Page 1

Abstract

NINA-B3 series

Stand-alone Bluetooth 5 low energy modules

System integration manual

This document describes the system integration of the NINA-B3 series stand-alone Bluetooth 5 low

energy modules.

UBX-17056748 - R11

C1-Public www.u-blox.com

Page 2

NINA-B3 series - System integration manual

u-blox or third parties may hold intellectual property rights in the products, names, logos and designs included in this

document. Copying, reproduction, modification or disclosure to third parties of this document or any part thereof is only

permitted with the express written permission of u

The information contained herein is provided “as is” and u

implied, is given, including but not limited to, with respect to the accuracy, correctness, reliability and fitness for a par

purpose of the information. This document may be revised by u

documents, visit www.u

Copyright © u

Document information

Title NINA-B3 series

Subtitle Stand-alone Bluetooth 5 low energy modules

Document type System integration manual

Document number UBX-17056748

Revision and date R11 8-Dec-2020

Disclosure restriction C1-Public

Product status

Functional Sample Draft For functional testing. Revised and supplementary data will be published later.

In Development /

Prototype

Engineering Sample Advance Information Data based on early testing. Revised and supplementary data will be published later.

Initial Production Early Production Information Data from product verification. Revised and supplementary data may be published later.

Mass Production /

End of Life

Corresponding content status

Objective Specification Target values. Revised and supplementary data will be published later.

Production Information Document contains the final product specification.

This document applies to the following products:

Open CPU:

Product name Type Number Product status

NINA-B301 NINA-B301-00B Early Production Information

NINA-B302 NINA-B302-00B Early Production Information

NINA-B306 NINA-B306-00B Early Production Information

NINA-B306 NINA-B306-01B Early Production Information Without external LFXO.

Comment

u-connectXpress:

Product name Type Number Product status

NINA-B311 NINA-B311-0xB Early Production Information x = SW version

NINA-B312 NINA-B312-0xB Early Production Information ‘’

NINA-B316 NINA-B316-0xB Early Production Information ‘’

Comment

UBX-17056748 - R11 Document information Page 2 of 67

C1-Public

-blox AG.

-blox.com.

-blox.

-blox assumes no liability for its use. No warranty, either express or

-blox at any time without notice. For the most recent

ticular

Page 3

NINA-B3 series - System integration manual

Contents

Document information ............................................................................................................................. 2

Contents ....................................................................................................................................................... 3

1 System description ............................................................................................................................ 6

1.1 Overview and applications ........................................................................................................................ 6

1.2 Architecture ................................................................................................................................................. 9

1.2.1 Block diagrams .................................................................................................................................... 9

1.2.2 Hardware options ............................................................................................................................... 9

1.2.3 Software options ................................................................................................................................ 9

1.3 Pin configuration and function ................................................................................................................. 9

1.4 Supply interfaces ...................................................................................................................................... 10

1.4.1 Main supply input ............................................................................................................................. 10

1.4.2 Digital I/O interfaces reference voltage (VCC_IO) ...................................................................... 10

1.4.3 VCC application circuits .................................................................................................................. 10

1.5 System function interfaces .................................................................................................................... 11

1.5.1 Module reset ...................................................................................................................................... 11

1.5.2 Internal temperature sensor .......................................................................................................... 11

1.6 Debug – Serial Wire Debug (SWD) ......................................................................................................... 11

1.7 Serial interfaces ........................................................................................................................................ 11

1.7.1 Universal Asynchronous Serial Interface (UART) ...................................................................... 11

1.7.2 Serial Peripheral Interface (SPI) ..................................................................................................... 12

1.7.3 Quad serial peripheral interface (QSPI) ........................................................................................ 12

1.7.4 I2C interface ....................................................................................................................................... 13

1.7.5 USB 2.0 interface .............................................................................................................................. 13

1.8 GPIO pins ..................................................................................................................................................... 13

1.8.1 Analog interfaces .............................................................................................................................. 14

1.9 Antenna interfaces ................................................................................................................................... 15

1.9.1 Antenna pin – NINA-B3x1 ................................................................................................................ 15

1.9.2 Integrated antenna – NINA-B3x2/B3x6........................................................................................ 16

1.9.3 NFC antenna ...................................................................................................................................... 16

1.10 Reserved pins (RSVD) .............................................................................................................................. 16

1.11 GND pins ..................................................................................................................................................... 16

2 Software ............................................................................................................................................. 17

2.1 u-connectXpress software ...................................................................................................................... 17

2.2 Open CPU .................................................................................................................................................... 17

2.2.1 Nordic SDK ......................................................................................................................................... 17

2.2.2 Bluetooth MAC address and other production data ................................................................. 22

2.3 Flashing the NINA-B31 u-blox software ............................................................................................... 22

2.3.1 UART flashing ................................................................................................................................... 22

2.4 Flashing the NINA-B30 open CPU software ........................................................................................ 26

2.4.1 SWD flashing ..................................................................................................................................... 26

UBX-17056748 - R11 Contents Page 3 of 67

C1-Public

Page 4

NINA-B3 series - System integration manual

3 Design-in ............................................................................................................................................. 28

3.1 Overview ...................................................................................................................................................... 28

3.2 Design for NINA family ............................................................................................................................. 28

3.3 Antenna interface ..................................................................................................................................... 28

3.3.1 RF transmission line design (NINA-B3x1 only) ........................................................................... 29

3.3.2 Antenna design (NINA-B3x1 only) ................................................................................................. 30

3.3.3 On-board antenna ............................................................................................................................. 33

3.4 Supply interfaces ...................................................................................................................................... 35

3.4.1 Module supply design ...................................................................................................................... 35

3.5 Serial interfaces ........................................................................................................................................ 36

3.5.1 Asynchronous serial interface (UART) design ............................................................................ 36

3.5.2 Serial peripheral interface (SPI) ..................................................................................................... 36

3.5.3 I2C interface ....................................................................................................................................... 36

3.5.4 QSPI interface .................................................................................................................................... 36

3.5.5 USB interface ..................................................................................................................................... 36

3.6 NFC interface ............................................................................................................................................. 36

3.6.1 Battery protection ............................................................................................................................ 37

3.7 General High Speed layout guidelines .................................................................................................. 37

3.7.1 General considerations for schematic design and PCB floor-planning ................................. 37

3.7.2 Module placement ............................................................................................................................ 38

3.7.3 Layout and manufacturing ............................................................................................................. 38

3.8 Module footprint and paste mask ......................................................................................................... 38

3.9 Thermal guidelines ................................................................................................................................... 39

3.10 ESD guidelines ........................................................................................................................................... 39

4 Handling and soldering ................................................................................................................... 40

4.1 Packaging, shipping, storage and moisture preconditioning .......................................................... 40

4.2 Handling ...................................................................................................................................................... 40

4.3 Soldering ..................................................................................................................................................... 40

4.3.1 Reflow soldering process ................................................................................................................ 40

4.3.2 Cleaning .............................................................................................................................................. 41

4.3.3 Other remarks ................................................................................................................................... 42

5 Regulatory information and requirements ............................................................................... 43

5.1 ETSI – European market .......................................................................................................................... 43

5.1.1 Compliance statement .................................................................................................................... 43

5.1.2 NINA-B3 Software security considerations ................................................................................ 43

5.1.3 Output power limitation .................................................................................................................. 43

5.1.4 Safety Compliance ........................................................................................................................... 44

5.2 FCC/ISED – US/Canadian markets ........................................................................................................ 45

5.2.1 Compliance statements .................................................................................................................. 45

5.2.2 RF Exposure ....................................................................................................................................... 45

5.2.3 Antenna selection ............................................................................................................................. 46

5.2.4 IEEE 802.15.4 channel map limitation ......................................................................................... 46

UBX-17056748 - R11 Contents Page 4 of 67

C1-Public

Page 5

NINA-B3 series - System integration manual

5.2.5 Change in ID/Multiple Listing process .......................................................................................... 46

5.2.6 End product verification requirements ........................................................................................ 47

5.2.7 End product labelling requirements ............................................................................................. 47

5.2.8 End product user manual requirements ...................................................................................... 48

5.3 MIC - Japanese market ............................................................................................................................ 49

5.3.1 Compliance statement .................................................................................................................... 49

5.3.2 48-bit address requirement ........................................................................................................... 49

5.3.3 End product labelling requirement................................................................................................ 50

5.3.4 End product user manual requirement ........................................................................................ 50

5.4 NCC – Taiwanese market ........................................................................................................................ 50

5.4.1 Compliance statements .................................................................................................................. 50

5.4.2 End product labelling requirement................................................................................................ 51

5.5 KCC – South Korean market ................................................................................................................... 52

5.5.1 Compliance statement .................................................................................................................... 52

5.5.2 End product labeling requirements .............................................................................................. 52

5.5.3 End product user manual requirements ...................................................................................... 53

5.6 Anatel Brazil compliance ......................................................................................................................... 53

5.7 Australia and New Zealand regulatory compliance ........................................................................... 53

5.8 South Africa regulatory compliance ..................................................................................................... 54

5.9 Integration checklist ................................................................................................................................ 54

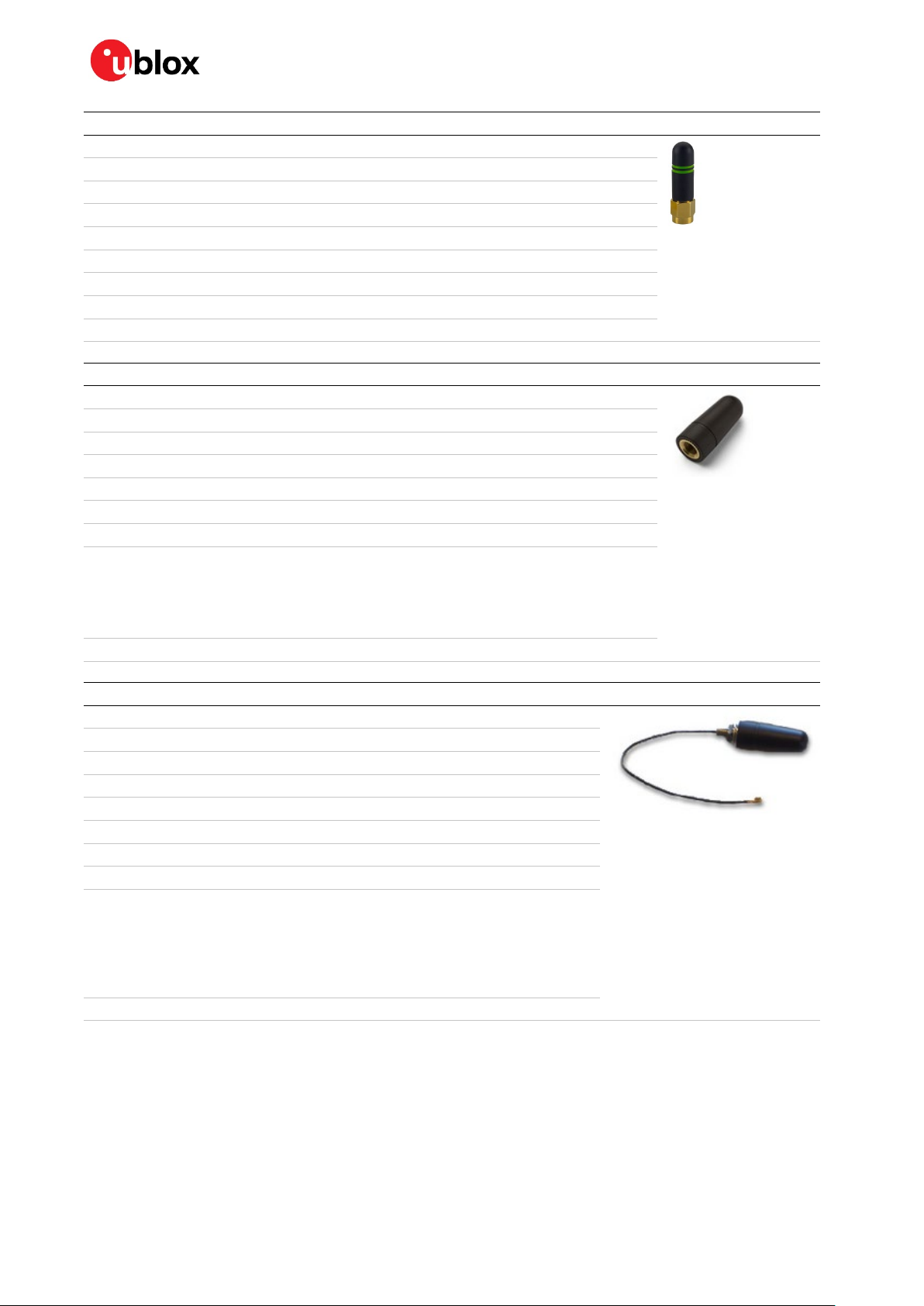

5.10 Pre-approved antennas list ..................................................................................................................... 55

5.10.1 Antenna accessories ........................................................................................................................ 56

5.10.2 Single band antennas ...................................................................................................................... 56

6 Product testing ................................................................................................................................. 59

6.1 u-blox In-Series production test ............................................................................................................. 59

6.2 OEM manufacturer production test ..................................................................................................... 59

6.2.1 “Go/No go” tests for integrated devices ...................................................................................... 60

Appendix .................................................................................................................................................... 61

A Glossary .............................................................................................................................................. 61

B Antenna reference designs ........................................................................................................... 62

B.1 Reference design for external antennas (U.FL connector) .................................................. 62

B.1.1 Floor plan .................................................................................................................................... 63

B.1.2 RF trace specification ............................................................................................................ 63

Related documents ................................................................................................................................ 65

Revision history ....................................................................................................................................... 66

Contact ....................................................................................................................................................... 67

UBX-17056748 - R11 Contents Page 5 of 67

C1-Public

Page 6

NINA-B3 series - System integration manual

art power performance.

B30 are open CPU modules that enable customer applications to run on the

class capacity

B302 comes with an internal PIFA antenna,

integrated in the module PCB. The internal antennas are

specifically designed for the small NINA form factor and provides an extensive range, independent of

flashed.

e,

all configurable

B31x modules provide top grade security, thanks to secure

B312 comes with an internal PIFA antenna,

B16 has an internal PCB antenna integrated in the module PCB. The internal antennas are

mall NINA form factor and provides an extensive range, independent of

1 System description

1.1 Overview and applications

The NINA-B3 series modules are small stand-alone Bluetooth 5 low energy microcontroller unit (MCU)

modules. The NINA-B3 features full Bluetooth 5, a powerful Arm

®

Cortex®-M4 with FPU, and state-ofthe-art power performance. The embedded low power crystal in the NINA-B3 series improves power

consumption by enabling optimal power save modes.

The NINA-B3x2 comes with an internal antenna, while the NINA-B3x1 has a pin for use with an

external antenna. The internal PIFA antenna is specifically designed for the small NINA form factor

and provides an extensive range, independent of ground plane and component placement. The

NINA-B3 series is globally certified for use with the internal antenna or a range of external antennas.

This greatly reduces time, cost, and effort for customers integrating the NINA-B3 in their designs.

The NINA-B3 series includes the following two sub-series as listed in the table below:

Model

NINA-B30 series Bluetooth 5 module with a powerful Arm Cortex-M4 with FPU, and state-of-the-

NINA-B31 series Bluetooth 5 module with a powerful Arm Cortex-M4 with FPU and u-connectXpress software pre-

Description

Both the variants of NINAbuilt-in Arm Cortex-M4 with FPU. With 1 MB flash and 256 kB RAM, they offer the best-infor customer applications on top of the Bluetooth low energy stack.

NINA-B301 has a pin for use with an external antenna, NINAand NINA-B06 has an internal PCB antenna

ground plane and component placement.

The NINA-B306-01B module variant comes without the LFXO (Low frequency crystal oscillator) mounted.

The software in NINA-B31 modules provides support for u-blox Bluetooth low energy Serial Port Servic

GATT client and server, beacons, NFC™, and simultaneous peripheral and central roles –

from a host using AT commands. The NINAboot, which ensures the module only boots up with original u-blox software.

NINA-B311 has a pin for use with an external antenna, NINAand NINAspecifically designed for the s

ground plane and component placement.

UBX-17056748 - R11 System description Page 6 of 67

C1-Public

Page 7

NINA-B3 series - System integration manual

NINA-B301

NINA-B302

NINA-B306

Grade

Automotive

Professional

• • •

Standard

Radio

v5.0 v5.0 v5.0

G G G

Bluetooth output power EIRP

[dBm]

10 10 10

Max range [meters]

1400 1400 1400

NFC for “Touch to Pair”

• • •

Antenna type

p i b

Application software

Open CPU for embedded

customer applications

• • •

Interfaces

UART

SPI

I2C

I

2

S

USB

GPIO pins

38 38 38

AD converters (ADC)

Features

GATT server and client

Throughput [Mbit/s]

1.4 1.4 14

Maximum Bluetooth

connections

20 20 20

Secure boot

Mesh networking

FOTA

G = GATT

p = Antenna pin

i = Internal PIFA antenna

b = Internal PCB antenna

= Feature enabled by HW. The actual

support depends on the open CPU

application SW.

Bluetooth qualif

Bluetooth prof

ication

iles

Table 1: NINA-B30 series main features summary

UBX-17056748 - R11 System description Page 7 of 67

C1-Public

Page 8

NINA-B3 series - System integration manual

NINA-B311

NINA-B312

NINA-B316

Grad

e

Automotive

Professional

• • •

Standard

Radio

v5.0 v5.0 v5.0

G G

G

Bluetooth output power EIRP

[dBm] *

10 10 10

Max range [meters]

*

1400 1400 1400

NFC for “Touch to Pair”

• • •

Antenna type

*

p i b

Application software

u-connectXpress

• • •

u-connectScript

• • •

Interfaces

UART

1 1 1

GPIO pins

28 28 28

Features

AT command interface

• • •

Script engine – JavaScript

• • •

GATT server and client

• • •

Extended Data Mode

• • •

Low Energy Serial Port Service

• • •

Throughput [Mbit/s]

0.8 0.8 0.8

Maximum Bluetooth

connections

8 8 8

Secure boot

• • •

G = GATT p = Antenna pin i = Internal PIFA antenna b = PCB antenna

Bluetooth qualif

Bluetooth prof

ication

iles

⚠ Regulations in the European market require the maximum output power of the radio to be limited.

Table 2: NINA-B31 series main features summary

See Section 5.1 for more information.

UBX-17056748 - R11 System description Page 8 of 67

C1-Public

Page 9

NINA-B3 series - System integration manual

accelerators

VCC_IO (1.7

VCC (1.7

32 MHz

Reset

UART

GPIO

power

I

PWM

I2S

comparator

NFC

nRF52840

QSPI

USB 2.0

QDEC

PDM

CryptoCell

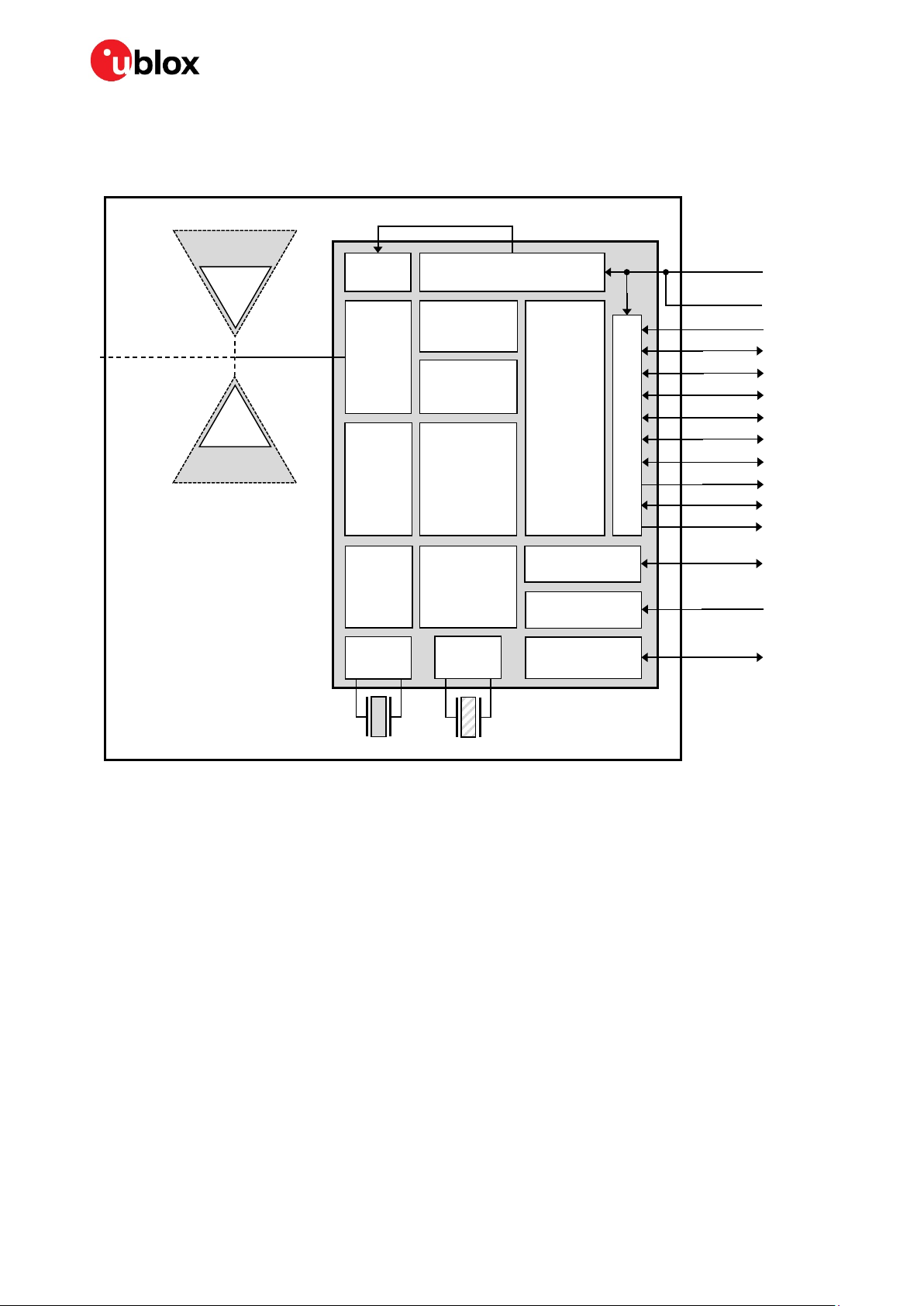

1.2 Architecture

1.2.1 Block diagrams

Antenna pin

NINA-B3x1

PIFA antenna

(NINA-B3x2)

(NINA-B3x6)

PCB trace antenna

1.3 V

System

RF

256 kB

RAM

PLL

DC/DC and LDO regulators

Cryptographic

hardware

BLE baseband

1 MB Flash

RTC, Timers

and Counters

PLL

Nordic Semiconductor

Arm Cortex-M4

USB device

ADC and

Passive NFC tag

- 3.6

– 3.6 V)

SPI

2

C

IO Buffers

Analog

32.768 kHz

Figure 1: Block diagram of the NINA-B3 series. 32.768 kHz crystal not part of NINA-B306-01B

1.2.2 Hardware options

The NINA-B3 series modules use an identical hardware configuration except for the different PCB

sizes and antenna solutions. An on-board 32.768 kHz low power crystal is included in all variants

except the NINA-B306-01B. An integrated DC/DC converter for higher efficiency under heavy load

situations is also included.

1.2.3 Software options

The NINA-B3 series module can be used either together with the pre-flashed u-connectXpress

software or as an open CPU module where you can run your own application developed with the Nordic

SDK development environment inside the NINA-B3 module. The various software options are

described in detail in section 2.

1.3 Pin configuration and function

See the NINA-B3 series Data Sheet [2] for information about pin configuration and function.

UBX-17056748 - R11 System description Page 9 of 67

C1-Public

Page 10

NINA-B3 series - System integration manual

1.4 Supply interfaces

1.4.1 Main supply input

The NINA-B3 series uses an integrated DC/DC converter to transform the supply voltage presented

at the VCC pin into a stable system core voltage. Because of this, the NINA-B3 modules are

compatible for use in battery powered designs.

While using the NINA-B3 with a battery, it is important that the battery type can handle the peak

power of the module. For the battery supply, consider adding extra capacitance on the supply line to

avoid capacity degradation. See the

supply requirements and current consumption.

Rail Voltage requirement Current requirement (peak)

VCC 1.7 V – 3.6 V 20 mA

VCC_IO Tied to VCC

Table 3: Summary of voltage supply requirements

☞ The current requirement in Table 3 considers using the u-connectXpress software with UART

communications. But it does not include any additional I/O current. Any use of external pushbuttons, LEDs, or other interfaces will add to the total current consumption of the NINA-B3

module. The peak current consumption of the entire design will need to be taken into account

when considering a battery powered solution.

NINA-B3 series Data Sheet [2]

for information about voltage

1.4.2 Digital I/O interfaces reference voltage (VCC_IO)

On the NINA-B3 series modules, the I/O voltage level is the same as the supply voltage and VCC_IO is

internally connected to the supply input VCC.

When using NINA-B3 with a battery, the I/O voltage level will vary with the battery output voltage,

depending on the charge of the battery. Level shifters might be needed depending on the I/O voltage

of the host system.

1.4.3 VCC application circuits

The power for NINA-B3 series modules is provided through the VCC pins, which can be one of the

following:

• Switching Mode Power Supply (SMPS)

• Low Drop Out (LDO) regulator

• Battery

The SMPS is the ideal choice when the available primary supply source has a higher value than the

operating supply voltage of the NINA-B3 series modules. The use of SMPS provides the best power

efficiency for the overall application and minimizes the current drawn from the main supply source.

⚠ While selecting SMPS, ensure that the AC voltage ripple at the switching frequency is kept as low

as possible. Layout shall be implemented to minimize impact of high frequency ringing.

The use of an LDO linear regulator is convenient for a primary supply with a relatively low voltage

where the typical 85-90% efficiency of the switching regulator leads to minimal current saving. Linear

regulators are not recommended for high voltage step-down, as they will dissipate a considerable

amount of energy.

DC/DC efficiency should be evaluated as a tradeoff between active and idle duty cycles of the specific

application. Although some DC/DC can achieve high efficiency at extremely light loads, a typical

UBX-17056748 - R11 System description Page 10 of 67

C1-Public

Page 11

NINA-B3 series - System integration manual

DC/DC efficiency quickly degrades as idle current drops below a few mA, greatly reducing the battery

life.

Due to the low current consumption and wide voltage range of the NINA-B3 series module, a battery

can be used as a main supply. The capacity of the battery should be selected to match the application.

Care should be taken so that the battery can deliver the peak current required by the module. See the

NINA-B3 series Data Sheet [2]

It is considered as best practice to have decoupling capacitors on the supply rails close to the NINAB3 series module, although depending on the design of the power routing on the host system,

capacitance might not be needed.

for the electrical specifications.

1.5 System function interfaces

1.5.1 Module reset

You can reset the NINA-B3 modules by applying a low level on the RESET_N input pin, which is

normally set high with an internal pull-up. This causes an “external” or “hardware” reset of the module.

The current parameter settings are not saved in the non-volatile memory of the module and a proper

network detach is not performed.

1.5.2 Internal temperature sensor

The radio chip in the NINA-B3 module contains a temperature sensor used for over temperature and

under temperature shutdown.

⚠ The temperature sensor is located inside the radio chip and should not be used if an accurate

temperature reading of the surrounding environment is required.

1.6 Debug – Serial Wire Debug (SWD)

The primary interface for debugging is the SWD interface. The NINA-B30 series modules provide an

SWD interface for flashing and debugging. The two pins SWDIO and SWDCLK should be made

accessible on header or test points.

The SWD interface is disabled on the NINA-B31 series modules.

1.7 Serial interfaces

⚠ As the NINA B3 module can be used with both the u-connectXpress and open CPU based

applications, based on the Nordic SDK, the available interfaces and the pin mapping may vary. For

detailed pin information, see the Pin configuration and function section.

1.7.1 Universal Asynchronous Serial Interface (UART)

The NINA-B3 series module provides a Universal Asynchronous Serial Interface (UART) for data

communication.

The following UART signals are available:

• Data lines (RXD as input, TXD as output)

• Hardware flow control lines (CTS as input, RTS as output)

• DSR and DTS are used to set and indicate system modes

UBX-17056748 - R11 System description Page 11 of 67

C1-Public

Page 12

NINA-B3 series - System integration manual

The UART can be used as both a 4-wire UART with hardware flow control and a 2-wire UART with only

TXD and RXD. If using the UART in 2-wire mode, CTS should be connected to GND on the

NINA-B3 module.

Depending on the bootloader used, the UART interface can also be used for software upgrades. See

the Software section for more information.

The u-connectXpress software adds the DSR and DTR pins to the UART interface. These pins are not

used as originally intended, but to control the state of the NINA-B3 module. Depending on the current

configuration, the DSR can be used to:

• Enter command mode

• Disconnect and/or toggle connectable status

• Enable/disable the rest of the UART interface

• Enter/wake up from the sleep mode

See the NINA-B3 series Data Sheet [2] for characteristics information about the UART interface.

Interface Default configuration

COM port 115200 baud, 8 data bits, no parity, 1 stop bit, hardware flow control

Table 4: Default settings for the COM port while using the u-connectXpress software

It is recommended to make the UART available either as test points or connected to a header for a

software upgrade.

The I/O level of the UART will follow the VCC voltage and it can thus be in the range of 1.8 V and 3.6 V.

If you are connecting the NINA-B3 module to a host with a different voltage on the UART interface, a

level shifter should be used.

1.7.2 Serial Peripheral Interface (SPI)

NINA-B3 supports up to three serial peripheral interfaces that can operate in both master and slave

modes with a maximum serial clock frequency of 8 MHz in both these modes. The SPI interfaces use

the following signals:

• SCLK

• MOSI

• MISO

• CS

• DCX (Data/Command signal) - This signal is optional but is sometimes used by the SPI slaves to

distinguish between SPI commands and data.

When using the SPI interface in master mode, it is possible to use GPIOs as additional Chip Select (CS)

signals to allow addressing of multiple slaves.

1.7.3 Quad serial peripheral interface (QSPI)

The Quad Serial Peripheral Interface enables connection of external memory to the NINA-B3 module

in order to increase the application program size. The QSPI uses the following signals:

• CLK, serial clock output, up to 32 MHz

• CS, Chip/Slave select output, active low, selects which slave on the bus to talk to

• D0, MOSI serial output data in single mode, data I/O signal in dual/quad mode

• D1, MISO serial input data in single mode, data I/O signal in dual/quad mode

• D2, data I/O signal in quad mode (optional)

• D3, data I/O signal in quad mode (optional)

UBX-17056748 - R11 System description Page 12 of 67

C1-Public

Page 13

NINA-B3 series - System integration manual

NINA-B3 pin

Configurable

GPIOs

1.7.4 I2C interface

The Inter-Integrated Circuit (I2C) interfaces can be used to transfer or receive data on a 2-wire bus

network. The NINA-B3 modules can operate as both master and slave on the I

2

C bus using both

standard (100 kbps) and fast (400 kbps) transmission speeds. The interface uses the SCL signal to

clock instructions and data on the SDA signal.

External pull-up resistors are required for the I

2

C interface. The value of the pull-up resistor should be

selected depending on the speed and capacitance of the bus. See Electrical specifications in the

NINA-B3 series data sheet [2] for recommended resistor values.

1.7.5 USB 2.0 interface

The NINA-B3 series modules include a full speed Universal Serial Bus (USB) device interface compliant

with version 2.0 of the USB specification. The pin configuration of the USB interface is provided below:

• VBUS, 5 V supply input, required in order to use the interface

• USB_DP, USB_DM, differential data pair

The USB interface has a dedicated power supply that requires a 5 V supply voltage for the VBUS pin.

This allows the USB interface to be used even though the rest of the module might be battery powered

or supplied by a 1.8 V supply etc.

1.8 GPIO pins

In an un-configured state, NINA-B3 modules have 38 GPIO pins and no analog or digital interfaces. All

interfaces or functions must be allocated to a GPIO pin before use. Eight of the 38 GPIO pins are analog

enabled, meaning that they can have an analog function allocated to them. In addition to the serial

interfaces, Table 6 shows the digital and analog functions that can be assigned to a GPIO pin.

Function Description Default

General purpose input Digital input with configurable pull-up, pull-down, edge detection

and interrupt generation

General purpose output Digital output with configurable drive strength, push-pull, open

collector or open emitter output

Pin disabled Pin is disconnected from the input and output buffers. All* Any

Timer/ counter High precision time measurement between two pulses/ Pulse

counting with interrupt/event generation

Interrupt/ Event trigger Interrupt/event trigger to software application/ Wake-up event Any

HIGH/LOW/Toggle on event Programmable digital level triggered by internal or external events

without CPU involvement

ADC input 8/10/12/14-bit analog to digital converter Any analog

Analog comparator input Compare two voltages, capable of generating wake-up events and

interrupts

PWM output Output simple or complex pulse width modulation waveforms Any

Connection status indicator Indicates if a BLE connection is maintained BLUE** Any

* = If left unconfigured ** = If using u-connectXpress software

Table 5: GPIO custom functions configuration

Any

Any

Any

Any

Any analog

UBX-17056748 - R11 System description Page 13 of 67

C1-Public

Page 14

NINA-B3 series - System integration manual

1.8.1 Analog interfaces

Eight out of the 38 digital GPIOs can be multiplexed to analog functions. The following analog

functions are available for use:

• 1x 8-channel ADC

• 1x Analog comparator*

• 1x Low-power analog comparator*

*Only one of the comparators can be used simultaneously.

ADC

The Analog to Digital Converter (ADC) can sample up to 200 kHz using different inputs as sample

triggers. Both one-shot conversion and continuous sampling are supported. Table 6 shows the

sample speed in correlation to the maximum source impedance. It supports 8/10/12-bit resolution.

The ADC includes 14-bit resolution if oversampling is used. Any of the 8 analog inputs can be used

both as single-ended inputs and as differential pairs for measuring the voltage across them.

The ADC supports the full 0 V to VCC input range. If the sampled signal level is much lower than VCC,

it is possible to lower the input range of the ADC to encompass the desired signal, and obtain a higher

effective resolution. Continuous sampling can be configured to sample at a configurable time interval,

or at different internal or external events, without CPU involvement.

ACQ [us] Maximum source resistance [kΩ]

3 10

5 40

10 100

15 200

20 400

40 800

Table 6: Acquisition vs. source impedance

Comparator

The comparator compares voltages from any analog pin with different references as shown in Table

7. It supports the full 0 V to VCC input range and can generate different software events to the rest

of the system. The comparator can operate in the one of the following two modes as explained below

- Single-ended or Differential:

• Single-ended Mode: A single reference level or an upper and lower hysteresis selectable from a

64-level reference ladder with a range from 0 V to VREF as described in Table 7

• Differential Mode: Two analog pin voltage levels are compared, optionally with a 50 mV hysteresis

Low power comparator

The low-power comparator operates in the same way as the normal comparator, with reduced

functionality. It can be used during system OFF modes as a wake-up source.

Analog pin options

The following table shows the supported connections of the analog functions.

☞ An analog pin may not be simultaneously connected to multiple functions.

UBX-17056748 - R11 System description Page 14 of 67

C1-Public

Page 15

NINA-B3 series - System integration manual

Symbol Analog function Connects to

ADCP ADC single-ended or differential positive input Any analog pin or VCC

ADCN ADC differential negative input Any analog pin or VCC

VIN+ Comparator input Any analog pin

VREF Comparator single-ended mode reference

ladder input

VIN- Comparator differential mode negative input Any analog pin

LP_VIN+ Low-power comparator IN+ Any analog pin

LP_VIN- Low-power comparator IN- GPIO_16 or GPIO_18, 1/16 to 15/16 VCC in steps of 1/16 VCC

Table 7: Possible uses of the analog pin

Any analog pin, VCC, 1.2 V, 1.8V or 2.4V

1.9 Antenna interfaces

☞ The antenna interface is different for each module variant in the NINA-B3 series.

1.9.1 Antenna pin – NINA-B3x1

The NINA-B3x1 is equipped with an RF pin. The RF pin has a nominal characteristic impedance of 50

Ω and must be connected to the antenna through a 50 Ω transmission line to allow reception of radio

frequency (RF) signals in the 2.4 GHz frequency band.

Choose an antenna with optimal radiating characteristics for the best electrical performance and

overall module functionality. An internal antenna integrated on the application board or an external

antenna that is connected to the application board through a proper 50 Ω connector can be used.

While using an external antenna, the PCB-to-RF-cable transition must be implemented using either a

suitable 50 Ω connector, or an RF-signal solder pad (including GND) that is optimized for 50 Ω

characteristic impedance.

Antenna matching

For optimal performance, the antenna return loss should be as good as possible across the entire

band when the system is operational. The enclosure, shields, other components and surrounding

environment will impact the return loss seen at the antenna port. Matching components are often

required to re-tune the antenna to bring the return loss within an acceptable range.

It is difficult to predict the actual matching values for the antenna in the final form factor. Therefore,

it is a good practice to have a placeholder in the circuit with a ”pi” network, with two shunt components

and a series component in the middle, to allow maximum flexibility while tuning the matching to the

antenna feed.

Approved antenna designs

NINA-B3 modules come with a pre-certified design that can be used to save costs and time during the

certification process. To take advantage of this service, the customer is required to implement an

antenna layout according to the u-blox reference designs. The reference design is described in

Appendix B.

The designer integrating a u-blox reference design into an end-product is solely responsible for the

unintentional emission levels produced by the end product.

The module may be integrated with other antennas. In this case, the OEM installer must certify his

design with the respective regulatory agencies.

UBX-17056748 - R11 System description Page 15 of 67

C1-Public

Page 16

NINA-B3 series - System integration manual

1.9.2 Integrated antenna – NINA-B3x2/B3x6

The NINA-B3x2 and NINA-B3x6 modules are equipped with an integrated antenna on the module. This

will simplify the integration, as there will be no need to do an RF trace design on the host PCB. By using

NINA-B3x2 or NINA-B3x6, the certification of the NINA-B3 series modules can be reused, thus

minimizing the effort needed in the test lab. The NINA-B3x2 modules use an internal metal sheet PIFA

antenna, while the NINA-B3x6 modules have a PCB trace antenna that uses antenna technology

licensed from Proant AB.

1.9.3 NFC antenna

The NINA-B3 series modules include a Near Field Communication interface, capable of operating as a

13.56 MHz NFC tag at a bit rate of 106 kbps. As an NFC tag, data can be read from or written to the

NINA-B3 modules using an NFC reader; however, the NINA-B3 modules are not capable of reading

other tags or initiating NFC communications. Two pins are available for connecting to an external NFC

antenna: NFC1 and NFC2.

1.10 Reserved pins (RSVD)

Do not connect the reserved (RSVD) pin. The reserved pins are allocated for future interfaces and

functionality.

1.11 GND pins

Good connection of the module's GND pins with a solid ground layer of the host application board is

required for correct RF performance. It significantly reduces EMC issues and provides a thermal heat

sink for the module.

See the Module footprint and paste mask and Thermal guidelines sections for information about

ground design.

UBX-17056748 - R11 System description Page 16 of 67

C1-Public

Page 17

NINA-B3 series - System integration manual

Nordic S140 SoftDevice

2 Software

The NINA-B3 series modules can be used either with the pre-flashed u-connectXpress software, or as

an open CPU module in which you can run your own application developed with the Nordic SDK

development environment inside the NINA-B3 module.

The software on the NINA-B3 module contains the following parts:

• SoftDevice S140 is a Bluetooth® low energy (LE) central and peripheral protocol stack solution

• Optional bootloader

• Application

NINA-B3 Software

structure

Radio

Stack

Bootloader

NINA-B31 series

Application

Figure 2: NINA-B3 software structure and available software options

u-connectXpress

NINA-B30 series

Nordic SDK

2.1 u-connectXpress software

The NINA-B31 series modules are delivered with the u-blox secure boot loader and u-connectXpress

software pre-flashed.

The u-connectXpress software enables use of the Bluetooth Low Energy functions, controlled by

AT commands over the UART interface. Examples of supported features are u-blox Low Energy Serial

Port Service, GATT server and client, central and peripheral roles, and multidrop connections. More

information on the features and capabilities of the u-connectXpress software and how to use it can

be found in NINA-B31 Getting Started [13] and the u-connect AT commands manual [3].

2.2 Open CPU

2.2.1 Nordic SDK

The Nordic nRF5 SDK provides a rich development environment for various devices and applications

by including a broad selection of drivers and libraries. The SDK is delivered as a plain zip archive, which

makes it easy to install. The SDK comes with support for the SEGGER Embedded Studio, Keil and IAR

IDEs, as well as the GCC compiler, which offers the freedom to choose the IDE and compiler.

Getting started on the Nordic SDK

When working with the Nordic SDK on the NINA-B3 series module, follow the steps below to get

started with the Nordic Semiconductor toolchain and examples:

UBX-17056748 - R11 Software Page 17 of 67

C1-Public

Page 18

NINA-B3 series - System integration manual

1. Download and install the nRF Connect application and install the Programmer app, which allows

programming over SWD, from www.nordicsemi.com.

2. Download and install the latest SEGGER Embedded Studio from www.segger.com.

3. Download and extract the latest nRF5 SDK found on

http://www.nordicsemi.com/eng/Products/Bluetooth-low-energy/nRF5-SDK to the directory that

you want to use to work with the nRF5 SDK.

4. Read the information in the SDK Release Notes and check the nRF5 software development kit

documentation available at the Nordic Semiconductor Infocenter [11].

2.2.1.1.1 Nordic tools

More information and links to all available tools as well as supported compilers can be found in the

Nordic Semiconductor Software and Tools page - https://www.nordicsemi.com/Software-and-Tools

2.2.1.1.2 Support – Nordic development forum

For support on questions related to the development of software using the Nordic SDK, refer to the

Nordic development zone

- https://devzone.nordicsemi.com/

Create a custom board for Nordic SDK

The predefined hardware boards included in the Nordic SDK are Nordic development boards only. To

add support for a custom board, a custom board support file with the name custom_board.h can be

created. This file should be located in the folder “…\components\boards\”. The custom board can then

be selected by adding the define statement - #define BOARD_CUSTOM.

☞ The above-mentioned file location is according to the Nordic nRF5 SDK version 15.3.0.

Figure 3 shows an example of how the custom board support file can look like for the EVK-NINA-B3.

UBX-17056748 - R11 Software Page 18 of 67

C1-Public

Page 19

NINA-B3 series - System integration manual

#ifndef CUSTOM_BOARD_H

#define CUSTOM_BOARD_H

#ifdef __cplusplus

extern "C" {

#endif

#include "nrf_gpio.h"

// In this file PIN 25 is used as button SWITCH_1, if the GREEN led

// should be used it is possible to defined that one instead.

#define LEDS_NUMBER 2

#define LED_1 NRF_GPIO_PIN_MAP(0,13) // RED

#define LED_2 NRF_GPIO_PIN_MAP(1,00) // BLUE

// #define LED_3 NRF_GPIO_PIN_MAP(0,25) // GREEN

#define LEDS_ACTIVE_STATE 0

#define LEDS_LIST { LED_1, LED_2 }

#define LEDS_INV_MASK LEDS_MASK

#define BSP_LED_0 LED_1

#define BSP_LED_1 LED_2

// #define BSP_LED_2 LED_3

#define BUTTONS_NUMBER 2

#define BUTTON_1 25 // SWITCH_1

#define BUTTON_2 2 // SWITCH_2

#define BUTTON_PULL NRF_GPIO_PIN_PULLUP

#define BUTTONS_ACTIVE_STATE 0

#define BUTTONS_LIST { BUTTON_1, BUTTON_2 }

#define BSP_BUTTON_0 BUTTON_1

#define BSP_BUTTON_1 BUTTON_2

#define RX_PIN_NUMBER NRF_GPIO_PIN_MAP(0,29)

#define TX_PIN_NUMBER NRF_GPIO_PIN_MAP(1,13)

#define CTS_PIN_NUMBER NRF_GPIO_PIN_MAP(1,12)

#define RTS_PIN_NUMBER NRF_GPIO_PIN_MAP(0,31)

#define HWFC true

#define BSP_QSPI_SCK_PIN 19

#define BSP_QSPI_CSN_PIN 17

#define BSP_QSPI_IO0_PIN 20

#define BSP_QSPI_IO1_PIN 21

#define BSP_QSPI_IO2_PIN 22

#define BSP_QSPI_IO3_PIN 23

// Arduino board mappings

#define ARDUINO_SCL_PIN 24 // SCL signal pin

#define ARDUINO_SDA_PIN 16 // SDA signal pin

#define ARDUINO_13_PIN NRF_GPIO_PIN_MAP(0, 7)

#define ARDUINO_12_PIN NRF_GPIO_PIN_MAP(0, 2)

#define ARDUINO_11_PIN NRF_GPIO_PIN_MAP(0, 15)

#define ARDUINO_10_PIN NRF_GPIO_PIN_MAP(0, 14)

#define ARDUINO_9_PIN NRF_GPIO_PIN_MAP(0, 12)

#define ARDUINO_8_PIN NRF_GPIO_PIN_MAP(1, 9)

#define ARDUINO_7_PIN NRF_GPIO_PIN_MAP(0, 10)

#define ARDUINO_6_PIN NRF_GPIO_PIN_MAP(0, 9)

#define ARDUINO_5_PIN NRF_GPIO_PIN_MAP(0, 11)

#define ARDUINO_4_PIN NRF_GPIO_PIN_MAP(0, 13)

#define ARDUINO_3_PIN NRF_GPIO_PIN_MAP(0, 31)

#define ARDUINO_2_PIN NRF_GPIO_PIN_MAP(1, 12)

Figure 3: Example of EVK-NINA-B3 custom board support file

UBX-17056748 - R11 Software Page 19 of 67

C1-Public

Page 20

NINA-B3 series - System integration manual

#define ARDUINO_A0_PIN NRF_GPIO_PIN_MAP(0, 4)

#endif // CUSTOM BOARD H

#define ARDUINO_A1_PIN NRF_GPIO_PIN_MAP(0, 30)

#define ARDUINO_A2_PIN NRF_GPIO_PIN_MAP(0, 5)

#define ARDUINO_A3_PIN NRF_GPIO_PIN_MAP(0, 2)

#define ARDUINO_A4_PIN NRF_GPIO_PIN_MAP(0, 28)

#define ARDUINO_A5_PIN NRF_GPIO_PIN_MAP(0, 3)

#define RASPBERRY_PI_3_PIN NRF_GPIO_PIN_MAP(0, 24)

#define RASPBERRY_PI_5_PIN NRF_GPIO_PIN_MAP(0, 16)

#define RASPBERRY_PI_7_PIN NRF_GPIO_PIN_MAP(0, 15)

#define RASPBERRY_PI_11_PIN NRF_GPIO_PIN_MAP(0, 14)

#define RASPBERRY_PI_13_PIN NRF_GPIO_PIN_MAP(0, 19)

#define RASPBERRY_PI_15_PIN NRF_GPIO_PIN_MAP(0, 17)

#define RASPBERRY_PI_19_PIN NRF_GPIO_PIN_MAP(0, 21)

#define RASPBERRY_PI_21_PIN NRF_GPIO_PIN_MAP(0, 23)

#define RASPBERRY_PI_23_PIN NRF_GPIO_PIN_MAP(0, 7)

#define RASPBERRY_PI_27_PIN NRF_GPIO_PIN_MAP(0, 26)

#define RASPBERRY_PI_29_PIN NRF_GPIO_PIN_MAP(1, 15)

#define RASPBERRY_PI_31_PIN NRF_GPIO_PIN_MAP(1, 11)

#define RASPBERRY_PI_33_PIN NRF_GPIO_PIN_MAP(1, 3)

#define RASPBERRY_PI_35_PIN NRF_GPIO_PIN_MAP(1, 2)

#define RASPBERRY_PI_37_PIN NRF_GPIO_PIN_MAP(1, 8)

#define RASPBERRY_PI_8_PIN RX_PIN_NUMBER

#define RASPBERRY_PI_10_PIN TX_PIN_NUMBER

#define RASPBERRY_PI_12_PIN NRF_GPIO_PIN_MAP(0, 13)

#define RASPBERRY_PI_16_PIN NRF_GPIO_PIN_MAP(0, 20)

#define RASPBERRY_PI_18_PIN NRF_GPIO_PIN_MAP(0, 22)

#define RASPBERRY_PI_22_PIN NRF_GPIO_PIN_MAP(0, 12)

#define RASPBERRY_PI_24_PIN NRF_GPIO_PIN_MAP(0, 27)

#define RASPBERRY_PI_26_PIN NRF_GPIO_PIN_MAP(0, 6)

#define RASPBERRY_PI_28_PIN NRF_GPIO_PIN_MAP(1, 14)

#define RASPBERRY_PI_32_PIN NRF_GPIO_PIN_MAP(1, 10)

#define RASPBERRY_PI_36_PIN NRF_GPIO_PIN_MAP(1, 1)

#define RASPBERRY_PI_38_PIN NRF_GPIO_PIN_MAP(1, 9)

#define RASPBERRY_PI_40_PIN NRF_GPIO_PIN_MAP(0, 11)

#ifdef __cplusplus

}

#endif

Figure 4: Example of EVK-NINA-B3 custom board support file (continued)

The custom board can then be selected by adding the define statement: #define BOARD_CUSTOM.

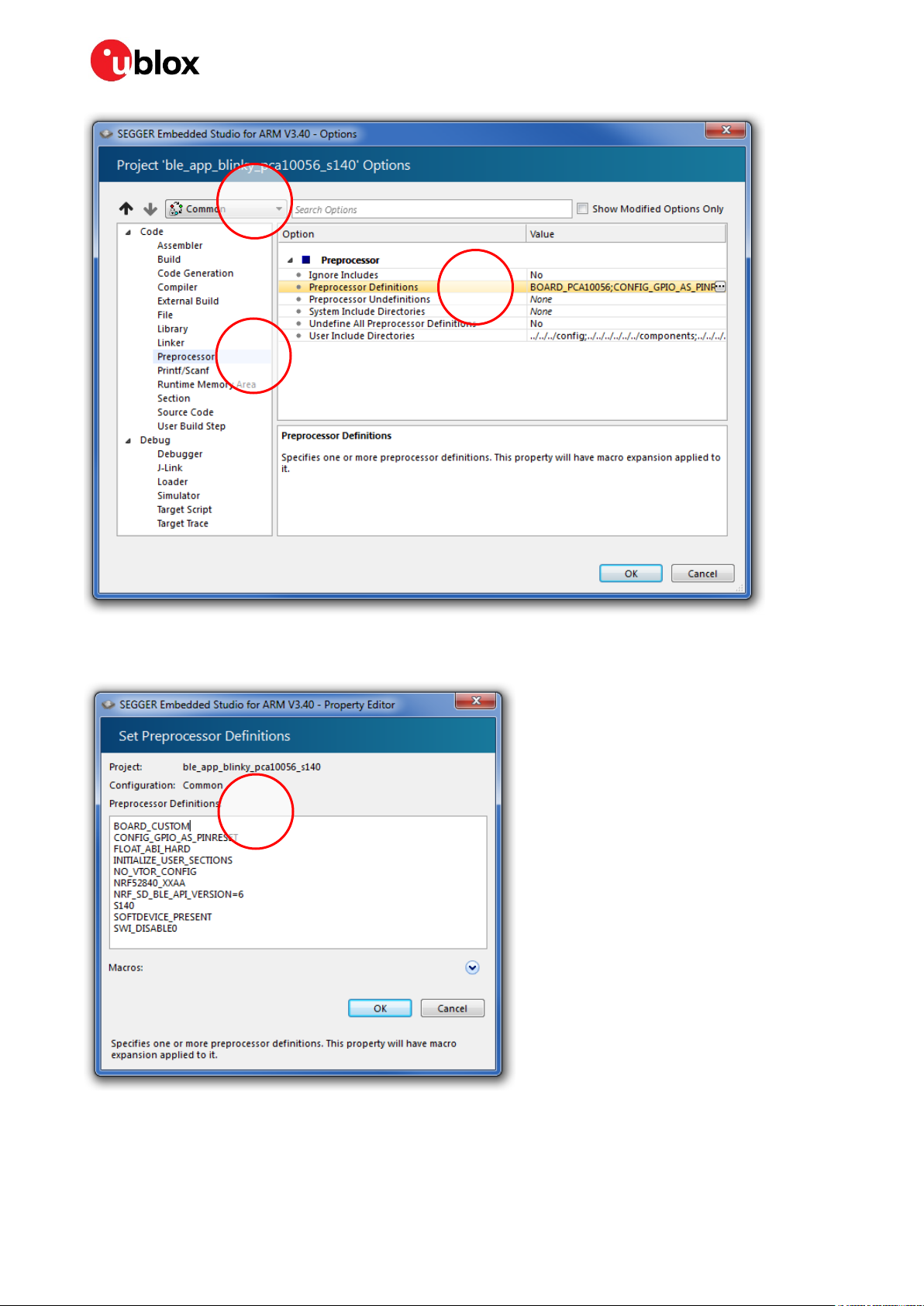

You can add the BOARD_CUSTOM define statement in SEGGER Embedded Studio 3.40 by following

the instructions provided below:

1. Right-click on the Project in “Project Explorer”

2. Select Edit Options…

1.

Figure 5: Screenshot with steps to modify the Define statement in SEGGER Embedded Studio

3. Select the “Common” configuration

4. Select the Code / Preprocessor

5. Select the Preprocessor Definitions

2.

UBX-17056748 - R11 Software Page 20 of 67

C1-Public

Page 21

NINA-B3 series - System integration manual

3.

5.

4.

Figure 6: Screenshot with steps to modify the Define statement in SEGGER Embedded Studio

6. Modify the “BOARD_” definition to define the BOARD_CUSTOM

6.

Figure 7: Screenshot with steps to modify the Define statement in SEGGER Embedded Studio

UBX-17056748 - R11 Software Page 21 of 67

C1-Public

Page 22

NINA-B3 series - System integration manual

LF clock source configuration

For more information regarding how to configure your application in the Nordic SDK to use the internal

RC oscillator or an external LFXO please see reference [15].

2.2.2 Bluetooth MAC address and other production data

The open CPU (B30x) variants of the NINA-B3 modules is provided with a Bluetooth MAC address

programmed similar to that in the u-connectXpress variant. If required, this address can be used by

the customer application.

The MAC address is programmed in the CUSTOMER[0] and CUSTOMER[1] registers in the UICR of

the nRF52840 chip. The address can be read and written for example, using Segger J-Link utilities or

the nrfjprog utility from Nordic.

$ nrfjprog.exe --memrd 0x10001080 --n 8

The memory area can be saved and, if the flash is erased, written back later using the savebin and

loadbin utilities in the Segger J-link tool suite.

The UICR memory area also holds the serial number and other information that can be valuable to

save. If you want to save the whole memory area use the following commands:

$ nrfjprog.exe --readuicr uicr.hex

...

$ nrfjprog.exe --program uicr.hex

For additional information and instructions on saving and using the public Bluetooth device address,

see reference [14].

2.3 Flashing the NINA-B31 u-blox software

It is possible to reflash the NINA-B31 module using the UART interface whenever a new version of the

u-connectXpress software is available.

2.3.1 UART flashing

The u-connectXpress software for UART flashing contains two separate .bin files. One bin file

contains the application and the other contains the SoftDevice as listed below:

• Application – NINA-B31X-SW-x.y.z-<build>.bin (Example:

• SoftDevice – NINA-S140-SD-a.b.c.bin (Example:

A signature file for each of the above-mentioned files is also included, as well as a .json header file.

NINA-S140-SD-6.1.1.bin)

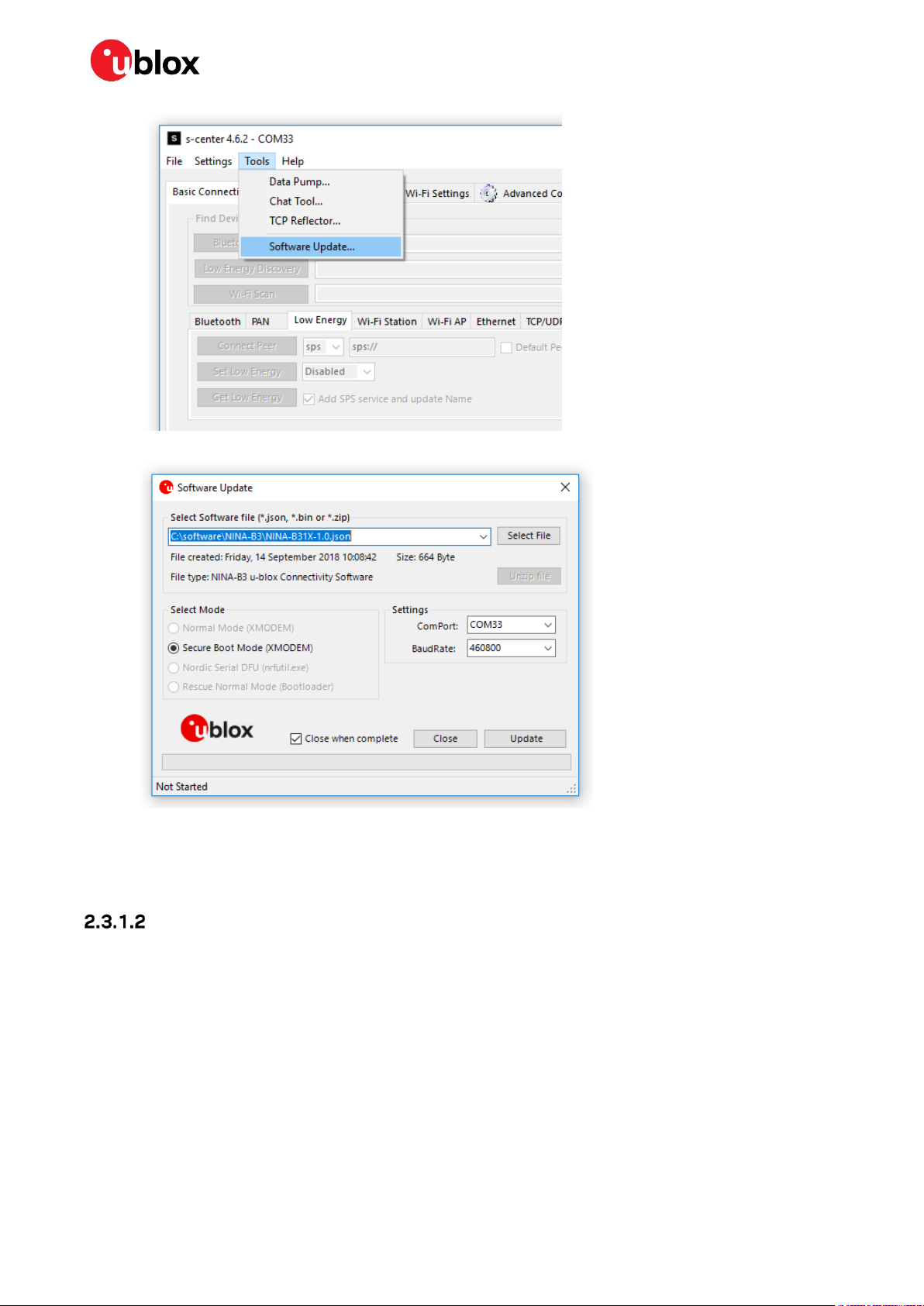

Software flashing using s-center

⚠ Flashing of u-blox software requires s-center software version 4.6.2 or later.

NINA-B31X-SW-3.0.0-005.bin)

To flash the module using s-center,

1. Select Tools > Software Update

UBX-17056748 - R11 Software Page 22 of 67

C1-Public

as shown in the following screenshot:

Page 23

NINA-B3 series - System integration manual

2. Select the .json file.

3. Secure Boot Mode will be set automatically, ensure that the correct COM port is selected then

click the Update button to start the process.

4. The module will then reboot into the bootloader and the flashing of the SoftDevice and the

application will start.

Software flashing using AT command

The flashing functionality in the NINA-B31x module can manage two signed binary images. Image0 is

the application. Image1 is the SoftDevice. The SoftDevice is updated using dual banked approach.

Hence a SoftDevice update will invalidate the application currently flashed in the module, so it is

required to flash the application after a SoftDevice update.

Use the

AT+UFWUPD=<mode>,<baud_rate>[,<id>,<size>,<signature>,<name>,<flags>]

AT+UFWUPD AT command to update the software.

The file download uses an XMODEM protocol. The UART hardware flow is not used during the software

update. See the u-connect AT commands manual [3] for information about the firmware update

command.

☞ The XMODEM protocol uses standard XMODEM-CRC16 protocol and 128 bytes packets.

UBX-17056748 - R11 Software Page 23 of 67

C1-Public

Page 24

NINA-B3 series - System integration manual

2.3.1.2.1 Sample commands executed while flashing the application only

1. Run the AT+UFWUPD command to trigger the u-connectXpress software to accept an application bin

file for download. The application size can be found in the

should be entered in decimal notation. The signature for the application is available in the

NINA-B31X-SI-x.x.x-xxx.txt file.

NINA-B31X-CF-x.x.json file; the size

2. When a ‘C’ character is received from the module, XMODEM download is ready to begin from the

host.

3. Send the application bin file using XMODEM protocol.

4. After a successful file transfer, the module will automatically start the application.

2.3.1.2.2 Sample commands executed when flashing the SoftDevice and application

1. Start the bootloader mode using either:

The AT command Press the SW1 and SW2 buttons during a module reset

2. The “

s <imageid> <signature>” command stores the SoftDevice signature. The image id of the

SoftDevice is 1. The signature is available in the

AT+UFWUPD=1,115200

NINA-S140-SI-x.x.x.txt file.

UBX-17056748 - R11 Software Page 24 of 67

C1-Public

Page 25

NINA-B3 series - System integration manual

3. The “x <imageaddress> <imagesize> <imagename> <permissions> <imageid>” command triggers

the bootloader to accept a file transfer using XMODEM protocol. The image address and image

size can be found in the NINA-B31X-CF-X.Y.json file. Set permission to read/write, rw.

4. When a “

C” character is received from the module, the XMODEM download is ready to begin from

the host.

5. After a successful download of the SoftDevice image, the application image must be flashed.

6. The application is flashed like the SoftDevice. Use image address and image size for the

application image, which can be found in the

NINA-B31X-CF-x.x.json under the label – u-connect.

The image id of the application is 0. The application’s signature is available in the NINA-B31X-SIx.x.x-xxx.txt file. Set permission to read/write/execute, rwx.

7. Store the application image (image id 0) as the startup image with the “

UBX-17056748 - R11 Software Page 25 of 67

C1-Public

f <imageid>” command.

Page 26

NINA-B3 series - System integration manual

8. Reset the module to start up the module with the newly flashed software.

2.4 Flashing the NINA-B30 open CPU software

The NINA-B30 open CPU module can be flashed with the SWD interface.

2.4.1 SWD flashing

For SWD flashing, an external debugger has to be connected to the SWD interface of the

NINA-B30 module. Then an external tool such as the J-flash or the nRF Connect Programmer from

Nordic Semiconductor.

☞ The external debugger SEGGER J-Link BASE works with the NINA-B30 modules.

☞ The EVK-NINA-B30 evaluation kit incorporates an onboard debugger and can therefore be flashed

without any external debugger.

Flashing the software

⚠ Flashing the software will erase the Bluetooth device address, which must be manually rewritten

to the module after flashing. Ensure that you make a note of your Bluetooth device address before

continuing with the flashing procedure. See section 2.2.2 for additional information.

In the nRF Connect Programmer, drag and drop the hex files you want to program into the GUI as

shown in the following screenshot:

UBX-17056748 - R11 Software Page 26 of 67

C1-Public

Page 27

NINA-B3 series - System integration manual

UBX-17056748 - R11 Software Page 27 of 67

C1-Public

Page 28

NINA-B3 series - System integration manual

3 Design-in

3.1 Overview

For an optimal integration of NINA-B3 series modules in the final application board, it is recommended

to follow the design guidelines stated in this chapter. Every application circuit must be properly

designed to guarantee the correct functionality of the related interface, although a number of points

require special attention during the design of the application device.

The following list provides some important points sorted by rank of criticality in the application

design, starting from the highest relevance:

1. Module antenna connection: Ant pad.

The antenna circuit affects the RF compliance of the device integrating the NINA-B3 modules with

the applicable certification schemes. Follow the recommendations provided in section 3.2 for

schematic and layout design.

2. Module supply: VCC, VCC_IO, and GND pins.

The supply circuit affects the performance of the device integrating the NINA-B3 series module.

Follow the recommendations provided in section 3.3.3.2 for schematic and layout design.

3. Analog signals: GPIO

Analog signals are sensitive to noise and should be routed away from high frequency signals.

4. High speed interfaces: UART, SPI and SWD pins.

High speed interfaces can be a source of radiated noise and can affect compliance with regulatory

standards for radiated emissions. Follow the recommendations provided in sections 3.5.1 and 3.3.3.2

for schematic and layout design.

5. System functions: RESET_N, I2C, GPIO and other System input and output pins.

Accurate design is required to guarantee that the voltage level is well defined during module boot.

6. Other pins:

Accurate design is required to guarantee proper functionality.

3.2 Design for NINA family

The NINA-B3 is based on the Nordic nRF52840 chip that has larger dimensions when compared to

the nRF52832 that is used in NINA-B1. Because of this and to enable more GPIO pins underneath the

module, the size of the NINA-B3 series needs to be increased. For instance, the module size of the

NINA B3x2 is 10 x 15.0 mm as compared to the NINA-B112, which is 10 x 14.0 mm.

Pinouts for both the NINA-B1 and W1 are supported so that all modules in the NINA series can be

placed interchangeably on each other’s footprints. However, to accommodate the larger dimension of

the NINA-B3, a keep-out area of 1 mm should be reserved during design. Otherwise the mechanical

design of the NINA-B3 is identical to the NINA-B1 and W1 modules.

3.3 Antenna interface

As the unit cannot be mounted arbitrarily, the placement should be chosen with consideration so that

it does not interfere with radio communications. The NINA-B3x2 with an internal surface mounted

antenna cannot be mounted inside a metal enclosure. No metal casing or plastics using metal flakes

should be used. Avoid metallic based paint or lacquer as well. The NINA-B3x1 offers more freedom, as

an external antenna can be mounted further away from the module.

UBX-17056748 - R11 Design-in Page 28 of 67

C1-Public

Page 29

NINA-B3 series - System integration manual

⚠ According to FCC regulations, the transmission line from the module’s antenna pin to the antenna

or antenna connector on the host PCB is considered part of the approved antenna design.

Therefore, module integrators must either follow exactly one of the antenna reference designs

used in the module’s FCC type approval or certify their own designs.

3.3.1 RF transmission line design (NINA-B3x1 only)

RF transmission lines, such as the ones from the ANT pad up to the related antenna connector or up

to the related internal antenna pad, must be designed so that the characteristic impedance is as close

as possible to 50 Ω. Figure 8 illustrates the design options and the main parameters to be taken into

account when implementing a transmission line on a PCB:

• The micro strip (a track coupled to a single ground plane, separated by dielectric material).

• The coplanar micro strip (a track coupled to ground plane and side conductors, separated by

dielectric materials).

• The strip line (a track sandwiched between two parallel ground planes, separated by dielectric

materials).

Figure 8: Transmission line trace design

To properly design a 50 Ω transmission line, the following remarks should be taken into account:

• The designer should provide enough clearance from surrounding traces and ground in the same

layer; in general, a trace to ground clearance of at least two times the trace width should be

considered and the transmission line should be ‘guarded’ by ground plane area on each side.

• The characteristic impedance can be calculated as a first iteration by using tools provided by the

layout software. It is advisable to ask the PCB manufacturer to provide the final values that are

usually calculated using dedicated software and available stack-ups from production. It could also

be possible to request an impedance coupon on the panel’s side in order to measure the real

impedance of the traces.

• FR-4 dielectric material, although its high losses at high frequencies can be considered in RF

designs providing that:

UBX-17056748 - R11 Design-in Page 29 of 67

C1-Public

Page 30

NINA-B3 series - System integration manual

o RF trace length must be minimized to reduce dielectric losses.

o If traces longer than a few centimeters are needed, it is recommended to use a coaxial

connector and cable to reduce losses.

o Stack-up should allow for thick 50 Ω traces and at least 200 µm of trace width is recommended

to ensure good impedance control over the PCB manufacturing process.

o FR-4 material exhibits poor thickness stability and thus less control of impedance over the

trace length. Contact the PCB manufacturer for specific tolerance of controlled impedance

traces.

• The transmission lines width and spacing to GND must be uniform and routed as smoothly as

possible: route RF lines in 45° angle or in arcs.

• Add GND stitching vias around transmission lines.

• Ensure solid metal connection of the adjacent metal layer on the PCB stack-up to the main ground

layer, providing enough vias on the adjacent metal layer.

• Route RF transmission lines far from any noise source (as switching supplies and digital lines) and

from any sensitive circuit to avoid crosstalk between RF traces and Hi-impedance or analog

signals.

• Avoid stubs on the transmission lines; any component on the transmission line should be placed

with the connected pad over the trace. Also avoid any unnecessary component on RF traces.

Figure 9: Example of RF trace and ground plane design from NINA-B3 Evaluation Kit (EVK)

3.3.2 Antenna design (NINA-B3x1 only)

NINA-B301 and NINA-B311 is suitable for designs where an external antenna is needed due to

mechanical integration or placement of the module.

Designers must take care of the antennas from all perspectives at the beginning of the design phase

when the physical dimensions of the application board are under analysis/decision, because the RF

compliance of the device integrating the NINA-B3 module with all the applicable required certification

schemes heavily depends on the radiating performance of the antennas. The designer is encouraged

to consider one of the u-blox suggested antenna part numbers and follow the layout requirements.

• External antennas, such as a linear monopole:

UBX-17056748 - R11 Design-in Page 30 of 67

C1-Public

Page 31

NINA-B3 series - System integration manual

o External antennas basically do not impose any physical restrictions on the design of the PCB

where the module is mounted.

o The radiation performance mainly depends on the antennas. It is required to select antennas

with optimal radiating performance in the operating bands.

o RF cables should be carefully selected with minimum insertion losses. Additional insertion loss

will be introduced by low quality or long cables. Large insertion loss reduces radiation

performance.

o A high quality 50 Ω coaxial connector provides proper PCB-to-RF-cable transition.

• Integrated antennas such as patch-like antennas:

o Internal integrated antennas impose physical restrictions on the PCB design:

An integrated antenna excites RF currents on its counterpoise, typically the PCB ground plane

of the device that becomes part of the antenna; its dimension defines the minimum frequency

that can be radiated. Therefore, the ground plane can be reduced down to a minimum size that

should be similar to the quarter of the wavelength of the minimum frequency that needs to be

radiated, given that the orientation of the ground plane related to the antenna element must

be considered.

The RF isolation between antennas in the system must be as high as possible and the

correlation between the 3D radiation patterns of the two antennas must be as low as possible.

In general, an RF separation of at least a quarter wavelength between the two antennas is

required to achieve a maximum isolation and low pattern correlation; increased separation

should be considered if possible to maximize the performance and fulfill the requirements in

Table 8.

As a numerical example, the physical restriction to the PCB design can be considered as shown

below:

Frequency = 2.4 GHz Wavelength = 12.5 cm Quarter wavelength = 3.125 cm

1

o Radiation performance depends on the entire product and antenna system design, including

product mechanical design and usage. Antennas should be selected with optimal radiating

performance in the operating bands according to the mechanical specifications of the PCB and

the entire product.

Table 8 summarizes the requirements for the antenna RF interface.

Item Requirements Remarks

Impedance

Frequency

Range

Return Loss S11 < -10 dB (VSWR < 2:1)

Efficiency > -1.5 dB ( > 70% )

Maximum Gain +3 dBi Higher gain antennas could be used, but must be evaluated and/or certified.

Table 8: Summary of antenna interface (ANT) requirements for NINA-B3

50 Ω nominal characteristic

impedance

2400 - 2500 MHz Bluetooth low energy.

recommended

< -6 dB (VSWR < 3:1)

S

11

acceptable

recommended

> -3.0 dB ( > 50% )

acceptable

The impedance of the antenna RF connection must match the 50 Ω

impedance of the ANT pin.

The Return loss or the S

power, measuring how well the primary antenna RF connection matches the

50 Ω characteristic impedance of the ANT pin.

The impedance of the antenna termination must match as much as possible

the 50 Ω nominal impedance of the ANT pin over the operating frequency

range, thus maximizing the amount of the power transferred to the antenna.

The radiation efficiency is the ratio of the radiated power to the power

delivered to the antenna input; the efficiency is a measure of how well an

antenna receives or transmits.

See Section 0 for more information on regulatory requirements.

, as the VSWR, refers to the amount of reflected

11

1

Wavelength referred to a signal propagating over the air

UBX-17056748 - R11 Design-in Page 31 of 67

C1-Public

Page 32

NINA-B3 series - System integration manual

While selecting external or internal antennas, the following recommendations should be observed:

• Select antennas that provide optimal return loss (or VSWR) figure over all the operating

frequencies.

• Select antennas that provide optimal efficiency figure over all the operating frequencies.

• Select antennas that provide an appropriate gain figure (that is, combined antenna directivity and

efficiency figure), so that the electromagnetic field radiation intensity does not exceed the

regulatory limits specified in some countries (for example, by the FCC in the United States).

RF Connector Design

If an external antenna is required, the designer should consider using a proper RF connector. It is the

responsibility of the designer to verify the compatibility between plugs and receptacles used in the

design.

Table 9 suggests some RF connector plugs that can be used by the designers to connect RF coaxial

cables based on the declaration of the respective manufacturers. The Hirose U.FL-R-SMT RF

receptacles (or similar parts) require a suitable mated RF plug from the same connector series. Due

to wide usage of this connector, several manufacturers offer compatible equivalents.

Manufacturer Series Remarks

Hirose U.FL® Ultra Small Surface Mount Coaxial Connector Recommended

I-PEX MHF® Micro Coaxial Connector

Tyco UMCC® Ultra-Miniature Coax Connector

Amphenol RF AMC® Amphenol Micro Coaxial

Lighthorse Technologies, Inc. IPX ultra micro-miniature RF connector

Table 9: U.FL compatible plug connector

Typically, the RF plug is available as a cable assembly. Different types of cable assembly are available;

the user should select the cable assembly best suited to the application. The key characteristics are:

• RF plug type: select U.FL or equivalent

• Nominal impedance: 50 Ω