuit design-in.

Reserved

RSVD

6

N/A

Reserved pin

This pin must be connected to ground.

See sections 1.13 and 2.9

RSVD

18, 19

N/A

Reserved pin

Test-Point for diagnostic access is recommended.

See sections 1.13 and 2.9

RSVD

1, 7-9, 29,

31, 33-43,

45, 47-49,

77, 84, 91

N/A

Reserved pin

Leave unconnected.

See sections 1.13 and 2.9

Table 3: TOBY-R2 series module pin definition, grouped by function

TOBY-R2 series - System integration manual

UBX-16010572 - R14 System description Page 14 of 151

C1-Public

1.4 Operating modes

TOBY-R2 series modules have several operating modes. The operating modes are defined in Table 4

and described in detail in Table 5, providing general guidelines for operation.

General status

Operating mode

Definition

Power-down

Not-powered mode

VCC supply not present or below operating range: module is switched off.

Power-off mode

VCC supply within operating range and module is switched off.

Normal operation

Idle mode

Module processor core runs with 32 kHz reference generated by the internal

oscillator.

Active mode

Module processor core runs with 26 MHz reference generated by the internal

oscillator.

Connected mode

RF Tx/Rx data connection enabled and processor core runs with 26 MHz reference.

Table 4: TOBY-R2 series modules operating modes definition

Mode

Description

Transition between operating modes

Not-Powered

Module is switched off.

Application interfaces are not accessible.

When VCC supply is removed, the modules enter not-powered mode.

When in not-powered mode, the modules cannot be switched on by

PWR_ON, RESET_N or RTC alarm

When in not-powered mode, the modules can be switched on by

applying VCC supply (see 1.6.1) so that the modules switch from

not-powered to active-mode

Power-Off

Module is switched off: normal shutdown

by an appropriate power-off event (see

1.6.2).

Application interfaces are not accessible.

When the modules are switched off by an appropriate switch-off

event (see 1.6.2), the modules enter power-off mode from

active-mode.

When in power-off mode, the modules can be switched on by

PWR_ON, RESET_N or an RTC alarm.

When in power-off mode, the modules enter not-powered mode by

removing VCC supply.

Idle

Module is switched on with application

interfaces temporarily disabled or

suspended: the module is temporarily

not ready to communicate with an

external device by means of the

application interfaces as configured to

reduce the current consumption.

The module enters the low power idlemode whenever possible if power saving

is enabled by AT+UPSV (see u-blox AT

commands manual [2]) reducing current

consumption (see 1.5.1.5).

The CTS output line indicates when the

UART interface is disabled/enabled due

to the module idle/active-mode

according to power saving and HW flow

control settings (see 1.9.1.3, 1.9.1.4).

Power saving configuration is not

enabled by default: it can be enabled by

AT+UPSV (see the u-blox AT commands

manual [2]).

The modules automatically switch from the active-mode to low power

idle-mode whenever possible if power saving is enabled (see sections

1.5.1.5, 1.9.1.4, 1.9.2.4 and u-blox AT commands manual [2],

AT+UPSV command).

The modules wake up from low power idle-mode to active-mode in the

following events:

• Automatic periodic monitoring of the paging channel for the

paging block reception according to network conditions (see

1.5.1.5, 1.9.1.4)

• Automatic periodic enable of the UART interface to receive / send

data, with AT+UPSV=1 (see 1.9.1.4)

• Data received over UART, according to HW flow control (AT&K)

and power saving (AT+UPSV) settings (see 1.9.1.4)

• RTS input set ON by the host DTE, with HW flow control disabled

and AT+UPSV=2 (see 1.9.1.4)

• DTR input set ON by the host DTE, with AT+UPSV=3 (see 1.9.1.4)

• USB detection, applying 5 V (typ.) to VUSB_DET input (see 1.9.2)

• The connected USB host forces a remote wakeup of the module as

USB device (see 1.9.2.4)

• The connected u-blox GNSS device forces a wakeup of the module

using the GNSS Tx data ready function over GPIO3 (see 1.9.3)

• The connected SDIO device forces a wakeup of the module as

SDIO host (see 1.9.4)

• A preset RTC alarm occurs (see u-blox AT commands manual [2],

AT+CALA)

TOBY-R2 series - System integration manual

UBX-16010572 - R14 System description Page 15 of 151

C1-Public

Mode

Description

Transition between operating modes

Active

Module is switched on with application

interfaces enabled or not suspended:

the module is ready to communicate

with an external device by means of the

application interfaces unless power

saving configuration is enabled by

AT+UPSV (see 1.9.1.4, 1.9.2.4 and u-blox

AT commands manual [2]).

When the modules are switched on by an appropriate power-on event

(see 1.6.1), the module enter active-mode from not-powered or

power-off mode.

If power saving configuration is enabled by the AT+UPSV command,

the module automatically switches from active to idle-mode whenever

possible and the module wakes up from idle to active-mode in the

events listed above (see idle-mode to active-mode transition

description above).

When a RF Tx/Rx data or voice connection is initiated or when RF

Tx/Rx is required due to a connection previously initiated, the module

switches from active to connected-mode.

Connected

RF Tx/Rx data connection is in progress.

The module is prepared to accept data

signals from an external device unless

power saving configuration is enabled by

AT+UPSV (see sections 1.9.1.4, 1.9.2.4

and u-blox AT commands manual [2]).

When a data or voice connection is initiated, the module enters

connected-mode from active-mode.

Connected-mode is suspended if Tx/Rx data is not in progress, due to

connected discontinuous reception and fast dormancy capabilities of

the module and according to network environment settings and

scenario. In such case, the module automatically switches from

connected to active mode and then, if power saving configuration is

enabled by the AT+UPSV command, the module automatically

switches to idle-mode whenever possible. Vice-versa, the module

wakes up from idle to active mode and then connected mode if RF

Tx/Rx is necessary.

When a data connection is terminated, the module returns to the

active-mode.

Table 5: TOBY-R2 series modules operating modes description

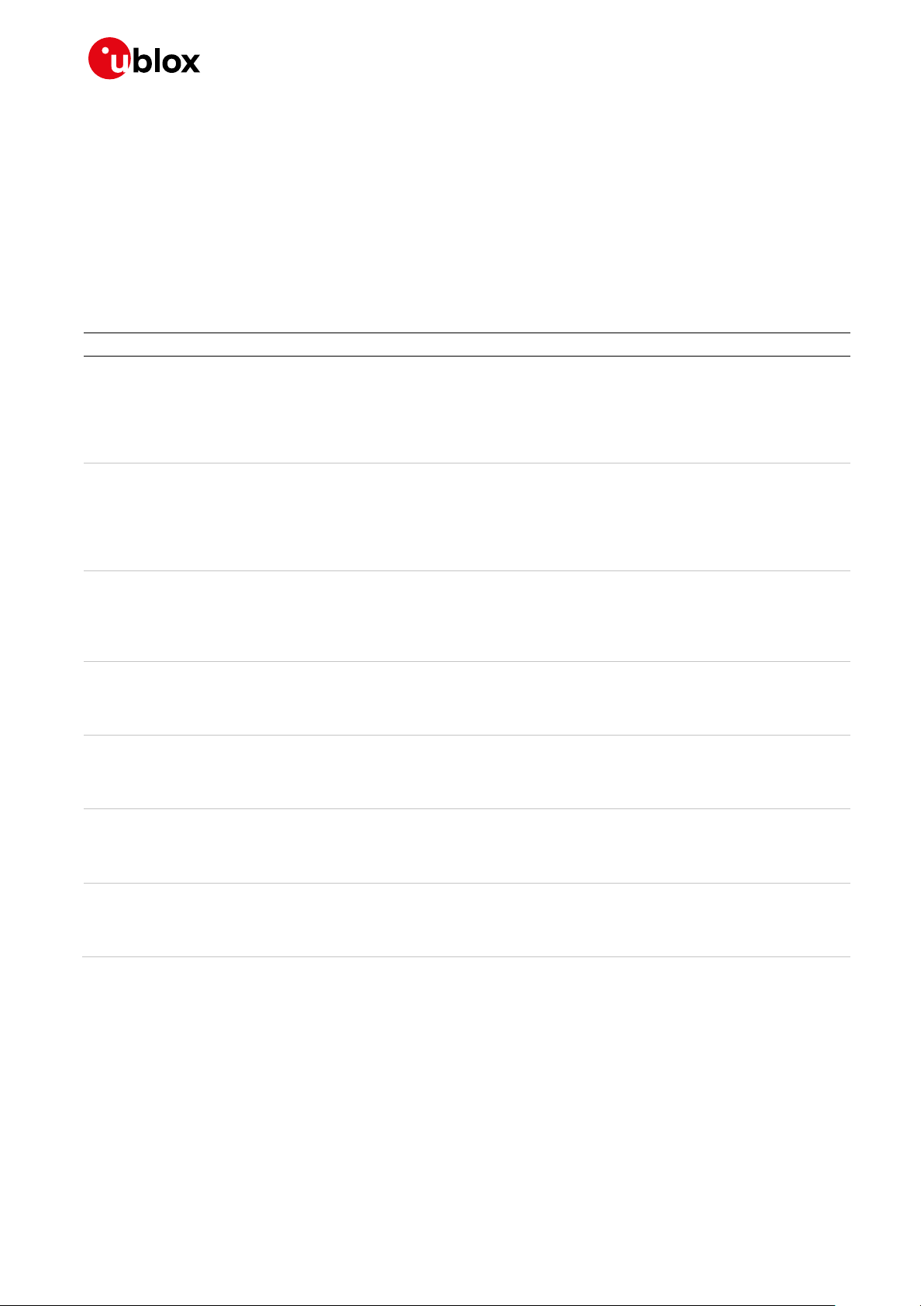

Figure 2 describes the transition between the different operating modes.

Switch ON:

• Apply VCC

If power saving is enabled

and there is no activity for

a defined time interval

Any wake up event described

in the module operating

modes summary table above

Incoming/outgoing call

or other dedicated device

network communication

No RF Tx/Rx in progress, Call

terminated, Communication

dropped

Remove VCC

Switch ON:

• PWR_ON

• RTC alarm

• RESET_N

Not

powered

Power off

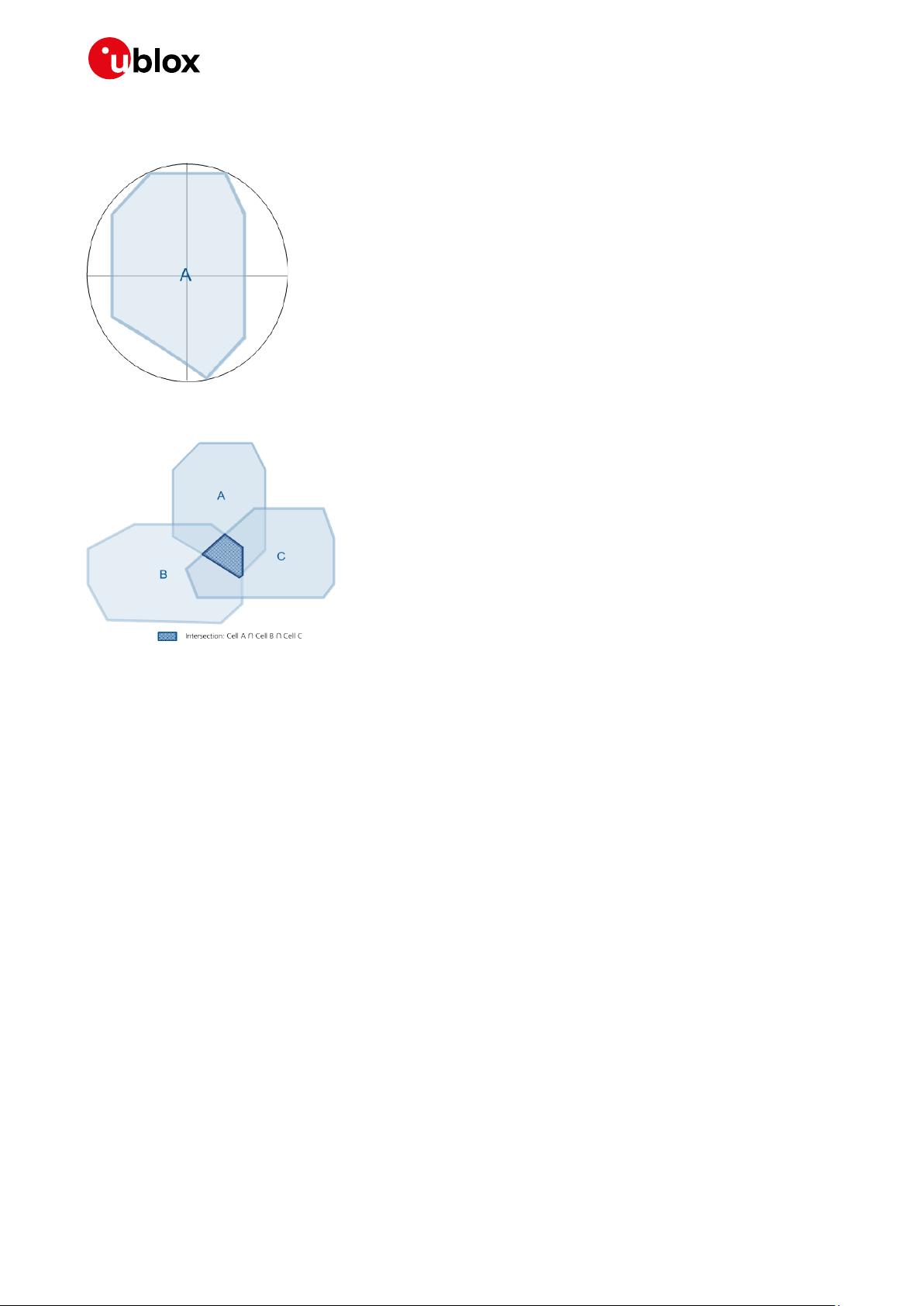

ActiveConnected Idle

Switch OFF:

• AT+CPWROFF

• PWR_ON

Figure 2: TOBY-R2 series modules operating modes transitions

TOBY-R2 series - System integration manual

UBX-16010572 - R14 System description Page 16 of 151

C1-Public

1.5 Supply interfaces

1.5.1 Module supply input (VCC)

The modules must be supplied via the three VCC pins that represent the module power supply input.

The VCC pins are internally connected to the RF power amplifier and to the integrated Power

Management Unit: all supply voltages needed by the module are generated from the VCC supply by

integrated voltage regulators, including V_BCKP Real Time Clock supply, V_INT digital interfaces

supply and VSIM SIM card supply.

During operation, the current drawn by the TOBY-R2 series modules through the VCC pins can vary

by several orders of magnitude. This ranges from the pulse of current consumption during GSM

transmitting bursts at maximum power level in connected-mode (as described in section 1.5.1.2) to

the low current consumption during low power idle-mode with power saving enabled (as described in

section 1.5.1.5).

TOBY-R200 modules provide separate supply inputs over the three VCC pins:

• VCC pins #71 and #72 represent the supply input for the internal RF power amplifier, demanding

most of the total current drawn of the module when RF transmission is enabled during a

voice/data call

• VCC pin #70 represents the supply input for the internal baseband Power Management Unit and

the internal transceiver, demanding minor part of the total current drawn of the module when RF

transmission is enabled during a voice/data call

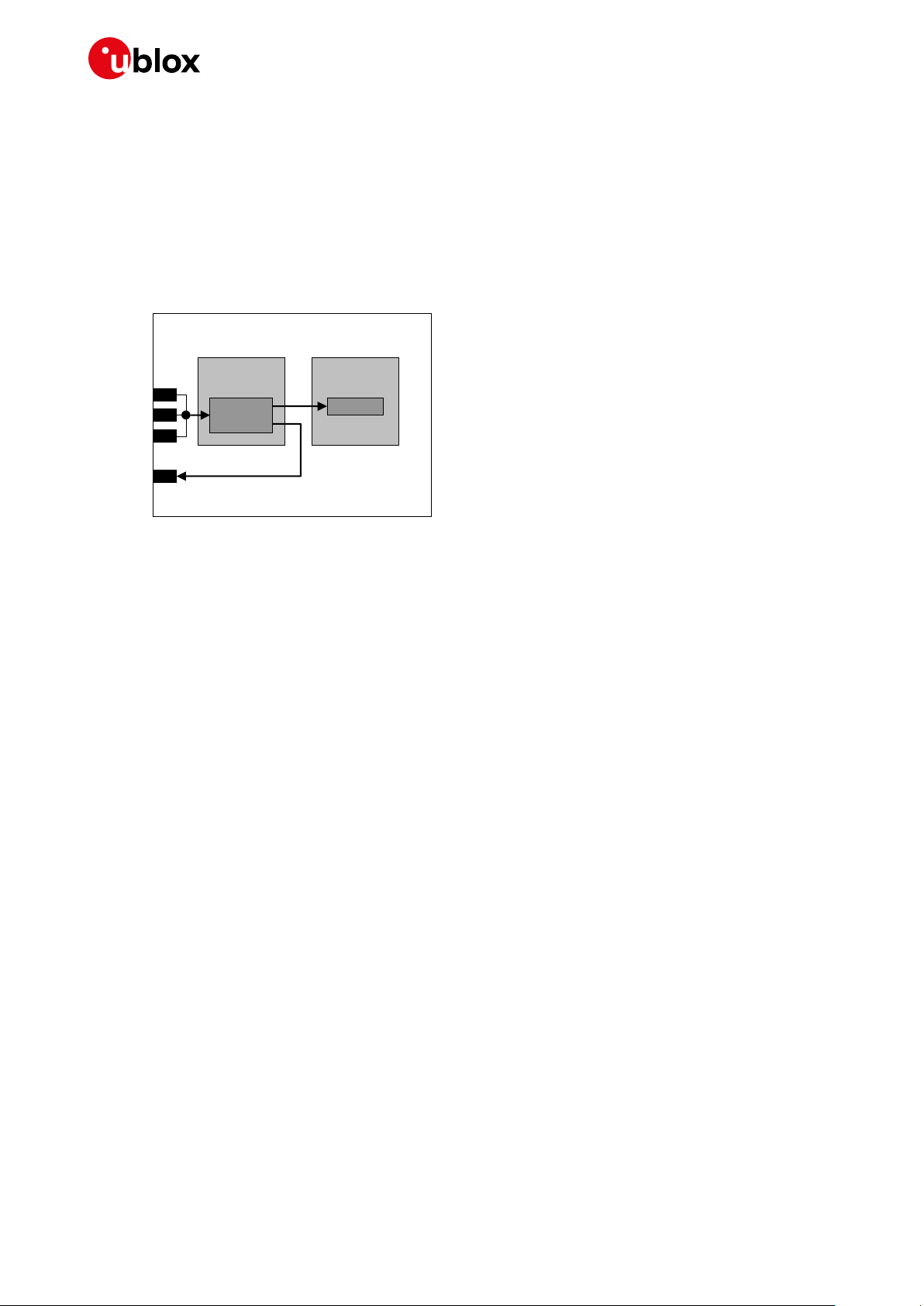

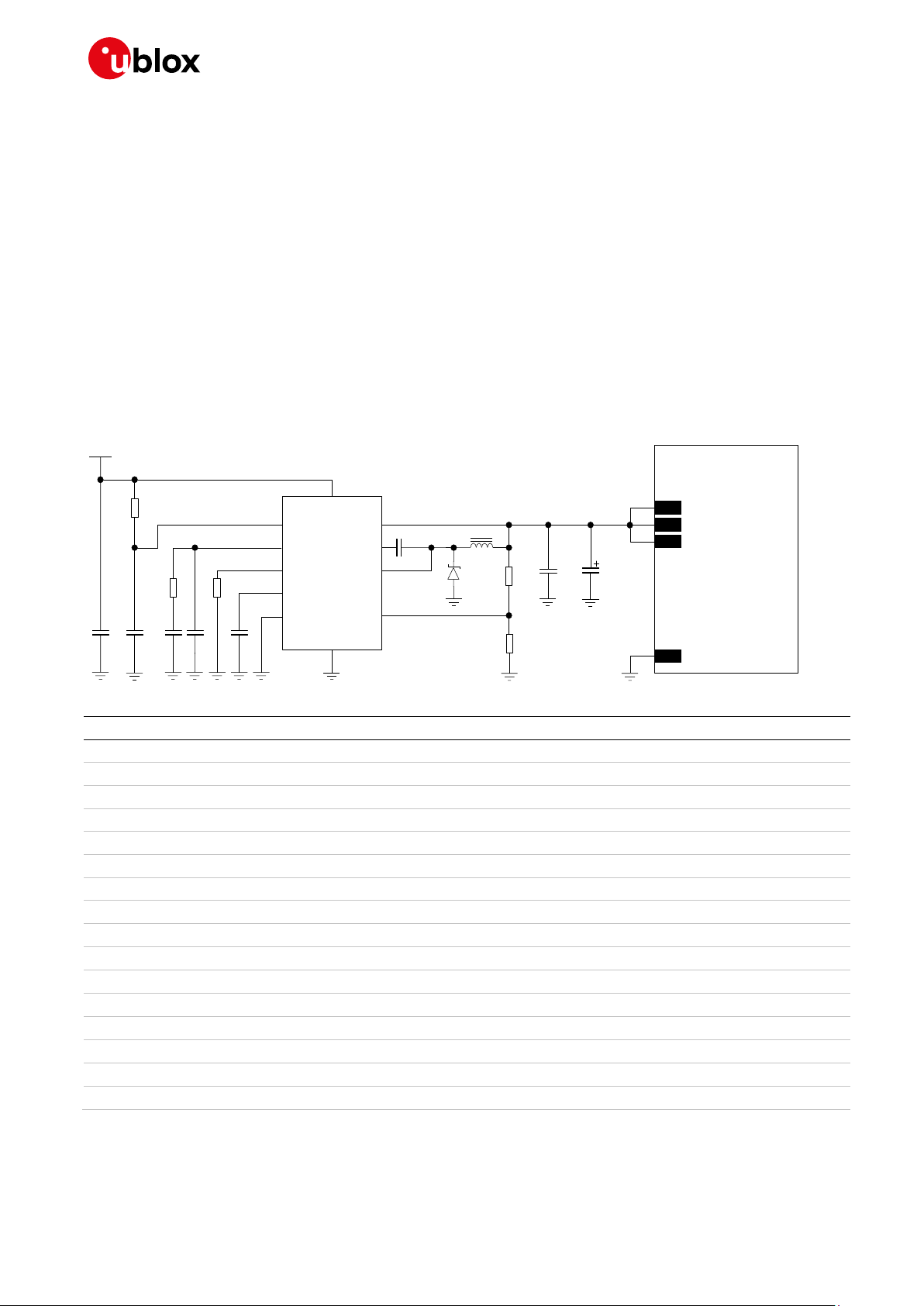

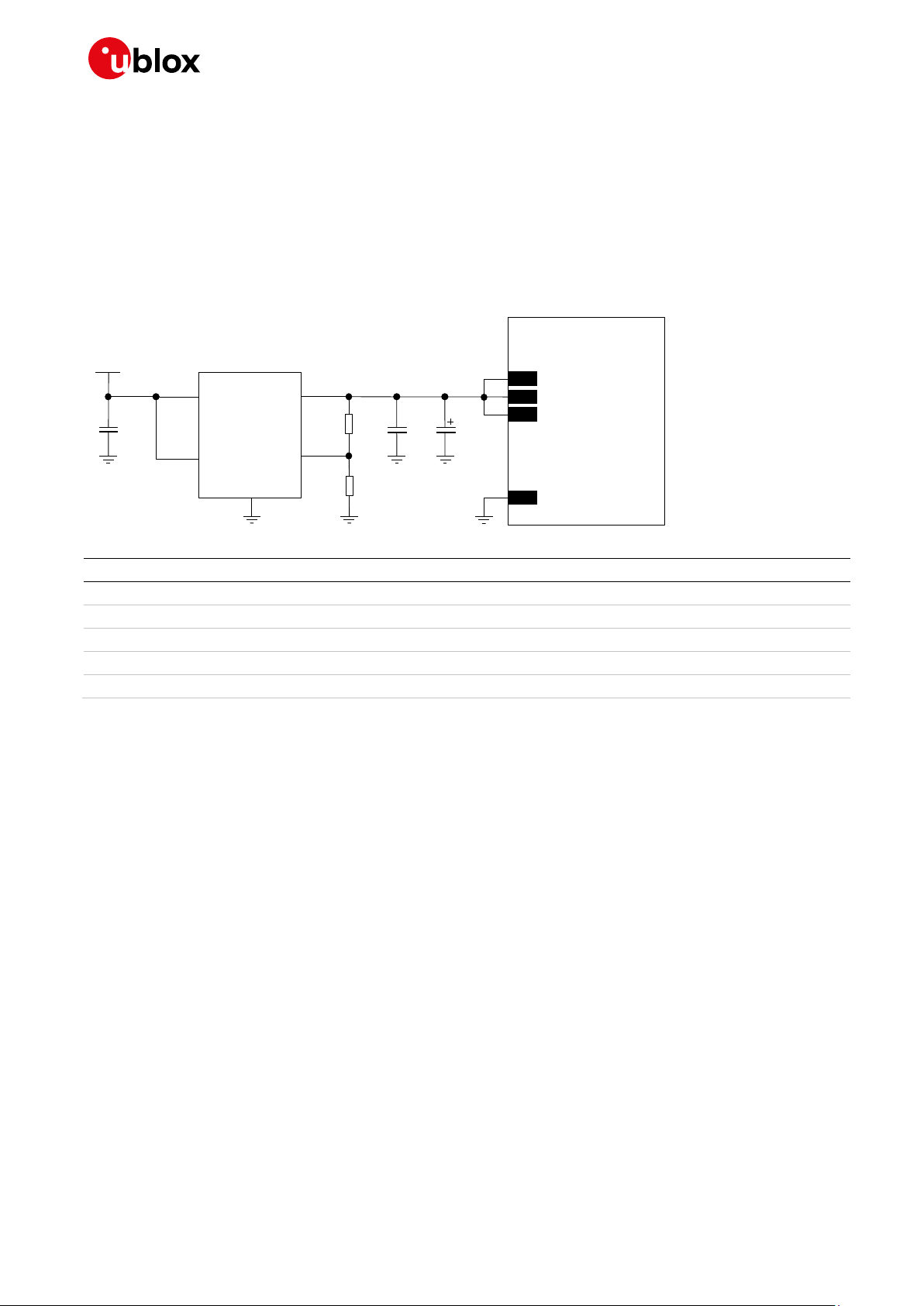

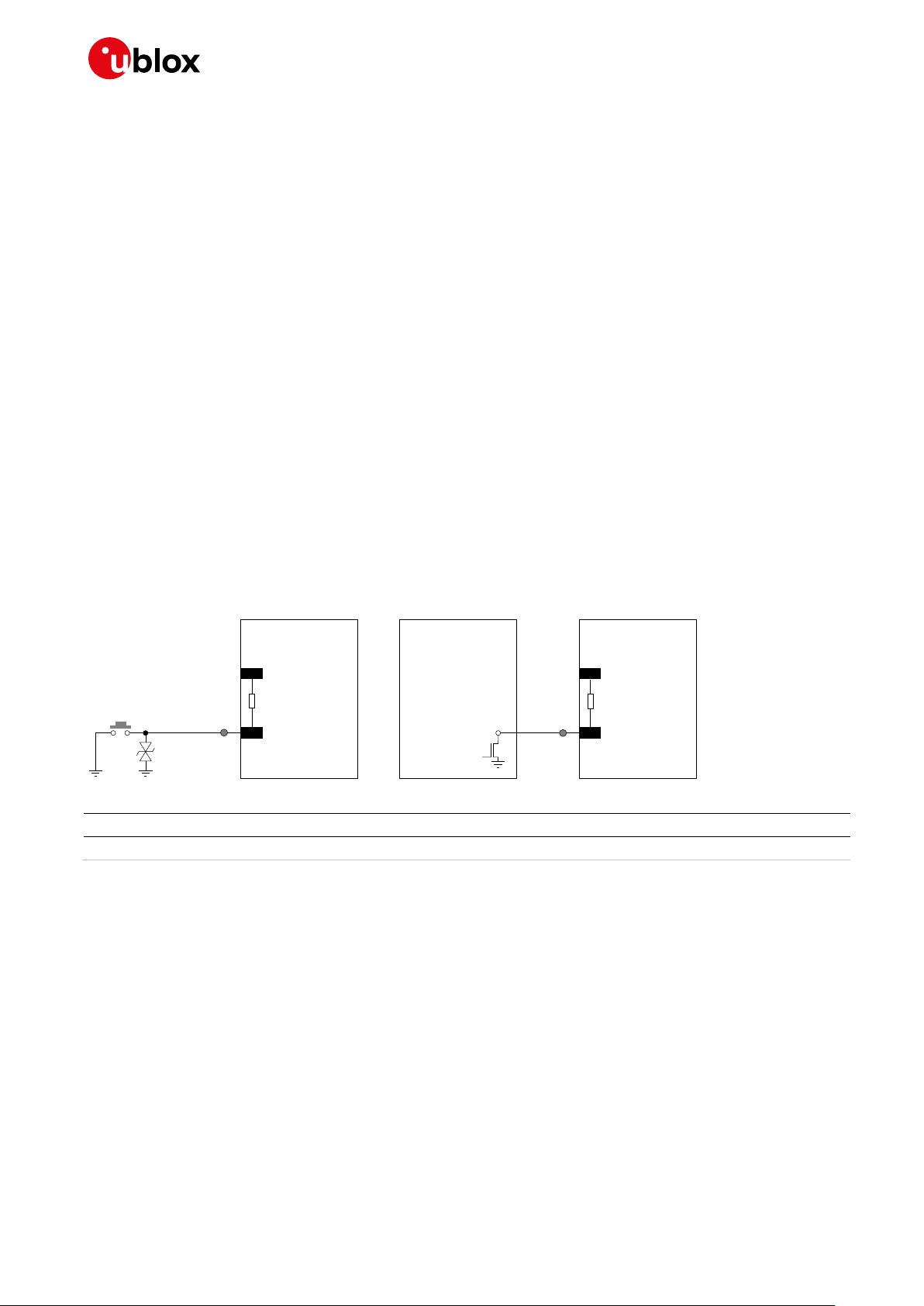

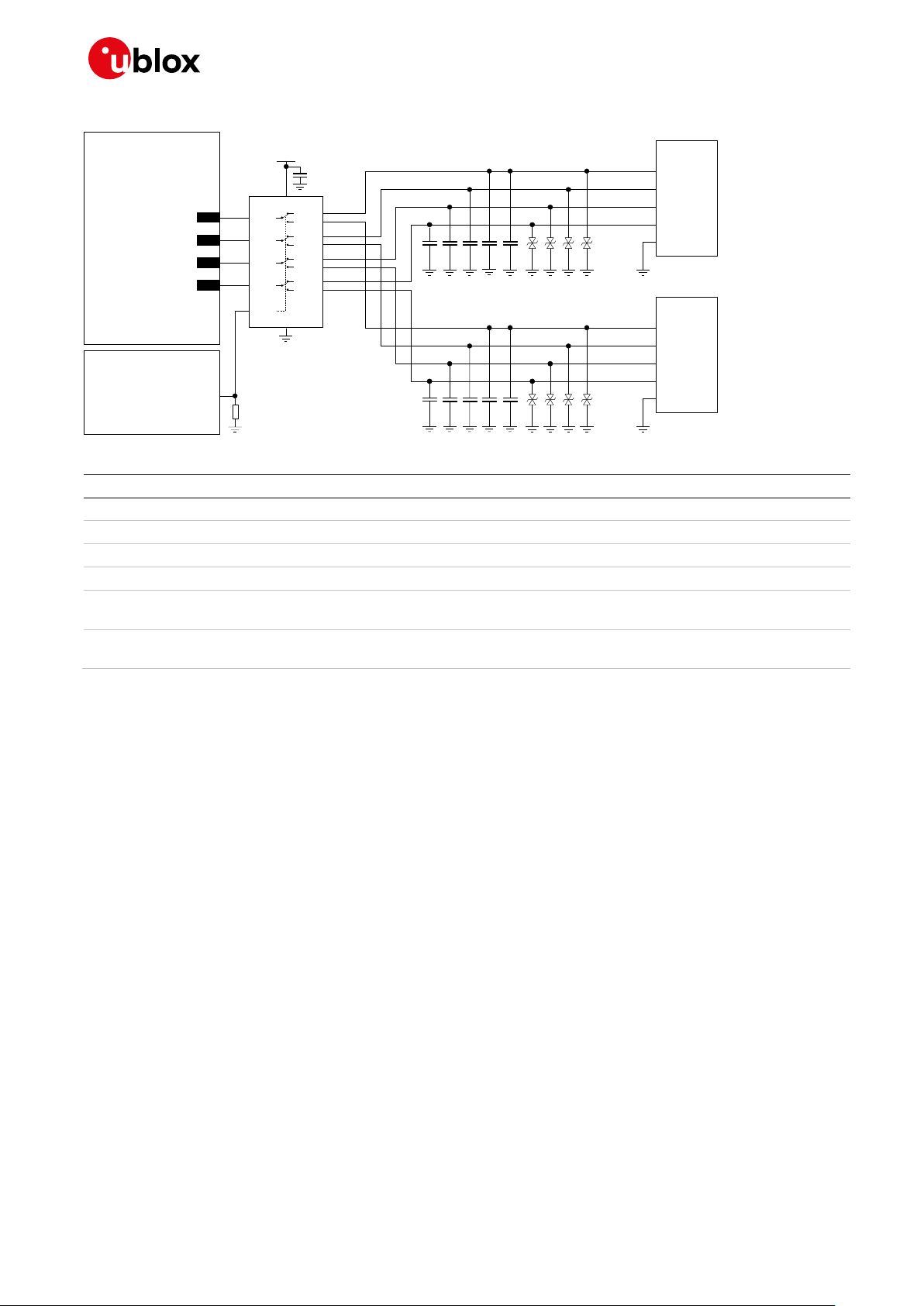

Figure 3 provides a simplified block diagram of TOBY-R2 series modules internal VCC supply routing.

72

VCC

71

VCC

70

VCC

TOBY-R202

Power

Management

Unit

Memory

Baseband

Processor

Transceiver

RF PMU

LTE/3G PAs

72

VCC

71

VCC

70

VCC

TOBY-R200

Power

Management

Unit

Memory

Baseband

Processor

Transceiver

RF PMU

LTE/3G/2G PAs

Figure 3: TOBY-R2 series modules internal VCC supply routing simplified block diagram

TOBY-R2 series - System integration manual

UBX-16010572 - R14 System description Page 17 of 151

C1-Public

1.5.1.1 VCC supply requirements

Table 6 summarizes the requirements for the VCC modules supply. See section 2.2.1 for suggestions

to properly design a VCC supply circuit compliant with the requirements listed in Table 6.

⚠ The VCC supply circuit affects the RF compliance of the device integrating TOBY-R2 series

modules with applicable required certification schemes as well as antenna circuit design.

Compliance is met by fulfilling the requirements for the VCC supply summarized in Table 6.

Item

Requirement

Remark

VCC nominal voltage

Within VCC normal operating range:

3.30 V min. / 4.40 V max

RF performance is guaranteed when VCC PA voltage is

inside the normal operating range limits.

RF performance may be affected when VCC PA voltage is

outside the normal operating range limits, though the

module is still fully functional until the VCC voltage is

inside the extended operating range limits.

VCC voltage during

normal operation

Within VCC extended operating range:

3.00 V min. / 4.50 V max

VCC voltage must be above the extended operating range

minimum limit to switch-on the module.

The module may switch-off when the VCC voltage drops

below the extended operating range minimum limit.

Operation above VCC extended operating range is not

recommended and may affect device reliability.

VCC average current

Support with adequate margin the highest

averaged VCC current consumption value

in connected-mode conditions specified in

TOBY-R2 data sheet [1].

The maximum average current consumption can be

greater than the specified value according to the actual

antenna mismatching, temperature and supply voltage.

Sections 1.5.1.2, 1.5.1.3 and 1.5.1.4 describe current

consumption profiles in 2G, 3G and LTE connected-mode.

VCC peak current

Support with margin the highest peak

VCC current consumption value in

connected-mode conditions specified in

TOBY-R2 data sheet [1]

The specified maximum peak of current consumption

occurs during GSM single transmit slot in 850/900 MHz

connected-mode, in case of mismatched antenna.

Section 1.5.1.2 describes 2G Tx peak/pulse current.

VCC voltage drop

during 2G Tx slots

Lower than 400 mV

Supply voltage drop values greater than recommended

during 2G TDMA transmission slots directly affect the RF

compliance with applicable certification schemes.

Figure 5 describes supply voltage drop during 2G Tx slots.

VCC voltage ripple

during 2G/3G/LTE Tx

Noise in the supply has to be minimized

High supply voltage ripple values during LTE/3G/2G RF

transmissions in connected-mode directly affect the RF

compliance with applicable certification schemes.

Figure 5 describes supply voltage ripple during RF Tx.

VCC under/over-shoot

at start/end of Tx slots

Absent or at least minimized

Supply voltage under-shoot or over-shoot at the start or

the end of 2G TDMA transmission slots directly affect the

RF compliance with applicable certification schemes.

Figure 5 describes supply voltage under/over-shoot

Table 6: Summary of VCC modules supply requirements

TOBY-R2 series - System integration manual

UBX-16010572 - R14 System description Page 18 of 151

C1-Public

1.5.1.2 VCC consumption in 2G connected-mode

When a GSM call is established, the VCC module current consumption is determined by the current

consumption profile typical of the GSM transmitting and receiving bursts.

The peak of current consumption during a transmission slot is strictly dependent on the RF

transmitted power, which is regulated by the network (the current base station). The transmitted

power in the transmit slot is also the more relevant factor for determining the average current

consumption.

If the module is transmitting in 2G single-slot mode in the 850 or 900 MHz bands, at the maximum

RF power level (approximately 2 W or 33 dBm in the allocated transmit slot/burst) the current

consumption can reach an high peak (see the “Current consumption” section in the TOBY-R2 series

data sheet [1]) for 576.9 µs (width of the transmit slot/burst) with a periodicity of 4.615 ms (width of

1 frame = 8 slots/burst), so with a 1/8 duty cycle according to GSM TDMA (Time Division Multiple

Access).

If the module is transmitting in 2G single-slot mode in the 1800 or 1900 MHz bands, the current

consumption figures are quite less high than the one in the low bands, due to 3GPP transmitter output

power specifications.

During a GSM call, current consumption is not so significantly high in receiving or in monitor bursts

and is low in the inactive unused bursts.

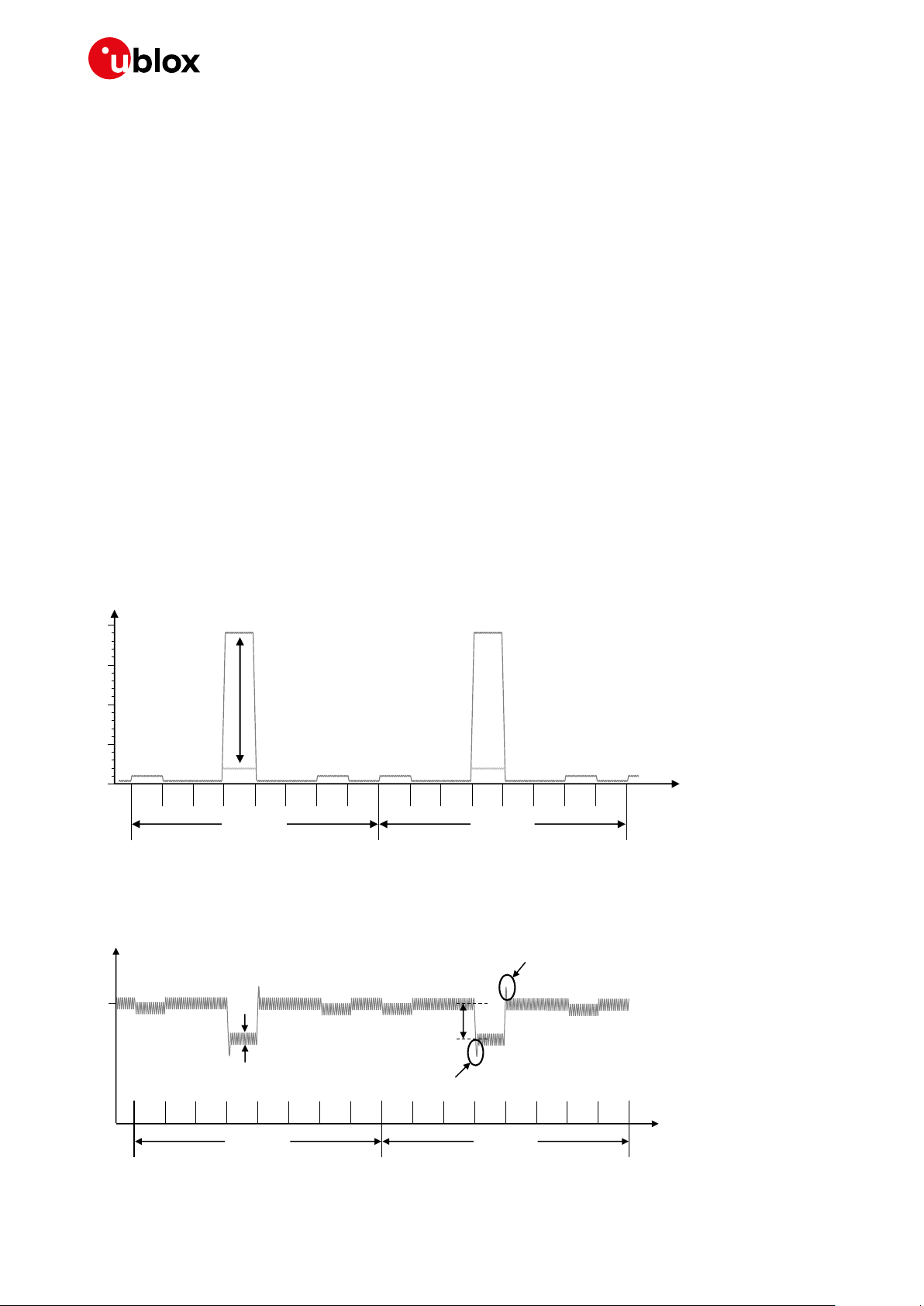

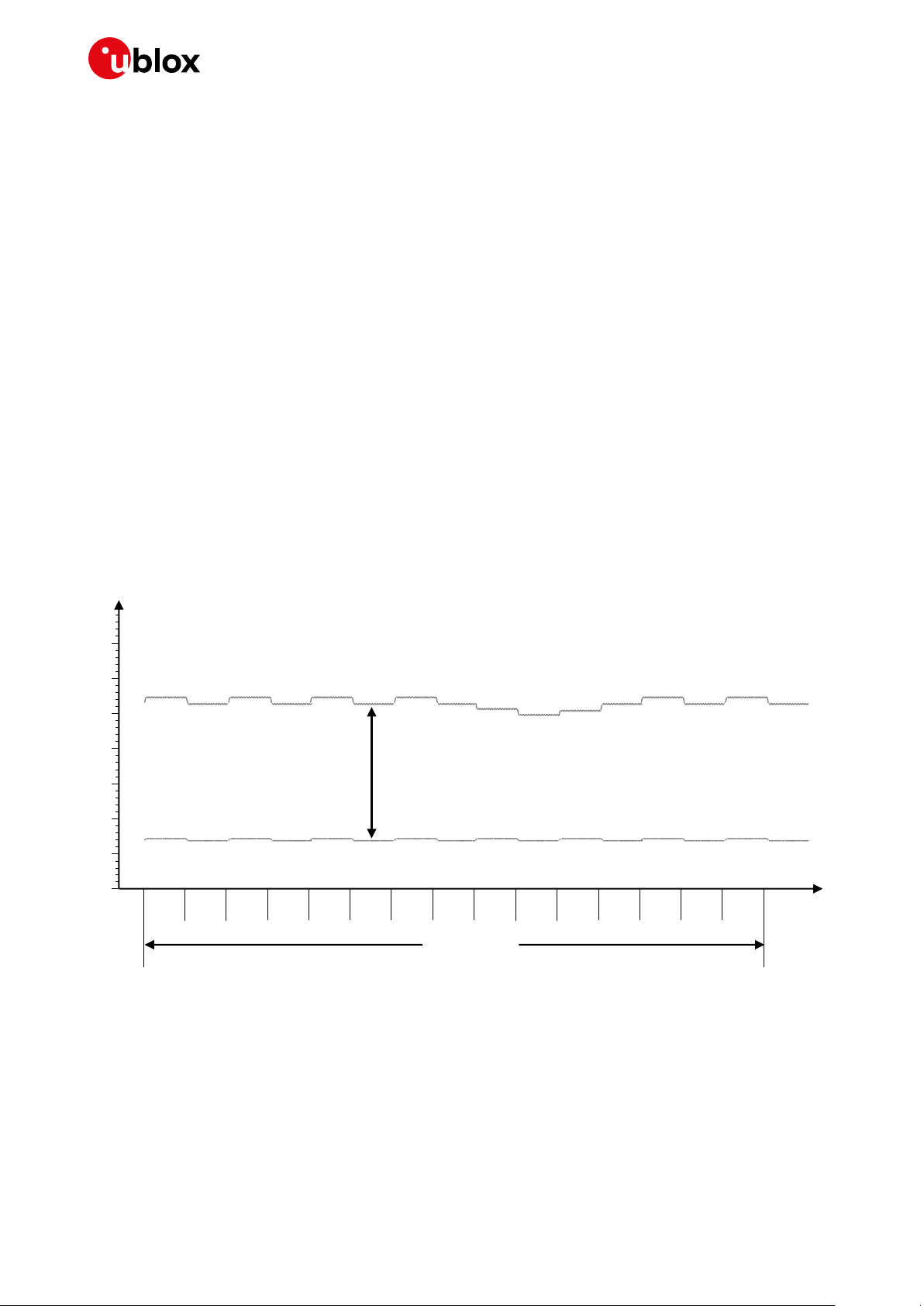

Figure 4 shows an example of the module current consumption profile versus time in 2G single-slot

mode.

Time [ms]

RX

slot

unused

slot

unused

slot

TX

slot

unused

slot

unused

slot

MON

slot

unused

slot

RX

slot

unused

slot

unused

slot

TX

slot

unused

slot

unused

slot

MON

slot

unused

slot

GSM frame

4.615 ms

(1 frame = 8 slots)

Current [A]

200 mA

60-120 mA

1900 mA

Peak current depends

on TX power and

actual antenna load

GSM frame

4.615 ms

(1 frame = 8 slots)

60-120 mA

10 -40 mA

0.0

1.5

1.0

0.5

2.0

Figure 4: VCC current consumption profile versus time during a 2G single-slot call (1 TX slot, 1 RX slot)

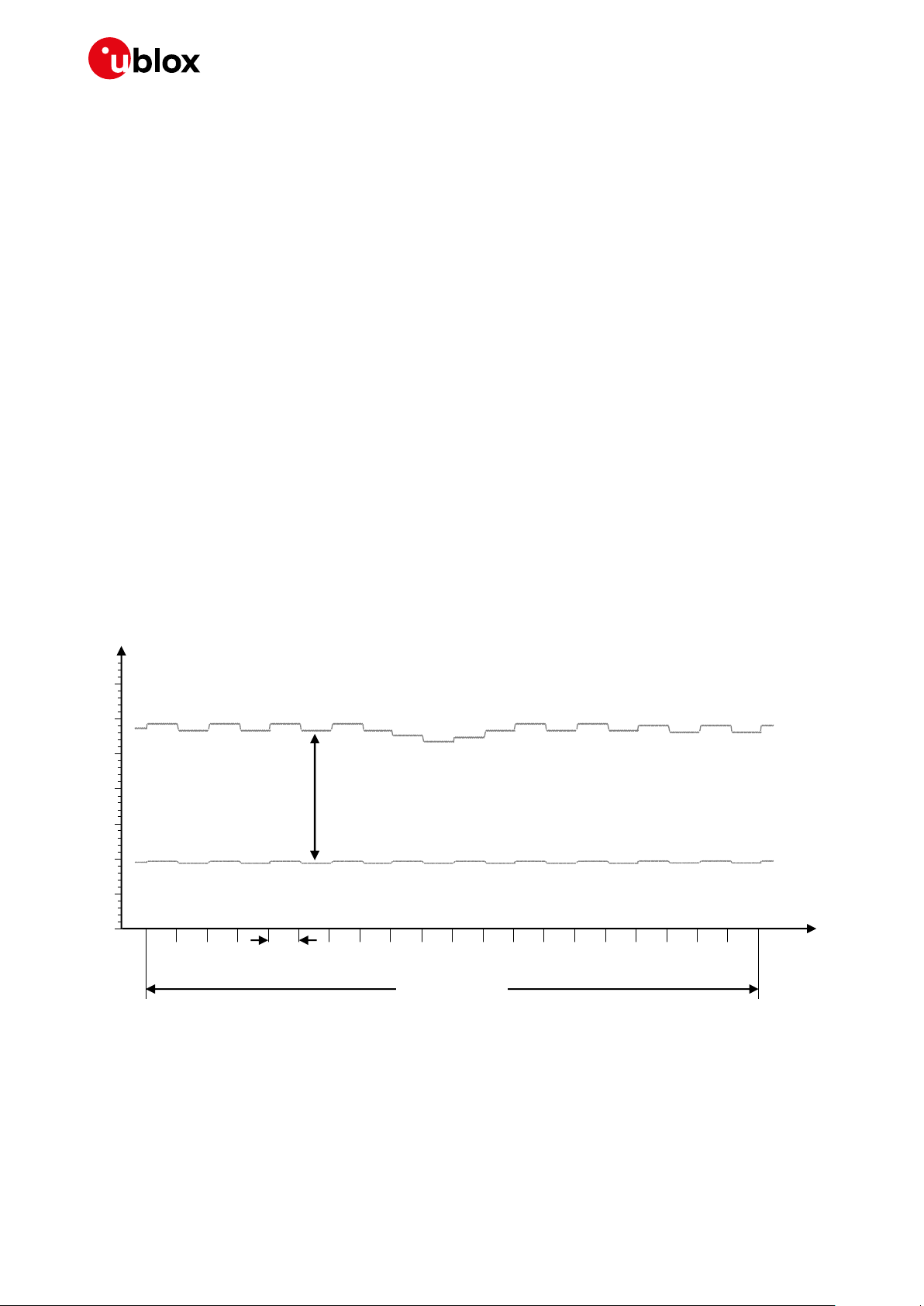

Figure 5 illustrates VCC voltage profile versus time during a 2G single-slot call, according to the

relative VCC current consumption profile described in Figure 4.

Time [ms]

undershoot

overshoot

ripple

drop

Voltage [mV]

3.8 V

(typ)

RX

slot

unused

slot

unused

slot

TX

slot

unused

slot

unused

slot

MON

slot

unused

slot

RX

slot

unused

slot

unused

slot

TX

slot

unused

slot

unused

slot

MON

slot

unused

slot

GSM frame

4.615 ms

(1 frame = 8 slots)

GSM frame

4.615 ms

(1 frame = 8 slots)

Figure 5: VCC voltage profile versus time during a 2G single-slot call (1 TX slot, 1 RX slot)

TOBY-R2 series - System integration manual

UBX-16010572 - R14 System description Page 19 of 151

C1-Public

When a GPRS connection is established, more than one slot can be used to transmit and/or more than

one slot can be used to receive. The transmitted power depends on network conditions, which set the

peak current consumption, but following the 3GPP specifications the maximum Tx RF power is

reduced if more than one slot is used to transmit, so the maximum peak of current is not as high as

can be in case of a 2G single-slot call.

The multi-slot transmission power can be further reduced by configuring the actual Multi-Slot Power

Reduction profile with the dedicated AT command, +UDCONF=40 (see the u-blox AT commands

manual [2]).

If the module transmits in GPRS class 12 in the 850 or 900 MHz bands, at the maximum RF power

control level, the current consumption can reach a quite high peak but lower than the one achievable

in 2G single-slot mode. This happens for 2.307 ms (width of the 4 transmit slots/bursts) with a

periodicity of 4.615 ms (width of 1 frame = 8 slots/bursts), so with a 1/2 duty cycle, according to 2G

TDMA.

If the module is in GPRS connected mode in the 1800 or 1900 MHz bands, the current consumption

figures are quite less high than the one in the low bands, due to 3GPP transmitter output power

specifications.

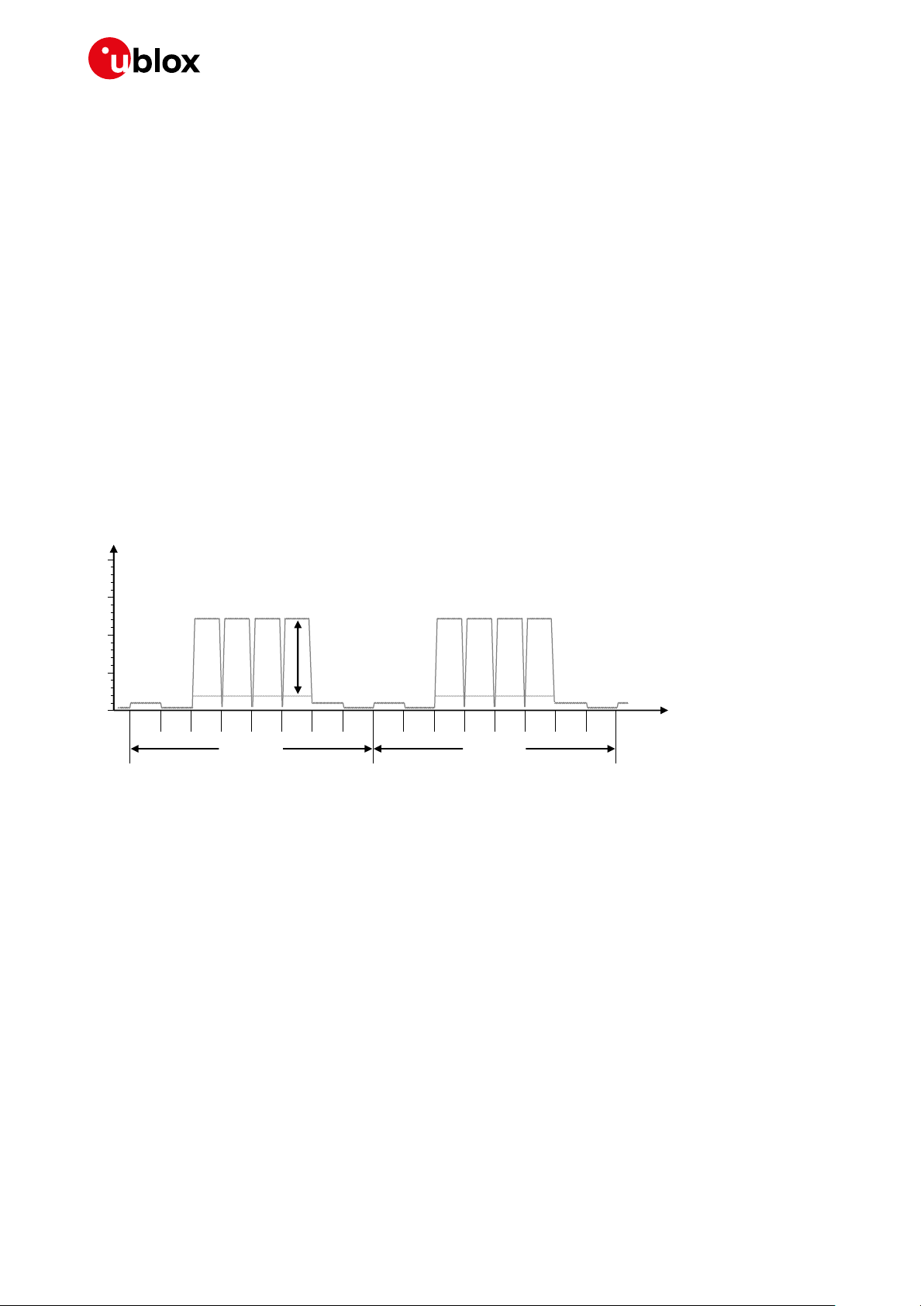

Figure 6 reports the current consumption profiles in GPRS class 12 connected mode, in the 850 or

900 MHz bands, with 4 slots used to transmit and 1 slot used to receive.

Time [ms]

RX

slot

unused

slot

TX

slot

TX

slot

TX

slot

TX

slot

MON

slot

unused

slot

RX

slot

unused

slot

TX

slot

TX

slot

TX

slot

TX

slot

MON

slot

unused

slot

GSM frame

4.615 ms

(1 frame = 8 slots)

Current [A]

200mA

60-130mA

Peak current depends

on TX power and

actual antenna load

GSM frame

4.615 ms

(1 frame = 8 slots)

1600 mA

0.0

1.5

1.0

0.5

2.0

Figure 6: VCC current consumption profile during a 2G GPRS/EDGE multi-slot connection (4 TX slots, 1 RX slot)

In case of EDGE connections the VCC current consumption profile is very similar to the GPRS current

profile, so the image shown in Figure 6, representing the current consumption profile in GPRS class

12 connected mode, is valid for the EDGE class 12 connected mode as well.

TOBY-R2 series - System integration manual

UBX-16010572 - R14 System description Page 20 of 151

C1-Public

1.5.1.3 VCC consumption in 3G connected mode

During a 3G connection, the module can transmit and receive continuously due to the Frequency

Division Duplex (FDD) mode of operation with the Wideband Code Division Multiple Access (WCDMA).

The current consumption depends on output RF power, which is always regulated by the network (the

current base station) sending power control commands to the module. These power control

commands are logically divided into a slot of 666 µs, thus the rate of power change can reach a

maximum rate of 1.5 kHz.

There are no high current peaks as in the 2G connection, since transmission and reception are

continuously enabled due to FDD WCDMA implemented in the 3G that differs from the TDMA

implemented in the 2G case.

In the worst scenario, corresponding to a continuous transmission and reception at maximum output

power (approximately 250 mW or 24 dBm), the average current drawn by the module at the VCC pins

is considerable (see the “Current consumption” section in TOBY-R2 series data sheet [1]). At the

lowest output RF power (approximately 0.01 µW or –50 dBm), the current drawn by the internal power

amplifier is strongly reduced. The total current drawn by the module at the VCC pins is due to

baseband processing and transceiver activity.

Figure 7 shows an example of current consumption profile of the module in 3G WCDMA/ HSPA

continuous transmission mode.

Time

[ms]

3G frame

10 ms

(1 frame = 15 slots)

Current [mA]

Current consumption value

depends on TX power and

actual antenna load

170

mA

1 slot

666 µs

850

mA

0

300

200

100

500

400

600

700

Figure 7: VCC current consumption profile versus time during a 3G connection (TX and RX continuously enabled)

TOBY-R2 series - System integration manual

UBX-16010572 - R14 System description Page 21 of 151

C1-Public

1.5.1.4 VCC consumption in LTE connected-mode

During an LTE connection, the module can transmit and receive continuously due to the Frequency

Division Duplex (FDD) mode of operation used in LTE radio access technology.

The current consumption depends on output RF power, which is always regulated by the network (the

current base station) sending power control commands to the module. These power control

commands are logically divided into a slot of 0.5 ms (time length of one Resource Block), thus the rate

of power change can reach a maximum rate of 2 kHz.

The current consumption profile is similar to that in 3G radio access technology. Unlike the 2G

connection mode, which uses the TDMA mode of operation, there are no high current peaks since

transmission and reception are continuously enabled in FDD.

In the worst scenario, corresponding to a continuous transmission and reception at maximum output

power (approximately 250 mW or 24 dBm), the average current drawn by the module at the VCC pins

is considerable (see the “Current consumption” section in TOBY-R2 series data sheet [1]). At the

lowest output RF power (approximately 0.1 µW or –40 dBm), the current drawn by the internal power

amplifier is strongly reduced and the total current drawn by the module at the VCC pins is due to

baseband processing and transceiver activity.

Figure 8 shows an example of the module current consumption profile versus time in LTE

connected-mode. Detailed current consumption values can be found in TOBY-R2 series data

sheet [1].

Time

[ms]

Current [mA]

Current consumption value

depends on TX power and

actual antenna load

1 Slot

1 Resource Block

(0.5 ms)

1 LTE Radio Frame

(10 ms)

0

300

200

100

500

400

600

700

Figure 8: VCC current consumption profile versus time during LTE connection (TX and RX continuously enabled)

TOBY-R2 series - System integration manual

UBX-16010572 - R14 System description Page 22 of 151

C1-Public

1.5.1.5 VCC consumption in cyclic idle/active mode (power saving enabled)

The power saving configuration is by default disabled, but it can be enabled using the AT+UPSV

command (see the u-blox AT commands manual [2]). When power saving is enabled, the module

automatically enters the low power idle-mode whenever possible, reducing current consumption.

During low power idle-mode, the module processor runs with 32 kHz reference clock frequency.

When the power saving configuration is enabled and the module is registered or attached to a

network, the module automatically enters the low power idle-mode whenever possible, but it must

periodically monitor the paging channel of the current base station (paging block reception), in

accordance to the 2G/3G/LTE system requirements, even if connected-mode is not enabled by the

application. When the module monitors the paging channel, it wakes up to the active-mode, to enable

the reception of paging block. In between, the module switches to low power idle-mode. This is known

as discontinuous reception (DRX).

The module processor core is activated during the paging block reception, and automatically switches

its reference clock frequency from 32 kHz to the 26 MHz used in active-mode.

The time period between two paging block receptions is defined by the network. This is the paging

period parameter, fixed by the base station through broadcast channel sent to all users on the same

serving cell:

• For 2G RAT, the paging period can vary from 470.8 ms (DRX = 2, length of 2 x 51 2G frames = 2 x

51 x 4.615 ms) up to 2118.4 ms (DRX = 9, length of 9 x 51 2G frames = 9 x 51 x 4.615 ms)

• For 3G RAT, the paging period can vary from 640 ms (DRX = 6, i.e. length of 2

6

3G frames = 64 x

10 ms) up to 5120 ms (DRX = 9, length of 29 3G frames = 512 x 10 ms).

• For LTE RAT, the paging period can vary from 320 ms (DRX = 5, i.e. length of 2

5

LTE frames = 32 x

10 ms) up to 2560 ms (DRX = 8, length of 28 LTE frames = 256 x 10 ms).

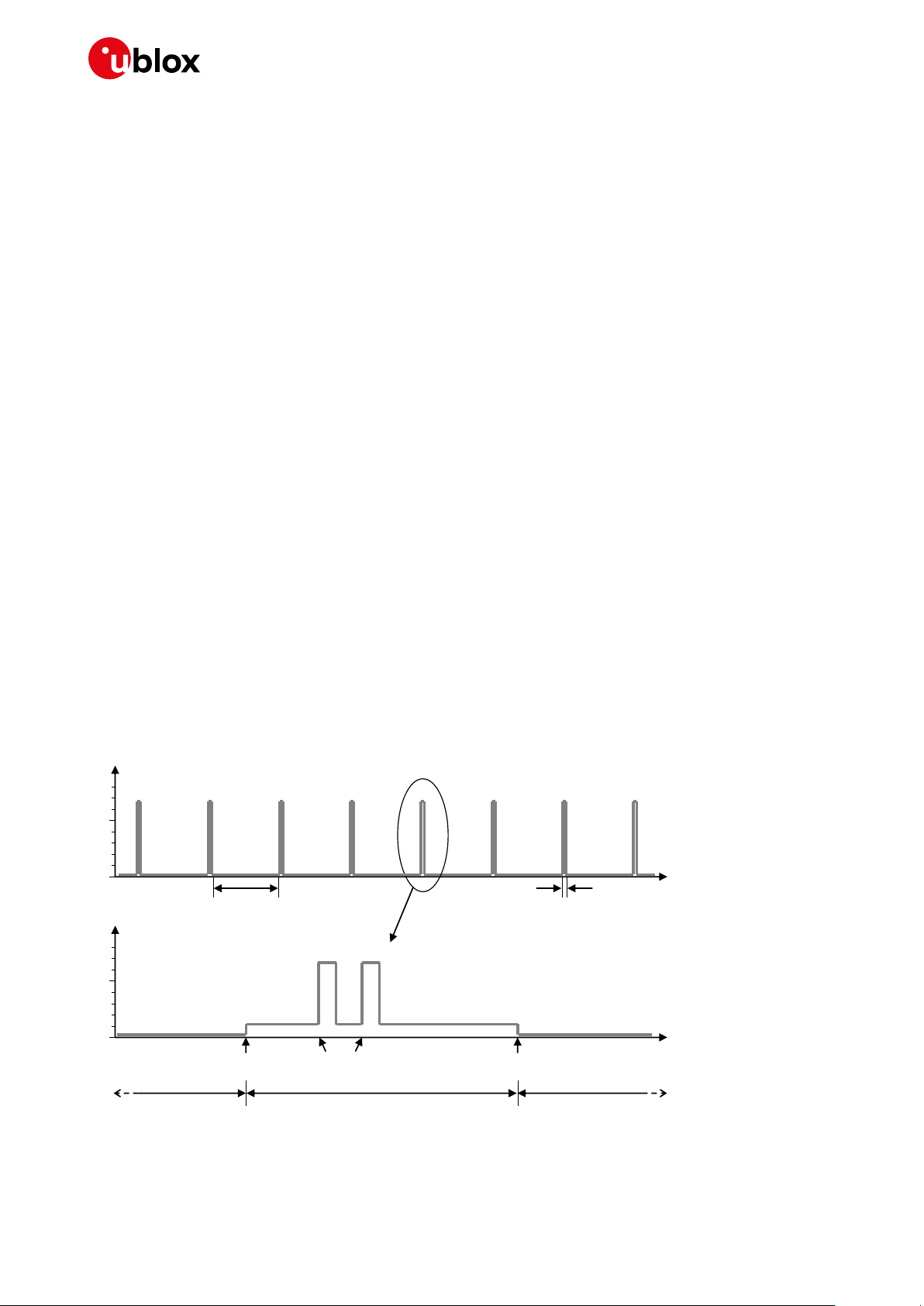

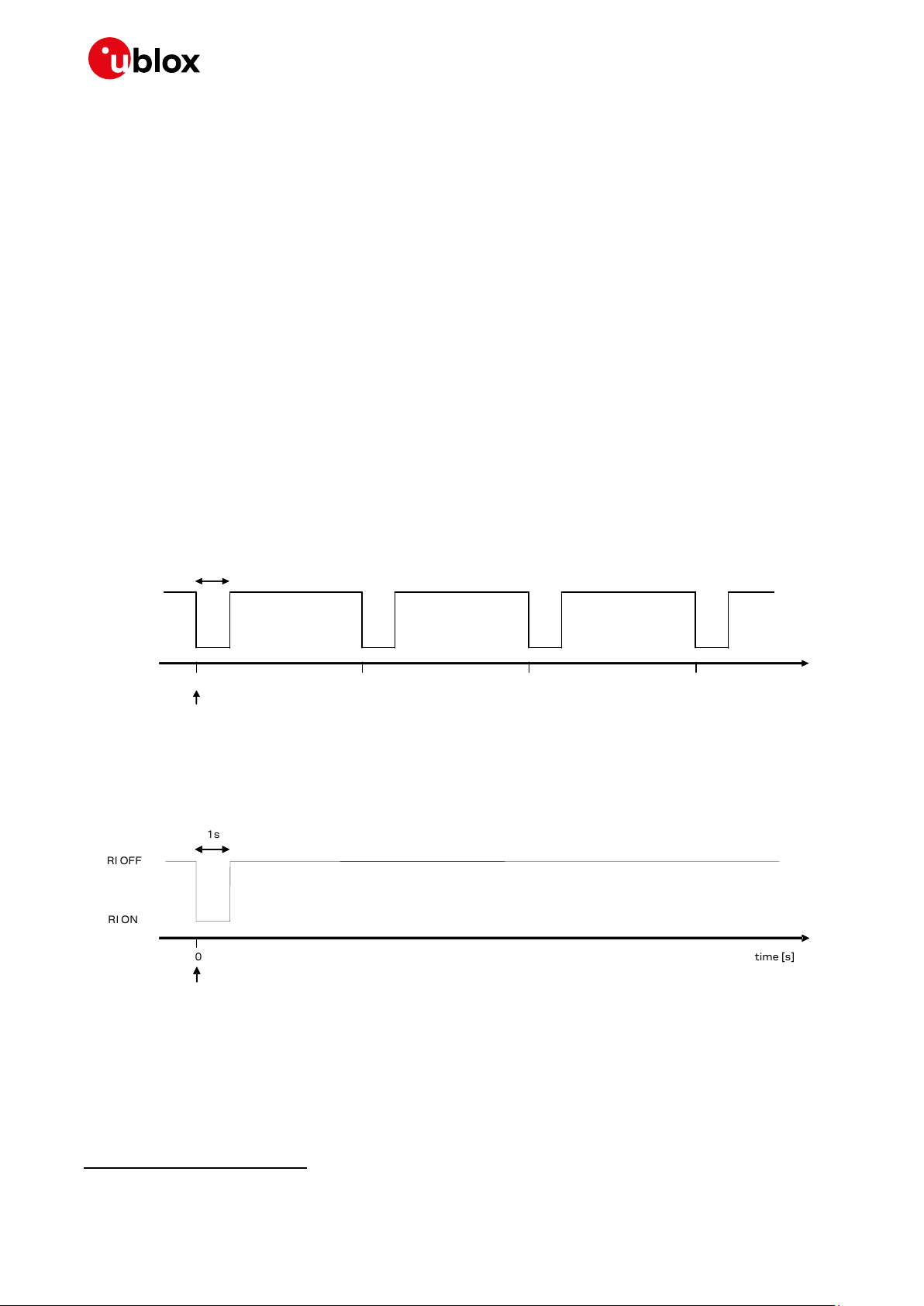

Figure 9 illustrates a typical example of the module current consumption profile when power saving is

enabled. The module is registered with network, automatically enters the low power idle-mode and

periodically wakes up to active-mode to monitor the paging channel for the paging block reception.

Detailed current consumption values can be found in TOBY-R2 series data sheet [1].

~50 ms

IDLE MODE ACTIVE MODE IDLE MODE

Active Mode

Enabled

Idle Mode

Enabled

2G case: 0.44-2.09 s

3G case: 0.61-5.09 s

LTE case: 0.27-2.51 s

IDLE MODE

~50 ms

ACTIVE MODE

Time [s]

Current [mA]

Time [ms]

Current [mA]

RX

Enabled

0

100

0

100

Figure 9: VCC current consumption profile with power saving enabled and module registered with the network: the module

is in low-power idle-mode and periodically wakes up to active-mode to monitor the paging channel for paging block reception

TOBY-R2 series - System integration manual

UBX-16010572 - R14 System description Page 23 of 151

C1-Public

1.5.1.6 VCC consumption in fixed active-mode (power saving disabled)

When power saving is disabled, the module does not automatically enter the low power idle-mode

whenever possible: the module remains in active-mode. Power saving configuration is by default

disabled. It can also be disabled using the AT+UPSV command (see u-blox AT commands manual [2]

for detail usage).

The module processor core is activated during idle-mode, and the 26 MHz reference clock frequency

is used. It would draw more current during the paging period than that in the power saving mode.

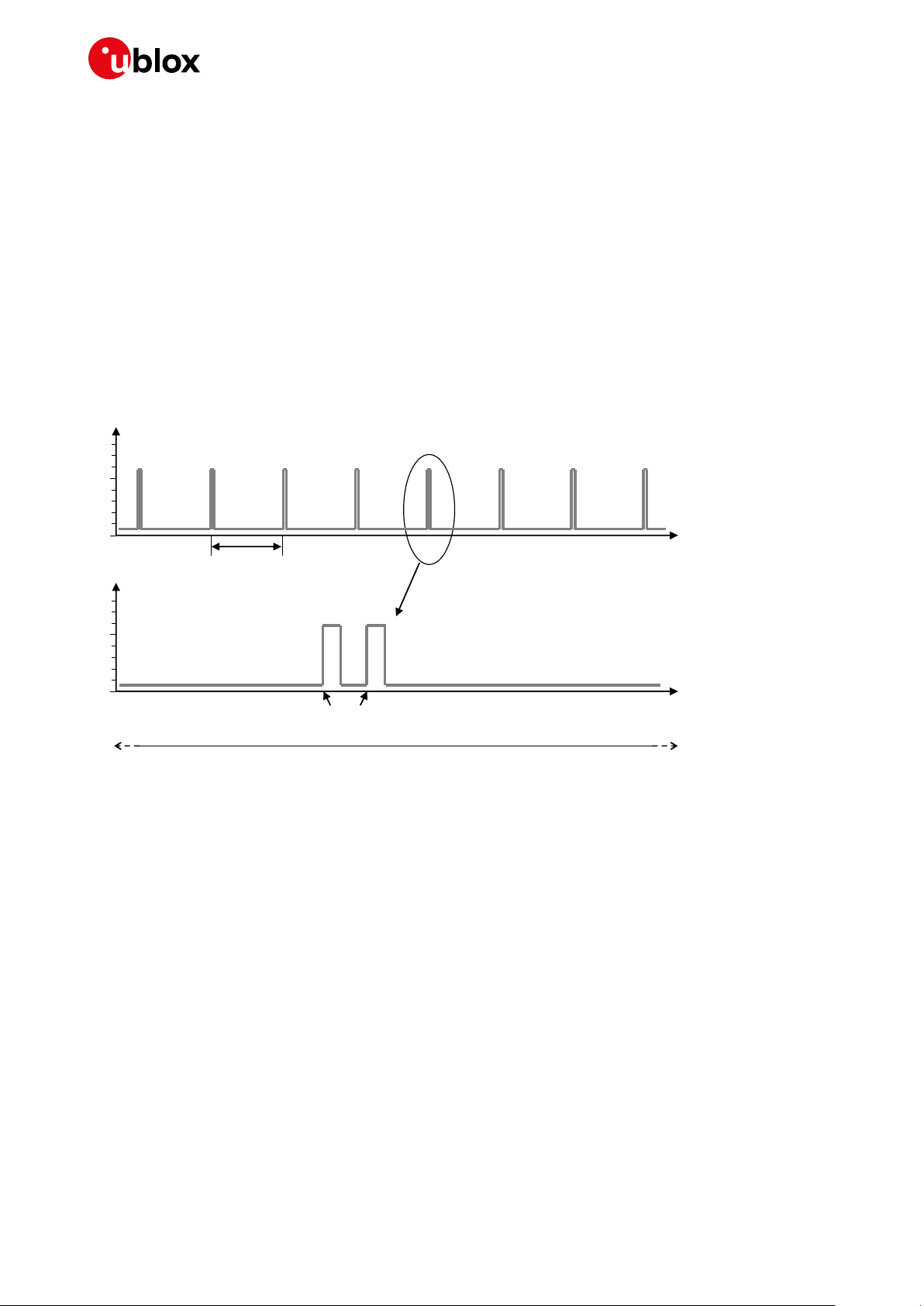

Figure 10 illustrates a typical example of the module current consumption profile when power saving

is disabled. In such case, the module is registered with the network and while active-mode is

maintained, the receiver is periodically activated to monitor the paging channel for paging block

reception. Detailed current consumption values can be found in TOBY-R2 series data sheet [1].

ACTIVE MODE

2G case: 0.44-2.09 s

3G case: 0.61-5.09 s

LTE case: 0.32-2.56 s

Paging period

Time [s]

Current [mA]

Time [ms]

Current [mA]

RX

Enabled

0

100

0

100

Figure 10: VCC current consumption profile with power saving disabled and module registered with the network: activemode is always held and the receiver is periodically activated to monitor the paging channel for paging block reception

TOBY-R2 series - System integration manual

UBX-16010572 - R14 System description Page 24 of 151

C1-Public

1.5.2 RTC supply input/output (V_BCKP)

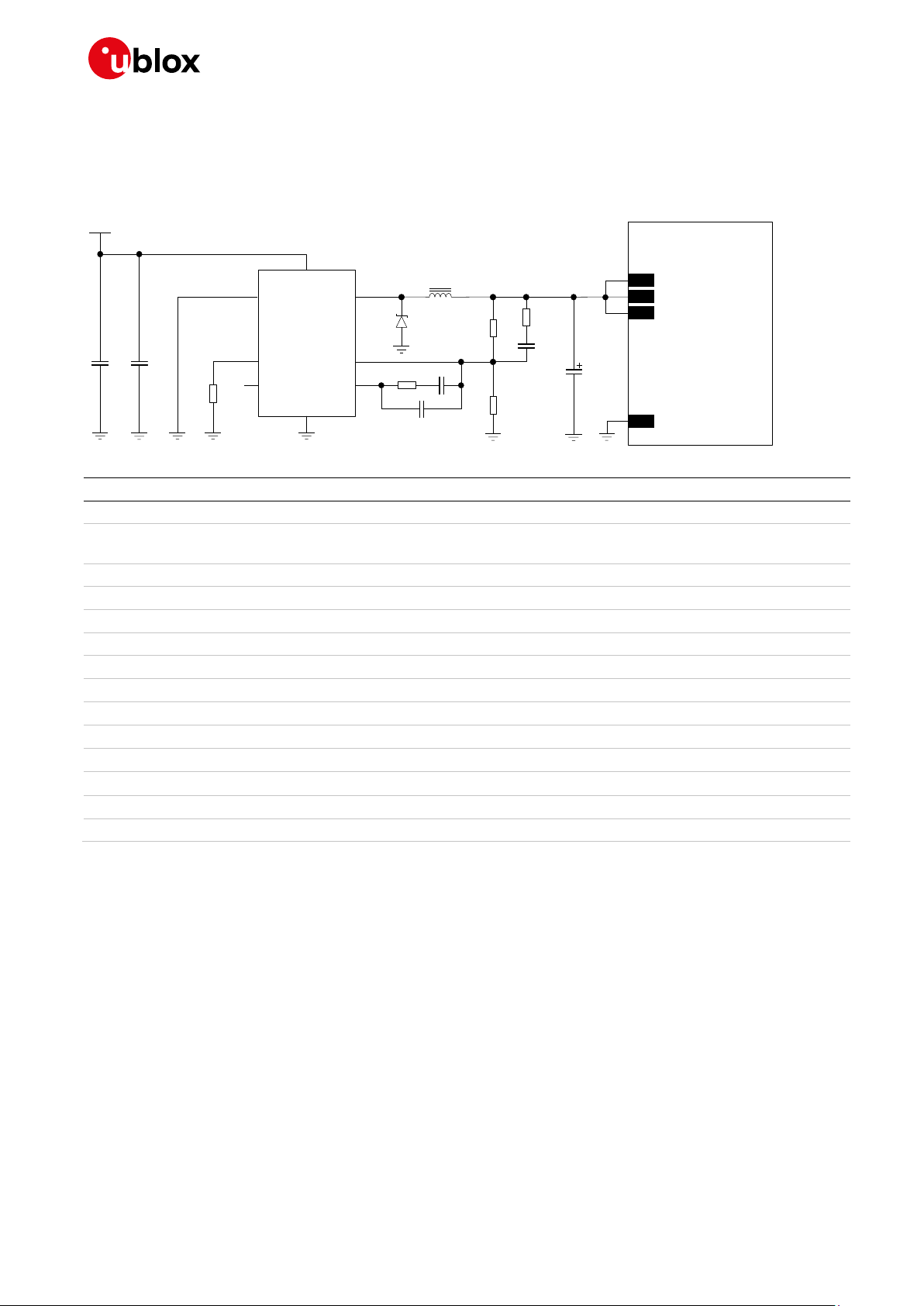

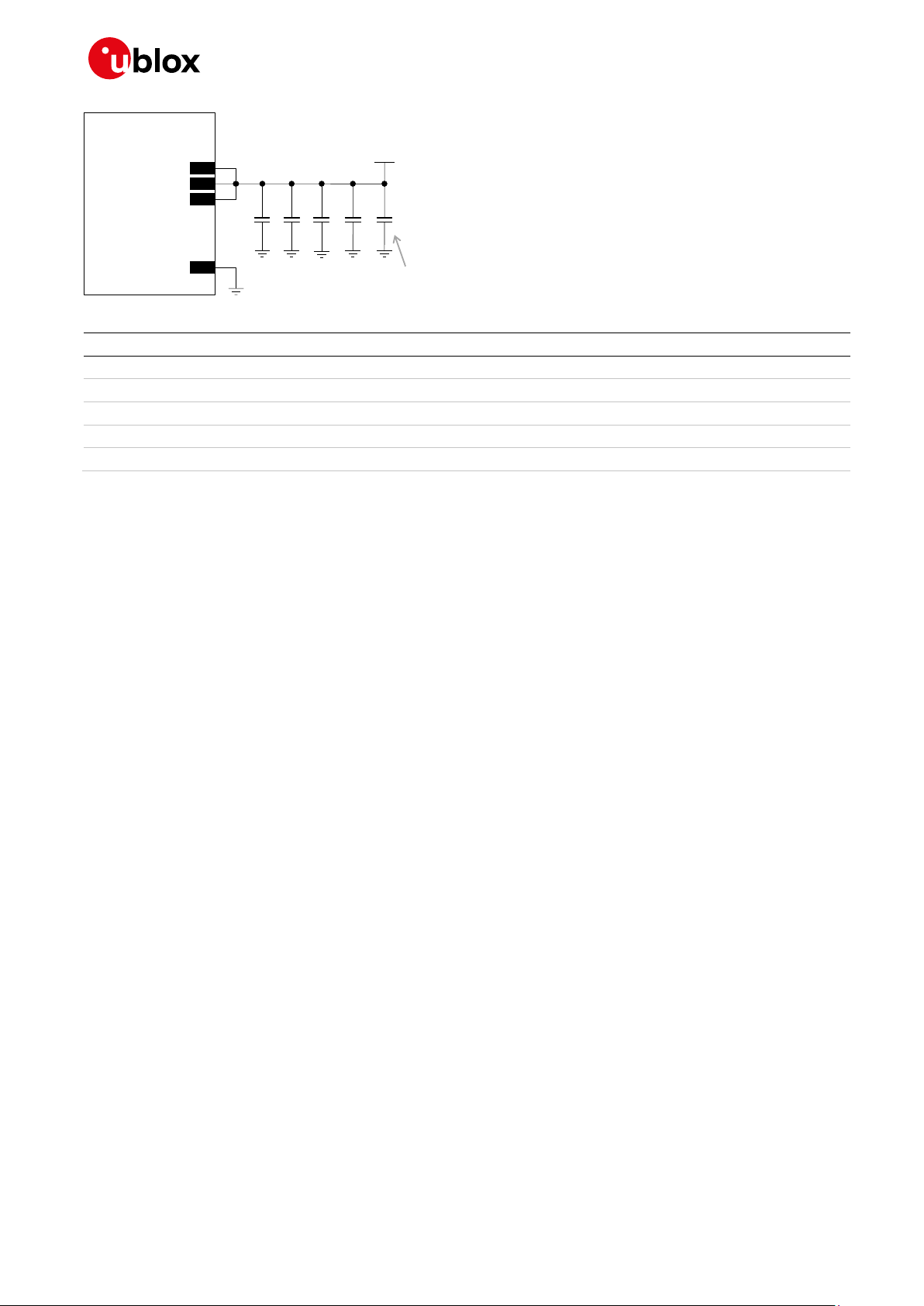

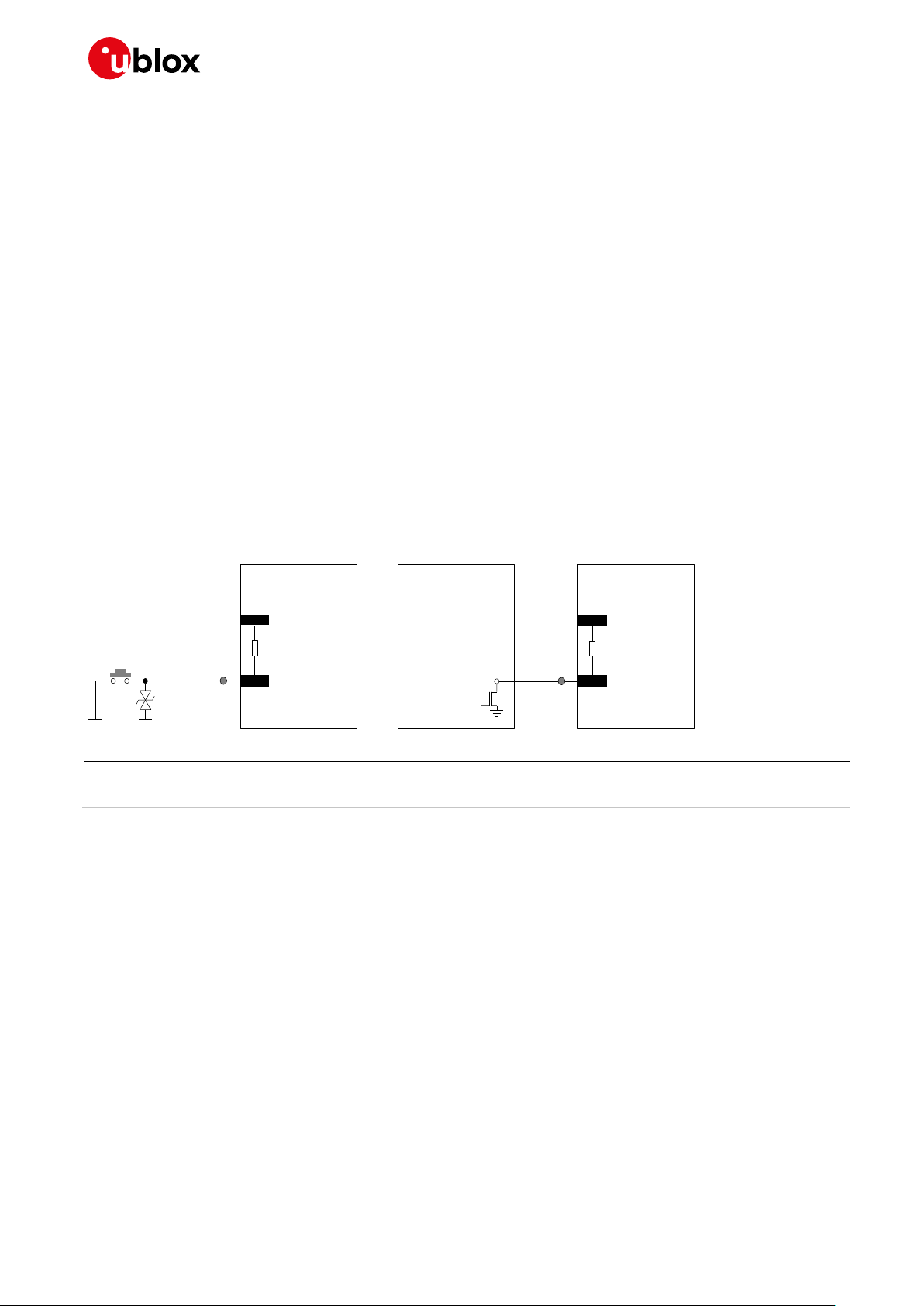

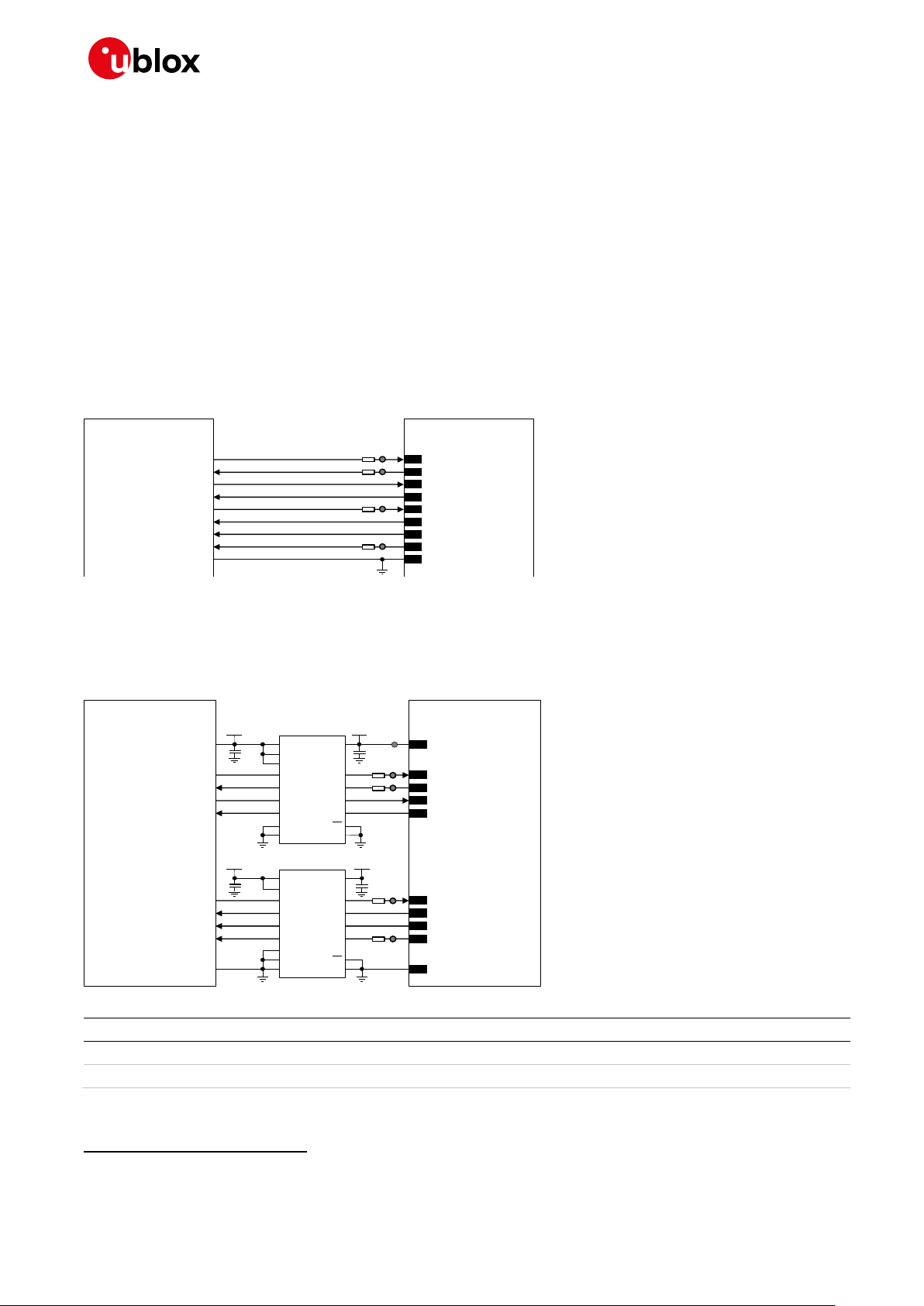

The V_BCKP pin of TOBY-R2 series modules connects the supply for the Real Time Clock (RTC). A

linear LDO regulator integrated in the Power Management Unit internally generates this supply, as

shown in Figure 11, with low current capability (see the TOBY-R2 series data sheet [1]). The output of

this regulator is always enabled when the main module voltage supply applied to the VCC pins is within

the valid operating range.

Baseband

Processor

70

VCC

71

VCC

72

VCC

3

V_BCKP

Linear

LDO

Power

Management

TOBY-R2 series

32 kHz

RTC

Figure 11: TOBY-R2 series RTC supply (V_BCKP) simplified block diagram

The RTC provides the module time reference (date and time) that is used to set the wake-up interval

during the low power idle-mode periods, and is able to make available the programmable alarm

functions.

The RTC functions are available also in power-down mode when the V_BCKP voltage is within its valid

range (specified in the “Input characteristics of Supply/Power pins” table in TOBY-R2 series data

sheet [1]). The RTC can be supplied from an external back-up battery through the V_BCKP, when the

main module voltage supply is not applied to the VCC pins. This lets the time reference (date and time)

run until the V_BCKP voltage is within its valid range, even when the main supply is not provided to

the module.

Consider that the module cannot switch on if a valid voltage is not present on VCC even when the RTC

is supplied through V_BCKP (meaning that VCC is mandatory to switch on the module).

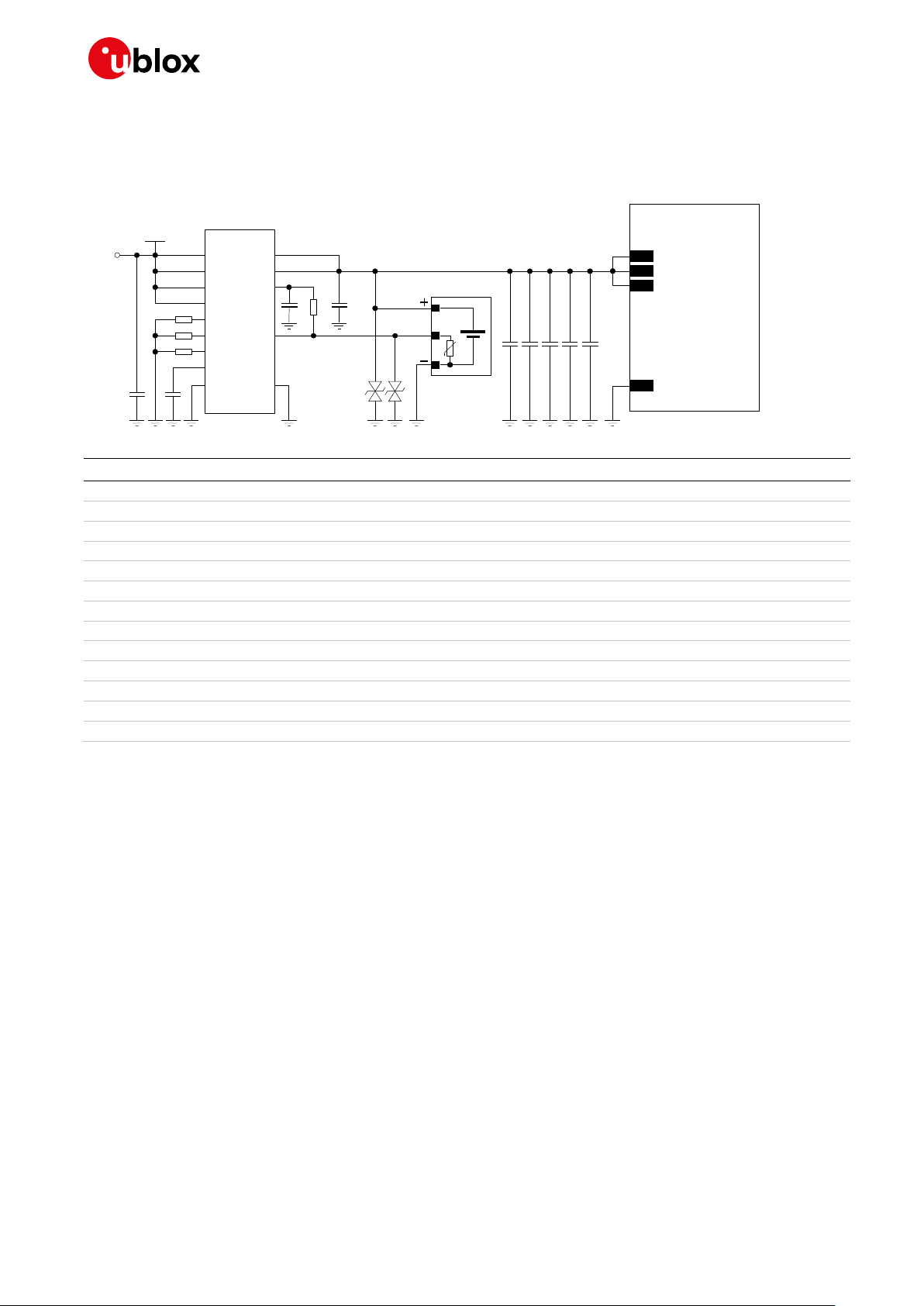

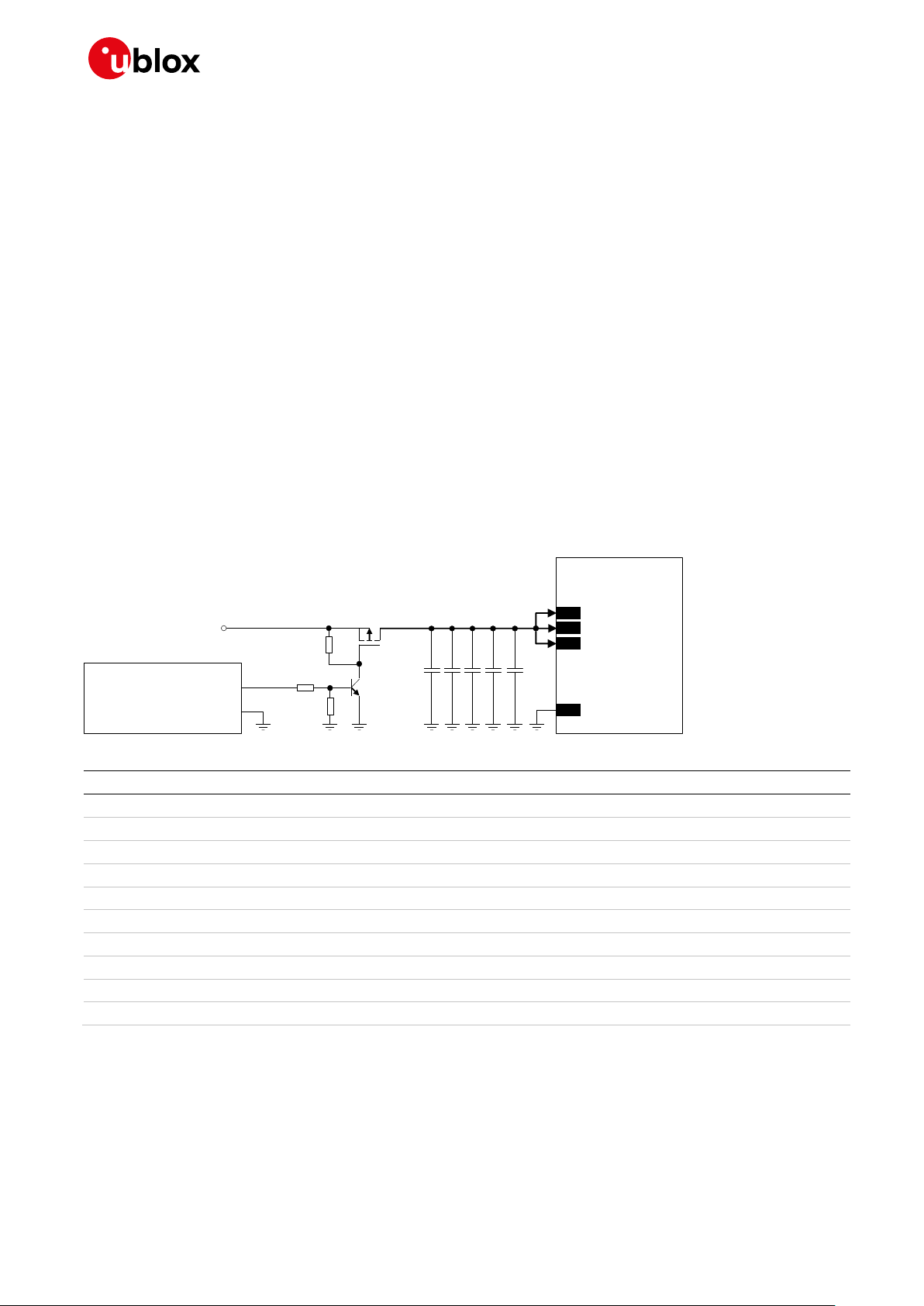

The RTC has very low current consumption, but is highly temperature dependent. For example,

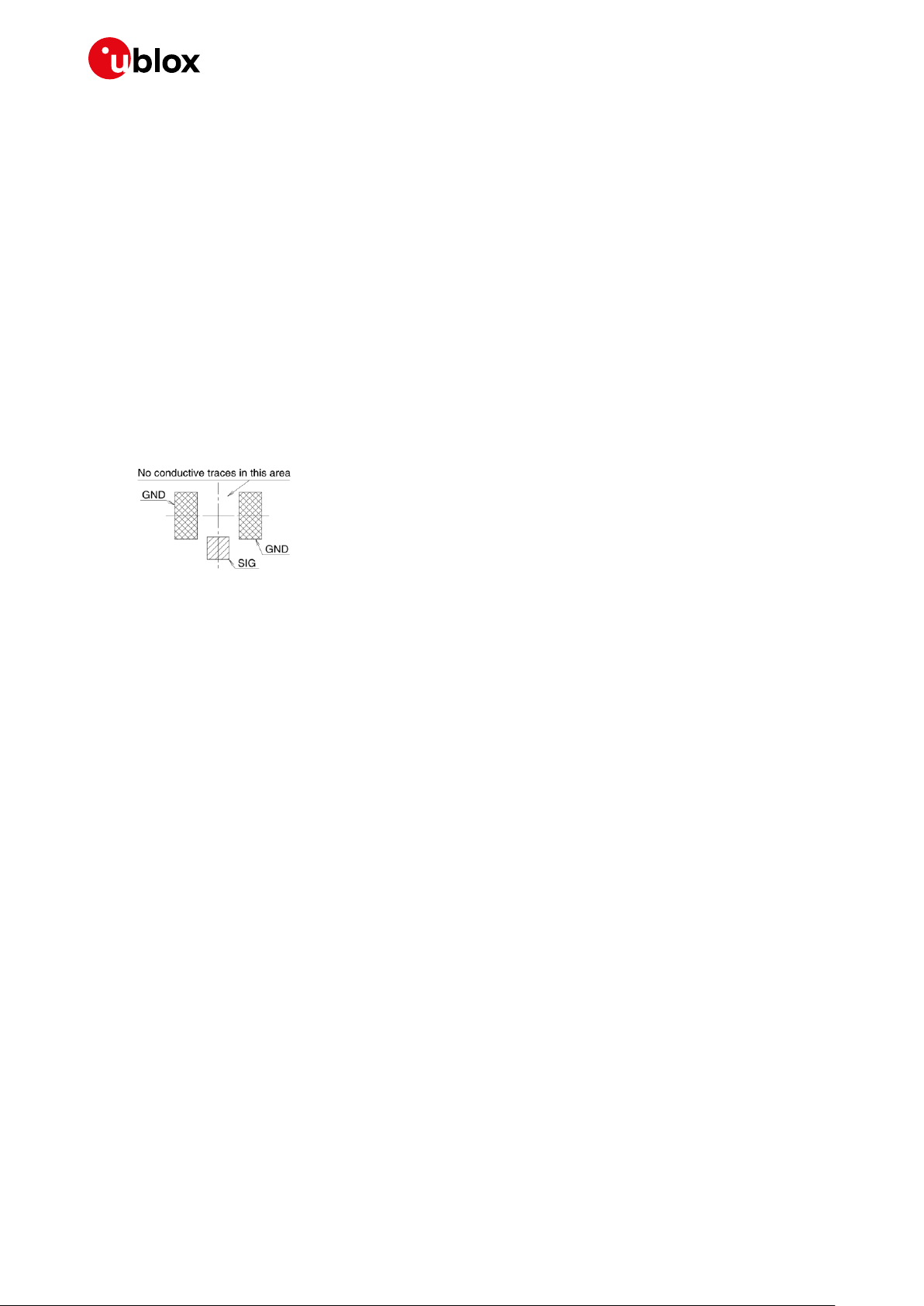

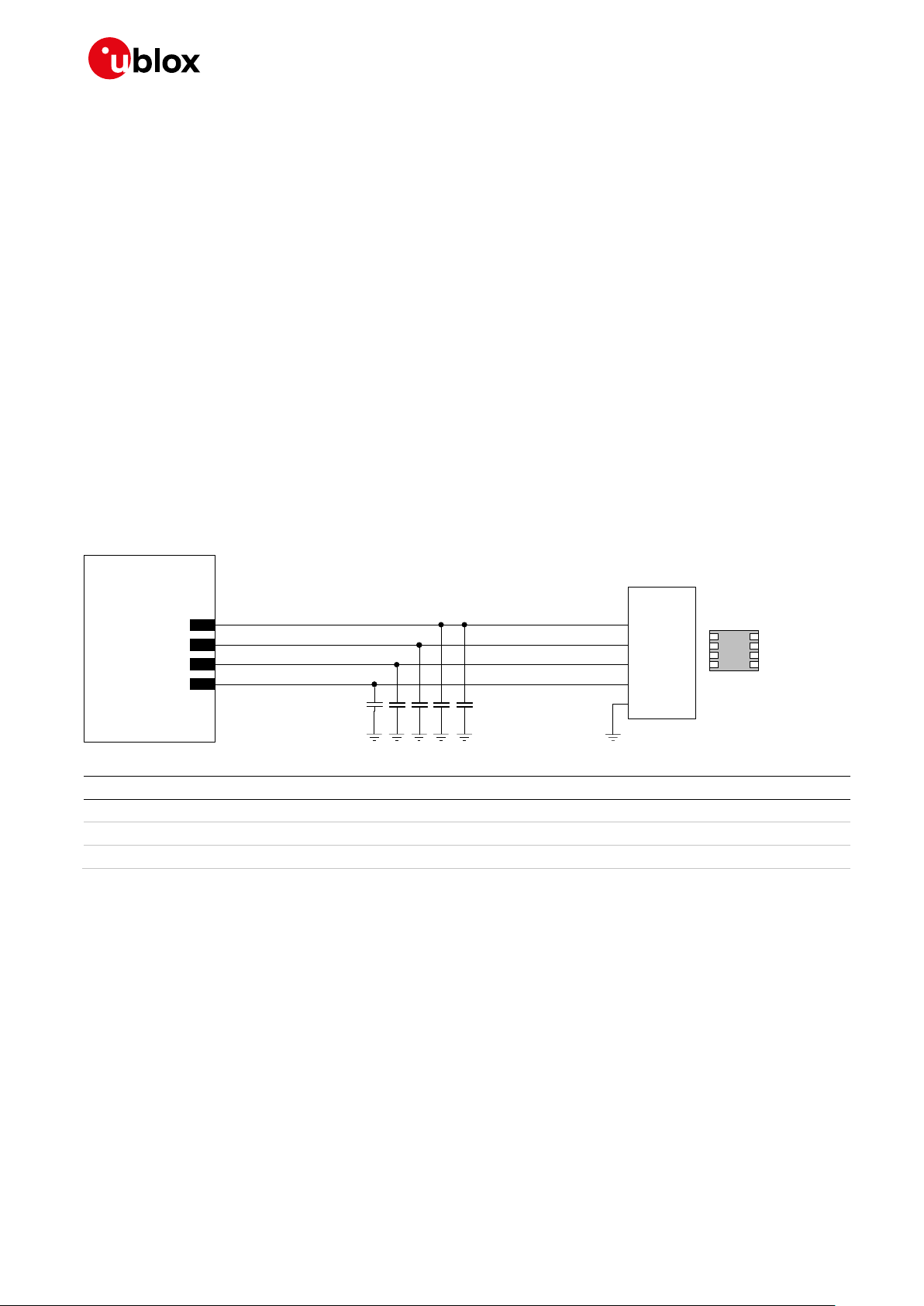

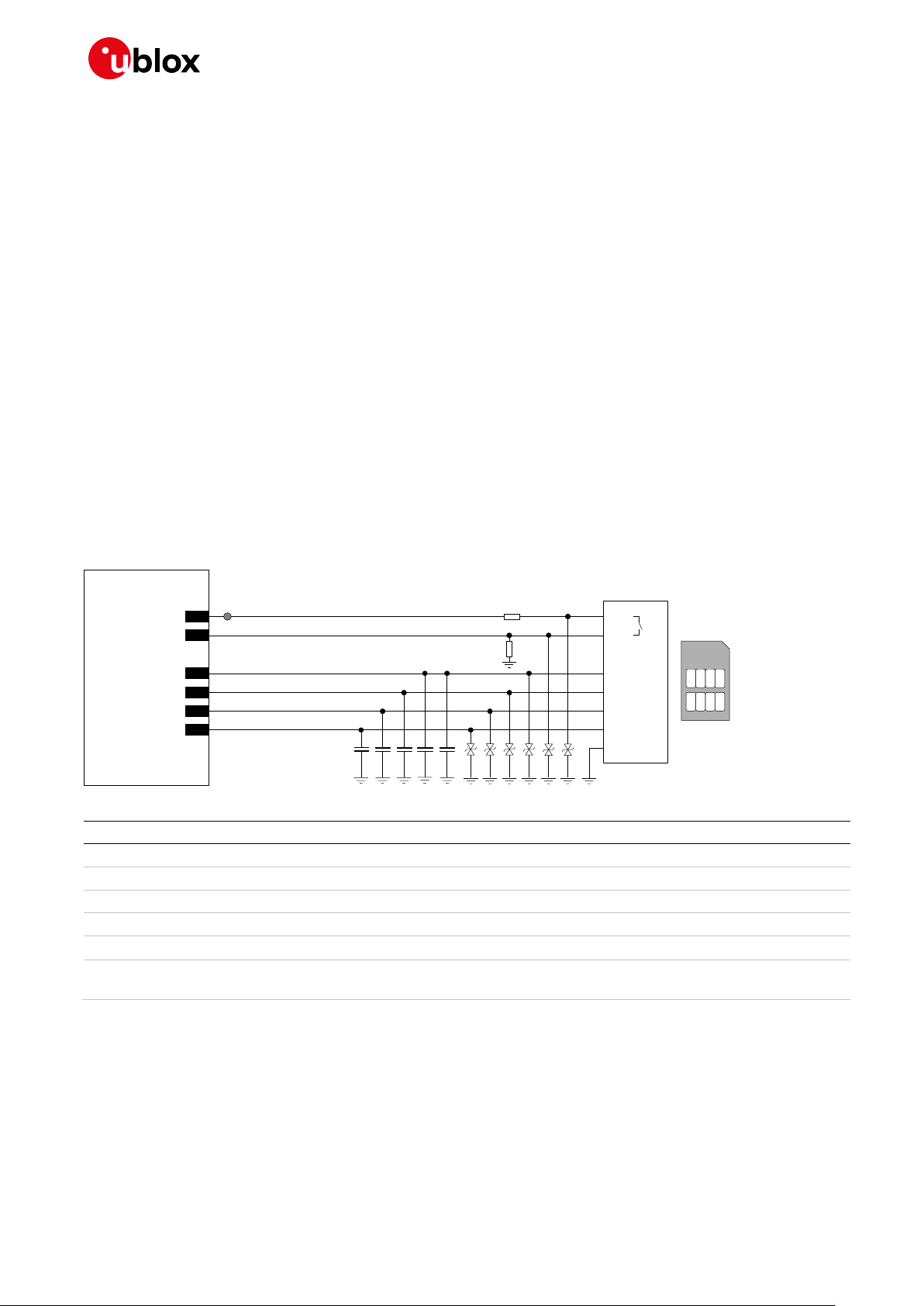

V_BCKP current consumption at the maximum operating temperature can be higher than the typical