Page 1

NEO-D9S

u-blox D9 correction data receiver

Integration manual

Abstract

This document describes the features and specifications of the u-blox D9

correction data receiver.

www.u-blox.com

UBX-19026111 - R05

C1-Public

Page 2

NEO-D9S-Integration manual

Document information

Title NEO-D9S

Subtitle u-blox D9 correction data receiver

Document type Integration manual

Document number UBX-19026111

Revision and date R05 17-Nov-2020

Document status Early production information

Disclosure restriction C1-Public

This document applies to the following products:

Product name Type number Firmware version PCN reference

NEO-D9S NEO-D9S-00B-00 PMP 1.04 N/A

u-blox reserves all rights to this document and the information contained herein. Products, names, logos and designs

described herein may in whole or in part be subject to intellectual property rights. Reproduction, use, modification or

disclosure to third parties of this document or any part thereof without the express permission of u-blox is strictly prohibited.

The information contained herein is provided "as is" and u-blox assumes no liability for the use of the information. No warranty,

either express or implied, is given with respect to, including but not limited to, the accuracy, correctness, reliability and fitness

for a particular purpose of the information. This document may be revised by u-blox at any time. For most recent documents,

please visit www.u blox.com.

Copyright © 2020, u-blox AG.

u-blox is a registered trademark of u-blox Holding AG in the EU and other countries.

UBX-19026111 - R05

C1-Public Early production information

Page 2 of 51

Page 3

NEO-D9S-Integration manual

Contents

1 Integration manual structure............................................................................................ 5

2 System description...............................................................................................................6

2.1 Overview.................................................................................................................................................... 6

2.1.1 Satellite L band DGNSS................................................................................................................6

2.2 Architecture..............................................................................................................................................6

2.2.1 Block diagram..................................................................................................................................6

3 Receiver functionality..........................................................................................................7

3.1 Receiver configuration........................................................................................................................... 7

3.1.1 Changing the receiver configuration..........................................................................................7

3.1.2 Default L band configuration.......................................................................................................7

3.1.3 Default interface settings............................................................................................................ 7

3.1.4 Basic receiver configuration.........................................................................................................8

3.1.5 L band service selection............................................................................................................... 8

3.1.6 Power management....................................................................................................................... 9

3.2 Communication interfaces................................................................................................................. 10

3.2.1 UART...............................................................................................................................................11

3.2.2 I2C interface..................................................................................................................................12

3.2.3 SPI interface..................................................................................................................................15

3.2.4 USB interface................................................................................................................................16

3.3 Predefined PIOs..................................................................................................................................... 17

3.3.1 D_SEL..............................................................................................................................................17

3.3.2 RESET_N........................................................................................................................................17

3.3.3 SAFEBOOT_N................................................................................................................................17

3.3.4 TX_READY..................................................................................................................................... 18

3.3.5 EXTINT............................................................................................................................................18

3.4 Antenna supervisor..............................................................................................................................18

3.4.1 Antenna voltage control - ANT_OFF........................................................................................20

3.4.2 Antenna short detection - ANT_SHORT_N............................................................................ 20

3.4.3 Antenna short detection auto recovery.................................................................................. 21

3.4.4 Antenna open circuit detection - ANT_DETECT................................................................... 21

3.5 Security................................................................................................................................................... 22

3.5.1 Receiver status monitoring....................................................................................................... 22

3.6 Forcing a receiver reset....................................................................................................................... 22

3.7 Firmware upload....................................................................................................................................22

4 Design..................................................................................................................................... 23

4.1 Pin assigment........................................................................................................................................ 23

4.2 Antenna...................................................................................................................................................24

4.2.1 Antenna bias.................................................................................................................................27

4.3 Power supply.......................................................................................................................................... 29

4.3.1 VCC: Main supply voltage.......................................................................................................... 29

4.3.2 NEO-D9S power supply.............................................................................................................. 29

4.4 NEO-D9S minimal design................................................................................................................... 30

4.5 EOS/ESD precautions.......................................................................................................................... 30

4.5.1 ESD protection measures.......................................................................................................... 31

UBX-19026111 - R05

C1-Public Early production information

Contents Page 3 of 51

Page 4

4.5.2 EOS precautions...........................................................................................................................31

4.5.3 Safety precautions...................................................................................................................... 32

4.6 Electromagnetic interference on I/O lines.......................................................................................32

4.6.1 General notes on interference issues...................................................................................... 32

4.6.2 In-band interference mitigation................................................................................................ 33

4.6.3 Out-of-band interference........................................................................................................... 33

4.7 Layout...................................................................................................................................................... 34

4.7.1 Placement......................................................................................................................................34

4.7.2 Thermal management................................................................................................................ 34

4.7.3 Package footprint, copper and paste mask........................................................................... 34

4.7.4 Layout guidance........................................................................................................................... 36

4.8 Design guidance....................................................................................................................................38

4.8.1 General considerations............................................................................................................... 38

4.8.2 RF front-end circuit options...................................................................................................... 38

4.8.3 Antenna/RF input........................................................................................................................ 39

4.8.4 Schematic design........................................................................................................................ 39

4.8.5 Layout design-in guideline......................................................................................................... 40

5 Product handling................................................................................................................. 41

5.1 ESD handling precautions.................................................................................................................. 41

5.2 Soldering.................................................................................................................................................41

5.3 Tapes....................................................................................................................................................... 44

5.4 Reels........................................................................................................................................................ 45

5.5 Moisture sensitivity levels.................................................................................................................. 45

Appendix.................................................................................................................................... 46

A Stacked patch antenna.......................................................................................................................... 46

B Glossary......................................................................................................................................................47

Related documents................................................................................................................ 49

Revision history.......................................................................................................................50

Page 5

NEO-D9S-Integration manual

1 Integration manual structure

This manual provides a wealth of information to enable a successful design with the u-blox D9

correction data receiver. The manual is structured according to system, software and hardware

aspects.

The first section, "System description" gives an overview of the u-blox D9 correction data receiver

with a block diagram of NEO-D9S.

The following section "Receiver functionality" provides an exhaustive description of the receiver's

functionality. Beginning with the new configuration messages, both existing and new users should

read this section to understand the new message types employed. Most of the following subsections should be familiar to existing users of u-blox positioning products, however some changes

are introduced owing to the new configuration messages.

The sections from "Design" onwards address hardware options when designing NEO-D9S into a new

product. This part gives power supply recommendations and provides guidance for circuit design

and PCB layout assistance. The antenna and RF front-end sections provide design information and

recommendations for these essential components. The final "Design guidance" section helps the

designer to check that crucial aspects of the design-in process have been carried out.

The final section addresses the general product handling concerns giving guidance on ESD

precautions, production soldering considerations and tape and reel packaging information.

UBX-19026111 - R05

C1-Public Early production information

1 Integration manual structure Page 5 of 51

Page 6

NEO-D9S-Integration manual

2 System description

2.1 Overview

NEO-D9S can receive the data stream of a GNSS correction service, broadcast via satellite L band

and compliant to the specification the product is designed for. Integrated with a high precision GNSS

receiver, such as from the u-blox F9 platform, it enables the positioning system to reach down to

centimeter-level accuracy.

2.1.1 Satellite L band DGNSS

Wide area correction services from several service providers are available via the L band

communication satellites. These satellites cover the bulk of the globe's populated surface. However

each DGNSS service provider using the L band channel will possibly have spot beams only covering

the relevant area their corrections are valid for. This ensures their correction coverage area is

accessible via a satellite and not simply broadcast over large areas of the earth with no feasible use.

Each service provider will be allocated a correction service ID and a frequency for a particular part of

the globe. In addition the service provider will have a data bit rate for their data stream.

This means that the frequency allocation for a particular service provider could change. It is

important that any deployed system can be re-configured if necessary. Service providers do provide

information on any frequency changes when required.

2.2 Architecture

The NEO-D9S receiver provides all the necessary RF and baseband processing to enable multi-band,

multi-constellation operation. The block diagram below shows the key functionality.

2.2.1 Block diagram

Figure 1: NEO-D9S block diagram

An active antenna is mandatory with the NEO-D9S.

UBX-19026111 - R05

C1-Public Early production information

2 System description Page 6 of 51

Page 7

NEO-D9S-Integration manual

3 Receiver functionality

This section describes the NEO-D9S operational features and their configuration.

3.1 Receiver configuration

u-blox positioning receivers are fully configurable with UBX protocol messages. The configuration

used by the receiver during normal operation is called the "current configuration". The current

configuration can be changed during normal operation by sending UBX configuration messages. On

start-up the current configuration held in RAM is built from the default firmware settings plus any

settings held in flash memory.

Configuration interface settings are held in a database consisting of separate configuration items.

An item is made up of a pair consisting of a key ID and a value. Related items are grouped together

and identified under a common group name: CFG-GROUP-*; a convention used in u-center and

within this document. Within u-center, a configuration group is identified as "Group name" and the

configuration item is identified as the "item name" under the "Generation 9 Configuration View" "Advanced Configuration" view.

The UBX messages available to change or poll the configurations are the UBX-CFG-VALSET, UBXCFG-VALGET, and UBX-CFG-VALDEL messages. For more information about these messages and

the configuration keys see the configuration interface section in the NEO-D9S Interface description

[3].

3.1.1 Changing the receiver configuration

The configuration messages UBX-CFG-VALSET, UBX-CFG-VALGET and UBX-CFG-VALDEL, will

result in a UBX-ACK-ACK or a UBX-ACK-NAK response.

3.1.2 Default L band configuration

The default L band configuration is:

• CFG-PMP-CENTER_FREQUENCY = 1539812500 Hz

• CFG-PMP-SEARCH_WINDOW = 2200 Hz

• CFG-PMP-USE_SERVICE_ID = 1 (true)

• CFG-PMP-SERVICE_ID = 50821

• CFG-PMP-DATA_RATE = 2400 (B2400) bps

• CFG-PMP-USE_DESCRAMBLER = 1 (true)

• CFG-PMP-DESCRAMBLER_INIT = 23560

• CFG-PMP-UWERRT = 4

• CFG-PMP-USE_PRESCRAMBLING = 0 (false)

• CFG-PMP-UNIQUE_WORD = 0xe15ae893e15ae893

The required satellite center frequency and service data rate might need changing based on

the receiver global location to aid acquisition of the required satellite/service (service ID).

The configuration settings can be modified using UBX protocol configuration messages. For more

information, see the NEO-D9S Interface description [3].

3.1.3 Default interface settings

Interface Settings

UART 9600 baud, 8 bits, no parity bit, 1 stop bit.

UBX-19026111 - R05

C1-Public Early production information

3 Receiver functionality Page 7 of 51

Page 8

NEO-D9S-Integration manual

Interface Settings

Output protocol: UBX.

Input protocols without need of additional configuration: UBX.

USB Output messages activated as in UART. Input protocols available as in UART.

I2C Output messages activated as in UART. Input protocols available as in UART.

SPI Output messages activated as in UART. Input protocols available as in UART.

Table 1: Default interface settings

The boot message is still output using $GNTXT messages, this is output when the NEOD9S is powered up.

Refer to the u-blox NEO-D9S Interface description [3] for information about further

settings.

3.1.4 Basic receiver configuration

This section summarizes the basic receiver configuration most commonly used.

3.1.4.1 Communication interface configuration

Several configuration groups allow operation mode configuration of the various communication

interfaces. These include parameters for the data framing, transfer rate and enabled input/output

protocols. See Communication interfaces section for details. The configuration groups available for

each interface are:

Interface Configuration groups

UART1 CFG-UART1-*, CFG-UART1INPROT-*, CFG-UART1OUTPROT-*

USB CFG-USB-*, CFG-USBINPROT-*, CFG-USBOUTPROT-*

Table 2: Interface configurations

3.1.4.2 Message output configuration

The rate of the supported output messages is configurable.

If the rate configuration value is zero, then the corresponding message will not be output. Values

greater than zero indicate how often the message is output.

For periodic output messages the rate relates to the event the message is related to. The rates

of the output messages are individually configurable per communication interface. See the CFGMSGOUT-* configuration group.

Some messages, such as UBX-MON-VER, are non-periodic and will only be output as an answer to

a poll request.

The UBX-INF-* information messages are non-periodic output messages that do not have a

message rate configuration. Instead they can be enabled for each communication interface via the

CFG-INFMSG-* configuration group.

All message output is additionally subject to the protocol configuration of the

communication interfaces. Messages of a given protocol will not be output until the protocol

is enabled for output on the interface (see the Communication interface configuration).

3.1.5 L band service selection

Any particular service provider will have several requirements that need to be configured before the

receiver will provide the relevant service provider data:

• Service provider service ID

UBX-19026111 - R05

C1-Public Early production information

3 Receiver functionality Page 8 of 51

Page 9

NEO-D9S-Integration manual

• Service provider frequency based on geographical location

• Service provider data rate

The service provider will provide the information on the frequency required per geographical

location.

All relevant configurations are done via the CFG-PMP message.

The main settings are shown below:

• CFG-PMP-SERVICE_ID - Example, 50821

• CFG-PMP-CENTER_FREQUENCY - Can be set from 1525000000 to 1559000000 Hz

• CFG-PMP-DATA_RATE - Can be set from 600 bps to 4800 bps

There may be additional settings required that can be configured from the information supplied by

the service provider.

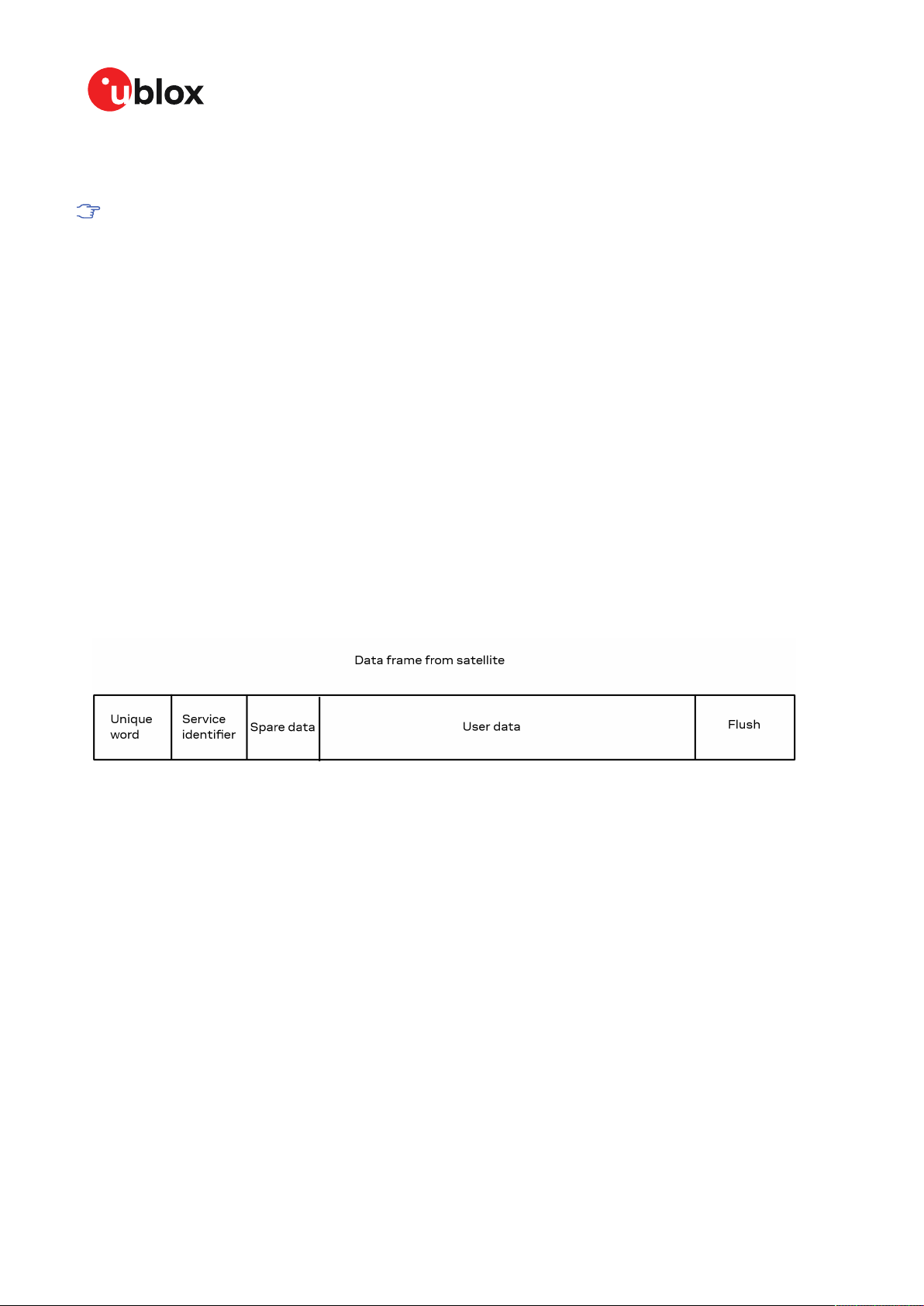

The receiver will output raw L band correction data when a service provider satellite data frame is

received. This will be output in the UBX-RXM-PMP message. This message is not output at a fixed

rate.

If no selected service provider data frame is detected, no UBX-RXM-PMP message is sent. The

output rate of the UBX-RXM-PMP message depends on the data rate of the satellite data stream

(600 bps - 4800 bps). The validity of the data frame must be verified by the host software. For frame

verification, quality indicators included in this message can be used.

For more information see the Configuration Interface section in the NEO-D9S Interface description

[3].

Figure 2: L band SESTB-28A data frame

3.1.6 Power management

u-blox D9 correction data receiver supports two different externally controlled power modes.

• External cycling of the receiver main power supply with the receiver in continuous mode when

powered (no battery backup software/hardware feature is supported, however V_BCKP must be

connected to VCC for correct core operation.)

• Instruct the receiver to turn on/off into software back-up mode (with main power still applied)

via the UBX-RXM-PMREQ message

3.1.6.1 Continuous mode

u-blox receivers use dedicated signal processing engines optimized for signal acquisition and

tracking. The acquisition engine delivers rapid signal searches during cold starts or when insufficient

signals are available for data download. The tracking engine delivers signal measurements for

message decoding.

UBX-19026111 - R05

C1-Public Early production information

3 Receiver functionality Page 9 of 51

Page 10

NEO-D9S-Integration manual

3.1.6.2 Power on/off command - software back-up

With message UBX-RXM-PMREQ the receiver can be forced to enter Inactive state (software backup mode) with main power still applied. It will stay in Inactive state for the time specified in the

message or until it is woken up by activity on the RXD1, NRESET pin or EXTINT pin.

3.1.6.2.1 Wake up

The receiver can be woken up by generating an edge on one of the following pins:

• Rising or falling edge on one of the EXTINT pins

• Rising or falling edge on the RXD1 pin

• Rising edge on NRESET pin

All wake-up signals are interpreted as an acquisition request, where the receiver wakes up and tries

to obtain the satellite. Wake-up signals have no effect if the receiver is already in Acquisition, Tracking

state.

3.1.6.2.2 Behavior while USB host connected

As long as the receiver is connected to a USB host, it will not enter the lowest possible power state.

This is because it must retain a small level of CPU activity to avoid breaching requirements of the

USB specification. The drawback, however, is that power consumption is higher.

Wake up by N_RESET, EXTINT pin or UART RX is possible even if the receiver is connected

to a USB host. In this case the state of the pin must be changed for a duration longer than

one millisecond.

3.2 Communication interfaces

u-blox receivers are equipped with a communication interface which is multi-protocol capable. The

interface ports can be used to transmit GNSS measurements, monitor status information and

configure the receiver.

A protocol (e.g. UBX, NMEA) can be assigned to several ports simultaneously, each configured with

individual settings (e.g. baud rate, message rates, etc.). More than one protocol (e.g. UBX protocol

and NMEA) can be assigned to a single port (multi-protocol capability), which is particularly useful

for debugging purposes.

The NEO-D9S provides UART1, UART2, SPI, I2C and USB interfaces for communication with a

host CPU. The interfaces are configured via the configuration methods described in the NEO-D9S

interface description [3].

The following table shows the port numbers reported in the UBX-MON-COMMS messages.

Port no. UBX-MON-COMMS portId Electrical interface

0 0x0000 I2C

1 0x0100 UART1

3 0x0300 USB

4 0x0400 SPI

Table 3: Port number assignment

It is important to isolate interface pins when VCC is removed. They can be allowed to float

or be connected to a high impedance (Float or tri-state: Hi-Z state). Open collector circuits

powered by module VCC are also suitable. They must be powered by module VCC to ensure

correct pin state when module VCC is removed.

Example isolation circuit is shown below.

UBX-19026111 - R05

C1-Public Early production information

3 Receiver functionality Page 10 of 51

Page 11

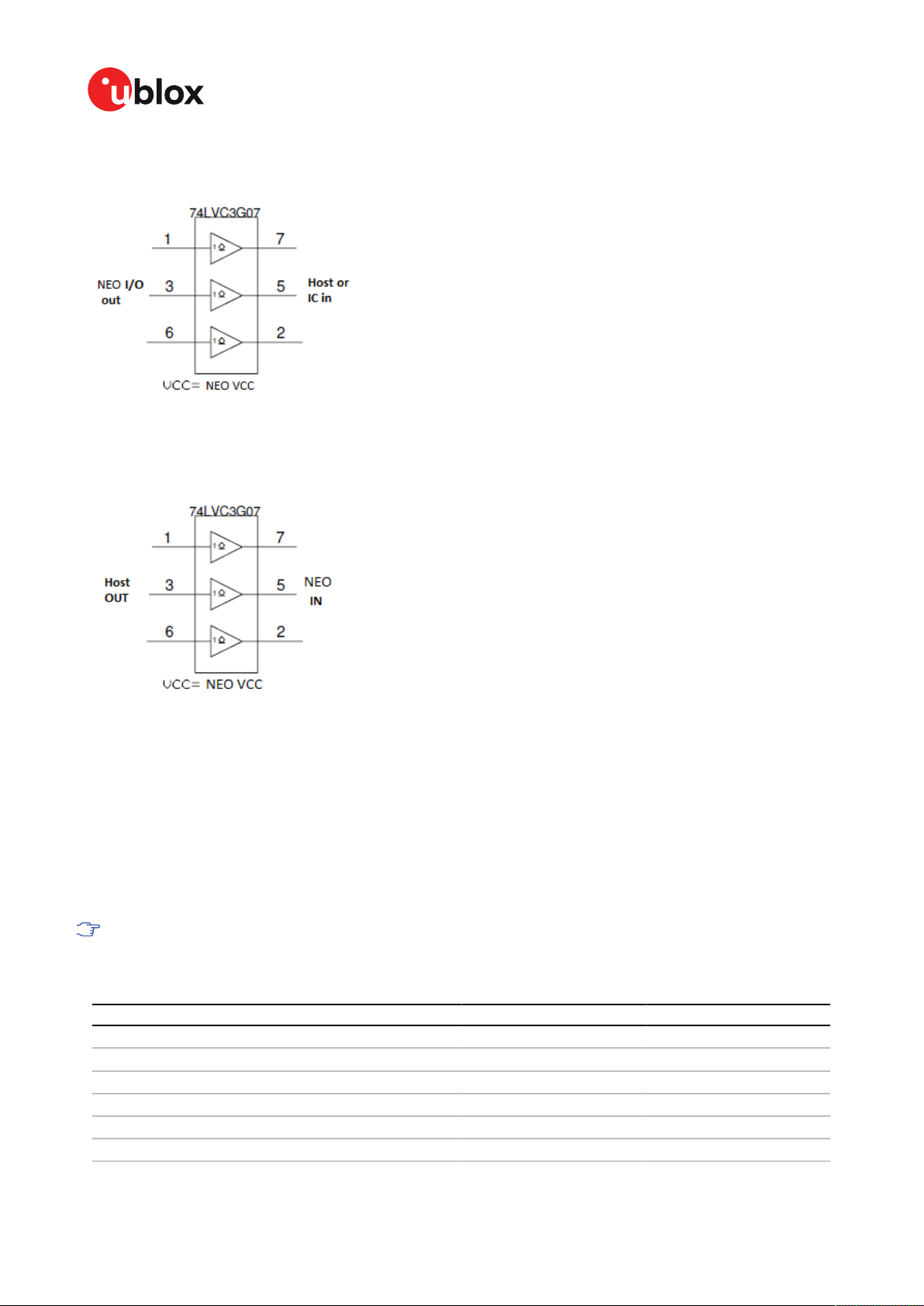

Figure 3: NEO-D9S output isolation

NEO-D9S-Integration manual

Figure 4: NEO-D9S input isolation

3.2.1 UART

A Universal Asynchronous Receiver/Transmitter (UART) port consists of an RX and a TX line. Neither

handshaking signals nor hardware flow control signals are available. The UART interface protocol

and baud rate can be configured but there is no support for setting different baud rates for reception

and transmission.

The NEO-D9S includes two UART serial ports. UART1 can be used as a host interface for

configuration, monitoring and control.

The UART RX interface will be disabled when more than 100 frame errors are detected

during a one-second period. This can happen if the wrong baud rate is used or the UART RX

pin is grounded. An error message appears when the UART RX interface is re-enabled at the

end of the one-second period.

Baud rate Data bits Parity Stop bits

9600 8 none 1

19200 8 none 1

38400 8 none 1

57600 8 none 1

115200 8 none 1

230400 8 none 1

UBX-19026111 - R05

C1-Public Early production information

3 Receiver functionality Page 11 of 51

Page 12

NEO-D9S-Integration manual

Baud rate Data bits Parity Stop bits

460800 8 none 1

921600 8 none 1

Table 4: Possible UART interface configurations

Note that for protocols such as UBX, it does not make sense to change the default word length

values (data bits) since these properties are defined by the protocol and not by the electrical

interface.

If the amount of data configured is too much for a certain port's bandwidth (e.g. all UBX messages

output on a UART port with a baud rate of 9600), the buffer will fill up. Once the buffer space is

exceeded, new messages to be sent will be dropped. To prevent message loss, the baud rate and

communication speed or the number of enabled messages should be carefully selected so that the

expected number of bytes can be transmitted in less than one second.

3.2.2 I2C interface

An I2C interface is available for communication with an external host CPU or u-blox cellular modules.

The interface can be operated in slave mode only. The I2C protocol and electrical interface are fully

compatible with the I2C industry standard fast mode. Since the maximum SCL clock frequency

is 400 kHz, the maximum transfer rate is 400 kb/s. The SCL and SDA pins have internal pull-up

resistors which should be sufficient for most applications. However, depending on the speed of the

host and the load on the I2C lines additional external pull-up resistors may be necessary.

To use the I2C interface D_SEL pin must be left open.

In designs where the host uses the same I2C bus to communicate with more than one ublox receiver, the I2C slave address for each receiver must be configured to a different value.

Typically most u-blox receivers are configured to the same default I2C slave address value.

To poll or set the I2C slave address, use the CFG-I2C-ADDRESS configuration item (see NEOD9S Interface description [3]).

The CFG-I2C-ADDRESS configuration item is an 8-bit value containing the I2C slave address

in 7 most significant bits, and the read/write flag in the least significant bit.The default value

for the CFG-I2C-ADDRESS configuration item is 0x86 (10000110). This indicates a standard

7-bit I2C slave address of 0x43 (1000011).

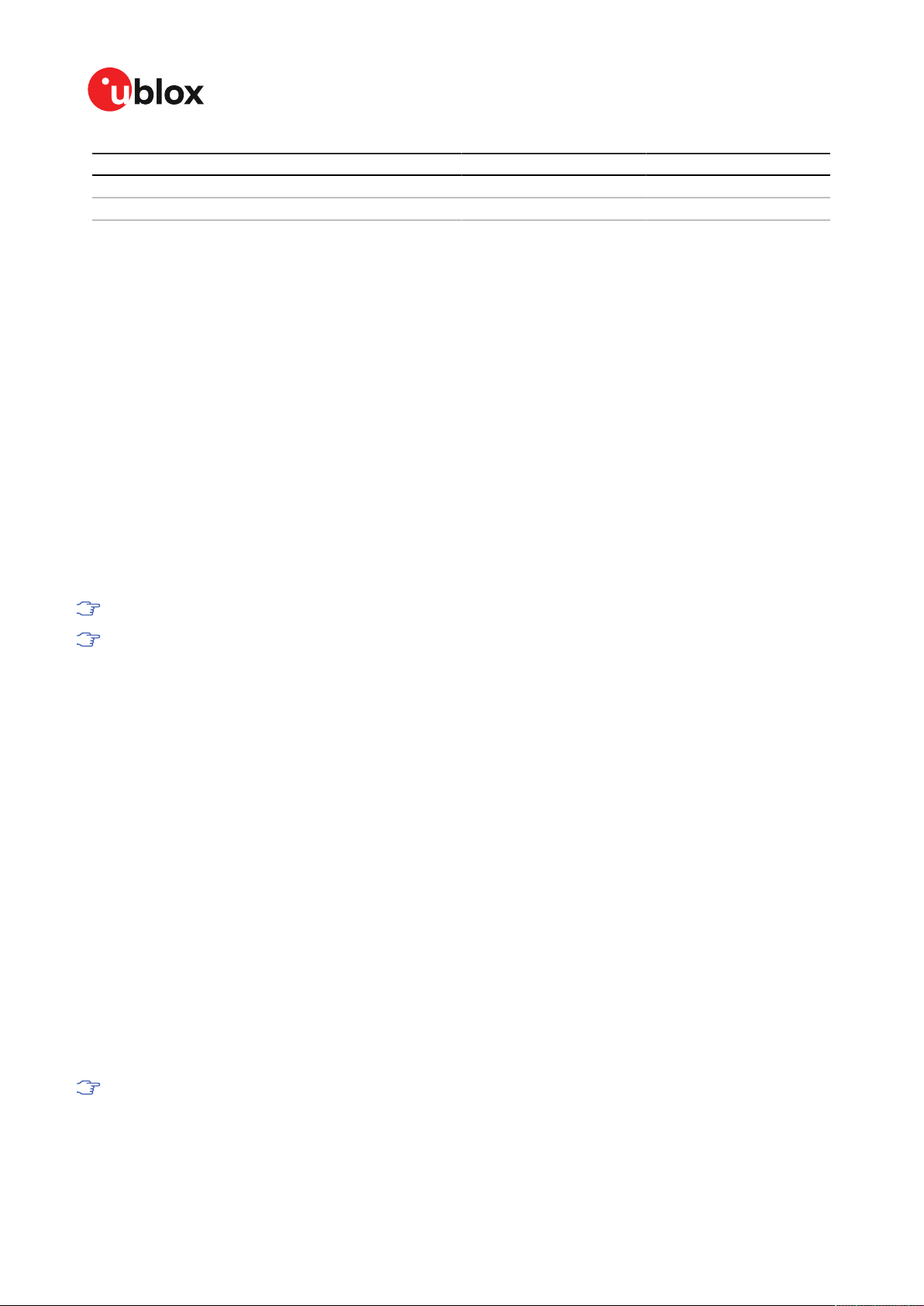

3.2.2.1 I2C register layout

The I2C interface allows 256 registers to be addressed. As shown in Figure 5, only three of these are

currently implemented.

The data registers 0 to 252 at addresses 0x00 to 0xFC contain reserved information, the result from

their reading is currently undefined. The data registers 0 to 252 are 1 byte wide.

At addresses 0xFD and 0xFE it is possible to read the currently available number of bytes.

The register at address 0xFF allows the data stream to be read. If there is no data awaiting

transmission from the receiver, then this register delivers value 0xFF, which cannot be the first byte

of a valid message. If the message data is ready for transmission, the successive reads of register

0xFF will deliver the waiting message data.

Do not use registers 0x00 to 0xFC. They are reserved for future use and they do not

currently provide any meaningful data.

UBX-19026111 - R05

C1-Public Early production information

3 Receiver functionality Page 12 of 51

Page 13

NEO-D9S-Integration manual

Figure 5: I2C register layout

3.2.2.2 Read access types

There are two I2C read transfer forms:

• The "random access" form: includes a slave register address and allows any register to be read.

• The "current address" form: omits the register address.

Figure 6 shows the format of the first one, the "random access" form of the request. Following the

start condition from the master, the 7-bit device address and the RW bit (which is a logic low for

write access) are clocked onto the bus by the master transmitter. The receiver answers with an

acknowledge (logic low) to indicate that it recognizes the address.

Next, the 8-bit address of the register to be read must be written to the bus. Following the receiver's

acknowledgment, the master again triggers a start condition and writes the device address, but this

time the RW bit is a logic high to initiate the read access. Now, the master can read 1 to N bytes

from the receiver, generating a not-acknowledge and a stop condition after the last byte being read.

UBX-19026111 - R05

C1-Public Early production information

3 Receiver functionality Page 13 of 51

Page 14

NEO-D9S-Integration manual

Figure 6: I2C random read access

If the second form, "current address" is used, an address pointer in the receiver is used to determine

which register to read. This address pointer will increment after each read unless it is already

pointing at register 0xFF, the highest addressable register, in which case it remains unaltered.

The initial value of this address pointer at start-up is 0xFF, so by default all current address reads

will repeatedly read register 0xFF and receive the next byte of message data (or 0xFF if no message

data is waiting).

Figure 7: I2C current address read access

3.2.2.3 Write access

The receiver does not provide any write access except for writing UBX and NMEA messages to the

receiver, such as configuration or aiding data. Therefore, the register set mentioned in the section

Read access is not writeable.

Following the start condition from the master, the 7-bit device address and the RW bit (which is a

logic low for write access) are clocked onto the bus by the master transmitter. The receiver answers

with an acknowledge (logic low) to indicate that it is responsible for the given address.

The master can write 2 to N bytes to the receiver, generating a stop condition after the last byte

being written. The number of data bytes must be at least 2 to properly distinguish from the write

access to set the address counter in random read accesses.

UBX-19026111 - R05

C1-Public Early production information

3 Receiver functionality Page 14 of 51

Page 15

NEO-D9S-Integration manual

Figure 8: I2C write access

3.2.3 SPI interface

The u-blox D9 correction data receiver has an SPI slave interface that can be selected by setting

D_SEL = 0. The SPI slave interface is shared with UART1 and I2C port, the physical pins are same.

The SPI pins available are:

• SPI_MISO (TXD)

• SPI_MOSI (RXD)

• SPI_CS_N

• SPI_CLK

See more information about communication interface selection from D_SEL section.

The SPI interface is designed to allow communication to a host CPU. The interface can be operated

in slave mode only.

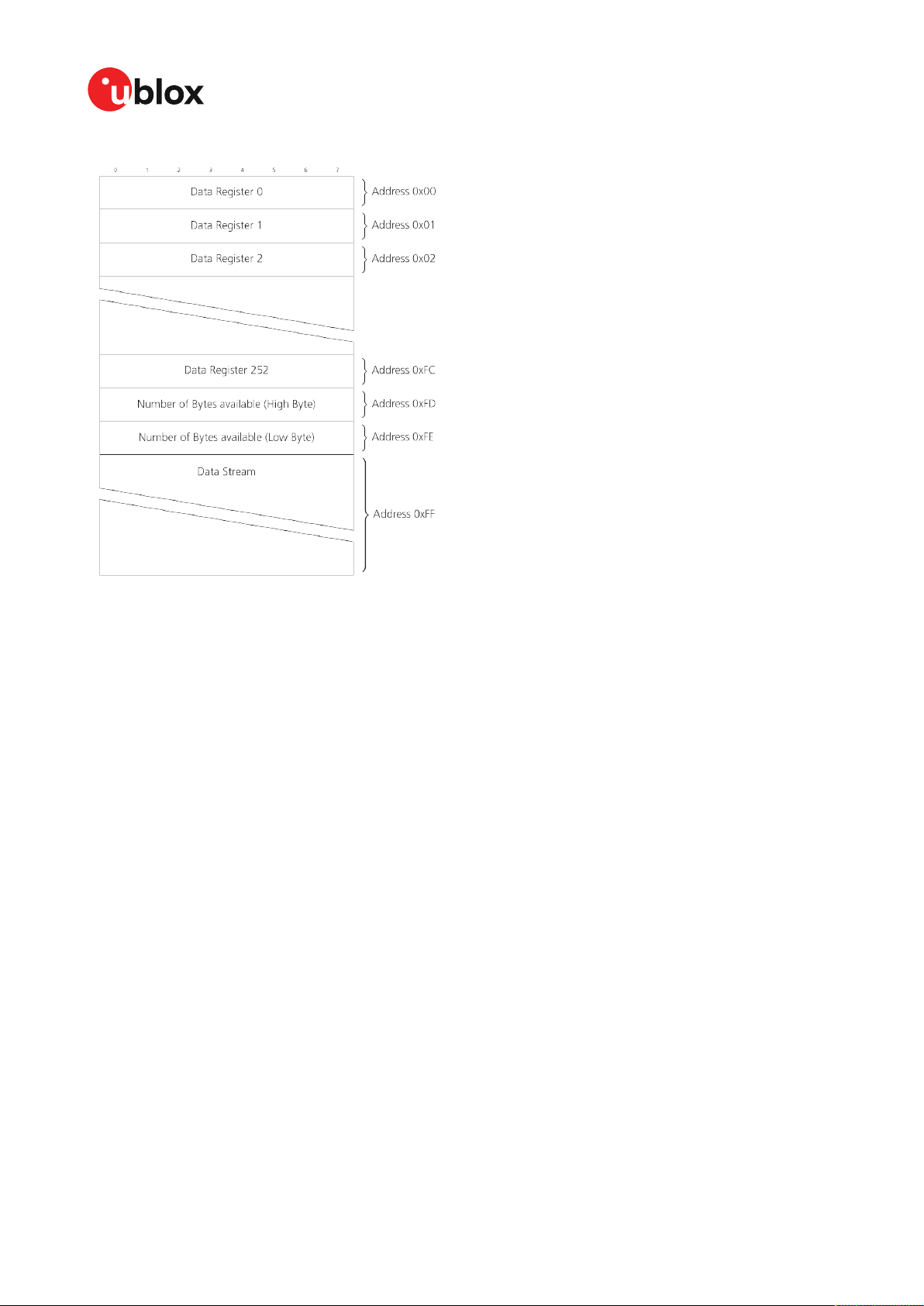

3.2.3.1 Read access

As the register mode is not implemented for the SPI port, only the UBX/NMEA message stream is

provided. This stream is accessed using the back-to-back read and write access (see section Back-

to-back read and write access below). When no data is available to be written to the receiver, MOSI

should be held logic high, i.e. all bytes written to the receiver are set to 0xFF.

To prevent the receiver from being busy parsing incoming data, the parsing process is stopped after

50 subsequent bytes containing 0xFF. The parsing process is re-enabled with the first byte not equal

to 0xFF.

If the receiver has no more data to send, it sets MISO to logic high, i.e. all bytes transmitted decode

to 0xFF. An efficient parser in the host will ignore all 0xFF bytes which are not part of a message and

will resume data processing as soon as the first byte not equal to 0xFF is received.

3.2.3.2 Back-to-back read and write access

The receiver does not provide any write access except for writing UBX and NMEA messages to

the receiver, such as configuration or aiding data. For every byte written to the receiver, a byte will

simultaneously be read from the receiver. While the master writes to MOSI, at the same time it needs

to read from MISO, as any pending data will be output by the receiver with this access. The data

on MISO represents the results from a current address read, returning 0xFF when no more data is

available.

UBX-19026111 - R05

C1-Public Early production information

3 Receiver functionality Page 15 of 51

Page 16

NEO-D9S-Integration manual

Figure 9: SPI back-to-back read/write access

3.2.4 USB interface

A single USB port is provided for host communication purposes.

The USB 2.0 FS (Full speed, 12 Mbit/s) interface can be used for host communication. Due to the

hardware implementation, it may not be possible to certify the USB interface.

If the receiver executes code from internal ROM (i.e. when a valid flash firmware image is not

detected), the USB behavior can differ compared to executing a firmware image from flash memory.

USB host compatibility testing is thus recommended in this scenario.

USB suspend mode is not supported.

USB bus-powered mode is not supported.

It is important to connect V_USB to ground and leave data lines open when the USB

interface is not used in an application.

The voltage range for V_USB is specified from 3.0 V to 3.6 V, which differs slightly from the

specification for VCC.

The boot screen is retransmitted on the USB port after enumeration. However, messages

generated between boot-up of the receiver and USB enumeration are not visible on the USB

port.

There are additional hardware requirements if USB is to be used:

• V_USB (pin 7) requires 1 uF capacitor mounted adjacent to the pin to ensure correct V_USB

voltage detection

• The V_USB (Pin 7) voltage should be sourced from an LDO enabled by the module VCC and

supplied from the USB host.

• A pull down resistor is required on the output of this V_USB LDO

• Pin 5 is USB_DM. Pin 6 is USB_DP.

• Apply USB_DM and USB_DP series resistors; typically 27 Ω

UBX-19026111 - R05

C1-Public Early production information

3 Receiver functionality Page 16 of 51

Page 17

NEO-D9S-Integration manual

Figure 10: NEO-D9S example circuit for USB interface

R11 = 100 k Ω is recommended

R12, R13 = 27 Ω is recommended

3.3 Predefined PIOs

In addition to the communication ports, there are some predefined PIOs provided by NEO-D9S to

interact with the receiver. These PIOs are described in this chapter.

If hardware backup mode is used a proper isolation of the interfaces is needed.

3.3.1 D_SEL

The D_SEL pin can be used to configure the functionality of the combined UART1, I2C, and SPI pins.

It is possible to configure the pins as UART1 + I2C, or as SPI. SPI is not available unless D_SEL pin

is set to low. See Table 5 below.

Pin no.

20 SPI_MISO UART1 TXD

21 SPI_MOSI UART1 RXD

18 SPI_CS_N I2C SDA

19 SPI_CLK I2C SCL

Table 5: D_SEL configuration

D_SEL == 0 D_SEL == 1

3.3.2 RESET_N

The NEO-D9S provides the ability to reset the receiver. The RESET_N pin is an input-only pin with

an internal pull-up resistor. Driving RESET_N low for at least 100 ms will trigger a cold start.

The RESET_N pin will delete all information and trigger a cold start. It should only be used

as a recovery option.

3.3.3 SAFEBOOT_N

The NEO-D9S provides a SAFEBOOT_N pin that is used to command the receiver safe boot mode.

If this pin is low at power up, the receiver starts in safe boot mode and L-band operation is disabled.

The safe boot mode can be used to recover from situations where the flash content has become

corrupted and needs to be restored.

In safe boot mode the receiver runs from a passive oscillator circuit with less accurate timing and

hence the receiver is unable to communicate via USB.

UBX-19026111 - R05

C1-Public Early production information

3 Receiver functionality Page 17 of 51

Page 18

NEO-D9S-Integration manual

In this mode only UART1 communication is possible. For communication via UART1 in safe boot

mode, the host must send a training sequence (0 x 55 55 at 9600 baud) to the receiver in order to

begin communication. After this the host must wait at least 2 ms before sending any data.

It is recommended to have the possibility to pull the SAFEBOOT_N pin low in the application. This

can be provided using an externally connected test point or a host I/O port.

3.3.4 TX_READY

This feature enables each port to define a corresponding pin, which indicates if bytes are ready to be

transmitted. A listener can wait on the TX-READY signal instead of polling the I2C or SPI interfaces.

The CFG-TXREADY message lets you configure the polarity and the number of bytes in the buffer

before the TX-READY signal goes active. By default, this feature is disabled. For USB, this feature

is configurable but might not behave as described below due to a different internal transmission

mechanism. If the number of pending bytes reaches the threshold configured for this port, the

corresponding pin will become active (configurable active-low or active-high), and stay active until

the last bytes have been transferred from software to hardware.

This is not necessarily equal to all bytes transmitted, i.e. after the pin has become inactive,

up to 16 bytes might still need to be transferred to the host.

The TX_READY pin can be selected from all PIOs which are not in use (see UBX-MON-HW3 in the

NEO-D9S Interface Description [3] for a list of the PIOs and their mapping). Each TX_READY pin is

exclusively associated to one port and cannot be shared. If PIO is invalid or already in use, only the

configuration for the specific TX_READY pin is ignored, the rest of the port configuration is applied

if valid. The acknowledge message does not indicate if the TX-READY configuration is successfully

set, it only indicates the successful configuration of the port. To validate successful configuration

of the TX_READY pin, the port configuration should be read back and the settings of TX-READY

feature verified (will be set to disabled/all zero if the settings are invalid).

The threshold when TX_READY is asserted should not be set above 2 kB as it is possible that the

internal message buffer limit is reached before this. This results in the TX_READY pin never being

set as the messages are discarded before the threshold is reached.

3.3.4.1 Extended TX timeout

If the host does not communicate over SPI or I2C for more than approximately 2 seconds, the device

assumes that the host is no longer using this interface and no more packets are scheduled for

this port. This mechanism can be changed by enabling "extended TX timeouts", in which case the

receiver delays idling the port until the allocated and undelivered bytes for this port reach 4 kB. This

feature is especially useful when using the TX-READY feature with a message output rate of less

than once per second, and polling data only when data is available, determined by the TX_READY

pin becoming active.

3.3.5 EXTINT

EXTINT is an external interrupt pin with fixed input voltage thresholds with respect to VCC. It is used

in software back-up mode to wake the module. Leave open if unused, this function is disabled by

default.

3.4 Antenna supervisor

An active antenna supervisor provides the means to check the antenna for open and short circuits

and to shut off the antenna supply if a short circuit is detected. Once enabled, the active antenna

supervisor produces status messages, reporting in NMEA and/or UBX protocol.

UBX-19026111 - R05

C1-Public Early production information

3 Receiver functionality Page 18 of 51

Page 19

NEO-D9S-Integration manual

The antenna supervisor can be configured through the CFG-HW-ANT_* configuration items. The

current configuration of the active antenna supervisor can also be checked by polling the related

CFG-HW_ANT_* configuration items.

The current active antenna status can be determined by polling the UBX-MON-RF message. If an

antenna is connected, the initial state after power-up is “Active Antenna OK" in the UBX-MON-RF

message in the u-center "Message View".

An active antenna supervisor circuit is connected to the ANT_DET, ANT_OFF, ANT_SHORT_N

pins. For an example the open circuit detection circuit using ANT_DET, "high" = Antenna detected

(antenna consumes current); "low" = Antenna not detected (no current drawn).

The following schematic details the required circuit and the sections following it explain how to

enable and monitor each feature:

Figure 11: NEO-D9S antenna supervisor

The bias-t inductor must be chosen for multi-band operation; a value of 47 nH ±5% is

required for our recommended Murata part, with the current limited below its 300 mA

rating. See Antenna bias section for additional information.

Circuit shows buffer [U4]. Buffer is not strictly necessary when supplied from VCC. It is only

required when supplying antenna voltage that is not obtained from or controlled by module

VCC or VCC_RF .

ESD diode not shown in the image above, it is mounted close to the PCB RF connector.

Part Recommendation Comment

L1 Murata LQG15HS47NJ02/47N 300mA and >500 Ω at L band frequencies

C2 Murata GRM033R71C103KE14 CAP CER X7R 0402 10N 10% 16V

UBX-19026111 - R05

C1-Public Early production information

3 Receiver functionality Page 19 of 51

Page 20

NEO-D9S-Integration manual

Part Recommendation Comment

TYCO, 0.25PF, PESD0402-140 -55/+125C ESD protection diode on RF trace

Table 6: Recommended components for antenna supervisor

3.4.1 Antenna voltage control - ANT_OFF

Antenna status (as reported in UBX-MON-RF and UBX-INF-NOTICE messages) is not

reported unless the antenna voltage control has been enabled.

Enable the antenna voltage control by setting the configuration item CFG-HWANT_CFG_VOLTCTRL to true (1).

Result:

• UBX-MON-RF in u-center "Message View": Antenna status = OK. Antenna power status = ON

• ANT_OFF pin = active high to turn antenna off therefore the pin is low to enable an external

antenna.

Start-up message at power up if configuration stored:

$GNTXT,01,01,02,ANTSUPERV=AC *00

$GNTXT,01,01,02,ANTSTATUS=INIT*3B

$GNTXT,01,01,02,ANTSTATUS=OK*25

ANTSUPERV=AC indicates antenna control is activated

3.4.2 Antenna short detection - ANT_SHORT_N

Enable the antenna short detection by setting the configuration item CFG-HWANT_CFG_SHORTDET to true (1).

Result:

• UBX-MON-RF in u-center "Message View": Antenna status = OK. Antenna power status = ON

• ANT_OFF = active high to disable an external antenna therefore the pin is low to enable an

external antenna.

• ANT_SHORT_N = active low to detect a short therefore the pin is high (PIO pull up enabled to be

pulled low if shorted)

Start-up message at power up if configuration is stored:

$GNTXT,01,01,02,ANTSUPERV=AC SD *37

$GNTXT,01,01,02,ANTSTATUS=INIT*3B

$GNTXT,01,01,02,ANTSTATUS=OK*25

ANTSUPERV=AC SD (Antenna control and short detection activated)

Then if shorted (ANT_SHORT_N pulled low):

• UBX-MON-RF in u-center "Message View": Antenna status = SHORT. Antenna power status =

ON (Antenna power control power down when short has not been enabled = off by default).

$GNTXT,01,01,02,ANTSTATUS=SHORT*73

• ANT_OFF = active high therefore still low (still enabled as auto power down is not enabled)

After a detected antenna short, the reported antenna status will keep on being reported as

shorted. If the antenna short detection auto recovery is enabled, then the antenna status

UBX-19026111 - R05

C1-Public Early production information

3 Receiver functionality Page 20 of 51

Page 21

NEO-D9S-Integration manual

can recover after a timeout. To recover the antenna status immediately, a power cycle is

required or configuring the antenna short detection functionality off and on.

3.4.3 Antenna short detection auto recovery

Enable the antenna short detection auto recovery by setting the configuration item CFG-HWANT_CFG_RECOVER to true (1).

Result:

• UBX-MON-RF in u-center "Message View": Antenna status = OK. Antenna power status = ON

• ANT_OFF = active high there for the PIO is low to enable an external antenna

• ANT_SHORT_N = high (PIO pull up enabled to be pulled low if shorted)

Start-up message at power up if configuration is stored:

$GNTXT,01,01,02,ANTSUPERV=AC SD PDoS SR*3E

$GNTXT,01,01,02,ANTSTATUS=INIT*3B

$GNTXT,01,01,02,ANTSTATUS=OK*25

ANTSUPERV=AC SD PDoS SR (indicates short circuit recovery added - SR)

Then if antenna is shorted (ANT_SHORT_N pulled low):

•

$GNTXT,01,01,02,ANTSTATUS=SHORT*73

• UBX-MON-RF in u-center "Message View": Antenna status = SHORT. Antenna power status =

OFF

• ANT_OFF = high (to disable - active high)

After a time out period receiver will re-test the short condition by enabling ANT_OFF = LOW

If a short is not present it will report antenna condition is OK:

$GNTXT,01,01,02,ANTSTATUS=OK*25

UBX-MON-RF in u-center "Message View": Antenna status = OK. Antenna power status = ON

3.4.4 Antenna open circuit detection - ANT_DETECT

Enable the antenna open circuit detection by setting the configuration item CFG-HWANT_CFG_OPENDET to true (1).

Result:

• UBX-MON-RF in u-center "Message View": Antenna status = OK. Antenna power status = ON

• ANT_OFF = active high therefore PIO is low to enable external antenna

• ANT_SHORT_N = active low therefore PIO is high (PIO pull up enabled to be pulled low if

shorted)

• ANT_DETECT = active high therefore PIO is high (PIO pull up enabled to be pulled low if antenna

not detected)

Start-up message at power up if configuration is stored:

$GNTXT,01,01,02,ANTSUPERV=AC SD OD PDoS SR*15

$GNTXT,01,01,02,ANTSTATUS=INIT*3B

$GNTXT,01,01,02,ANTSTATUS=OK*25

ANTSUPERV=AC SD OD PDoS SR (indicates open circuit detection added - OD)

UBX-19026111 - R05

C1-Public Early production information

3 Receiver functionality Page 21 of 51

Page 22

NEO-D9S-Integration manual

Then if ANT_DETECT is pulled low to indicate no antenna:

$GNTXT,01,01,02,ANTSTATUS=OPEN*35

Then if ANT_DETECT is left floating or it is pulled high to indicate antenna connected:

$GNTXT,01,01,02,ANTSTATUS=OK*25

3.5 Security

3.5.1 Receiver status monitoring

Messages in the UBX class UBX-MON are used to report the status of the parts of the embedded

computer system that are not related to the received satellite system specific info.

The main purposes are:

• Hardware and software versions, using UBX-MON-VER.

3.6 Forcing a receiver reset

The NEO-D9S is not a GNSS receiver and does not operate to the same principles as a standard

GNSS. However it does support the standard UBX-CFG-RST command.

Data stored in flash memory is not cleared by any of the options provided by UBX-CFG-RST.

The resetMode must be specified. This is not related to L band, but to the way the software restarts

the system.

• Hardware reset (watchdog), immediately uses the on-chip watchdog, in order to electrically

reset the chip. This is an immediate, asynchronous reset. No Stop events are generated.

• Controlled software reset terminates all running processes in an orderly manner and, once the

system is idle, restarts operation, reloads its configuration and starts to acquire and track L

band satellites.

• Hardware reset (watchdog), after shutdown uses the on-chip watchdog, in order to electrically

reset the chip after shutdown.

3.7 Firmware upload

NEO-D9S is supplied with firmware. u-blox may release updated images containing, for example,

security fixes, enhancements, bug fixes, etc. Therefore it is important that customers implement a

firmware update mechanism in their system.

A firmware image is a binary file containing the software to be run by the GNSS receiver. A firmware

update is the process of transferring a firmware image to the receiver and storing it in non-volatile

flash memory.

Contact u-blox for more information on firmware update.

UBX-19026111 - R05

C1-Public Early production information

3 Receiver functionality Page 22 of 51

Page 23

NEO-D9S-Integration manual

4 Design

This section provides information to help carry out a successful schematic and PCB design

integrating the NEO-D9S.

4.1 Pin assigment

The pin assignment of the NEO-D9S module is shown in Figure 12. The defined configuration of the

PIOs is listed in Table 7.

UART2, V_BCKP software function, are not available in the current software version.

V_BCKP hardware pin must be connected to VCC to ensure correct hardware operation.

UART2 is reserved for future direct connection to u-blox F9 high precision GNSS receivers. It will be

enabled in following FW versions.

Do not permanently connect the NEO-D9S UART2 with the ZED-F9 UART2 as the current

software in both modules does not support this. A conflict could possibly occur with the

default software settings in both modules. Instead, provide a jumper to connect the two

UART2 ports when the firmware is supported.

Figure 12: NEO-D9S pin assignment

Pin no. Name I/O Description

1 SAFEBOOT_N I SAFEBOOT_N (used for FW updates and reconfiguration, leave open)

2 D_SEL I UART 1 / SPI select. (open or high = UART 1)

3 TXD2 O UART 2 TXD

4 RXD2 I UART 2 RXD

5 USB_DM I/O USB data (DM)

UBX-19026111 - R05

C1-Public Early production information

4 Design Page 23 of 51

Page 24

NEO-D9S-Integration manual

Pin no. Name I/O Description

6 USB_DP I/O USB data (DP)

7 V_USB I USB supply

8 RESET_N I RESET (active low)

9 VCC_RF O External LNA power

10 GND I Ground

11 RF_IN I Active antenna L band signal input

12 GND I Ground

13 GND I Ground

14 ANT_OFF O External LNA disable - default active high

15 ANT_DETECT I Active antenna detect - default active high

16 ANT_SHORT_N O Active antenna short detect- default active low

17 EXTINT I External interrupt pin

18 SDA / SPI CS_N I/O I2C data if D_SEL = VCC (or open); SPI chip select if D_SEL = GND

19 SCL / SPI SLK I/O I2C clock if D_SEL = VCC (or open); SPI clock if D_SEL = GND

20 TXD / SPI MISO O UART output if D_SEL = VCC (or open); SPI MISO if D_SEL = GND

21 RXD / SPI MOSI I UART input if D_SEL = VCC (or open); SPI MOSI if D_SEL = GND

22 V_BCKP I Connect to VCC

23 VCC I Supply voltage

24 GND I Ground

Table 7: NEO-D9S pin assigment

4.2 Antenna

u-blox mandates the use of an active antenna for the NEO-D9S. The NEO-D9S needs to receive L

band signals in order to operate.

A separate L band antenna should be used to meet the requirement of +4 dBic patch

element gain.

A suitable ground plane is required for the antenna to achieve good performance for the L

band antenna.

Location of the antenna is critical for reaching good performance.

Figure 13: Typical L band active antenna structure

UBX-19026111 - R05

C1-Public Early production information

4 Design Page 24 of 51

Page 25

NEO-D9S-Integration manual

Figure 14: Typical recommended separate NEO-D9S and ZED-F9P RF front end and system

L band refers to the operating frequency range of 1–2 GHz in the radio spectrum. However in this

case we are referring to a corrections receiver that can operate at 1525.0 - 1559.0 MHz. The active

antenna must be selected for the required corrections band. Open jumper for UART2 is for future

firmware versions. It must not be connected by default.

An LNA gain of 20 - 25 dB is recommended to reach the ZED-F9P and NEO-D9S RF_IN pins.

For more information on the ZED-F9P design in and interfaces see the ZED-F9P Integration Manual

[4].

Recommended single L band antenna required specifications

Parameter Specification

Antenna type Active antenna

Typical gain 30 dB

Maximum gain 40 dBActive antenna recommendations

Maximum noise figure 3 dB

L band antenna gain

Polarization RHCP

1

Measured with a ground plane d=150 mm

2

The recommended gain is important for good performance

1

1525 MHz - 1559 MHz: 4 dBic typical in the L

2

band

UBX-19026111 - R05

C1-Public Early production information

4 Design Page 25 of 51

Page 26

NEO-D9S-Integration manual

Parameter Specification

Axial ratio 2 dB max at zenith

EMI immunity out-of-band

3

30 V/m

Out-of-band Rejection 40 dB typ

ESD circuit protection 15 kV human body model air discharge

Table 8: Antenna specifications for NEO-D9S modules

It is not recommended to use a combined antenna due to limitations of combined patch element

gain for L band. However if this is still a consideration the combined required specification is detailed

below:

Combined L1 + L2 + L band active antenna required specifications

Parameter Specification

Antenna type Active antenna

Typical gain 30 dB

Maximum gain 40 dBActive antenna recommendations

Maximum noise figure 2 dB

L1/L band band antenna gain

L2/E5b band antenna gain

4

6

Polarization RHCP

Axial ratio 2 dB max at zenith

Phase center variation <10 mm over elevation/azimuth

Group delay variation in-band

EMI immunity out-of-band

7

8

Out-of-band 9 Rejection

ESD circuit protection 15 kV human body model air discharge

Table 9: Antenna specifications for NEO-D9S modules

1525 - 1606 MHz: 3 dBic typ, 4 dBic typical in L

5

band

1197 - 1249 MHz: 2 dBic typ.

10 ns max at each GNSS system bandwidth. Note:

Inter-signal requirement 50 ns max.

30 V/m

40 dB typ

Recommended L band C/N0 levels

Baud rate Target C/N0 level Target optimized

600 37 dBHz 40 dBHz

1200 40 dBHz 43 dBHz

2400 43 dBHz 46 dBHz

Table 10: C/N0 specifications for NEO-D9S modules

3

Exception L1 and L2 bands +/- 200 MHz, emphasis on cellular bands

4

Measured with a ground plane d=150 mm

5

The recommended gain is important for good performance

6

Measured with a ground plane d=150 mm

7

GNSS system bandwidths: 1559… 1563 MHz; 1573… 1578 MHz; 1598… 1606 MHz; 1192… 1212 MHz; 1197… 1217

MHz; 1223… 1231 MHz; 1242… 1249 MHz

8

Exception L1 and L2 bands +/- 200 MHz, emphasis on cellular bands

9

GNSS system bandwidths: 1559… 1563 MHz; 1573… 1578 MHz; 1598… 1606 MHz; 1192… 1212 MHz; 1197… 1217

MHz; 1223… 1231 MHz; 1242… 1249 MHz

UBX-19026111 - R05

C1-Public Early production information

4 Design Page 26 of 51

C/N0 level

Page 27

NEO-D9S-Integration manual

The antenna system should include filtering to ensure adequate protection from nearby

transmitters. Care should be taken in the selection of antennas placed close to cellular or Wi-Fi

transmitting antennas.

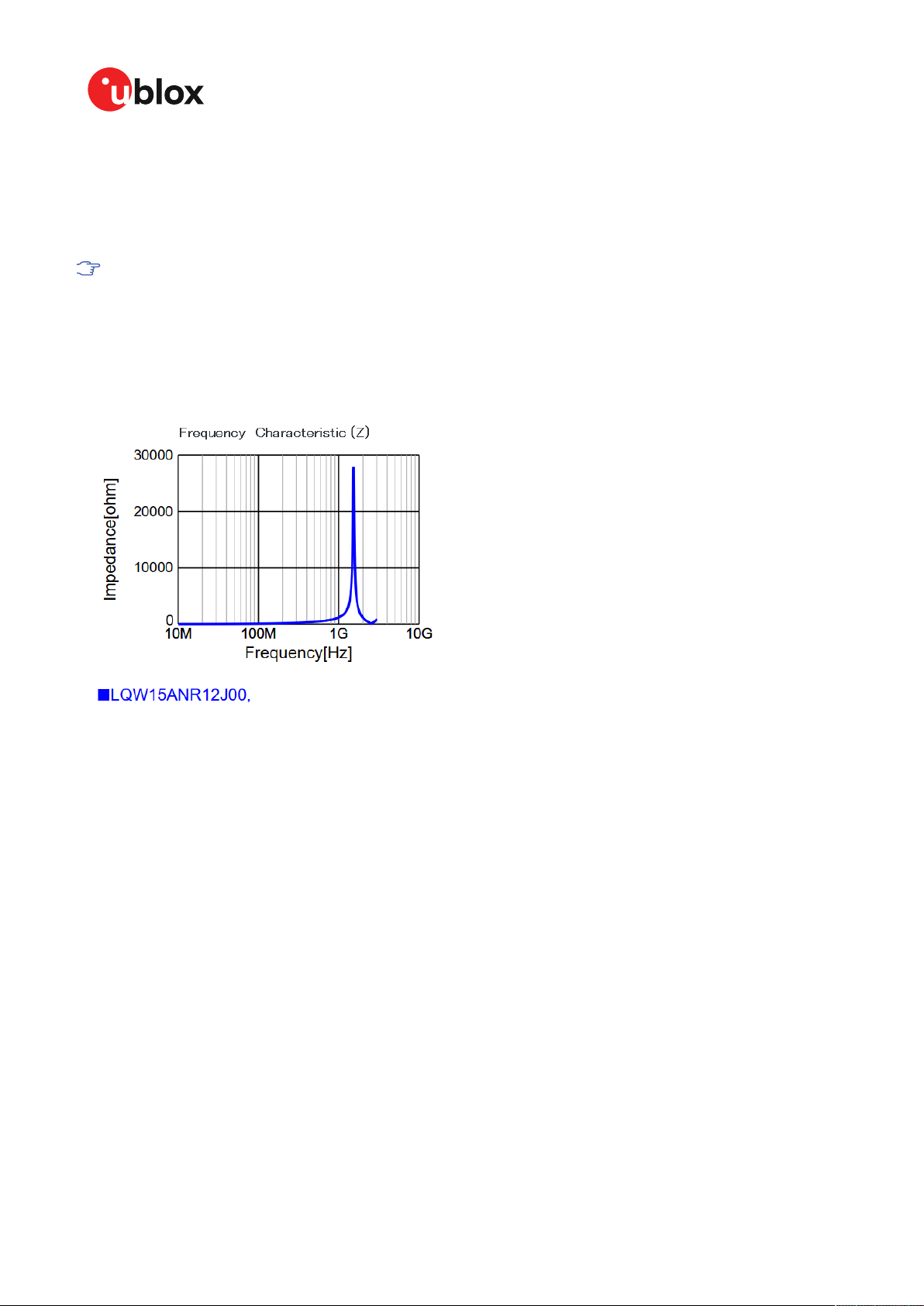

4.2.1 Antenna bias

The bias-t inductor must be chosen for multi-band operation, a value of 47 nH ±5% is

recommended for the recommended Murata L part. It has a self-resonance frequency of 1

GHz and a high impedance (> 500 Ω) at L band frequencies.

The recommended bias-t inductor (Murata LQG15HS47NJ02) has a maximum current capacity of

300 mA. Hence the current is limited to 70 mA at 3.3V using an active limiter in the recommended

circuit shown in Figure 16 below. A 10 Ω resistor (R2) is provided to measure the current. This resistor

power rating must be chosen to ensure reliability in the chosen circuit design.

Figure 15: NEO-D9S antenna bias inductor impedance

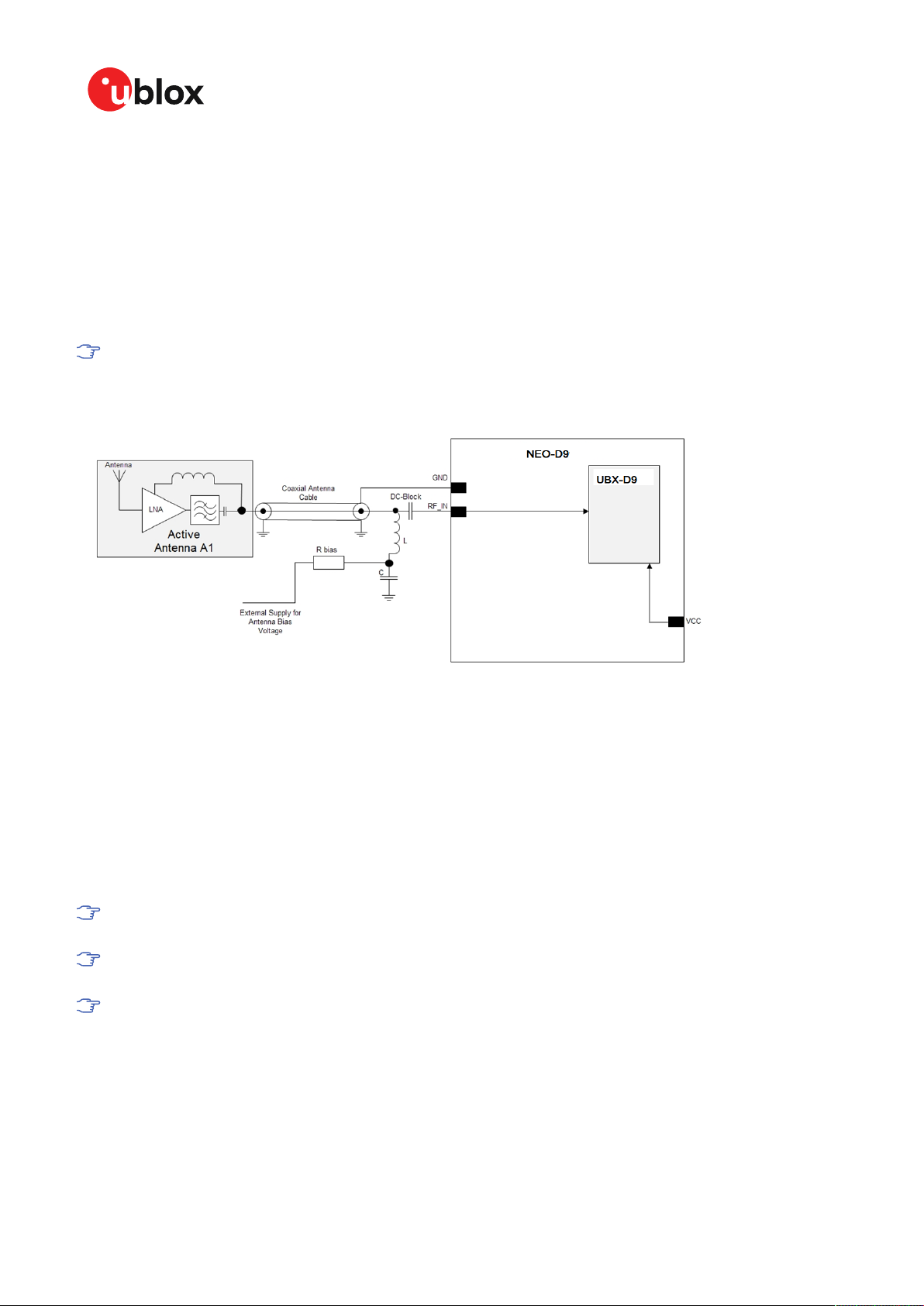

A recommended circuit design for an active antenna bias is shown below. This example shows an

external voltage of 3.3 V with current limiting as described above. An ESD protection diode should

also be connected to the input as shown.

UBX-19026111 - R05

C1-Public Early production information

4 Design Page 27 of 51

Page 28

NEO-D9S-Integration manual

Figure 16: NEO-D9S reference design for antenna bias

L1: Murata LQG15HS47NJ02 0402 47 N 5% 0.30 A -55/+125 C

D1: TYCO, 0.25PF, PESD0402-140 -55/+125C

C3: Murata GRM155R61A104KA01 CER X5R 0402 100N 10% 10V

R2: RES THICK FILM CHIP 1206 10R 5% 0.25W

It is recommended to use active current limiting. If active current limiting is not used, the important

points covered below need to be taken into account:

Figure 17: NEO-D9S VCC_RF antenna bias

The bias-t inductor and current limiting resistor must be selected to be reliable with a shortcircuit on the antenna feed if no active current limiter is used. Our recommended part has

a limit of 300 mA. A part with a higher current capability will be needed if the short circuit

current is as described here. This will also be affected by the voltage level of the antenna

UBX-19026111 - R05

C1-Public Early production information

4 Design Page 28 of 51

Page 29

NEO-D9S-Integration manual

bias supply due to power dissipation. Take the current limit capability of the antenna bias

supply into consideration. In the case where the module supplies the voltage via VCC_RF, a

higher value resistor will be needed to ensure the module supply inductor is protected. The

current should be limited to below 150 mA at the module supply voltage under short-circuit

conditions. In this case a value of 17 Ω or more is required at a module supply of 3 V to limit

short circuit current to 150 mA. The DC resistance of the bias-t inductor is assumed to be

1-2 Ω and the module internal feed inductor is assumed to be 1.2 Ω.

If the VCC_RF voltage does not match with the supply voltage of the active antenna, use a filtered

external supply.

The power dissipation in the resistor and inductor needs to be taken into account based on

the supply voltage and short circuit current. The bias-t inductor current capability and the

bias resistor value need to be calculated as shown above. The supply voltage for the bias-t

and its current capability is part of the calculation.

Figure 18: NEO-D9S external voltage antenna bias

4.3 Power supply

The u-blox NEO-D9S module has two power supply pins: VCC and V_USB.

4.3.1 VCC: Main supply voltage

The VCC pin is connected to the main supply voltage. During operation, the current drawn by the

module can vary by some orders of magnitude. For this reason, it is important that the supply

circuitry be able to support the peak power for a short time (see the NEO-D9S Data sheet [1] for

specification).

To reduce peak current during power on, users can employ an LDO that has an in-built

current limiter.

Do not add any series resistance greater than 0.2 Ω to the VCC supply as it will generate

input voltage noise due to dynamic current conditions.

For the NEO-D9S module the equipment must be supplied by an external limited power

source in compliance with the clause 2.5 of the standard IEC 60950-1.

4.3.2 NEO-D9S power supply

The NEO-D9S requires a low-noise, low-dropout voltage, and a very low source impedance power

supply of 3.3 V typically. No inductors or ferrite beads should be used from LDO to the module

VCC pin. The peak currents need to be taken into account for the source supplying the LDO for the

module.

UBX-19026111 - R05

C1-Public Early production information

4 Design Page 29 of 51

Page 30

NEO-D9S-Integration manual

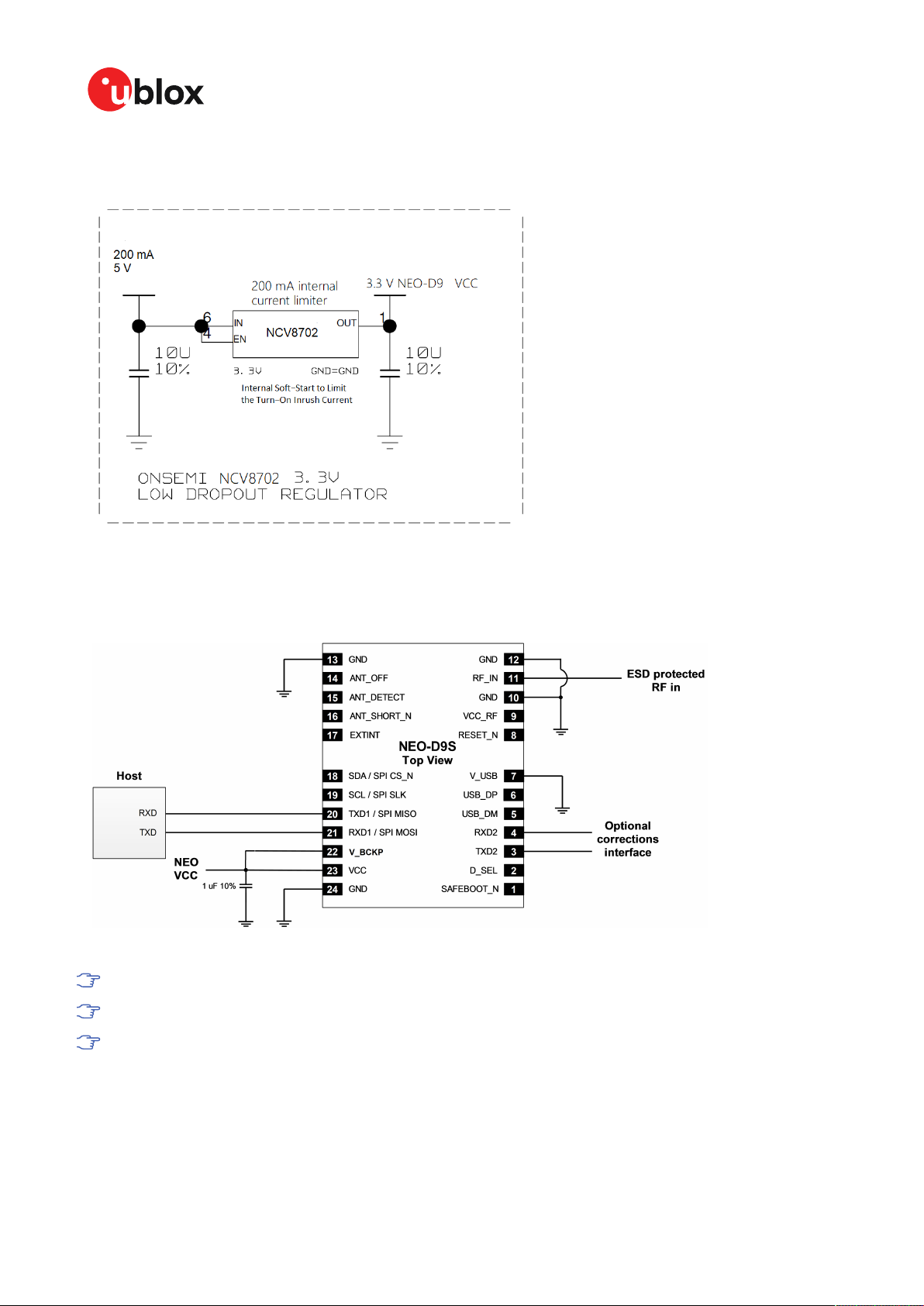

A power supply fed by 5 V is shown in the figure below. This example circuit is intended only for the

module supply.

Figure 19: NEO-D9S power supply

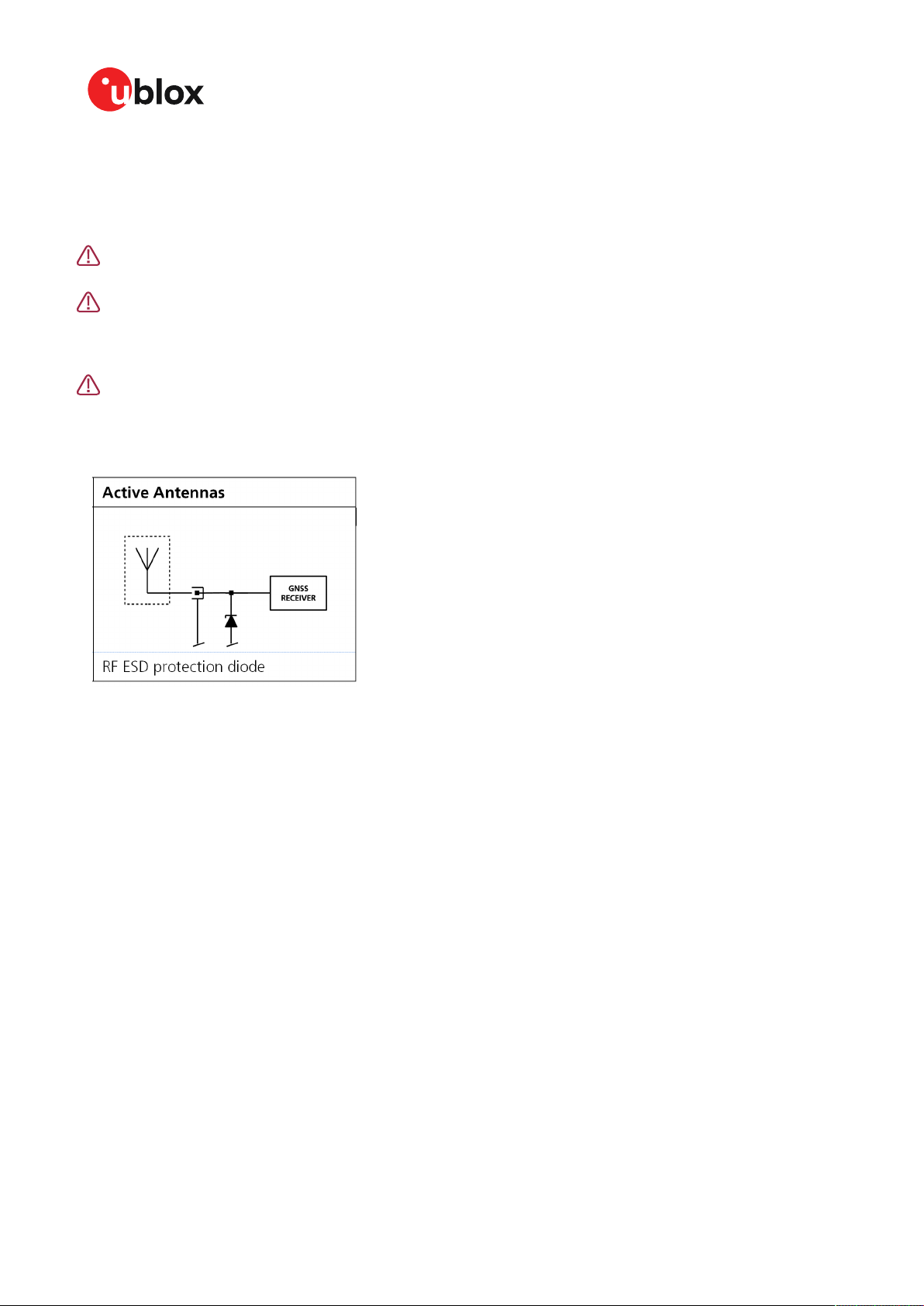

4.4 NEO-D9S minimal design

The minimal electrical circuit for NEO-D9S operation using the UART1 interface is shown below:

Figure 20: Minimal NEO-D9S design

It is important to connect V_USB to ground if USB is not used.

UART2 software functionality will be available in a later firmware update.

Connect the power supply to VCC and V_BCKP.

4.5 EOS/ESD precautions

When integrating L-band receivers into wireless systems, careful consideration must be given to

electromagnetic and voltage susceptibility issues. Wireless systems include components which

can produce Electrostatic Discharge (ESD), Electrical Overstress (EOS) and Electro-Magnetic

UBX-19026111 - R05

C1-Public Early production information

4 Design Page 30 of 51

Page 31

NEO-D9S-Integration manual

Interference (EMI). CMOS devices are more sensitive to such influences because their failure

mechanism is defined by the applied voltage, whereas bipolar semiconductors are more susceptible

to thermal overstress. The following design guidelines are provided to help in designing robust yet

cost-effective solutions.

To avoid overstress damage during production or in the field it is essential to observe strict

EOS/ESD/EMI handling and protection measures.

To prevent overstress damage at the RF_IN of your receiver, never exceed the maximum

input power as specified in the u-blox NEO-D9S Data sheet [1].

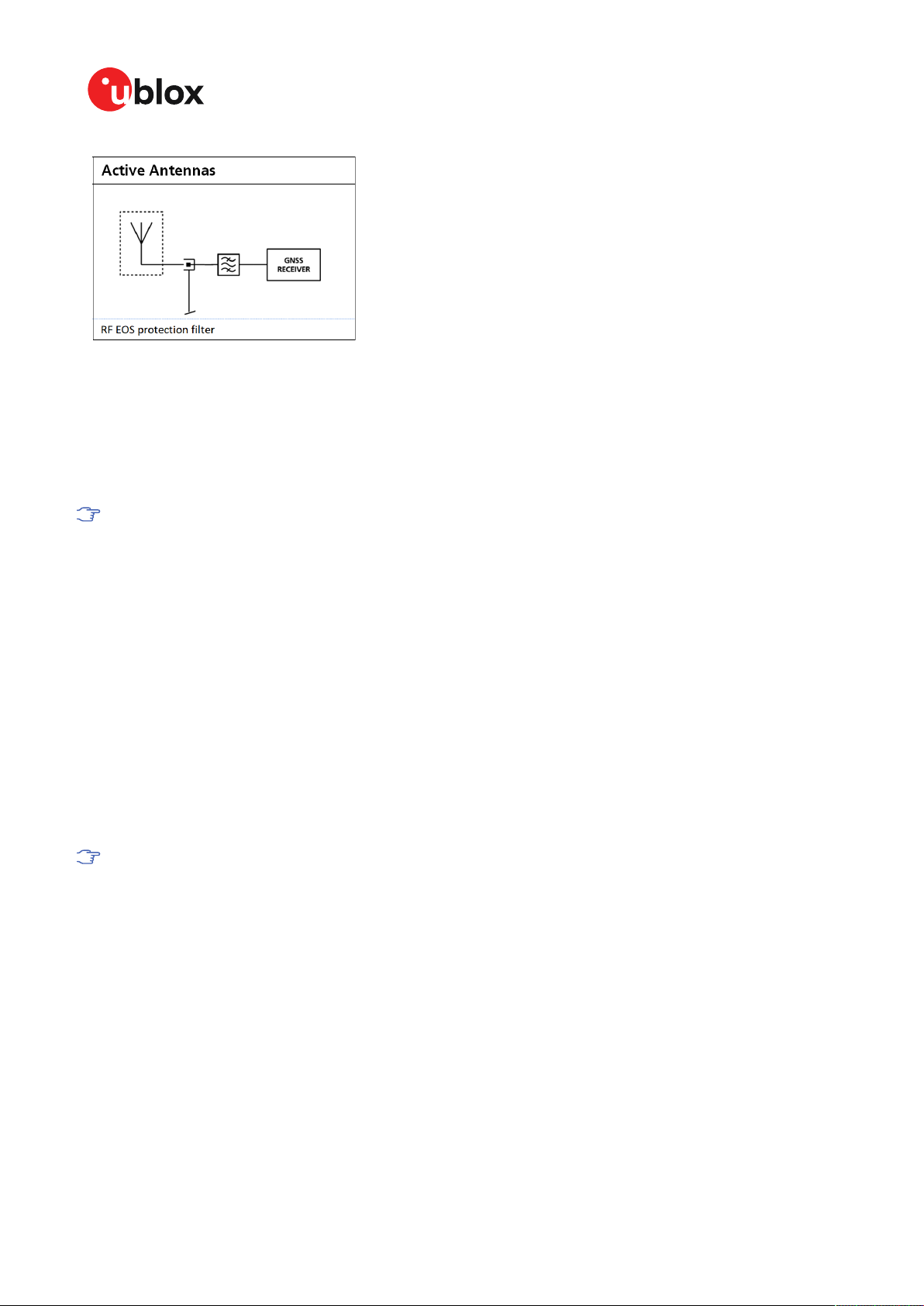

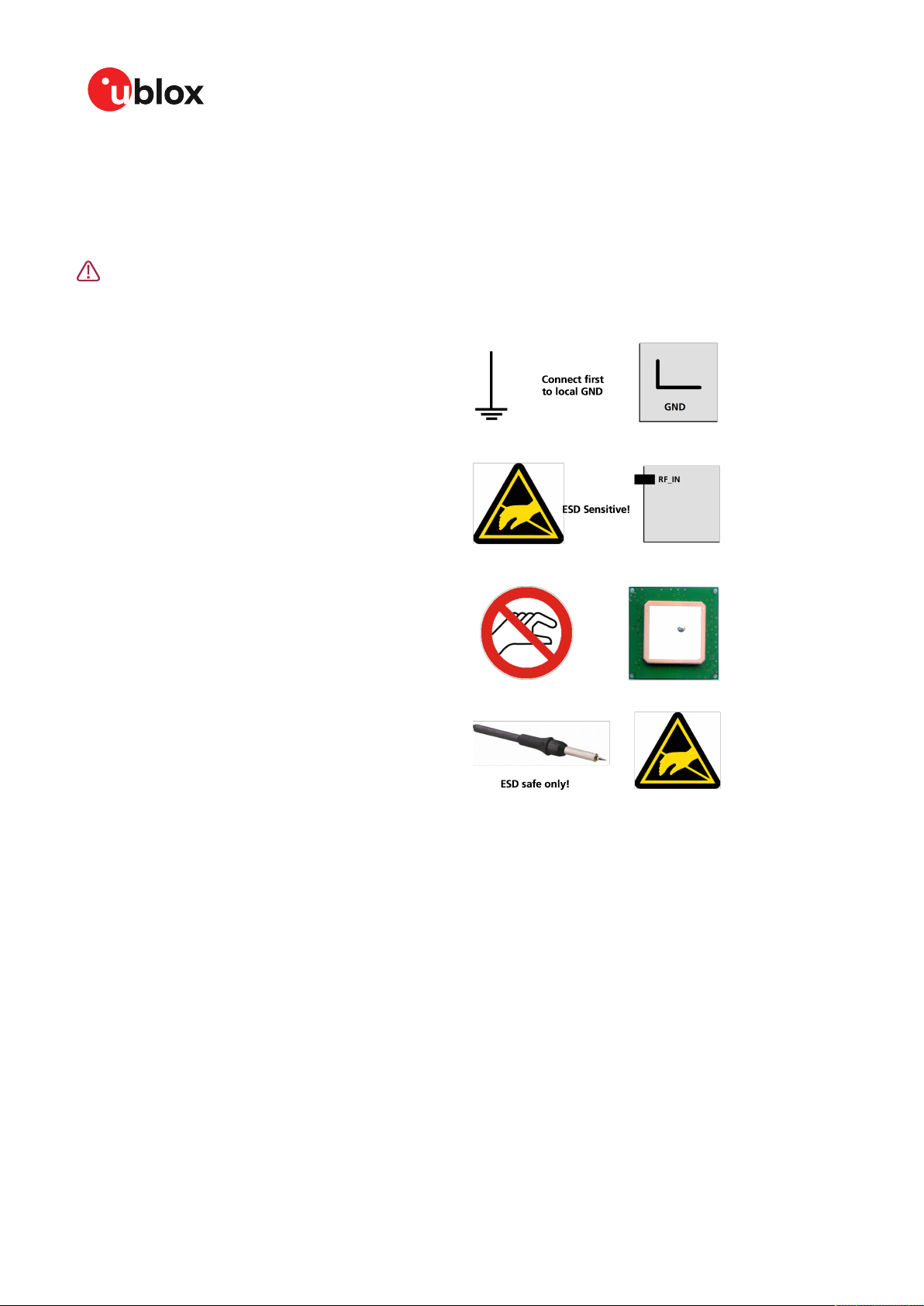

4.5.1 ESD protection measures

L-band receivers are sensitive to Electrostatic Discharge (ESD). Special precautions are

required when handling. Most defects caused by ESD can be prevented by following strict

ESD protection rules for production and handling. When implementing passive antenna

patches or external antenna connection points, then additional ESD measures as shown in

the figure below can also avoid failures in the field.

Figure 21: RF ESD precautions

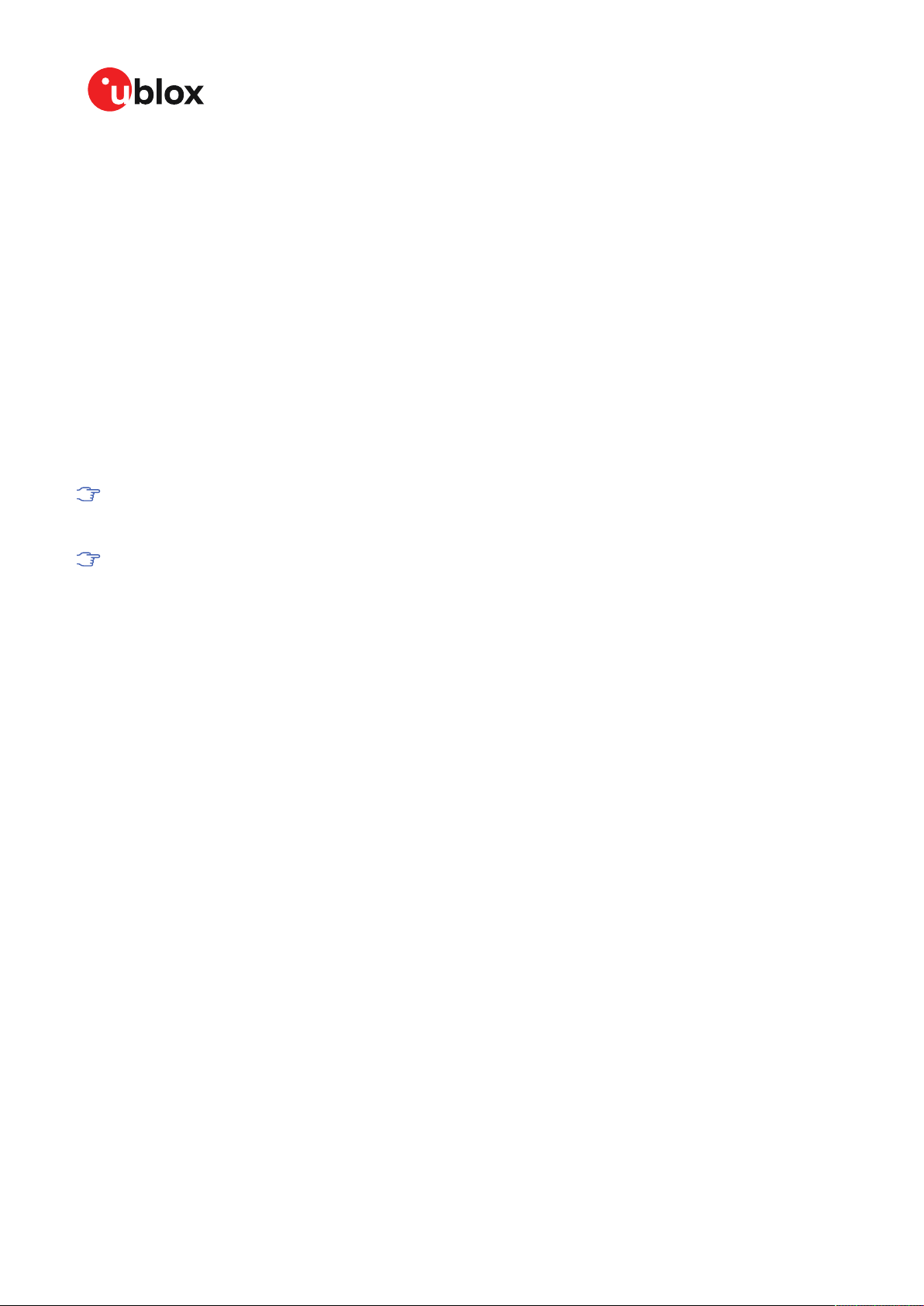

4.5.2 EOS precautions

Electrical overstress (EOS) usually describes situations when the maximum input power exceeds

the maximum specified ratings. EOS failure can happen if RF emitters are close to a L-band receiver

or its antenna. EOS causes damage to the chip structures. If the RF_IN is damaged by EOS, it is hard

to determine whether the chip structures have been damaged by ESD or EOS.

EOS protection measures as shown in the figure below are recommended for any designs combining

wireless communication transceivers (e.g. GSM, GPRS) and L-band in the same design or in close

proximity.

UBX-19026111 - R05

C1-Public Early production information

4 Design Page 31 of 51

Page 32

NEO-D9S-Integration manual

Figure 22: Active antenna EOS protection

4.5.3 Safety precautions

The NEO-D9S must be supplied by an external limited power source in compliance with the clause

2.5 of the standard IEC 60950-1. In addition to external limited power source, only Separated or

Safety Extra-Low Voltage (SELV) circuits are to be connected to the module including interfaces and

antennas.

For more information about SELV circuits see section 2.2 in Safety standard IEC 60950-1.

4.6 Electromagnetic interference on I/O lines

Any I/O signal line with a length greater than approximately 3 mm can act as an antenna and may

pick up arbitrary RF signals transferring them as noise into the receiver. This specifically applies to

unshielded lines, in which the corresponding GND layer is remote or missing entirely, and lines close

to the edges of the printed circuit board.

If, for example, a cellular signal radiates into an unshielded high-impedance line, it is possible to

generate noise in the order of volts and not only distort receiver operation but also damage it

permanently. Another type of interference can be caused by noise generated at the PIO pins that

emits from unshielded I/O lines. Receiver performance may be degraded when this noise is coupled

into the L-band antenna.

EMI protection measures are particularly useful when RF emitting devices are placed next to the

L-band receiver and/or to minimize the risk of EMI degradation due to self-jamming. An adequate

layout with a robust grounding concept is essential in order to protect against EMI.

Intended Use: In order to mitigate any performance degradation of a radio equipment under

EMC disturbance, system integration shall adopt appropriate EMC design practice and not

contain cables over three meters on signal and supply ports.

4.6.1 General notes on interference issues

Received L-band signal power at the antenna is very low. At the nominal received signal strength

(-128 dBm) it is below the thermal noise floor of -111 dBm. Due to this fact, a L-band receiver is

susceptible to interference from nearby RF sources of any kind. Two cases can be distinguished:

• Out-of-band interference: Typically any kind of wireless communications system (e.g. LTE,

GSM, CDMA, 3G, WLAN, Bluetooth, etc.) may emit its specified maximum transmit power in

close proximity to the L-band receiving antenna, especially if such a system is integrated with

the L-band receiver. Even at reasonable antenna selectivity, destructive power levels may reach

the RF input of the L-band receiver. Also, larger signal interferers may generate intermodulation

products inside the L-band receiver front-end that fall into the L-band band and contribute to

in-band interference.

UBX-19026111 - R05

C1-Public Early production information

4 Design Page 32 of 51

Page 33

NEO-D9S-Integration manual

• In-band interference: Although the L-band band is kept free from intentional RF signal sources

by radio-communications standards, many devices emit RF power into the L-band band at

levels much higher than the L-band signal itself. One reason is that the frequency band above

1 GHz is not well regulated with regards to EMI, and even if permitted, signal levels are much

higher than L-band signal power. Notably, all types of digital equipment, such as PCs, digital

cameras, LCD screens, etc. tend to emit a broad frequency spectrum up to several GHz of

frequency. Also wireless transmitters may generate spurious emissions that fall into L-band

band.

As an example, GSM uses power levels of up to 2 W (+33 dBm). The absolute maximum power input

at the RF input of the L-band receiver can be +15 dBm. The GSM specification allows spurious

emissions for GSM transmitters of up to +36 dBm, while the L-band signal is less than -128

dBm. By simply comparing these numbers it is obvious that interference issues must be seriously

considered in any design of a L-band receiver. Different design goals may be achieved through

different implementations:

• The primary focus is to prevent damaging the receiver from large input signals. Here the Lband performance under interference conditions is not important and suppression of the

signal is permitted. It is sufficient to just observe the maximum RF power ratings of all of the

components in the RF input path.

• L-band performance must be guaranteed even under interference conditions. In such a case,

not only the maximum power ratings of the components in the receiver RF path must be

observed. Further, non-linear effects like gain compression, NF degradation (desensitization)

and intermodulation must be analyzed.

Pulsed interference with a low-duty cycle such as GSM may be destructive due to the high

peak power levels.

4.6.2 In-band interference mitigation

With in-band interference, the signal frequency is very close to the L-band frequency. Such

interference signals are typically caused by harmonics from displays, micro-controller operation, bus

systems, etc. Measures against in-band interference include:

• Maintaining a good grounding concept in the design

• Shielding

• Layout optimization

• Low-pass filtering of noise sources, e.g. digital signal lines

• Remote placement of the L-band antenna, far away from noise sources

• Adding an LTE, CDMA, GSM, WCDMA, BT band-pass filter before antenna

4.6.3 Out-of-band interference

Out-of-band interference is caused by signal frequencies that are different from the L-band carrier

frequency. The main sources are wireless communication systems such as LTE, GSM, CDMA,

WCDMA, Wi-Fi, BT, etc.

Measures against out-of-band interference include maintaining a good grounding concept in the

design and adding a L-band band-pass filter into the antenna input line to the receiver.

For GSM applications, such as typical handset design, an isolation of approximately 20 dB can be

reached with careful placement of the antennas. If this is insufficient, an additional SAW filter is

required on the L-band receiver input to block the remaining GSM transmitter energy.

UBX-19026111 - R05

C1-Public Early production information

4 Design Page 33 of 51

Page 34

NEO-D9S-Integration manual

4.7 Layout

This section details layout and placement requirements of the u-blox D9 correction data receiver.

4.7.1 Placement

L-band signals at the surface of the Earth are below the thermal noise floor. A very important

factor in achieving maximum GNSS performance is the placement of the receiver on the PCB. The

placement used may affect RF signal loss from antenna to receiver input and enable interference

into the sensitive parts of the receiver chain, including the antenna itself. When defining a GNSS

receiver layout, the placement of the antenna with respect to the receiver, as well as grounding,

shielding and interference from other digital devices are crucial issues and need to be considered

very carefully.

Signal loss on the RF connection from antenna to receiver input must be minimized as much as

possible. Hence, the connection to the antenna must be kept as short as possible.

Ensure that RF critical circuits are clearly separated from any other digital circuits on the system

board. To achieve this, position the receiver digital part closer to the digital section of the system

PCB and have the RF section and antenna placed as far as possible away from the other digital

circuits on the board.

A proper GND concept shall be followed: The RF section shall not be subject to noisy digital supply

currents running through its GND plane.

4.7.2 Thermal management

During design-in do not place the receiver near sources of heating or cooling. The receiver oscillator

is sensitive to sudden changes in ambient temperature which can adversely impact satellite signal

tracking. Sources can include co-located power devices, cooling fans or thermal conduction via the

PCB. Take into account the following questions when designing in the receiver.

• Is the receiver placed away from heat sources?

• Is the receiver placed away from air-cooling sources?

• Is the receiver shielded by a cover/case to prevent the effects of air currents and rapid

environmental temperature changes?

High temperature drift and air vents can affect the GNSS performance. For best

performance, avoid high temperature drift and air vents near the receiver.

4.7.3 Package footprint, copper and paste mask

Copper and solder mask dimensioning recommendations for the NEO-D9S module packages are

provided in this section.

The module edge pads are 0.8 mm x 0.9 mm. Implement a pad size on your PCB as a copper

pad size of 0.8 mm x 1.8 mm. Solder mask for the same pad is 0.9 mm x 1.9 mm. Paste

mask for the same pad is 0.8 mm x 2.1 mm.

These are recommendations only and not specifications. Consider the paste mask outline

when defining the minimal distance to the next component. The exact copper, solder and

paste mask geometries, distances, stencil thickness and solder paste volumes must be

adapted to the specific production processes (e.g. soldering etc.) of the customer.

UBX-19026111 - R05

C1-Public Early production information

4 Design Page 34 of 51

Page 35

4.7.3.1 Mechanical dimensions

NEO-D9S-Integration manual

Figure 23: NEO-D9S mechanical dimensions

4.7.3.2 Footprint

Figure 24: NEO-D9S suggested footprint (i.e. copper mask)

UBX-19026111 - R05

C1-Public Early production information

4 Design Page 35 of 51

Page 36

4.7.3.3 Paste mask

Figure 25: NEO-D9S suggested paste mask

NEO-D9S-Integration manual

To improve the wetting of the half vias, reduce the amount of solder paste under the module and

increase the volume outside of the module by defining the dimensions of the paste mask to form a

T-shape (or equivalent) extending beyond the copper mask.

4.7.4 Layout guidance

The presented layout guidance reduces the risk of performance issues at design level.

4.7.4.1 RF In trace

The RF In trace has to work in the middle L band frequencies.