Page 1

UBX-17005143 - R13

C1-Public www.u-blox.com

SARA-N2 / N3 series

Multi-band NB-IoT (LTE Cat NB1 / NB2) modules

System integration manual

Abstract

This document describes the features and the system integration of the SARA-N2 series and the

SARA-N3 series NB-IoT modules. These modules are a complete and cost efficient solution offering

from single-band up to multi-band data transmission for the Internet of Things technology in the

compact SARA form factor.

SARA-N2 / N3

Page 2

SARA-N2 / N3 series - System integration manual

UBX-17005143 - R13 Document information Page 2 of 95

C1-Public

Document information

Title

SARA-N2 / N3 series

Subtitle

Multi-band NB-IoT (LTE Cat NB1 / NB2) modules

Document type

System integration manual

Document number

UBX-17005143

Revision and date

R13

14-Oct-2020

Disclosure restriction

C1-Public

Product status

Corresponding content status

Functional sample

Draft

For functional testing. Revised and supplementary data will be published later.

In development /

Prototype

Objective specification

Target values. Revised and supplementary data will be published later.

Engineering sample

Advance information

Data based on early testing. Revised and supplementary data will be published later.

Initial production

Early production information

Data from product verification. Revised and supplementary data may be published later.

Mass production /

End of life

Production information

Document contains the final product specification.

This document applies to the following products:

Product name

Type number

Modem version

Application version

PCN reference

Product status

SARA-N200

SARA-N200-02B-00

06.57

A07.03

UBX-18005015

End of life

SARA-N200-02B-01

06.57

A09.06

UBX-18048558

End of life

SARA-N200-02B-02

06.57

A10.08

UBX-19030865

End of life

SARA-N201

SARA-N201-02B-00

06.57

A07.03

UBX-18005015

End of life

SARA-N201-02B-01

06.57

A08.05

UBX-19030865

End of life

SARA-N210

SARA-N210-02B-00

06.57

A07.03

UBX-18005015

End of life

SARA-N210-02B-01

06.57

A09.06

UBX-18048558

End of life

SARA-N210-02B-02

06.57

A10.08

UBX-19030865

End of life

SARA-N211

SARA-N211-02X-00

06.57

A07.03

UBX-18005015

End of life

SARA-N211-02X-01

06.57

A09.06

UBX-18048558

End of life

SARA-N211-02X-02

06.57

A10.08

UBX-19030865

End of life

SARA-N280

SARA-N280-02B-00

06.57

A07.03

UBX-18005015

End of life

SARA-N280-02B-01

06.57

A09.06

UBX-19030865

End of life

SARA-N300

SARA-N300-00B-00

18.10

A01.04

UBX-20026729

Engineering sample

SARA-N310

SARA-N310-00X-00

18.13

A01.00

UBX-20033555

Initial production

u-blox or third parties may hold intellectual property rights in the products, names, logos and designs included in this document.

Copying, reproduction, modification or disclosure to third parties of this document or any part thereof is only permitted with the

express written permission of u-blox.

The information contained herein is provided “as is” and u-blox assumes no liability for its use. No warranty, either express or

implied, is given, including but not limited to, with respect to the accuracy, correctness, reliability and fitness for a particular

purpose of the information. This document may be revised by u-blox at any time without notice. For the most recent documents,

visit www.u-blox.com.

Copyright © u-blox AG.

Page 3

SARA-N2 / N3 series - System integration manual

UBX-17005143 - R13 Contents Page 3 of 95

C1-Public

Contents

Document information ................................................................................................................................ 2

Contents .......................................................................................................................................................... 3

1 System description ............................................................................................................................... 6

1.1 Overview ........................................................................................................................................................ 6

1.2 Architecture ................................................................................................................................................. 8

1.3 Pin-out ........................................................................................................................................................... 9

1.4 Operating modes ....................................................................................................................................... 13

1.5 Supply interfaces ...................................................................................................................................... 15

1.5.1 Module supply input (VCC) ............................................................................................................. 15

1.5.2 RTC supply (V_BCKP) ....................................................................................................................... 16

1.5.3 Interfaces supply output (V_INT) ................................................................................................... 17

1.6 System function interfaces .................................................................................................................... 18

1.6.1 Module power-on .............................................................................................................................. 18

1.6.2 Module power-off .............................................................................................................................. 20

1.6.3 Module reset .......................................................................................................................................21

1.6.4 Voltage selection of interfaces (VSEL) .........................................................................................21

1.7 Antenna interface ..................................................................................................................................... 22

1.7.1 Cellular antenna RF interface (ANT) ............................................................................................. 22

1.7.2 Bluetooth antenna RF interface (ANT_BT) ................................................................................. 23

1.7.3 Antenna detection interface (ANT_DET)..................................................................................... 23

1.8 SIM interface .............................................................................................................................................. 23

1.9 Serial interfaces ........................................................................................................................................ 24

1.9.1 Main primary UART interface ........................................................................................................ 24

1.9.2 Secondary auxiliary UART interface ............................................................................................. 27

1.9.3 Additional UART interface .............................................................................................................. 27

1.9.4 DDC (I2C) interface ........................................................................................................................... 28

1.10 ADC .............................................................................................................................................................. 28

1.11 General Purpose Input/Output (GPIO) .................................................................................................. 28

1.12 Reserved pins (RSVD) .............................................................................................................................. 29

2 Design-in ................................................................................................................................................ 30

2.1 Overview ......................................................................................................................................................30

2.2 Supply interfaces ...................................................................................................................................... 31

2.2.1 Module supply input (VCC) ............................................................................................................. 31

2.2.2 RTC supply (V_BCKP) ....................................................................................................................... 40

2.2.3 Interfaces supply output (V_INT) .................................................................................................. 41

2.3 System functions interfaces .................................................................................................................. 42

2.3.1 Module power-on (PWR_ON) .......................................................................................................... 42

2.3.2 Module reset (RESET_N) ................................................................................................................. 43

2.3.3 Voltage selection of interfaces (VSEL) ........................................................................................ 44

2.4 Antenna interface ..................................................................................................................................... 45

Page 4

SARA-N2 / N3 series - System integration manual

UBX-17005143 - R13 Contents Page 4 of 95

C1-Public

2.4.1 Cellular antenna RF interface (ANT) ............................................................................................. 45

2.4.2 Bluetooth antenna RF interface (ANT_BT) ................................................................................. 52

2.4.3 Antenna detection interface (ANT_DET)..................................................................................... 52

2.5 SIM interface .............................................................................................................................................. 55

2.6 Serial interfaces ........................................................................................................................................ 60

2.6.1 Main primary UART interface ........................................................................................................ 60

2.6.2 Secondary auxiliary UART interface ............................................................................................. 65

2.6.3 Additional UART interface .............................................................................................................. 66

2.6.4 DDC (I2C) interface ........................................................................................................................... 66

2.7 ADC .............................................................................................................................................................. 67

2.8 General Purpose Input/Output (GPIO) .................................................................................................. 68

2.9 Reserved pins (RSVD) .............................................................................................................................. 68

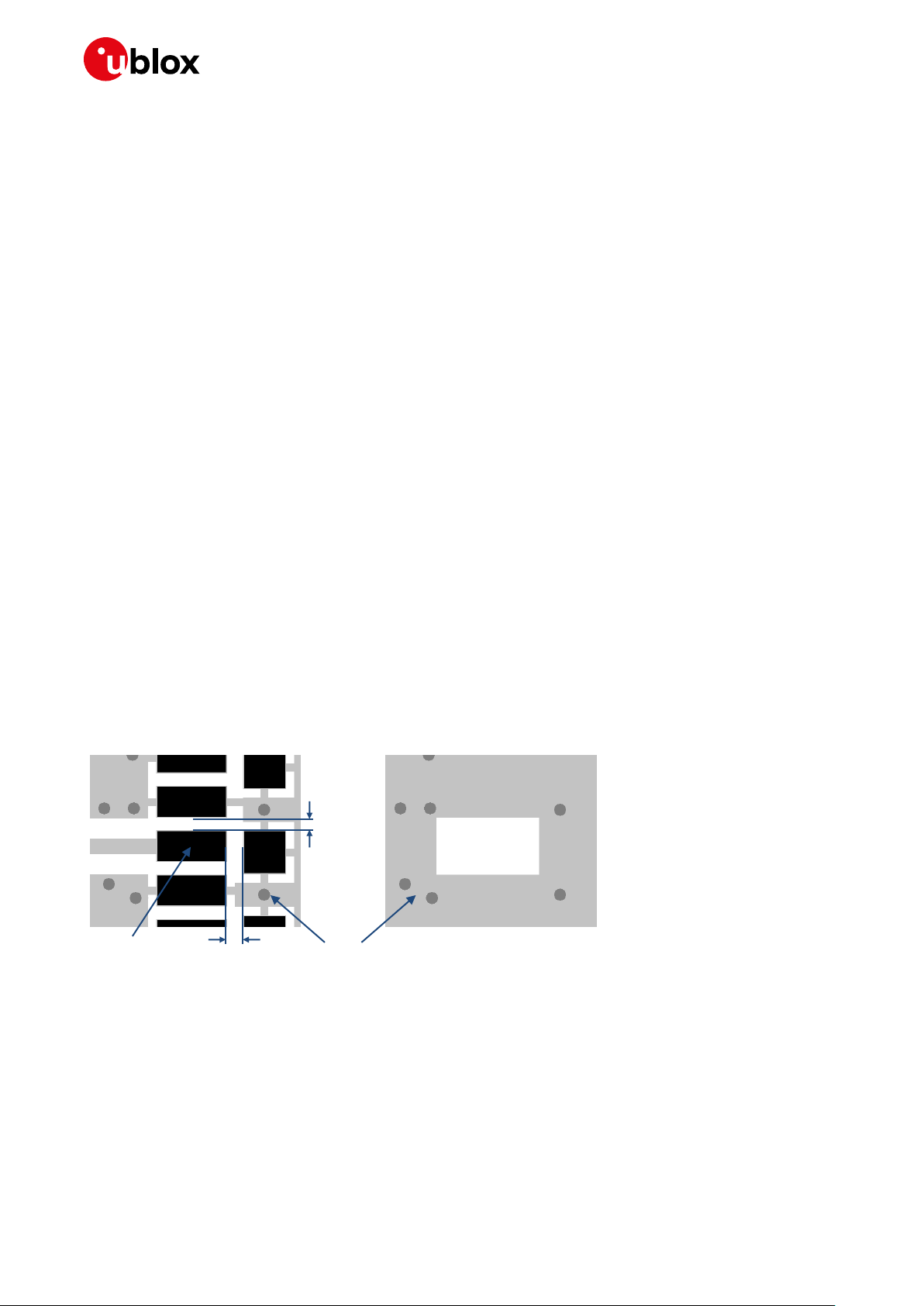

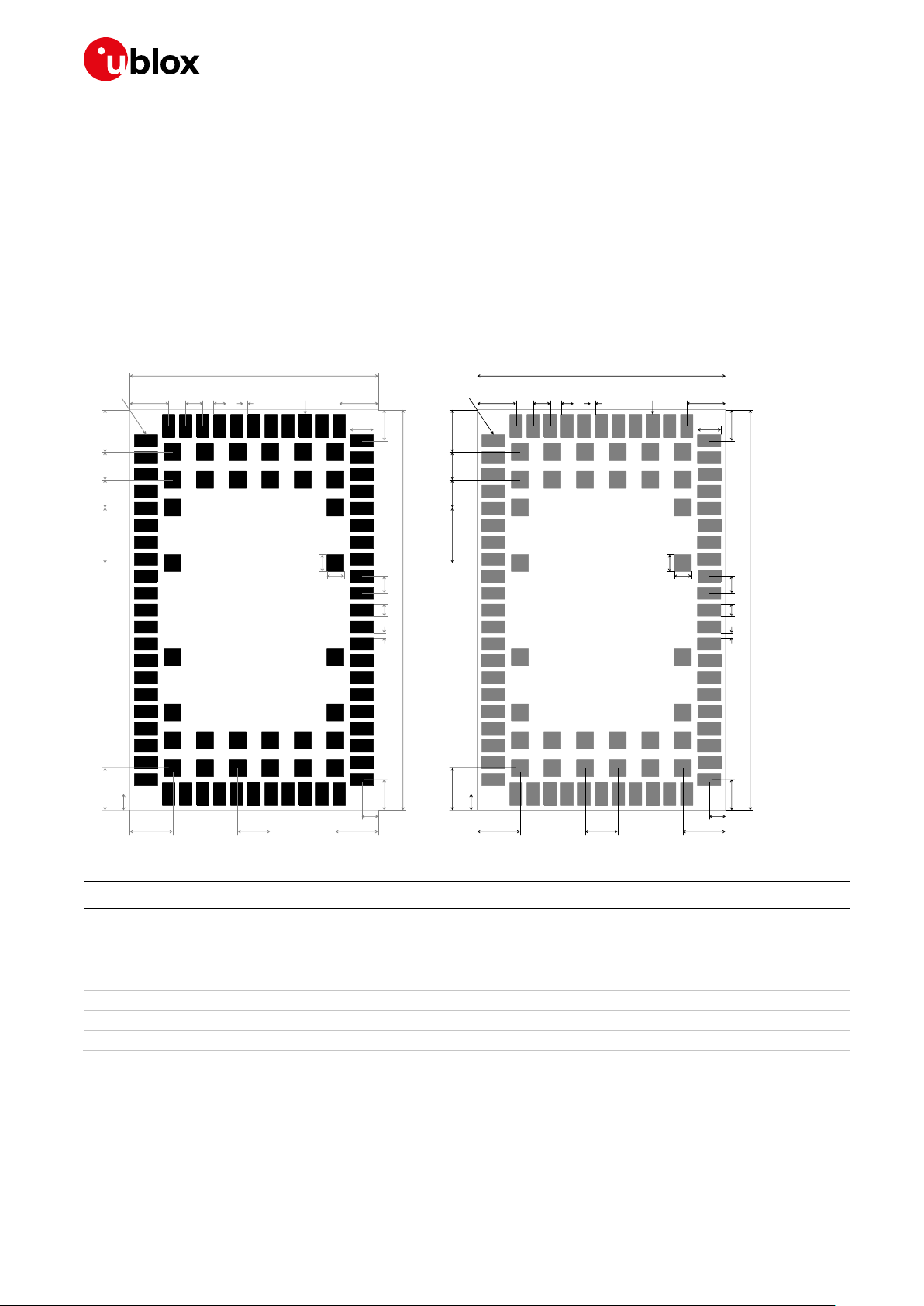

2.10 Module placement .................................................................................................................................... 69

2.11 Module footprint and paste mask ......................................................................................................... 70

2.12 Integration in devices intended for use in potentially explosive environments ............................ 71

2.12.1 General guidelines ............................................................................................................................. 71

2.12.2 Guidelines for VCC supply circuit design ..................................................................................... 72

2.12.3 Guidelines for antenna RF interface design ................................................................................ 74

2.13 Schematic for SARA-N2 / N3 series module integration .................................................................. 75

2.14 Design-in checklists ................................................................................................................................. 77

2.14.1 Schematic checklist ......................................................................................................................... 77

2.14.2 Layout checklist ................................................................................................................................ 77

2.14.3 Antenna checklist ............................................................................................................................. 77

3 Handling and soldering ...................................................................................................................... 78

3.1 Packaging, shipping, storage and moisture preconditioning .......................................................... 78

3.2 Handling ...................................................................................................................................................... 78

3.3 Soldering ..................................................................................................................................................... 79

3.3.1 Soldering paste ................................................................................................................................. 79

3.3.2 Reflow soldering ................................................................................................................................ 79

3.3.3 Optical inspection ............................................................................................................................ 80

3.3.4 Cleaning ............................................................................................................................................. 80

3.3.5 Repeated reflow soldering .............................................................................................................. 81

3.3.6 Wave soldering .................................................................................................................................. 81

3.3.7 Hand soldering .................................................................................................................................. 81

3.3.8 Rework ................................................................................................................................................ 81

3.3.9 Conformal coating ............................................................................................................................ 81

3.3.10 Casting ................................................................................................................................................ 82

3.3.11 Grounding metal covers .................................................................................................................. 82

3.3.12 Use of ultrasonic processes ........................................................................................................... 82

4 Approvals ............................................................................................................................................... 83

4.1 Approvals overview ................................................................................................................................... 83

4.2 European Conformance ........................................................................................................................... 84

Page 5

SARA-N2 / N3 series - System integration manual

UBX-17005143 - R13 Contents Page 5 of 95

C1-Public

4.3 ATEX / IECEx conformance ..................................................................................................................... 85

4.4 Chinese conformance .............................................................................................................................. 86

4.5 Taiwanese conformance ......................................................................................................................... 87

4.6 Australian conformance .......................................................................................................................... 87

5 Product testing ................................................................................................................................... 88

5.1 u-blox in-series production test ............................................................................................................. 88

5.2 Test parameters for OEM manufacturer ............................................................................................. 88

5.2.1 “Go/No go” tests for integrated devices ...................................................................................... 89

5.2.2 RF functional tests ........................................................................................................................... 89

Appendix ........................................................................................................................................................ 91

A Migration between SARA modules ................................................................................................ 91

B Glossary .................................................................................................................................................. 91

Related documents ................................................................................................................................... 93

Revision history .......................................................................................................................................... 94

Contact .......................................................................................................................................................... 95

Page 6

SARA-N2 / N3 series - System integration manual

UBX-17005143 - R13 System description Page 6 of 95

C1-Public

1 System description

1.1 Overview

SARA-N2 / N3 series modules are Narrow Band Internet of Things (NB-IoT) solutions in the miniature

SARA LGA form factor (26.0 x 16.0 mm, 96-pin), offering LTE Cat NB1 / NB2 data communication over

an extended operating temperature range of –40 to +85 °C, with extremely low power consumption.

SARA-N2 series include four variants supporting single-band LTE Cat NB1 data communication for

Europe, China, APAC and South America, plus a dual-band variant mainly designed for Europe.

SARA-N3 series offer multi-band LTE Cat NB2 data communication enabling multi-regional coverage,

supporting several new functionalities for NB-IoT products, including features like TCP, MQTT,

MQTT-SN, DTLS, SSL/TLS, LwM2M, HTTP(S) and many others.

SARA-N2 / N3 series modules are ideally suited to battery-powered IoT applications characterized by

occasional communications of small amounts of data.

The modules are the optimal choice for IoT devices designed to operate in locations with very limited

coverage and requiring low energy consumption to permit a very long operating life with the primary

batteries. Examples of applications include and are not limited to: smart grids, smart metering,

telematics, street lighting, environmental monitoring and control, security and asset tracking.

Table 1 describes a summary of interfaces and features provided by SARA-N2 / N3 series modules.

Module

Region

Cellular RAT

Interfaces

Features

Grade

3GPP release baseline 3GPP LTE Category LTE FDD bands UARTs USB

DDC (I2C) USIM

ADCs

GPIOs Antenna supervisor Power Save Mode eDRX

Bluetooth 4.2 (BR/EDR and BLE) Embedded TCP/UDP stack Embedded CoAP

, MQTT

, MQTT

-SN

Embedded HTTP, FTP, PPP, DNS Embedded

TLS, DTLS

IPv4

IPv4 / IPv6 LwM2M

Device Management

Last gasp FW update over AT (FOAT) FW update over the air (FOTA) Standard Professional Automotive

SARA-N200

Europe

APAC

13

NB1

8 ●

● ● ● ●

●

1

●

2

● ● ● ●

SARA-N201

APAC

13

NB1

5 ●

● ● ● ●

●

1

●

2

● ● ● ●

SARA-N210

Europe

13

NB1

20 ●

● ● ● ●

●

1

●

2

● ● ● ●

SARA-N211

Europe

13

NB1

8,20

● ● ● ● ●

●

1

●

2

● ● ● ●

SARA-N280

S.America

APAC

13

NB1

28 ●

● ● ● ●

●

1

●

2

● ● ● ●

SARA-N300

China

14

NB2

3,5,8

● ○ ● ● ● ● ● ● ○ ●

●3 ● ● ● ● ● ● ● ●

SARA-N310

Global

14

NB2

3,5,8

20,28,★

● ○ ● ● ● ● ● ● ○ ● ● ●

● ● ● ● ● ● ● ●

● = Supported ○ = Available in future FW ★ = Additional bands (1, 2, 4, 12, 13, 18, 19, 26, 66, 71, 85) available in future FW

Table 1: SARA-N2 / N3 series characteristics summary

1

Only embedded UDP stack is supported

2

Only embedded CoAP is supported

3

Only embedded CoAP and MQTT-SN are supported

Page 7

SARA-N2 / N3 series - System integration manual

UBX-17005143 - R13 System description Page 7 of 95

C1-Public

Table 2 summarizes cellular radio access technology characteristics of SARA-N2 / N3 series modules.

Item

SARA-N2 series

SARA-N3 series

Protocol stack

3GPP release 13

3GPP release 144

Radio Access Technology

LTE Category NB1

Half-Duplex

Single-tone

Single HARQ process

eDRX

Power Saving Mode

Coverage enhancement A and B

LTE Category NB2

Half-Duplex

Multi-tone

Two HARQ process

eDRX

Power Saving Mode

Coverage enhancement A and B

Operating band

SARA-N200:

• Band 8 (900 MHz)

SARA-N201:

• Band 5 (850 MHz)

SARA-N210:

• Band 20 (800 MHz)

SARA-N211:

• Band 8 (900 MHz)

• Band 20 (800 MHz)

SARA-N280:

• Band 28 (700 MHz)

SARA-N300:

• Band 5 (850 MHz)

• Band 8 (900 MHz)

• Band 20 (800 MHz)

SARA-N3105:

• Band 3 (1800 MHz)

• Band 5 (850 MHz)

• Band 8 (900 MHz)

• Band 20 (800 MHz)

• Band 28 (700 MHz)

Power Class

Class 3 (23 dBm)6

Class 3 (23 dBm)6

Deployment mode

In-Band

Guard-Band

Standalone

In-Band

Guard-Band

Standalone

Data rate

Up to 31.25 kb/s UL

Up to 27.2 kb/s DL

Up to 140 kb/s UL

Up to 125 kb/s DL

Protocols and other

UDP IP

CoAP

TCP IP / UDP IP

CoAP

DTLS

MQTT7

MQTT-SN

LwM2M Device Management Objects7

HTTP/HTTPS

FTP

PPP/DNS

SSL, TLS

Radio Policy Manager7

SIM provisioning7

Table 2: SARA-N2 / N3 series NB-IoT characteristics summary

4

Key subset of features

5

Additional bands (1, 2, 4, 12, 13, 18, 19, 26, 66, 71, 85) available in future FW versions

6

Configurable to other Power Class by AT command

7

Not supported by SARA-N300-00B

Page 8

SARA-N2 / N3 series - System integration manual

UBX-17005143 - R13 System description Page 8 of 95

C1-Public

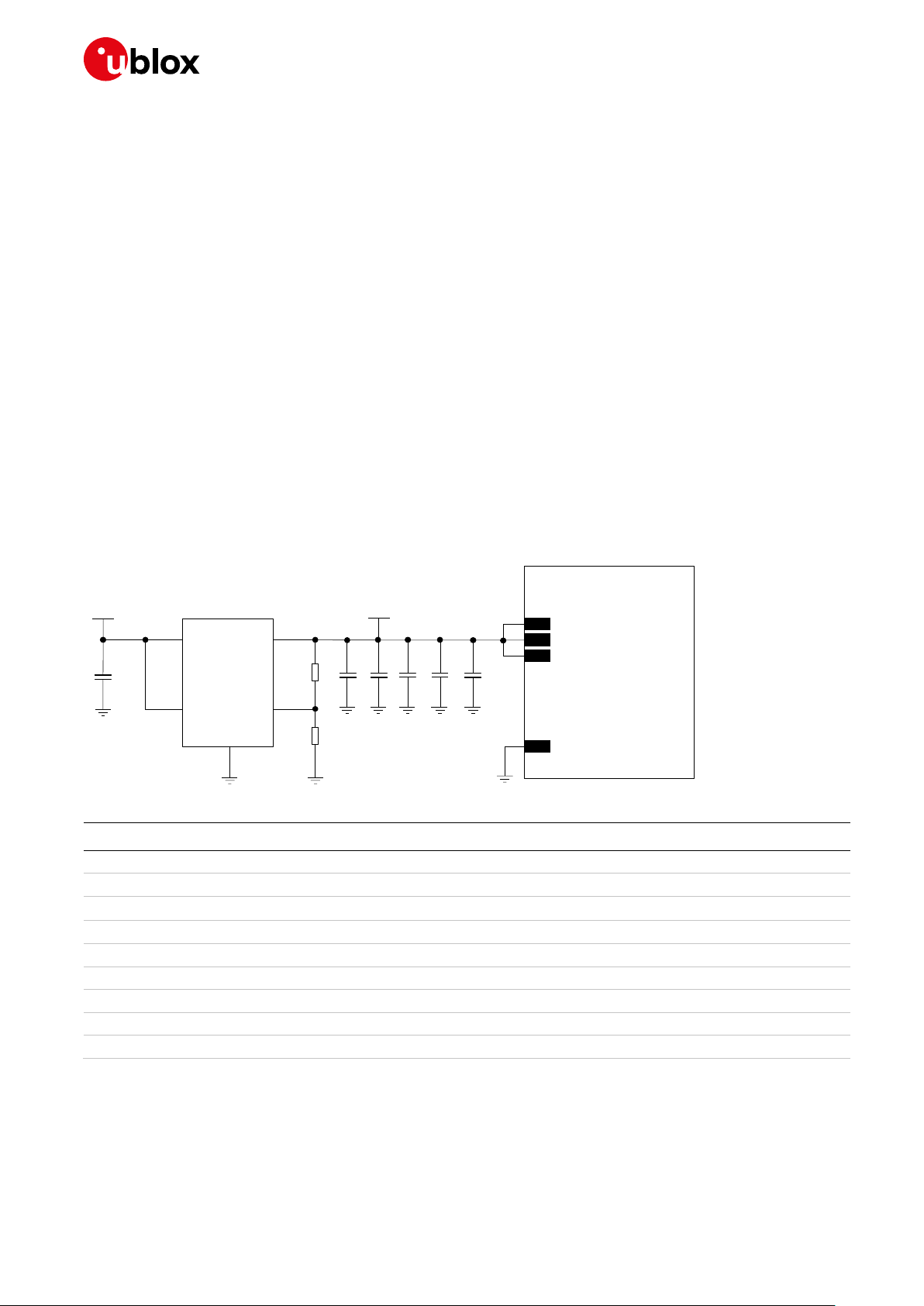

1.2 Architecture

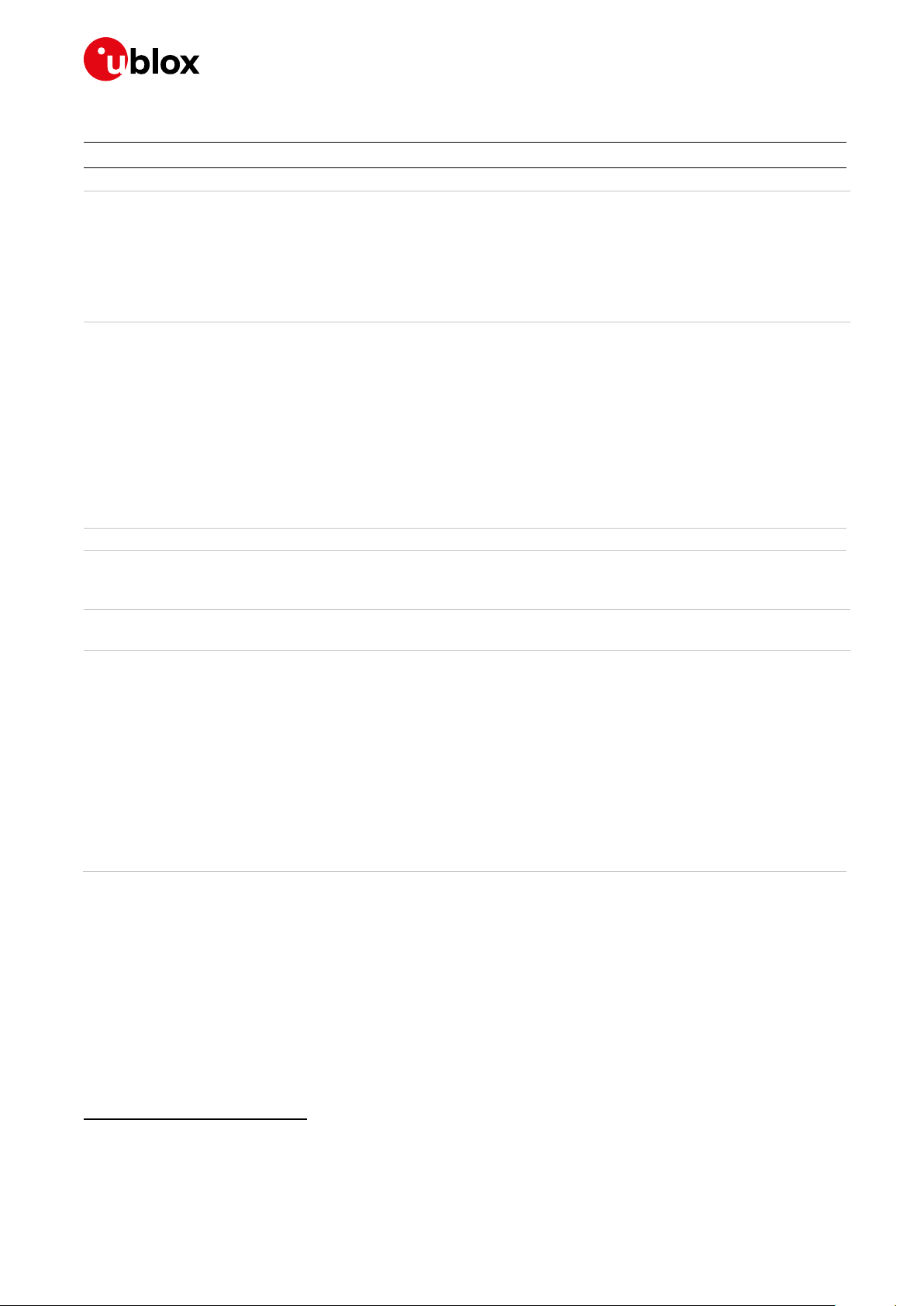

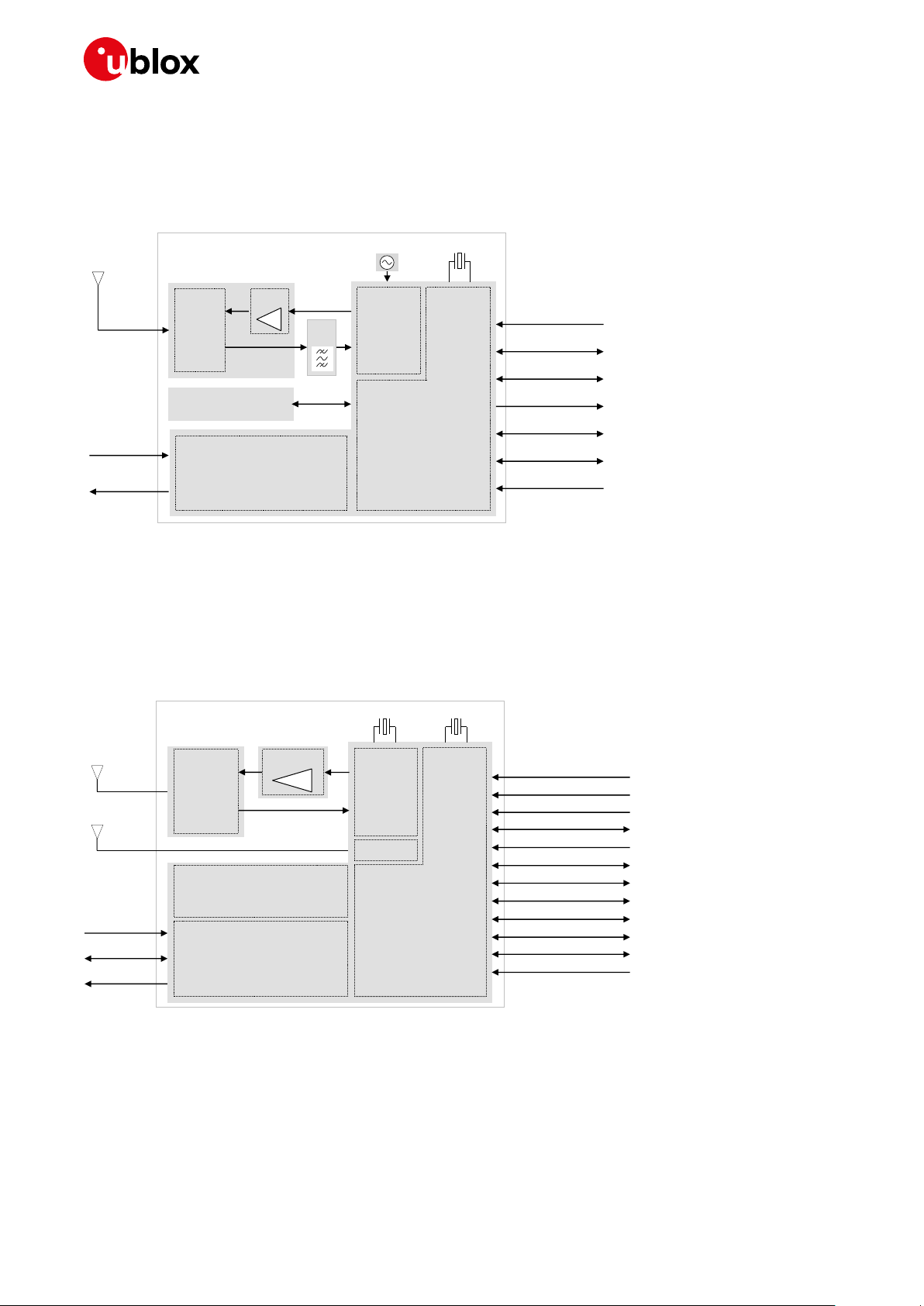

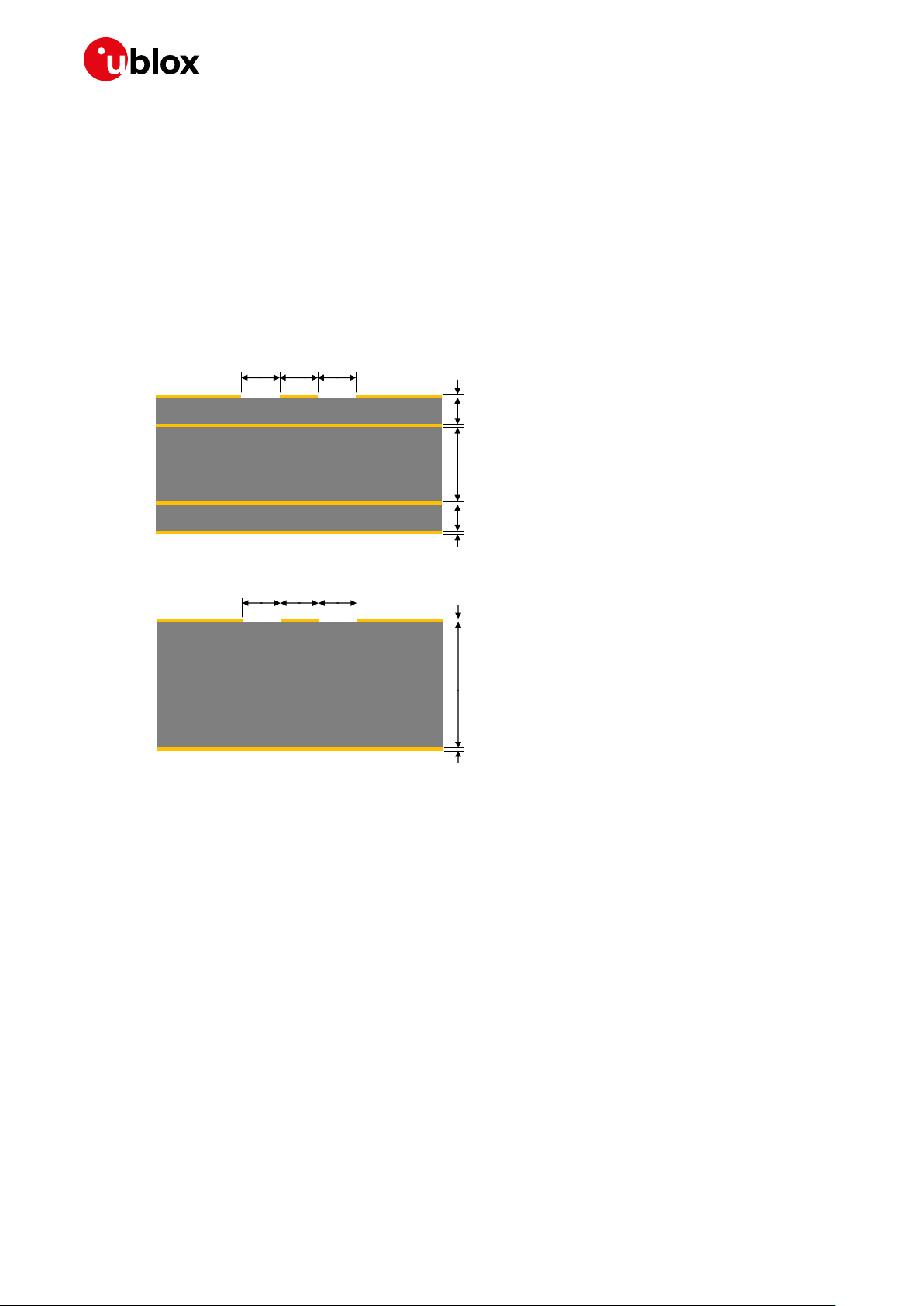

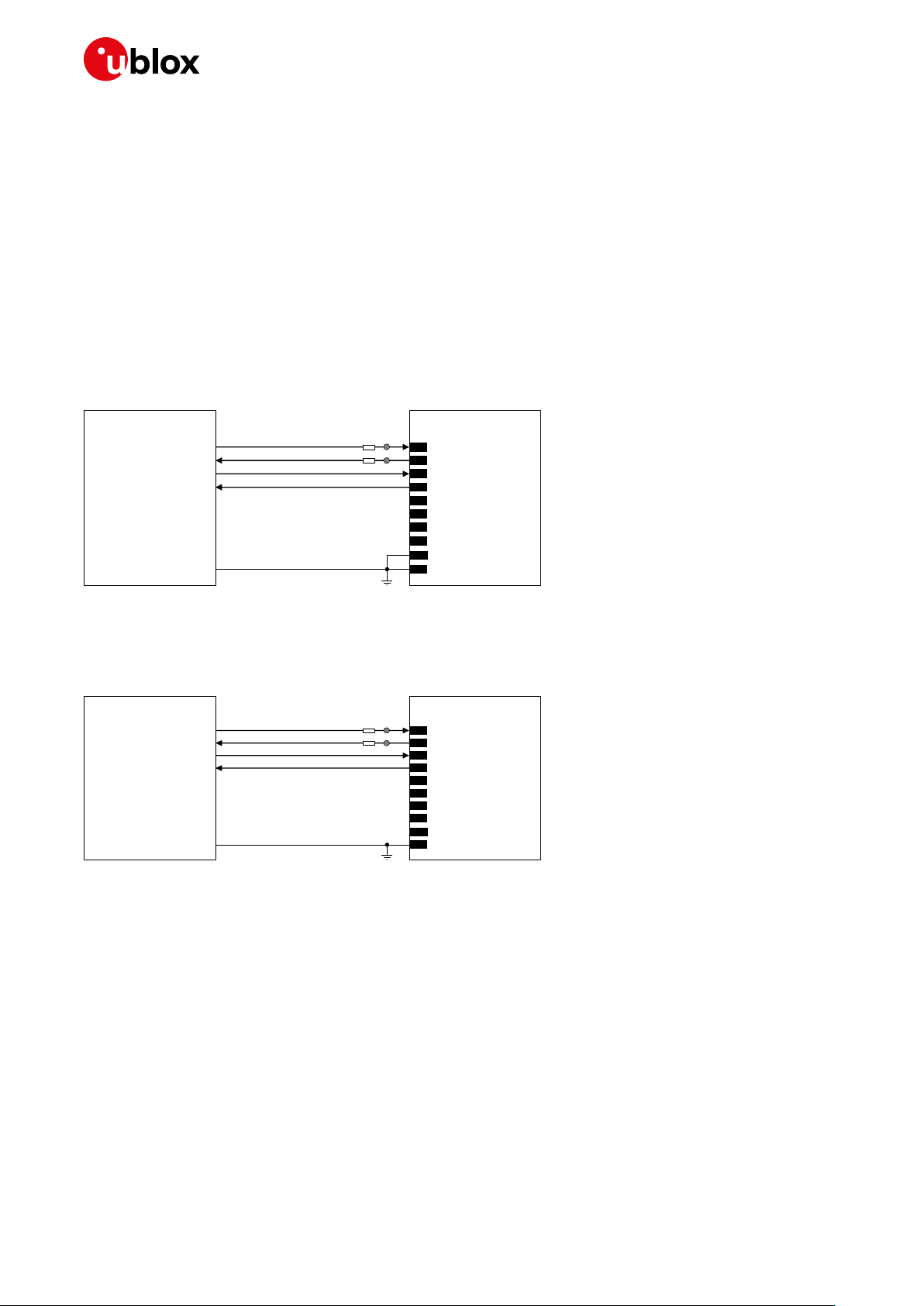

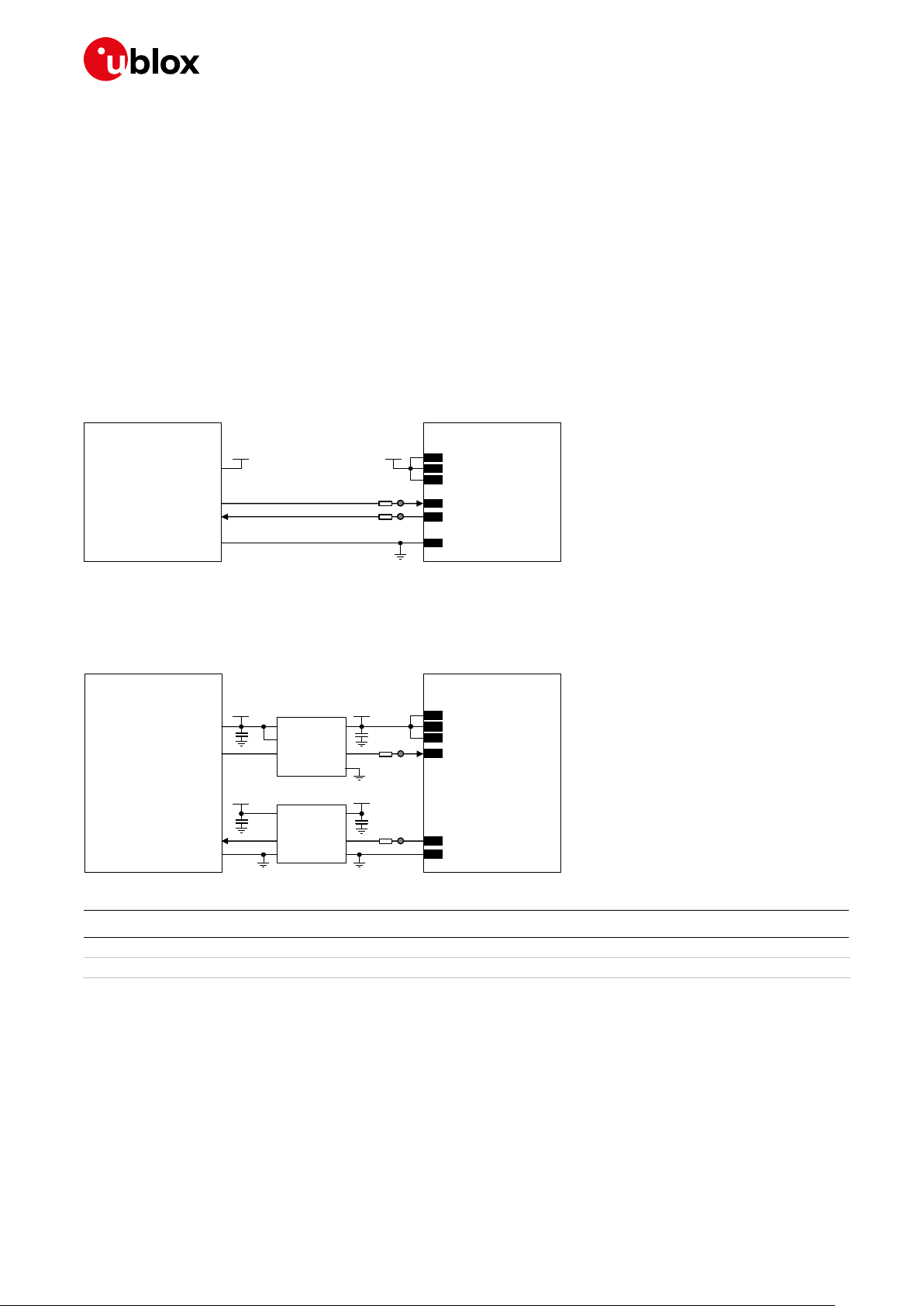

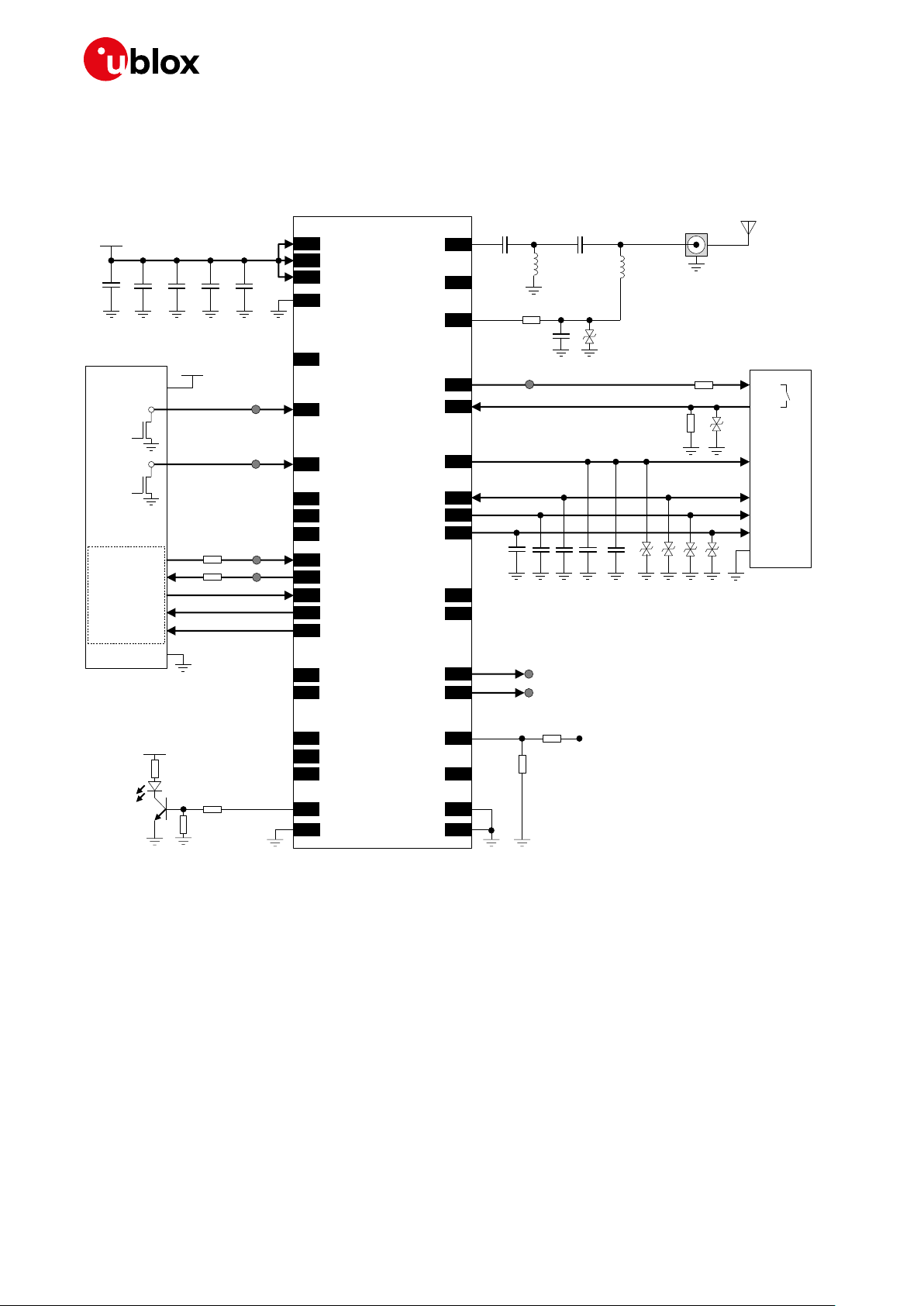

Figure 1 and Figure 2 summarize the architecture of SARA-N2 series and SARA-N3 series modules

respectively, describing the internal blocks of the modules, consisting of the RF, Baseband and Power

Management main sections, and the available interfaces.

Memory

V_INT

38.4 MHz

32.768 kHz

RF

transceiver

Power

management

Baseband

ANT

SAW

Filter

Switch

PA

VCC (supply)

DDC (I2C)

UART

SIM

Secondary UART

RESET_N

GPIO

Antenna detection

Figure 1: SARA-N2 series modules block diagram

☞ The “02" product version of SARA-N2 series modules do not support the following interfaces,

which should not be driven by external devices:

o Antenna detection

o DDC (I2C) interface

26 MHz

32.768 kHz

RF

transceiver

Baseband

ANT

Switch

PA

V_BCKP (RTC)

V_INT (I/O)

Power

management

VCC (supply)

Memory

Reset

Power-on

SIM

SIM card detection

UART (Primary main)

UART (Secondary auxiliary)

DDC (I2C)

ADC

GPIOs

Antenna detection

VSEL (I/O voltage selection)

UART (Flashing & tracing)

BT

ANT_BT

Figure 2: SARA-N3 series block diagram

☞ The “00" product version of SARA-N3 series modules do not support the following interfaces,

which should not be driven by external devices:

o Bluetooth interface (ANT_BT)

o Secondary auxiliary UART interface (UART AUX)

o DDC (I2C) interface

Page 9

SARA-N2 / N3 series - System integration manual

UBX-17005143 - R13 System description Page 9 of 95

C1-Public

The RF section is composed of the following main elements:

• LTE power amplifier, which amplifies the signals modulated by the RF transceiver

• RF switches, which connect the antenna input/output pin (ANT) of the module to the suitable

RX/TX path

• RX low-loss filters

• 38.4 MHz (SARA-N2 series) / 26.0 MHz (SARA-N3 series) crystal oscillator for the clock reference

in active-mode and connected-mode

The Baseband and Power Management section is composed of the following main elements:

• Baseband processor

• Flash memory

• Voltage regulators to derive all the system supply voltages from the module supply VCC

• Circuit for the RTC clock reference in low power deep-sleep

1.3 Pin-out

Table 3 lists the pin-out of the SARA-N2 / N3 series modules, with pins grouped by function

Function

Pin name

Modules

Pin No

I/O

Description

Remarks

Power

VCC

All

51,52,53

I

Module supply

input

All VCC pins must be connected to external supply.

VCC supply circuit affects the RF performance and

compliance of the device integrating the module with

applicable required certification schemes.

See section 1.5.1 for description and requirements.

See section 2.2.1 for external circuit design-in.

GND

All

1,3,5,14,

20,22,30,

32,43,50,

54,55,57,

58,60,61,

63-96

N/A

Ground

All GND pins have to be connected to external ground.

External ground connection affects the RF and thermal

performance of the device.

See section 2.2.1.8 for external circuit design-in.

GND

SARA-N2

21,59

N/A

Ground

All GND pins have to be connected to external ground.

External ground connection affects the RF and thermal

performance of the device.

See section 2.2.1.8 for external circuit design-in.

V_BCKP

SARA-N3

2

I/O

RTC supply

input/output

See section 1.5.2 for functional description.

See section 2.2.2 for external circuit design-in.

V_INT

All 4 O

Generic Digital

Interfaces supply

output

SARA-N2 series modules:

• Supply output generated by internal linear LDO

regulator when the radio is on

• Voltage domain of I2C and GPIOs

• V_INT = 1.8 V (typical)

SARA-N3 series modules:

• Supply output generated by internal linear LDO

regulator when the module is on

• Voltage domain of UARTs, I2C and GPIOs

• V_INT = 1.8 V (typ.), if VSEL is connected to GND

• V_INT = 2.8 V (typ.), if VSEL is unconnected

Provide a test point on this pin for diagnostic purpose.

See section 1.5.3 for functional description.

See section 2.2.3 for external circuit design-in.

Page 10

SARA-N2 / N3 series - System integration manual

UBX-17005143 - R13 System description Page 10 of 95

C1-Public

Function

Pin name

Modules

Pin No

I/O

Description

Remarks

System

PWR_ON

SARA-N3

15 I Power-on input

Internal pull-up.

Provide a test point on this pin for diagnostic purpose.

See section 1.6.1, 1.6.2 for functional description.

See section 2.3.1 for external circuit design-in.

RESET_N

All

18 I HW reset input

Internal pull-up.

Provide a test point on this pin for diagnostic purpose.

See section 1.6.3 for functional description.

See section 2.3.2 for external circuit design-in.

VSEL

SARA-N3

21 I Voltage selection

Input to select the operating voltage of the V_INT

supply output, voltage domain of UARTs, I2C, GPIOs.

V_INT = 1.8 V (typical), if VSEL pin is connected to GND

V_INT = 2.8 V (typical), if VSEL pin is unconnected

See section 1.6.4 for functional description.

See section 2.3.3 for external circuit design-in.

Antenna

ANT

All

56

I/O

Cellular RF

input/output

50 nominal characteristic impedance.

Antenna circuit affects the RF performance and

compliance of the device integrating the module with

applicable required certification schemes.

See section 1.7.1 for description and requirements.

See section 2.4.1 for external circuit design-in.

ANT_BT

SARA-N3

59

I/O

Bluetooth RF

input/output

50 nominal characteristic impedance.

See section 1.7.2 for description and requirements.

See section 2.4.2 for external circuit design-in.

ANT_DET

All

62

I

Input for antenna

detection

ANT_DET not supported by SARA-N2 modules.

ADC input usable for antenna detection function.

See section 1.7.3 for functional description.

See section 2.4.3 for external circuit design-in.

SIM

VSIM

All

41

O

SIM supply

output

Supply output for external SIM / UICC

See section 1.8 for functional description.

See section 2.5 for external circuit design-in.

SIM_IO

All

39

I/O

SIM data

Data line for communication with external SIM,

operating at VSIM voltage level.

Internal 4.7 k pull-up to VSIM.

See section 1.8 for functional description.

See section 2.5 for external circuit design-in.

SIM_CLK

All

38 O SIM clock

Clock for external SIM, operating at VSIM voltage level.

See section 1.8 for functional description.

See section 2.5 for external circuit design-in.

SIM_RST

All

40 O SIM reset

Reset for external SIM, operating at VSIM voltage level

See section 1.8 for functional description.

See section 2.5 for external circuit design-in.

UART

(main)

RXD

All

13 O Data output

Circuit 104 (RXD) in ITU-T V.24

SARA-N2 series modules:

• Supporting AT communication, FOAT and FW

upgrade via dedicated tool

• VCC voltage level

SARA-N3 series modules:

• Supporting AT communication and FOAT

• V_INT voltage level

Provide a test point on this pin for diagnostic purpose.

See section 1.9.1 for functional description.

See section 2.6.1 for external circuit design-in.

Page 11

SARA-N2 / N3 series - System integration manual

UBX-17005143 - R13 System description Page 11 of 95

C1-Public

Function

Pin name

Modules

Pin No

I/O

Description

Remarks

TXD

All

12 I Data input

Circuit 103 (TXD) in ITU-T V.24

SARA-N2 series modules:

• Supporting AT communication, FOAT and FW

upgrade via dedicated tool

• VCC voltage level, without internal pull-up/down

SARA-N3 series modules:

• Supporting AT communication and FOAT

• V_INT voltage level, with internal pull-up

Provide a test point on this pin for diagnostic purpose.

See section 1.9.1 for functional description.

See section 2.6.1 for external circuit design-in.

CTS

All

11

O

Clear To Send

output

Circuit 106 (CTS) in ITU-T V.24

SARA-N2 series modules:

• HW flow control not supported by “02” versions

• Configurable as RI and other

• VCC voltage level

SARA-N3 series modules:

• HW flow control output

• Configurable as RI and other

• V_INT voltage level

See section 1.9.1 and 1.11 for functional description.

See section 2.6.1 for external circuit design-in.

RTS

All

10

I

Request To Send

input

Circuit 105 (RTS) in ITU-T V.24

SARA-N2 series modules:

• HW flow control not supported by “02” versions

• VCC voltage level, with internal pull-up

SARA-N3 series modules:

• HW flow control input

• V_INT voltage level, with internal pull-up by default

See section 1.9.1 and 1.11 for functional description.

See section 2.6.1 for external circuit design-in.

RI

SARA-N3

7 O Ring Indicator

Circuit 125 (RI) in ITU-T V.24, at V_INT voltage level

See section 1.9.1 and 1.11 for functional description.

See section 2.6.1 for external circuit design-in.

DSR

SARA-N3

6 O Data Set Ready

Circuit 107 (DSR) in ITU-T V.24, at V_INT voltage level

DSR not supported by ‘00’ product versions.

See section 1.9.1 for functional description.

See section 2.6.1 for external circuit design-in.

DCD

SARA-N3

8

O

Data Carrier

Detect

Circuit 109 (DCD) in ITU-T V.24, at V_INT voltage level

DCD not supported by ‘00’ product versions.

See section 1.9.1 for functional description.

See section 2.6.1 for external circuit design-in.

DTR

SARA-N3

9

I

Data Terminal

Ready

Circuit 108/2 (DTR) in ITU-T V.24, at V_INT voltage level

DTR not supported by ‘00’ product versions.

See section 1.9.1 for functional description.

See section 2.6.1 for external circuit design-in.

UART

(auxiliary)

RXD_AUX

SARA-N3

19 O Data output

Circuit 104 (RXD) in ITU-T V.24, at V_INT voltage level

UART AUX not supported by ‘00’ product versions.

See section 1.9.2 for functional description.

See section 2.6.2 for external circuit design-in.

TXD_AUX

SARA-N3

17 I Data input

Circuit 103 (TXD) in ITU-T V.24, at V_INT voltage level

UART AUX not supported by ‘00’ product versions.

See section 1.9.2 for functional description.

See section 2.6.2 for external circuit design-in.

Page 12

SARA-N2 / N3 series - System integration manual

UBX-17005143 - R13 System description Page 12 of 95

C1-Public

Function

Pin name

Modules

Pin No

I/O

Description

Remarks

UART

(additional)

RXD_FT

SARA-N3

28 O Data output

Circuit 104 (RXD) in ITU-T V.24, at V_INT voltage level.

Supporting FW update via u-blox EasyFlash tool and

Trace log.

Provide a test point for FW upgrade and diagnostic.

See section 1.9.3 for functional description.

See section 2.6.3 for external circuit design-in.

TXD_FT

SARA-N3

29 I Data input

Circuit 103 (TXD) in ITU-T V.24, at V_INT voltage level.

Supporting FW update via u-blox EasyFlash tool and

Trace log.

Provide a test point for FW upgrade and diagnostic.

See section 1.9.3 for functional description.

See section 2.6.3 for external circuit design-in.

GPIO1

SARA-N2

16 O Data output

Circuit 104 (RXD) in ITU-T V.24, at V_INT voltage level.

Supporting Trace diagnostic logging.

Provide a test point on this pin for diagnostic.

See sections 1.9.3 and 1.11 for functional description.

See sections 2.6.3 and 2.8 for external circuit design-in.

DDC

SCL

All

27 O I2C bus clock line

Open drain, at V_INT voltage level.

I2C not supported by SARA-N2 "02" versions.

I2C not supported by SARA-N3 "00" versions.

See section 1.9.4 for functional description.

See section 2.6.4 for external circuit design-in.

SDA

All

26

I/O

I2C bus data line

Open drain, at V_INT voltage level.

I2C not supported by SARA-N2 "02" versions.

I2C not supported by SARA-N3 "00" versions.

See section 1.9.4 for functional description.

See section 2.6.4 for external circuit design-in.

GPIO

GPIO1

SARA-N3

16

I/O

GPIO

GPIO, at V_INT voltage level.

See section 1.11 for functional description.

See section 2.8 for external circuit design-in.

GPIO2

SARA-N2

24

I/O

GPIO

GPIO2 not supported by "02" product versions.

SARA-N3

23

I/O

GPIO

GPIO, at V_INT voltage level.

See section 1.11 for functional description.

See section 2.8 for external circuit design-in.

GPIO3

SARA-N3

24

I/O

GPIO

GPIO, at V_INT voltage level.

See section 1.11 for functional description.

See section 2.8 for external circuit design-in.

GPIO4

SARA-N3

25

I/O

GPIO

GPIO, at V_INT voltage level.

See section 1.11 for functional description.

See section 2.8 for external circuit design-in.

GPIO5

SARA-N3

42

I/O

GPIO

GPIO, at V_INT voltage level.

See section 1.11 for functional description.

See section 2.8 for external circuit design-in.

ADC

ADC1

SARA-N3

33 I ADC input

See section 1.10 for functional description.

See section 2.7 for external circuit design-in.

Reserved

RSVD

SARA-N2

33

N/A

RESERVED pin

This pin can be connected to GND.

See sections 1.12 and 2.9.

RSVD

SARA-N2

2, 6-9,

15,17,19,

23, 25,

28,29,42

N/A

RESERVED pin

Leave unconnected.

See sections 1.12 and 2.9.

RSVD

All

31,34-37,

44-49

N/A

RESERVED pin

Leave unconnected.

See sections 1.12 and 2.9.

Table 3: SARA-N2 / N3 series modules pin definition, grouped by function

Page 13

SARA-N2 / N3 series - System integration manual

UBX-17005143 - R13 System description Page 13 of 95

C1-Public

1.4 Operating modes

SARA-N2 / N3 series modules have several operating modes as defined in Table 4.

General Status

Operating Mode

Definition

Power-down

Not-Powered mode

VCC supply not present or below the operating range. The module is switched off.

Power-Off mode 8

VCC supply within the operating range, with the module switched off.

Normal operation

Deep-sleep mode

Module processor runs with internal 32 kHz reference.

Lowest possible power mode, with current consumption in the ~µA range.

Sleep mode 8

Module processor runs with internal 32 kHz reference.

PSRAM does not power down, with current consumption in the ~100 µA range.

Idle mode 8

Module processor runs with internal 32 kHz reference.

Low power mode, with current consumption in the ~mA range.

Active mode

Module processor runs with internal 38.4 MHz / 26 MHz reference.

Data transmission or reception not in progress.

Connected mode

Module processor runs with internal 38.4 MHz / 26 MHz reference.

Data transmission or reception in progress.

Table 4: SARA-N2 / N3 series modules’ operating modes definition

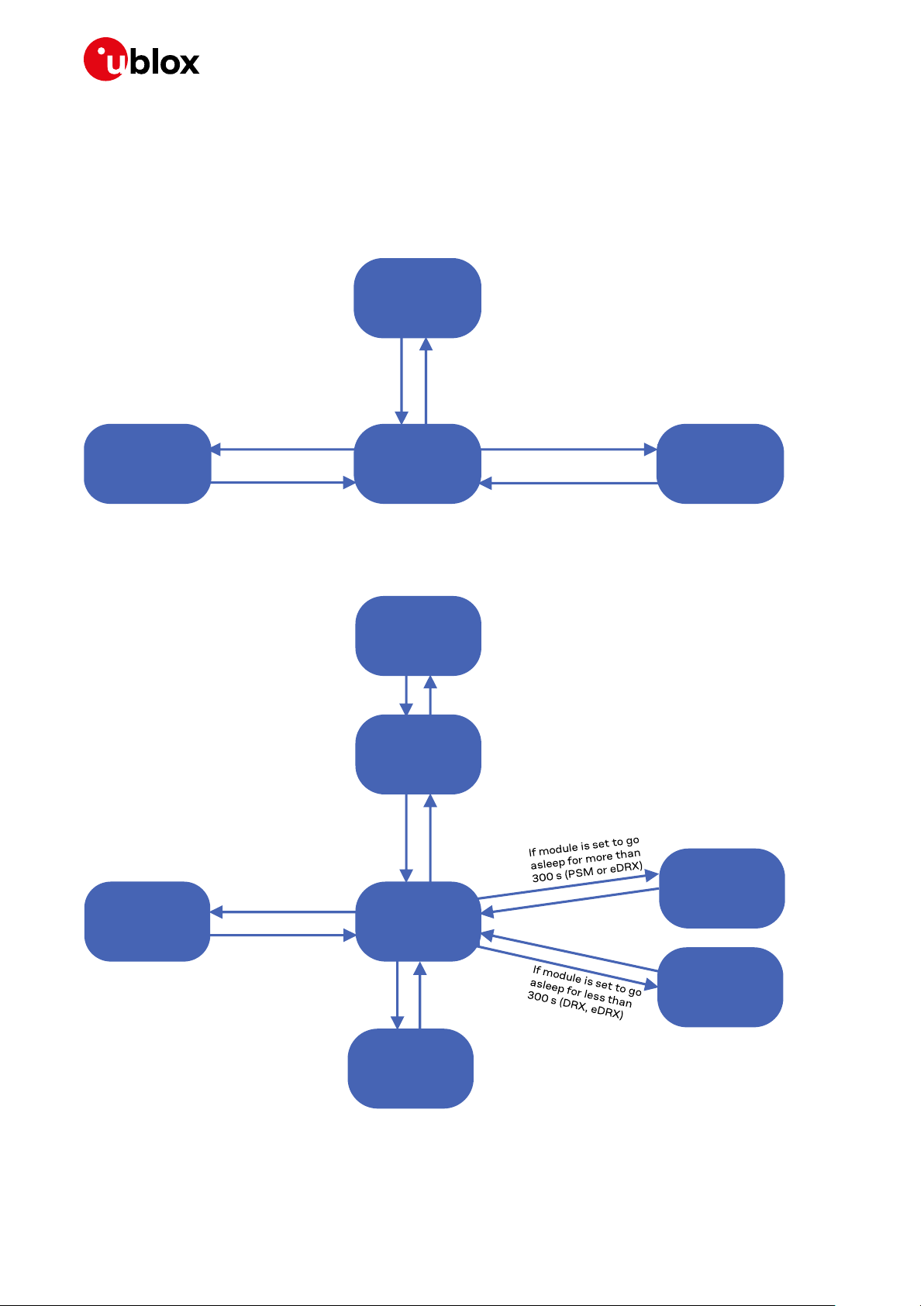

Figure 3 and Figure 4 illustrate the transition between the different operating modes.

The initial operating mode of SARA-N2 / N3 series modules is the one with VCC supply not present or

below the operating range: the modules are switched off in non-powered mode.

Once a valid VCC supply is applied to the SARA-N2 modules, this event triggers the switch on routine

of the modules that subsequently enter the active mode.

On the other hand, once a valid VCC supply is applied to the SARA-N3 series modules, they remain

switched off in power-off mode. Then the proper toggling of the PWR_ON input line is necessary to

trigger the switch on routine of the modules that subsequently enter the active mode.

SARA-N2 / N3 series modules are fully ready to operate when in active mode.

Then, the SARA-N2 series modules switch from active mode to deep sleep mode whenever possible,

entering the lowest possible power mode, with current consumption in the ~µA range. The UART

interface is still completely functional and the module can accept and respond to any AT command,

entering back into the active mode as in case of network paging reception and as in case of expiration

of the “Periodic Update Timer” according to the Power Saving Mode defined in 3GPP release 13.

Instead, the SARA-N3 series modules switch from active mode to the idle mode whenever possible,

entering the low power mode, if enabled by a dedicated AT command, with current consumption in

the ~mA range. The UART interface is still completely functional and the module can accept and

respond to any AT command, entering back into the active mode as in case of network paging

reception.

According to AT+NVSETPM setting, the SARA-N3 series can switch between modes. It can switch

from active mode to sleep mode if the eDRX feature is enabled and set to let the module go to sleep

for time periods of less than 300 s. It can switch from active mode to deep sleep mode if the Power

Saving Mode is enabled or if the eDRX feature is enabled and set to let the module go to sleep for time

periods of more than 300 s, thus entering the lowest possible power mode, with current consumption

in the ~µA range (Power Saving Mode and eDRX are defined in 3GPP release 13). In both sleep mode

and deep sleep mode, the UART interface is not functional: a wake up event, consisting for example

in proper toggling of the PWR_ON line or in expiration of the “Periodic Update Timer”, is necessary to

trigger the wake up routine of the modules that subsequently enter back into the active mode.

☞ See the SARA-N2 / SARA-N3 series AT commands manual [4] for the +NVSETPM AT command

and for configuration of PSM and eDRX features.

8

Not available in SARA-N2 series modules

Page 14

SARA-N2 / N3 series - System integration manual

UBX-17005143 - R13 System description Page 14 of 95

C1-Public

SARA-N2 / N3 series modules switch from active mode to connected mode upon RF transmission or

reception operations turning back to active mode once RF operations are terminated or suspended.

The switch off routine of the SARA-N3 series modules can be properly triggered by the dedicated AT

command or by proper toggling of the PWR_ON line. The modules subsequently enter the power-off

mode and then they enter the non-powered mode by removing the VCC supply.

Switch ON:

• Apply VCC

If there is no activity for

a defined time interval

• Network paging

• Data received over UART

• Expiration of Periodic Update Timer

Incoming/outgoing data

or other dedicated device

network communication

No RF Tx/Rx in progress

Not

powered

ActiveConnected

Deep

Sleep

Switch OFF:

• Remove VCC

Figure 3: SARA-N2 series modules’ operating modes transitions

• Using PWR_ON

• Expiration of timer

Incoming/outgoing data

or other dedicated device

network communication

No RF Tx/Rx in progress

Remove VCC

Switch ON:

• PWR_ON

Not

powered

Power off

ActiveConnected

Deep

sleep

Switch OFF:

• AT+CPWROFF

• PWR_ON

Apply VCC

If low power mode is enabled,

if AT inactivity timer is expired

Idle

• Network paging

• Data received

over UART

Sleep

Figure 4: SARA-N3 series modules’ operating modes transitions

Page 15

SARA-N2 / N3 series - System integration manual

UBX-17005143 - R13 System description Page 15 of 95

C1-Public

1.5 Supply interfaces

1.5.1 Module supply input (VCC)

The modules must be supplied via all the three VCC pins that represent the module power supply

input.

The VCC pins are internally connected to the RF power amplifier and to the integrated Power

Management Unit: all supply voltages needed by the module are generated from the VCC supply by

integrated voltage regulators, including V_INT (digital interfaces supply) and VSIM (SIM card supply).

During operation, the current drawn by the SARA-N2 / N3 series modules through the VCC pins can

vary by several orders of magnitude. This ranges from the high peak of current consumption during

data transmission at maximum power level in connected mode, to the low current consumption during

deep-sleep mode (as described in section 1.5.1.2).

1.5.1.1 VCC supply requirements

Table 5 summarizes the requirements for the VCC module supply. See section 2.2.1 for all the

suggestions to properly design a VCC supply circuit compliant to the requirements listed in Table 5.

⚠ VCC supply circuit design may affect the RF compliance of the device integrating SARA-N2 / N3

series modules with applicable required certification schemes. Compliance is not guaranteed if

the VCC requirements summarized in the Table 5 are not fulfilled.

Item

Requirement

Remark

VCC nominal voltage

Within VCC normal operating range:

• SARA-N2: 3.1 V min. / 4.0 V max

• SARA-N3: 3.2 V min. / 4.2 V max

The module cannot be switched on if VCC voltage

value is below the normal operating range minimum

limit.

Ensure that the input voltage at VCC pins is above

the minimum limit of the normal operating range for

at least more than 3 s after the module switch-on.

VCC voltage during

normal operation

Within VCC extended operating range:

• SARA-N2: 2.75 V min. / 4.2 V max

• SARA-N3: 2.6 V min. / 4.2 V max

The module may switch off when VCC voltage drops

below the extended operating range minimum limit.

Operation above extended operating range limit is

not recommended and may affect device reliability.

When operating below the normal operating range

minimum limit, the internal PA may not be able to

transmit at the network-required power level.

VCC average current

Support with margin the highest averaged VCC

current consumption value in connected mode

specified in the SARA-N2 data sheet [1] or in the

SARA-N3 data sheet [2].

The maximum average current consumption can be

greater than the specified value according to the

actual antenna mismatching, temperature and

supply voltage.

VCC voltage ripple

Noise in the supply has to be minimized

High supply voltage ripple values during RF

transmissions in connected-mode directly affect the

RF compliance with applicable certification schemes.

Table 5: Summary of VCC supply requirements

☞ For the additional specific requirements applicable to the integration of the SARA-N211 and the

SARA-N310 modules in devices intended for use in potentially explosive atmospheres, see the

guidelines reported in section 2.12.

Page 16

SARA-N2 / N3 series - System integration manual

UBX-17005143 - R13 System description Page 16 of 95

C1-Public

1.5.1.2 VCC current consumption profile

Figure 5 shows an example of the module VCC current consumption profile starting from the switch-

on event, followed by different phases and operating modes:

• Network registration and context activation procedure

• Transmission of an up-link datagram

• RRC connection release and related signaling operations

• Cyclic paging reception

• Deep sleep mode

Timings in the figure are purely indicative since these may significantly change depending on the

network signaling activity. The current consumption peaks occur when the module is in the connected

(transmitting) mode and the value of these peaks is strictly dependent on the transmitted power,

which is regulated by the network. See the electrical specification section in the SARA-N2 series data

sheet [1] or SARA-N3 series data sheet [2] for more details about the current consumption values in

the different modes and the influence of the transmitting power level.

A proper power supply circuit for SARA-N2 / N3 series modules must be able to withstand the current

values present during the data transmission at maximum power, even though NB-IoT systems should

be designed to keep the module in deep-sleep mode for most of the time, with an extremely low

current consumption in the range of few microamps.

Current [mA]

200

1 50

1 00

50

0

5 10 15 20 25 30 4035

Time [s]

Registration and

context activation

RRC connection release

(signaling operations)

Up-link

data

45 50 6055

Cyclic paging reception Deep Sleep

250

65 70 8075 85 90 1 00950

Figure 5: Example of module current consumption from the switch-on event up to deep-sleep mode

1.5.2 RTC supply (V_BCKP)

☞ The RTC supply (V_BCKP pin) is not available on SARA-N2 series modules.

V_BCKP is the Real Time Clock (RTC) supply of SARA-N3 series modules. When VCC voltage is within

the valid operating range, the internal Power Management Unit (PMU) supplies the RTC and the same

supply voltage is available on the V_BCKP pin. If the VCC voltage is under the minimum operating limit

(e.g. during non powered mode), the RTC can be externally supplied through the V_BCKP pin.

Page 17

SARA-N2 / N3 series - System integration manual

UBX-17005143 - R13 System description Page 17 of 95

C1-Public

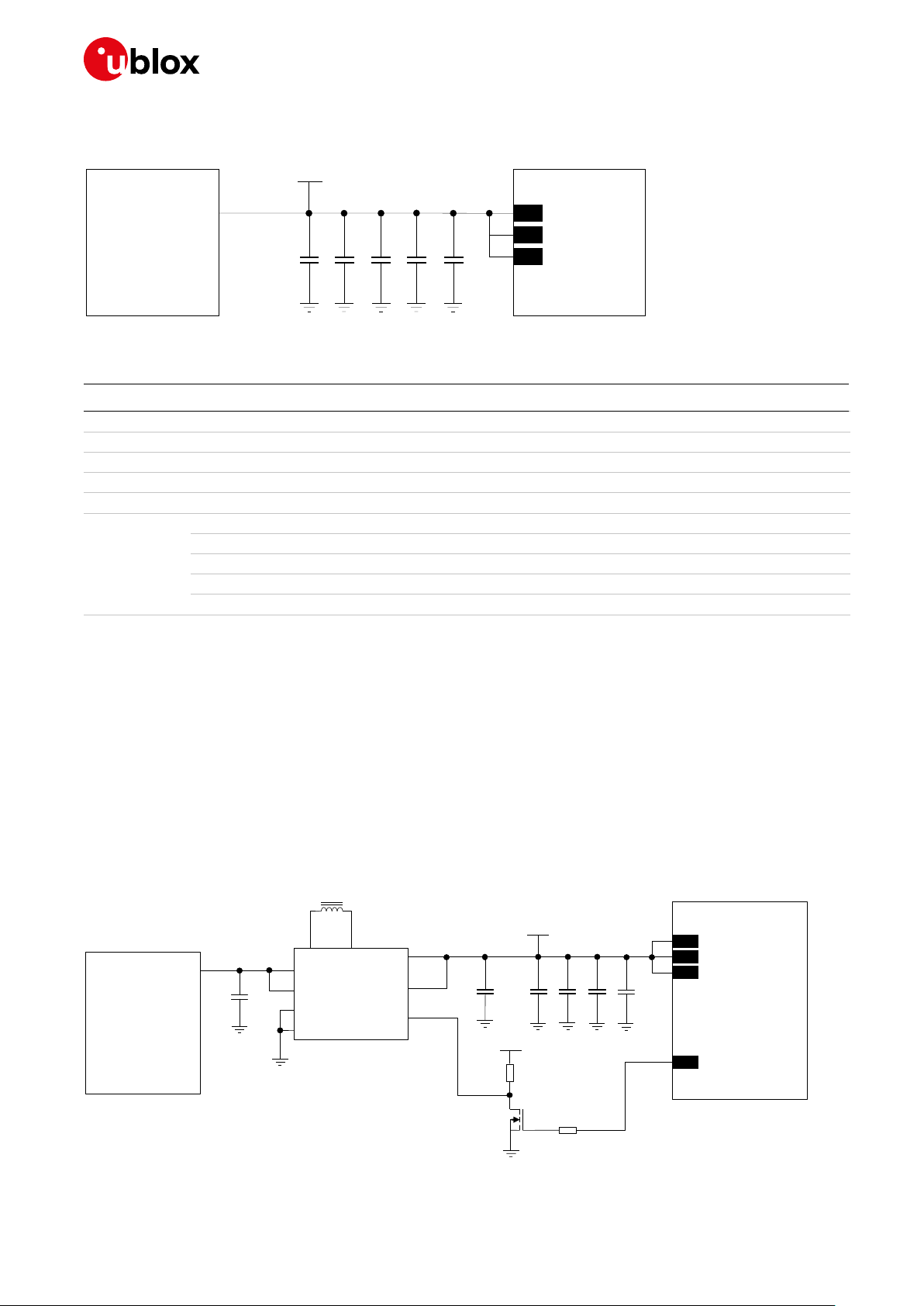

1.5.3 Interfaces supply output (V_INT)

The same voltage domain internally used as supply for the generic digital interfaces of SARA-N2 / N3

series modules is also available on the V_INT output pin, as illustrated in Figure 6.

In detail, the V_INT supply rail is used internally to supply the:

• I2C interface, and the GPIO pins of SARA-N2 series modules

• UART interfaces, the I2C interface, and the GPIO pins of SARA-N3 series modules

The internal regulator that generates the V_INT supply output is a low drop out (LDO) converter, which

is directly supplied from the VCC main supply input of the module.

The V_INT supply output provides internal short circuit protection to limit start-up current and

protect the load to short circuits.

The V_INT voltage regulator output of SARA-N2 series modules is disabled (i.e. 0 V) when the module

is switched off, and it can be used to monitor the operating mode when the module is switched on:

• When the radio is off, the voltage level is low (i.e. 0 V)

• When the radio is on, the voltage level is high (i.e. 1.8 V)

The V_INT voltage regulator output of SARA-N3 series modules is disabled (i.e. 0 V) when the module

is switched off, and it can be used to monitor the operating mode of the module as follows:

• When the module is off, or in deep sleep mode, the voltage level is low (i.e. 0 V)

• When the module is on, outside deep sleep mode, the voltage level is high (i.e. 1.8 V or 2.8 V)

The V_INT operating voltage of SARA-N3 series modules can be selected using the VSEL input pin:

• If the VSEL input pin is connected to GND, the digital I/O interfaces operate at 1.8 V

• If the VSEL input pin is left unconnected, the digital I/O interfaces operate at 2.8 V

☞ If the VSEL input pin is left unconnected, the VCC voltage shall be inside normal operating range

to let the digital I/O interfaces work correctly (see SARA-N3 series data sheet [2] for more details).

☞ Provide a test point connected to the V_INT pin for diagnostic purpose.

Baseband

processor

51

VCC

52

VCC

53

VCC

4

V_INT

LDO

Digital I/O

interfaces

Power

management

SARA-N2/N3 series

Figure 6: SARA-N2 / N3 series interfaces supply output (V_INT) simplified block diagram

Page 18

SARA-N2 / N3 series - System integration manual

UBX-17005143 - R13 System description Page 18 of 95

C1-Public

1.6 System function interfaces

1.6.1 Module power-on

1.6.1.1 Switch-on events

When the SARA-N2 series modules are in the non-powered mode (i.e. switched off, with the VCC

module supply not applied), the switch on routine of the module can be triggered by:

• Rising edge on the VCC supply input to a valid voltage value for module supply, starting from a

voltage value lower than 1.8 V, so that the module switches on applying a proper VCC supply within

the normal operating range (see SARA-N2 series data sheet [1]).

• Alternately, the RESET_N pin can be held low during the VCC rising edge, so that the module

switches on by releasing the RESET_N pin when the VCC voltage stabilizes at its nominal value

within the normal range.

When the SARA-N3 series modules are in the non-powered mode (i.e. switched off, with the VCC

module supply not applied), the switch on routine of the module can be triggered by:

• Applying a VCC supply within the normal operating range of the module, and then forcing a low

level on the PWR_ON input pin (normally high due to internal pull-up) for a valid time period (see

SARA-N3 series data sheet [2]).

• Alternately, the RESET_N pin can be held low during the VCC rising edge, so that the module

switches on by releasing the RESET_N pin when the VCC voltage stabilizes at its nominal value

within the normal range.

When the SARA-N3 series modules are in power off mode (i.e. switched off, with valid VCC supply

applied), the switch on routine of the module can be triggered by:

• Forcing a low level on the PWR_ON input pin (normally high due to internal pull-up) for a valid time

period (see SARA-N3 series data sheet [2]).

When the SARA-N3 series modules are in deep sleep mode (i.e. in the Power Saving Mode defined by

3GPP Rel. 13, with valid VCC supply applied), the wake-up routine of the module can be triggered by:

• Forcing a low level on the PWR_ON input pin (normally high due to internal pull-up) for a valid time

period (see SARA-N3 series data sheet [2]).

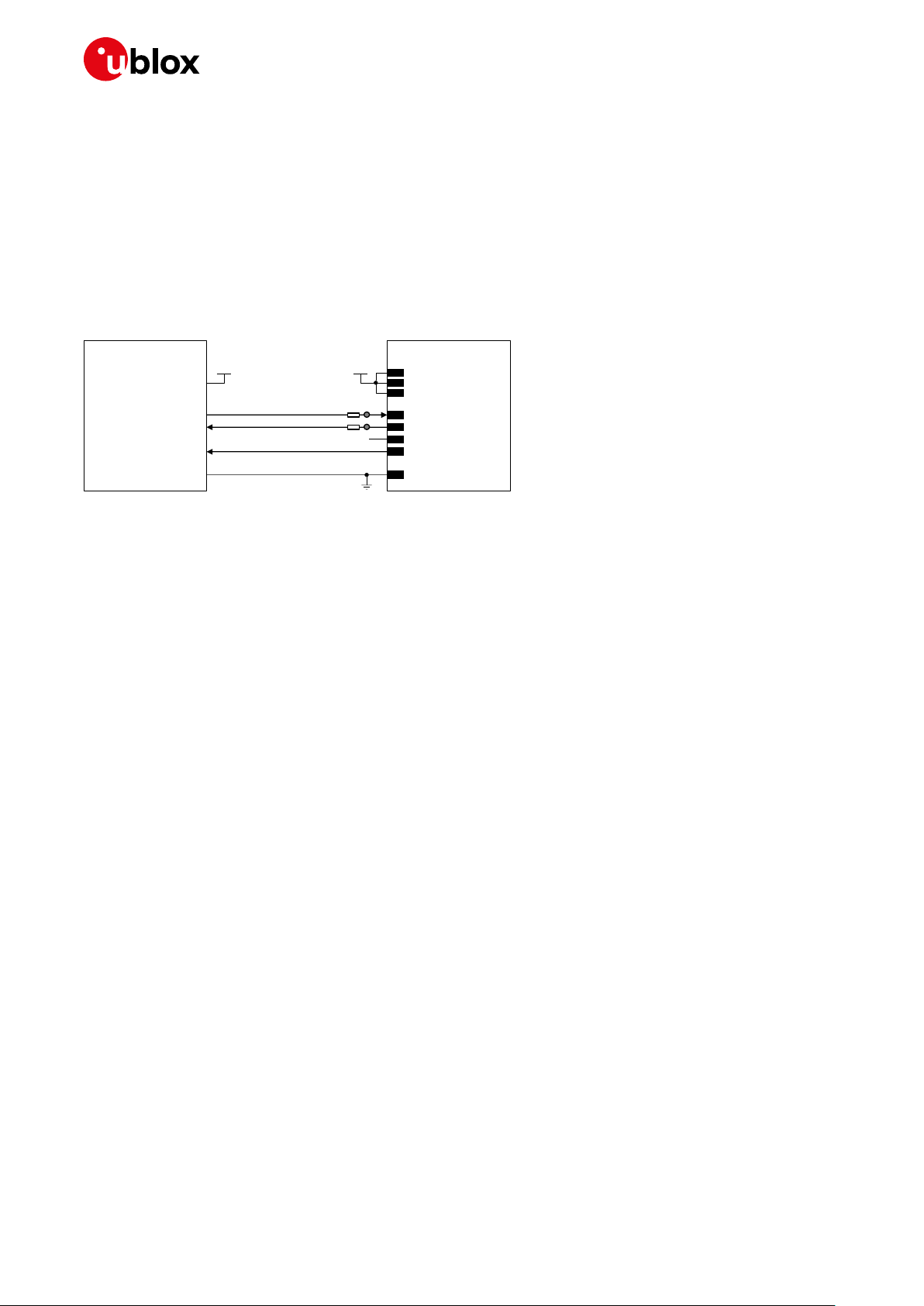

As illustrated in Figure 7, the PWR_ON line of SARA-N3 series modules is equipped with an internal

pull-up.

Baseband processor

15

PWR_ON

SARA-N3 series

Power-on

Power management

Power-on

1.1 V

Figure 7: SARA-N3 series PWR_ON input equivalent circuit description

☞ The PWR_ON input pin is not available on SARA-N2 series modules.

Page 19

SARA-N2 / N3 series - System integration manual

UBX-17005143 - R13 System description Page 19 of 95

C1-Public

1.6.1.2 Switch-on sequence from not-powered mode

Figure 8 shows the switch-on sequence of SARA-N2 modules starting from the non-powered mode:

• The external supply is being applied to the VCC inputs, representing the start-up event.

• The RESET_N line rises suddenly to high logic level due to internal pull-up to VCC.

• Then, the V_INT generic digital interfaces supply output is enabled by the integrated PMU.

• The RXD UART data output pin also rises to the high logic level, at VCC voltage value

• A greeting message is sent on the RXD pin (for more details see AT commands manual [4])

• From now on the module is fully operational and the UART interface is functional

VCC

RESET_N

V_INT

HIGH when radio is ON

LOW when radio is OFF

RXD

System state

OFF

ON

0 s

~3.5 s

Module is

operational

Start-up

event

Greeting te xt

Figure 8: SARA-N2 series power-on sequence from not-powered mode

Figure 9 shows the switch on sequence of SARA-N3 modules starting from the non-powered mode:

• The external supply is being applied to the VCC inputs.

• The PWR_ON and RESET_N lines rise suddenly to high logic level due to internal pull-up.

• Then, the PWR_ON line is set low for a proper time period, representing the start-up event.

• Then, the V_INT generic digital interfaces supply output is enabled by the integrated PMU.

• The RXD UART data output pin also rises to the high logic level, at V_INT voltage value.

• A greeting message is sent on the RXD pin (for more details, see AT commands manual [4])

• From now on the module is fully operational and the UART interface is functional

VCC

PWR_ON

RESET_N

V_INT

RXD

System state

OFF

ON

Module is

operational

Start-up

event

Greeting te xt

Figure 9: SARA-N3 series power-on sequence from not-powered mode

☞ No voltage driven by an external application should be applied to the UART interface of the module

before applying the VCC supply, to avoid latch-up of circuits and allow a proper boot of the module.

☞ No voltage driven by an external application should be applied to any generic digital interface of

the module (GPIOs, I2C interface) before the switch-on of the generic digital interface supply

source of the module (V_INT), to avoid latch-up of circuits and allow a proper boot of the module.

Page 20

SARA-N2 / N3 series - System integration manual

UBX-17005143 - R13 System description Page 20 of 95

C1-Public

1.6.2 Module power-off

The SARA-N2 series modules enter the non-powered mode by removing the VCC supply.

The switch-off routine of the SARA-N3 series modules can be properly triggered, with storage of

current parameter settings in the module’s non-volatile memory and clean network detach, by:

• AT+CPWROFF command (see the SARA-N2 / SARA-N3 series AT commands manual [4]).

• Low level on the PWR_ON input pin, i.e. forcing the pin (normally high due to internal pull-up) to a

low level for a valid time period (see SARA-N3 series data sheet [2]).

An abrupt under-voltage shutdown occurs on the SARA-N3 series modules when the VCC supply

drops below the extended operating range minimum limit (see the SARA-N3 series data sheet [2]),

but in this case it is not possible to perform the storing of the current parameter settings in the

module’s non-volatile memory as well as a clean network detach.

Figure 10 shows the switch-off sequence of the SARA-N3 series modules started by means of the

AT+CPWROFF command, allowing storage of current parameter settings in the module’s non-volatile

memory and a clean network detach, with the following phases:

• When the +CPWROFF AT command is sent, the module starts the switch-off routine.

• Then, the module replies OK on the AT interface: the switch-off routine is in progress.

• At the end of the switch-off routine, the internal voltage regulator generating the V_INT supply rail

is turned off.

Then, the module remains in switch-off mode as long as a switch on event does not occur (e.g.

applying a low level to PWR_ON), and enters not-powered mode if the VCC supply is removed.

VCC

PWR_ON

RESET_N

V_INT

System state

OFF

ON

AT+CPWROFF

sent to the module

OK

replied by the module

VCC can be

removed

Figure 10: SARA-N3 series modules switch-off sequence by means of AT+CPWROFF command

☞ It is highly recommended to monitor the V_INT pin to sense the end of the switch-off sequence.

☞ It is highly recommended to avoid an abrupt removal of the VCC supply during module normal

operations: the VCC supply can be removed only when the V_INT rail is switched off by the module.

☞ The duration of each phase in the SARA-N3 series modules’ switch-off routines can largely vary

depending on the application / network settings and the concurrent module activities.

Page 21

SARA-N2 / N3 series - System integration manual

UBX-17005143 - R13 System description Page 21 of 95

C1-Public

1.6.3 Module reset

SARA-N2 / N3 series modules can be properly reset (rebooted) by:

• AT command (see the SARA-N2 / SARA-N3 AT commands manual [4] for more details).

This command causes an “internal” or “software” reset of the module, which is an asynchronous reset

of the module baseband processor. The current parameter settings are saved in the non-volatile

memory of the module and a proper network detach is performed.

An abrupt hardware reset occurs on SARA-N2 / N3 series modules when a low level is applied on the

RESET_N input pin for a specific time period. In this case, storage of the current parameter settings

in the module’s non-volatile memory and a proper network detach cannot be performed.

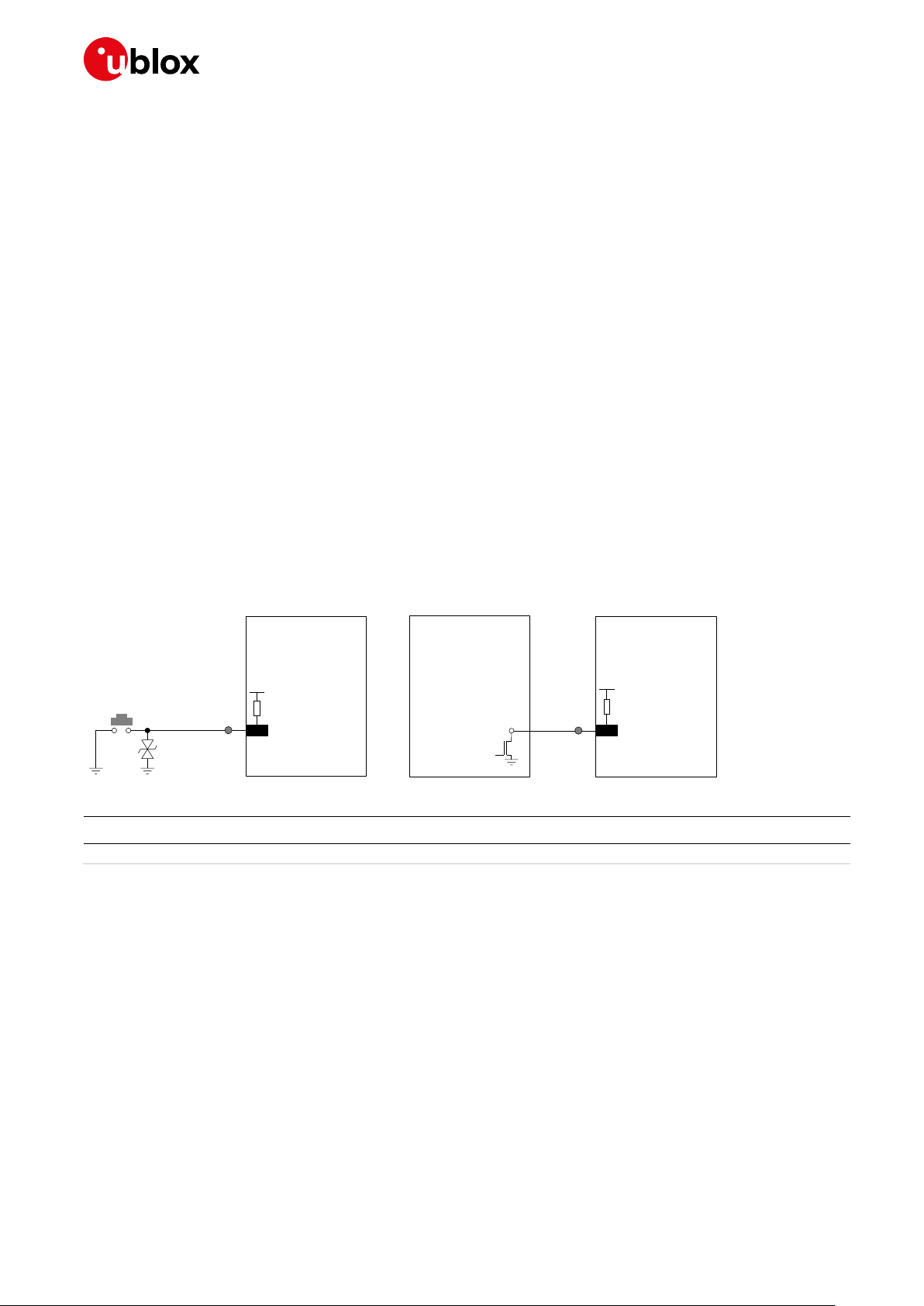

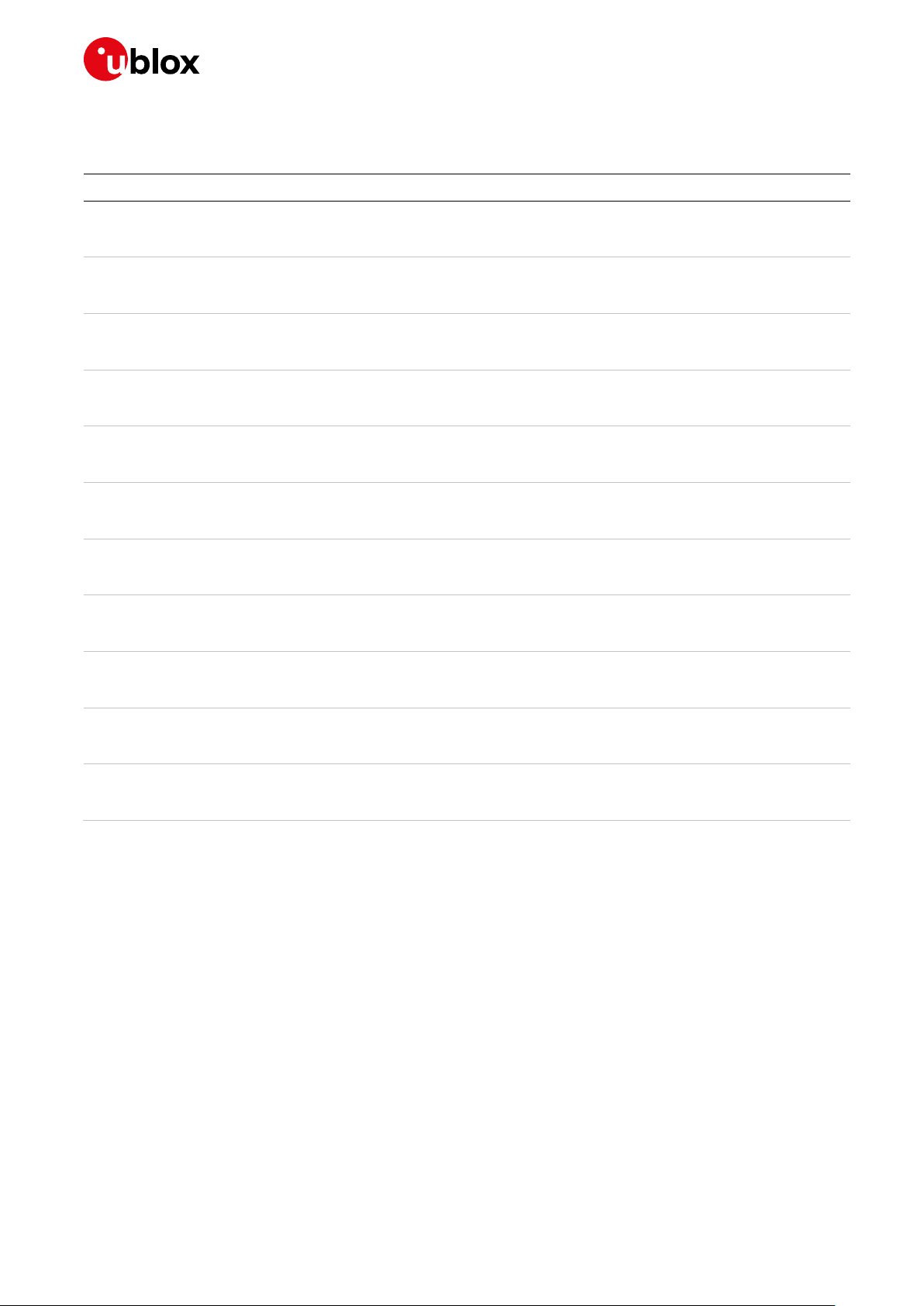

As described in Figure 11, the RESET_N input pin is equipped with an internal pull-up on SARA-N2 / N3

series modules, with sligthly different internal circuits.

Baseband processor

18

RESET_N

SARA-N2 series

VCC

Reset

Baseband processor

18

RESET_N

SARA-N3 series

Reset

Power management

Reset

1.1 V

Figure 11: SARA-N2 / N3 series RESET_N input equivalent circuit description

☞ It is highly recommended to avoid an abrupt hardware reset of the module by forcing a low level on

the RESET_N input pin during module normal operation: the RESET_N line should be set low only

if reset via AT command fails or if the module does not provide a reply to a specific AT command

after a time period longer than the one defined in the SARA-N2 / N3 series AT commands

manual [4].

☞ Provide a test point connected to the RESET_N pin for diagnostic purpose.

1.6.4 Voltage selection of interfaces (VSEL)

☞ The digital interfaces’ voltage selection functionality is not available in SARA-N2 series modules.

The digital I/O interfaces of the SARA-N3 series modules (the UARTs, I2C, and GPIOs pins) operate at

the V_INT voltage, which can be set to 1.8 V or 2.8 V using the VSEL input:

• If the VSEL input pin is externally connected to GND, the digital I/O interfaces operate at 1.8 V

• If the VSEL input pin is left unconnected, the digital I/O interfaces operate at 2.8 V

The operating voltage cannot be changed dynamically: the VSEL input pin configuration has to be set

before the boot of the SARA-N3 series modules and then it cannot be changed after switched on.

☞ If the VSEL input pin is left unconnected, the VCC voltage shall be inside normal operating range

to let the digital I/O interfaces work correctly (see SARA-N3 series data sheet [2] for more details).

Page 22

SARA-N2 / N3 series - System integration manual

UBX-17005143 - R13 System description Page 22 of 95

C1-Public

1.7 Antenna interface

1.7.1 Cellular antenna RF interface (ANT)

The ANT pin of SARA-N2 / N3 series modules represents the RF input/output for the cellular RF

signals reception and transmission. The ANT pin has a nominal characteristic impedance of 50 and

must be connected to the external cellular antenna through a 50 transmission line for proper

reception and transmission of cellular RF signals.

1.7.1.1 Cellular antenna RF interface requirements

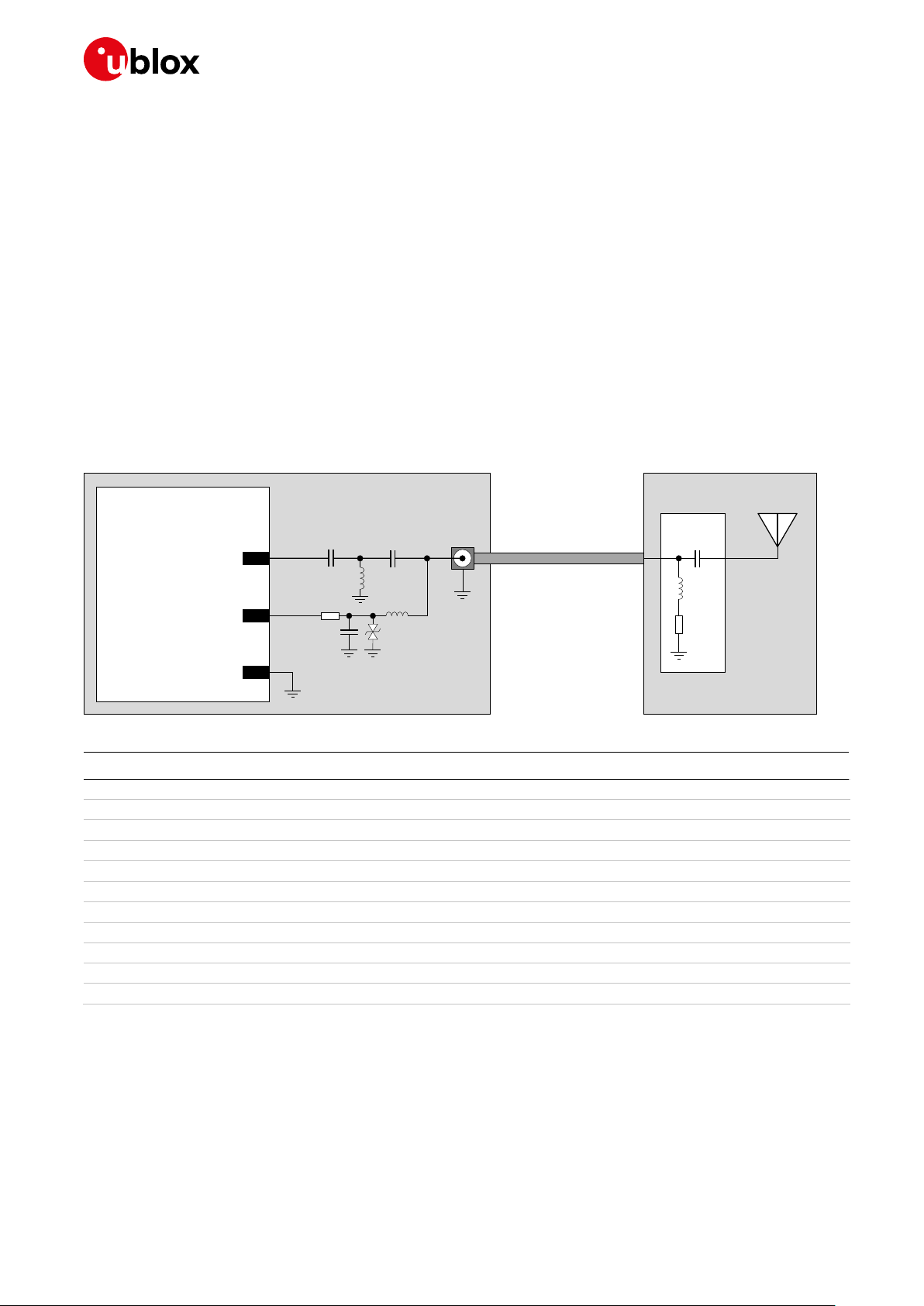

Table 6 summarizes the requirements for the cellular antenna RF interface (ANT). See section 2.4.1

for suggestions to properly design an antenna circuit compliant to these requirements.

⚠ The cellular antenna circuit affects the RF compliance of the device integrating SARA-N2 / N3

series module with applicable required certification schemes.

Item

Requirements

Remarks

Impedance

50 nominal characteristic impedance

The nominal characteristic impedance of the

antenna RF connection must match the ANT pin

50 impedance.

Frequency range

See the SARA-N2 series data sheet [1] and

SARA-N3 series data sheet [2]

The required frequency range of the antenna

depends on the operating bands supported by the

cellular module.

Return loss

S11 < -10 dB (VSWR < 2:1) recommended

S11 < -6 dB (VSWR < 3:1) acceptable

The return loss or the S11, as the VSWR, refers to

the amount of reflected power, measuring how well

the RF antenna connection matches the 50

impedance.

The impedance of the antenna RF termination must

match as much as possible the 50 impedance of

the ANT pin over the operating frequency range,

reducing as much as possible the amount of

reflected power.

Efficiency

> -1.5 dB ( > 70%) recommended

> -3.0 dB ( > 50%) acceptable

The radiation efficiency is the ratio of the radiated

power to the power delivered to antenna input: the

efficiency is a measure of how well an antenna

receives or transmits.

The efficiency needs to be enough high over the

operating frequency range to comply with the

Over-The-Air radiated performance requirements,

as Total Radiated Power and Total Isotropic

Sensitivity, specified by certification schemes

Maximum gain

See section 4.2 for maximum gain limits

The power gain of an antenna is the radiation

efficiency multiplied by the directivity: the

maximum gain describes how much power is

transmitted in the direction of peak radiation to

that of an isotropic source.

The maximum gain of the antenna connected to

ANT pin must not exceed the values stated in

section 4.2 to comply with regulatory agencies

radiation exposure limits.

Input power

> 0.5 W peak

The antenna connected to ANT pin must support

the maximum power transmitted by the modules.

Table 6: Summary of antenna RF interface (ANT) requirements

☞ For the additional specific requirements applicable to the integration of the SARA-N211 and the

SARA-N310 modules in devices intended for use in potentially explosive atmospheres, see the

guidelines reported in section 2.12.

Page 23

SARA-N2 / N3 series - System integration manual

UBX-17005143 - R13 System description Page 23 of 95

C1-Public

1.7.2 Bluetooth antenna RF interface (ANT_BT)

☞ The Bluetooth functionality is not available in SARA-N2 series modules.

☞ The Bluetooth functionality is not supported by “00” product version of SARA-N3 series modules.

The ANT_BT pin can be left unconnected or it can also be connected to GND.

The ANT_BT pin has an impedance of 50 and provides the Bluetooth RF antenna interface of the

SARA-N3 series modules.

1.7.3 Antenna detection interface (ANT_DET)

☞ Antenna detection interface is not supported in the “02” version of SARA-N2 series modules.

The ANT_DET pin is an Analog to Digital Converter (ADC) input used to sense the antenna presence

evaluating the resistance from the ANT pin to GND by means of an external antenna detection circuit

implemented on the application board. This optional functionality can be managed by dedicated AT

command (for more details see the SARA-N2 / N3 series AT commands manual [4]).

1.8 SIM interface

SARA-N2 / N3 series modules provide a high-speed SIM/ME interface on the VSIM, SIM_IO, SIM_CLK

and SIM_RST pins, which is available to connect an external SIM / UICC.

The SIM interface of the SARA-N2 series modules can operate at 1.8 V (VSIM domain), with activation

and deactivation of the SIM interface implemented according to the ISO-IEC 7816-3 specifications.

The SIM interface of the SARA-N3 series modules can operate at 1.8 V and/or 3.0 V voltage (VSIM

domain), with activation and deactivation of the SIM interface, and automatic 1.8 V / 3.0 V voltage

switch according to the voltage class of the external SIM connected to the module implemented

according to the ISO-IEC 7816-3 specifications.

The VSIM supply output of SARA-N2 / N3 series modules provides internal short circuit protection to

limit start-up current and protect the external SIM / UICC to short circuits.

☞ If a 3.0 V SIM is used, the VCC voltage shall be inside normal operating range to let the SIM

interface work correctly (see SARA-N3 series data sheet [2] for more details).

Page 24

SARA-N2 / N3 series - System integration manual

UBX-17005143 - R13 System description Page 24 of 95

C1-Public

1.9 Serial interfaces

SARA-N2 / N3 series modules provide the following serial communication interfaces:

• Main primary UART interface (see 1.9.1):

o In the VCC voltage domain (~3.6 V) on the SARA-N2 series modules, supporting:

▪ AT communication

▪ FW upgrades by means of the FOAT feature

▪ FW upgrades by means of the dedicated tool

o In the V_INT voltage domain (1.8 V or 2.8 V) on the SARA-N3 series modules, supporting:

▪ AT communication

▪ FW upgrades by means of the FOAT feature

• Auxiliary secondary UART interface (see 1.9.2):

o Not available on the SARA-N2 modules

o In the V_INT voltage domain (1.8 V or 2.8 V) on the SARA-N3 series modules:

▪ Not supported by the “00” product versions

• Additional UART interface (see 1.9.3):

o In the V_INT voltage domain (1.8 V) on the SARA-N2 series modules, supporting:

▪ Diagnostic trace log

o In the V_INT voltage domain (1.8 V or 2.8 V) on the SARA-N3 series modules, supporting:

▪ FW upgrades by means of the u-blox EasyFlash tool

▪ Diagnostic trace log

• DDC I2C-bus compatible interface (see 1.9.4):

o In the V_INT voltage domain (1.8 V) on the SARA-N2 series modules:

▪ Not supported by the “02” product versions

o In the V_INT voltage domain (1.8 V or 2.8 V) on the SARA-N3 series modules:

▪ Not supported by the “00” product versions

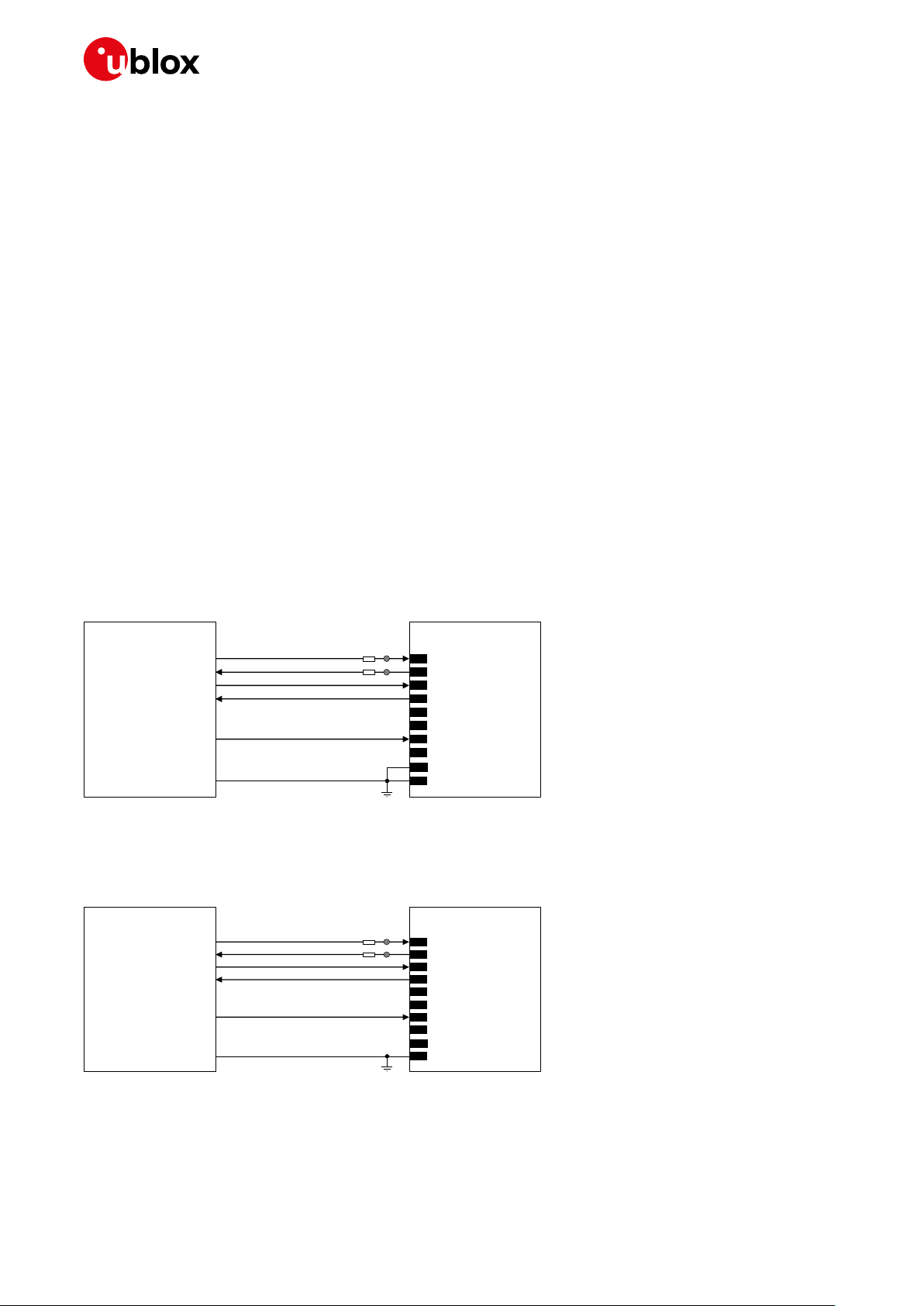

1.9.1 Main primary UART interface

1.9.1.1 UART features

SARA-N2 modules include the RXD, TXD, CTS, RTS pins as main primary UART interface, supporting:

• AT communication

• FW upgrades by means of the FOAT feature

• FW upgrades by means of the dedicated tool

The main characteristics of the SARA-N2 modules primary UART interface are the following:

• Serial port with RS-232 functionality conforming to ITU-T V.24 recommendation [7]

• It operates at VCC voltage level

o 0 V for low data bit or ON state

o VCC, i.e. ~3.6 V, for high data bit or OFF state

• Data lines (RXD as module data output, TXD as module data input) are provided

• The CTS hardware flow control output is not supported by “02” product version: the CTS output

line can be configured as RING indicator, to signal an incoming message received by the module or

an URC event, or as Network status indicator (for more details see section 1.11 and the SARA-N2 /

SARA-N3 series AT commands manual [4], +URING, +UGPIOC AT commands),

• The RTS hardware flow control input is not supported by “02” product version

• Default baud rate: 9600 b/s (4800, 57600 and 115200 b/s baud rates are also supported)

• Default frame format: 8N1 (8 data bits, No parity, 1 stop bit)

Page 25

SARA-N2 / N3 series - System integration manual

UBX-17005143 - R13 System description Page 25 of 95

C1-Public

SARA-N3 series modules include the RXD, TXD, CTS, RTS, DTR, DSR, DCD, RI pins as main primary

UART interface, supporting:

• AT communication

• FW upgrades by means of the FOAT feature

The main characteristics of the SARA-N3 series modules main primary UART interface are the

following:

• Serial port with RS-232 functionality conforming to ITU-T V.24 recommendation [7]

• It operates at V_INT level, with voltage value set as per external VSEL pin configuration

o 0 V for low data bit or ON state

o V_INT, i.e. 1.8 V or 2.8 V, for high data bit or OFF state

• Data lines (RXD as module data output, TXD as module data input) are provided

• Hardware flow control lines (CTS as output, RTS as input) and RI output line are provided, and they

can be alternatively configured as described in section 1.11 (for more details see also the SARA-N2

/ SARA-N3 series AT commands manual [4])

• The modem status and control lines (DTR as input, DSR as output, DCD as output) are not

supported by “00” product versions

• Hardware flow control disabled by default

• One-shot automatic baud rate detection enabled by default

• UART works in low power idle mode, supporting 4800, 9600, 19200, 38400, 57600 b/s baud rates

• 8N1 default frame format

The UART interface provides RS-232 functionality conforming to the ITU-T V.24 Recommendation

(more details available in ITU recommendation [7]): SARA-N2 / N3 series modules are designed to

operate as a cellular modem, which represents the Data Circuit-terminating Equipment (DCE)

according to ITU-T V.24 recommendation [7]. The application processor connected to the module

through the UART interface represents the Data Terminal Equipment (DTE).

The UART interface settings can be suitably configured by AT commands (for more details, see the

SARA-N2 / SARA-N3 series AT commands manual [4]).

☞ The signal names of the SARA-N2 / N3 series modules’ UART interface conform to the ITU-T V.24

recommendation [7]: e.g. the TXD line represents the data transmitted by the DTE (application

processor data line output) and received by the DCE (module data line input).

Figure 12 describes the 8N1 frame format.

D0 D1 D2 D3 D4 D5 D6 D7

Start of 1-Byte

transfer

Start Bit

(Always 0)

Possible Start of

next transfer

Stop Bit

(Always 1)

t

bit

= 1/(Baudrate)

Normal Transfer, 8N1

Figure 12: Description of UART default frame format (8N1) with fixed baud rate

Page 26

SARA-N2 / N3 series - System integration manual

UBX-17005143 - R13 System description Page 26 of 95

C1-Public

1.9.1.2 UART signal behavior

At the module switch-on, before the UART interface initialization (as described in the power-on

sequence reported in Figure 8 and Figure 9), each pin is first tri-stated and then is set to its related

internal reset state. At the end of the boot sequence, the UART interface is initialized and the UART

interface is enabled as AT commands interface.

The configuration and the behavior of the UART signals after the boot sequence are described below.

See section 1.4 for definition and description of module operating modes referred to in this section.

RXD signal behavior

The module data output line (RXD) is set by default to the OFF state (high level) at UART initialization.

The greeting message is sent on the RXD line after the completion of the boot sequence to indicate

the completion of the UART interface initialization. For more details regarding how to set greeting

text, see the SARA-N2 / SARA-N3 series AT commands manual [4].

The module holds RXD in the OFF state until the module does not transmit some data.

TXD signal behavior

The module data input line (TXD) is assumed to be controlled by the external host once UART is

initialized.

There is no internal pull-up / pull-down inside the SARA-N2 modules on the TXD input. Instead, the

SARA-N3 series modules have an internal pull-up on the TXD input.

1.9.1.3 UART and deep sleep mode