Page 1

Operating Manual

Spare Parts List

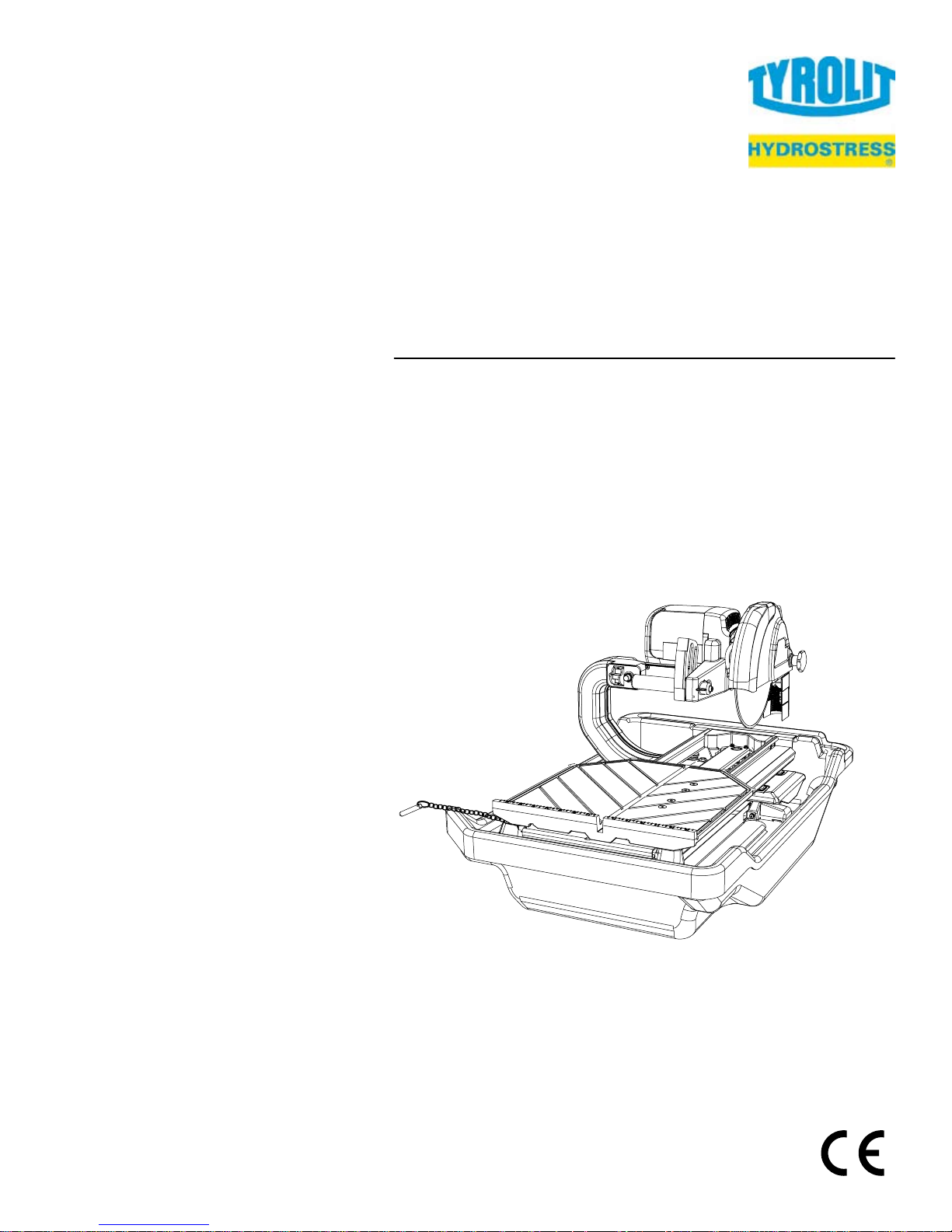

Wet Tile Saw

TTE250

Index / Indice «001»

10984578 EN / 18.05.2009

Page 2

Manufacturer's address:

TYROLIT Hydrostress AG

Witzbergstrasse 18

CH-8330 Pfäffikon

Switzerland

Tel.

+41

(0)44 952 18 18

Fax +41

(0)44 952 18 00

www.

tyrolit

.com

TYROLIT Hydrostress AG reserves the right to make technical changes without prior notice.

Copyright © 2005 TYROLIT Hydrostress AG, CH-8330 Pfäffikon ZH, Switzerland

All rights rese

rved, in particular copyrighting and translating rights.

Printing of this operating manual, including extracts from it, is prohibited. No parts of it may be repr

o-

duced in any form or processed using electronic systems, duplicated or disseminated without th

e wri

t-

ten permission of TYROLIT Hydrostress AG.

Page 3

TABLE OF CONTENTS

PAGE

I. GENERAL SAFETY RULES FOR ALL POWER TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

II. SYMBOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

III. FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

IV. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

V. GETTING TO KNOW YOUR SAW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

VI. BLADE INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

VII. SAFE OPERATING PRACTICES FOR TILE SAW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

VIII. USING THE CUTTING TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

XIX. CARE AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-13

X. CUTTING DEPTH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

XI. REPLACEMENT PART LISTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-18

XII. ACCESSORIES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

XIII. HOW TO ORDER PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

XIV. ELECTRICAL MOTOR SPECIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

XV. TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Page 4

i. GENERAL SAFETY RULES FOR ALL POWER TOOLS

WARNING!

Read all instructions. As with all machinery there are certain hazards involved with operation and

use of the machine. The following basic safety precautions should be followed at all times to reduce the risk of fire,

electric shock and serious personal injury to you or others. Keep these important operating instructions with this

product.

1. Know your power tool - read owner’s/operator’s manual carefully. Learn its applications and limitations as well as the

specific potential hazards unique to this tool.

2. Keep guards in place - and in working order.

3. Ground all tools - if tools are equipped with three prong plug, it should be plugged into a three-hole electrical

receptacle. If an adapter is used to accommodate a two-prong receptacle, the adapter lug must be attached to a

known ground. Never remove the third prong.

4. Remove wrenches - Form a habit of checking to see that adjusting wrenches are removed from tool before turning it

“on”.

5. Keep work area clean. Cluttered areas and benches invite accidents.

6. Do not use in dangerous environment. Do not use power tools in damp or wet locations, or expose them to rain.

Keep work area well lighted. Do not use tool in the presence of flammable liquids or gasses.

7. Keep children and visitors away. All children and visitors should be kept at a safe distance from work area.

8. Make workshop childproof with padlocks, master switches or by removing starter keys.

9. Do not force tool. It will do the job better and be safer at the rate for which it was designed.

10. Use right tool. Do not force tool or attachment to do a job for which it was not designed.

11. Wear proper apparel. Do not wear loose clothing, gloves, neckties, rings, bracelets or other jewelry that may get

caught in moving parts. Non-slip footwear is recommended. Wear protective hair covering to contain long hair.

Always use safety glasses. Wear safety glasses at all times. Everyday eyeglasses only have impact

12.

resistant lenses; they are not safety glasses. Use face or dust mask if cutting operation is dusty, and ear protectors

(plugs or muffs) during extended periods of operation.

13. Do not overreach. Keep proper footing and balance at all times.

14. Maintain tools in top condition. Keep tools sharp and clean for best and safest performance. Follow instructions for

lubricating and changing accessories. Inspect tool cords periodically and if damaged, have repaired by authorized

service facility.

15. Disconnect tools. When not in use, before servicing, and when changing accessories, such as blades, bits, cutters.

16. Avoid accidental starting. Make sure switch is in “off” position before plugging in power cord.

17. Use recommended accessories only. Consult the owner’s manual for recommended accessories. The use of

improper accessories may cause risk of injury to persons.

18. Never stand on tool. Serious

19. Check Damaged Parts. Before further use of the tool, a guard or other part that is damaged should be carefully

checked to ensure that it will operate properly and perform it’s intended function. Check for alignment of moving

parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect it’s operation.

A guard or part that is damaged should be properly repaired or replaced.

injury could occur if the tool is tipped or if the cutting tool is accidentally contacted.

20. Never leave tool running unattended. Turn power “off”. Do not leave tool until it comes to a complete stop.

– 3 – – 4 –

Page 5

21. Extension cords. Make sure your extension cord is in good condition. When using an extension cord, be sure to use

one heavy enough to carry the current your product will draw. An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. Extension cord tables

depending on cord length and nameplate ampere rating. If in doubt, use the next heavier gage. The smaller the

gage numbers the heavier the cord.

22. Do not abuse cord. Never carry tool by cord or pull it to disconnect from receptacle, Keep cord from heat, oil, and

sharp edges.

23. Guard against electric shock. Prevent body contact with grounded surfaces. For example, pipes, radiators, ranges

and refrigerator enclosures.

24. Outdoor use extension cords. When tool is used outdoors, use only extension cords intended for use outdoors and

so marked.

25. Stay alert. Watch what you are doing. Use common sense. Do not operate tool when you are tired.

26. Drugs, alcohol, medication. Do not operate tool while under the influence of drugs, alcohol or any medication.

27. Store idle tool. When not in use, tool should be stored in a dry and locked place, out of reach of children.

Sawing generates dust. Excessive airborne particles may cause irritation to eyes, skin and

WARNING!

respiratory tract. To avoid breathing impairment always employ dust controls and protection suitable to the material

being saw. Diamond blades improperly used are dangerous. Comply with safety regulations covering speed, safety

guards, flanges, mounting procedures, general operating rules, handling, storage and general machine condition.

(refer to page 21) show the correct size to use

KEEP GUARD IN

PLACE

DIAMOND BLADE

BLADE CUTTING

DEPTH

ELECTRIC SWITCH OFF

ELECTRIC SWITCH ON

ELECTRICAL HAZARD

REMOVE TOOLS

PAY EXTREME

ATTENTION

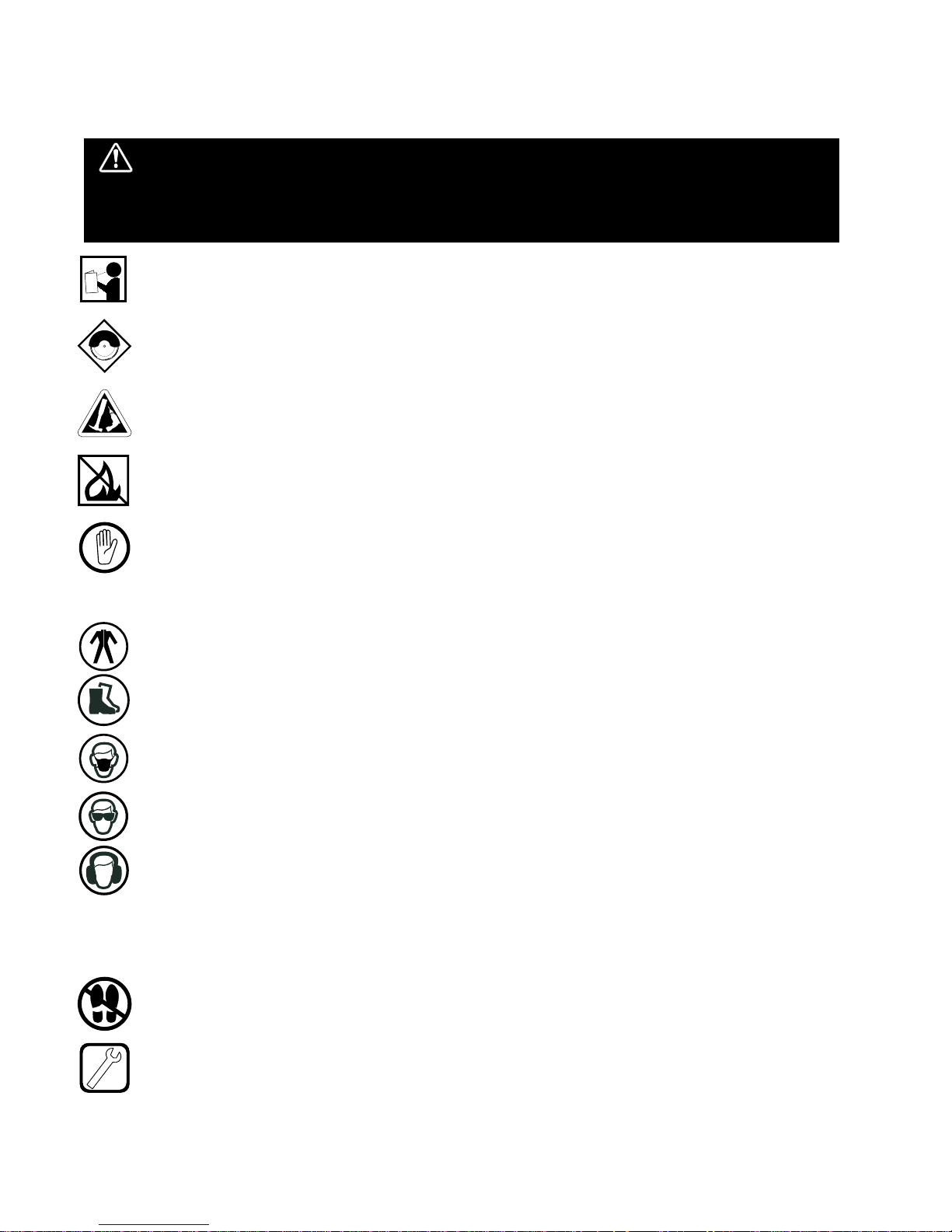

ii. SYMBOLS

REPAIRS TO BE DONE

MACHINE HAZARD

FLAMMABLE

READ INSTRUCTIONS

CAREFULLY

WARNING

FRAGILE

KEEP DRY

DO NO STEP ON

WEAR HEARING

PROTECTION

WEAR EYE PROTECTION

WEAR BREATHING

PROTECTION

WEAR HARD HAT

WEAR PROTECTIVE

CLOTHING

WEAR SAFETY SHOES

WELL VENTILATED

NO NON-WORKING

PERSONNEL

Page 6

iii. FEATURES

The TYROLIT TTE250 is a portable professional tile saw. Lightweight and compact it has innovative built

in features that enable it to cut larger format tiles. The unique coaction movement of the cutting head and

main table allow the saw to increase its cutting capacity whenever needed. The main table and extension

carriage are supported by low friction, self cleaning, adjustable guide wheels. Water flow to the blade is

provided by two (2) nozzles that direct the water to both sides of the blade. The rugged powder coated

metal and aluminum frame sets in a removable water tray for easy clean up.

• Powerful Motor - 1.1 kW.

• Circuit breaker protects your saw from power surges and overheating.

• High Impact ABS Water Tray.

• Adjustable Cutting Head allows user to align saw at any time.

• Cutting alignment not affected by water tray maintenance.

• Blade Capacity 250mm.

• Diagonal cut up to 460mm tiles and rip cut up to 730mm in length.

The heavy duty, cast to last construction and quality components were designed to meet the highest

demands of the professional.

Read this manual completely and then let the TYROLIT TTE250 take your cutting capabilities to new

dimensions.

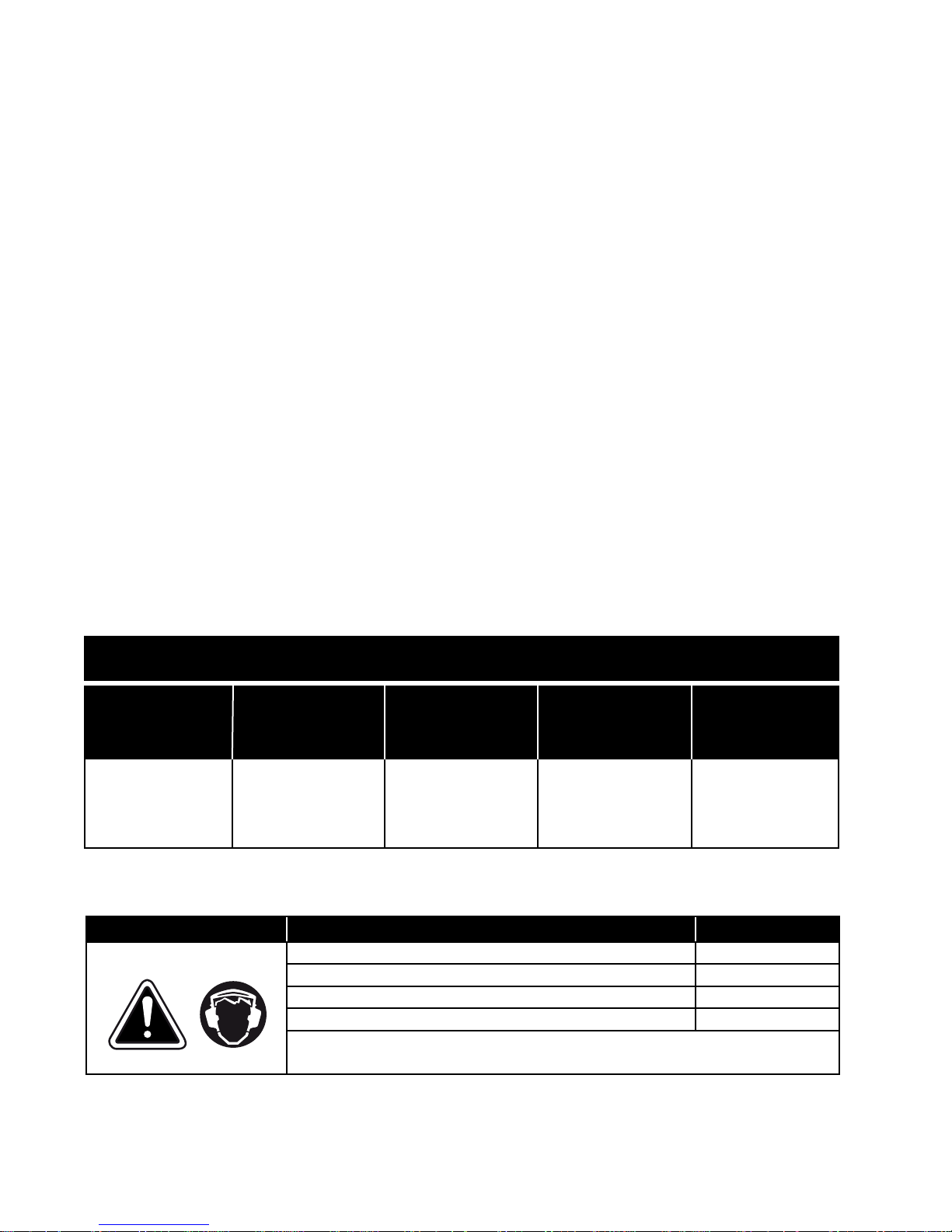

iv. SPECIFICATIONS

TYROLIT TTE250 TILE SAW

MOTOR

1.1kW

110 V, 50 Hz or

ARBOR SHAFT

ROTATION

Counter-

Clockwise

230V, 50 Hz

Single phase*

* The motor is designed to operate on either 110V or 230V mains, but not both. Refer to the name plate located behind

the motor for power requirements specific to your motor.

Noise level at the ear of the user (Leq) 93.7 dB(A)*

Noise level at workplace (LPA) 80.5 dB(A)*

Sound power level in accordance with ISO 3744 (LwA) 100.5 dB(A)*

Vibrations DIN EN ISO 5349-2 < 2.5 m/s²

*Value applies under the following condition: With Sawblade Ø250mm Type EB No. 5504014.

Higher noise levels may be generated in cutting operation.

MAX. BLADE

CAPACITY

WEIGHT

25.4mm arbor blade,

250mm Blade

Noise level and vibrations

DIMENSIONS

26 kg Width: 600mm

Length: 900mm

Hight: 500mm

ATTENTION! Hearing protection must be worn when 90 dB(A) is exceeded!

– 5 – – 6 –

Page 7

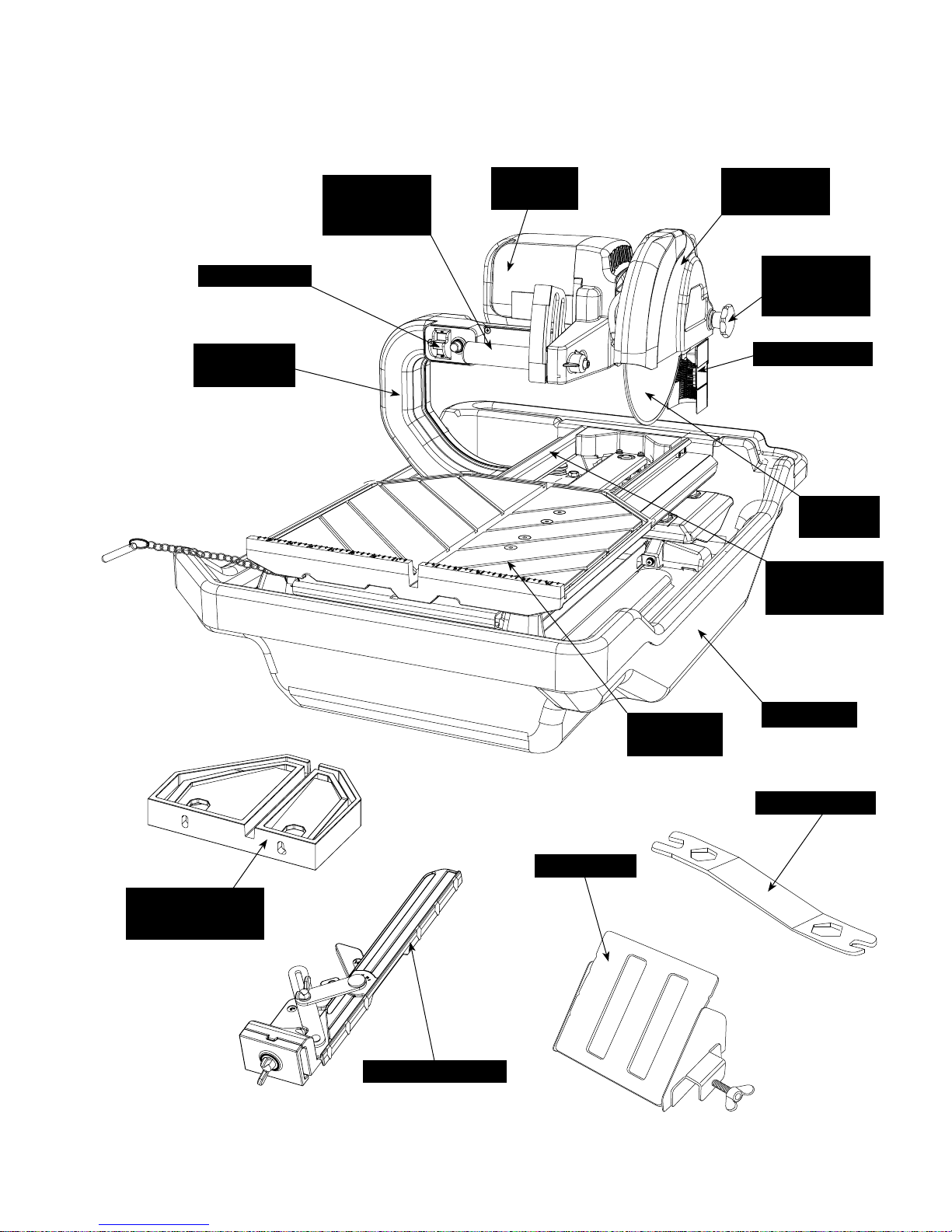

v. GETTING TO KNOW YOUR SAW

Power Switch

Vertical Arm

Assembly

Cutting Head

Adjustment

Handle

Motor

Assembly

Blade Guard

Assembly

Blade Guard

Adjustment

Knob

Splash Guard

Diamond

Blade

Rail Platform

Assembly

Side Extension

Table

MasterGuide

Miter Block

Main Table

Assembly

Water Tray

Blade Wrench

Page 8

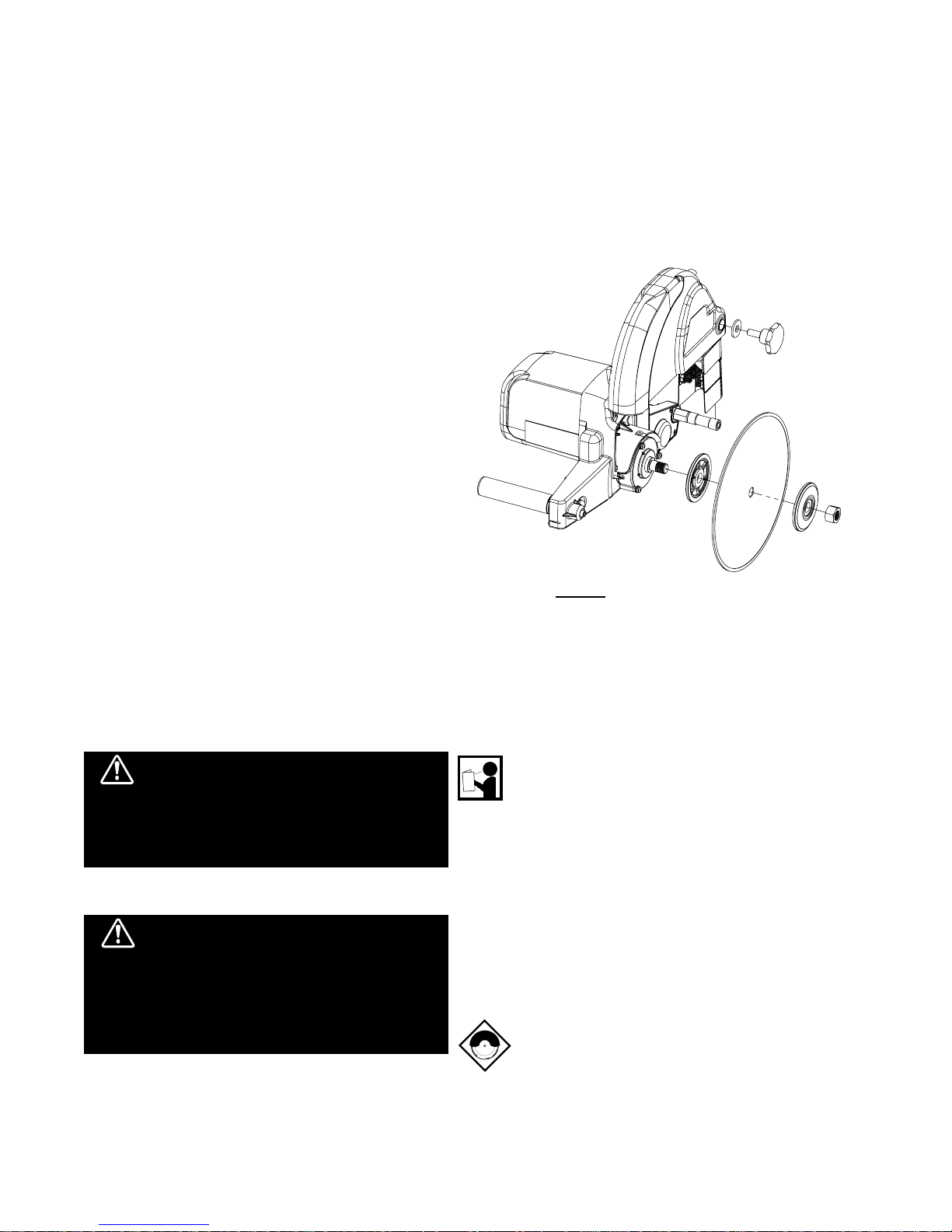

vi. BLADE INSTALLATION

1. Carefully raise the cutting head to its highest

position and secure it into place by tightening the

cutting head adjustment knob located in the front

of the saw, to the right of the power switch.

2. Raise the blade guard to the highest position and

tighten the blade guard adjustment knob.

3. Remove the blade shaft nut and outer flange.

4. Place the blade onto the shaft making sure that the

directional arrows are pointing in the direction of

rotation.

5. After making sure that the blade is firmly placed

against the inner flange, secure it into place with

the outer flange and blade shaft nut. Make certain

the nut is firmly tightened with the wrench provided,

do not over tighten!

but

7. Lower the blade guard and tighten the adjustment

knob.

8. Slightly loosen the cutting head adjustment knob

and lower the cutting head to its lowest position,

and then tighten the adjustment knob firmly to hold

the cutting head in place.

WARNING: Setting the blade too high may cause

the blade to grap the material being cut, causing

damage and possibly injury.

Figure 1

vii. SAFE OPERATING PRACTICES FOR TILE SAW

WARNING!

For your own safety and the safety

of others do not attempt to operate this saw until you

have read and understand the general safety rules

for all power tools and the following additional safety

precaution unique to this saw.

1. Use safety equipment - wear safety approved

hearing, eye, head and respirator protection.

WARNING!

The dust generated by cutting of

tile, marble, stone, bricks etc. can be injurious to your

health. Always operate machinery in well ventilated

areas and provide proper dust removal. Always wear a

dust mask approved for respiratory protection against

these types of dusts and mists.

2. Read and understand the symbol definitions

contained in this manual.

3. Read and understand all warnings and instructions

on the machine.

4. Read all safety materials and instructions that

accompany any blade or accessory used with this

machine.

5. Establish a training program for all operations of

this machine.

6. Always provide a copy of this manual to the

equipment user. If you need extra copies call our

Customer Service Department.

7. Always select a diamond blade according to the

manufacturers recommendation suitable for the

material to be cut. Never use a blade having a

maximum operating speed lower than the “No load

R.P.M.” marked on the tool nameplate. Do not

operate any saw without safety guards in place

or with a blade diameter larger than the maximum

– 7 – – 8 –

Page 9

saw blade capacity.

8. Before mounting a blade on the saw clean and

inspect the arbor shaft, blade flanges and the

diamond blade for uneven wear or damage. If it

appears to be damaged, Do not operate the tool.

Have it serviced by a qualified service technician.

9. Before each use of the saw, inspect the diamond

blade for hairline fatigue cracks. If such a crack

or flaw is evident, discard the blade. Using a

damaged blade may cause injury to the operator

or others.

14. Before using the saw fill the water tub enough to

submerge the water pump with clean water only.

Replenish as necessary and clean the water tub

frequently. Do not operate a wet cutting blade

without adequate water flow to both sides of the

blade. Never run the pump dry.

15. When cutting, always hold the material firmly lying

flat, supported by the main table with one edge

resting against the main table backstop.

• Do not attempt to cut pieces too small to

safely hold down on the main table.

10. Be sure that the blade arbor hole matches the

blade adapter flange supplied with the saw. Use

only blade adapter flanges that came on your

saw. Never use damaged or worn blade adapter

flanges.

11. Installing the blade, install the blade with the

arrow pointing the same direction as the rotation

of the arbor shaft or the arrow on the blade guard.

Be sure to tighten the blade shaft arbor nut with the

wrench provided. Be careful not to over tighten.

WARNING!

Not dressing the blade frequently or

setting the blade too high will cause it to grab the tile

possibly causing injury to the operator and the saw.

12. Check that the blade tracks near the center of the

channel in the main table, and that the table moves

freely from front to back.

13. Sometimes the material being cut is not abrasive

enough to expose new diamonds on the blade.

If the blade is not sharpened, it will rub against

the surface resulting in heat build up in the core.

To prevent this, it is necessary to dress the

blade. To dress the blade simply cut something

that is very abrasive such as a piece of cement

block. Indications that the blade needs dressing

includes:

• The diamond in the matrix appear shiny

because they are worn flat.

• Never use the side of the blade to cut or grind

with, only cut in a straight line.

• Keep all parts of your body away from the

blade and all other moving parts.

• Never touch or try to stop a moving blade with

your hand.

16. When cutting dry - always unplug the water pump

first. Never run the pump dry.

• Do not use a wet cutting blade for dry cutting.

Select the proper dry cutting blade for your

application.

• Never make long continuous cuts with dry

cutting blades. To avoid heat build up, allow

the blade to cool, remove the tile and allow

the blade to run freely for a few minutes.

IMPORTANT - If there is any tendency for the

saw to move during certain operations, such as

when cutting large heavy tile; the saw must be

securely fastened to a supporting table.

17. Make certain all adjusting knobs or locks are tight

and engaged in their detents and that movable

parts not intended to move during operation are

securely locked before making a cut.

Be careful

not to over tighten.

18. Before connecting the machine to a power source

check to see that the “On/Off” switch is in the “off”

position.

• The blade stops cutting or noticeably slows

down.

Blade dressing stones are available from your local TYROLIT

distributor.

• Make sure the blade is not contacting anything

before connecting to a power source and

starting the motor.

• Know how to stop the machine quickly in case

of an emergency.

Page 10

(A) (B) (C)

Cover of grounded

outlet box

Grounding pin

Grounding

Means

(Lug)

Metal

Screw

(D)

(E)

Grounding pin

Figure 2

Grounding Methods

19. Grounding Instructions

• In the event of a malfunction or breakdown,

grounding provides a path of least resistance

for electric current to reduce the risk of

electric shock. This tool is equipped with an

electric cord having an equipment-grounding

conductor and a grounding plug. The plug

must be plugged into a matching outlet that is

properly installed and grounded in accordance

with all local codes and ordinances.

• Do not modify the plug provided - if it will not

fit the outlet, have the proper outlet installed

by a qualified electrician.

• Improper connection of the equipment

grounding conductor can result in a risk of

electric shock.

• Check with a qualified electrician or service

personnel if the grounding instructions are

not completely understood, or if in doubt as to

whether the tool is properly grounded.

• Use only 3 wire extension cords that have 3

prong grounding plugs and 3 pole receptacles

that accept the tool’s plug.

Repair or replace damaged or worn cord immediately.

This tool is intended for use on a circuit that has an outlet

that looks like the one illustrated in

Figure 2. The tool has a

grounding plug that looks like the plug illustrated in Figure

2(A). A temporary adapter, which looks like the adapter

illustrated in Figure 2(B) and 2(C), may be used to connect

this plug to a 2 pole receptacle as shown in Figure 2(B) if

a properly grounded outlet is not available. The temporary

adapter should be used only until a properly grounded outlet

can be installed by a qualified electrician. The green-colored

rigid ear, lug, and the like, extending from the adapter must be

connected to permanent ground such as a properly grounded

outlet box.

NOTE - Use of a Temporary Adapter is not permitted

in certain countries. Please check local regulations

before using a Temporary Adapter.

Additionally, water pump requires the use of a Ground Fault

Circuit Interrupter. Therefore, when using the water pump

receptacle, this tool must be plugged into a properly installed

Ground Fault Circuit Interrupter outlet. See Figure 2(D). If

a Ground Fault Circuit Interrupter outlet is not available,

TYROLIT Hydrostress AG has it available as an accessory

item. A plug-in Ground Fault Circuit Interrupter may be

plugged into a properly installed and grounded 3-pole outlet.

Refer to

Figure 2(E).

20. Position of the Tile Saw

• To avoid the possiblity of the appliance plug or

receptacle getting wet, position tile saw to one

side of a wall mounted receptacle to prevent

water from dripping onto the receptacle or

plug. The user should arrange a "drip loop" in

the cord connecting the saw to a receptacle.

The "drip loop" is that part of the cord below

the level of the receptacle, or the connector if

an extension cord is used, to prevent water

traveling along the cord and coming in contact

with the receptacle.

See Figure 3.

• If the plug or receptacle does get wet, Do

not unplug the cord

. Disconnect the fuse or

circuit breaker that supplies power to the tool.

Then unplug and examine for presence of

water in the receptacle.

To reduce the risk of electrocution, keep

all connections dry and off the ground.

Do not touch plug with wet hands.

– 9 – – 10 –

Page 11

21. Extension Cords

TOOL

• Use only extension cords that are intended

for outdoor use. These extension cords are

indentified by a marking

"Acceptable for use

with outdoor appliances; store indoors while

not in use." Use only extension cords having

an electrical rating not less than the rating of

the product.

Refer to chart on page 21. Do

no use damaged extension cords. Examine

extension cord before using and replace if

damaged. Do no abuse extension cords

and do not pull on any cord to disconnect.

Keep cord away from heat and sharp edges.

Always disconnect the extension cord

from the receptacle before disconnecting

the saw from the extension cord.

• Ground Fault Circuit Interrupter (GFCI)

protection should be provided on the circuit(s)

or outlet(s) to be used for the tile saw.

Receptacles are available having built-in

GFCI protection and may be used for this

measure of safety.

Supporting

Surface

Power Cord

Figure 3

Drip Loop

Drip Loop

Features:

• Cutting table marked in inches for precision cuts.

• 350mm cutting table provides more support during

larger cutting jobs than the standard 280mm

cutting tables.

Using MasterGuide:

1. Set the MasterGuide by positioning it at the desired

dimension on the measurement rail and firmly

tighten the horizontal threaded knob. When using

the attached ruler, the guide can be used to make

cuts betwen 45º and 90º. To adjust the cutting

angle first loosen the vertical threaded knob.

2. The guide can also be used without the ruler

attachment to make 90º cuts on either the left

or right edge. The guide contains multiple 45º

templates to allow diagonal cuts of common tile

sizes. Position the guide for a diagonal cut by

aligning the desired template along a diagonal

groove on the table. To remove the ruler first

remove the vertical threaded knob.

3. After positioning the guide, place the material flat

against the guide and the table measurement rail.

Now you are ready to make your cut.

viii. USING THE CUTTING TABLE

Making Miter Cuts (Using Miter Block):

1. For miter cuts, place the lip of the miter block on

the measurement rail, with the threaded knobs

facing you.

2. Tighten the threaded knobs to secure the miter

block in place.

3. Place material onto miter block and you are ready

to cut.

Figure 4

Cutting large tile

TTE250 can cut a 610mm tile and

diagonally cut a 460mm tile.

TTE250 shown with optional drip trays.

Page 12

xix. CARE AND MAINTENANCE

WARNING!

For your safety before performing any maintenance on the saw turn off the power switch and unplug

the power cord.

TYROLIT TTE250 requires very little maintenance.

However, keeping your saw clean and properly adjusted will

ensure optimum performance. Take great care not to get

water into the motor. Do no use pressure washer to clean

motor area.

1. Cleaning

• Form a habit of cleaning your saw after each

use. To clean the water tub, remove drain

plug provided in bottom of tub. Remove

saw including water pump from tub. Remove

residual water and clean tub using soap and

water only. Reinstall saw with pump into tub.

• To increase water pump life remove tile grit

by purging water. Pump with fresh water after

each use.

• With a damp cloth or sponge wipe clean the

guide rails and all other surfaces on the saw

where dust and debris has accumulated.

NOTE - Do not lubricate the guide rails. The presence

of oil or grease will cause an accumulation of dust

and dirt.

2. Transporting

• Unplug the power cord and store it in the

empty, dry water tub. For convenience and

safety, the saw should be transported with the

main table

locked, motor in upper position

and all adjustment knobs tightened.

3. Sliding Vertical Arm Assembly Adjustment

C. Tighten nyloc nut when finished to secure

rollers in place. Be sure not to overtighten.

Set screw to adjust

roller tension

Nyloc nut is found

under the base

Assembly Roller Adjustment

Figure 5

4. Table Roller Adjustment

A. Loosen (4) hex screws on table top.

B. Adjust tension on rollers by turning set screw

(on outside of table) until desired tension is

achieved.

DO NOT OVERTIGHTEN. See

Figure 6.

C. Re-tighten the (4) hex screws on table top.

Check table movement and re-adjust if

necessary. Table should roll free but without

side movement.

Figure 6

Table Roller Adjustment

Adjust table tension

through this set screw

• Make sure that all rails and rollers are clean.

• If the vertical arm assembly does not slide

smoothly, it will require tension adjustment as

follows:

A. Locate the two tension rollers mounted onthe

black base of the vertical arm assembly

furthest from the arm. Use a wrench to loosen

the nyloc nut directly below each roller. Use

another wrench to prevent the bolt on top from

turning.

See Figure 5.

B. Use the horizontal set screw to adjust roller

tension against the rails. The rollers should

roll free but without side movement.

NOTE - Whenever making tension adjustments to

rollers on the vertical arm assembly or table, the

stainless steel wire linking the two components

together should be disconnected first. Otherwise, it

will not be possible to determine which rollers will

require adjustment. See Section 5 for steps.

– 11 – – 12 –

Page 13

5. Unlinking Coaction Wire

A. Remove the wire shield located between the

rails by removing the screws at both ends.

B. Loosen the nyloc nuts on the wire anchor

underneath the table so that the wire can pass

freely through the bolt. Be sure to use an

allen key to prevent the bolt from turning.

Failure to do so may cause the wire to

break. See Figure 7.

Loosen both nyloc nuts

C. Perform the necessary adjustments. Proceed

to next step once completed.

D. Move the table towards the user, such that

the forward-most roller touches the rubber

stopper at the end of the rail. Then move the

vertical arm assembly to the opposite end,

while leaving a small gap between the rearmost roller and frame.

E. Tighten the nyloc nuts on the wire anchor,

while preventing the bolts from turning.

F. Replace the wire shield.

6. Aligning the Blade to the Table

• While cutting, the material being cut must

move in a straight line parallel to the saw

blade. If the blade is out of plane it will bind

at one end of the cut. To align the blade,

perform the following:

Figure 7

Unlinking the Table

Insert allen key to

prevent bolt from turning

Pivot adjuster

C. Tighten lower socket hex bolt when finished.

D. Check alignment by placing an L-shaped

L-shaped

straight edge

Resistance encountered while turning the

pivot adjuster indicates that rollers are being

forced against the rail. Lower roller tension

before proceeding.

Figure 8

Blade Alignment

Loosen socket hex bolt

With the pivot adjuster secured, adjust the

remaining rollers to obtain proper tension

against the rails.

See Section 3.

straight edge on the table with the short arm

resting flat against the table back stop. The

long arm should rest against the blade with

the cutting head completely lowered. Check

to see if there are any gaps between the

leading or trailing edges of the blade and

the straight edge. If gaps exist, then repeats

steps A - C until alignment is attained.

See

Figure 9.

Figure 9

Table Roller Adjustment

Blade

A. Locate the pivot adjuster on the black base

of the vertical arm assembly next to the arm.

Loosen the socket hex bolt directly below the

adjuster.

See Figure 8.

B. Turn pivot adjuster using a wrench either

clockwise (putting the roller into the rail) or

counterclockwise (pulling the roller away from

the rail). While the pivot adjuster determines

blade alignment, the rollers on the opposite

side of the assembly base

must also be adjusted simultaneously so

that they run parallel to the rollers closest to

the vertical arm. Do not apply excessive

force when turning the pivot adjuster.

(see Section 3)

Table back stop

7. Positioning the Saw in the Tub

A. Orient the saw such that the front is pointing

towards the short side of the tub with the

beveled corner.

B. While lowering the saw into the tub, ensure

that brackets at both ends of the saw frame

Page 14

fit over the recessed portions of the tub wall.

See Figure 10.

Figure 10

Positioning the Saw

E. Remove the water pump underneath the rails

and install a new one in its place. Remove the

water tube and adapter from the failed pump.

F. Insert power cable from the new pump through

the cable gland and shield sleeve and route it

up the vertical arm. The gland must be

oriented such that it can attach to the sleeve.

G. Connect wiring from the water pump power

cable to the same wires made available when

disconnecting the failed pump.

Recessed wall

8. Tub & Tray

A. Insert the large rubber stopper in the drain

Figure 11

.

9. Replacing the Water Pump

• In the event of a water pump failure, replace

Bracket

See Figure 11.

hole.

Rubber stopper

the pump by performing the following steps:

H. Install shield onto vertical arm using screws.

I. Gently extract excess cable stored within

vertical arm; some slack is ideal. Tugging the

cable may dislodge or disconnect critical

electrical components. Attach cable gland

onto the shield sleeve by turning clockwise.

If properly attached, the gland should secure

the cable in place.

J. Attach the adapter to the pump and hand

tighten. Do not use a wrench as it can strip

the thread.

K. Connect clear tubing to male section of the

adapter until it fits securely.

Figure 14

Water tubing

See Figure 14.

Adapter

A. Remove the cable gland located at the bottom

of the vertical arm shield by turning it counterclockwise. Once removed, the cable should

slide freely within the underlying sleeve.

Figure 13.

B. Remove screws from the vertical arm shield,

then remove the shield.

C. Disconnect wiring from the water pump power

cable within the vertical arm.

D. Extract the power cable from the vertical arm

through the sleeve at the bottom of the shield.

Keep the cable gland.

See

Figure 13

Remove Cable Gland

– 13 – – 14 –

Page 15

x. CUTTING DEPTH

The recommended cutting depth is 6mm below the cutting

table surface. To adjust the cutting depth, loosen the cutting

head adjustment handle and set it to the lowest position, so

that the blade is 6mm below the top of the table surface.

WARNING: Setting the blade too high may

cause the blade to grab the material being cut,

possibly causing injury to the operator and the

saw.

xi. REPLACEMENT PARTS LIST

MAIN ASSEMBLY

82018 17 10 9

11

3

BLADE DIAMETER CUTTING DEPTH

250mm 60mm

5 14 15

16

13

6 19

4

7

12

2

Pos Art. No. Description

1 10985786 EOSM-420150 RAIL PLATFORM ASSEMBLY

2 10985678 EOSM-420002 TABLE ASSEMBLY

3 10985787 EOSM-420151 VERTICAL ARM (110V/50HZ)

10985788 EOSM-420152 VERTICAL ARM (230V/50HZ)

4 10985789 EOSM-420153 CUTTING HEAD (110V/50HZ)

10985790 EOSM-420154 CUTTING HEAD (230V/50HZ)

5 10985791 EOSM-420155 BLADE GUARD ASSEMBLY

6 10985679 EOSM-420006 DIA 5/8” OUTER FLANGE

7 250mm Cont. general purpose blade

8 10985680 EOSM-420007 D30 X 120L HANDLE

9 10985681 EOSM-420008 SPRING

10 10985682 EOSM-420009 SLIP COLLAR

11 10985683 EOSM-420010 INTERLOCK WASHER

12 10985792 EOSM-420156 WATER PUMP (110V/50HZ)

10985793 EOSM-420157 WATER PUMP (230V/50HZ)

13 10985684 EOSM-420012 M6X1.0X25L HEAD HEX BOLT

1

Pos Art. No. Description

14 10985685 EOSM-420013 M10 NARROW WASHER

15 10985686 EOSM-420014 MALE M10 X 1.5 X 25L KNOB

16 10985687 EOSM-420015 M8 X 1.25 ACORN NUT

17 10985688 EOSM-420016 M8 NARROW WASHER

18 10985689 EOSM-420017 M8X1.25X35L CROSS SCREW

19 10985912 EOSM-PSV00004 5/8” - 11 HEX NUT

20 10985806 EOSM-420170 DIA 1” INNER FLANGE

20 10987292 EOSM-420305 DIA 1” INNER FLANGE 1/ -1.5

20 10987293 EOSM-420306 DIA 1” INNER FLANGE 2/ -1

20 10987294 EOSM-420307 DIA 1” INNER FLANGE 3/ -0.5

20 10985806 EOSM-420305 DIA 1” INNER FLANGE 4/ 0

20 10987295 EOSM-420308 DIA 1” INNER FLANGE 5/ 0.5

20 10987296 EOSM-420309 DIA 1” INNER FLANGE 6/ 1

20 10987297 EOSM-420310 DIA 1” INNER FLANGE 7/ 1.5

Page 16

CUTTING HEAD ASSEMBLY

8

910

32

25

26

11 24

28 29

3

12

13

17

181920

7

16

15

4

5 31 1430 22

Pos Art. No. Description

1 10985690 EOSM-420027 CUTTING HEAD

2 10985691 EOSM-420028 GEAR CAP

3 10985692 EOSM-420029 BLADE GUARD SHAFT

4 10985693 EOSM-420030 BLADE SHAFT

5 10985694 EOSM-420031 HELICAL GEAR

6 10985794 EOSM-420158 BRUSH MOTOR (110V/50HZ)

10985795 EOSM-420159 BRUSH MOTOR (230V/50HZ)

7 10985695 EOSM-420033 FAN COVER

8 10985696 EOSM-420034 SPRING TENSION PLATE

9 10985697 EOSM-420035 TORSIONAL SPRING

10 10985698 EOSM-420036 SPRING SPACER

11 10985699 EOSM-420037 SPRING HOUSING COVER

12 10985700 EOSM-420038 17MM X 7MM CARBON BRUSH

10985796 EOSM-420160 CARBON BRUSH (230V/50HZ)

13 10985701 EOSM-420039 CARBON BRUSH CAP

14 10985702 EOSM-420040 D40 D24 OIL SEAL

15 10985703 EOSM-420041 M5 NARROW WASHER

21 2 152716 23

6 1

Pos Art. No. Description

16 10985704 EOSM-420042 M5 SPRING WASHER

17 10985705 EOSM-420043 M5X0.8X25L CROSS SCREW

18 10985706 EOSM-420044 M4 NARROW WASHER

19 10985707 EOSM-420045 M4 SPRING WASHER

20 10985708 EOSM-420046 M4X0.7X20L CROSS SCREW

21 10985709 EOSM-420047 5MM X 16MM WOODRUFF KEY

22 10985710 EOSM-420048 M20 EXTERNAL C-CLIP

23 10985711 EOSM-420049 M5X0.8X15L CROSS SCREW

24 10985712 EOSM-420050 M4X0.7X10L CROSS SCREW

25 10985713 EOSM-420051 M8 SPRING WASHER

26 10985714 EOSM-420052 M8 X 1.25 X 20L HEX BOLT

27 10985715 EOSM-420053 M10 X 1.5 NUT

28 10985685 EOSM-420013 M10 NARROW WASHER

29 10985716 EOSM-420054 D6 CIRCULAR RUBBER STOP

30 10985717 EOSM-420055 D22 D8 608 RADIAL BEARING

31 10985718 EOSM-420056 D47 D20 RADIAL BEARING

32 10985719 EOSM-420057 M8 REGULAR WASHER

– 15 – – 16 –

Page 17

VERTICAL ARM ASSEMBLY

29

32 36 33 34

110V/50Hz

5

28

11

22

10

6

17

16

15

30

18

44

45

230V/50Hz

1 21

13

14

42

43

3

2

30

4

27

26

1

23

35

7

46

24

37

39

38

19

8

31 92514

Pos Art. No. Description

1 10985797 EOSM-420161 POST

2 10985798 EOSM-420162 POST ELECTR. ACCESS PLATE

3 10985720 EOSM-420060 RUBBER GASKET

4 10985799 EOSM-420163 PLATE

5 10985721 EOSM-420062 CUTTING HEAD BRACKET

6 10985800 EOSM-420164 POST BASE

7 10985722 EOSM-420064 ROLLER ADJUSTMENT MOUNT

8 10985723 EOSM-420065 ROLLER MOUNT

9 10985714 EOSM-420052 M8 X 1.25 X 20L HEX BOLT

10 10985724 EOSM-420066 WIRE ANCHOR BRACKET

11 10985725 EOSM-420067 M6 X 1.0 X 15L HEX BOLT

12 10985726 EOSM-420068 M8 X 1.25 X 45L HEX BOLT

13 10985704 EOSM-420042 M5 SPRING WASHER

14 10985711 EOSM-420049 M5X0.8X15L CROSS SCREW

15 10985727 EOSM-420069 1/4”-20X1/2” FLAT SCREW

16 10985728 EOSM-420070 1/4” - 20 NUT

17 10985729 EOSM-420071 M6 NARROW WASHER

18 10985730 EOSM-420072 M8 X 1.25 X 35L HEX BOLT

19 10985731 EOSM-420073 LOWER ROLLER SPACER

20 10985732 EOSM-420074 1/4” NARROW WASHER

21 10985703 EOSM-420041 M5 NARROW WASHER

22 10985733 EOSM-420075 WIRE TENSION BOLT

23 10985734 EOSM-420076 1/4”-20X2”X3/4” CAP BOLT

20 40

1241

Pos Art. No. Description

24 10985735 EOSM-420077 1/4”-20X1-1/4”X3/4” BOLT

25 10985736 EOSM-420078 1/4” - 20 NYLON NUT

26 10985737 EOSM-420079 M8 X 1.25 NYLON NUT

27 10985738 EOSM-420080 DIA 8MM CABLE GLAND

28 10985739 EOSM-420081 M8X1.25X20L CROSS SCREW

29 10985740 EOSM-420082 M5X0.8X16L CROSS SCREW

30 10985741 EOSM-420083 M4X0.7X13L CROSS SCREW

31 10985742 EOSM-420084 M6 SPRING WASHER

32 10985743 EOSM-420085 20A 125V/12A 250V SWITCH

33 10985744 EOSM-420086 15A CIRCUIT BREAKER

34 10985745 EOSM-420087 POWER SWITCH GASKET

35 10985746 EOSM-420088 M6 X 1.0 NYLON NUT

36 10985747 EOSM-420130 POWER SWITCH PLATE

37 10985916 EOSM-V31005-MA WATER SHIELD

38 10985915 EOSM-V31004-MA BYPASS SPACER

39 10985748 EOSM-420090 TYPE 5 GUIDE ROLLER

40 10985713 EOSM-420051 M8 SPRING WASHER

41 10985688 EOSM-420016 M8 NARROW WASHER

42 10985706 EOSM-420044 M4 NARROW WASHER

43 10985749 EOSM-420091 M4 X 0.7 X 8L CROSS SCREW

44 10985801 EOSM-420165 12A 220V-250V EL. SWITCH

45 10985802 EOSM-420166 POWER SWITCH PLATE

46 10985803 EOSM-420167 DIA 7MM CABLE GLAND

Page 18

TABLE ASSEMBLY

18 17 7 2

6 13 5

19

15

16

Pos Art. No. Description

1 10985750 EOSM-420092 MAIN TABLE

2 10985751 EOSM-420093 WIRE ANCHOR PLATE

3 10985917 EOSM-V31014-MA ROLLER MOUNTING PLATE

4 10985918 EOSM-V31015-MA NUT PLATE, TABLE

5 10985752 EOSM-420094 WIRE BOLT ANCHOR

6 10985746 EOSM-420088 M6 X 1.0 NYLON NUT

7 10985729 EOSM-420071 M6 NARROW WASHER

8 10985753 EOSM-420095 UPPER ROLLER SPACER

9 10985916 EOSM-V31005-MA WATER SHIELD

10 10985915 EOSM-V31004-MA BYPASS SPACER

11 10985754 EOSM-420096 ROLLER

12 10985731 EOSM-420073 LOWER ROLLER SPACER

13 10985755 EOSM-420097 M6 WIDE WASHER

14 10985756 EOSM-420098 1/4”-20X1-1/4”X3/4” BOLT

15 10985924 EOSM-V3816 1/4”-20X1-1/4” HEAD SCREW

16 10985728 EOSM-420070 1/4” - 20 NUT

17 10985742 EOSM-420084 M6 SPRING WASHER

18 10985757 EOSM-420099 M6 X 1.0 X 14L HEX BOLT

19 10985923 EOSM-V3815 1/4”-20X1.5”L HEX BOLT

BLADE GUARD ASSEMBLY

12

11

10

14

1

3

8

4

9

9

1 6 7 10 5

Pos Art. No. Description Description

1 10985804 EOSM-420168 TYROLIT 250MM BLADE GUARD

2 10985758 EOSM-420101 SPLASH GUARD

3 10985729 EOSM-420071 M6 NARROW WASHER

4 10985759 EOSM-420102 M6 X 1.0 X 10L HEX BOLT

5 10985708 EOSM-420046 M4X0.7X20L CROSS SCREW

6 10985760 EOSM-420103 12CM PIPE

7 10985761 EOSM-420104 120CM PIPE

8 10985762 EOSM-420105 39CM PIPE

9 10985763 EOSM-420106 D8MM Y-SHAPE CONNECTORS

10 10985706 EOSM-420044 M4 NARROW WASHER

9

8

3

4

2

– 17 – – 18 –

Page 19

RAIL PLATFORM ASSEMBLY

21

11

21

20

19

2

7

8

10

12

5

1

9

4

26

23

24

14

15

6

21

13

3

25

24

23

18

17

22

5

25

24

23

23

24

25

Pos Art. No. Description

1 10985805 EOSM-420169 RAIL PLATFORM

2 10985764 EOSM-420108 PULLEY MOUNT AND CAP

3 10985765 EOSM-420109 FRONT PLATFORM ANCHOR

4 10985766 EOSM-420110 REAR PLATFORM ANCHOR

5 10985767 EOSM-420111 RAIL

6 10985768 EOSM-420112 SKID PLATE

7 10985769 EOSM-420113 SHAFT SPACER

8 10985770 EOSM-420114 SHAFT

9 10985771 EOSM-420115 RUBBER BUMPER

10 10985772 EOSM-420116 WIRE PULLEY ASSEMBLY

11 10985773 EOSM-420117 WIRE SHIELD

12 10985774 EOSM-420118 D2 STAINLESS STEEL WIRE

13 10985775 EOSM-420119 SCREW DRIVEN WIRE CLAMP

Pos Art. No. Description

14 10985776 EOSM-420120 RUBBER FEET

15 10985777 EOSM-420121 M5X0.8X10L CROSS SCREW

16 10985778 EOSM-420122 CHAIN

17 10985779 EOSM-420123 D21 RING

18 10985780 EOSM-420124 D8 X 45L QUICKRELEASE PIN

19 10985706 EOSM-420044 M4 NARROW WASHER

20 10985707 EOSM-420045 M4 SPRING WASHER

21 10985781 EOSM-420125 M4X0.7X10L CROSS SCREW

22 10985922 EOSM-V3808 1/4”-20X5/8”L HEX BOLT

23 10985703 EOSM-420041 M5 NARROW WASHER

24 10985704 EOSM-420042 M5 SPRING WASHER

25 10985777 EOSM-420121 M5X0.8X10L CROSS SCREW

26 10985782 EOSM-420126 M4 X 0.7 NUT

Page 20

xii. ACCESSORIES

Name (Qty.)

ABS WATER TRAY (1)

Art. No.

10985783

Part Number

420127

EOSM-

Name (Qty.)

JOLLY-TISCH (1)

Art. No.

10978736

Part Number

S700-34

EOSM-

Name (Qty.)

MASTERGUIDE (1)

Art. No.

10980453

Part Number

EOSM-S1000-MG

Name (Qty.)

SIDE EXTENSION

TABLE (1)

Art. No.

10985921

Part Number

EOSM-V38008

Optional

Name (Qty.)

KNOB RIP GUIDEMITER

BLOCK (1)

Art. No.

10985920

Part Number

EOSM-V35016

Name (Qty.)

ABLAUFSTOPFEN (1)

Art. No.

10980464

Part Number

EOSM-V35015

Optional

Name (Qty.)

SÄGETISCH FALTBAR (1)

Art. No.

10984479

Part Number

EOSM-CX10ST

– 19 – – 20 –

Page 21

xiii. HOW TO ORDER PARTS

Type TTE250 Article No. 10983906

Serial No. Index 001250070001

Power 1,1 kW Voltage 230V/50Hz

Weight 26 kg Year 2007

Please have the following information ready before ordering spare parts:

• Machine type according to nameplate (e.g. TTE250)

• Machine serial number according to nameplate (e.g. 250070001)

• Machine index according to nameplate (e.g. 001)

• Spare part number according to the spare parts list (e.g. 12345678)

To avoid incorrect deliveries you should check the order details above for correctness and completeness prior to shipment. You should

ensure that the delivery address is given in full.

For orders, questions and information please contact your responsible branch office below:

TYROLIT Hydrostress AG

Witzbergstrasse 18

CH-8330 Pfäffikon

Switzerland

Tel. 0041 (0)44 952 18 18

Fax 0041 (0)44 952 18 00

www.tyrolit.com

Disclaimer: TYROLIT Hydrostress AG reserves the right to make changes or improvements on its products without incurring an

additional obligation including any obligation to make corresponding changes or improvements to products previously manufactured

or sold. TYROLIT reserves the right to discontinue products at any time without notice.

All illustrations displayed in this manual are the property of TYROLIT Hydrostress AG and shall not be duplicated or reproduced without

the express written consent of TYROLIT Hydrostress AG.

Page 22

xiv. ELECTRICAL MOTOR SPECIFICATION

Power 1.1 kW

Volts* 110 V 230V

Amps 13 amps 7.5 amps

Motor RPM 22,000 rpm

Cycle 50 Hz

Phase 1

Class F

Blade Shaft 3,420 rpm

* The motor is designed to operate on either 110V or 230V

mains, but not both. Refer to the name plate located behind

the motor for power requirements specific to your motor.

TTE250

TTE250

AL203

Brown Brown Brown

Switch

13 14

Recommendations:

• Before connecting the saw to a power source,

ensure that the voltages match.

• It is recommended that a 15 amp circuit

be used while operating this saw if equipped

with a 110V motor. If the saw is equipped with

a 230V motor, a 10 amp circuit should be

used instead. This will prevent possible power

interruption or loss.

• Always plug saw as close as possible to the power

source while operating. This will allow you to

receive optimum electricity.

Motor

Blue Blue Blue

23 24

Green/Yellow

WARNING:

To avoid permanent motor damage you must use

the correct extension cord. Never use more than

one extension cord at a time. Follow the chart

below for proper size.

Water

Pump

AWG

GAUGE

No. 12

No. 10

No. 8

No. 6

Green/Yellow

BrownBlue

Green/Yellow

LENGTH OF CORD

1.1 kW

110V

7 m

15 m

22 m

–

1.1 kW

230V

30 m

45 m

76 m

–

– 21 – – 22 –

Page 23

xv. TROUBLESHOOTING

For your safety and the safety of others, turn the power switch off and always remove the plug

WARNING!

from power source before troubleshooting. Repairs performed by unauthorized personnel could cause serious

hazard. We recommend that service to this tool be performed by a qualified service technician with original

equipment replacement parts.

EXCESSIVE NOISE. Lack of lubrication to the gearbox and

or possible bearing wear. Have tool serviced.

BLADE WILL NOT CUT. Check for worn out diamond

edge. Be sure that the arrow on the blade is rotating the same

direction as the motor arbor and/or arrow on the blade guard.

Make sure the blade is suitable for the material to be cut. If

blade has been used to cut a material that is hard, it may have

become dull, dress the blade by cutting a light weight abrasive

building block to expose fresh diamonds. Blade dressing stones

are available from your local TYROLIT distributor.

MOTOR WILL NOT START. Check power supply. If

the water pump turns on when the power switch is in the “on”

position, but the motor does not, have the motor serviced.

MOTOR WILL NOT STOP. The contacts in the switch

may have become arched together in the on position, have it

serviced.

MOTOR SHUTS OFF DURING OPERATION. Check

to see that the circuit you are using is not overloaded with lights

or other equipment. The fuse or circuit breaker may not have

sufficient capacity, use 20-amp power. If you are using an

extension cord check the extension cord table to be sure it is

heavy enough to carry the current this product will draw.

Page 21 for electric cord reference.

See

NOT CUTTING SQUARE. Check the main table and

carriage adjustment as well as the blade alignment procedure

located in the care and maintenance section.

MAIN TABLE DOES NOT MOVE FREELY. Inspect

the guide rails and rollers for build up of tile chips or dry slurry

deposits. Clean and check guide roll or adjustments, according

to the procedure in the care and maintenance section.

NO WATER FLOW TO BLADE. Check the water feed

tube for kinks or obstructions. Check the inlet screen to ensure

it is not clogged. Remove the pump inlet and turn the impeller

to ensure it is not damaged or jammed. Clean the impeller if

necessary and apply a drop of light oil to the shaft - be sure the

impeller spins freely.

POOR MACHINE PERFORMANCE WITH LITTLE

POWER. Check cord/extension cable for appropriate length

and gage. Check power network for sufficient power and circuit

breaker capacity.

CENTER HOLE IN BLADE OVERSIZE OR WORN.

Saw blade has slipped on shaft while running. Check shaft for

damage and replace blade.

EXCESSIVE VIBRATION Check to see that the blade is

mounted properly according to safe operating practices section.

Blade may be out of balance, try a different blade. Arbor shaft

bearings possibly worn, have tool serviced.

Page 24

DISPOSAL

GENERAL

The operator can recycle or dispose of the Table saw himself provided he observes the

statutory provisions. In order to dismantle the Table saw correctly and to properly remove the

materials some knowledge in the area of mechanics and knowledge about differentiation of

waste materials is necessary.

If during correct disposal doubts arise that represent a hazard for persons or the environment,

the after-sales service of TYROLIT Hydrostress AG will be happy to provide information.

DANGER

Voltage warning

Before working in an area identied in this way, the installation or device must be fully

disconnected from the power (voltage) and secured against being accidentally powered up

again.

Failure to head this warning may lead to death or serious injury.

PERSONNEL QUALIFICATIONS

Only personnel with basic technical training and who are in a position to identify the various material groups should be involved

in disposal.

DISPOSAL REGULATIONS

The normal local and regional rules and guidelines must be observed when disposing of the machines making up the Table

saw.

DISPOSAL REGULATIONS

The dismantled parts of the table saw are sorted by material and sent separately to the appropriate collection points. Ensure that

the following parts in particular are properly disposed of.

The Table saw consists of the following materials:

- Cast aluminium - Rolled aluminium products

- Bronze - Steel

- Rubber - Rubber / Nylon fabric

- Synthetic grease - Plexiglas

OBLIGATION OF NOTIFICATION

When a Table saw is taken out of service and disposed of the manufacturer TYROLIT Hydrostress AG or the corresponding

service centre must be informed of this.

– 23 – – 24 –

Page 25

Declaration of conformity

Description: Tile saw TTE250P

with electric engine 1.1 kW/110V or 230V

Type: TTE250P

Article number: 10983906 (230V)

Article number: 10984480 (110V)

Serial number: 25000001 – 2500_ _ _

Index 001

Year of construction: 2009

The TYROLIT Hydrostress AG certifies that the inspected above

machine against the following guidelines and that we confirm compliance

with these standards:

Guidelines:

Machine Directive 98/37/CE, 2006/42/CE

2002/95/EC Restriction of the use of certain hazardous 2002/95/CE

substances in electrical and electronic equipment

Electrical Directive 93/68 EWG

Electromagnetic compatibility 89/336/CEE

Waste electrical and electronic equipment 2002/96/CE

Vibration Directive 2002/44/CE

Noise Emission 2000/14/CE

Standards:

EN 12418:2000 Masonry and stone-off machines for job site - Safety

EN ISO 14121 Safety of machinery: Principles of risk assessment

EN 61000-6-3 Electromagnetic compatibility

Tyrolit Hydrostress AG

Witzbergstrasse 18

CH-8330 Pfäffikon ZH

Pfäffikon, 07.04.2009

Mario Facchin

Head of Research and Development

Loading...

Loading...