Page 1

Operating manual

Spare parts list

Stone cutoff saw

TME700P

Index «000»

10995348 en I 16.07..2015

Page 2

2

Manufacturer's address:

TYROLIT Hydrostress AG

Witzbergstrasse 18

CH-8330 Pfäffikon

Switzerland

Tel. +41 44 952 18 18

Fax +41 44 952 18 00

e-mail: info@tyrolit.com

www.hydrostress.com

TYROLIT Hydrostress AG reserves the right to make technical changes without prior notice.

Copyright© 2014 TYROLIT Hydrostress AG, CH-8330 Pfäffikon ZH, Switzerland

All rights reserved, in particular copyrighting and translating rights.

Printing of this operating manual, including extracts from it, is prohibited. No parts of it may be

reproduced in any form or processed using electronic systems , duplicated or disseminated without the

written permission of TYROLIT Hydrostress AG.

Page 3

3

Preface to the operating manual

This operating manual makes it easier to become familiar with the machine and to use it properly.

The operating manual contains important information on how to operate the machine safely, properly and

efficiently. Following the operating manual helps avoid danger, avoid repair costs and downtime, and

increase the machine's reliability and life.

The operating manual must be supplemented with instructions based on national regulations for accident

prevention and environmental protection.

The operating manual must always be readily available at the location where the machine is used.

The operating manual must be read and used by any person assigned tasks with the machine, such as:

- operation, including set-up, repair of malfunctions during operation, disposal of production

waste, maintenance, disposal of materials

- maintenance (service, inspection, or repair) and/or Transport

In addition to the operating manual and the regulations for accident prevention in force in the country and

at the location where the machine is used, recognised technical rules for safe and correct operation must

be followed.

Table of contents

1.

Basic safety instructions

2.

Machine description

3.

Assembly and initial preparation for operation

4.

Transport

5.

Operation

6.

Disassembly

7.

Maintenance

8.

Malfunctions

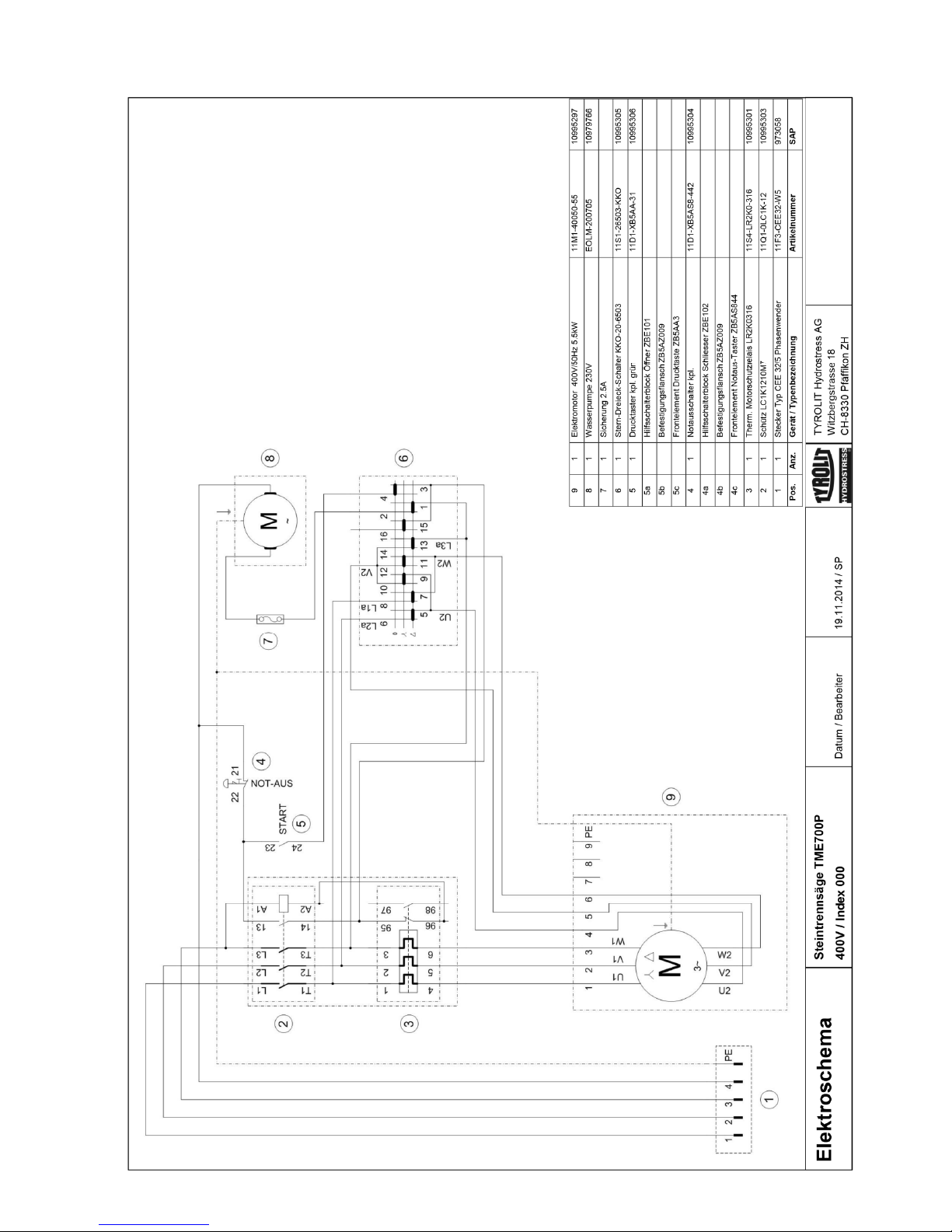

9. Electric scheme

10. Declaration of conformity

Page 4

4

1.

Basic safety instructions

1.1

Warnings and symbols in this manual

Danger! Points out that serious or even fatal injuries may result if not followed.

Caution! Points out that injuries may result if not followed.

Notice! Points out that damage to the machine or other equipment may result if not followed.

1.2

Principle of intended use

Danger! 1.2.1 The stone cutoff saw is designed exclusively for wet sawing of building blocks made of

mineral materials. Sawing of wood or metal is prohibited!

The manufacturer/supplier is not liable for damages resulting from improper use.

Compliance with the operating manual and observation of inspection and service

1.2.2 Use the machine only in correct working order and for its intended purpose. The operator

requirements are essential components of proper use.

must follow the instructions in the operating manual and be fully aware of the safety

requirements and hazards posed by the machine. In particular, any faults that may

compromise safety must be repaired immediately.

1.3

Organisational measures

1.3.1 Always keep the operating manual readily available at the location where the machine is used!

Danger! 1.3.2 lnstruct users to observe supplements to the operating manual as weil as all generally

applicable legal and other mandatory regulations on accident prevention and

environmental protection!

Obligations of this nature may also relate to the use of dangerous substances, for

example, or the wearing of personal protective equipment or to road traffic regulations.

Danger! 1.3.3 Personnel assigned to work with the machine must have read the

operating instructions and, in particular, the chapter on safety before beginning work.

Reading the manual for the first time when working on the machine is too late.

This applies especially to persons who work on the machine only occasionally, such as

those performing set-up and maintenance.

Page 5

5

1.3.4 Check at least from time to time whether personnel are performing the work in

compliance with the operating manual and paying attention to risks and safety

factors!

Caution! 1.3.5 Use personal protective equipment where necessary or if required by regulations.

Danger! 1.3.6. Obey all safety and danger notices on the machine!

Danger! 1.3.7 Ensure that all safety and danger notices on the machine remain clearly legible!

Danger! 1.3.8 In the event of safety-relevant changes to the machine or its operating performance,

stop the machine immediately and report the malfunction to the responsible

authorities/ person!

Danger! 1.3.9 Never make any modifications, additions or conversions which might affect safety

without the supplier's approval!

Danger! 1.3.10 Use only manufacturer's original parts!

Danger! 1.3.11 Observe the stipulated periods or the periods given in the operating manual for

inspections! The machine must be inspected annually by an expert.

1.3.12 The machine must be thoroughly cleaned before inspection.

Danger! 1.3.13 The power cord must be unplugged before all inspection or repair work.

1.4

Personnel selection and qualification; fundamental duties

Danger! 1.4.1 Only persons aged 18 years and over and who have been instructed on how

to operate the machine may be entrusted with operating it independently.

Danger! 1.4.2

Danger! 1.4.3

Danger! 1.4.4

Danger! 1.4.5 Personnel who are being trained, instructed or in training as part of a general

People must not remain unnecessarily on the machine or in its area of movement!

During all machine movements, operating personnel must always ensure that they

do not endanger themselves or others .

Work on electrical equipment on the machine may only be carried out by an

electrician or by instructed persons under the guidance and supervision of an

electrician in accordance with electrical regulations.

education programme may only be permitted to work on the machine while under

the constant supervision of an experienced person !

Page 6

6

1.5

Safety instructions during specific operating phases

1.5.1

1.5.1.1 Avoid all actions and working methods which may compromise safety.

Danger! 1.5.1.2 Take steps to ensure that the machine is operated only in a safe and proper

1.5.1.3

Danger!

Danger! 1.5.1.5 The stone cutoff saw is designed exclusively for wet sawing of building blocks.

Danger! 1.5.1.6 The machine must not be connected to a circuit without a ground-fault circuit

Danger! 1.5.1.7 Before beginning cutting operations each day, check the following:

Normal operation

condition!

Check the machine for visible external damage and defects at least once per shift.

lmmediately report any changes (including in operational performance) to the appropriate

office/individual! lf necessary, stop the machine immediately and make it secure.

1.5.1.4 In case of malfunction, stop the machine immediately and make it

secure. lmmediately repair any malfunctions!

Sawing of wood or metal is prohibited!

interrupter (FI) in the electrical line or distribution box.

- condition of the diamond saw blade (cracked saw blades must be replaced - when

in doubt, by an expert)

- functional condition of the safety devices

- adequate cooling water supply - dry sawing is not permitted!

Danger! 1.5.1.8 Do not jam saw blade.

Danger! 1.5.1.9 The electrical plug must not be pulled when the machine is running.

Notice! 1.5.1.10 When there is danger of freezing, remove the water pump from the pan

(do not switch on pumps that are already frozen - thaw them out slowly).

1.5.2 Special work in conjunction with use of the machine and maintenance and repairs

during operation; disposal

Caution! 1.5.2.1 Observe all the setting, maintenance and inspection activities and timetables,

including instructions for replacing parts/secondary devices, as described in the

operating manual! Only technically qualified personnel should carry out these

activities.

Caution! 1.5.2.2 Brief operating personnel before beginning special operations and maintenance

work! Appoint supervisory personnel.

Danger! 1.5.2.3 lf the machine is completely shut down during maintenance and repair work, it must

be mechanically secured to prevent accidental activation.

Page 7

7

Note 1.5.2.4 Before cleaning the machine with water or other cleaning agents, cover/seal all

openings that, for reasons of safety and/or functioning, water/steam/cleaning agents

must not be allowed to enter. Particularly endangered are electrical motors, switches

and plug connections. Cleaning with a steam jet is not permitted.

Note 1.5.2.5 After cleaning, the covers and tapes must be removed completely!

Danger! 1.5.2.6 Always tighten loose screw connections during servicing and maintenance work!

Danger! 1.5.2.7 Any safety devices removed during set-up, maintenance or repair must be

reinstalled and checked immediately upon completion of the maintenance and repair

work!

1.5.2.8 Dispose of fuel and consumable materials and replacement parts in a safe and

environmentally-friendly manner!

1.6

Notice on specific hazard types

1.6.1 Electricity

Danger! 1.6.1.1 Only use original fuses with the specified amperage! lf the electrical power supply is

interrupted, shut down the machine immediately!

Danger! 1.6.1.2 Perform maintenance or repair work only when the machine is separated from the

electric circuit.

Danger! 1.6.1.4 The electrical equipment on the machine should be inspected/checked on a regular

basis. Defects, such as loose connections or scorched cables, must be repaired

1.6.2

Dust

1.6.2.1 Observe applicable national regulations when working in enclosed spaces!

immediately .

Page 8

8

1.7 Transport

Danger! 1.7.1 Use a four ring suspension gear of sufficient carrying force when dislocating

the machine.

Danger! 1.7.2 Determine an expert to give the appropriate handling instructions for the lifting

procedure!

Danger! 1.7.3 Lift machine according to the instructions as provided in the operation manual

(stop points for load carrying devices etc.) by means of the lifting gear in a

workmanlike manner!

Danger! 1.7.4 Use only suitable transport vehicles with sufficient lifting capacities!

Danger! 1.7.5 Secure the load reliably. Use suitable lifting points!

Danger! 1.7.6 Disconnect all power sources before moving the machine, even for very short

distances! Ensure that the machine is correctly reconnected to the power supply

before restarting !

Danger! 1.7.7 Restart the machine strictly in accordance with the operating manual!

Page 9

9

2.

Saw blade

diameter

650/700

mm

Height

910 mm

Machine description

2.1

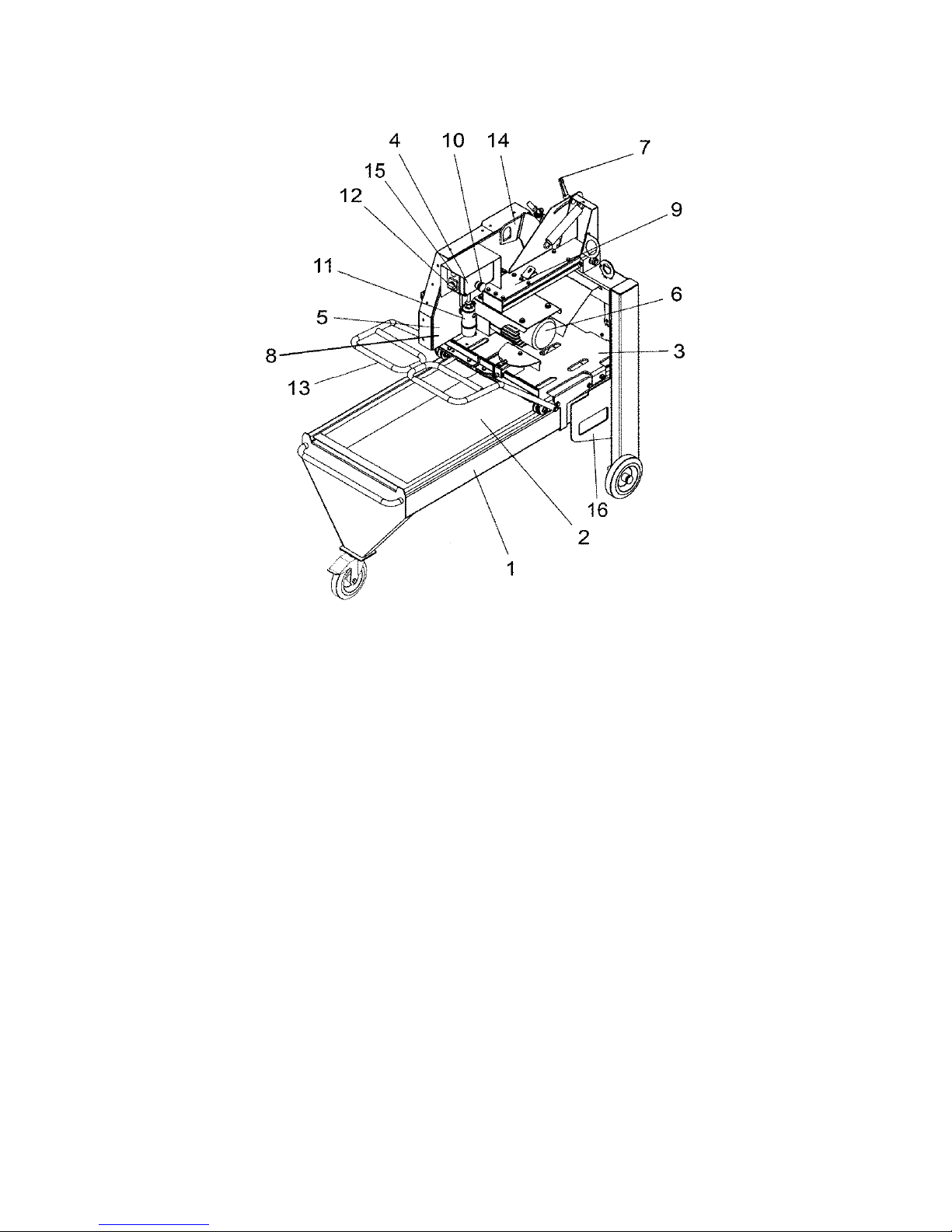

Overview of components

ltem 1 Frame

ltem 2 Water tub

ltem 3 Saw table

ltem 4 Switchbox

ltem 5 Saw hood

ltem 6 Motor

ltem 7 Cutting height adjustment

ltem 8 Saw blade

ltem 9 Saw head

ltem 10 Emergency switch

ltem 11 Connector plug

ltem 12 Switch

ltem 13 Feed grip

ltem 14 Jack ring

Item 15

Switch start

Item 16

2.2

Protective equipment

suspension point

ltem 5 - Saw hood

ltem 10 - Emergency switch

2.3

Technical data

Motor power

Operation voltage

Current consumption

Connected load

Safety class

Saw blade shaft r.p.m. 1380 r.p.m.

Saw blade arbor

Cutting depth

Cutting length.

Table width

Width

Lenght 1470 mm

Weight 220 kg

5,5kW

400V

13 A

400 V/ 32 A

IP 55

60mm

245/270 mm

600mm

630mm

1350 mm

Subject to technical changes!

Page 10

10

Page 11

11

2.4

Sound

power

level LwA

Sound

power

level at the

Noise emission values

The measurements were made in accordance to the norms EN ISO 3744, EN ISO 11201 and EN

12418. Therefore it was used a standard saw blade Type W3 0700 mm (not a silent blade).

Parameter

continuous sound

pressure level

at work LoA

ear of user

Value

91 dB (A)

92 dB (A)

106 dB (A)

2.5 Vibration at the grab handle

When cutting the oscillation total value is under 2,5 m/s

2

.

3.

Assembly and initial preparation for operation

3.1

Assembly tools

- Combination wrench size 13/46

3.2

Set up and assembly

- Put the saw on a clean and capable of bearing ground

- Remove the packing

3.3

Installation of the saw blade (or checking the installation)

- Loose the clamp handle (item 7).

- Lift up the saw head and tighten the clamping lever (item 7).

- Remove the side protecting sheet metal.

- Remove the flange nut (left-hand thread) and thrust washer.

ATTENTION! When installing the saw blade, observe the following:

-

All receptacle surfaces must be clean.

- Rotation direction arrow on the saw blade must match the one on the hood.

- Use only diamond saw blades provided by the manufacturer.

- lnstall thrust washer and flange nut. (Combination wrench size 13/46).

- Mount the side protecting sheet metal.

3.4

Saw preparations

- Fill the tub with water until the pump is submerged.

- Open the water valve.

- Plug the supply line cable (400 V, 32 A) into the connector plug (item 11).

- Check protective equipment (see 2.2).

Page 12

12

Page 13

13

3.5 Test direction of rotation of the saw blade

- Press the switch start (15).

- Switch the Star-delta-switch (item 12) short to "Star''.

- Check the direction of rotation of the saw blade.

*

3.6 Change direction of rotation

The direction of rotation is clockwise, seen from the left (direction arrow on the saw hood).

3.7

- Turn off main switch (item 12).

- Remove power cord from the socket (item 11).

- Change phase of the power supply plug (item 11) with a screwdriver.

Test run

- Place block on table.

- Press the switch start (15)

- Push the block to the stop.

- Press the main switch (item 12) to "Star".

- Wait until the motor has a regular revolution (regular sound)

- Turn the switch (item 12) further to "triangle"

ATTENTION! ls the saw blade adequately supplied with cooling water?

Caution!

-

Dry cutting is not permitted.

- lnadequate cooling water results an early wear or malfunctioning of the saw blade.

- Start feed movement via handle (item 13) on the saw table.

*

First cut with low feed speed.

*

Adjust feed speed to the feed force.

4.

Transport

4.1 Preparation for transport

- Remove the power cord from the saw.

- Empty the water from the tub.

- Saw blade height adjustment (item 7) is tightened.

- Lock the device on the saw table

4.2 Displace with the crane

- Hang up the suspension gear with sufficient carrying force into the eyelets provided for

this purpose at the suspension point (Pos.16).

- By displacing-keep the saw in youre By

4.3 Transport with the truck

- fix the saw on the suspensions point (Pos.16)

Page 14

14

Page 15

15

5.

Operation

5.1

Setting up the saw

- Set up the saw on a clean and stable foundation.

-

Test the saw's steadiness.

5.2 Saw preparations

5.3

Test the direction of rotation of the saw blade

(see 3.4)

(see 3.5)

5.4 Changing direction of rotation

5.5

Sawing

(see 3.7)

(see 3.6)

5.6

Cutting guality of the saw blade

lf the saw blade looses its sharpness after langer use, you can "sharpen" it by making some cuts

in sand-lime bricks or similar material.

5.7 Cooling water

Very dirty water reduces the life of the pump and saw blade.

- By frequent use replace the water daily and remove the saw sludge.

- Also clean the pump's suction strainer with each water change.

5.8

Height adjustment

The saw blade height adjustment is needed for:

- cutting through blocks with height over 270 mm in the reversing tool.

Performing the height adjustment.

- The motor is turned off.

- Loosen the clamping lever (item 7).

- Set the saw head to the desired height.

- Tighten the clamping lever (item 7).

5.9

Changing the saw blade

(see 3.3)

6.

Disassembly

- Turn back the star delta switch (item 12).

- Remove the connecting cable.

- lf there is danger of freezing, take the water pump out of the water and let the water drain off.

ATTENTION! Frozen pumps have to be thawed out before switching them on.

-

Transport (see 4)

Page 16

16

7.

Maintenance

-

Thoroughly clean the saw once per week (in off circuit condition) .

8.

Malfunctions

Malfunction

Possible cause

Remedv

Motor does not run

lncorrect saw blade rotation direction

Motor shuts down during sawing,

but can be restarted after a short

break.

No water at saw blade

- Power cord is defective

- Motor is defective

- Switch is defective

- Motor incorrectly polarised

- Feed too fast

- Saw blade blunt

- Saw blade worn

(coating > 2 mm)

- Pump is not running

- Line system clogged

- New power cord

- May only be repaired by

an electrician

- Reverse the phase inverter

- Cut with slower feed

- Sharpen saw blade with

10- 15 cuts in sand-lime

bricks

- Change the safety

device in the switchbox.

Only by an electrician

expert.

- Clean line system

Page 17

17

Page 18

18

Loading...

Loading...