Page 1

information for

C102-F9R

Application board

User guide

Abstract

This document describes the structure and use of the C102-F9R and provides

evaluating and testing u-blox F9 high precision sensor fusion positioning technology.

UBX-20029244 - R03

C1-Public www.u-blox.com

Page 2

C102-F9R - User guide

u

document. Copying, reproduction, modification or disclosure to third parties of this document or any part thereof is only

permitted with the express wr

The information contained herein is provided “as is” and u

implied, is given, including but not limited

purpose of the information. This document may be revised by u

documents, visit www.u

Copyright © u

Document information

Title C102-F9R

Subtitle Application board

Document type User guide

Document number UBX-20029244

Revision and date R03 29-Oct-2020

Disclosure Restriction

C1-Public

This document applies to the following products:

Product name Type number Firmware version PCN reference

C102-F9R C102-F9R-0-00 HPS 1.00

C100 v1.0

C100-MSG v1.0

N/A

-blox or third parties may hold intellectual property rights in the products, names, logos and designs included in this

itten permission of u-blox.

-blox assumes no liability for its use. No warranty, either express or

to, with respect to the accuracy, correctness, reliability and fitness for a particular

-blox at any time without notice. For the most recent

-blox.com.

-blox AG.

UBX-20029244 - R03 Document information Page 2 of 32

C1-Public

Page 3

C102-F9R - User guide

Contents

Document information ................................................................................................................................ 2

Contents .......................................................................................................................................................... 3

1 Introduction ............................................................................................................................................. 5

1.1 Highlights ..................................................................................................................................................... 5

1.2 Kit includes ................................................................................................................................................... 5

1.3 System requirements ................................................................................................................................ 5

1.4 Evaluation steps .......................................................................................................................................... 5

2 Device description ................................................................................................................................. 6

2.1 USB................................................................................................................................................................. 6

2.2 UART .............................................................................................................................................................. 6

2.3 Antenna ......................................................................................................................................................... 6

2.4 14-pin front connector ............................................................................................................................... 6

2.5 10-pin rear connector ................................................................................................................................. 7

2.6 Reset and safe boot buttons .................................................................................................................... 7

2.7 I2C/SPI slide switch .................................................................................................................................... 7

2.8 LED ................................................................................................................................................................. 7

3 Setting up ................................................................................................................................................. 8

3.1 Preparation ................................................................................................................................................... 8

3.2 Installation .................................................................................................................................................... 8

3.2.1 Mounting the device and the antenna to the vehicle .................................................................. 8

3.2.2 Connecting the cables ....................................................................................................................... 8

3.3 Configuring the device ............................................................................................................................... 9

3.3.1 ADR configuration .............................................................................................................................. 9

4 Configurable CAN interface ............................................................................................................ 10

4.1 Valid configurations .................................................................................................................................10

4.2 Configuring the interface ........................................................................................................................10

4.3 C100 MSG ...................................................................................................................................................10

4.3.1 Configuration parameters ..............................................................................................................11

4.4 Configuration process ..............................................................................................................................11

4.4.1 Connections .......................................................................................................................................11

4.4.2 RealTerm ............................................................................................................................................11

4.5 Updating the MCU firmware ...................................................................................................................13

Appendix ....................................................................................................................................................... 14

A.1 CAN termination ................................................................................................................................. 14

B CAN configuration examples .......................................................................................................... 14

B.1 Wheel tick configurations ................................................................................................................ 14

B.1.1 Two rear-wheel ticks and direction ...................................................................................... 14

B.1.2 Single tick and direction .......................................................................................................... 15

B.2 Speed configurations ........................................................................................................................ 16

B.2.1 Two rear wheels and direction ............................................................................................... 16

UBX-20029244 - R03 Contents Page 3 of 32

C1-Public

Page 4

C102-F9R - User guide

B.2.2 Single speed ................................................................................................................................. 16

B.2.3 Signed speed ............................................................................................................................... 17

B.2.4 Offset speed ................................................................................................................................ 17

C Step-by-step example ...................................................................................................................... 18

D Schematic ............................................................................................................................................. 25

Related documents ................................................................................................................................... 31

Revision history .......................................................................................................................................... 31

Contact .......................................................................................................................................................... 32

UBX-20029244 - R03 Contents Page 4 of 32

C1-Public

Page 5

C102-F9R - User guide

1 Introduction

The C102-F9R application board can be used to evaluate and test the high precision sensor fusion

positioning technology of the ZED-F9R module. The built-in USB interface provides both power supply

and a high-speed communications interface. The device is compact, and it provides a flexible and

user-friendly interface between the GNSS module and test vehicles. Furthermore, it can be used with

a notebook or PC running the GUI-driven u-center application, making it the perfect companion

through all stages of evaluation and design-in phases of projects.

1.1 Highlights

• Multi-band multi-constellation GNSS

• Automotive Dead Reckoning (ADR)

• Real-time kinematic (RTK)

• Configurable CAN interface

• Dedicated pins for wheel tick and direction inputs

• USB, UART, RS-232 connections

• A short-term battery-backed RAM (BBR)

1.2 Kit includes

• Application board with enclosure

• USB cable

• Active multi-band GNSS antenna with a 5 m cable

• 14-pin breakout cable

• One-month trial license from correction service provider (available in regions defined by the

service provider)

1.3 System requirements

• A PC with Windows operating system

• u-center GNSS evaluation software

• Odometer input from vehicle

• Internet connection for correction data

1.4 Evaluation steps

Experience the lane-accurate performance of the u-blox F9R module in four simple steps:

1. Set up

2. Calibrate

3. Test

4. Analyze

UBX-20029244 - R03 Introduction Page 5 of 32

C1-Public

Page 6

C102-F9R - User guide

2 Device description

2.1 USB

A USB 2.0-compatible serial port is featured for data communication and power supply. USB drivers

are installed automatically through Windows update.

2.2 UART

The unit includes an RS-232 port which can be dynamically connected to the UARTs of the ZED-F9R

module or the MCU. Selection of the UART connection is controlled by the NEO_UART_SEL and

MCU_UART _SEL pins on the front connector.

NEO_UART_SEL MCU_UART_SEL Connected component

LOW OPEN Reserved

OPEN LOW MCU

OPEN OPEN ZED-F9R

LOW LOW None

The selected UART interface is also available via the RxD and TxD pins on the front connector.

☞ RxD and TxD pins on the front connector are at TTL voltage levels.

⚠ Flow control should not be used with the RS-232 port.

2.3 Antenna

The kit includes u-blox ANN-MB L1/L2 active multi-band GNSS antenna with a 5-meter cable. There

is a female SMA connector (RF IN) available on the front side of the unit for connecting the antenna.

⚠ Do not use the SMA connector in the back. It is reserved for future use.

2.4 14-pin front connector

The connector and its signals are described in the table below.

Pin no. Pin name I/O Level Description

14 VIN 5-24V I 5 - 24 V Power input – can be used in place of USB

13 GND Common ground pin for case-work, power and serial interface connections

12 CAN_H I Connect to the vehicle CAN high wire (ISO 11898-2)

11 CAN_L I Connect to the vehicle CAN low wire (ISO 11898-2)

10 NEO_UART_SEL I - Reserved

9 MCU_UART_SEL I - Pull-down signal for enabling UART communication with the MCU

8 TIME_MARK I Time mark input

7 WHEELTICK I 5 - 24 V Wheel tick pulse input

6 DIRECTION I 5 - 24 V Direction of travel input

5 SDA Reserved

4 SCL Reserved

3 TxD I/O 3.3 V UART TxD

2 RxD I/O 3.3 V UART RxD

1 GND_A Ground for wheel tick and direction signals

⚠ Leave the reserved pins open.

UBX-20029244 - R03 Device description Page 6 of 32

C1-Public

Page 7

C102-F9R - User guide

2.5 10-pin rear connector

This connector is used for updating the MCU firmware. See section 4.5 for more information.

2.6 Reset and safe boot buttons

The reset button on the front panel resets the unit.

The safe boot button is used to set the unit in safe boot mode. In this mode the receiver executes only

the minimal functionality, such as updating new firmware into the SQI flash. USB communication is

disabled while in safe boot mode.

To set the receiver in safe boot mode:

• Press and hold the BOOT button.

• Press the RST button.

• Release the RST button.

• Release the BOOT button.

To use UART in safe boot mode, a training sequence needs to be sent to the receiver. The training

sequence is a transmission of two bytes (0x55 0x55) at the baud rate of 9600. Wait for at least 100

milliseconds before the interface is ready to accept commands.

2.7 I2C/SPI slide switch

⚠ The switch must be kept at the I2C position to ensure correct operation of the device!

⚠ Contact u-blox technical support for assistance if required.

2.8 LED

On the front panel of the unit, a single blue LED may be configured to follow the receiver time pulse

signal. If there is no GNSS fix, the LED will be lit without flashing.

UBX-20029244 - R03 Device description Page 7 of 32

C1-Public

Page 8

C102-F9R - User guide

3 Setting up

3.1 Preparation

ADR requires odometer sensor input from the vehicle reference point (VRP), that is, wheel ticks or

speed, and direction. The following options are available:

1. WHEELTICK and DIRECTION pins

2. UBX-ESF-MEAS messages

3. CAN_H and CAN_L pins

See the ZED-F9R documentation ([1], [2]) for more information about options 1 and 2. For option 3,

refer to chapter 4.

☞ By default, the CAN bus is terminated by the unit. See appendix A.1 for how to change the

termination.

⚠ Take care when connecting to the vehicle to avoid blocking the CAN bus traffic, potentially

creating serious malfunction of the vehicle.

High-precision positioning uses RTK, which can be easily configured with the u-center NTRIP client.

Refer to the ZED-F9R documentation ([1], [2]) and u-center User guide [3] for more information.

☞ The provided correction service provider credentials are valid only in certain regions. Check the

validity of the license in your region from the correction service provider webpage.

3.2 Installation

Follow these steps to complete the installation.

3.2.1 Mounting the device and the antenna to the vehicle

Attach the device to the vehicle firmly to avoid any movement or vibration. For testing purposes, a

good location is near the VRP, that is, the center of the rear axle.

⚠ Dead reckoning performance can be seriously impaired by changes in the orientation of the device.

Place the provided GNSS antenna in a location with an unobstructed view of the sky, for example, the

roof of the vehicle. For best performance, ensure that the antenna has contact to a ground plane with

a minimum of 100–150 mm diameter.

⚠ To achieve the best possible performance, the GNSS antenna should be positioned on the vehicle

roof over the EVK. If the antenna is placed at a significant distance from the EVK, a position offset

can be introduced which might affect the accuracy of the navigation solution. To compensate for

the position offset, advanced configurations can be applied. Contact u-blox support for more

information on advanced configurations.

3.2.2 Connecting the cables

1. Connect the GNSS antenna to the RF connector on the front panel.

2. Connect the ADR signals to the related pins on the front connector:

a. Analog wheel tick and direction signals to pins WHEELTICK and DIRECTION, or

b. CAN high to CAN_H, CAN low to CAN_L.

3. Connect the device to a PC via USB for host interface and to power the device.

UBX-20029244 - R03 Setting up Page 8 of 32

C1-Public

Page 9

C102-F9R - User guide

Alternatively, host interface can be established via UART pins on the front connector or the RS-232

connector. In this case, power must be provided via USB or the VIN and GND pins on the front

connector.

☞ Use the provided 14-pin breakout cable to securely connect the front connector pins. The unused

wires must be isolated.

3.3 Configuring the device

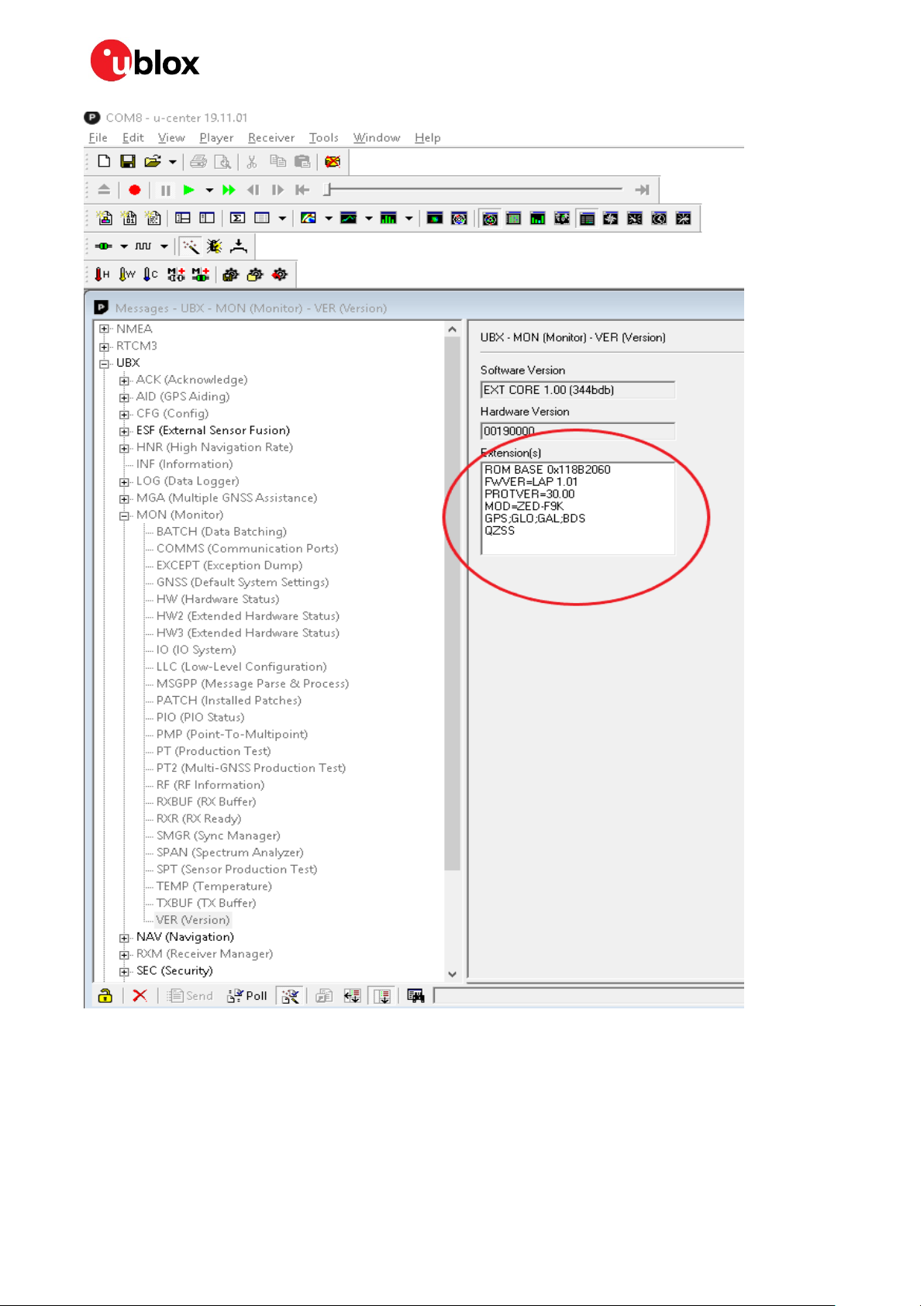

With u-center connected to the COM port assigned to the ZED-F9R module, verify that the host

interface to the ZED-F9R is established. This can be verified with u-center “Messages” view by polling

the UBX-MON-VER message. A valid response proves that the host interface is connected correctly.

3.3.1 ADR configuration

The receiver can be configured with UBX-CFG-VALSET messages. Consult the ZED-F9R

documentation ([1], [2]) for more information about the configuration.

1. Enable automatic alignment of the IMU with key ID CFG-SFIMU-AUTO_MNTALG_ENA. Set the

value to 1.

2. Configure the odometer sensor input depending on the used sensor:

a. If the wheel tick and direction pins on the front connector are used, enable the use of the wheel

tick pin by setting the value for key ID CFG-SFODO-USE_WT_PIN to 1.

b. If using the CAN interface or the software interface, the wheel tick pin must be disabled. Set

the value for key ID CFG-SFODO-USE_WT_PIN to 0. See chapter 4 for instructions on how to

configure the CAN interface.

☞ It is highly recommended to verify that the configuration is correct and to perform system sanity

checks.

UBX-20029244 - R03 Setting up Page 9 of 32

C1-Public

Page 10

C102-F9R - User guide

4 Configurable CAN interface

The device has a configurable high-speed CAN (ISO 11898-2) interface. The on-board MCU converts

the configured CAN messages into UBX-ESF-MEAS messages which are sent to the receiver via I2C.

4.1 Valid configurations

The CAN interface supports the following configurations:

• Single tick from VRP + direction

• Wheel ticks from both rear wheels + direction

• Speed from VRP + direction

• Speed from both rear wheels + direction

See appendix B for example configurations.

4.2 Configuring the interface

Communication with the MCU can be established via UART. Connect the front connector pin

MCU_UART_SEL to ground to enable the MCU communication.

The MCU UART runs at baud rate 115200.

The following messages are supported:

• CONFIG GET – Reports the current CAN configuration.

o Hex string: 0x43 0xa2 0x10 0x00 0x10 0x20

• CONFIG CLEAR – Deletes the current CAN configuration.

o Hex string: 0x43 0xa2 0x12 0x00 0x12 0x24

• CONFIG SET – Sends a configuration for one data field.

o Hex string: generate with the tool

Sending the commands to the MCU can be done through a terminal program. We recommend using

RealTerm. For more information, see [4].

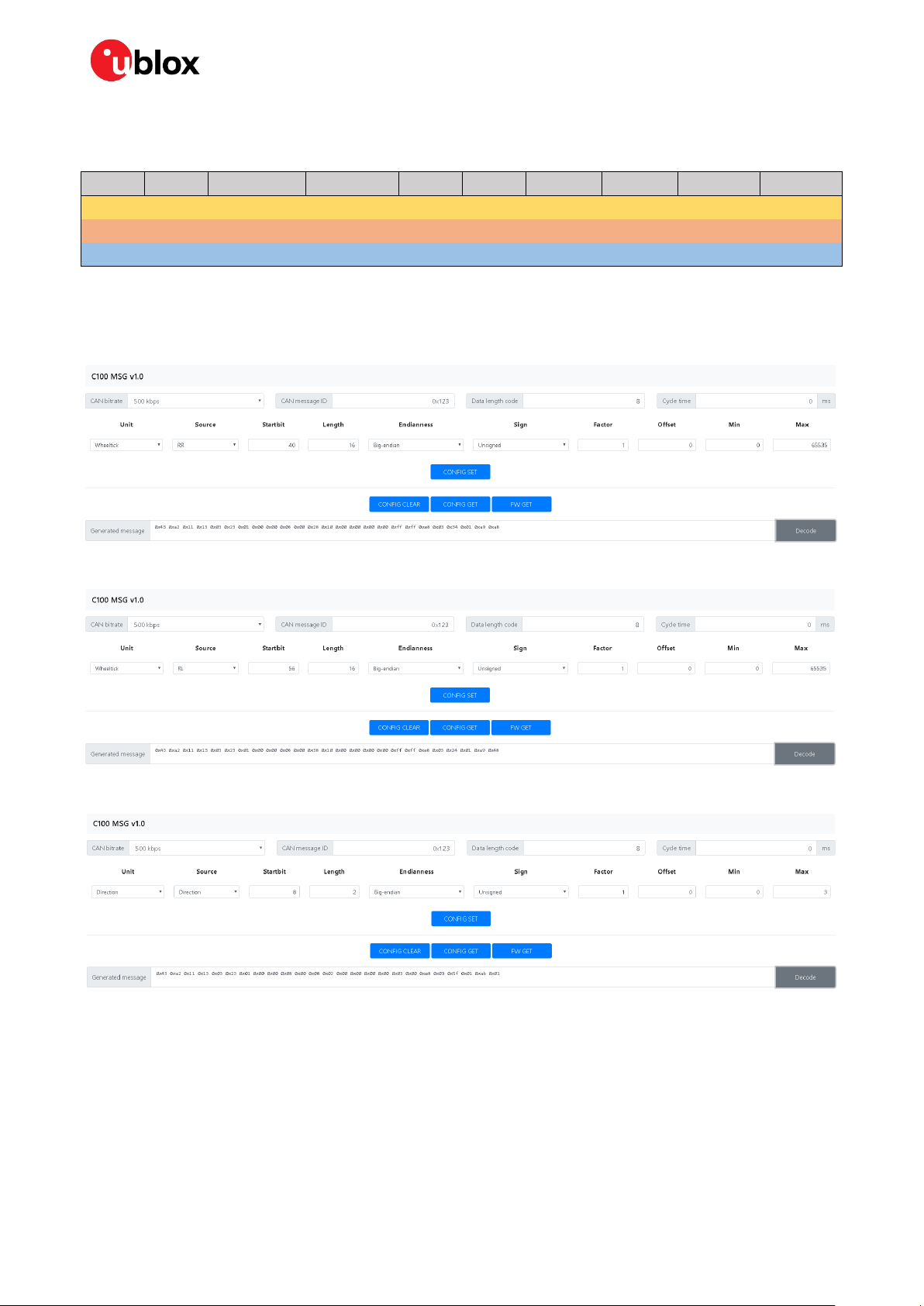

4.3 C100 MSG

C100 MSG is a browser-based tool for generating C100 MCU configuration messages for the

configurable CAN feature. It can be run entirely locally, without an internet connection. Figure 1 shows

a screenshot of the tool.

Figure 1: C100 MSG tool

UBX-20029244 - R03 Configurable CAN interface Page 10 of 32

C1-Public

Page 11

C102-F9R - User guide

The numbers in the list below refer to Figure 1:

• 1: Select the blue buttons in the middle to generate messages.

• 2: Fill these fields for CONFIG SET messages.

• 3: The generated message is displayed in the text field at the bottom. It is automatically copied to

the clipboard.

• 4: Use the decode button to parse the contents of a message pasted in the text field (3).

☞ Ensure that the version number of the tool matches the MCU firmware version. Compatibility

between versions is not guaranteed.

4.3.1 Configuration parameters

The following fields are required to generate a CONFIG SET message:

• CAN bitrate: bitrate of the CAN bus

• CAN message ID: ID of the message containing the wanted data

• Data length code: number of bytes in the CAN message

• Cycle time: time between consecutive messages

• Unit: the unit of measurement for the data

• Source: rear-left, rear-right wheel, etc.

• Startbit: index of the LSB of the value field within the CAN message

• Length: the bit-length of the value field

• Endianness: Big-endian (Motorola) or Little-endian (Intel)

• Sign: value is signed or unsigned

• Factor: scaling factor representing the value of one bit in the selected unit

• Offset: positive offset which shifts the zero point of the raw value

• Min/Forward:

o Wheel tick and speed – sets the minimum value. Values smaller than this are discarded.

o Direction – represents the value indicating forward movement

• Max/Backward:

o Wheel tick and speed – sets the maximum value. Values greater than this are discarded.

o Direction – represents the value indicating backward movement

4.4 Configuration process

Follow these steps to configure the CAN interface:

4.4.1 Connections

1. Connect the pin MCU_UART_SEL to the GND pin. Ensure that the pin NEO_UART_SEL is

disconnected.

2. Connect a PC to the MCU via RS-232 cable or the front connector UART pins.

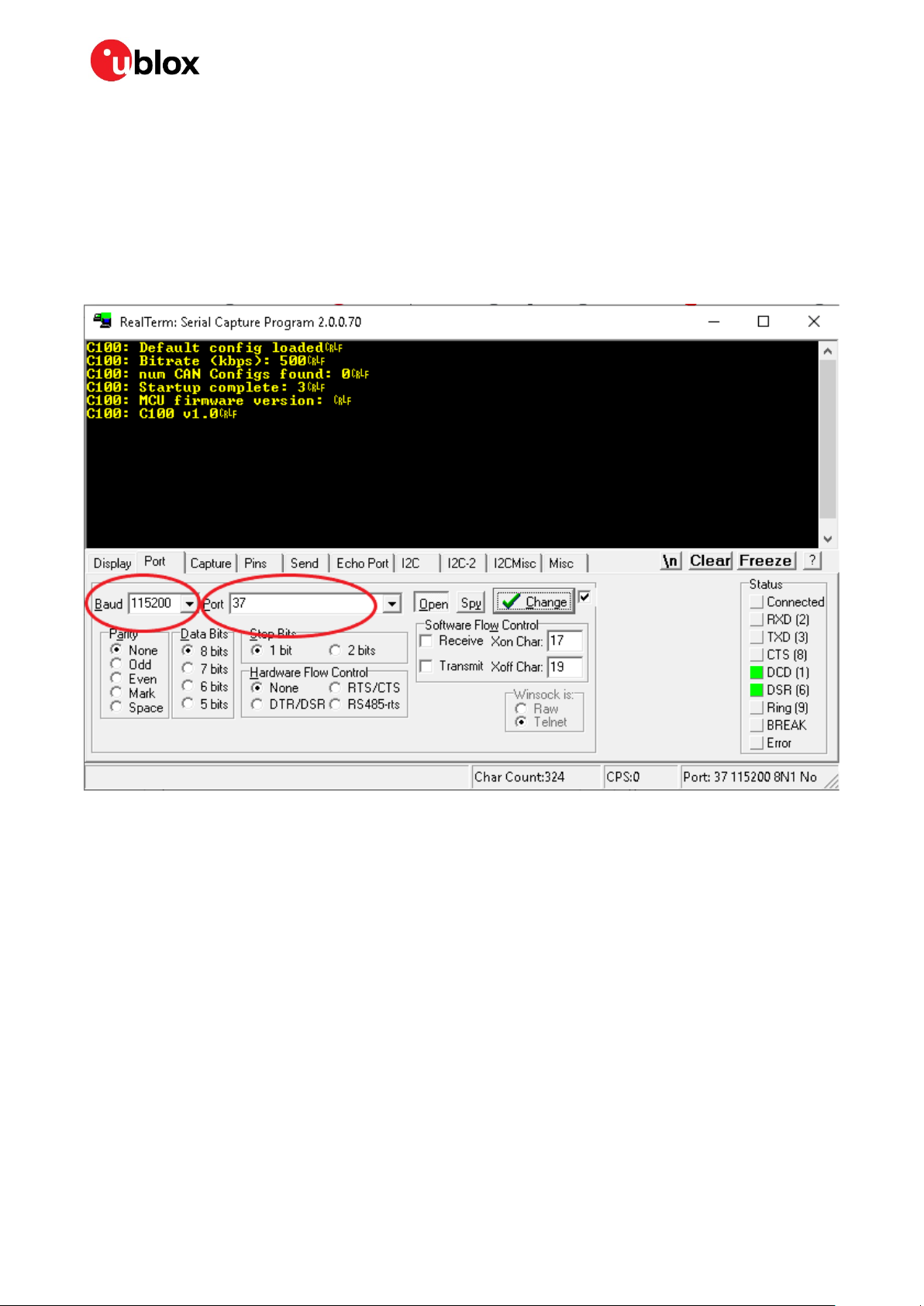

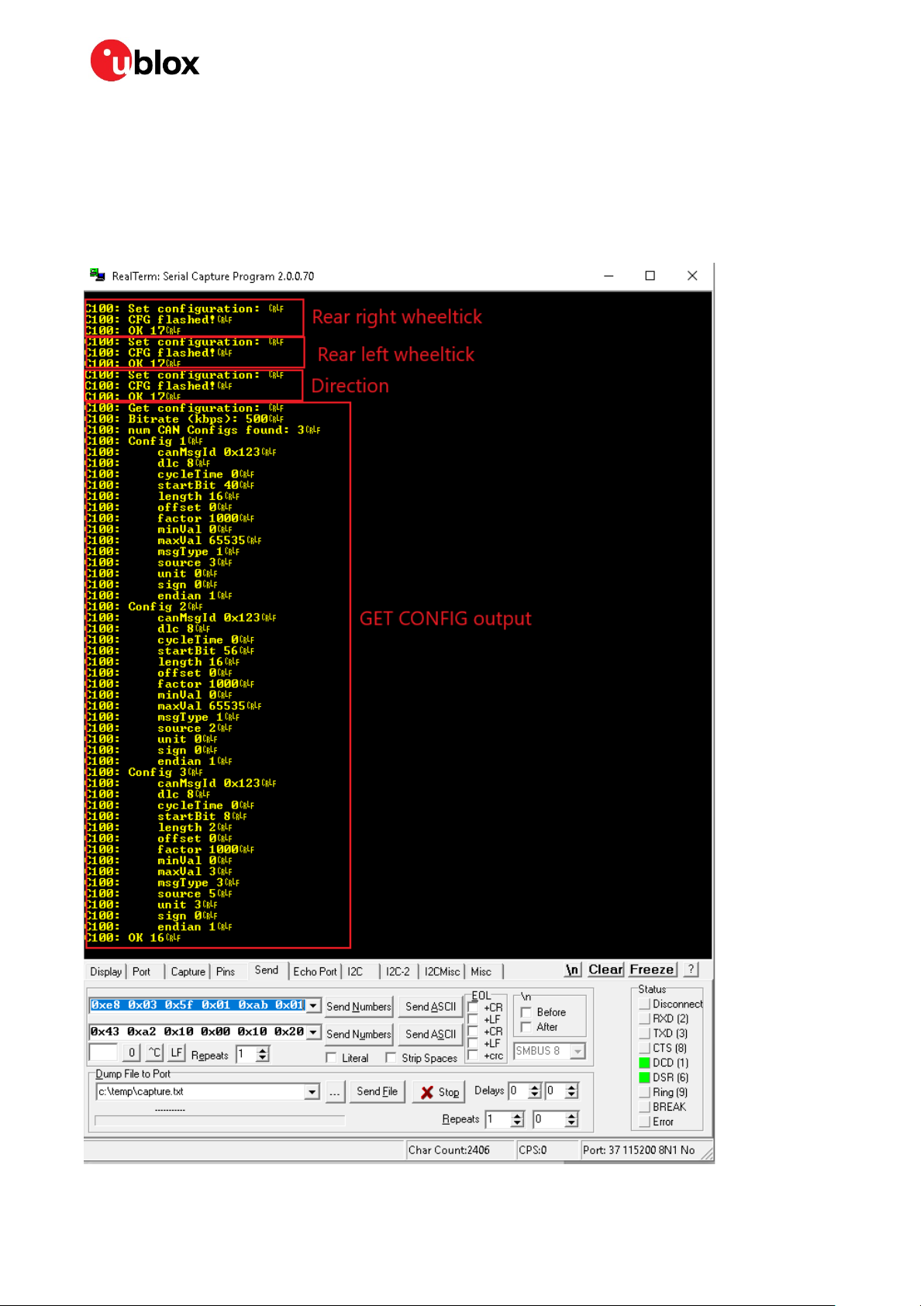

4.4.2 RealTerm

1. Select the port associated with the UART connection in the Port tab.

2. Set baud rate to 115200.

3. Apply changes by selecting the Change button. See the figure below.

UBX-20029244 - R03 Configurable CAN interface Page 11 of 32

C1-Public

Page 12

C102-F9R - User guide

Power on the device. The following startup message should be displayed in the terminal window:

4. Setting up the configurable CAN feature:

4.1. Open the RealTerm Send tab.

4.2. Generate CONFIG SET message(s) in the MSG tool.

4.3. Copy and paste a CONFIG SET message into the text field.

4.4. Send the message by selecting the Send Numbers button.

The following dialog should be displayed when a configuration has been accepted:

When all configuration messages have been sent:

4.5. Generate a CONFIG GET message.

4.6. Send the CONFIG GET message.

4.7. A dialog similar to the one shown below should be displayed and can be used to validate the

configurations.

UBX-20029244 - R03 Configurable CAN interface Page 12 of 32

C1-Public

Page 13

C102-F9R - User guide

A configuration entry can be overwritten by sending a new CONFIG SET message with the same unit

and source.

☞ All configuration entries can be deleted with the CONFIG CLEAR message.

4.5 Updating the MCU firmware

New MCU firmware and corresponding tool versions may be released e.g. to support new features or

to increase the performance of the application. To update the firmware, the following equipment is

required:

- Silicon Labs IDE or Flash Programming Utilities software [5], and

- USB debug adapter for 8-bit MCUs [6]

Follow these steps to flash the new firmware:

1. Power up the device.

2. Connect the debugger to the 10-pin rear connector.

3. If using the Silicon Labs IDE:

a. Select Debug > Connect

b. Select Debug > Download

to connect the Debugger to the MCU.

object file

and input the correct file to the opened window.

c. Select Download to start the flashing process.

4. If using Flash Programming Utilities, follow the instructions accompanying the software.

5. After the device is flashed, disconnect the debugger and reboot the device.

6. Confirm that the firmware version string matches by either checking what the MCU outputs

during bootup, or by sending a FW GET command.

UBX-20029244 - R03 Configurable CAN interface Page 13 of 32

C1-Public

Page 14

C102-F9R - User guide

Startbit

Length

Byte order

Value type

Factor

Offset

Min

Max

Unit

Source

40

16

big-endian

unsigned

1 0 0

65535

tick

RR

56

16

big-endian

unsigned

1 0 0

65535

tick

RL 8 2

big-endian

unsigned

1 0 0

3

direction

direction

Appendix

A.1 CAN termination

The CAN bus is terminated by including the jumper circled in Figure 2. The jumper is included by

default. If the termination needs to be removed, open the enclosure and remove the jumper.

Figure 2: Jumper (circled)

B CAN configuration examples

This appendix contains example CAN configurations. Each example uses the following settings for

the CAN bus:

• CAN bitrate: 500 kbps

• CAN message ID: 0x123

• DLC: 8

• Cycle time: 0 ms

The example messages are compatible with firmware C100 v1.0.

B.1 Wheel tick configurations

B.1.1 Two rear-wheel ticks and direction

This configuration uses wheel ticks from two rear wheels and a separate direction signal. The

configuration entries are described in the tables below.

UBX-20029244 - R03 Page 14 of 32

C1-Public

Page 15

C102-F9R - User guide

byte/bit 7 6 5 4 3 2 1 0 0

1 msb

lsb 2

3

4 msb

5

lsb 6 msb

7

lsb

Startbit

Length

Byte order

Value type

Factor

Offset

Min

Max

Unit

Source

32

16

big-endian

unsigned

1 0 0

65535

tick

combined 8 2

big-endian

unsigned

1 0 0

3

direction

direction

byte/bit 7 6 5 4 3 2 1 0 0

1 msb

lsb 2

3 msb

4

lsb 5

6

7

The following CONFIG SET messages are generated for this configuration:

• RR: 0x43 0xa2 0x11 0x13 0x03 0x23 0x01 0x00 0x00 0x08 0x00 0x28 0x10 0x00 0x00 0x00 0x00

0xff 0xff 0xe8 0x03 0x34 0x01 0xa9 0xa8

• RL: 0x43 0xa2 0x11 0x13 0x03 0x23 0x01 0x00 0x00 0x08 0x00 0x38 0x10 0x00 0x00 0x00 0x00

0xff 0xff 0xe8 0x03 0x24 0x01 0xa9 0x48

• dir: 0x43 0xa2 0x11 0x13 0x03 0x23 0x01 0x00 0x00 0x08 0x00 0x08 0x02 0x00 0x00 0x00 0x00

0x03 0x00 0xe8 0x03 0x5f 0x01 0xab 0x01

B.1.2 Single tick and direction

This configuration uses single-tick data and a separate direction signal. The configuration entries are

described in the tables below.

The following CONFIG SET messages are generated for this configuration:

• tick: 0x43 0xa2 0x11 0x13 0x03 0x23 0x01 0x00 0x00 0x08 0x00 0x20 0x10 0x00 0x00 0x00 0x00

0xff 0xff 0xe8 0x03 0x44 0x01 0xb1 0x68

• dir: 0x43 0xa2 0x11 0x13 0x03 0x23 0x01 0x00 0x00 0x08 0x00 0x08 0x02 0x00 0x00 0x00 0x00

0x03 0x00 0xe8 0x03 0x5f 0x01 0xab 0x01

UBX-20029244 - R03 Appendix Page 15 of 32

C1-Public

Page 16

C102-F9R - User guide

Startbit

Length

Byte order

Value type

Factor

Offset

Min

Max

Unit

Source

52

12

big-endian

unsigned

0.1 0 0

409.6

km/h

RR

56

12

big-endian

unsigned

0.1 0 0

409.6

km/h

RL 8 2

big-endian

unsigned

1 0 0

3

direction

direction

byte/bit 7 6 5 4 3 2 1 0 0

1 msb

lsb 2

3

4

5 msb

6

lsb

msb

7

lsb

Startbit

Length

Byte order

Value type

Factor

Offset

Min

Max

Unit

Source

24

8

little-endian

unsigned

1 0 0

255

mph

combined 8 2

little-endian

unsigned

1 0 0

3

direction

direction

byte/bit 7 6 5 4 3 2 1 0 0

1 msb

lsb 2

3 msb

lsb 4

5

6

B.2 Speed configurations

B.2.1 Two rear wheels and direction

This configuration uses speed from two rear wheels and a separate direction signal. The configuration

entries are described in the tables below.

The following CONFIG SET messages are generated for this configuration:

• RR: 0x43 0xa2 0x11 0x13 0x03 0x23 0x01 0x00 0x00 0x08 0x00 0x34 0x0c 0x00 0x00 0x00 0x00

0x00 0x10 0x64 0x00 0x39 0x01 0x41 0x58

• RL: 0x43 0xa2 0x11 0x13 0x03 0x23 0x01 0x00 0x00 0x08 0x00 0x38 0x0c 0x00 0x00 0x00 0x00

0x00 0x10 0x64 0x00 0x29 0x01 0x35 0x68

• dir: 0x43 0xa2 0x11 0x13 0x03 0x23 0x01 0x00 0x00 0x08 0x00 0x08 0x02 0x00 0x00 0x00 0x00

0x03 0x00 0xe8 0x03 0x5f 0x01 0xab 0x01

B.2.2 Single speed

This configuration uses a single-speed signal and a separate direction signal. The configuration

entries are described in the tables below.

UBX-20029244 - R03 Appendix Page 16 of 32

C1-Public

Page 17

C102-F9R - User guide

7

Startbit

Length

Byte order

Value type

Factor

Offset

Min

Max

Unit

Source

36

16

big-endian

signed

0.01

0

-327.68

327.67

km/h

RR

52

16

big-endian

signed

0.01

0

-327.68

327.67

km/h

RL

byte/bit 7 6 5 4 3 2 1 0 0

1

2 msb

3

4

lsb

msb

5

6

lsb 7

Startbit

Length

Byte order

Value type

Factor

Offset

Min

Max

Unit

Source

16

16

little-endian

unsigned

0.01

50

-50

605.35

mph

RR

32

16

little-endian

unsigned

0.01

50

-50

605.35

mph

RL

byte/bit 7 6 5 4 3 2 1 0 0

1

2

lsb 3 msb

4

lsb

The following CONFIG SET messages are generated for this configuration:

• speed: 0x43 0xa2 0x11 0x13 0x03 0x23 0x01 0x00 0x00 0x08 0x00 0x18 0x08 0x00 0x00 0x00

0x00 0xff 0x00 0xe8 0x03 0x4a 0x00 0xa7 0xc0

• dir: 0x43 0xa2 0x11 0x13 0x03 0x23 0x01 0x00 0x00 0x08 0x00 0x08 0x02 0x00 0x00 0x00 0x00

0x03 0x00 0xe8 0x03 0x5f 0x00 0xaa 0x00

B.2.3 Signed speed

This configuration uses a signed speed signal from both rear wheels. The configuration entries are

described in the tables below.

The following CONFIG SET messages are generated for this configuration:

• RR: 0x43 0xa2 0x11 0x13 0x03 0x23 0x01 0x00 0x00 0x08 0x00 0x24 0x10 0x00 0x00 0x00 0x80

0xff 0x7f 0x0a 0x00 0x39 0x03 0xcb 0x03

• RL: 0x43 0xa2 0x11 0x13 0x03 0x23 0x01 0x00 0x00 0x08 0x00 0x34 0x10 0x00 0x00 0x00 0x80

0xff 0x7f 0x0a 0x00 0x29 0x03 0xcb 0xa3

B.2.4 Offset speed

This configuration uses an offset speed signal from both rear wheels. The configuration entries are

described in the tables below.

UBX-20029244 - R03 Appendix Page 17 of 32

C1-Public

Page 18

C102-F9R - User guide

5

msb

6

7

The following CONFIG SET messages are generated for this configuration:

• RR: 0x43 0xa2 0x11 0x13 0x03 0x23 0x01 0x00 0x00 0x08 0x00 0x10 0x10 0x88 0x13 0x78 0xec

0x77 0xec 0x0a 0x00 0x3a 0x00 0x19 0xb2

• RL: 0x43 0xa2 0x11 0x13 0x03 0x23 0x01 0x00 0x00 0x08 0x00 0x20 0x10 0x88 0x13 0x78 0xec

0x77 0xec 0x0a 0x00 0x2a 0x00 0x19 0x52

C Step-by-step example

This step-by-step guide will use the example from section B.1.1.

Assumptions:

• User is familiar with u-center.

• USB will be used for powering the device and for the u-center interface.

• Odometer sensor measurements will be provided from the vehicle CAN bus via CAN_H and CAN_L

pins on the front connector.

• UART RS-232 connector will be used for the configurable CAN.

• RealTerm is used as the PC terminal application for the configurable CAN.

• u-center NTRIP client is used for supplying RTK corrections.

Connecting the device:

1. Connect a cable between MCU_UART_SEL and ground. This will select the MCU UART.

2. Connect UART cable to PC.

3. Connect USB cable to PC. Check that the blue light on the front panel is active.

Checking u-center:

4. Open u-center.

5. Connect to the ZED-F9R:

o Receiver > Connection > COMxx

6. Verify that the connection is established. Poll UBX-MON-VER, and check that the FWVER is

correct as shown in the figure below.

UBX-20029244 - R03 Appendix Page 18 of 32

C1-Public

Page 19

C102-F9R - User guide

7. Update ZED-F9R if necessary (Tools > Firmware Update).

UBX-20029244 - R03 Appendix Page 19 of 32

C1-Public

Page 20

C102-F9R - User guide

Configuring ZED-F9R

ZED-F9R configuration can be set with UBX-CFG-VALSET message and the appropriate

configuration keys.

8. Disable output messages on I2C (MCU is connected to I2C):

o CFG-I2COUTPROT-UBX = false

o CFG-I2COUTPROT-NMEA = false

9. Enable automatic alignment:

o CFG-SFIMU-AUTO_MNTALG_ENA = true

10. (Optional) Enable priority navigation mode (10 Hz):

o CFG-RATE-NAV_PRIO = 10

o CFG-UART1-BAUDRATE = 115200

• You need to increase UART1 baud rate if you are using the priority navigation mode.

Enabling logging/debug messages

Messages can be enabled with UBX-CFG-VALSET with CFG-MSGOUT-xx configuration keys.

The following hex string contains the recommended minimum set of debug messages required by ublox for any issues which may need investigation.

B5 62 06 8A 54 00 00 05 00 00 3E 02 91 20 01 98 02 91 20 01 9D 02 91 20 01 44 01 91 20 01 3F

01 91 20 01 39 02 91 20 01 66 02 91 20 01 26 01 91 20 01 7A 02 91 20 01 0D 01 91 20 01 08 01

91 20 01 09 00 91 20 01 18 00 91 20 01 6B 02 91 20 01 16 02 91 20 01 2F 02 91 20 01 3B 7C

☞ The debug messages are supplied here as a hex string because it contains some proprietary

messages.

11. Copy and paste the hex string into the Custom Messages field in u-center Messages view, and

select the Send button (circled in the figure below).

UBX-20029244 - R03 Appendix Page 20 of 32

C1-Public

Page 21

C102-F9R - User guide

UBX-20029244 - R03 Appendix Page 21 of 32

C1-Public

Page 22

C102-F9R - User guide

Configuring the CAN interface in RealTerm

1. Open RealTerm.

2. Select the Port tab.

3. Select the PC port corresponding to the MCU UART.

4. Set baud rate to 115200.

5. Restart the C100.

6. MCU startup dialog should appear in the terminal.

UBX-20029244 - R03 Appendix Page 22 of 32

C1-Public

Page 23

C102-F9R - User guide

Startbit

Length

Byte order

Value type

Factor

Offset

Min

Max

Unit

Source

40

16

big-endian

unsigned

1 0 0

65535

tick

RR

56

16

big-endian

unsigned

1 0 0

65535

tick

RL 8 2

big-endian

unsigned

1 0 0

3

direction

direction

Generating the CONFIG SET strings with the MSG tool

From B.1.1:

7. Use the MSG tool to generate the CONFIG SET messages.

Rear-right wheel tick:

Rear-left wheel tick:

Direction:

The following CONFIG SET messages are generated for this configuration:

• RR: 0x43 0xa2 0x11 0x13 0x03 0x23 0x01 0x00 0x00 0x08 0x00 0x28 0x10 0x00 0x00 0x00 0x00

0xff 0xff 0xe8 0x03 0x34 0x01 0xa9 0xa8

• RL: 0x43 0xa2 0x11 0x13 0x03 0x23 0x01 0x00 0x00 0x08 0x00 0x38 0x10 0x00 0x00 0x00 0x00

0xff 0xff 0xe8 0x03 0x24 0x01 0xa9 0x48

• dir: 0x43 0xa2 0x11 0x13 0x03 0x23 0x01 0x00 0x00 0x08 0x00 0x08 0x02 0x00 0x00 0x00 0x00

0x03 0x00 0xe8 0x03 0x5f 0x01 0xab 0x01

UBX-20029244 - R03 Appendix Page 23 of 32

C1-Public

Page 24

C102-F9R - User guide

Sending CONFIG SET strings to MCU:

8. Open RealTerm.

9. Select the Send tab.

10. Copy and paste the rear-right wheel tick CONFIG SET string to the RealTerm text box.

11. Select the Send Numbers button.

Verify configurations with CONFIG GET string, 0x43 0xa2 0x10 0x00 0x10 0x20.

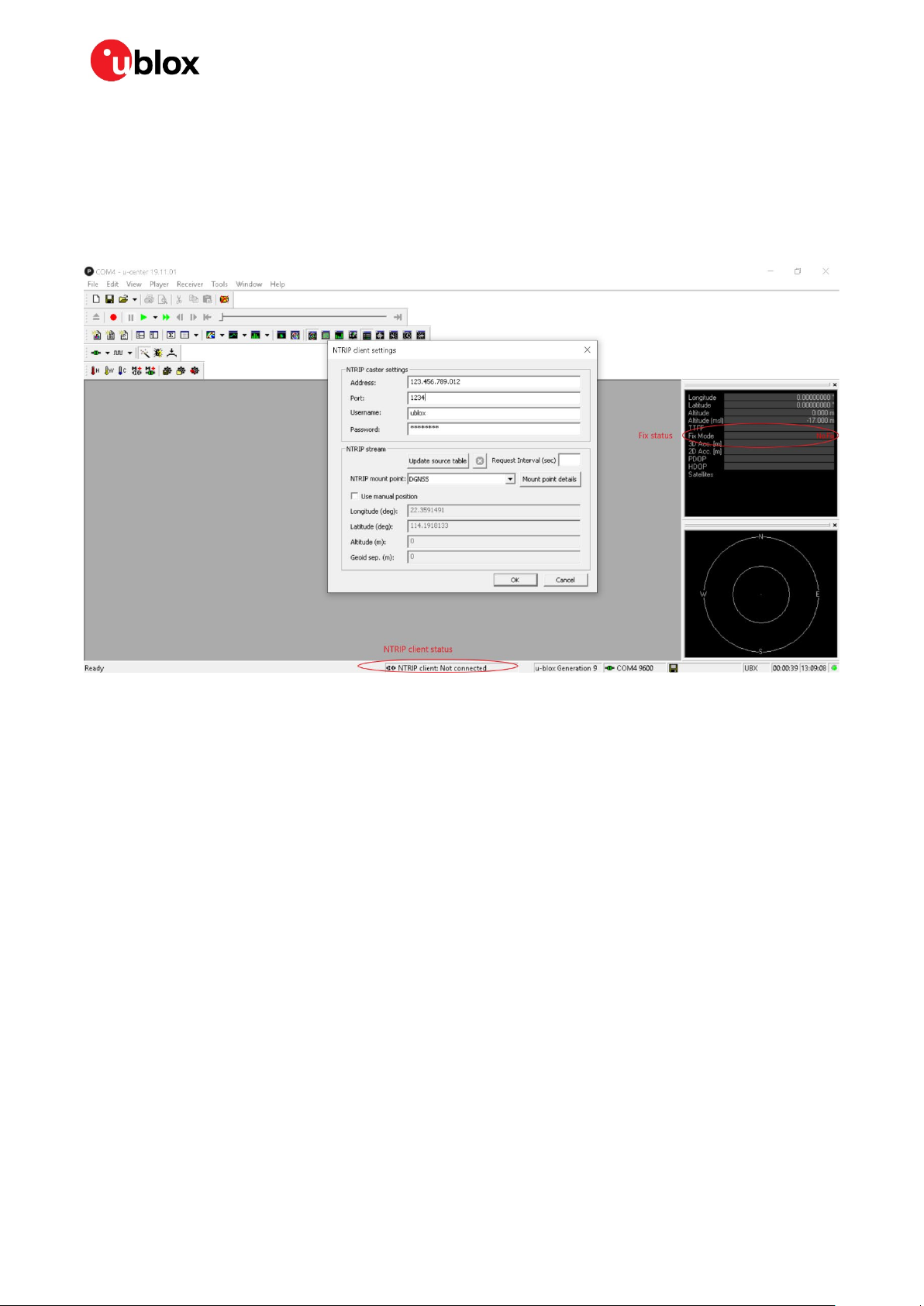

Configuring u-center NTRIP client

UBX-20029244 - R03 Appendix Page 24 of 32

C1-Public

Page 25

C102-F9R - User guide

12. Connect receiver to u-center.

13. Open NTRIP client: Receiver > NTRIP client.

14. Input correction service provider credentials.

15. Select OK.

16. NTRIP client status can be monitored in the lower part of the u-center frame, see the circle in the

figure below.

17. Fix status can be monitored with the docking windows > data view.

D Schematic

The following pages include the complete schematic for the C102-F9R board. Note that the GNSS

module in the schematic is F9K, but otherwise the schematic is accurate.

UBX-20029244 - R03 Appendix Page 25 of 32

C1-Public

Page 26

C102-F9R - User guide

UBX-20029244 - R03 Appendix Page 26 of 32

C1-Public

Page 27

C102-F9R - User guide

UBX-20029244 - R03 Appendix Page 27 of 32

C1-Public

Page 28

C102-F9R - User guide

UBX-20029244 - R03 Appendix Page 28 of 32

C1-Public

Page 29

C102-F9R - User guide

UBX-20029244 - R03 Appendix Page 29 of 32

C1-Public

Page 30

C102-F9R - User guide

UBX-20029244 - R03 Appendix Page 30 of 32

C1-Public

Page 31

C102-F9R - User guide

Related documents

[1] ZED-F9R Integration manual, UBX-20039643

[2] ZED-F9R Interface description, UBX-19056845

[3] u-center user guide, UBX-13005250

[4] RealTerm Serial Terminal, https://realterm.sourceforge.io/

[5] Silicon Labs 8-bit Microcontroller Software, https://www.silabs.com/products/development-

tools/software/8-bit-8051-microcontroller-software

[6] Silicon Labs 8-bit USB Debug Adapter, https://www.silabs.com/development-tools/mcu/8-bit/8-

bit-usb-debug-adapter

☞ For regular updates to u-blox documentation and to receive product change notifications, register

on our homepage (www.u-blox.com).

Revision history

Revision Date Name Status / Comments

R01 21-Jul-2020 jilm Initial release

R02 02-Oct-2020 jilm Corrected HPS FW number.

Added chapter 4.5 for updating the MCU FW.

Added mention about advanced DR config. application note in 3.2.1.

R03 29-Oct-2020 jilm Updated related documents

UBX-20029244 - R03 Related documents Page 31 of 32

C1-Public

Page 32

C102-F9R - User guide

Contact

For complete contact information, visit us at www.u-blox.com.

u-blox Offices

North, Central and South America

u-blox America, Inc.

Phone: +1 703 483 3180

E-mail: info_us@u-blox.com

Regional Office West Coast:

Phone: +1 408 573 3640

E-mail: info_us@u-blox.com

Technical Support:

Phone: +1 703 483 3185

E-mail: support@u-blox.com

Headquarters

Europe, Middle East, Africa

u-blox AG

Phone: +41 44 722 74 44

E-mail: info@u-blox.com

Support: support@u-blox.com

Asia, Australia, Pacific

u-blox Singapore Pte. Ltd.

Phone: +65 6734 3811

E-mail: info_ap@u-blox.com

Support: support_ap@u-blox.com

Regional Office Australia:

Phone: +61 2 8448 2016

E-mail: info_anz@u-blox.com

Support: support_ap@u-blox.com

Regional Office China (Beijing):

Phone: +86 10 68 133 545

E-mail: info_cn@u-blox.com

Support: support_cn@u-blox.com

Regional Office China (Chongqing):

Phone: +86 23 6815 1588

E-mail: info_cn@u-blox.com

Support: support_cn@u-blox.com

Regional Office China (Shanghai):

Phone: +86 21 6090 4832

E-mail: info_cn@u-blox.com

Support: support_cn@u-blox.com

Regional Office China (Shenzhen):

Phone: +86 755 8627 1083

E-mail: info_cn@u-blox.com

Support: support_cn@u-blox.com

Regional Office India:

Phone: +91 80 405 092 00

E-mail: info_in@u-blox.com

Support: support_in@u-blox.com

Regional Office Japan (Osaka):

Phone: +81 6 6941 3660

E-mail: info_jp@u-blox.com

Support: support_jp@u-blox.com

Regional Office Japan (Tokyo):

Phone: +81 3 5775 3850

E-mail: info_jp@u-blox.com

Support: support_jp@u-blox.com

Regional Office Korea:

Phone: +82 2 542 0861

E-mail: info_kr@u-blox.com

Support: support_kr@u-blox.com

Regional Office Taiwan:

Phone: +886 2 2657 1090

E-mail: info_tw@u-blox.com

Support: support_tw@u-blox.com

UBX-20029244 - R03 Contact Page 32 of 32

C1-Public

Loading...

Loading...