TYROLIT Hydrostress SK-SD Operating Instructions & Spare Parts

Operating Instructions

Spare Parts List

10994442 en / 26.8.13

Wire saw SK-SD

Index 007

Operating Instructions

10994442 en / 26.8.13

Manufacturer’s address:

TYROLIT Hydrostress AG

Witzbergstrasse 18

CH-8330 Pfäffikon

Switzerland

Phone +41 (0) 44 / 952 18 18

Fax +41 (0) 44 / 952 18 00

TYROLIT Hydrostress AG reserves the right to make technical changes

without prior notice.

Copyright © 2005 TYROLIT Hydrostress AG, CH-8330 Pfäffikon ZH

All rights reserved, in particular the copying and translation rights.

The reprinting of these Operating Instructions, including extracts, is

prohibited. No parts may be reproduced or processed, copied or distributed

using electronic systems, in any form whatsoever, without the written

permission of TYROLIT Hydrostress AG.

Operating Instructions Overview

SK-SD / 007 I (II)

Overview

Page

0 Introduction 1

0.1 Congratulations!- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

0.2 Validity of these Operating Instructions - - - - - - - - - - - - - - 2

0.3 Standards - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

0.4 Delimitation of the system- - - - - - - - - - - - - - - - - - - - - - - - 2

0.5 Document structure - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3

1 Product description 1

1.1 Important information on the wire saw SK-SD- - - - - - - - - - 1

1.2 Technical data - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

2 Safety instructions 1

2.1 General- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

2.2 Safety principles - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

2.3 General safety rules - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3

2.4 Information and symbols- - - - - - - - - - - - - - - - - - - - - - - - - 4

2.5 Generally applicable warnings of residual dangers - - - - - - 5

2.6 Responsibility - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6

3 Design and function 1

3.1 General- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

4 Assembly / disassembly 1

4.1 Assembly / disassembly of the saw system - - - - - - - - - - - 1

4.2 Transport and place of installation - - - - - - - - - - - - - - - - - - 3

4.3 Assembly wire saw SK-SD - - - - - - - - - - - - - - - - - - - - - - - 3

4.4 Removal wire saw SK-SD- - - - - - - - - - - - - - - - - - - - - - - - 11

5 Operation 1

5.1 Operation wire saw SK-SD - - - - - - - - - - - - - - - - - - - - - - - 1

5.2 Troubleshooting- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

5.3 Putting into operation - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

6 Servicing and Maintenance 1

6.1 General- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

6.2 Maintenance and servicing table - - - - - - - - - - - - - - - - - - - 3

6.3 Warranty - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

6.4 Wearing parts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Overview Operating Instructions

II (II) SK-SD / 007

Operating Instructions Introduction

SK-SD / 007 0-1

0 Introduction

0.1 Congratulations!

You have decided to buy an advanced, tried and tested Hydrostress system and have thus acquired a highly sophisticated and reliable state-of-theart unit.

Thanks to our efforts in the quality assurance area, your Hydrostress system is another top-of-the-range Swiss product:

• High performance

• Reliable operation

• High portability

• Easy handling

• Low maintenance costs

Only using original Hydrostress spare parts provides quality and inter-

changeability.

In the case of neglected or inappropriate maintenance, we will be unable

to accept the warranty commitment as specified in our terms of delivery.

All repair work must be carried out by trained personnel only.

Should you need more details concerning your Hydrostress system in or-

der to keep it in perfect condition, please contact our after-sales service for

further information.

We hope that you will not experience any problems while working with your

Hydrostress system.

TYROLIT Hydrostress AG

Management

Copyright © Hydrostress, October 2006

TYROLIT Hydrostress AG

Witzbergstrasse 18

CH-8330 Pfäffikon

Switzerland

Phone +41 (0) 44 / 952 18 18

Fax +41 (0) 44 / 952 18 00

Introduction Operating Instructions

0-2 SK-SD / 007

0.2 Validity of these Operating Instructions

These Operating instructions are just one part of the documentation accompanying the wire saw SK-SD. These Operating Instructions are supplemented by the “Wire saws Safety Manual / System Description”, see

document structure 0.5, 0-3.

This manual is only valid for the following system:

Wire saw SK-SD

0.3 Standards

This Operating Manual has been prepared in accordance with CE Machinery Directive Appendix I and with the relevant standards in force at the time

of printing.

0.4 Delimitation of the system

These Operating Instructions describe the use of the wire saw SK-SD.

Operating Instructions Introduction

SK-SD / 007 0-3

0.5 Document structure

The wire saw SK-SD documentation is structured as follows:

0.5.1 Wire saws Safety Manual / System Description

Hydrostress Machines and components have a modular design and can be

assembled into various machine systems.

The “Wire saws Safety Manual / System Description” has been provided to

help you operate the wire saw systems safely.

0.5.2 Operating Instructions / Spare parts list wire saw SK-SD

0.5.2.1 Operating Instructions

These Operating Instructions describe the characteristics of the wire saw

SK-SD only.

0.5.2.2 Spare Parts List

The spare parts list is a standard part of the Operating Instructions.

0.5.3 Instruction leaflet

Instruction leaflets are used for system components that do not have their

own Operating Instructions, but still require information to be provided for

safe assembly or trouble-free operation.

Document

General system: Wire saws Safety Manual / System Description

Machine Operating Instructions / Spare parts list

wire saw SK-SD

Components Instruction leaflet

Information

These Operating Instructions are supplemented by the primary “Wire

saws Safety Manual / System Description” documentation and by the

documentation accompanying the product.

Introduction Operating Instructions

0-4 SK-SD / 007

Operating Instructions Product description

SK-SD / 007 1-1

1 Product description

1.1 Important information on the wire saw SK-SD

1.1.1 Description of the main components

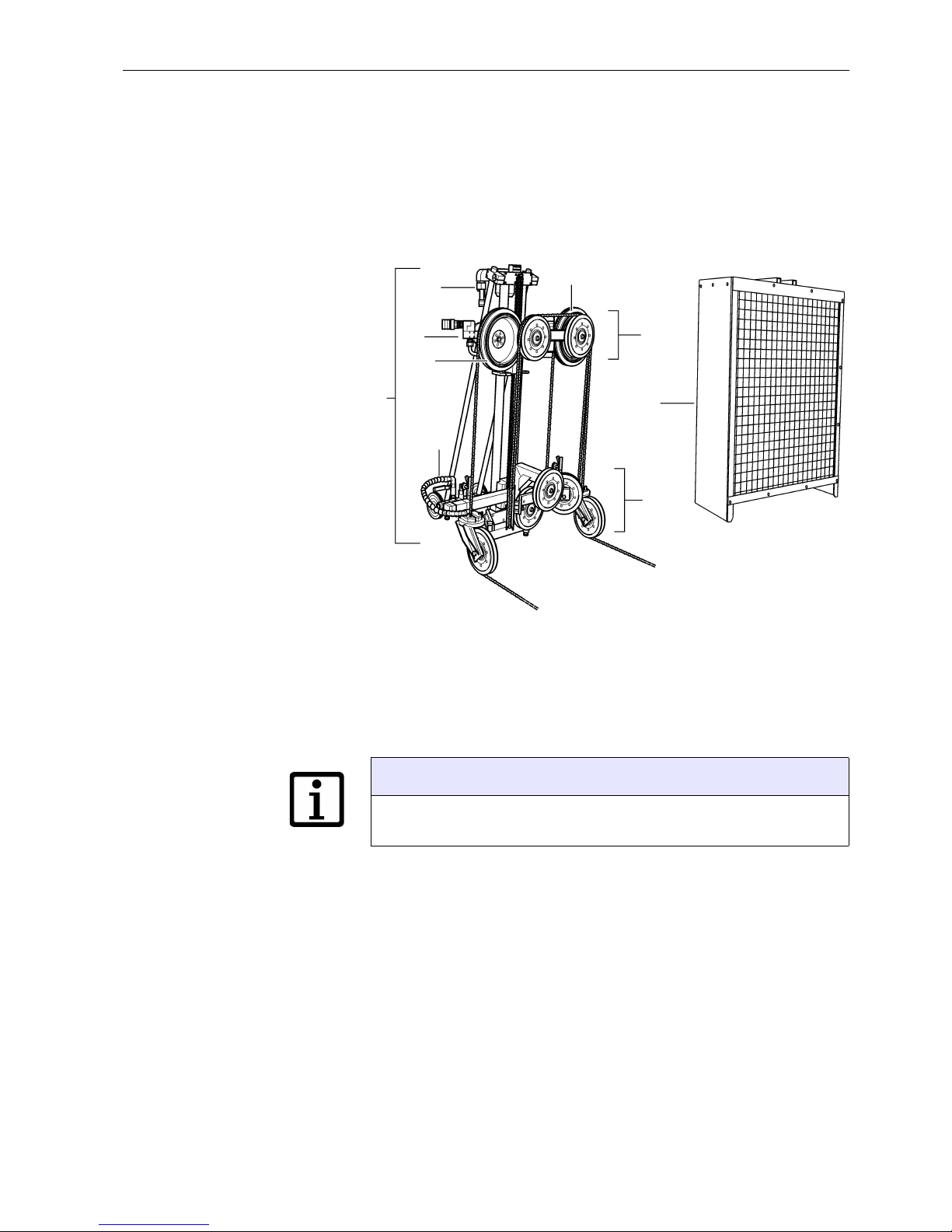

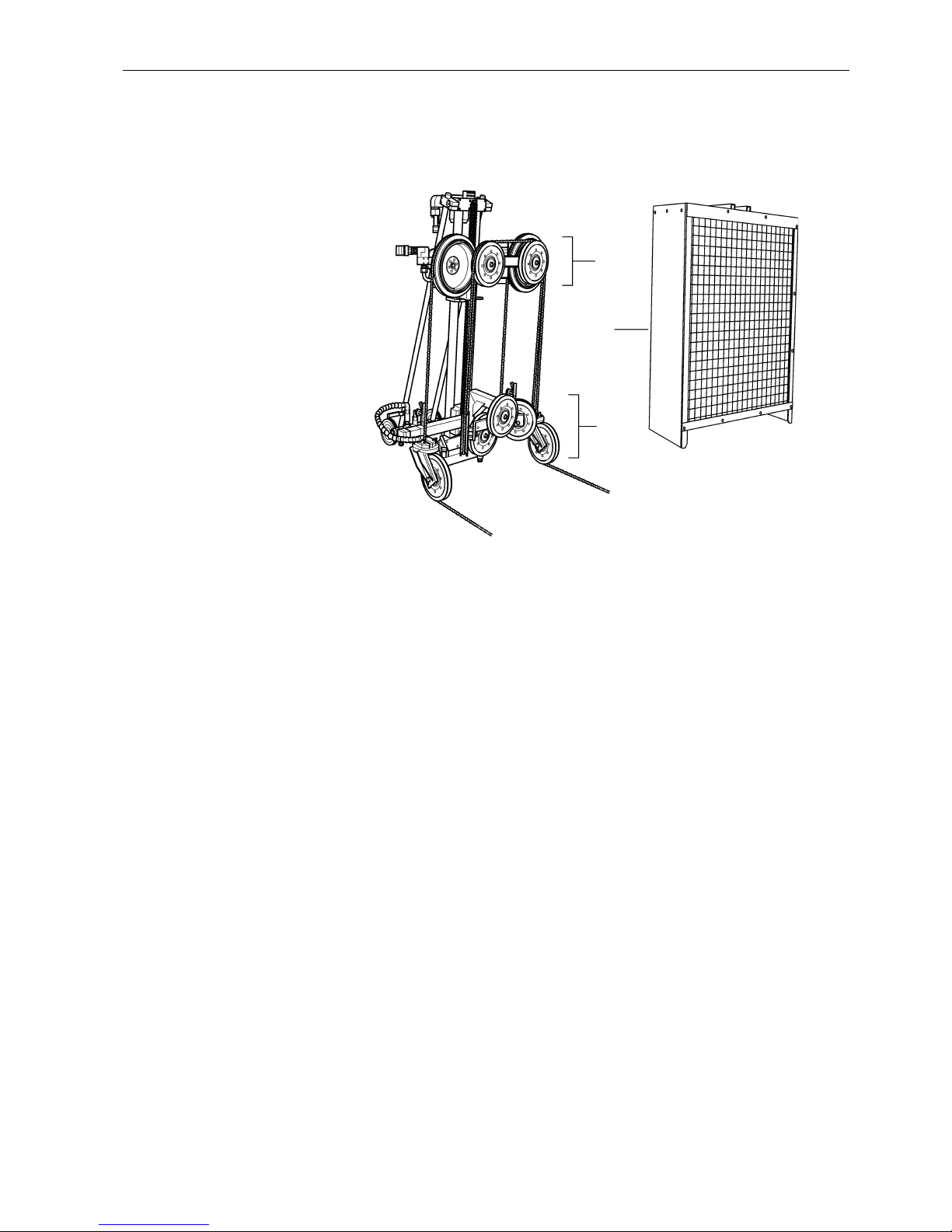

Fig. 1-1 Main components

1 Drill rig BC-2 6 Water supply

2 Drive roll unit 7 Drive motor unit

3 Diverter roll unit 8 Feed motor unit

4 Drive roll 1 9 Diamond wire guard

5 Drive roll 2

Information

The wire saw SK-SD consists of drill rig BC-2 (No. 974266) and the wire

saw kit SK-SD (No. 977084).

1

2

5

4

6

7

3

8

9

Product description Operating Instructions

1-2 SK-SD / 007

1.1.2 Application

The wire saw SK-SD is designed and built for the following application:

• Cutting concrete (including reinforced concrete) and natural stone, for

other materials please contact us.

• Cutting of parting cuts, flush cuts and angle cuts in ceilings, floors or

walls.

• The wire saw SK-SD should only be used and operated with the authorised anchoring systems.

• Only original TYROLIT cutting tools, diamond wire connectors and accessories should be used.

The applicable mandatory limitations on use and parameters are contained

in Chapter 1 "Technical Data" 1.2, 1-4.

1.1.2.1 Safety measures

Any use other than for the intended purpose (see Chapter 1.1.2, 1-2)

constitutes abuse or misuse.

1.1.3 Name plate

Fig. 1-2 Name plate

Operating Instructions Product description

SK-SD / 007 1-3

1.1.4 EC Declaration of Conformity

We declare under our sole responsibility that this product complies with the

following directives and standards:

1.1.4.1 Directive applied:

EC Machinery Directive 98/37/EEC

EC EMC Directives 89/336/EC

1.1.4.2 Standards applied:

TYROLIT Hydrostress AG

Roland Kägi

Department Manager

Description Wire saw

Type designation SK-SD

Year of construction 1994

EN 12100-1

EN 12100-2

Safety of machines – basic concepts, general design principles.

EN 294 Safety of machinery – Safety distances to prevent upper

limbs reaching danger areas.

EN 349 Safety of machinery – Safety distances to avoid crushing of

body parts.

EN 982 Safety of machines

Safety requirements of safety systems and their components - Hydraulics.

Product description Operating Instructions

1-4 SK-SD / 007

1.2 Technical data

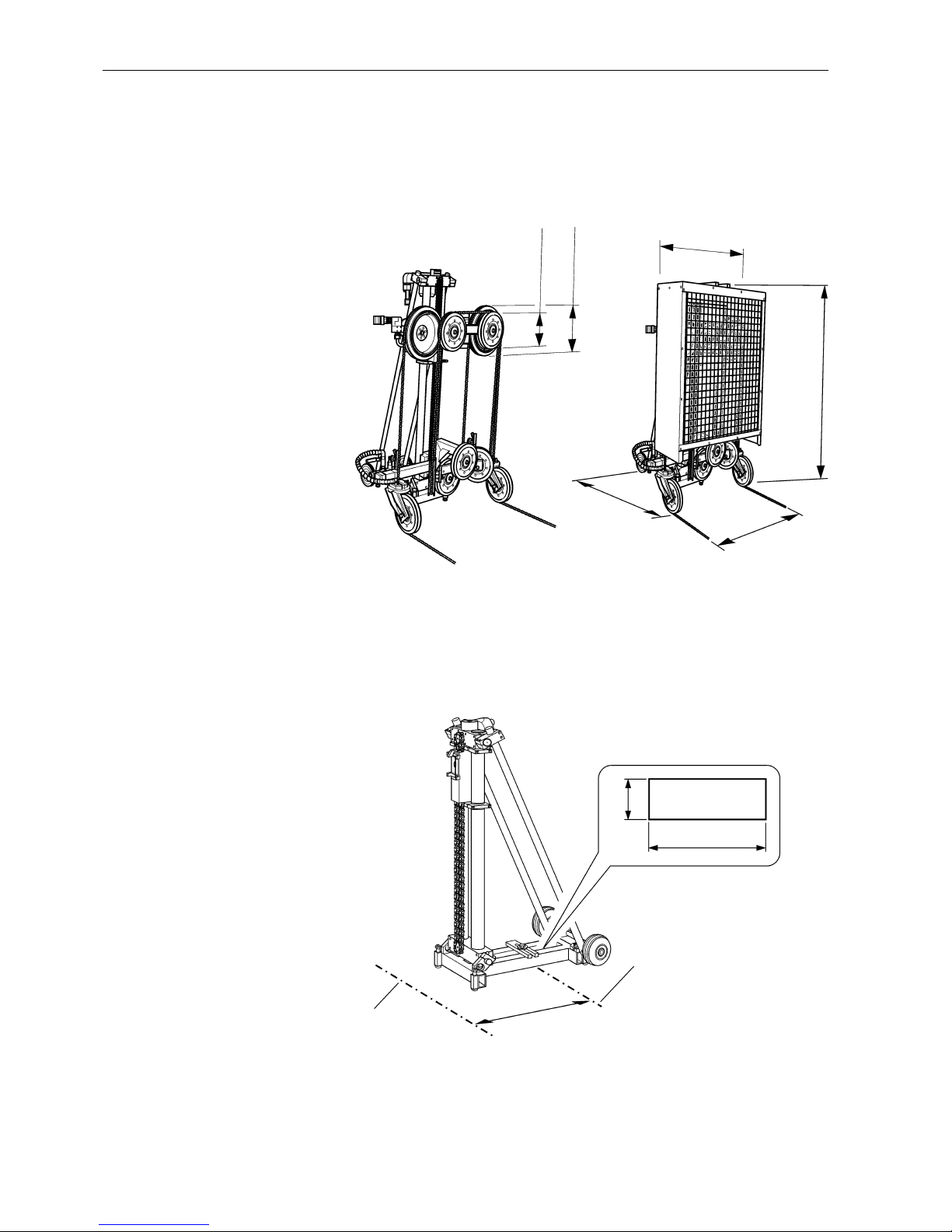

1.2.1 Dimensions

1.2.1.1 Main dimensions

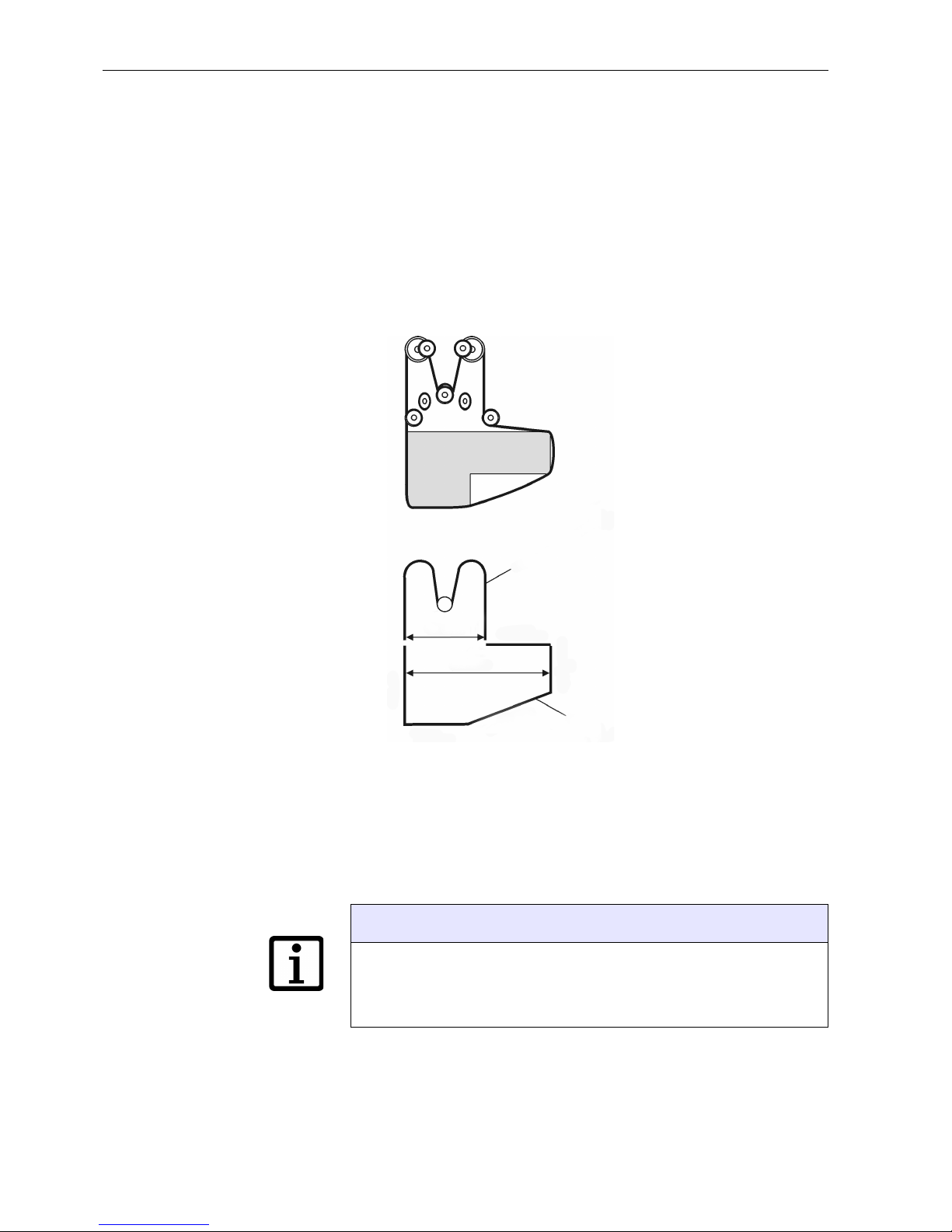

Fig. 1-3 Main dimensions

1.2.1.2 Dowel dimension

The dowel dimension for anchoring the drill rig is 42 cm from the cutting line

to the middle of the dowel space.

Fig. 1-4 Dowel dimension

A Cutting line

B Middle line of dowel space

Ø20cm

90cm

134cm

Ø28cm

78cm

80cm

28cm

5cm

42cm

B

A

Operating Instructions Product description

SK-SD / 007 1-5

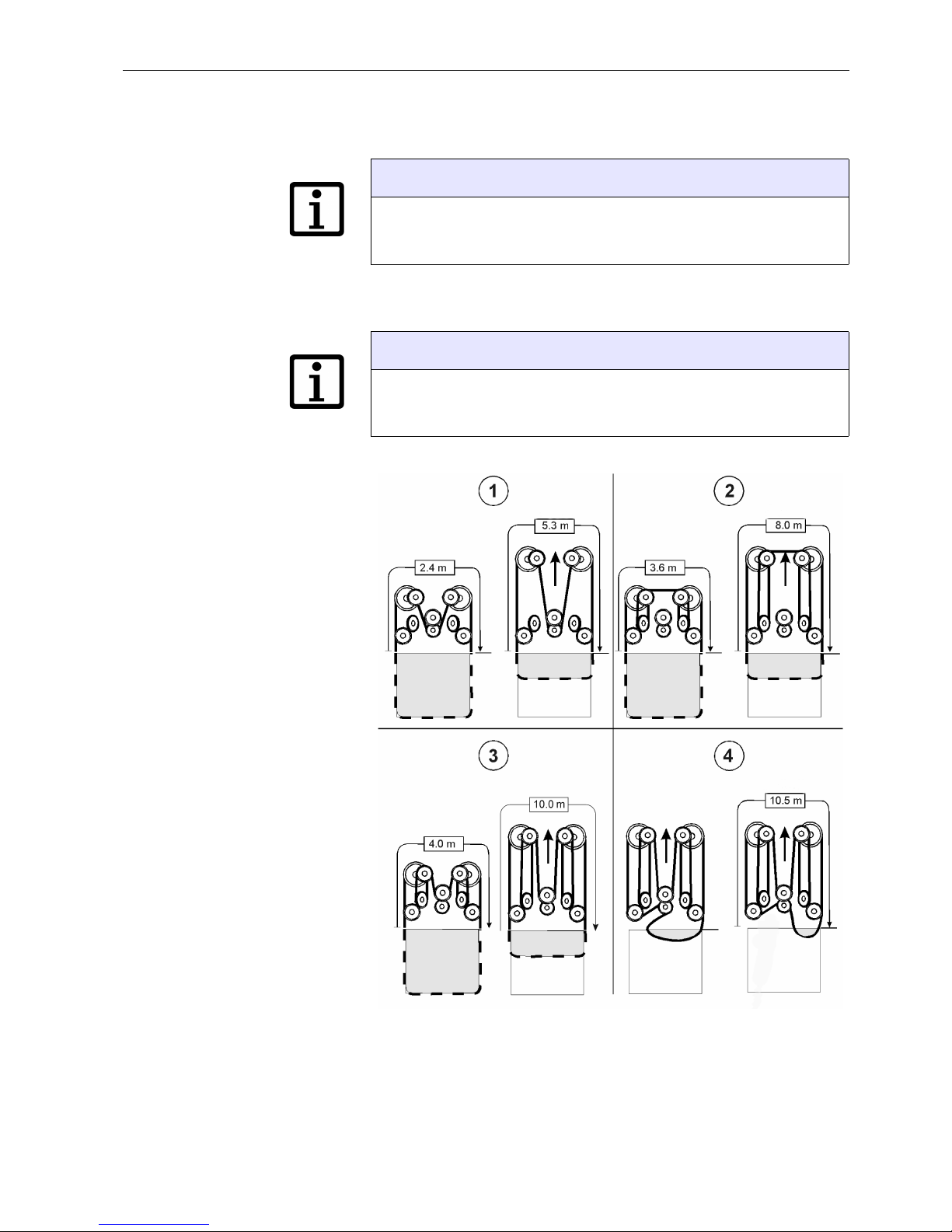

1.2.2 Diamond wire

1.2.3 Wire guide

Fig. 1-5 Wire guide

Information

Detailed information on the diamond wire and the diamond wire joining

elements can be found in the diamond wire saw Safety Manual / System

Description.

Information

Depending on the wire guide, the length of the stored diamond wire varies between 1.8 m and 4.0 m. Also, 1.5 m to 6.5 metres of wire is stored

due to the stroke during the cut, depending on the wire guide.

Product description Operating Instructions

1-6 SK-SD / 007

1.2.4 Diamond wire lengths

1.2.4.1 Wire length calculation

The minimum length of the wire results from:

L Total = L1+ L2 + 0.5 m

L1 = Circumference of main body - 0.8 m (width of saw system)

L2 = Length of stored wire at start of cut + 0.5 m

Example:

Fig. 1-6 Wire length calculation

L1 = 1m + 0.8m + 1.3m + 0.6m + 2.2m - 0.8m = 5.1 m

L2 = 2.4 m (wire guide variant 1) + 0.5m = 2.9 m

L Total = 8 m

Information

In order to be able to reap the benefits of the wire saw SK-SD, we recommend always using 1.5 m of diamond wire. This means that cuts of

0 to 9 m can be made on the main body without shortening the diamond

wire.

L1

L2

0.8m

2.2m

0.8m

1

.

3

m

0.6m

1m

Operating Instructions Product description

SK-SD / 007 1-7

1.2.5 Weights

1.2.5.1 Weights of attachment parts

Fig. 1-7 Weights of attachment parts

1.2.5.2 Drill rig

1 Drive roller unit 26.85 kg

2 Diverter roll unit 35.35 kg

3 Diamond wire guard 11.55 kg

Drill rig BC-2 1355 28.00 kg

1

2

3

Product description Operating Instructions

1-8 SK-SD / 007

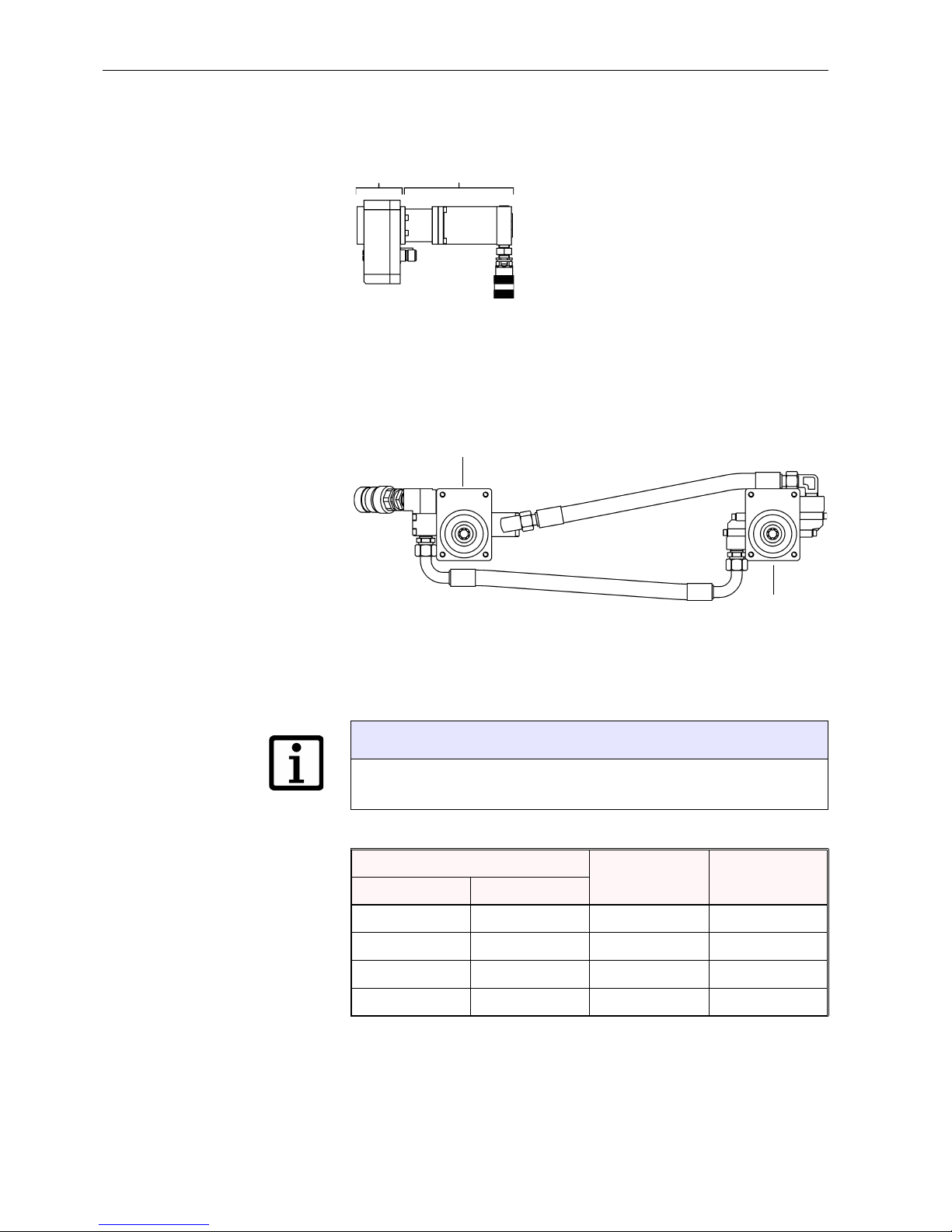

1.2.6 Feed motor unit

Fig. 1-8 Feed motor unit

1 Feed motor with mounting flange and coupling Article no. 977584

2 Feed transmission (1:8.6 and 1:2.2) Article no. 974263

1.2.7 Drive motor unit

Fig. 1-9 Drive motor unit

1 Drive motor I

2 Drive motor II

Information

Four motor units are available for the wire saw SK-SD with different capacities (19ccm / 27ccm / 33ccm / 41ccm).

Drive motor unit

Capacity Article no.

Drive motor I Drive motor II

11 ccm 30ccm 41 ccm 980680

11 ccm 22ccm 33 ccm 980679

8 ccm 19ccm 27 ccm 976655

8 ccm 11ccm 19 ccm 977235

1

2

1

2

Operating Instructions Product description

SK-SD / 007 1-9

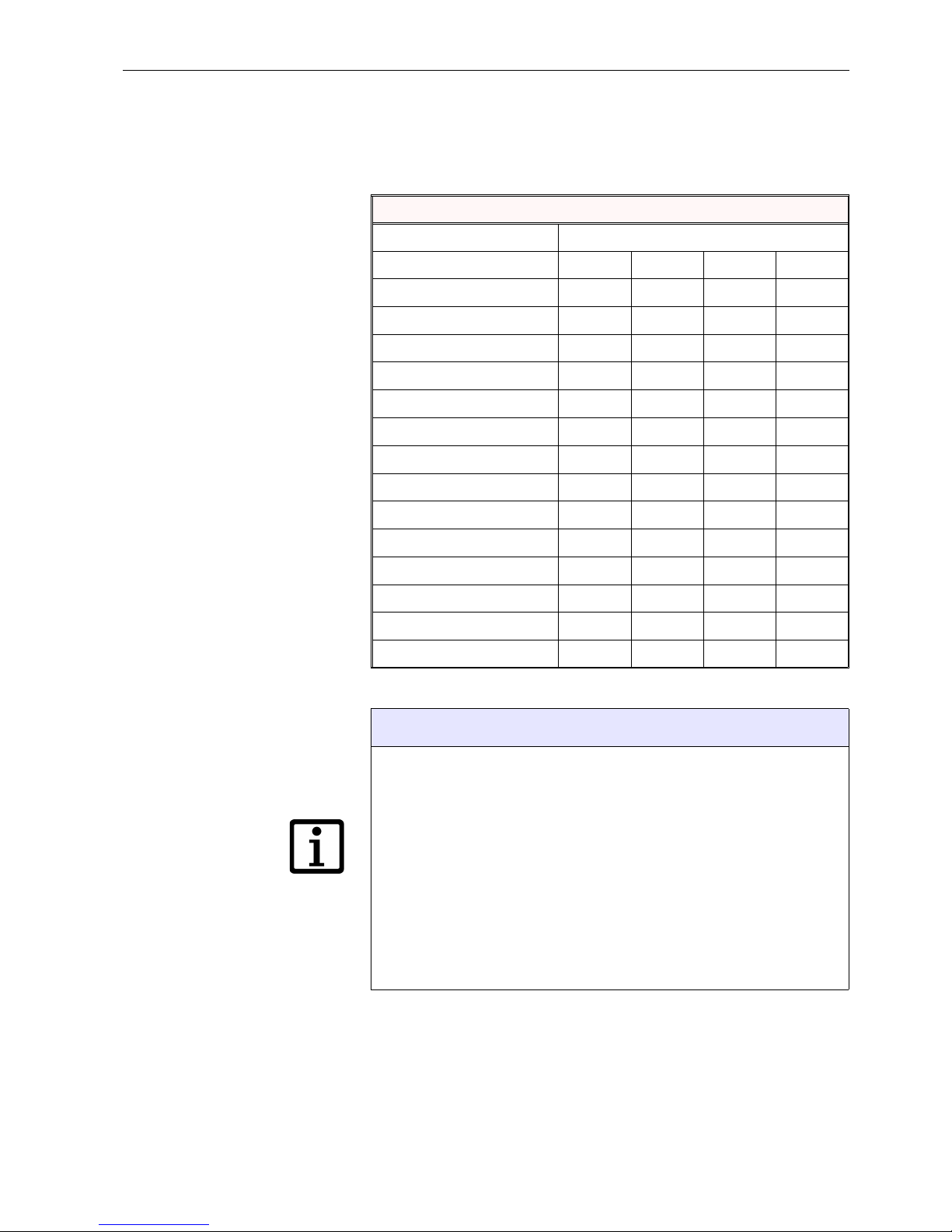

1.2.8 Cutting speed:

The cutting speed is determined by the drive unit and the motor unit.

Wire speed in m/s

Hydraulic motor unit

Drive unit output 19ccm 27ccm 33ccm 41ccm

30 l/min 21 - - 33 l/min 24 - - 40 l/min 29 20 - 45 l/min - 23 19 46 l/min - 23 19 47 l/min - 24 19 50 l/min - 25 21 57 l/min - 29 24 19

60 l/min - 31 25 20

61 l/min - - 25 21

70 l/min - - 29 24

76 l/min - - 31 26

80 l/min - - 33 27

90 l/min - - - 31

Information

The cutting speed must be selected according to the nature of the material.

The recommended values are:

20 -25 m/s for

granite, marble, old concrete with or without reinforcement

25 - 30 m/s for

abrasive materials, fresh concrete, asphalt, sandstone

The maximum permissible cutting speed for TYROLIT diamond

wires is 35 m/s.

Product description Operating Instructions

1-10 SK-SD / 007

1.2.9 Water connection

Pressure: min. 1 bar to max. 6 bar

Quantity: min. 4 l/min.

Temperature: 25°C

1.2.10 Connectable drive units

1.2.11 Noise exposure (noise level)

Depending on the working environment, the wire saw SK-SD can cause excessive noise during operation.

Noise level 75dB

Sound pressure 85dB

The noise can cause permanent harm to the hearing of operating personnel and of other people nearby within a short time.

Ear protectors must therefore always be worn while working.

Information

The wire saw SK-SD must only be operated with TYROLIT HydrostressAG

drive units. Obtain advice from TYROLIT Hydrostress AG when selecting

the drive unit.

Danger

Noise danger.

When using the wire saw SK-SD hearing protection must be worn.

If this instruction is not followed irreparable hearing damage may

result.

Operating Instructions Product description

SK-SD / 007 1-11

1.2.12 Tool chest

Tool chest with contents Part number 975746

Tool chest excluding contents Part number 973801

1.2.12.1 Tool chest contents

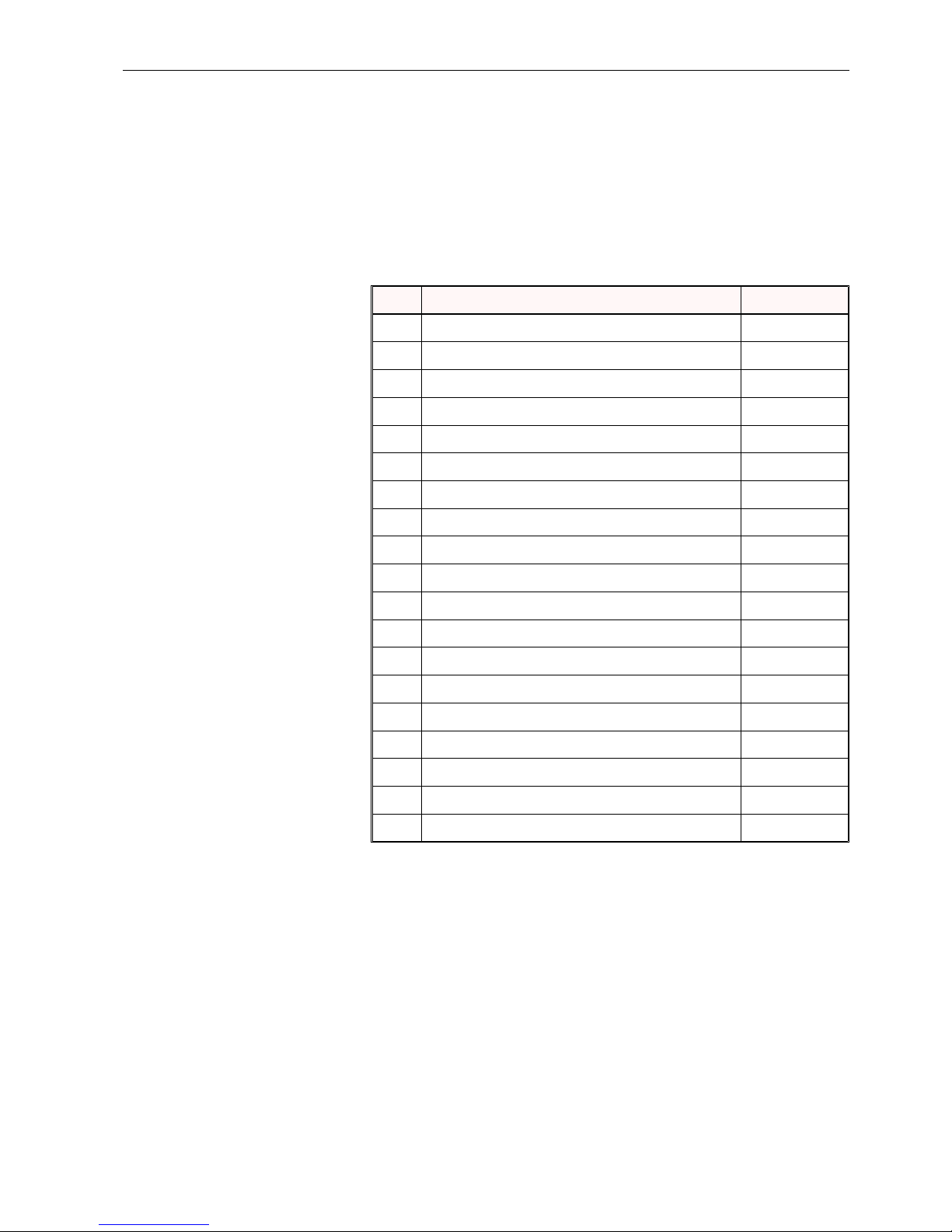

Quan. Description Part Number

1 Fork wrench, size across flats 41 973779

1 Fork wrench, size across flats 36 973777

1 Ring fork wrench, size across flats 24 973786

1 Ring fork wrench, size across flats 19 973784

1 Allen key, size across flats 4 973790

1 Allen key, size across flats 5 973791

1 Allen key, size across flats 6 973792

1 Allen key, size across flats 8 973793

1 Screwdriver size 5 973803

10 Drive-in dowel 971622

1 Dowel iron 977153

1 1250g steel hammer 973770

1 Tension spindle fixing point 977619

2 Hose nipple 972788

1 Chain lock 972480

1 Grease gun 975056

1 Spare cartridge 975057

5 Support ring 974984

1 Ear plugs 977224

Product description Operating Instructions

1-12 SK-SD / 007

Loading...

Loading...