Page 1

10981449 en / 06.06.2009

Operating Instructions

TBE350** Table Saw

Index / Indice «000»

Page 2

2

Manufacturer's address:

TYROLIT Hydrostress AG

Witzbergstrasse 18

CH-8330 Pfäffikon

Switzerland

Tel. +41 (0)44 952 18 18

Fax +41 (0)44 952 18 00

www.hydrostress.com

TYROLIT Hydrostress AG reserves the right to make technical changes without prior notice.

Copyright © 2003 TYROLIT Hydrostress AG, CH-8330 Pfäffikon ZH, Switzerland

All rights reserved, in particular copyrighting and translating rights.

Printing of this operating manual, including extracts from it, is prohibited.

No parts of it may be reproduced in any form or processed using electronic systems, duplicated

or disseminated without the written permission of TYROLIT Hydrostress AG.

Page 3

3

TBE350** Owner manual text

TABLE OF CONTENTS

Contents……………………………...........

Safety precautions………………………..

General safety rules…………………….

Health warnings………………………….

Unpack, assembly & set-up…………….

Diamond blade installation……………...

Inspection & specification……………….

Features……………………………………

Cutting table assembly………………….

The rip guide…………………………….

Cutting depth……………………………...

Water pump installation………………….

Slide-In legs………………………………

Electric motor specifications…………….

Do’s & Don’ts for blades…………………

Saw maintenance…………………………

Troubleshooting…………………………..

Customer service…………………………

Contact us…………………………………

Warranty……………………………………

Spare parts list……………………………

Explode view…………………………….

3

4

5

5

6

6

7

8

9

10

10

11

12

13

14

15

16

19

19

20

21

22

Page 4

4

SAFETY PRECAUTIONS

Saw blade should be inspected daily for excessive wear, core cracks, and arbor

damage. Replace any blade that shows signs of damage.

• To mount blade, clean arbor and outer flanges, tightening nut securely.

• DO NOT place any portion of body in line with blade while it is rotating.

• To reduce risk of electrical shock, it is recommended to use GFCI and refer

servicing to qualified professional.

We recommends the use of these safety items when operating the saw:

USE PROPER GROUND CICUIT !

USE BLADE GUARD WHEN OPERATING SAW !

ALWAYS WEAR SAFETY GEAR !

Page 5

5

GENERAL SAFETY RULES

• Never use the machine improperly or work in an unsafe manner.

• Always wear safety goggles, dust mask, and ear protection while operating

the saw (to comply with ANSI-Z87.1).

• Always remain alert when the saw is in use. Failure to pay attention on the

operator’s part may lead to serious injury.

• Before you start working, familiarize yourself with the work site and its

surroundings. Take notice of circumstances, which may impede working or

traffic, observe soil conditions (good bearing or not), and take measures to

ensure safety (i.e. the shielding of road works from public traffic).

• Take measures to ensure that the machine is in a safe and trouble-free

condition prior to usage. Use the machine only when all protective devices

(i.e. guards, noise absorbers, emergency-off devices) are operating in the

intended locations.

• A visual check of the machine must be made at least once a shift to ensure

that visible damages or faults are recognized. Any changes (including

changes in the performance or behavior of the machine) must be reported to

the supervisor. If necessary, stop the machine at once and secure it.

• In the case of a malfunction, stop the machine immediately and secure it. Fix

the problem as soon as possible.

• For starting and stopping the machine follow the operating instruction steps

and observe any indicator lights.

• Before switching the machine on make sure that the activated machine will be

of no danger to anyone.

• Be sure to connect the plug to a properly grounded receptacle to reduce the

risk of electric shock.

HEALTH WARNINGS

Some dust are created by power sanding, sawing, grinding, drilling, and cause

other construction activities contains chemicals known to cause cancer, birth

defects or other reproductive harm. Some examples of these chemicals are:

• Lead from lead based paints.

• Crystalline silica from bricks and cement and other masonry products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type

of work. To reduce your exposure to these chemicals: work in a well ventilated

are, and work with approved safety equipment, such as those dust masks that

are specially designed to filter out microscopic particles.

Page 6

6

UNPACKING, ASSEMBLY & SET-UP

Open the container, carefully lift the saw frame handles and place it on a flat,

level working area. Be certain that you have the following items before you

discard the container:

• Saw

• 45° / 90° rip guide

• Universal wrench

• Owner’s manual

DIAMOND BLADE INSTALLATION

1. Move the blade shaft cover upwards.

To remove the blade lock nut, open

the shaft space.

2. Place the blade onto the blade shaft.

Make sure that the directional arrow is

pointing in the direction of the shaft

rotation

3. Lock the blade lock nut with the outer

flange. Use the multiple wrench

provided to fasten the blade tightly

Page 7

7

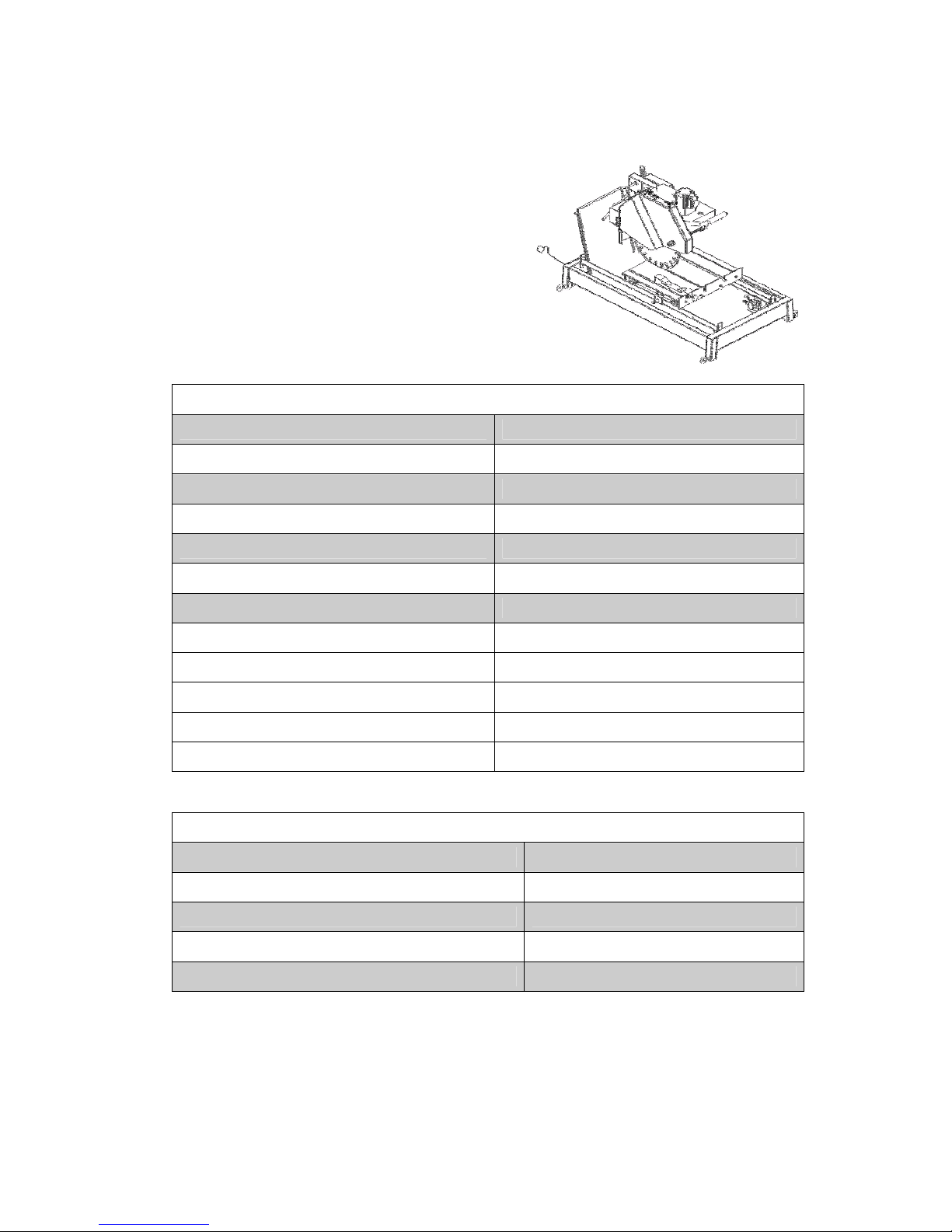

INSPECTIONS & SPECIFICATION

The compact TBE350** table saws are

shipped completely assembled and ready

for use except for the diamond blade.

Inspect the saw for shipping damage. If any

damage is found, contact the shipper

immediately and file a freight claim. We are

not responsible for any freight related

damages. Remove the saw from the

shipping container.

TBE350** SPECIFICATIONS

Power

2,2 kW

Volts

230 V (110 V)

Amps

10 A (20)

Cycles

50 Hz (60 Hz)

Blade Shaft Speed

2,800 rpm

Max. Blade Size

15,7” / 400 mm

Arbor Size

1” / 25,4 mm

Max. Cutting Length

23,6” / 600 mm

Length

1140 mm

Width

640 mm

Hight

1230 mm

Wight

79 Kg

NOISE LEVEL AND VIBRATIONS

Parameter Wert

Noise level at the ear of the user (Leq) 81.9 dB(A)*

Noise level at workplace (LPA) 69.3 dB(A)*

Sound power level in acc. ISO 3744 (LwA) 89.3 dB(A)*

Vibrations DIN EN ISO 5349-2 < 2.5 m/s²

*Value applies under the following condition: With Sawblade Ø350mm Type

EB No. 5696.

Higher noise levels may be generated in cutting operation.

ATTENTION! Hearing protection must be worn when 90 dB(A) is exceeded!

Page 8

8

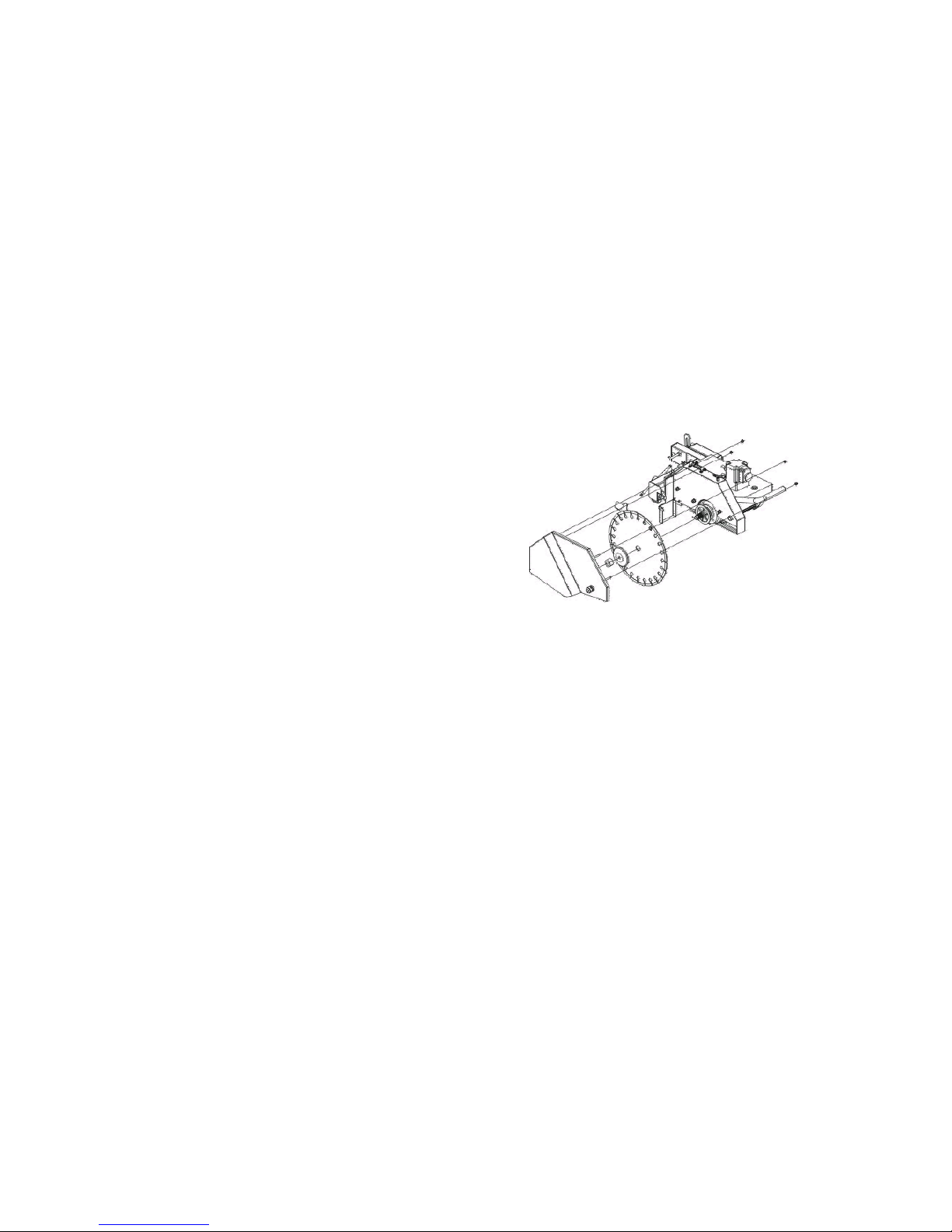

FEATURES

The TBE350** table saw is designed for the professional contractor in mind. It

enhances performance with a multitude of features facilitating operation.

Page 9

9

CUTTING TABLE ASSEMBLY

To install the cutting table to the machine:

1. Set the cutting table on the rails

2. Install the screw and brackets to

the cutting table

3. To remove the cutting table do

the reverse of the above two

steps.

THE CUTTING TABLE

Features:

• The heavy-duty cutting table with

steel wheels provides the durability

to handle large materials.

Only use the Ø14" (350 mm) blade for this saw. Setting smaller size of

diamond blade may grab the material being cut, causing damage and

possibly injury.

USE PROPER GROUND CICUIT !

USE BLADE GUARD WHEN OPERATING SAW !

ALWAYS WEAR SAFETY GEAR !

Page 10

10

THE RIP GUIDE

Steps to use the 45º / 90º rip guide

1. Set the rip guide by positioning it on the desired dimension and tighten the

threaded knob. Make sure that the rip guide is firmly tightened to avoid

slippage. The rip guide can be used for 90º rip cuts and 45º angle cuts from

both the left and right side. (Note the straight and 45º angled slits on the

bottom of the rip guide

2. After the rip guide is positioned for the desired cut, place material flat against

the rip guide and the measurement rail. After the rip guide is positioned for

the desired cut, place material flat against the rip guide and the measurement

rail. For 45º rip cuts, place the corner of material in the open slot of the

measurement rail.

3. Simply line up the material being cut with the appropriate pre-marked lines on

the cutting table.

4. Now you are ready to make your cut

CUTTING DEPTH

The recommended cutting depth is ¼" below the cutting table surface. The

cutting clearance has been fixed from original designed.

Only use the Ø14" (350 mm) blade for this saw. Setting smaller size of

diamond blade may grab the material being cut, causing damage and

possibly injury.

max. Blade Diameter max. Cutting Depth

400 mm 120 mm

Page 11

11

WATER PUMP INSTALLATION

1. Remove the water pump from the box and check that it is not damaged.

2. Place the pump into the middle of the water tray along its side so that the

water outlet is positioned horizontally. Connect the water hose from the blade

guard to the pump and plug the power cord into the 3-prong receptacle.

3. Fill the water tray so that the water intake is fully immersed.

4. Be sure to support the pump during installation to prevent pump failure or

damage.

Disconnect the pump before attempting to handle the pump.

Never operate pump without water in the tray

Page 12

12

SLIDE-IN LEGS

1. Slide each of the four legs into the housing at the four corners of the saw

frame.

2. After sliding the leg as far as possible, lock the leg in place with the ring bolt

located on the leg housing.

Page 13

13

ELECTRICAL MOTOR SPECIFICATIONS

Features:

Power 2,2 kW

Volts 230 V (110 V)

Amps 15 Amps (30A)

otor RPM 2800 RPM

Cycle 50 Hz (60 Hz)

Recommendations:

It is recommended that a 15 A (30 A) CIRCUIT be used while operating this saw.

This will prevent any loss of power or interruption.

Always plug saw as close as possible to the power source while operating. This

will allow you to receive optimum electricity.

To avoid permanent motor damage you must use the correct extension

cord. Never use more than one extension cord at a time. Follow the

chart for proper size:

Wiregauge Length of cord

2,2 kW – 230 V (110V)

Ø5 mm (Ø10 mm) 8 m

Ø8 mm (Ø16 mm) 15 m

Ø15 mm (Ø32 mm) 20 m

Page 14

14

DO’S AND DON’TS FOR BLADES

WET CUT BLADES

DO'S

• Inspect blades daily for cracks or uneven wear.

• Always use appropriate blade for material being cut.

• Inspect arbor shaft for uneven wear before mounting blade.

• Always use blades with the correct arbor shaft size.

• Ensure that blade is mounted in the correct direction.

• Secure the blade to the arbor with a wrench.

• Use proper safety equipment when operating the saw.

• Periodically check the blade for cracks or bond fatigue.

• Always have a continuous flow of water on both sides of blade.

DON'TS

• Do not operate the saw without safety guards in position.

• Do not operate the saw with blades larger than Ø 15,7" (400 mm)

• Do not cut dry with blades marked "Use Wet".

• Do not exceed manufacturer's recommended maximum RPM.

• Do not force blade into material let blade cut at its own speed.

DRY CUT BLADES

DO'S

• In addition to the following, always follow wet recommendations.

• Use appropriate blade for material being cut.

• Inspect segment blades for segment cracking or loss.

• Do not use damaged blades.

• Use proper safety equipment when operating the saw.

DON'TS

• In addition to the following, always follow wet recommendations.

• Do not make long cuts with dry blades--allow them to air cool periodically.

• Do not use the edge or side of blade to cut or grind.

• Do not attempt to cut a radius or curve.

• Do not cut too deep or too fast into the material.

• Do not cut any material not recommended by blade manufacturer.

Page 15

15

SAW MAINTENANCE

Maintenance interval Wath to do for maintenance and care

After ecery use ot the

machine

- Remove dirty water from container.

- Remove dirt and mud from the bottom of the container

- Rinse teh immersion pump with fresh water to prevent water

pump dogging from residual dirt.

After wet clearing and

before using the machine

again

Connect the machine to an electric power outlet equipped with

a“GFI” safety power breaker. If the safety power breaker cuts off

the electrical power supply, do not try to operate the machine but

have it checked by an authorized dealer first.

Before not using the

machine for a prolonged

period of time

Clean and lubricate all movable part.

Before not using the

machine for a prolonged

period of time

- Check that the stand is safely fixed.

- Check that all screw joints and nuts are fixed.

- Check that the roller table is in its guides and that it easliy

moves to and fro.

- With the saw blade removed, switch on the motor for an

instant and switch it off again. If the motor does not run, have

the machine inspected by a qualified electrician.

- Check that the immersion pump works properly. Turn on the

cooling water tap and switch the machine on. If the pump

does not give any water or only a little, switch the machine off

at once. Clean the pump, or replace of necessary.

Ambient temperture

below 0°C

(operation in winter)

To prevent the water in the pump and cooling system from

freezing, remove the water after using the machine or when there

will be a long break. Make sure that the cooling system is entirely

drained so that there is no water left inside the pump, water hose

and bearing housing

For your safety, before performing any maintenance on the saw turn off

the power switch and unplug the power card

Page 16

16

TROUBLESHOOTING

Problem Possible cause Solution

Power cord not properly

fixed / plugged in

Check that the machine is properly

connected to the power supply.

Power cord defective Have the power cord checked, replace

if necessary.

Main power switch

defective

Have the main power switch checked

and replace if necessary by a qualified

electrician.

Loose eleectrical

connection inside the

electric system

Have the whole electric system of the

machine checked by a qualified

electrician.

Machine does not run

when switched on

Motor defective Have the motor checked and replace if

necessary by a qualified techician.

To much pressure exerted

while cutting

Exert less pressure when cutting

Incorrect specification for

saw blade

Use a saw blade which corresponds to

the material being cut

Motor stops

(power cut out)

Saw has a defective electric

system

Have the electric system of the saw

checked by a qualified technician

Power cord/extension cable

too long or cable still wound

up inside cable drum

Use a power cord/ectension cable of

the rated length, use a cable drum with

cable fully extended

Power network is

insufficient

Observe the electrical ratings of the

machine and connect it only to a power

network which complies with these

ratings

Poor machine

performance little

power

Drive motor no longer runs

at rated speed (r.p.m.)

Have the motor checked by a qualified

electrician and have it replaced if

necessary

Page 17

17

TROUBLESHOOTING

Problem Possible Cause Solution

Irregular run of the

saw blade

Poor tension in the blade

material

Return the saw blade to the

manufacture

Saw blade is damaged or

bent

- Have the saw blade

aligned/flattened

- Clean the receiving flange

- Solder the diamond segments of

the old blade onto another swa

blade or use a new blade

Flange of the saw blade is

damaged

Replace the saw blade flange

Saw blade wobbles

when running

Shaft of the motor is bent Replace the electric motor

Diamond segment

becomes loose

Overheating of the saw

blade, cooling water not

sufficient

Have the diamond segment soldered on

the blade again, ensure optimum flow of

cooling water

Wrongtype of saw blade Use harder saw bldes

Shaft of motor causes

wobbling

Have bearings of the motor or the motor

replaced

Excessive wear

Overheating Ensure optimum flow of cooling water

Saw blade too hard Use a softer blade

Fixed flange is worn out Have the fixed flange replace

Cracks in or near the

diamond segment

Motor shaft bearing Replace the bearing of the motor shaft

Page 18

18

TROUBLESHOOTING

Problem Possible cause Solution

- Saw blade type is

unsuitable for the

meterial being cut

- Saw blade type is

unsuitable for the

machine performance

- Saw blade too hard

Use appropriate type of saw blade

Saw blade is blunt

Diamond segments are

blunt

Sharpen the diamond saw blade

Poor tension in the blade

material

Return the saw blade to the

manufacture

Too much load placed on

the saw blade

Use a suitable saw blade

Appearance of cut is

not optimal

Diamond segments are

blunt

Sharpen the saw blade

The arbor otr the saw blade must be

fitted with an appropriate adapter ring

The center hole in the

saw blade has become

wider due to wear

The saw blade has slipped

on the motor shaft when

running

Check the receiving flange and have it

replaced if necessary

Saw blade shows

blooming colors

Lateral friction when cutting The material feed is too high; proceed

more slowly

Ensure that the direction of feed is

absolutley parallel to the saw blade

Material is not being feed

parallel to the saw blade

Adjust the roller table/have it adjusted

Poor tension in the blade

material

Have the saw blade tensioned

Grinding marks on the

saw blade

Too much load on the saw

blade

The material feed is too high, proseed

more slowly

Page 19

19

CUSTOMER SERVICE

AFTER SALE SERVICE

All customer service (technical questions, re-order of parts, etc.) will be provided

by us.

CLAIMS FOR LOST OR DAMAGED GOODS

If merchandise is delivered in damaged condition or cartons are missing, a

notation must be placed on all papers signed by the receiver. If unreported or

concealed damages are noticed after delivery, the carrier should be contacted by

telephone and if carrier fails to send an inspector within five days, a request

should be made in writing to the carrier, confirming the telephone request for an

inspection.

All requests for credit due to transportation loss or damage should be

accompanied by properly signed papers. A claim for loss or damage must be

filed with the carrier within 60 days from the shipping date for UPS or other

common carriers. Credit cannot be allowed for damage claims that are not

properly substained with supporting papers or received by us too late for timely

filing with the carrier.

CONTACT US

We pride ourselves on our customer service. If you have any questions

regarding our products, whether it may be product inquiry or troubleshooting,

please don’t hesitate to contact us at our corporate office. We will do our best to

answer your questions. In some cases we may even refer you to a local sales

representative that can better service you.

Page 20

20

WARRANTY

For a period of one (1) year from the original date of purchase, if the product is

determined to be defective, we will repair or replace the product, at its option, at

no charge to the customer, or pay the associated repair costs to an authorized

service facility. All replacement parts, new or rebuilt, supplied at our option for

repairs will be warranted for the remainder of the original warranty period of one

(1) year. All defective products or components replaced under this limited

warranty will become our property. This limited warranty excludes all components

not manufactured by OUR COMPANY, which are listed below with their

corresponding independent warranty periods. Such components are warranted

by their respective manufacturer, whose warranty will be the governing warranty

for that particular product.

Excluded Components Manufacturer’s Warranty

Electric Motors 1 Year

EXCLUSIONS FROM WARRANTY

We cannot assume responsibility for claims arising from abuse of the our

product:

• Due to abuse by the Purchaser in their processing.

• Due to improper installation practices or procedures.

• Due to abuse or improper usage by the end-user.

• Due to contaminants, including, but not limited to, exposure to salt or fresh

water, chemicals and any other form of contamination from a source outside

of our control.

LIMITED WARRANT

This product is covered by a one year warranty from the date of purchase. If the

product is defective in workmanship or material, TYROLIT Hydrostress AG will

repair and /or replace it free of charge upon returning the product to

distributor/dealer in its original packaging.

This warranty does not cover normal wear or damage resulting from operator

abuse. TYROLIT Hydrostress AG obligations under this warranty shall be limited

to the repair and/or replacement of the product. TYROLIT Hydrostress AG shall

not be liable for consequential damages resulting from the improper use of the

product. This warranty is void if the product or any of its components are

modified, altered, or in any way changed. Selected components such as

motor/engines are excluded from this warranty and are subject to the

manufacturer’s warranty. This warranty is in lieu of all warranties expressed or

implied.

Page 21

21

DISPOSAL

GENERAL

The operator can recycle or dispose of the Table saw

himself provided he observes the statutory provisions. In

order to dismantle the Table saw correctly and to properly

remove the materials some knowledge in the area of

mechanics and knowledge about differentiation of waste

materials is necessary.

If during correct disposal doubts arise that represent a

hazard for persons or the environment, the after-sales

service of TYROLIT Hydrostress AG will be happy to

provide information.

DANGER

Voltage warning

Before working in an area identified in this way, the

installation or device must be fully disconnected from

the power (voltage) and secured against being

accidentally powered up again.

Failure to head this warning may lead to death or

serious injury.

PERSONNEL QUALIFICATIONS

Only personnel with basic technical training and who are in

a position to identify the various material groups should be

involved in disposal.

DISPOSAL REGULATIONS

The normal local and regional rules and guidelines must be

observed when disposing of the machines making up the

Table saw.

Page 22

22

DISPOSAL OF TABLE SAW

DISPOSAL REGULATIONS

The dismantled parts of the table saw are sorted by material and sent separately to the

appropriate collection points. Ensure that the following parts in particular are properly

disposed of.

The Table saw consists of the following materials:

Cast aluminium Rolled aluminium products

Bronze Steel

Rubber Rubber / Nylon fabric

Synthetic grease Plexiglas

OBLIGATION OF NOTIFICATION

When a Table saw is taken out of service and disposed of the manufacturer TYROLIT

Hydrostress AG or the corresponding service centre must be informed of this.

Page 23

23

TBE350** Spare Part List

1 Water hose plug EOSM-121 01 034

10981925

2 Outer blade guard EOSM-131 04 034 10981926

3 Inner blade guard EOSM-113 02 034 10981927

4 Water flow “T” adapter EOSM-123 04 005 10981928

5 Water valve EOSM-130 01 005 10981929

6 Hose clip EOSM-113 28 005 10981930

7 Water splash guard EOSM-130 04 034 10981931

8 Motor bracket EOSM-131 03 034 10981932

9 Switch 230 V EOSM-132 01 041 10986216

Switch 110 V EOSM-132 05 034 10986025

10 Cabl e sleeve EOSM-122 08 033 10981934

11 Back splash guard EOSM-123 06 034 10986217

12 Splash g uard holder EOSM-112 25 034 10986218

13 Angle lockin g handle EOSM-130 01 034 10981937

14 Cro s s beam EOSM-131 06 034 10981938

15 U style ho se clip EOSM-113 37 033 10981939

16 Load spring EOSM-112 18 034 10981940

17 Drai n plug EOSM-130 02 034 10981946

18 Guide rail EOSM-113 03 041 10986219

19 Chai n EOSM-131 19 033 10981943

20 Main frame EOSM-131 01 041 10986220

21 Height slot EOSM-113 10 034 10981945

22 Heig ht locking handle EOSM-130 01 047 10986221

23 Multiple wren ch EOSM-113 28 034 10981947

24 Wrench bracket EOSM-113 29 034 10981948

25 Bolt EOSM-121 01 002 10986222

26 Leg with wheel EOSM-130 06 034 10986223

27 Pump adapter EOSM-121 11 001 10981951

28 Wate r pump 230 V EOSM-132 03 005 10981952

Water pump 110 V EOSM-8000060101 10986026

29 Straight leg EOSM-112 17 034 10981953

30 Roller wheel EOSM-112 31 033 10981954

31 Sleeve EOSM-112 13 005 10981956

32 Cutting table EOSM-131 12 034 10986224

33 Cutting table fence EOSM-113 20 034 10981958

34 Guide Wheel EOSM-112 29 033 10981959

35 Cutting table locking assembly EOSM-130 05 034 10981960

36 Rip guide EOSM-130 03 005 10986225

37 Motor 230 V EOSM-132 01 005 10981961

Motor 110 V EOSM-1900160101 10986027

38 Inner flange EOSM-111 06 005 10986226

39 Blade

40 Outer flange EOSM-111 02 013 10981963

41 Lock Nut M20 (left) EOSM-338019 977631

42* Cable with connector CEE 16 110V EOSM-7200020101 10986028

Page 24

24

TBE350** EXPLODE VIEW

Page 25

25

Declaration of conformity

Description: Masonry saw TBE350S

with electric engine 2.2 kW/110V or 230V

Type: TBE350S

Article number: 10981424 (110V)

Article number: 10981423 (230V)

Serial number: 35200001 – 3500_ _ _

Index: 001

Year of construction: 2009

The TYROLIT Hydrostress AG certifies that the inspected above

machine against the following guidelines and that we confirm

compliance with these standards:

Guidelines:

Machine Directive 98/37/CE, 2006/42/CE

2002/95/EC Restriction of the use of certain hazardous 2002/95/CE

substances in electrical and electronic equipment

Electrical Directive 93/68 EWG

Electromagnetic compatibility 89/336/CEE

Waste electrical and electronic equipment 2002/96/CE

Vibration Directive 2002/44/CE

Noise Emission 2000/14/CE

Standards:

EN 12418:2000 Masonry and stone-off machines for job site - Safety

EN ISO 14121 Safety of machinery: Principles of risk assessment

EN 61000-6-3 Electromagnetic compatibility

Tyrolit Hydrostress AG

Witzbergstrasse 18

CH-8330 Pfäffikon ZH

Pfäffikon, 07.04.2009

Mario Facchin

Head of Research and Development

Loading...

Loading...