Page 1

EVK-VERA-P174

Evaluation kit for VERA-P1 host-based V2X transceiver

modules

User guide

Abstract

This document describes how to set up the EVK-VERA-P174 evaluation kit to evaluate the VERAP1 series host-based 802.11p V2X transceiver modules.

UBX-17048707 - R08

C1 Public www.u-blox.com

Page 2

EVK-VERA-P174 - User guide

u-blox or third parties may hold intellectual property rights in the products, names, logos and designs included in this

document. Copying, reproduction, modification

permitted with the express written permission of u

The information contained herein is provided “as is” and u

implied, is given, including but not limited

purpose of the information. This document may be revised by u

d

Copyright © u

Document information

Title EVK-VERA-P174

Subtitle Evaluation kit for VERA-P1 host-based V2X transceiver modules

Document type User guide

Document number UBX-17048707

Revision and date R08 6-Nov-2020

Disclosure Restriction C1 Public

This document applies to the following products:

Product name Type number Firmware version PCN reference

EVK-VERA-P174 EVK-VERA-P174-00A-00 N/A

ocuments, visit www.u-blox.com.

-blox AG.

UBX-17048707 - R08 Document information Page 2 of 31

C1 Public

or disclosure to third parties of this document or any part thereof is only

-blox.

-blox assumes no liability for its use. No warranty, either express or

to, with respect to the accuracy, correctness, reliability and fitness for a particular

-blox at any time without notice. For the most recent

Page 3

EVK-VERA-P174 - User guide

Contents

Document information ............................................................................................................................. 2

Contents ....................................................................................................................................................... 3

1 Evaluation kit description ................................................................................................................ 5

1.1 Overview ........................................................................................................................................................ 5

1.2 Kit includes ................................................................................................................................................... 6

1.3 Software and documentation ................................................................................................................... 6

1.4 System requirements ................................................................................................................................ 6

1.5 Specifications .............................................................................................................................................. 7

2 Getting started .................................................................................................................................... 8

3 Board description ................................................................................................................................ 9

3.1 Block diagram .............................................................................................................................................. 9

3.2 Overview ........................................................................................................................................................ 9

3.2.1 Main board ......................................................................................................................................... 10

3.2.2 USB and power supply board .......................................................................................................... 11

3.3 Connectors ................................................................................................................................................. 12

3.3.1 Power supply and configuration .................................................................................................... 12

3.3.2 USB interface ..................................................................................................................................... 12

3.3.3 Bootstrapping .................................................................................................................................... 12

3.3.4 SPI interface ...................................................................................................................................... 12

3.3.5 SPI chip select ................................................................................................................................... 13

3.3.6 1PPS interface ................................................................................................................................... 13

3.3.7 GNSS interface .................................................................................................................................. 13

3.3.8 SMA connectors ............................................................................................................................... 14

3.3.9 Host interface connector ................................................................................................................ 14

3.4 LEDs ............................................................................................................................................................. 14

3.5 Buttons ........................................................................................................................................................ 14

3.6 Design files ................................................................................................................................................. 15

4 Software ............................................................................................................................................. 20

4.1 Quick start instructions ........................................................................................................................... 20

4.2 Module calibration .................................................................................................................................... 22

4.3 Usage examples ........................................................................................................................................ 22

4.3.1 Transmit and receive counters ...................................................................................................... 23

4.3.2 Channel configuration ..................................................................................................................... 24

4.3.3 Transmitter test ............................................................................................................................... 24

4.3.4 Receiver test ...................................................................................................................................... 25

4.3.5 LLC native IPv6 functionality ......................................................................................................... 26

4.4 Building the software for a different target platform ....................................................................... 27

Appendix .................................................................................................................................................... 28

A Glossary .............................................................................................................................................. 28

Related documents ................................................................................................................................ 29

UBX-17048707 - R08 Contents Page 3 of 31

C1 Public

Page 4

EVK-VERA-P174 - User guide

Revision history ....................................................................................................................................... 30

Contact ....................................................................................................................................................... 31

UBX-17048707 - R08 Contents Page 4 of 31

C1 Public

Page 5

EVK-VERA-P174 - User guide

1 Evaluation kit description

1.1 Overview

VERA-P1 is a compact, embedded transceiver module that enables development of electronics for

Vehicle-to-Everything (V2X) communication systems. The module includes an integrated

MAC/LLC/Baseband processor and the required RF front-end components. It connects to a host

processor through USB or SPI interface.

The EVK-VERA-P174 evaluation kit provides a simple way to evaluate the VERA-P1 series hostbased V2X transceiver modules. The evaluation kit serves as an evaluation and development

platform providing full access to the interfaces of the VERA-P1 radio module, and allows integration

of the VERA-P1 module with an external PC or host processor development platform.

The main features of the EVK-VERA-P174 evaluation kit are:

• Enables host communication via Micro USB connector or SPI pin header

• Provides two SMA antenna connectors for the VERA-P1 module

• Has an integrated u-blox NEO-M8U GNSS module with SMA antenna connector

• Has an on-board SPI flash for evaluating different boot options

• Provides an integrated USB 2.0 hub to access VERA-P1, GNSS, and SPI flash via a single

connector

• Has 9 – 28 V DC power supply input with the option to provide external supplies separately and

measure current consumption

Table 1 lists the available versions of the evaluation kit:

Evaluation kit Description Suitable for evaluation of

EVK-VERA-P174 Evaluation kit for the VERA-P1 module VERA-P173 (with single radio firmware)

VERA-P174 (with dual radio firmware)

Table 1: EVK-VERA-P174 evaluation kit

☞ For further information about the features supported by VERA-P1 series V2X modules, see the

VERA-P1 series data sheet [1] and VERA-P1 series system integration manual [2].

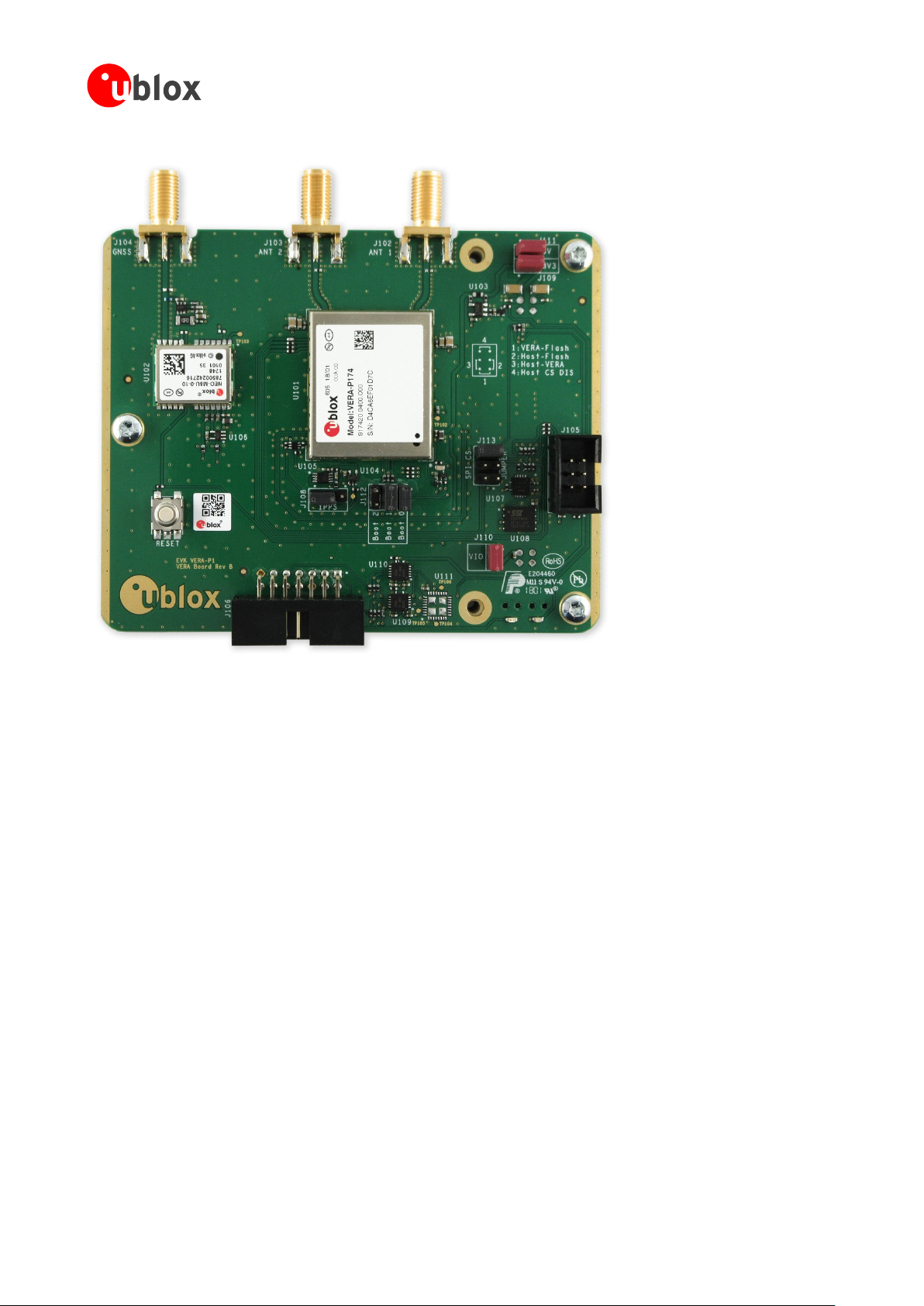

The EVK-VERA-P174 consists of two boards, which are connected by a board-to-board connector.

The upper main board contains the VERA-P174 and the NEO-M8U GNSS module. The USB interface

and main power supply are included on the lower power supply board. The board-to-board connector

allows the main board to be directly connected to a compatible host board.

UBX-17048707 - R08 Evaluation kit description Page 5 of 31

C1 Public

Page 6

EVK-VERA-P174 - User guide

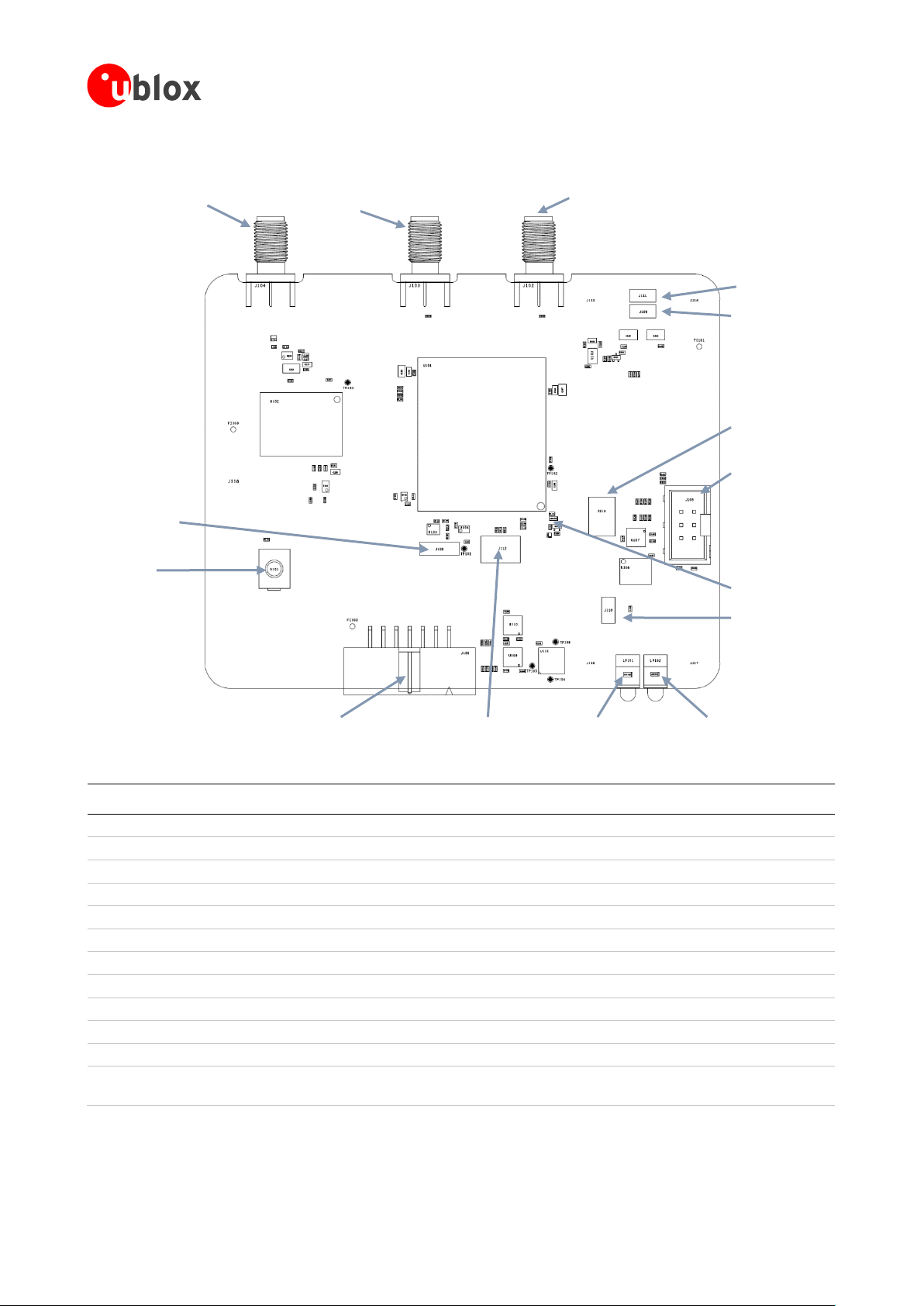

Figure 1: EVK-VERA-P174 main board

1.2 Kit includes

The EVK-VERA-P174 evaluation kit includes the following:

• Evaluation board with the VERA-P174 module (main and power supply boards)

• Two 5.9 GHz DSRC antennas (Triton TD.10 5 dBi)

• Micro USB cable

• Quick Start card

1.3 Software and documentation

The Linux drivers, firmware, and basic evaluation tools for the VERA-P1 series modules are available

via u-blox support. Distribution of the software requires signing of the u-blox Limited Use License

Agreement (LULA-N).

☞ Contact u-blox support for your area as listed in the Contact section to obtain the software

package.

1.4 System requirements

• Host PC with a USB 2.0 interface

• Native Linux OS or virtual machine for building and running the software (for example, Ubuntu

18.04)

UBX-17048707 - R08 Evaluation kit description Page 6 of 31

C1 Public

Page 7

EVK-VERA-P174 - User guide

1.5 Specifications

Table 2 and Table 3 list the absolute maximum ratings and operating conditions for the

EVK-VERA-P174:

Symbol Description Min. Max. Unit

V_Sys Main power supply 9 – 28 V -0.3 28.0 V

5V0_A1,

5V0_A2

3V3 Power supply voltage 3.3 V -0.3 3.9 V

VIO I/O supply voltage 1.8 V/3.3 V -0.3 3.9 V

T

Table 2: Absolute maximum ratings

Symbol Description Min. Typ Max. Unit

V_Sys Main power supply voltage 9 12 28 V

5V0_A1,

5V0_A2

3V3 Power supply voltage 3.3 V 3.0 3.3 3.6 V

VIO I/O supply voltage 1.8 V/3.3 V 1.65 1.8 1.95 V

3.0 3.3 3.6 V

TA Ambient operating temperature - 40 - + 95 ºC

Ripple Noise Peak-to-peak voltage ripple on 3V3 supply lines - - 175 mV

Peak-to-peak voltage ripple on 5V0 supply lines. 125 mV

Table 3: Operating conditions

Storage temperature -40 +95 ºC

STORAGE

Power supply voltage 5 V -0.3 6.0 V

Power supply voltage 5.0 V 4.5 5.0 5.5 V

Symbol Description Conditions Typ Max. Unit

VIH Input high voltage 0.7*VIO1 VIO1 V

VIL Input low voltage -0.3 0.62 V

V

Input hysteresis 0.18 - V

HYS

VOH Output high voltage IOmax = 5 mA VIO - 0.4 - V

VOL Output low voltage IOmax = -5 mA - 0.4 V

Table 4: Digital pad ratings

1

1PPS pad always uses 1.8 V internally generated IO supply regardless of the VIO pad voltage.

2

RSTn pad is internally pulled high to VIO voltage by 100k. During reset, it should be below 0.2 V.

UBX-17048707 - R08 Evaluation kit description Page 7 of 31

C1 Public

Page 8

EVK-VERA-P174 - User guide

5V

3V3

VIO

Boot

mode

2 Getting started

The basic steps to evaluate the VERA-P1 series modules using the EVK-VERA-P174 evaluation kit

are provided below:

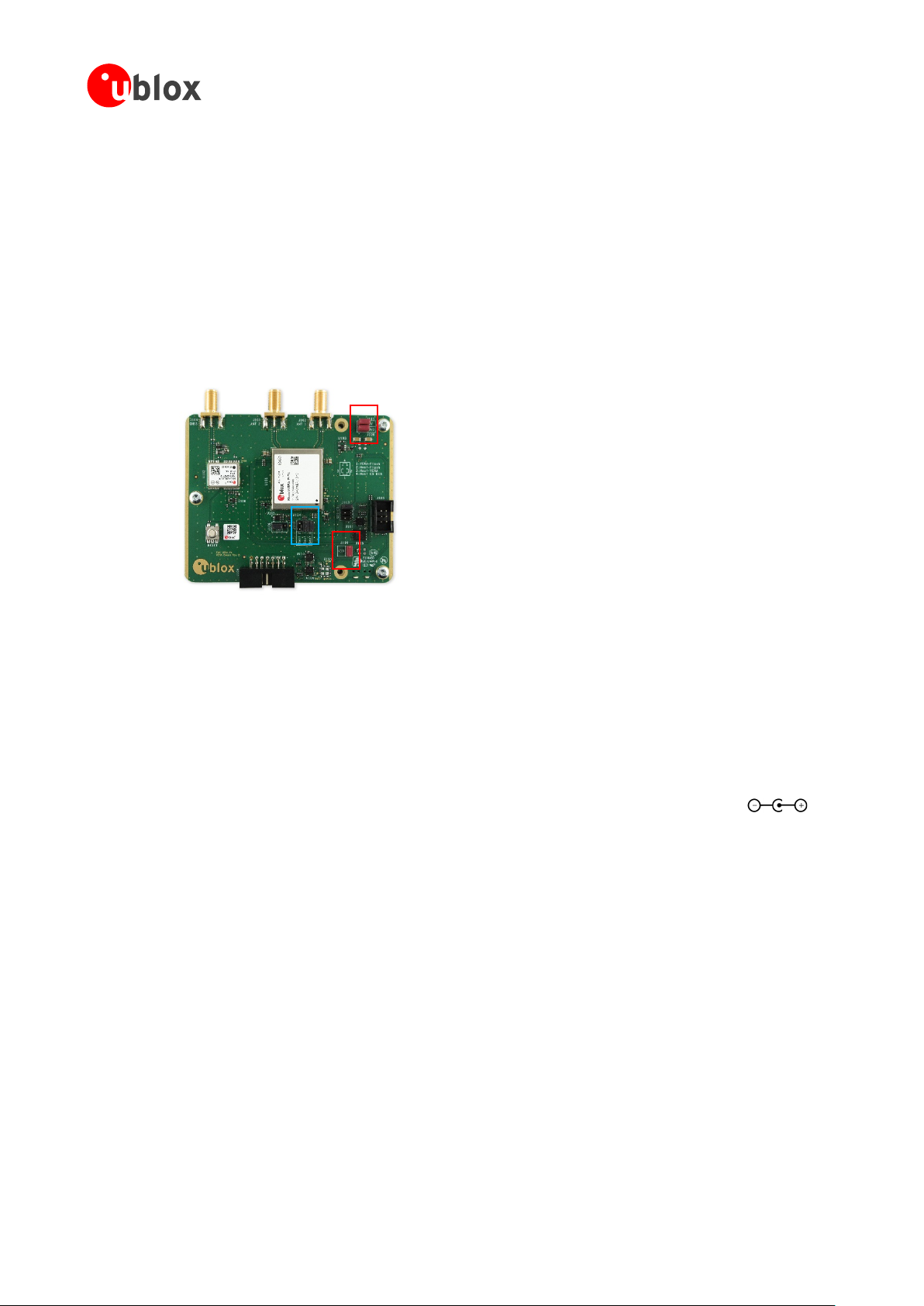

1. Make sure that jumpers are placed on the current measurement pin headers on the main board

as shown in Figure 2. The jumpers for 5 V, 3.3 V, and 1.8 V supply must be placed on the power

supply board to use the on-board voltage regulators. The jumper for VIO voltage selection on the

power supply board is set to 3.3 V by default. See the description on the back of the board for the

jumper locations.

Figure 2: Jumper locations on the main board

2. Place jumpers on Boot_0 and Boot_1 to select the USB DFU boot mode.

3. Connect two external 5.9 GHz antennas to the SMA antenna connectors of the VERA-P1 series

module.

⚠ Always make sure that the RF ports are properly terminated to a 50 Ω load such as an antenna,

spectrum analyzer or 802.11p receiver. If you directly connect the RF ports of the two

EVK-VERA-P174 evaluation kits, include a minimum attenuation of 50 dB, to avoid damage to

the modules.

4. Connect a 9 – 28 V, 12 W power adapter to the 2.5 x 5.5 mm barrel power connector ( ) on

the power supply board. The power and reset LEDs will be on.

5. Connect the micro USB connector on the power supply board to a host processor or a PC. The

USB LED will be on.

6. Follow the quick start instructions in section 4.1 to build the Linux driver and applications for the

VERA-P1 series modules and download the firmware to the VERA-P1 series module.

UBX-17048707 - R08 Getting started Page 8 of 31

C1 Public

Page 9

EVK-VERA-P174 - User guide

VERA-P1

GNSS

SMA

SMA

SMA

8 MBit Flash

SPI

USB-to-UART

Bridge

UART

USB

Hub

USB-to-SPI

Bridge

Power Supply

9V ... 28V

USB

USB

USB & Power Board

VERA-P1 Main Board

Host Connector

& Pin Header

5V

3.3V

1.8V

1PPS

3 Board description

This section describes the EVK-VERA-P174 evaluation board, the available connectors, and

configuration settings.

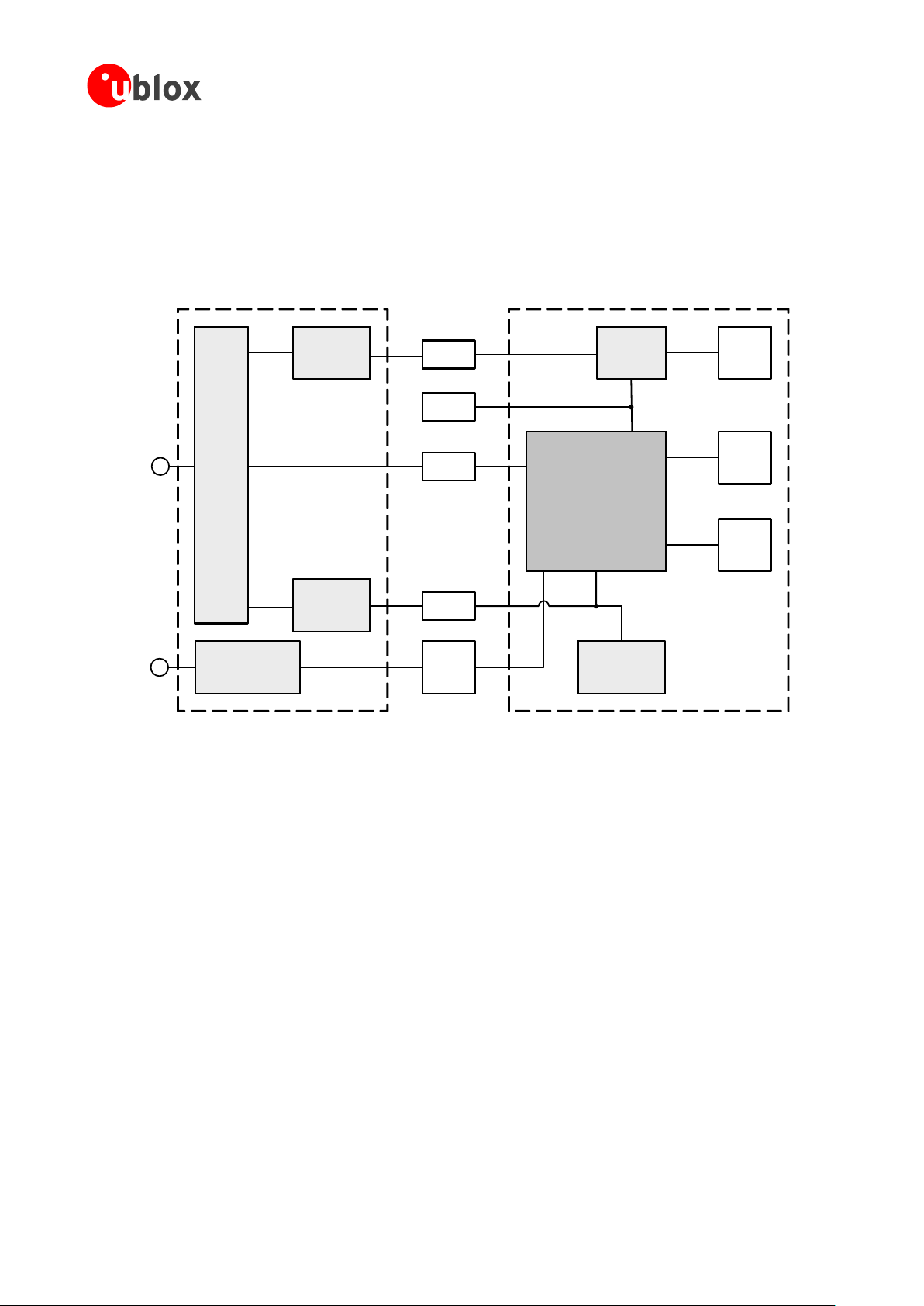

3.1 Block diagram

Figure 3 shows a general block diagram of the evaluation board.

Figure 3: Block diagram of the EVK-VERA-P174 evaluation board

3.2 Overview

Table 5 lists the available connectors on the upper main board of the EVK-VERA-P174 and their

functions. Table 6 lists the available connectors on the lower power supply board of the

EVK-VERA-P174 and their functions.

UBX-17048707 - R08 Board description Page 9 of 31

C1 Public

Page 10

3.2.1 Main board

Bootstrapping

(J112)

1PPS

(J108)

Reset

button

VERA-P1 ANT 1

(J102)

VERA

(J103)

GNSS antenna

connector

GNSS (J106)

Reset LED

Firmware LED

1PPS LED

5V (J111)

3V3

(J109)

SPI CS

(J113)

SPI (J105)

VIO (J110)

EVK-VERA-P174 - User guide

-P1 ANT 2

Figure 4: EVK-VERA-P1 Main board assembly overview

Designator Connector Description

J112 Bootstrapping Jumpers to select the VERA-P1 boot mode

J105 SPI SPI interface connector

J108 1PPS Jumper and connector for the internal or external 1PPS signal

J109 3V3 current measure Pin header to measure current on 3V3 rail

J110 VIO current measure Pin header to measure current on VIO rail

J111 5V current measure Pin header to measure current on 5V rail

J102 ANT1 SMA connector for antenna 1 of VERA-P1

J103 ANT2 SMA connector for antenna 2 of VERA-P1

J113 SPI CS Jumper to configure SPI chip select routing between VERA-P1, SPI flash, and host

J104 GNSS antenna SMA connector for the GNSS antenna

J106 GNSS connector Connector for GNSS UART/1PPS signals

J101 Host interface

connector

Table 5: EVK-VERA-P174 Main board connector description

Board-to-board connector to the power supply board

UBX-17048707 - R08 Board description Page 10 of 31

C1 Public

Page 11

3.2.2 USB and power supply board

5V supply

(J8+J5)

Power supply

reset button

VIO select

(J10)

Main supply

jack (J1)

USB LED

Power LED

Micro USB

(J2)

3V supply

(J4+J7)

1.8V supply

(J6+J9)

EVK-VERA-P174 - User guide

Figure 5: USB Power supply board assembly overview

Designator Connector Description

J1 Main supply 2.5 x 5.5 mm barrel connector for 9 – 28 V power supply

Connect jumpers J7, J8, J9 and J10 before using

J8 Jumper for 5 V supply Disconnect to use external 5 V supply on J5

J7 Jumper for 3.3 V supply Disconnect to use external 3.3 V supply on J4

J5 External 5 V supply Connector for external 5 V supply

J4 External 3.3 V supply Connector for external 3.3 V supply

J10 VIO select Jumper to select VIO voltage 1.8 V or 3.3 V

J9 Jumper for 1.8 V supply Disconnect to use external 1.8 V supply on J6

J6 External 1.8 V supply Connector for external 1.8 V supply

J2 Micro USB USB interface connector

J3 Host interface

connector

Table 6: EVK-VERA-P174 Power supply board connector description

Board-to-board connector to the main board

UBX-17048707 - R08 Board description Page 11 of 31

C1 Public

Page 12

EVK-VERA-P174 - User guide

3.3 Connectors

3.3.1 Power supply and configuration

The VERA-P1 module is supplied with 3.3 V, 5 V, and a VIO that can be either 3.3 V or 1.8 V. Power

supply for the evaluation board is provided through a DC power jack connector (J1) with an input

voltage of 9-28 V.

All supply voltages can be generated from the on-board DC-DC converters and LDO regulators or

supplied externally via the connectors J5 (5 V), J4 (3.3 V) and J6 (1.8 V) of the power supply board.

Disconnect the jumpers J8, J7 or J9 on the power supply board to use the external power supply

connectors. The VIO voltage for the VERA-P1 module can be selected with jumper J10 on the power

supply board between 1.8 V and 3.3 V.

Individual current consumption on the 3.3 V, 5 V, and VIO rails of the VERA-P1 module can be

measured with the respective pin headers J109, J111, and J110 on the main board.

3.3.2 USB interface

The USB host communication for the VERA-P1 module is provided through the micro USB connector

J2 on the power supply board. The connector J2 is connected to a USB 2.0 hub on the power supply

board, which connects the USB port to the following downstream devices:

• The USB interface of the VERA-P1 module on the main board

• The u-blox NEO-M8U GNSS module on the main board via a USB-to-UART bridge (FT234XD-T)

• The SPI interface of the VERA-P1 module or on-board SPI flash on the main board via a USB-to-

SPI bridge (FT2232H port A)

3.3.3 Bootstrapping

The bootstrapping jumper J112 on the main board is used to select the boot mode of the VERA-P1

module. The valid bootstrap options are listed in Table 7. To set a logic level 0, connect the boot pin

with a jumper to GND. Leave the pin open for logic level 1.

Boot mode Boot 2 Boot 1 Boot 0 Description

SPI master 1 1 0 VERA-P1 acts as an SPI master and automatically downloads a

bootloader or firmware from an SPI flash.

SPI slave 1 0 1 Firmware download is under the control of an external SPI master.

VERA-P1 acts as SPI slave.

USB-DFU 1 0 0 USB Device Firmware Upgrade (DFU) boot mode. The VERA-P1 module

presents itself on the USB bus as a DFU device for downloading the

SDR firmware.

Table 7: Boot mode configuration

The EVK-VERA-P174 contains an on-board SPI flash to support the SPI master boot option. See

section 3.3.5 for further configuration of the SPI chip select routing options.

3.3.4 SPI interface

The SPI interface connector J105 on the main board can be used to connect to the SPI interface of

the VERA-P1 module or the on-board SPI flash. The SPI chip select jumpers are used to select either

the VERA-P1 module or the SPI flash.

UBX-17048707 - R08 Board description Page 12 of 31

C1 Public

Page 13

EVK-VERA-P174 - User guide

Pin No. Assignment

1 SPI data MISO

2 VIO

3 SPI clock

4 SPI data MOSI

5 SPI chip select

6 GND

3.3.5 SPI chip select

The EVK-VERA-P174 contains an 8 Mbit SPI flash (SST25VF080B), which can be used to store the

radio firmware or a different bootloader for the VERA-P1 module. The SPI chip select pin header

(J113) on the main board is used to configure the routing of the SPI chip select signal between the

VERA-P1, host, and SPI flash. Table 8 shows the possible configurations:

SPI CS routing Jumper settings3

(J113)

Host to flash via USB 2 (1-3) Used to program the flash from the host over USB. The SPI flash is

Host to flash via J105 2 (1-3), 4 (5-6) Used to program the flash from the host directly over SPI. The SPI flash is

VERA-P1 to flash

Host to VERA-P1 via

J105

Table 8: SPI Chip select configuration

1

(1-2), 4 (5-6) Used to connect VERA-P1 to the SPI flash for firmware or bootloader

3

(2-4), 4 (5-6) Used to connect VERA-P1 to the host over SPI, when boot mode “SPI slave”

Description

accessible via the USB interface on the power supply board. A USB-to-SPI

bridge (FT2232H) connects the SPI flash to the USB.

accessible via the SPI interface connector or the host interface connector.

Jumper on 5-6 is used to disable the USB-to-SPI bridge.

download, when boot mode “SPI master” is selected (see 3.3.3).

is selected (see 3.3.3). The VERA-P1 SPI interface is accessible via the SPI

interface connector or the host interface connector.

3.3.6 1PPS interface

A 1PPS UTC reference signal is required by the IEEE1609.4 MAC inside the module to align

transmissions during channel switching and timekeeping. The 1PPS pin header J108 on the main

board can be used to connect the 1PPS signal from the on-board NEO-M8U GNSS receiver to the

1PPS signal input of the VERA-P1 module.

Place a jumper on pins 1 and 2 of the 1PPS pin header to connect the 1PPS signal from the NEO-M8U

GNSS module to the VERA-P1 module. The Pin 2 (VERA-P1 1PPS) and 3 (GND) can be used to

connect a 1PPS signal from an external GNSS to the VERA-P1 module. The signal level for the

external 1PPS can be in the range from 1.8 – 5 V and is converted to 1.8 V via a level shifter.

3.3.7 GNSS interface

The signals of the GNSS UART and 1PPS signal are available on the connector J106.

3

Italic number is the designation as printed on the EVK

UBX-17048707 - R08 Board description Page 13 of 31

C1 Public

Page 14

EVK-VERA-P174 - User guide

Pin No. Pin name Type Level Description

5 VIO2 Power VIO VIO voltage

7 GND Ground

10 1PPS I/O I: 1.8 - 5.5 V

O: 3.3 V

11 NEO_UART_RX I 0 - 3.3 V GNSS UART RX

12 NEO_UART_TX O 3.3 V GNSS UART TX

13 GND Ground

1PPS signal output from GNSS (J108 1-2) or input to VERA-P1 (J108 2-

3)

3.3.8 SMA connectors

The EVK-VERA-P174 includes two SMA connectors, ANT1 (J102) and ANT2 (J103), which are used

to connect external antennas or measurement instruments to the antenna pins of the VERA-P1

module.

A third SMA connector (J104) is included to connect an active antenna to the on-board NEO-M8U

GNSS module.

The SMA connectors on the EVK are specified for RF signals up to 18 GHz.

⚠ Always ensure that the RF ports of the VERA-P1 module are properly terminated to a 50 Ω load

such as an antenna, spectrum analyzer, or 802.11p receiver. If you directly connect the RF ports

of two EVK-VERA-P174 evaluation kits, include a minimum attenuation of 50 dB, to avoid

damage to the modules.

3.3.9 Host interface connector

The host interface connector is used in the EVK to connect the VERA-P1 main board to the power

supply and USB interface board. Additionally, it can be used to connect the VERA-P1 main board

directly to a compatible host board. The connector on the main board is a QMS-052-0675-L-D-PC4

and the counterpart on the power supply board is a QFS-052-0675-L-D-PC4.

3.4 LEDs

Table 9 lists the available LEDs on the EVK-VERA-P174:

Name Designator Location Function

Power LED1 Power supply board Indicates 3.3 V supply (LED on)

USB LED2 Power supply board Indicates USB connection to the host (LED on)

Reset LED103 Main board, near pin 1 of VERA-P1 Indicates VERA-P1 module in reset (LED off)

1PPS LED102 Main board Indicates 1PPS signal (LED blinking)

Firmware LED101 Main board Indicates firmware loaded (LED on) through current

measurement

Table 9: LED Description

3.5 Buttons

The reset button on the main board (S101) resets the VERA-P1 module. The button on the power

supply board (S1) is used to reset the on-board power supply for the EVK.

UBX-17048707 - R08 Board description Page 14 of 31

C1 Public

Page 15

EVK-VERA-P174 - User guide

3.6 Design files

The schematics for the EVK-VERA-P174 are shown in Figure 6 and Figure 7. Full design files are also

available via u-blox support. To obtain these documents, send an email to the support team email

address for your area, as listed in the Contact section.

UBX-17048707 - R08 Board description Page 15 of 31

C1 Public

Page 16

EVK-VERA-P174 - User guide

Figure 6: Schematic of the VERA-P1 main board, page 1/2

UBX-17048707 - R08 Board description Page 16 of 31

C1 Public

Page 17

EVK-VERA-P174 - User guide

Figure 7: Schematic of the VERA-P1 main board, page 2/2

UBX-17048707 - R08 Board description Page 17 of 31

C1 Public

Page 18

EVK-VERA-P174 - User guide

Figure 8: Schematic of the power supply board, page 1/2

UBX-17048707 - R08 Board description Page 18 of 31

C1 Public

Page 19

EVK-VERA-P174 - User guide

Figure 9: Schematic of the power supply board, page 2/2

UBX-17048707 - R08 Board description Page 19 of 31

C1 Public

Page 20

EVK-VERA-P174 - User guide

$ tar -xzf V2X_LLC_Remote_V15.0.0.tar.gz

$ cd llc-remote

$ sudo ./install.sh

$ make

$ ln -sr bsp/app/libpcap/$(uname -m)/libpcap.a cohda/app/llc/lib/

4 Software

A standalone software package for the VERA-P1 modules called “LLC Remote” is available through

u-blox support. The “LLC Remote” software package contains the following:

• A firmware image that has to be downloaded to the module on system start

• A driver, which is placed between the bus driver and network layer of the V2X stack

• Various test tools and example applications

• Precompiled executables to run on a Linux x86 PC

The LLC driver and part of the tools are provided as source code. The SDR firmware and LLC driver is

developed by Cohda Wireless Pty, as a subcontractor of NXP Semiconductors N.V. The release

process of the firmware binary and the associated LLC Remote driver implementation is combined

with the major release of the Cohda MKx Software Development Kit

the LLC Remote package follows the numbering of the Cohda SDK.

A release notes document with quick start instructions for compiling the software is available with

each software package. Recipes for integrating the software package into Yocto-based projects can

be provided by u-blox on request.

To evaluate the VERA-P1 series module, the EVK-VERA-P174 can be connected via USB to a native

Linux PC or a virtual machine running Linux. For this user guide, a virtual machine running Ubuntu

18.04 LTS with Linux kernel 4.15.0-23-generic (x86_64) has been used.

4

and the version numbering of

4.1 Quick start instructions

Copy the LLC Remote package archive into the target Linux development environment. Extract the

package content and change to the extracted directory.

Run the

dependencies. The script requires system privileges and an active Internet connection for

downloading the packages. The main dependencies of the LLC Remote package are:

• dfu-util, for downloading the radio firmware to the module in USB DFU boot mode

• linux-headers, for building the LLC remote driver

• bison, flex, for building the included libpcap library used by the LLC user-space library

The next step is to run

☞ If the make process fails because of a missing

This will compile and install the following parts:

install.sh

script once in a new development environment to automatically install the package

make

to build the whole software package:

pcap

the missing symbolic link to the library and then run

library, run the following command to create

make

again:

• cw-llc driver for the active running Linux kernel

• LLC user-space library libLLC.so

4

A full SDK supporting IEEE 1609 and ETSI ITS software stacks is available from Cohda Wireless.

UBX-17048707 - R08 Software Page 20 of 31

C1 Public

Page 21

• LLC user-space tool and plugins5

$ lsusb

Bus 001 Device 002: ID 1fc9:0102 NXP Semiconductors

$ ./load

Resetting USB to switch back to runtime mode

$ ./load

0

EVK-VERA-P174 - User guide

The LLC user-space tool, plugins and library will be installed to the

driver will be copied to the

./drivers/<kernel_version>

subdirectory.

./bin

subdirectory and the cw-llc

Connect the EVK-VERA-P174 evaluation kit to the PC and connect the USB device to the virtual

machine, if required. The VERA-P1 module enumerates itself on the USB as “NXP SAF510x DFU”

device with the USB device ID 1fc9:0102, which can be checked using the

Run the

load

script to detect the VERA-P1 module and download the radio firmware through USB via

lsusb

command:

the Device Firmware Update (DFU) protocol, if required. If prompted for a firmware, select option 2 to

download the SDRMK5Dual.bin for evaluation of VERA-P174 or option 4 to select SDRMK5Single.bin

for evaluation of VERA-P173.

Load SAF5X00 firmware via DFU-util

** NOTE: dfu-util may fail under VMWare; you may need to unplug your board after

download and restart ./load **

1] DFUBootLoader.bin

2] SDRMK5Dual.bin

3] SDRMK5DualSPI.bin

4] SDRMK5Single.bin

Select file to download (1-4): 2

Using firmware file images/SDRMK5Dual.bin

[sudo] password for user:

dfu-util 0.9

Copyright 2005-2009 Weston Schmidt, Harald Welte and OpenMoko Inc.

Copyright 2010-2016 Tormod Volden and Stefan Schmidt

This program is Free Software and has ABSOLUTELY NO WARRANTY

Please report bugs to http://sourceforge.net/p/dfu-util/tickets/

dfu-util: Invalid DFU suffix signature

dfu-util: A valid DFU suffix will be required in a future dfu-util release!!!

Deducing device DFU version from functional descriptor length

Opening DFU capable USB device...

ID 1fc9:0102

Run-time device DFU version 0100

[…]

DFU mode device DFU version 0100

Device returned transfer size 4096

Copying data from PC to DFU device

Download [=========================] 100% 436316 bytes

Download done.

state(8) = dfuMANIFEST-WAIT-RESET, status(0) = No error condition is present

Done!

dfu-util: can't detach

In case of a virtual machine environment, repeat to run the

loaded. As the USB device changes roles after firmware download, ensure that the new 802.11p radio

device with the USB device ID 1fc9:0103 is automatically connected to the virtual machine.

Once the device is properly detected, the

load

script will display an output as shown below:

5

LLC plugins for channel configuration, sending, and receiving packets are provided as source code. Other plugins are provided

as binary only.

UBX-17048707 - R08 Software Page 21 of 31

C1 Public

load

script until the cw-llc driver module is

Page 22

EVK-VERA-P174 - User guide

Echo loading cw-llc module for kernel 4.15.0-23-generic_x86_64

LLC 4

$ ./bin/llc version

Last Reset Source : External (54, 1024)

$ sudo ldconfig $(realpath ./bin)

$ ./llc -c

cw_llc 143360 0

1

☞ Kernel crashes have been observed in some cases when loading the driver on systems where

NetworkManager is running. In such a case, either stop the NetworkManager before loading the

driver via

sudo systemctl stop NetworkManager.service

or configure it to ignore the LLC IPv6 interfaces by adding the following lines to

/etc/NetworkManager/NetworkManager.conf:

[keyfile]

unmanaged-devices=interface-name:llc-*

Then, restart the NetworkManager service via

sudo systemctl restart NetworkManager.service

Execute the “llc version” command to check the connection to the module and to verify the firmware

version:

WISPA Variant : TEF5200

WISPA Version : 0x0

PCB Version : 2

PCB Load : 1

Boot Pins : 0xc

SDR Firmware : 69189

SDR Revision Date : 2018-01-22 12:14

SDR Build Date : 2018-01-22 12:15

Security Accel. : No

Antenna Mask : 3

Radio B Present : 1

Last Reset Source : External (36, 1024)

Last Reset Source : External (53, 1024)

☞ The llc tool and plugins require the shared library -

linker. This is set up during the make process by calling

overwritten during system startup. In this case,

4.2 Module calibration

The EVK-VERA-P174 modules do not contain valid calibration settings. The calibration must be

performed manually, by executing llc commands after each power cycle and loading of the firmware.

The instruction for loading the calibration parameters and calibration files for the EVK-VERA-P174

modules are provided in the VERA-P1 series system integration manual [2].

4.3 Usage examples

After loading the firmware and the LLC driver, basic tests can be performed using the LLC tool and

the provided plugins. The LLC tool and plugins are installed in the

available commands or plugins can be obtained by running the following command:

Some basic plugins and their purpose are described in Table 10.

libLLC

ldconfig

so that it can be located by the run-time

ldconfig

with the library path and could be

must be called manually again:

./bin

subdirectory. A list of the

UBX-17048707 - R08 Software Page 22 of 31

C1 Public

Page 23

EVK-VERA-P174 - User guide

$ ./llc <command-name> --help

$ ./llc count

Rx MAC Valid Unmatched RTS Frame 0 0 0 0

Plugin Description

count Displays the transmit and receive counters for both radios

config Displays the configuration (mode/antenna/freq) of both radios

txqueue Displays the state of the Tx MAC, together with the counts of all of the queues

status Displays the instantaneous status of the radio, including the number of packets that

are queued and also the state of the medium

cfg Command to read or write the current RadioConfig data, as stored in the baseband

version Reports the version details of the SDR firmware image

dmesg Displays the debug print messages of the ARM/VDSP1/VDSP2 processor

rxphylast Displays details of the last received frames by the PHY

txphylast Displays details of the last transmitted frames by the PHY

chconfig Sets the channel configuration for both radios

test-tx Generates and transmits test packets

test-rx Receives test packets

Table 10: Description of LLC plugins

☞ The source code for the chconfig, test-rx and test-tx plugins is provided in the

cohda/app/llc/plugin/simtdapi

Instructions on how to use the individual commands are printed with the “--help” option.

subdirectory.

4.3.1 Transmit and receive counters

Use the command “llc count” to print out transmit and receive counters for both the radios as shown

below.

☞ This command can be used to easily verify the access to the module.

RadA Ch0 RadA Ch1 RadB Ch0 RadB Ch1

Tx MAC Unconfigured Frames 0 0 282 0

Tx MAC Failed Enqueue 0 0 0 0

Tx MAC Broadcast Enqueued Frames 5331 0 3 0

Tx MAC Broadcast Success Frames 5331 0 2 0

Tx MAC Broadcast Failed TTL 0 0 0 0

Tx MAC Broadcast Retired Frames 5331 0 2 0

Tx MAC Unicast Enqueued Frames 0 0 0 0

Tx MAC Unicast RTS/CTS Enq Frame 0 0 0 0

Tx MAC Unicast Success Frames 0 0 0 0

Tx MAC Unicast Failed Retry 0 0 0 0

Tx MAC Unicast Failed TTL 0 0 0 0

Tx MAC Unicast Retired Frames 0 0 0 0

Tx MAC Unicast Retry Frames 0 0 0 0

Tx MAC Unicast Ack Frames 0 0 0 0

Tx MAC Unicast RTS Frames 0 0 0 0

Tx MAC Unicast CTS Frames 0 0 0 0

Tx PHY Frames 5332 0 3 0

Tx PHY Aborted Frames 2 0 0 0

Tx PHY Aborted Resp (Ack/CTS/..) 0 0 0 0

Rx PHY AGC Firings 0 0 0 0

Rx PHY Acquisitions 0 2765 0 0

Rx PHY Failed SF 0 2 0 0

Rx PHY Valid SF Frames 0 2763 0 0

Rx MAC Failed FCS 0 0 0 0

Rx MAC Valid Matched RTS Frames 0 0 0 0

UBX-17048707 - R08 Software Page 23 of 31

C1 Public

Page 24

EVK-VERA-P174 - User guide

Rx MAC Valid Matched CTS Frames 0 0 0 0

Rx Frame Firings 0 2765 0 0

$ ./llc chconfig -s -w CCH -c 184 -r a -a 3

MAC Address: 04:e5:48:00:10:00

$ ./llc test-tx -c 184 -p 40 -a 3 -m MK2MCS_R12QPSK -n 100 -l 200

NMCS: 1

Rx MAC Valid Unmatched CTS Frame 0 0 0 0

Rx MAC Valid Data Frames 0 2763 0 0

Rx MAC Valid Matched Ack Frames 0 0 0 0

Rx MAC Valid Unmatched Ack Frame 0 0 0 0

Rx MAC Valid Matched Late Ack Fr 0 0 0 0

Rx MAC Broadcast Frames 0 2763 0 0

Rx MAC Address Matched Frames 0 0 0 0

Rx MAC Address Dropped Frames 0 0 0 0

Rx MAC Buffer Overflow Frames 0 0 0 0

Rx MAC Duplicate Frames 0 0 0 0

Rx MAC USB Transferred Frames 0 2763 0 0

Rx MAC USB Callbacks 2763 0 0 0

CS Active Firings 2 2751 0 0

CS Idle Firings 2 40 0 0

CCA Active Firings 0 51 0 0

CCA Idle Firings 0 2765 0 0

4.3.2 Channel configuration

Two different channel configurations are available per radio on the VERA-P1, which can be configured

by using the

uses the LLC Remote API to set up, start, stop, or get the CCH/SCH configurations.

chconfig

LLC plugin via the Control Channel (CCH) or Service Channel (SCH). The plugin

The following example configures and starts the control channel (radio channel configuration 0) on

radio A, channel 184, using both the antennas:

Interface: wave-raw

Channel: CCH

Radio: A

ChannelNumber: 184

DefaultMCS: 10

DefaultTxPower: 40

DefaultTRC: 0

DefaultTPC: 0

Bandwidth: 10

DualTxControl: 0

ChannelUtilisationPeriod: 49

TxAntenna: 3

RxAntenna: 3

MACAddr: 04:e5:48:00:10:00

Filter: 0x88b5

4.3.3 Transmitter test

The

test-tx

prior to transmitting a burst and their settings define the default configuration for the packets.

LLC plugin is used to transmit a burst of packets. The CCH or SCH must be configured

The following example transmits 100 test packets of 200 bytes length on channel 184 and both

antennas, with the output power set to 40 and modulation set to ½ QPSK:

Mode: CREATE

Number Of Packets: 100

Target Packet Rate: 10.00

Priority: 4

Service: 1

MCS[0]: 10

UBX-17048707 - R08 Software Page 24 of 31

C1 Public

Page 25

EVK-VERA-P174 - User guide

TxPwrCtrl: 0

Tx: Last SeqNum: 100 [/100]. Packet rate: Current 9.8, Target 10.0

$ ./llc chconfig -s -w CCH -c 184

$ ./llc test-rx -c 184

$ ./llc chconfig -s -w CCH -c 184

$ ./llc test-tx -c 184 -a1 -p30 -n1000 -r100

Packet Log File:

Rx: Un/Matched Frames: 0/0

TxPower: 40

TxAntenna[0]: 3

NTxAnt: 1

Expiry: 0

PayloadLength[0]: 200

Destination MAC Address: ff:ff:ff:ff:ff:ff

EtherType: 0x88b5

ChannelNumber: 184

PayloadMode: increment

Source MAC Address: 04:e5:48:00:10:00

Packet Log File:

DumpPayload: 0

DumpToStdout: 0

Interface: wave-raw

Tx: Last SeqNum: 10 [/100]. Packet rate: Current 9.6, Target 10.0

Tx: Last SeqNum: 20 [/100]. Packet rate: Current 10.0, Target 10.0

Tx: Last SeqNum: 30 [/100]. Packet rate: Current 10.0, Target 10.0

Tx: Last SeqNum: 40 [/100]. Packet rate: Current 10.0, Target 10.0

Tx: Last SeqNum: 50 [/100]. Packet rate: Current 10.0, Target 10.0

Tx: Last SeqNum: 60 [/100]. Packet rate: Current 10.0, Target 10.0

Tx: Last SeqNum: 70 [/100]. Packet rate: Current 10.0, Target 10.0

Tx: Last SeqNum: 80 [/100]. Packet rate: Current 10.0, Target 10.0

Tx: Last SeqNum: 90 [/100]. Packet rate: Current 10.0, Target 10.0

4.3.4 Receiver test

The

test-rx

command. The receiving application periodically informs about the number of received packets, the

calculated packet error rate and also dumps per packet and statistics logs. The receive test should be

running before starting the transmission to receive all the packets.

☞ The LLC driver supports only one VERA-P1 module connected to the host system. In order to test

packet transmission with two modules, two host PCs or virtual machines must be used in parallel.

The following example sets the channel configuration and starts to receive and transmit test packets

between two different VERA-P1 modules:

On the receiving side:

On the transmitting side, sends 1000 packets at a rate of 100 packets per second:

The output on the receiver will look like the following:

Report File: RxReport.txt

LogUnMatched: 0

DumpPayload: 0

DumpToStdout: 0

ReportPeriod: 100

Filter SA: None

Interface: wave-raw

ChannelNumber: 184

Rx: Report [Last SeqNum: -1 (0xffffffff)]

Rx: Approx PER: -nan% [Missed: 0, Payload Error: 0 / Tx: 0] (264.6% [-67108864, 1975612572 / -772014096)

command is used to receive test packets sent by another module via the

test-tx

UBX-17048707 - R08 Software Page 25 of 31

C1 Public

Page 26

EVK-VERA-P174 - User guide

Total 0 0

Total 1000 0

$ cd drivers; ./load IPv6Enabled=1; cd -

$ llc chconfig -s -w CCH -r a -c 180

$ ip link set llc-cch-ipv6 up

valid_lft forever preferred_lft forever

$ ping6 -I llc-cch-ipv6 fe80::8a8c:22ae:976d:cdde

Rx: Report [Last SeqNum: 100 (0x00000064)]

Rx: Approx PER: 0.0% [Missed: 0, Payload Error: 0 / Tx: 101] (0.0% [0, 0 / 100)

Rx: Un/Matched Frames: 0/101

Rx: Channel 184: 00000101 Matched Packets.

# MCS Len Matched Payload Err

11 104 101 0

Total 101 0

[…]

Rx: Report [Last SeqNum: 999 (0x000003e7)]

Rx: Approx PER: 0.0% [Missed: 0, Payload Error: 0 / Tx: 1000] (0.0% [0, 0 / 99)

Rx: Un/Matched Frames: 0/1000

Rx: Channel 184: 00001000 Matched Packets.

# MCS Len Matched Payload Err

11 104 1000 0

4.3.5 LLC native IPv6 functionality

Native IPv6 functionality using the Linux IPv6 stack is supported in the LLC driver since release 15.

The driver creates two network interfaces - llc-cch-ipv6 and llc-sch-ipv6, which can be used for IPv6

communication between two or more VERA-P1 modules. The network interfaces, llc-cch-ipv6 and llcsch-ipv6 map to the channel configuration 0 of radio A and radio B respectively. All communicating

VERA-P1 modules must be configured to use the same DSRC channel.

The module option IPv6Enabled=1 must be provided when the driver module is loaded to enable IPv6

support. The optional argument, IPv6MCS can be used to set the rate for transmitted IPv6 packets.

The module options can be passed to the

level load script to download the radio firmware:

☞ The Network Manager in the Linux host system should be deactivated, or the IPv6 configuration

of the LLC IPv6 network interfaces should be set to Link-Local only and IPv4 should be disabled, in

order to not interfere with the interface configuration.

The

chconfig

set the channel configuration 0 of radio A to channel 180 for communication using the

network interface:

The following commands are used to enable the

automatically assigned link-local IPv6 address:

$ ip addr show llc-cch-ipv6

39: llc-cch-ipv6: <BROADCAST,MULTICAST,UP,LOWER_UP> mtu 1500 qdisc noqueue state

UNKNOWN group default qlen 1000

link/ether fa:8b:7f:64:0e:eb brd ff:ff:ff:ff:ff:ff

inet6 fe80::8a8c:22ae:976d:cdde/64 scope link noprefixroute

plugin is used to configure the DSRC channel on all VERA-P1 modules, for example to

load

script in the ./drivers subdirectory, after using the top

llc-cch-ipv6

llc-cch-ipv6

network interface and to get the

The IPv6 address can then be used to send an IPv6 ping request from another VERA-P1 module over

the

llc-cch-ipv6

interface:

The throughput over IPv6 between two VERA-P1 modules can be tested using the iperf3 tool for

example. To do this, start the iperf3 server on one side:

UBX-17048707 - R08 Software Page 26 of 31

C1 Public

Page 27

EVK-VERA-P174 - User guide

$ iperf3 -s -D

$ iperf3 -6 -c fe80::8a8c:22ae:976d:cdde%llc-cch-ipv6

$ cd cohda/kernel/drivers/cohda/llc

KERNELDIR=/home/duser/work/linux-3.10.107/

$ cd cohda/app/llc

LD=arm-linux-gnueabi-ld

Then start the throughput test on the client side and connect to the IPv6 address of the server:

4.4 Building the software for a different target platform

Building the LLC Remote package for a different target system requires a toolchain and configured

kernel sources for the target platform. The following example shows how to manually cross-compile

the LLC driver and tools for an Arm

configured kernel sources should be available in the

☞ Recipes for integrating the software package into Yocto-based projects can be provided by u-blox

on request.

To cross-compile the LLC driver:

$ make BOARD=mk5 ARCH=arm CROSS_COMPILE=arm-linux-gnueabi-

To cross-compile the LLC tool, library, and plugins6:

®

architecture using the

/home/duser/work/linux-3.10.107/

gcc-arm-linux-gnueabi

toolchain. The

directory.

$ make BOARD=mk5 ARCH=arm CROSS_COMPILE=arm-linux-gnueabi- CC=arm-linux-gnueabi-gcc

After successful compilation, the following files must be deployed on the target system:

• cohda/app/llc/llc – LLC tool

• cohda/app/llc/lib/libLLC.so* – LLC library

• cohda/app/llc/plugin/*.so – LLC plugins (to plugin subdirectory)

• cohda/kernel/drivers/cohda/llc/cw-llc.ko – LLC kernel module

• cohda/kernel/drivers/cohda/llc/SDRMK5*.bin – SDR firmware images

The

dfu-util

tool is required on the target system to download the SDR firmware to the VERA-P1

module.

6

Not all plugins are provided as source code. The Binary plugins are available only for i686, x86-64 and mk5 (Arm) architectures.

UBX-17048707 - R08 Software Page 27 of 31

C1 Public

Page 28

Appendix

A Glossary

Abbreviation Definition

1PPS 1 Pulse Per Second

API Application Programming Interface

CMOS Complementary Metal-Oxide-Semiconductor

DFU Device Firmware Upgrade

DSRC Dedicated Short Range Communication

ETSI European Telecommunications Standards Institute

EVB Evaluation Board

EVK Evaluation Kit

IEEE Institute of Electrical and Electronics Engineers

ITS Intelligent Transport Systems

GNSS Global Navigation Satellite System

GPS Global Positioning System

MAC Medium Access Control

LLC Logical Link Control

OS Operating System

PC Personal Computer

PHY Physical Layer

QPSK Quadrature Phase-Shift Keying

RF Radio Frequency

SDK Software Development Kit

SDR Software Defined Radio

USB Universal Serial Bus

UTC Coordinated Universal Time

V2X Vehicle-to-Everything

Table 11: Explanation of the abbreviations and terms used

EVK-VERA-P174 - User guide

UBX-17048707 - R08 Appendix Page 28 of 31

C1 Public

Page 29

EVK-VERA-P174 - User guide

Related documents

[1] VERA-P1 series data sheet, UBX-17004377

[2] VERA-P1 series system integration manual, UBX-17006502

[3] CohdaMobility MKx Radio LLCremote API Specification, CWD-MKx-0208

☞ For regular updates to u-blox documentation and to receive product change notifications, register

on our homepage (www.u-blox.com).

UBX-17048707 - R08 Related documents Page 29 of 31

C1 Public

Page 30

EVK-VERA-P174 - User guide

Updated for Rev B of the evaluation board. Removed references to

Added iperf3 instructions in

.

Revision history

Revision Date Name Comments

R01 24-Aug-2017 mzes, shoe, kgom Initial release.

R02 20-Oct-2017 mzes, kgom Removed references to VERA-P175.

R03 25-Apr-2018 shoe Fixed a typo in the calibration command in section 4.2.

R04 22-Jun-2018 mzes, kgom

VERA-P171.

R05 20-Jul-2018 mzes Updated calibration sequence in section 4.2.

section 4.3.5.

R06 17-Apr-2019 mzes Included a note with respect to Kernel crashes and workaround in section 4.1

Removed references to Hardware Security Module (HSM) from NXP.

R07 9-Jul-2019 mzes Modified the size of the barrel connector in section 2 (step 4) and section 3.2.2

(first row in Table 6).

R08 6-Nov-2020 mzes Replaced calibration instructions in section 4.2 with a reference to the SIM.

UBX-17048707 - R08 Revision history Page 30 of 31

C1 Public

Page 31

Contact

For complete contact information, visit us at www.u-blox.com.

u-blox Offices

North, Central and South America

u-blox America, Inc.

Phone: +1 703 483 3180

E-mail: info_us@u-blox.com

Regional Office West Coast:

Phone: +1 408 573 3640

E-mail: info_us@u-blox.com

Technical Support:

Phone: +1 703 483 3185

E-mail: support@u-blox.com

Headquarters

Europe, Middle East, Africa

u-blox AG

Phone: +41 44 722 74 44

E-mail: info@u-blox.com

Support: support@u-blox.com

EVK-VERA-P174 - User guide

Asia, Australia, Pacific

u-blox Singapore Pte. Ltd.

Phone: +65 6734 3811

E-mail: info_ap@u-blox.com

Support: support_ap@u-blox.com

Regional Office Australia:

Phone: +61 2 8448 2016

E-mail: info_anz@u-blox.com

Support: support_ap@u-blox.com

Regional Office China (Beijing):

Phone: +86 10 68 133 545

E-mail: info_cn@u-blox.com

Support: support_cn@u-blox.com

Regional Office China (Chongqing):

Phone: +86 23 6815 1588

E-mail: info_cn@u-blox.com

Support: support_cn@u-blox.com

Regional Office China (Shanghai):

Phone: +86 21 6090 4832

E-mail: info_cn@u-blox.com

Support: support_cn@u-blox.com

Regional Office China (Shenzhen):

Phone: +86 755 8627 1083

E-mail: info_cn@u-blox.com

Support: support_cn@u-blox.com

Regional Office India:

Phone: +91 80 405 092 00

E-mail: info_in@u-blox.com

Support: support_in@u-blox.com

Regional Office Japan (Osaka):

Phone: +81 6 6941 3660

E-mail: info_jp@u-blox.com

Support: support_jp@u-blox.com

Regional Office Japan (Tokyo):

Phone: +81 3 5775 3850

E-mail: info_jp@u-blox.com

Support: support_jp@u-blox.com

Regional Office Korea:

Phone: +82 2 542 0861

E-mail: info_kr@u-blox.com

Support: support_kr@u-blox.com

Regional Office Taiwan:

Phone: +886 2 2657 1090

E-mail: info_tw@u-blox.com

Support: support_tw@u-blox.com

UBX-17048707 - R08 Contact Page 31 of 31

C1 Public

Loading...

Loading...