Page 1

User’s Manual

PRP-076N

PRP-076C

PRP-076D

Impact Dot-Matrix Printer

Specifications subject to change without notice

Page 2

1

Table of Contents

1. General Information ………………………………………………………………..2

1.1) Models

1.2) Features

2. Quick Start…………………………………………………………………………..3

2.1) Unpacking & Parts Identification

2.2) Loading the Paper Roll and Ink Ribbon

3. Printer Interface and Connection……………………………………………………5

3.1) Connecting the Interface Cable

3.2) Connecting to a Cash Drawer

3.3) Connecting the AC Adapter

4. Configuration………………………………………………………………………..7

4.1) Printer Status

4.2) DIP Switch Settings

4.3) Printer Self Test

4.4) Hexadecimal Dumping

4.5) Driver Installation

5. Safety and Maintenance……………………………………………………………11

5.1) Safety Information

5.2) Periodical Cleaning

5.3) Preventing Paper Jams

5.4) Fixing Paper Jam

6. Appendix………………………………...………………………………………....13

- Product Specifications

- General Printer Commands

- International Character Fonts

Page 3

2

1. General Information

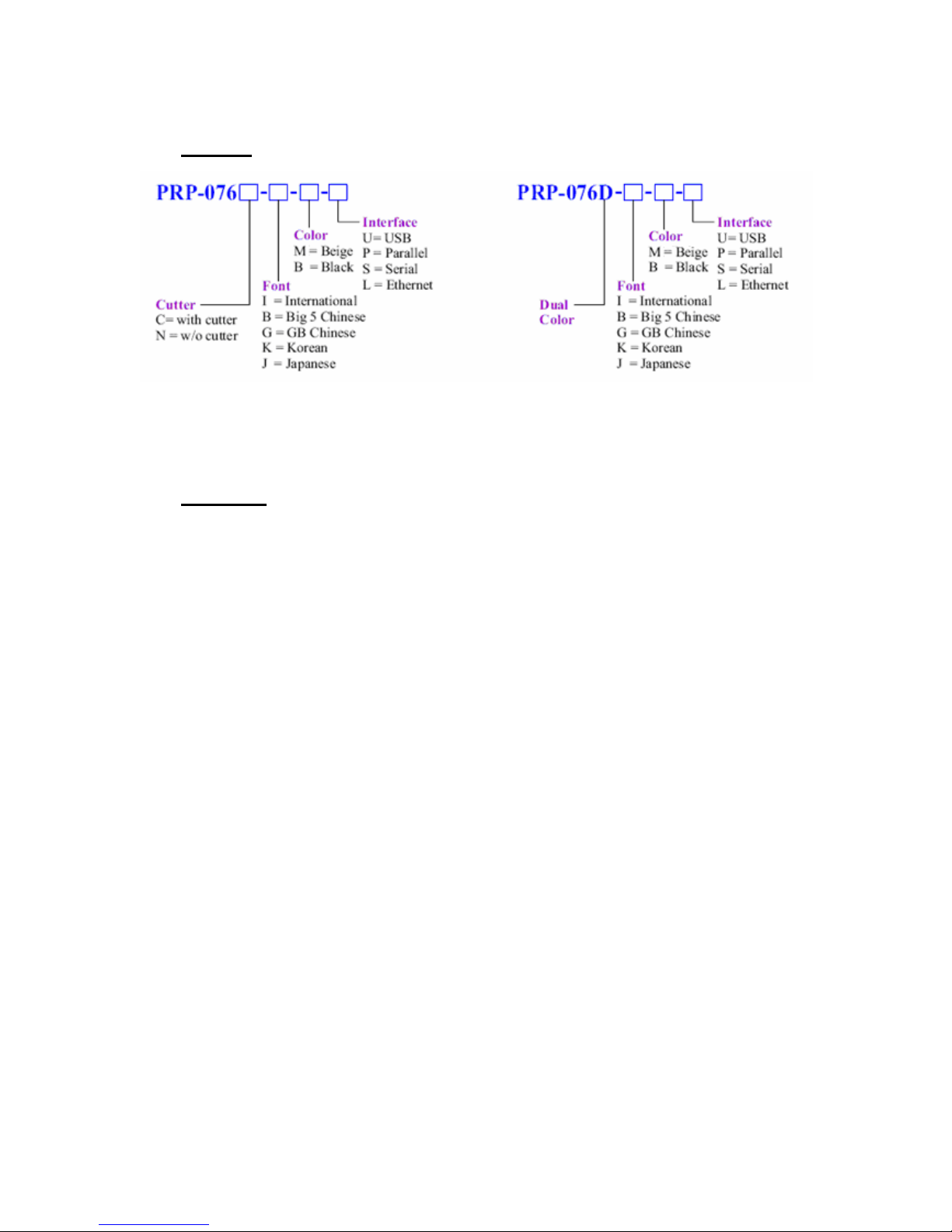

1.1) Models

Note: International font can be combined with others languages, for example

PRP-076C-BI-M-S, with cutter, Big5+International, beige, serial interface.

1.2) Features

Main Features:

-3.5 characters line/sec / 4.5 characters line/sec (32 bit ARM CPU)

-76 mm ± 5 mm Max. label width

-Low-noise dot matrix printing

-High reliability due to a stable mechanism

-Command protocol is based on the ESC/POS standard

-Support black mark anchor testing print

-Various Layouts are possible by using page mode

-Repeated operation and copy printing are possible

-Easy paper-roll installation

-Easy paper jam clearance

-Easy maintenance for tasks such as head cleaning

-Built-in interface provides control capability for cash drawer

Available fields:

-Print POS system receipts

-Print EFT POS system receipts

-Print gym, post, hospital, civil aviation system receipts

-Print inquiry, service system receipts

-Print instrument test receipts

-Print tax, tab receipts

2. Quick Start

Page 4

3

2.1) Unpacking & Parts Identification

Unpacking:

Parts Identification:

Power swit c h

Page 5

4

2.2) Loading the Paper Roll and Ink Ribbon

a. Make sure that the paper roll matches the printer’s specification. Do not use paper rolls that

have the paper glued to the core because the printer cannot detect the paper end correctly.

Important: The printing quality and lifespan of the printer head cannot be guaranteed if

any paper other than that recommended is used. Thus, the warranty will be void

automatically if any fault occurs due to the use of wrong paper rolls.

b. Open the top cover

Important: Do not open the printer cover when printing is in progress.

c. Install the paper roll as the picture showing direction

d. Pull the paper out of some length to outside, then close the cover.

e. Open the printer’s cover, turn the knob five or six times in the direction of the arrow, insert

the ink ribbon, and push the ribbon cassette down until it clicks.

Open Cover

Page 6

5

3. Printer Interface and Connection

3.1) Connecting the Interface Cable

Printer Interface:

a) Before connecting/disconnecting the interface cable, make sure that power to the printer and

all the devices connected to the printer is turned off.

b) Connect the interface cable to the connector on the rear panel of the printer.

c) In the case of a serial interface, tighten the connector screws. In the case of a parallel interface, fasten

the connector clasps.

Page 7

6

3.2) Connecting to a Cash Drawer

Important:

z Make sure that the printer is turned off and unplugged from the AC outlet and that the

computer is turned off before making connections.

z Do not connect a telephone line into the peripheral drive connector. Failure to observe this

may result in damage to the printer.

3.3) Connecting the AC Adapter

a. Connect the AC power cord to the inlet of AC adapter, and then connect the power cord plug

to a suitable electrical outlet.

b. Connect the adapter cable to power connector of printer; make sure the printer power switch

is OFF before making any connections.

Page 8

7

CAUTION:

DO NOT USE ANY AC POWER ADAPTERS OTHER THAN SPECIFIED.

c. Turn on the power switch; the POWER lamp on the control panel will light up.

Page 9

8

4. Configuration

Printer Control Panel & Status Indication

4.1) Printer Status

z Power (POWER) LED: Green

On: Power is on.

Off: Power is off.

z Error (ERROR) LED: Red

On: Offline (except during paper feeding using the FEED button and test printing,

and the error state.)

Off: Normal condition.

z Paper roll end (PAPER) LED: Red

Flash: The paper roll end is detected.

Off: Paper is loaded (Normal condition).

z FEED (Button)

Press the FEED button to feed roll paper.

Press the FEED button for 1 second and the roll paper will be fed continuously.

Page 10

9

4.2) DIP Switch Settings

The DIP switch panel is locating at bottom of the printer as shown:

DIP Switch Functions:

SW 7 SW 8 Baudrate

On On 38400

Off On 4800

On Off 9600

Off Off 19200

Note:

Before configure the DIP switch settings, please first turn the printer power off and remove

the paper roll.

Switch Function ON OFF

1 Black mark mode No Yes

2 Select Cutter No Yes

3 Cut mode Partial Full

4 Select characters per line (CPL) 7

x 9 / 9 x 9

40CPL/33CPL 42CPL/35CPL

5 Unidirectional No Yes

6 Two-byte character Yes No

Page 11

10

(*) Baud Rate is only available for serial interface models.

4.3) Printer Self Test

This is to test whether the printer is working properly or not and also checks the printing

quality, firmware version, and DIP switch settings

1. Hold the FEED button first and then turn on the power at the same time, release the button

after around 2 seconds.

2. If the printer is working properly, it should then automatically print the self-testing result

that indicating the firmware version number, printer connection type, English alphanumeric

characters, and few Taiwanese fonts.

3. The test print will be ended with the following message:

*** COMPLETED ***

Note: The above procedure does not test parallel or serial, USB, Ethernet ports. Please use

communication utility such as Windows HyperTerminal to test the printer connection.

4.4) Hexadecimal Dumping

1) Hexadecimal Dumping

This function prints the data transmitted from the host computer in hexadecimal numbers

and in its corresponding characters.

2) Starting hexadecimal dumping

Turn the power on while pressing the FEED button or executing GS ( A command). The

printer first prints “Hexadecimal Dump” on paper roll and prints the received print data in

hexadecimal numbers and in its corresponding characters.

NOTES: 1. When using the hexadecimal dump mode, please set the SW-4 of the DIP switch

to OFF.

2. During hexadecimal dumping, any commands do not function.

3. If no characters correspond to the data received, the printer prints “."。

3) Ending hexadecimal dumping

Hexadecimal dumping ends by turning the power off, or pressing the FEED button three

times.

<Printing example>

Page 12

11

4.5) Driver Installation

1. To install the PRP-076 driver, please insert the bundled CD disk into the CD-ROM drive.

2. In the CD-Rom menu, please go to Receipt Printer > PRP-076 folder and double click the

SetupEn.exe file to begin the driver installation process and follow the installation

instructions.

3. Please choose the OS that matches with your computer system and press Next.

4. Please select PRP-076 Series for Install Module. For Printer Port Setting, if you are

connecting the printer to PC COM ports via RS-232 connection, the FlowControl must

be set to Hardware. Press Finish when you done all the setting to end installation.

Page 13

12

5. Safety and Maintenance

5.1) Safety Information

1. Do not touch the HEAD of printer with anything.

2. Do not touch the cutter blade.

3. Only use the power supply that is come along with the printer.

4. Do not bend the power cord excessively or place any heavy objects onto it.

5. When connecting or disconnecting the plug, always hold the plug – not the cord.

6. Keep the distance out of children’s reach.

7. Use only approved accessories and do not try to disassemble, repair or remodel it for

yourself.

8. Do not let water or other foreign objects in the printer.

9. Install the printer on the stable surface. Choose a firm, level surface where the printer will

not be exposed to vibration.

10. Do not use the printer when it is out of order. This can cause a fire or an electrocution.

11. Do not connect a telephone line into the peripheral drive connector.

12. We recommend that you unplug the printer from the power outlet whenever you do not

plan to use it for long periods.

5.2) Periodical Cleaning

Printed characters may become partially unclear due to accumulated paper dust and dirt. To prevent

Page 14

13

such a problem, paper dust collected in the paper holder and paper transport section and on the surface

of the printer head must be removed periodically. Such cleaning is recommended to be carried out once

six month or one million lines.

Cleaning the Paper Holder

Use a soft cloth to remove paper dust from the paper holder and paper transport section.

5.3) Preventing Paper Jams

The paper should not be touched during printing. Shift the paper during paper ejection may cause a

feed failure or paper jam.

5.4) Fixing Paper Jam

The Status LED (Red) on the printer control panel will flash with beeps if paper is jammed.

Please follow the below instruction to remove paper jam.

(a) Switch the printer power off.

(b) Open the printer cover.

(c) If the printer cover opens, removed the jammed paper gently (take care not to touch the

printer head.) And reinstall the paper roll.

Caution:

Since working on the cutter may be dangerous, be sure to turn off the printer first.

Note:

Do not apply extreme force to open the front cover to prevent damages to the cutter. If the

front cover will not open properly, please contact your dealer.

(d) Return the cutter to its home-position and release or clean out the jammed paper in inside

the front cover. Open the top cover, and then reinstall paper roll.

Page 15

14

6. Appendix

Product Specifications

1.1) Printing Specifications

1) Printing method: 9 pins Impact Dot Matrix

2) Print density: 400 dpi (half dot)

385 dpi (half dot)

3) Printing direction: Bidirectional, adjustable by dipswitch

4) Printing width: 42CPL ( 7 x 9 ) / 35CPL ( 9 x 9 )

40CPL ( 7 x 9 ) / 33CPL ( 9 x 9 )

5) Printing speed: 4.5 characters line/sec

6) Paper feed speed: 120 mm/sec

NOTE: There may be variations in printing after switching the mode of the printing speed. To prevent this

for logo printing with ESC command, using a downloaded bit image is recommended. Change in printing speed

does not occur during down loaded bit image printing. Printing speed may be slower depending on the data

transmission speed and the combination of control commands. Low transmission speed may cause intermittent

printing. It is recommended to transmit data to the printer as quickly as possible.

1.2) Print font

1) ASCII code: 7 x 9 dots, 1.2 (W) x 3.1 (H) mm

9 x 9 dots, 1.6 (W) x 3.1 (H) mm

2) Graphic font: 16 x 16 dots, 2.54 (W) x 2.82 (H) mm

1.3) Mechanical Specification

1) Weight: 1600g / 1680g (PRP-076D)

2) Dimension: 260 (L) x 155 (W) x 130 (H) mm

1.4) Paper Specification

1) Paper type: Continuous multipart, original plus carbonless copies

2) Form: Paper roll

3) Paper width: 75 ± 0.5 mm

4) Paper roll size: Roll diameter: Maximum 75 mm

Minimum 12 mm

1.5) Interface

1) Serial port: Dsub 25 pin female connector, 4800,9600,19200 or 38400 bps

baud-rate, none parity, 8 data bits, and 1 stop bit, supports RTS/CTS &

Page 16

15

XON/XOFF protocol

2) Parallel port: 36 pin Centronics connector. 8 bits parallel, supports BUSY/nAck

protocol

3) USB port: USB1.0

4) Ethernet port: Transmission speed: 10M (Max)

Communication protocol: TCP/IP protocol

Connector: 10 Base-T RJ-45 connector

5) Cash drawer port: DC 24V/1A, 6 wires RJ-11 socket

1.6) Electrical Characteristics

1) Supply voltage: Input: AC 110V/220V, 50~60Hz

Output: DC 24V/2.5A

1.7) Reliability

MCBF: 10,000,000 lines

(This is an average failure interval based on failures relating to

wear out and random failures up to the life of 15 million lines.)

1.8) Environmental Conditions

1) Temperature: Operating: 0 to 50C (41 to 113F)

Storage: -10 to 60C (14 to 122F) (except paper)

2) Humidity: Operating: 10 to 80% RH

Storage: 10 to 90% RH (except for paper)

NOTE: If the printer is not used for a long time with paper installed, some part of the printing may be light

due to the deformation of the paper. If the printer is not used for a long time with paper installed, be

sure to feed paper approximately 30 mm before printing

.

3) Acoustic noise (Operating): When using auto cutter Approximately 50 dB

(Bystander position) When not using auto cutter: Approximately 40 dB

(Bystander position)

1.9) Installation

The PRP-076 series printer must be installed horizontally. (Vibration during paper cutting and using a drawer

should be considered. Take measures to prevent the printer from moving. Affixing tapes are provided as an

option.) An optional hanging bracket can attach the printer to a wall. (Following the procedures describes in the

installation manual, install the wall mount and change the location of the paper roll near-end sensor, then install

Page 17

16

the paper roll stopper and other parts.)

2. CONFIGURATION

2.1) Interface

2.1.1) RS-232 serial interface

2.1.1.1) RS-232 Specifications

Data transmission: Serial

Synchronization: Asynchronous

Handshaking: DTR/DSR or XON/XOFF control

Signal levels: MARK = -3 to -15 V: Logic "1"/ OFF

SPACE = +3 to +15 V: Logic "0"/ ON

Baud rate: 9600, 19200 bps

Data word length: 8 bits

Parity Settings: None

Stop bits: 1 or more

Connector (printer side): Female DSUB-25 pin connector

NOTES: The data word length, baud rate, and parity depend on the DIP switch settings.

The stop bit for the printer side is fixed to 1.

2.1.1.2 Serial interface connection example

Printer Side DB-25 POS RS-232 Connection DB9

NOTES: Set the handshaking so that the transmit data can be received.

Transmit data to the printer after turning on the power and initializing the printer.

Page 18

17

Interface connector terminal assignments and signal functions

Pin number Signal name Signal Source Description

2 TXD Printer

When using XON/XOFF

handshake protocol, printer

transmits control code

XON/XOFF

3 RXD Host Printer receives data from host

4 RTS Printer

Indicates printer current status,

whether the printer is Busy or

Ready to receive data

7 GND —— Signal ground

20 DTR Printer

Same as RTS (pin 4)。

2.1.2) IEEE 1284 Bidirectional Parallel Interface (Parallel Interface Specifications)

2.1.2.1) Parallel Specifications

Data transmission: Parallel

Synchronization: Externally supplied nStrobe signals

Handshaking: nAck and Busy signals

Signal levels: TTL compatible

Data word length: 8 bits

Connector (printer side): 36 pins Centronics connector

Page 19

18

2.1.2.2) Parallel Interface Pin Assignments for Each Mode

Pin Mode Source Description

1 /STB Host

The computer presents the data

on the data lines, and pulses

STB

2

3

4

5

6

7

8

9

DATA0

DATA1

DATA2

DATA3

DATA4

DATA5

DATA6

DATA7

Host

Host

Host

Host

Host

Host

Host

Host

Indicates the 1st data bit through 8th

data bit

10 nAck Printer Printer acknowledge signal which

indicates that printer has received

previous data bit

11 BUSY Printer Printer is busy and cannot receive

data

12 GND

——

Ground

13 Select Printer High electric potential

14,15

NC

——

No Connect

16,17

GND

——

Ground

18 Logic-H Printer High electric potential

19~30

GND

——

Ground

31 NC

——

No Connect

32 NError

(nFault)

Printer Printer Error Signal

33 GND

——

Ground

34~36

NC

——

No Connect

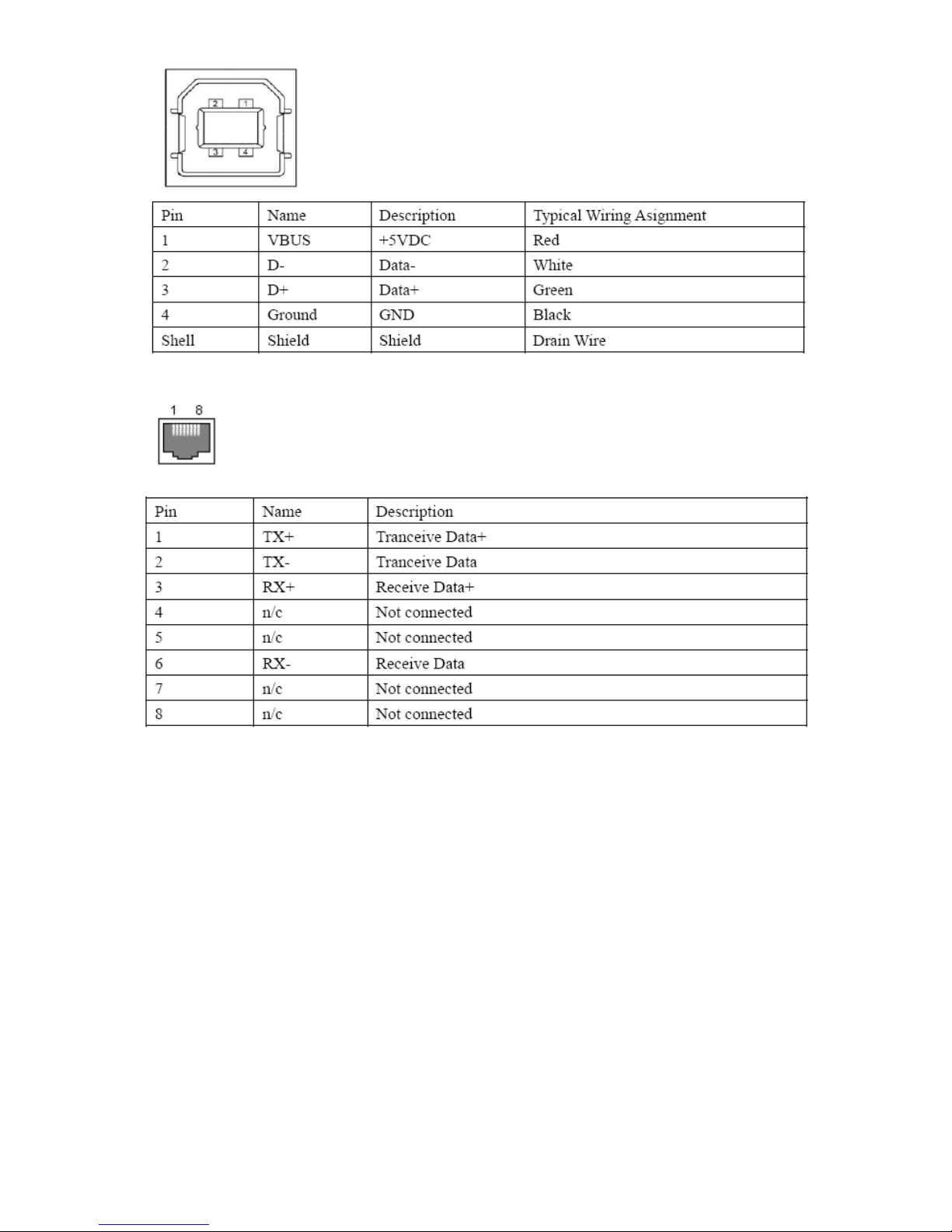

2.1.3) USB and Ethernet Interface Pin Assignments

2.1.3.1) USB Pin Assignments

Page 20

19

2.1.3.1) Ethernet Pin Assignments

Page 21

20

2.2 Connectors

2.2.1 Interface Connectors

Refer to Interface explain.

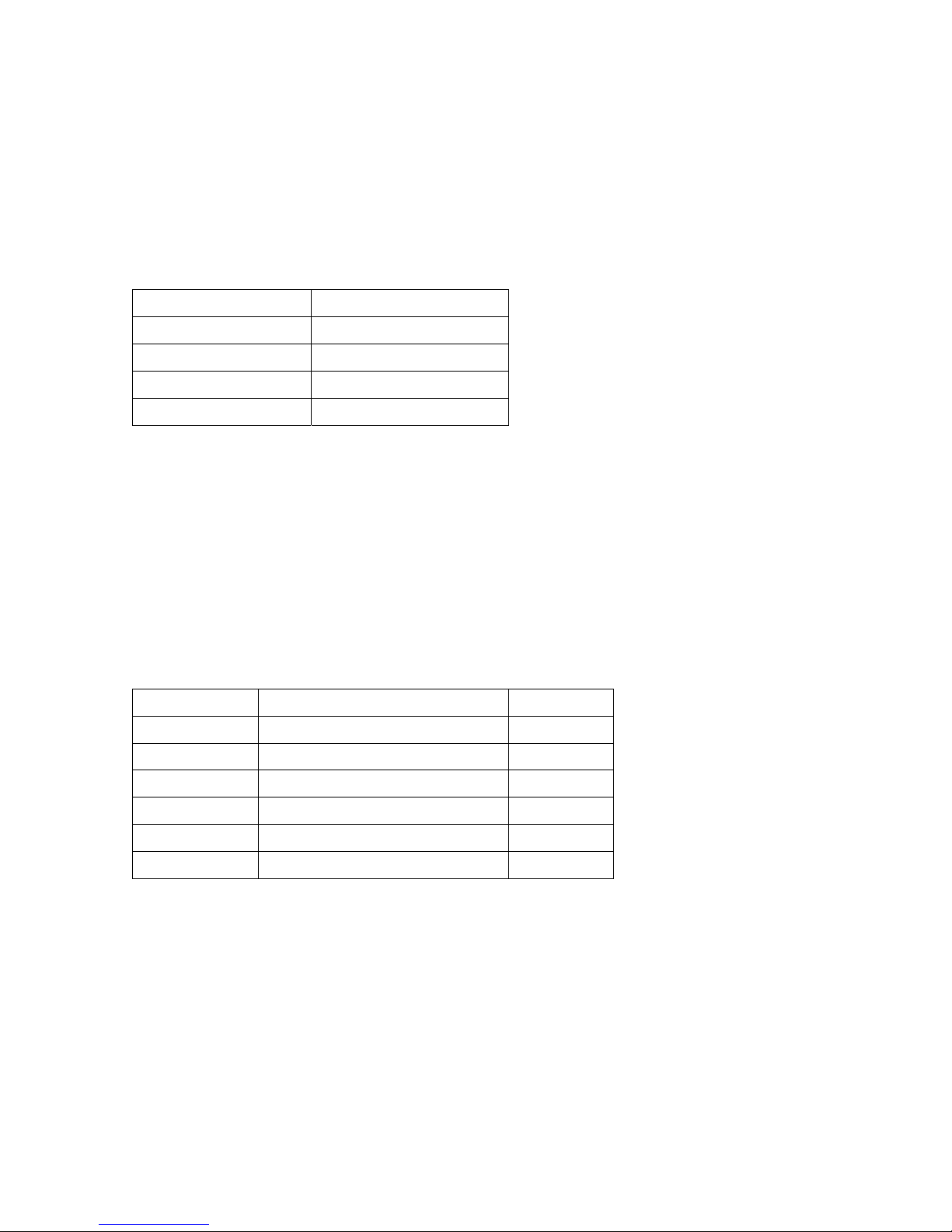

2.2.2 Power Supply Connector

This connector is used to connect the printer to an external power source.

Power Supply Connector Pin Assignments

Pin Number Signal Name

1 +24 VDC

2 GND

3 NC

Shell Frame GND

2.2.3 Drawer Kick-out Connector (Modular Connector)

The pulse specified by ESC p or DLE DC4 is output to this connector. The host can confirm the status of the

input signal by using the DLE EOT, GS a, or GS r commands.

1) Pin assignments: Refer to Table

2) Connector model: Printer side: MOLEX 52065-6615 or RJ11 telephone jack

User side: 6-position 6-contact (RJ11 telephone jack)

Drawer Kick-out Connector Pin Assignments

Pin Number Signal Name Direction

1 NC

2 Frame GND Output

3 NC

4 Drawer kick-out drive signal Output

5 NC

6 NC

1) Drawer kick-ou t drive signal

Output signal: Output voltage: Approximately 24 V

Output current: 1A or less

Page 22

21

General Printer Commands

COMMANDS LIST

Command Name

LF Print and line feed

CR Print and carriage return

ESC SP n Set right-side character spacing

ESC ! n Select print mode(s)

ESC % n Select/cancel user-defined character set

ESC & Define user-defined characters

ESC * m nL nH d1…dk Select bit-image mode

ESC – n Turn underline mode on/off

ESC 2 Select default line spacing

ESC 3 n Set line spacing

ESC ? n Cancel user-defined characters

ESC @ Initialize printer

ESC D [n]k NUL Set horizontal tab positions

HT n Print horizontal tab processing

ESC J n Print and feed paper n x 0.1 76 mm

ESC K n Print and reverse paper n x 0.176 mm

ESC R n Select an international character set

ESC U n Enable/Disable single print direction

ESC c 5 n Enable/disable panel buttons

ESC d n Print and feed n lines

ESC e n Print and reverse n lines

ESC p m t1 t2 Generate cash drawer pulse

GS ( A pL pH n m Enter hexadecimal dump test mode

GS V m [n] Select cut mode and cut paper

GS z 0 t1 t2 Set online recovery waiting time

FS ! n Set print mode(s) for Kanji characters

FS & Enter Kanji character mode

FS .

Exit Kanji character mode

FS 2 c1 c2 d1…dk Define user-defined Kanji characters

FS ? c1 c2 Cancel user-defined Kanji characters

FS S n1 n2 Set left- and right-side Kanji character spacing

FS W n Turn quadruple-size mode on/off for Kanji characters

GS ( F pL pH a m nL nH Set relative black mark anchor position

GS FF Set black mark anchor to start of printing position

Esc r n Select print color (PRP-076D only)

Page 23

22

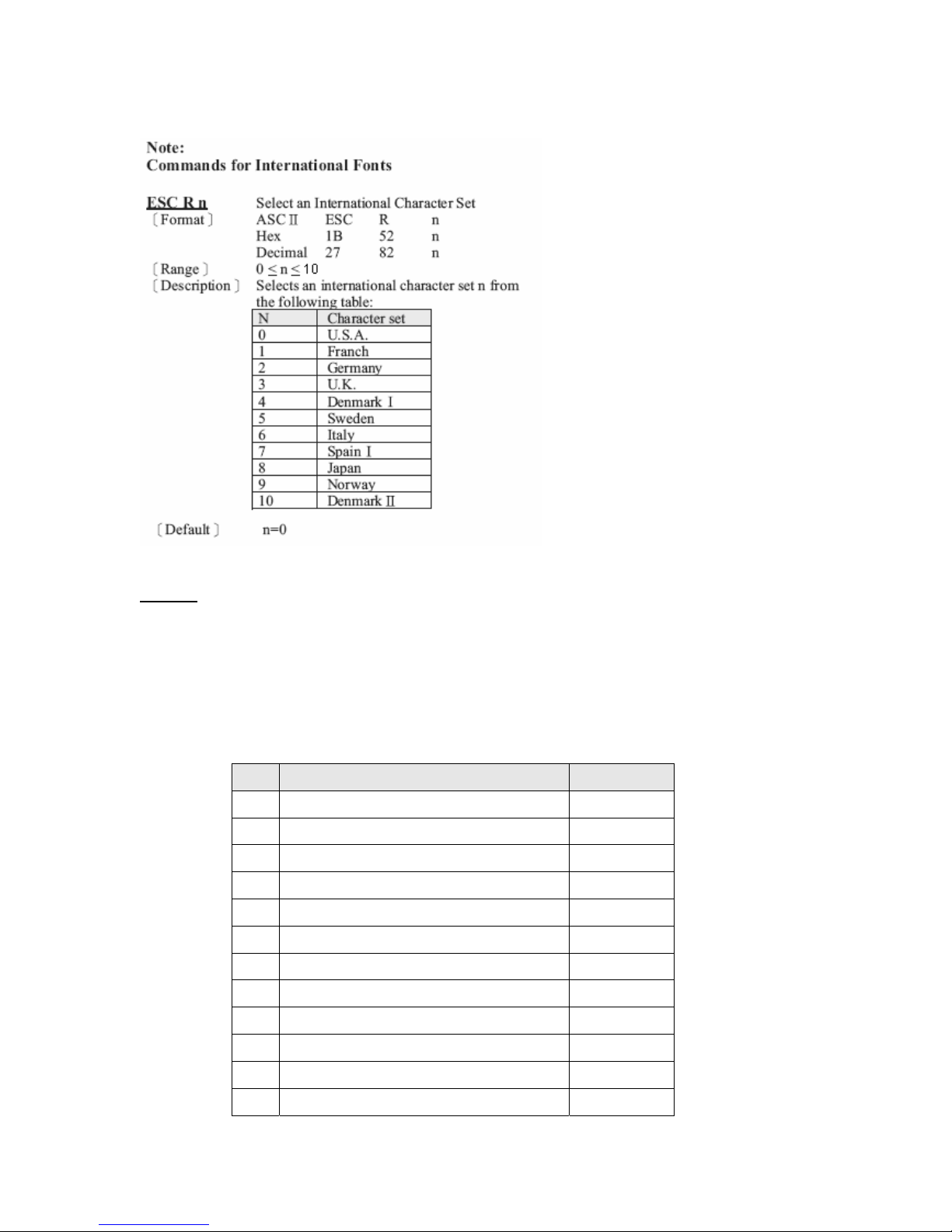

International Character Fonts

Esc t n Select character code table

[format] ASCII ESC t n

Hex 1B 74 n

Decimal 27 116 n

[Range] 0 <= n <= 5, 16 <= n <= 19

[Description] Selects a page n from the character code table

N Page comment

0 PC 437 (USA,Standard Europe)

1 Katakana (Japan)

2 PC 850 (Multilingual)

3 PC 860 (Portuguese)

4 PC 863 (Canadian-French)

5 PC 865 (Nordic)

16 WPC 1252

17 PC 866 (Cyrillic #2)

18 PC 852 (Latin 2)

19 PC 858

Big 5 Chinese Optional

GB Chinese Optional

Page 24

23

Korean Optional

Esc r n Select print color (PRP-076D only)

[format] ASCII ESC t n

Hex 1B 72 n

Decimal 27 114 n

[Range] n=0, 48,1 ,49

[Description] Select print color

n Select Color

0, 48 Black

1, 49 Red

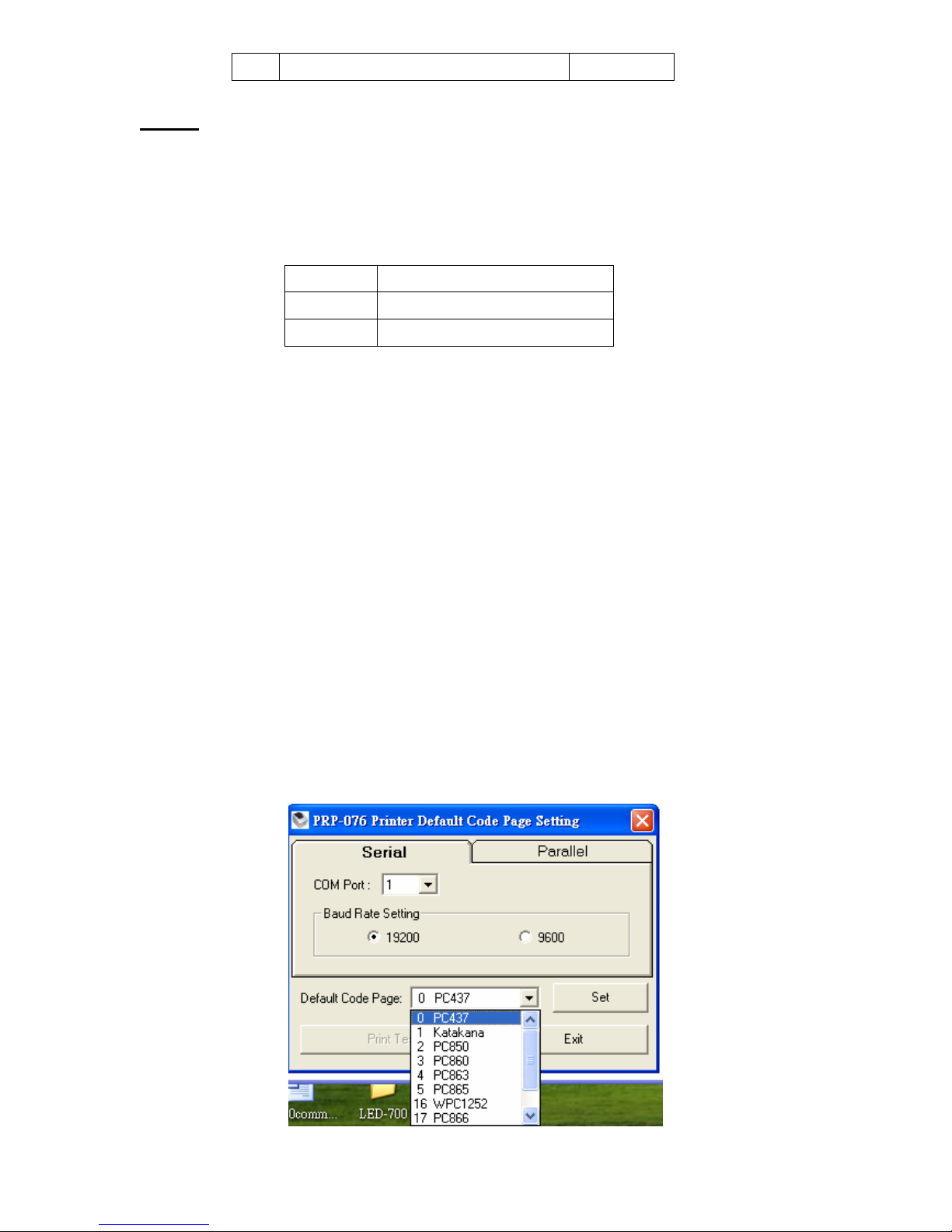

Character code can also be selected by utility program:

1. To install the PRP-076 Default Code Page Setting utility, please insert the bundled CD disk

into the CD-ROM drive.

2. In the CD-Rom menu, please go to Receipt Printer > PRP-076 > Code Page and double

click the setup.exe file to begin the installation process and follow the installation

instructions.

3. After installation is done, go to Program Files > CodePageSet > CodePageSet to start the

utility.

4. For Serial interface connection, please select the proper COM port and baud rate which

matches the current setting of the printer. For Parallel interface connection, select the

proper LPT ports.

Page 25

24

Optional multilingual character model supports printing with one of the following characters:

a. B - Traditional Chinese (Big 5)

b. G - Simplify Chinese (GB)

c. K - Korean

d. J- Japanese Kanji (JIS)

To enable/disable the multilingual character code use the following commands: (*)

FS “&” Select Multilingual Character Mode ON

[Format] ASCII FS &

Hex 1C 26

Decimal 28 38

[Description] Enable multilingual character mode

----------------------------------------------------------------------FS “.” Select Multilingual Character Mode OFF

[Format] ASCII FS .

Hex 1C 2E

Decimal 28 46

[Description] Disable multilingual character mode

(*)Note: This command enable/disable the specific language according to the model (B, G, K

or J)

International Character Code:

ASCII code (Hexadecimal)

Country

23 24 40 5B 5C 5D 5E 60 7B 7C 7D 7E

USA # $ @ [ \ ] ^ ` { ¦ } ~

France # $ à ° ç § ^ `

é ù è ¨

Germany # $ § Ä Ö Ü ^ ` ä ö

ü

ß

UK

£

$ @ [ \ ] ^ ` { ¦ } ~

Denmark I # $ @ Æ Ø Å ^ ` æ ø å ~

Sweden # ¤ É Ä Ö Å Ü

é

ä ö å

ü

Page 26

25

Italy # $ @ ° \

é

^

ù à ò è ì

Spain I Pt $ @ ì Ň ¿ ^ `

¨

ñ } ~

Japan # $ @ [

¥

] ^ ` { ¦ } ~

Norway # ¤ É Æ Ø Å Ü

é

æ ø å

ü

Denmark II # $ É Æ Ø Å Ü

é

æ ø å

ü

Loading...

Loading...