Operating Instructions

Spare Parts List

10983823 en / 17.7.07

Drive Unit PPH25RR***

Index 000

Operating Instructions

10983823 en / 17.7.07

Manufacturer's address:

TYROLIT Hydrostress AG

Witzbergstrasse 18

CH-8330 Pfäffikon

Switzerland

Phone +41 (0) 44 / 952 18 18

Fax +41 (0) 44 / 952 18 00

TYROLIT Hydrostress AG reserves the right to make technical changes

without prior notice.

Copyright © 2007 TYROLIT Hydrostress AG, CH-8330 Pfäffikon ZH

All rights reserved, in particular the copying and translation rights.

The reprinting of these Operating Instructions, including extracts, is prohib-

ited. No part of these Operating Instructions may be reproduced in any

form whatsoever or be processed, copied or distributed using electronic

systems without the written permission of TYROLIT Hydrostress AG.

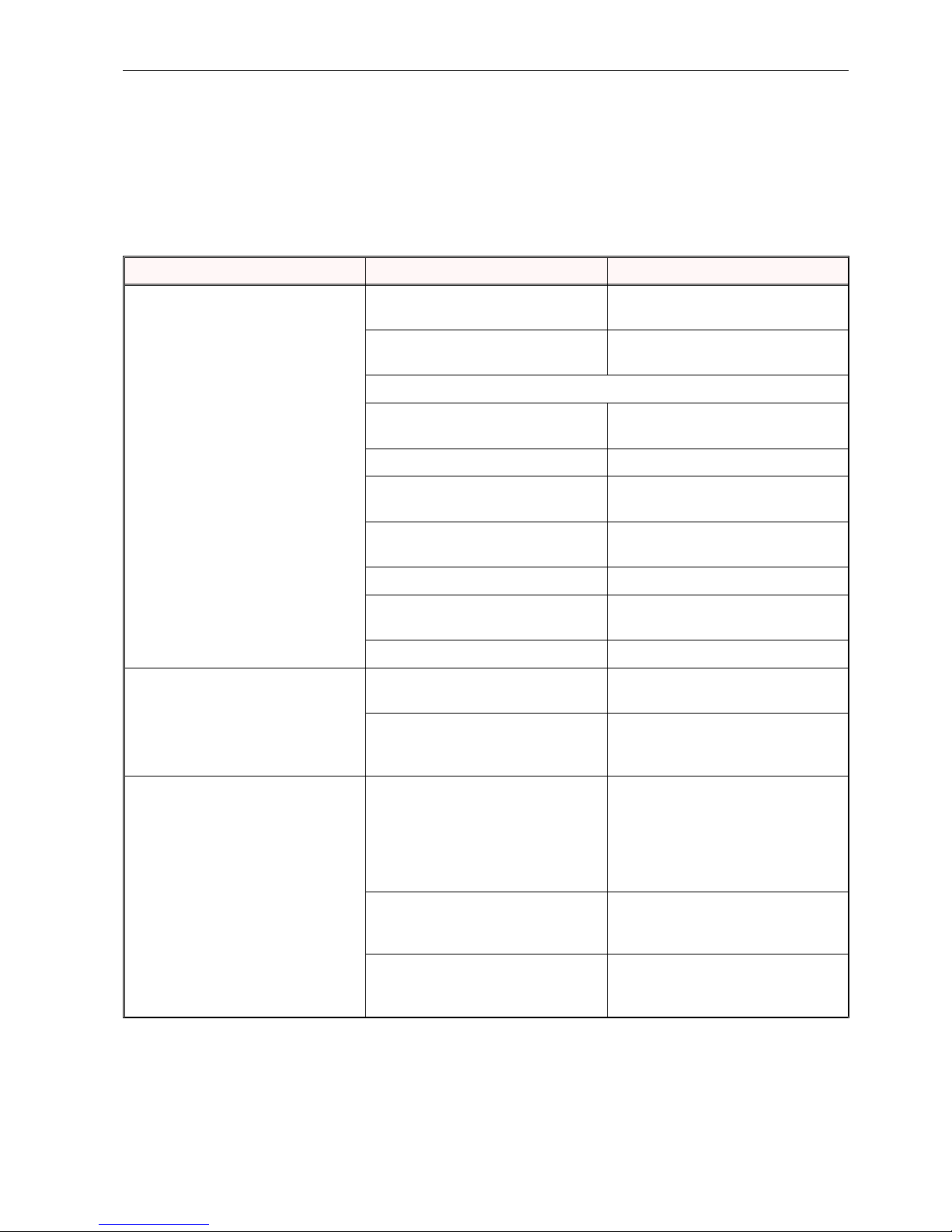

Operating Instructions Overview

PPH25RR*** / 000 I (II)

Overview

Page

0 Introduction 1

0.1 Congratulations!- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

0.2 Validity of these Operating Instructions - - - - - - - - - - - - - - 2

0.3 Standards - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

0.4 Delimitation of the system- - - - - - - - - - - - - - - - - - - - - - - - 2

1 Product description 1

1.1 Application - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

1.2 Safety measures - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

1.3 Operating instructions for connectable equipment- - - - - - - 1

1.4 Name plate - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

1.5 Information sign- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

1.6 EC Declaration of Conformity - - - - - - - - - - - - - - - - - - - - - 3

1.7 Technical data - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

1.8 Hydraulics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

1.9 Electrical equipment- - - - - - - - - - - - - - - - - - - - - - - - - - - - 6

1.10 Water - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

1.11 Noise exposure (noise level)- - - - - - - - - - - - - - - - - - - - - - 7

1.12 Scope of supply- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

1.13 Country list for radio transmission frequency- - - - - - - - - - - 8

2 Safety instructions 1

2.1 General- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

2.2 General safety rules- - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

2.3 Safety principles - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

2.4 Responsibility - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3

2.5 Generally applicable warnings of residual dangers - - - - - - 5

3 Design and function 1

3.1 Design - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

3.2 Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

3.3 Radio remote control - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

4 Controls and displays 1

4.1 Controls - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

4.2 Electric controls - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

4.3 Displays - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

5Operation 1

5.1 Personnel qualifications - - - - - - - - - - - - - - - - - - - - - - - - - 1

5.2 System requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

5.3 Preparatory operations - - - - - - - - - - - - - - - - - - - - - - - - - - 2

5.4 Working - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

5.5 After the work - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

6 Servicing 1

6.1 Servicing and maintenance table- - - - - - - - - - - - - - - - - - - 1

Overview Operating Instructions

II (II) PPH25RR*** / 000

7 Corrective maintenance 1

7.1 Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

7.2 Storage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

8 Transport 1

8.1 Transport- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

8.2 Safety instructions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

8.3 Crane shackles and transport handles - - - - - - - - - - - - - - - 2

9 Disposal 1

9.1 General - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

9.2 Disposal regulations - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

9.3 Disposal of the Drive Unit PPH25RR*** - - - - - - - - - - - - - - 2

Operating Instructions Introduction

PPH25RR*** / 000 0-1

0 Introduction

0.1 Congratulations!

You have decided to purchase a tried and tested TYROLIT

Hydrostress AG system and have thus acquired a highly sophisticated and

reliable state-of-the-art unit.

Thanks to the emphasis we place on quality assurance, your TYROLIT

Hydrostress AG system is another top-of-the-range Swiss product:

• High performance

• Reliable operation

• High portability

• Easy handling

• Low maintenance costs

Only original TYROLIT Hydrostress AG spare parts can guarantee quality

and interchangeability.

In the case of neglected or inappropriate maintenance, we will be unable

to accept the warranty commitment as specified in our terms of delivery.

Any repair work must be carried out by trained personnel only.

If you need more details about how to keep your TYROLIT Hydro stress AG

system in perfect condition, please con tact our after-sales service fo r further information.

We hope that working with your TYROLIT Hydrostress AG system will be

a problem-free and fault-free experience.

TYROLIT Hydrostress AG

Management

Copyright © TYROLIT Hydrostress AG, May 2007

TYROLIT Hydrostress AG

Witzbergstrasse 18

CH-8330 Pfäffikon

Switzerland

Phone +41 (0) 44 / 952 18 18

Fax +41 (0) 44 / 952 18 00

Introduction Operating Instructions

0-2 PPH25RR*** / 000

0.2 Validity of these Operating Instructions

This manual is only valid for the following system:

Drive Unit PPH25RR***

0.3 Standards

These Operating Instructions have been prepared in accordance with the

CE Machinery Directive Appendix I and with the relevant standar ds in force

at the time of printing.

0.4 Delimitation of the system

These Operating Instructions describe the use of the Drive Unit

PPH25RR***.

Operating Instructions Product description

PPH25RR*** / 000 1-1

1 Product description

1.1 Application

The Drive Unit PPH25RR*** has been designed as a component for the following concrete processing systems:

• Hydraulic wall saw systems

• Hydraulic diamond wire saw systems

• Hydraulic core drilling systems

• Hydraulic chainsaws

The applicable mandatory limitations on use and other parameters are con -

tained in Chapter 1 "Technical data" 1.7, 1-4

1.2 Safety measures

Any use other than for the intended purpose (see Chapte r 1.1 , 1-1) constitutes abuse or misuse.

1.3 Operating instructions for connectable

equipment

In order to ensure safety in the work place and in dan ger ar eas, as we ll as

the safe operation of connectable equipment, the relevant Operating Instructions must in all cases be followed.

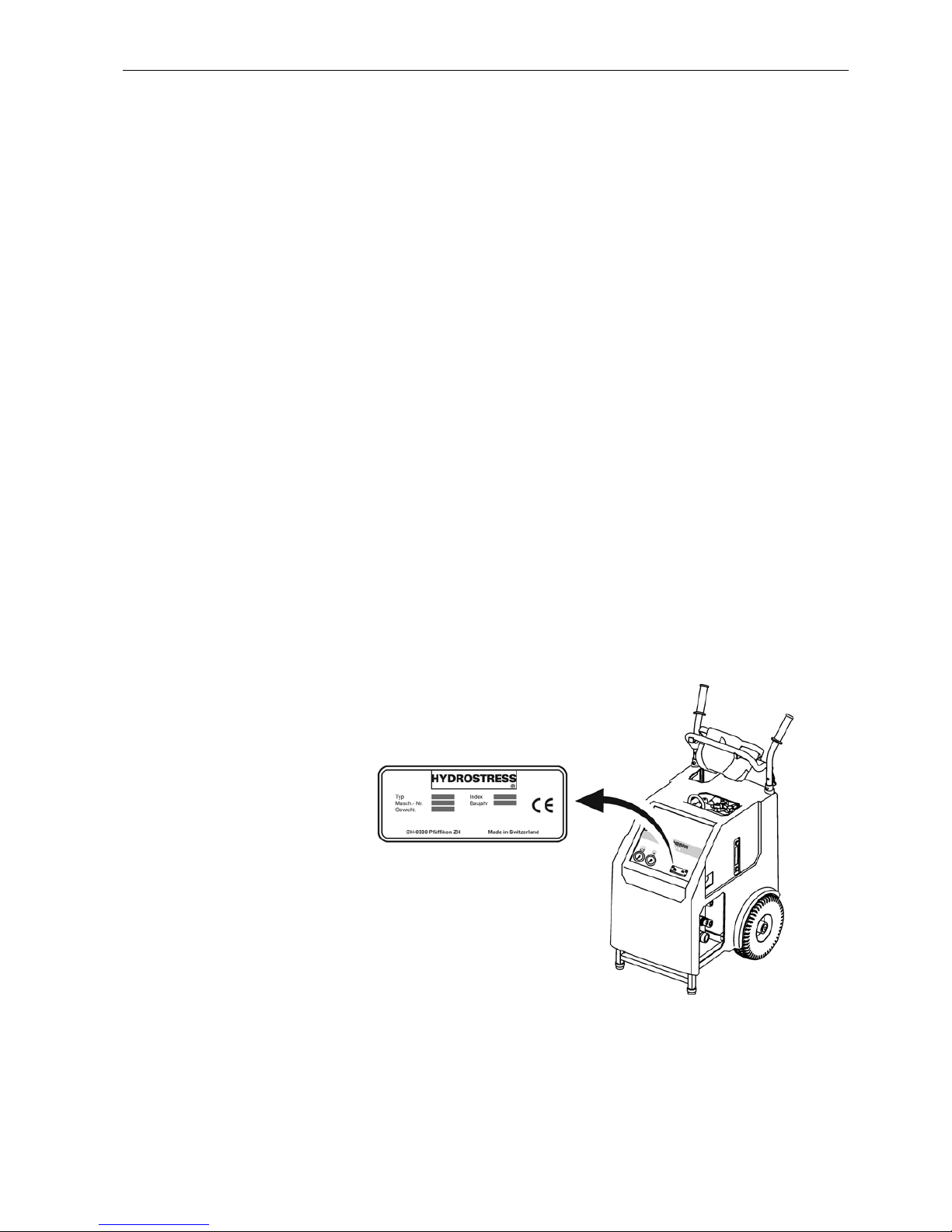

1.4 Name plate

Fig. 1-1 Name plate

Product description Operating Instructions

1-2 PPH25RR*** / 000

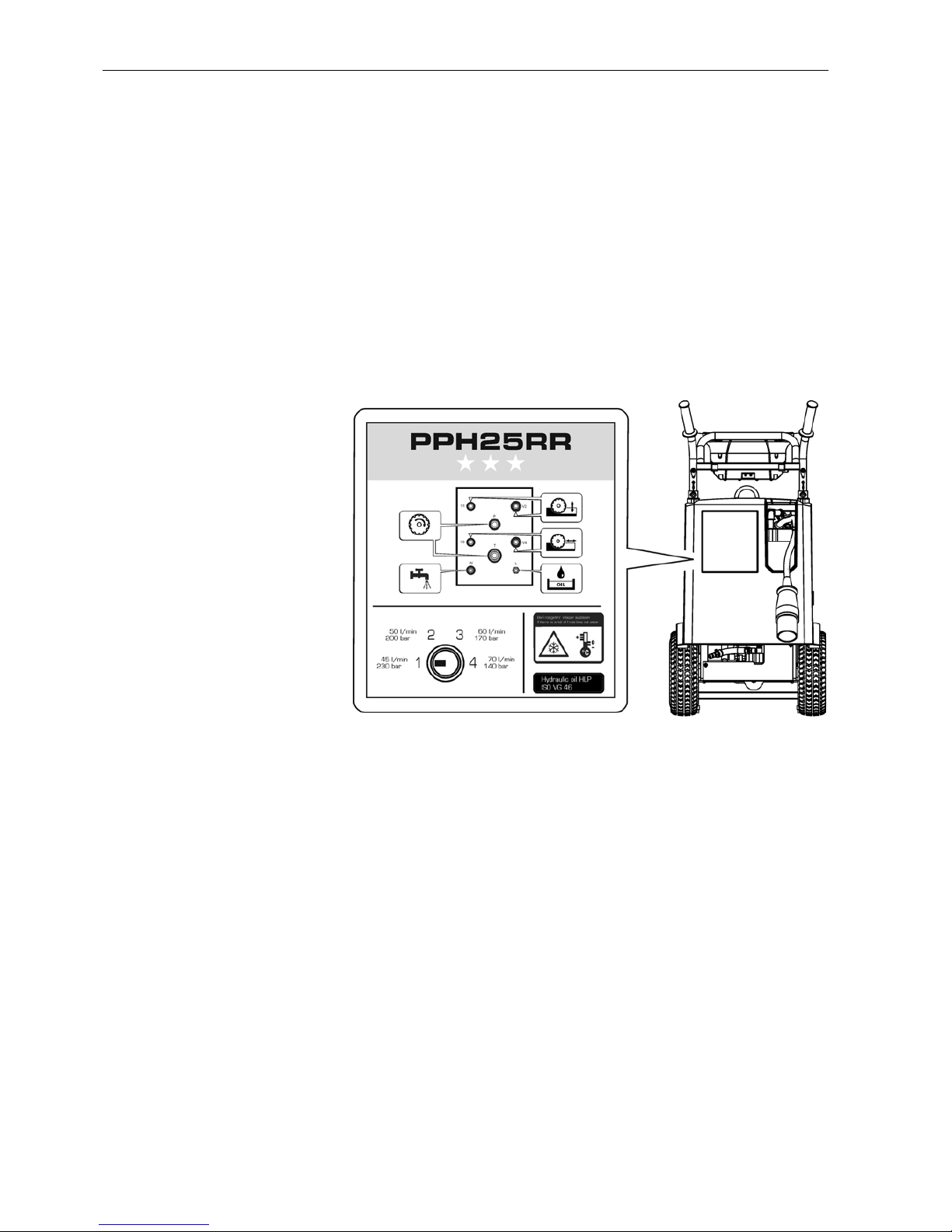

1.5 Information sign

Attached to the plastic hood is an information sign containing the following

information:

• Hose connections

(For a description see "Chapter 5" 5.3.2.1, 5-2)

• Pressure stages

(For a description see "Chapter 5" 5.4.3, 5-8)

• Risk of frost

(For a description see "Chapter 6" 6.1.1, 6-2)

• Hydraulic oil

(For a description see "Chapter 6" 6.1.2.1, 6-2)

Fig. 1-2 Information sign

Operating Instructions Product description

PPH25RR*** / 000 1-3

1.6 EC Declaration of Conformity

We declare under our own liability that this product complies with the following directives and standards:

1.6.0.1 Directive applied:

Machinery Directive 2006/42/EC

EC EMC Directive 89/336/EC

EC Low Voltage Directive 73/23/EC

1.6.0.2 Standards applied:

Description Hydraulic drive unit

Type designation Drive Unit PPH25RR***

Year of construction 2007

EN 12100-1

EN 12100-2

Safety of machinery – Basic concepts, general design

principles

EN 294 Safety of machinery – Safety distances to prevent upper limbs

reaching danger areas

EN 349 Safety of machinery – Safety distances to avoid crushing of

body parts

EN 982 Safety of machinery

Safety requirements of safety systems and their components Hydraulics

EN 60204-1Safety of machinery - Electrical equipment of machines

Product description Operating Instructions

1-4 PPH25RR*** / 000

1.7 Technical data

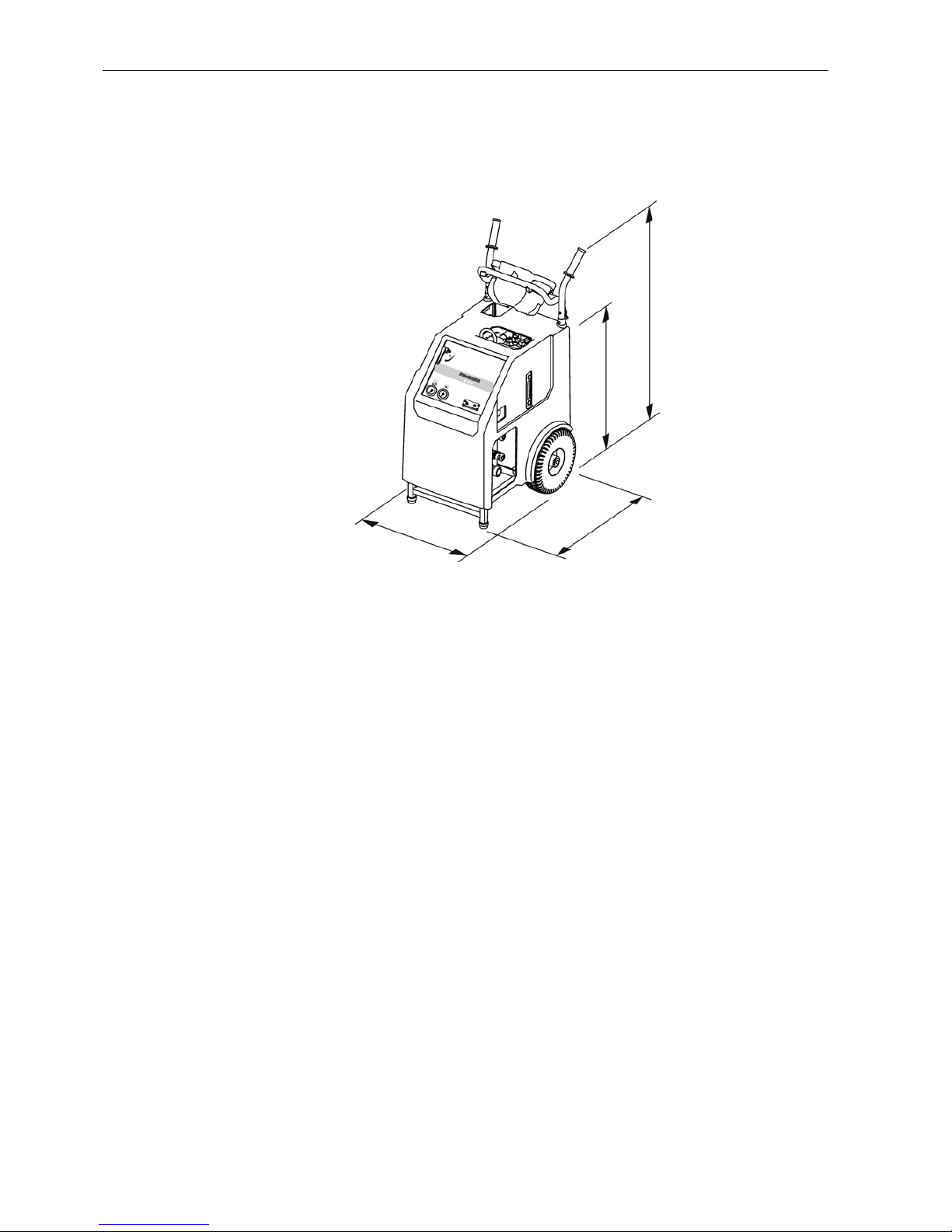

1.7.1 Dimensions

Fig. 1-3 Dimensions

1.7.2 Weight

Operating weight 160 kg

1.7.3 Tyres

Wheel Ø 30 cm

Operating pressure 3 bar

65 cm

105 - 120 cm

75 cm

55 cm

Operating Instructions Product description

PPH25RR*** / 000 1-5

1.8 Hydraulics

1.8.1 Main circuit

Main circuit 3 pumps

Flow rates can be set to 45 / 50 / 60 / 70 l/min., depending on the cutting

tool speed required

Flow rates and pressures

Stage I 45 l/min 230 bar

Stage II 50 l/min 200 bar

Stage III 60 l/min 170 bar

Stage IV 70 l/min 140 bar

Same power in all stages

1.8.2 Feed circuits

Feed circuits: 1 pump

Two hydraulic feed outputs which can be regulated independently of each

other, controlled using radio remote control.

1.8.3 Oil tank

Oil tank volume: 10 litres

Filter quality: 20 µm

1.8.4 Return oil filter

Type: Tank-mounted filter

1.8.5 Oil cooling

Oil cooler: Water/oil heat exchanger

1.8.6 Couplings and hoses

Plug-in couplings Type FD and FF, non-drip

Hoses Length 8m (filled with hydraulic oil)

1.8.7 Oil quality

TYROLIT Hydrostress AG recommends:

Hydraulic oil: HLP/ISO VG 46

Product description Operating Instructions

1-6 PPH25RR*** / 000

1.9 Electrical equipment

1.9.1 Different voltages

For countries where different mains networks operate the following types

are available:

Drive Unit PPH25RR*** 380-420 V 50 Hz

Drive Unit PPH25RR*** 420-480 V 60 Hz

1.9.2 Motor

Electric motor water-cooled

Power supply 3 P / LNPE 380 - 420 V / 50 Hz

420 - 480 V / 60 Hz

Current consumption 380 - 420 V / 50 Hz 40 A

420 - 480 V / 60 Hz 38 A

Output P1 25 kW / P2 21 kW

Speed at 50 Hz 2910 rpm

at 60 Hz 3480 rpm

1.9.2.1 Motor protection

Thermal protection Winding thermostat

Electrical protection Thermal relay

1.9.2.2 Cooling

Water cooling Cooling channels in the aluminium

Throughput of cooling water min. 6 l/min at max. 25° C

Water connection min. 2 bar, max. 6 bar

Information

Electrical data are only valid for the installed loads

3 P / LNPE 400 VAC / 50 Hz

Warning

A danger will arise if the Drive Unit PPH25RR*** is operated with a

different mains network voltage.

The details on the name plate must correspond to the mains network values (voltage and frequency).

Damage may be caused to the unit if it is connected to a different

voltage; there is also a risk of fire and personal injury.

Operating Instructions Product description

PPH25RR*** / 000 1-7

1.9.2.3 Protection class

IP 65

1.9.2.4 Internal control voltage (valve control)

24V / DC

1.9.2.5 Secondary socket

Connections 2 sockets 230V / 10A

with fault current tripping at 10 mA

1.10 Water

Pressure min. 2 bar to max. 6 bar

Quantity min. 6 l/min at max 25°C

1.11 Noise exposure (noise level)

Depending on the working environment and the connected device, the

Drive Unit PPH25RR*** can produce high noise levels during operation.

1.11.0.1 Noise level measurement

Noise level measured at the ear of the operator 0.5 m from the Drive Unit

PPH25RR***; noise power level according to ISO 3744; drive unit only;

highest value taken from all operating states at full load; mean values from

three series of measurements.

Noise level 83 dB (A) noise power level 92 dB (A)

1.12 Scope of supply

• Drive Unit PPH25RR***

• Radio remote control

• Water purge pump

• Operating Instructions / Spare parts list

Danger

Noise danger

When operating the PPH25RR*** drive unit, the wearing of hearing

protection is mandatory at all times.

If this instruction is not followed irreparable hearing damage may

result.

Product description Operating Instructions

1-8 PPH25RR*** / 000

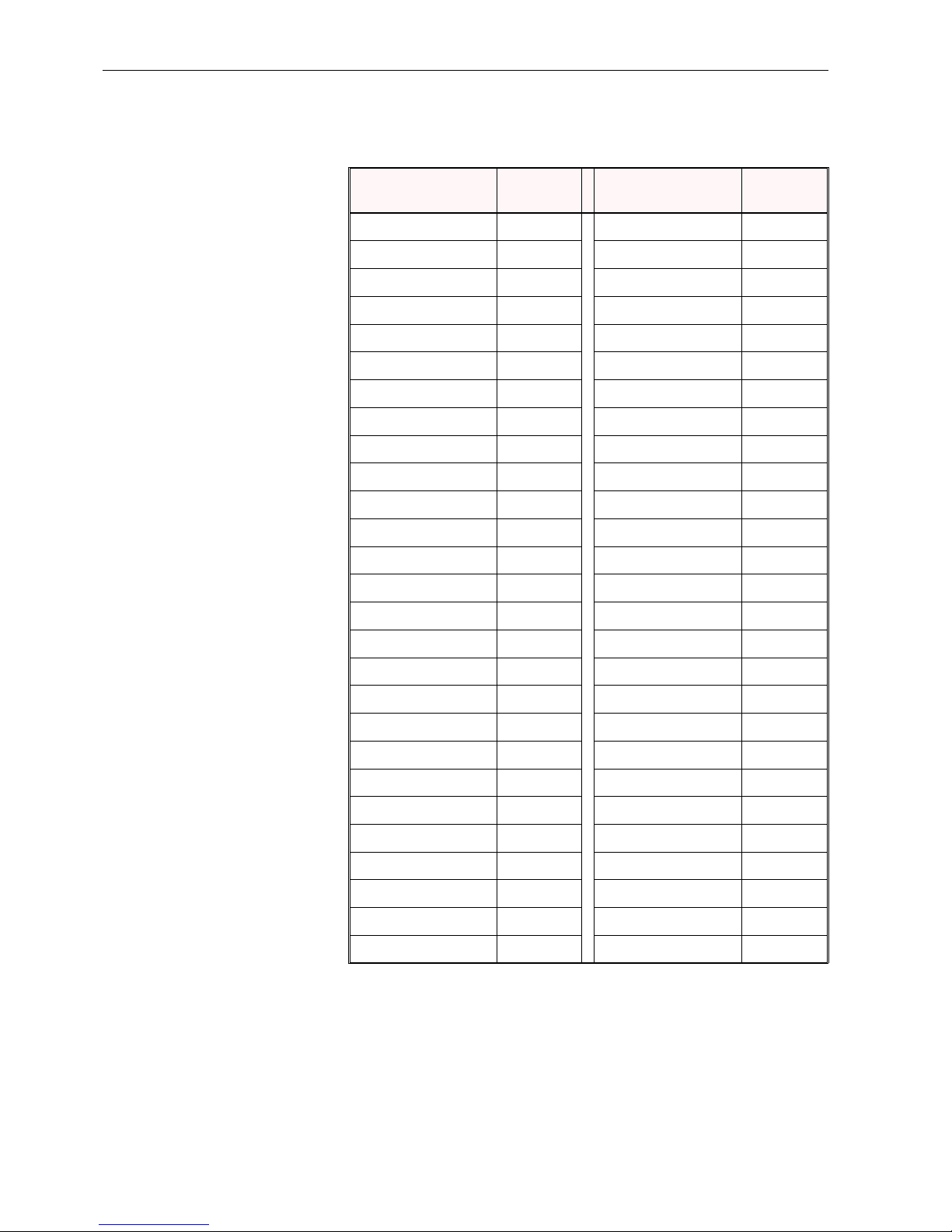

1.13 Country list for radio transmission frequency

Fig. 1-4 Country list for radio transmission frequency

*** On request

Country Frequency

MHz

Country Frequency

MHz

Australia 434 Mexico 458

Belgium 434 New Zealand 434

Bolivia 434 Netherlands 434

Brazil 434 Norway 434

Brunei 434 Austria 434

Bulgaria 434 Poland 434

China 419 Portugal 434

Denmark 434 Puerto Rico 458

Germany 434 Romania 434

Finland 434 Russia 434

France 434 Sweden 434

Greece 434 Switzerland 434

Great Britain 434 Singapore 434

Hong Kong 458 Slovenia 434

India, Mumbai 434 Spain 434

India, New Delhi 434 South Korea 447

Indonesia 434 South Africa 434

Ireland 434 Taiwan 480

Iceland 434 Thailand 434

Italy 434 Turkey 434

Japan 429 Ukraine 434

Canada 458 USA 458

Croatia 434 USA (South America) 434

Liechtenstein 434 Venezuela 434

Lithuania 434 United Arab Emirates 434

Luxembourg 434 Philippine 434

Malaysia 434

Operating Instructions Safety instructions

PPH25RR*** / 000 2-1

2 Safety instructions

2.1 General

All persons who work on and with the Drive Unit PPH25RR*** have a duty

to read and understand the Operating Instructions.

2.1.1 Observance of the safety instructions

The Drive Unit PPH25RR*** has been inspected before being shipped and

is delivered in perfect condition. TYROLIT Hydrostress AG does not accept

any liability for damage which is caused by failure to observe the instructions and information provided in the Operating Instructions. This a pplies in

particular to:

• Damage caused by improper use and operator error.

• Damage caused by failure to observe safety-related information in the

Operating Instructions or shown on the warning signs attached to the

machine.

• Damage caused by defective or neglected maintenance work.

Independently performed conversions and alterations may affect safety

and are not permitted.

2.2 General safety rules

2.2.1 Statutory provisions

The generally applicable national and local safety and accident prevention

provisions and the supplementary operator regulations must be followed

and complied with.

2.2.2 Inspection and maintenance obligation

The operator is under an obligation to use the Drive Unit PPH25RR*** only

when it is in a perfect and undamaged condition. The maintenance intervals shown in the Operating Instructions must be adhered to without fail.

Malfunctions and mechanical damage must be rectified without delay.

2.2.3 Spare parts

Only TYROLIT Hydrostress A G original spare parts may be used. Othe rwise, damage can be caused to the Drive Unit PPH25RR*** or other property and may result in personal injury.

2.2.4 Power connections

The Drive Unit PPH25RR*** must be connected and coupled in accordance with the Operating Instructions.

Safety instructions Operating Instructions

2-2 PPH25RR*** / 000

2.3 Safety principles

2.3.1 Delimitation of the safety concept

The Drive Unit PPH25RR*** does not affect the safety concept of the connected systems, equipment and installations.

2.3.2 Safety elements

Protection from live electrical parts

All functional units containing parts which carry hazardous voltages are

shock-protected by suitable covers.

2.3.3 Removal of protective devices

Protective devices may only be removed if the unit has been switched off,

disconnected from the mains and is at standstill. Safety components, in

particular, may only be removed and refitted by authorised personnel, see

"Chapter 2" 2.4.1, 2-3.

Before switching the Drive Unit PPH25RR*** back on again, the safety elements must be checked to ensure correct operation.

2.3.4 Safety measures (organisational)

2.3.4.1 Product monitoring obligation

Operating personnel must notify changes in operational behaviour or safety-related components to a responsible person or the manufacturer, immediately.

2.3.4.2 Location of the Operating Instructions

A copy of the Operating Instructions must be available to staff at all times

at the place of use of the equipment.

Operating Instructions Safety instructions

PPH25RR*** / 000 2-3

2.4 Responsibility

2.4.1 Authorised personnel

Work on or with the TYROLIT Hydrostress AG machines or systems may

only be performed by authorised personnel. Personnel are considered by

TYROLIT Hydrostress AG to be authorised if they meet the necessary

training and know-how requirements and they have been assigned a precise functional role.

The personnel qualifications for the corresponding work are contained in

the introduction under "General" of the respective chapters.

2.4.2 Manufacturer

TYROLIT Hydrostress AG or a company expressly nominated by TYROLIT Hydrostress AG is deemed to be the manufacturer of the products

supplied by TYROLIT Hydrostress AG. Within the context of an integrated

quality and safety control system, the manufacturer is entitled to request

from the operator information about the products.

2.4.3 Operator (owner)

The operator named by TYROLIT Hydrostress AG is the primary, legal entity responsible for the correct us e of the product and for the tr aining and

assignment of the authorised personnel. The operator sets out the mandatory skills and level of training of the authorised personnel for his company.

2.4.4 Operator (user)

User is the term employed by TYROLIT Hydrostress AG to designate a

person who independently performs the following work:

• Sets up TYROLIT Hydrostress AG machines or systems for tasks according to the intended purpose.

• Performs tasks independently and monitors these.

• Locates malfunctions and initiates or performs troubleshooting.

• Carries out servicing and simple maintenance.

• Monitors the correct functioning of the safet y device s.

2.4.5 Service engineer

Service engineer is a term used by TYROLIT Hydrostress AG to designate

a person who independently performs the following work:

• Installs TYROLIT Hydrostress AG machines and systems and controls

their correct application.

• Makes adjustments to machines and systems for which special access

rights are required.

• Performs repairs, complex service work and maintenance work.

Safety instructions Operating Instructions

2-4 PPH25RR*** / 000

2.4.6 Qualification and training

2.4.6.1 Operator (owner)

• A technically trained person in a management position.

• Has relevant experience in personnel management and danger assessment.

• Has read and understood the "Safety instructions" chapter.

2.4.6.2 Operator (user)

• Has trained as a concrete cutting expert or has professional experience.

• Has received an introduction (basic training) to the operation of the

TYROLIT Hydrostress AG machines and systems from a service engineer.

• Has read and understood Chapter 2 "Safety instructions".

2.4.6.3 Service engineer

• Has specialist professional training (mechanical / electrotechnical).

• Has attended specialist courses at TYROLIT Hydrostress AG.

• Has read and understood the "Safety instructions" chapter.

Operating Instructions Safety instructions

PPH25RR*** / 000 2-5

2.5 Generally applicable warnings of residual

dangers

Danger

Electric shock due to defective electronic equipment.

The electrotechnical equipment must be checked prior to each use

and from time to time during prolonged use. Defective parts, such

as e.g. cables and plugs, must be replaced immediately in the deenergized state by electrotechnically trained personnel.

Failure to comply with this regulation may lead to serious physical

injury or death. Secondary damage such as fires may also occur.

Warning

Danger of allergic reactions if skin comes into contact with hydraulic oil.

Persons who have an allergic reaction to hydraulic oil must wear

protective gloves and goggles when carrying o ut work whe re they

come into contact with hydraulic oil. Any areas of the skin affected

must be rinsed immediately with copious amounts of water.

Failure to observe this regulation may result in allergic reactions or

injury to the eyes.

Safety instructions Operating Instructions

2-6 PPH25RR*** / 000

Operating Instructions Design and function

PPH25RR*** / 000 3-1

3 Design and function

3.1 Design

Fig. 3-1 Main components

1 Hydraulic unit 10 Antenna

2 Oil cooler 11 Oil level indicator

3 Pressure gauge 12 Radio receiver

4 Water valve 13 Electrical connection

5 Suspension shackle 14 Electrical box

6 Electric motor 15 Wheel

7 Radio remote control 16 Hood

8 Transport handle with hose bracket 17 Oil tank

9 Pump assembly

1

5

6

3

7

4

8

9

10

11

12

13

14

17

2

15

16

Design and function Operating Instructions

3-2 PPH25RR*** / 000

3.2 Function

3.2.1 Hydraulic circuit diagram

Fig. 3-2 Hydraulic circuit diagram

1 Electric motor 18 Leak-oil nipple

2 Pump assembly 19 Coupling

3 Proportional valve 0-260 bar 20 Nipple

4 Check valve 21 Coupling

5 Pressure relief valve 22 Nipple

6 Pressure gauge 0-400 bar 23 Coupling

7 Oil and water cooler 24 Water valve

8 Aeration filter 25 Pressure valve 20 bar

9 Oil level 26 Proportional valve 5-120 bar

10 Return filter 27 2/2-way seat valve

11 Screw plug 28 Bijour-nozzle

12 2/2-way seat valve 29 Pressure-maintaining valve

13 4/3-way valve 30 Check valve

14 Pressure relief valve 150 bar 31 Water filter

15 Pressure gauge 0-250 bar 32 Water valve

16 Nipple 33 Radial piston pump

17 Coupling

Operating Instructions Design and function

PPH25RR*** / 000 3-3

3.2.2 Wiring diagram

Fig. 3-3 Wiring diagram

1 Elec. box 8 EMERG. STOP

2 Reversing switch 9a Hour counter

3 Contactor 9b Rotation lock

4 Thermal relay 10 Phase sequence relay

5 Interlock 11 Time relay

6 Circuit breaker 12 Connector CEE 63/5

7a Device protective switch 13 Relay

7b Protective hood 14 Power supply unit

Design and function Operating Instructions

3-4 PPH25RR*** / 000

3.3 Radio remote control

3.3.1 Design

Fig. 3-4 Remote controller

1 Controls

2 Plastic housing

3.3.1.1 Accessories

Fig. 3-5 Accessories

1 2x interchangeable battery

2 Battery charger

3 Cable insert

4 Battery insert

3.3.2 Function

The radio remote control allows a secure, simple and mobile method of

working. The operator can at all times be in a position where he has a full

view of the unit during operation.

Warning

The battery charger is exclusively for recharging the interchangeable rechargeable battery. The battery insert and the cable insert must not be

inserted.

2

1

2

1

3

4

Operating Instructions Controls and displays

PPH25RR*** / 000 4-1

4 Controls and displays

4.1 Controls

Fig. 4-1 Controls

1 Water and hydraulic couplings 6 EMERG. STOP

2 Safety socket 7 Water valve

3 Schuko socket 8 Suspension shackle

4 Forward/reverse switch 9 Remote controller

5 Device protective switch 10 Cable connection of remote controller

4.1.1 Radio remote control

Fig. 4-2 Radio remote control

1 Locking switch 7 Pressure stage selector switch

2 Pilot lamp (radio & battery) 8 Water In / Out

3 EMERG. STOP 9 Main motor potentiometer

4 Main switch of drive unit 10 Main motor On / Off

5 Start switch 11 Feed motor potentiometer

6 Feed joystick

1

2

5

3

4

6

7

8

9

10

3

1

4

68

9

7

11

2

5

10

Controls and displays Operating Instructions

4-2 PPH25RR*** / 000

4.2 Electric controls

4.2.1 Secondary sockets

The Drive Unit PPH25RR*** is equipped with 2 x 230V / 10 A seco ndary

sockets with fault current tripping at 10 mA.

The secondary sockets may only be used with a neutral conductor.

Fig. 4-3 Secondary sockets

1 On / Off switch 3 Safety socket

2 Test button 4 Schuko socket

4.2.1.1 Safety socket

The safety socket has integral residual current protection and is the active

personnel safety device. The operating principle of the safety socket is the

same as that of a residual current circuit breaker.

Monitoring

The safety socket must be checked monthly during operation. The check

can be performed with or without the plug inserted, as follows:

• The switch must be in the (I) position

• Press the Test button

– the switch must switch off (0 position)

• Push the switch back into the (I) position

4.2.1.2 Schuko socket

The Schuko socket is connected and protec te d via th e sa fet y s oc ke t.

Information

Equipment on which the safety socket interrupts the power circuit during

operation is defective and must be checked by an electrical engineer

and, if necessary, repaired.

1

3

2

4

Operating Instructions Controls and displays

PPH25RR*** / 000 4-3

4.2.2 Forward/reverse switch

If the phase position of the power supply to the site is wrong, the phases

can be turned.

4.2.3 Device protective switch

The device protective switch protects the secondary sockets and thereby

protects the devices connected to the sockets.

The device switch interrupts the circuit in the event of a current surge (more

than 13A). The circuit is restored by pressing the device switch.

4.2.4 Cable connection of remote controller

The radio remote control can be connected to the Drive Unit PPH25RR***

power supply by means of the cable insert.

4.2.5 EMERGENCY STOP

Pressing the EMERGENCY STOP button switches the system off and prevents the system being accidentally switched on again.

Fig. 4-4 EMERGENCY STOP

1 EMERG. STOP on the Drive Unit PPH25RR***

2 EMERG. STOP on the radio remote control

1

2

Controls and displays Operating Instructions

4-4 PPH25RR*** / 000

4.3 Displays

Fig. 4-5 Displays

1 Hour counter 4 Pressure gauge of main motor

2 Pilot lamp (radio & battery) 5 Oil level indicator

3 Pressure gauge of feed motors

4.3.1 Hour counter

The hour counter allows for precise observance of the service intervals.

Fig. 4-6 Hour counter

4.3.2 Pilot lamp (radio & battery)

Fig. 4-7 LED pilot lamp

The LED pilot lamp on the radio remote control flashes green to indicate

operational readiness. When the battery voltage becomes low, the colour

changes from green to red.

1

3

5

4

2

Operating Instructions Controls and displays

PPH25RR*** / 000 4-5

4.3.3 Pressure gauge

Fig. 4-8 Pressure gauge

1 Pressure gauge of main motor (0 bar to 400 bar)

2 Pressure gauge of feed motors (0 bar to 250 bar)

4.3.4 Oil level indicator

Fig. 4-9 Oil level indicator

Information

The quantity of oil between oil MIN and oil MAX is 1.5 litres.

Different types of hydraulic oil should not be mixed together, otherwise

the oil will age prematurely.

Recommended hydraulic oil: HLP / ISO VG 46

1

2

MIN.

MAX.

Controls and displays Operating Instructions

4-6 PPH25RR*** / 000

Operating Instructions Operation

PPH25RR*** / 000 5-1

5 Operation

5.1 Personnel qualifications

The Drive Unit PPH25RR*** must not be operated by unauthorised personnel. Personnel are only authorised if they meet the following requirements.

• Have trained as a concrete c utting expert or have profes sional experience.

• Have received an introduction (basic training) to the operation of the

Drive Unit PPH25RR*** from a service engineer.

• Have read and understood chapter 2 "Safety instructions".

5.2 System requirements

5.2.1 Connectable equipment

All hydraulic units that are designed for the pressure and delivery volume

of the Drive Unit PPH25RR**** (see "Chapter 1" 1.8, 1-5).

Warning

A danger will arise if the Drive Unit PPH25RR*** is operated with a

different mains network voltage.

The details on the name plate must correspond to the mains network values (voltage and frequency).

The system may be damaged by connecting it to a diff erent voltage.

There is also a danger of fire and injury.

Information

The Drive Unit PPH25RR*** is one of a series of drive pr oducts available

from TYROLIT Hydrostress AG.

In order to allow expansion of your Drive Unit PPH25RR*** with suitable

devices to create an hydraulic saw or drilling system with optimum performance, please talk to TYROLIT Hydrostress AG.

Operation Operating Instructions

5-2 PPH25RR*** / 000

5.3 Preparatory operations

5.3.1 Visual inspection

Before starting work always complete the following visual inspections:

• Is the power supply earthed, fitted with a neutral conductor and a residual current circuit breaker?

• Does the mains network have fuse protection for a minimum of 45A?

• Is the cable cross section 5x6mm² (from 25m to 50m / 5x10mm²)?

• Is the water line properly connected to the Drive Unit PPH25RR***?

• Is there sufficient oil in the Drive Unit PPH25RR***?

• Is there any damage to cables or plugs?

• Has the EMERGENCY STOP been reset?

5.3.2 Connecting the Drive Unit PPH25RR***

5.3.2.1 Connecting the hoses

Information

Ensure that the water supply is not interrupte d while work is in progress.

Warning

Danger from uncontrolled movements and uncontr olled escape of

oil.

Never connect or disconnect hoses while the drive unit is runnin g.

Failure to observe this regulation may result in cut wounds or injury to body parts as well as damage to property.

Operating Instructions Operation

PPH25RR*** / 000 5-3

5.3.2.2 Hose connections

Fig. 5-1 Hose connections

1 Couplings of main motor

2 Water connection

3 Couplings of feed motor 1

4 Couplings of feed motor 2

5 Leak-oil connection (hydraulic motor Gr.3)

Proceed as follows:

• Visual inspection

Check:

– Oil leaks from hoses and couplings

– Couplings for damage and contamination

– Hoses for damage

• Push the hose coupling on to its counterpart until you hear it "click".

• Twist the locking ring of the coupling.

5.3.2.3 Release pressure in the Drive Unit PPH25RR***

Proceed as follows:

• Turn the forward/reverse switch on the Drive Unit PPH25RR*** to posi-

tion 1 (2).

• Switch on the radio remote control by means of the Start switch.

• Press the main switch once, on the radio remote control.

• Briefly push the feed joystick in all directions.

Information

If hoses cannot be connected or this cannot be done easily, they are under pressure. Release pressure in hoses via the pressure relief device.

Release pressure in the Drive Unit PPH25RR***, see "Chapter 5"

5.3.2.3, 5-3.

Never use force to connect couplings!

1

2

3

4

5

Operation Operating Instructions

5-4 PPH25RR*** / 000

5.3.3 Radio remote control provision

5.3.3.1 Power sources

The radio remote control can be operated using a rechargeable battery,

disposable battery or via cable.

Rechargeable battery operation:

The interchangeable rechargeable battery is inserted at the housing base.

The operating period with a fully charged battery is approximately 12 hours.

The reception distance is 25 m.

Cable operation:

The cable insert included in the scope of supply allows connection of the

remote controller to the Drive Unit PPH25RR***. The cable length is 10 m.

Cable operation makes it possible to work in areas where radio operation

is not allowed (e.g. hospitals).

Fig. 5-2 Cable operation

Battery operation:

The battery insert included in the scope of supply allows operation with

three 1.5 V AA batteries. The reception distance is 25 m.

Information

The transmitter and receiver are a pair of matched units. They cann ot be

used with other devices.

Information

When working with the cable connection, all control signals are transmitted via the electric cable.

Operating Instructions Operation

PPH25RR*** / 000 5-5

5.3.4 EMERGENCY STOP

In danger situations the EMERGENCY STOP button must be pressed immediately.

Fig. 5-3 EMERGENCY STOP

1 EMERG. STOP on the Drive Unit PPH25RR***

2 EMERG. STOP on the radio remote control

Deactivating EMERGENCY STOP

Fig. 5-4 Deactivating EMERGENCY STOP

Proceed as follows:

• The following controls must be moved into the 0 position:

- Feed joystick (3)

- Main motor On/Off (5)

• Turn the EMERG. STOP button (1 / 2) clockwise.

• Push the main switch (4) to the ON position.

Information

If the EMERG. STOP is activated on the radio remote control, the LED

pilot lamp flashes quickly.

1

2

1

2

3

4

5

Operation Operating Instructions

5-6 PPH25RR*** / 000

5.4 Working

5.4.1 Starting the Drive Unit PPH25RR***

Proceed as follows:

• Check that the EMERG. STOP buttons on the radio remote control and

on the Drive Unit PPH25RR*** are deactivated.

• Move the controls shown below on the remote controller in to the 0 p osition.

Fig. 5-5 0 position

1 Start switch

2 Feed joystick

3 Main motor On/Off

• Turn the forward/reverse switch on the Drive Unit PPH25RR*** to position 1.

• Switch on the radio remote control by means of the Start switch.

– Pilot lamp lights up red, first of all

– A signal tone sounds simultaneously

– Pilot lamp lights up green

– Second signal tone sounds

– Pilot lamp flashes green

• Push the main switch on the radio remote control twice, into the ON position.

– The electric motor starts

Information

The Drive Unit PPH25RR*** should only be switched on in a level and

upright position. If the surface has an incline, secure the drive unit to prevent rolling away.

Information

If the electric motor does not start, the forward/reverse switch on the

Drive Unit PPH25RR*** must be turned to position 2.

3

2

1

Operating Instructions Operation

PPH25RR*** / 000 5-7

• Press the Water On/Off button on the remote controller to I

• Open the water valve on the Drive Unit PPH25RR***

– water emerges from the cutting tool

• The Drive Unit PPH25RR*** is ready for operation

5.4.2 Soft start

The Drive Unit PPH25RR*** provides the option of a soft start.

The soft start is used mainly for diamond wire sawing.

Proceed as follows

• Start the Drive Unit PPH25RR***,

see "Chapter 5" 5.4.1, 5-6

• Turn the main motor potentiometer to the 0 position

• Select the desired pressure stage,

see "Chapter 5", 5.4.3, 5-8

• Turn the main motor potentiometer slowly to

100% power

Information

If the Drive Unit PPH25RR*** is switched off after the electric motor has

once been started up, in order to start up again it is only necessary to

press the main switch on the remote controller just once more.

Operation Operating Instructions

5-8 PPH25RR*** / 000

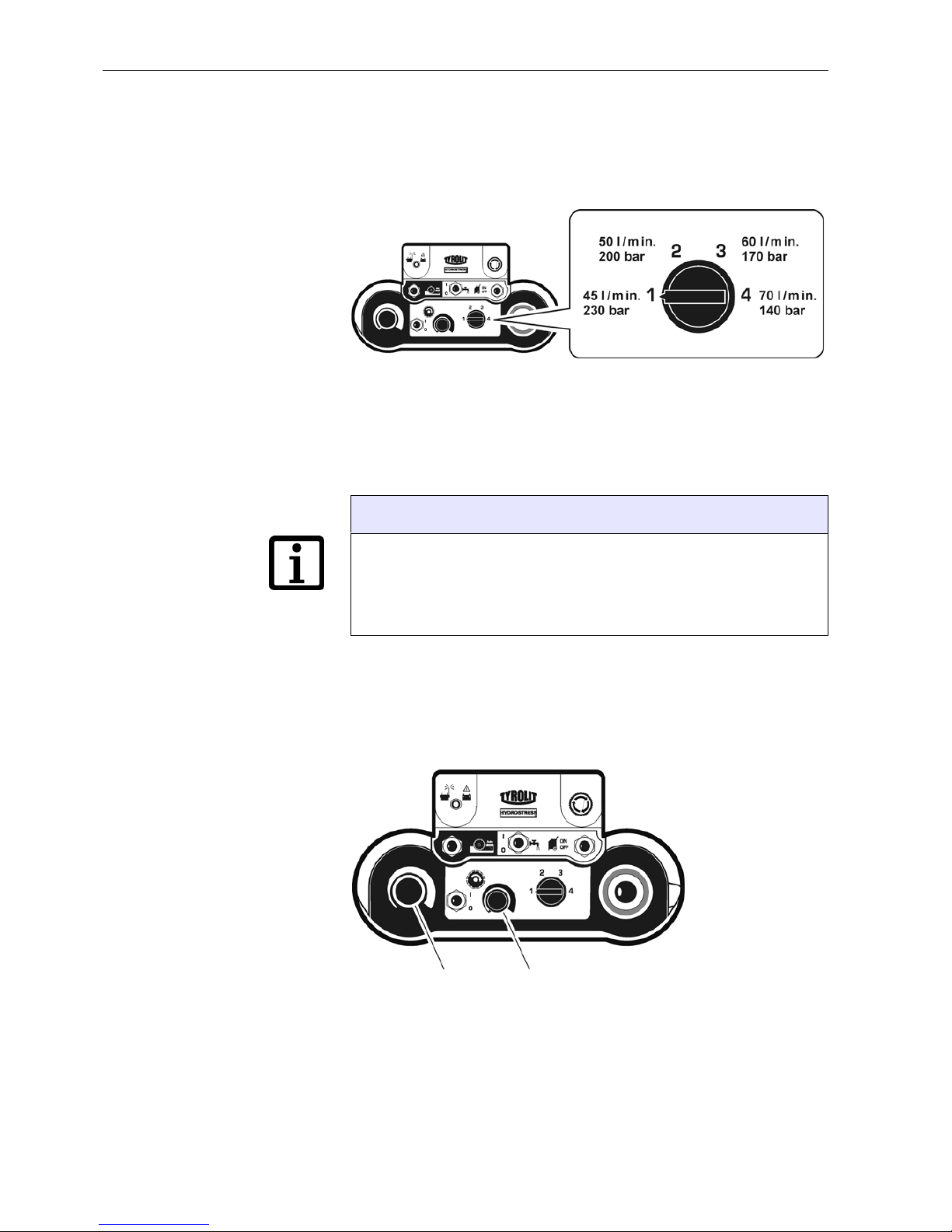

5.4.3 Selecting the pressure stage

Once the Drive Unit PPH25RR*** has been started properly, you can select

the pressure stage.

Fig. 5-6 Selecting the pressure stage

Proceed as follows

• Set the pressure stage selector switch to the desired pressure stage and

turn the main motor potentiometer from 0 to 100%.

5.4.4 Power control

The power of the main motor and the feed mot or is controlled via the potentiometer.

Fig. 5-7 Potentiometers

1 Feed motor potentiometer

2 Main motor potentiometer

Information

The pressure stages can be freely changed and selected during the

work operation. When changing the pressure stage, the cutting tools

should not be under load.

To ensure the optimal tool speeds, the data for the relevant connected

devices must be taken into consideration.

1

2

Operating Instructions Operation

PPH25RR*** / 000 5-9

5.4.5 Feed movements

The feed motors for the travel motion and the swivelling can only be controlled individually by means of the feed joystick.

Fig. 5-8 Feed

ATravel feed

B Swivel feed

5.4.6 Feed locking

So that the joystick does not have to be held in position during the travel

feed motion, the travel feed can be locked.

Proceed as follows

• Push the joystick in the desired travel d irection and, at the same time,

press the locking switch.

• When the joystick and the locking button are released, the feed is

locked.

Information

In order to release the feed lock, move the joystick slightly in any desired

direction.

Operation Operating Instructions

5-10 PPH25RR*** / 000

5.4.7 Shutting down the Drive Unit PPH25RR***

Proceed as follows

• Switch off the electric motor (main switch of radio remote control)

• Shut off the cooling water (Water On/Off button of radio remote control)

• Close the water valve on the Drive Unit PPH25RR***

• Turn the Start switch on the radio remote control into the 0 position

• Turn the forward/reverse switch on the Drive Unit PPH25RR*** to the 0

position

5.5 After the work

Proceed as follows:

• Unplug the mains plug (Drive Unit PPH25RR***)

• Uncouple the water supply on the Drive Unit PPH25RR***

• Open the water valve on the Drive Unit PPH25RR***

• Blow out the water from all the lines (purge pump)

• Uncouple the hydraulic hoses

• Clean the Drive Unit PPH25RR*** with water

Information

Only shut down the Drive Unit PPH25RR*** with the EMERGENCY

STOP in a genuine emergency.

Information

In order to prevent frost damage, if there is a risk of frost the entire water

system must be emptied and blown out upon finishing work or prior to

extended breaks in the work.

Operating Instructions Servicing

PPH25RR*** / 000 6-1

6 Servicing

6.1 Servicing and maintenance table

Before each start-up

Upon completion of work

Weekly

Annually

In the event of malfunction

In the event of damage

Hydraulic system Hydraulic hose inspection

(leakproof condition / cleanliness)

XX XX

Coupling inspection

(leakproof condition / cleanliness)

XX XX

Check oil level,

see "Chapter 4" 4.3.4, 4-5

XX X

Replace hydraulic oil,

see "Chapter 6" 6.1.2, 6-2

X

Water economy Water line

(leakproof condition / cleanliness)

XX XX

If there is a risk of frost, blow out the

water, see "Chapter 6" 6.1.1, 6-2

X

Mechanical Retighten accessible screws and nuts X X

Major service

First service after

100 operating hours

After every 200 operating

hours, thereafter

May only be carried out by

TYROLIT Hydrostress AG

or an authorised representative

Servicing Operating Instructions

6-2 PPH25RR*** / 000

6.1.1 Blowing out the water

6.1.2 Oil change

6.1.2.1 Oil quality

TYROLIT Hydrostress AG recommends:

Hydraulic oil: HLP / ISO VG 46

Other hydraulic oils can be used if they comply with the following specifications:

Information

In order to prevent damage from frost-cracks, if there is a risk of frost or

prior to extended breaks in work the cooling water must be blown out o f

the system. Use the TYROLIT purge pump No. 10982667.

Pour point: -42° C

Viscosity index: 170

Viscosity class: HLP VG 46 or ISO 3498 HV 46

Wear-protection according to DIN 51524 Part 3 (HV46)

Information

Different types of hydraulic oil should not be mixed together, otherwise

the oil will age prematurely.

Operating Instructions Servicing

PPH25RR*** / 000 6-3

6.1.2.2 Replacing hydraulic oil

In order to replace the hydraulic oil you will need:

• A collecting pan for the used hydraulic oil with a capacity of approx.

15 litres

• Open-ended spanner, size across flats 18 mm for the oil drain plug

• Approx. 10 litres of hydraulic oil

Fig. 6-1 Replacing hydraulic oil

1 Oil drain plug

Proceed as follows

• Place the collecting pan below the oil drain plug (1)

• Open tank cover

• Remove oil drain plug (1)

• Drain hydraulic oil completely

• Screw in oil drain plug (1)

• Fill tank with new hydraulic oil

• Bleeding the system

• Close the tank cover

• Dispose of waste hydraulic oil in accordance with local regulations

1

Servicing Operating Instructions

6-4 PPH25RR*** / 000

Bleeding the system

Proceed as follows

• Open tank cover

• Fill oil to maximum mark

• Do not refit the tank cover, yet

• Short-circuit the main circuit with hose

• Start the Drive Unit PPH25RR***,

see "Chapter 5" 5.4.1, 5-6

• Select the pressure stage 4,

see "Chapter 5" 5.4.3, 5-8

• Allow the Drive Unit PPH25RR*** to run for a maximum of 5 seconds

• Switch off the Drive Unit PPH25RR***,

see "Chapter 5" 5.4.7, 5-10

• Wait for 1 minute

• Repeat the start-up and shutdown process three times

• Check the oil level and top up the hydraulic oil as necessary

• Fit tank cover

• The system is now free of air

Information

Air must be bled from the system whenever the tank has been completely emptied and refilled.

Operating Instructions Corrective maintenance

PPH25RR*** / 000 7-1

7 Corrective maintenance

7.1 Troubleshooting

The following table will help you to narrow down and rectify the source of

the fault.

Fault Possible cause Solution

Drive Unit PPH25RR*** does not

run, although the mains cable is

connected

Forward/reverse switch in wrong

position

see "Chapter 5" 5.4.1, 5-6

Emergency stop has been activated Release emergency Stop,

see "Chapter 5" 5.3.4, 5-5

No voltage at drive unit because:

Automatic circuit breaker in

electric controller has tripped

Reset automatic circuit breaker

Mains cable is defective Replace the mains cable

No voltage at the power supply

(building site)

Check power supply

Power supply phases incorrectly

connected

Check power supply

Phase missing Check power supply

Remote controller not switched on

or controls in wrong position

see "Chapter 5" 5.4.1, 5-6

No radio connection Test with cable insert

Drive unit starts up, but then

switches off again

Fuse of building site power supply

trips

- Fuse protection too weak

- Change power supply

Incorrect voltage The details on the name plate must

correspond to the mains network

values (voltage and frequency).

No power, although electric motor is

running and valves are open

Motor runs in wrong direction Change direction of rotation with for-

ward/reverse switch

For drive unit with monitoring

Inform TYROLIT Hydrostress AG

after-sales service

Defective pump Have pump replaced by

TYROLIT Hydrostress AG

or an authorised representative

Defective toothed belt Have toothed belt replaced by

TYROLIT Hydrostress AG

or an authorised representative

Corrective maintenance Operating Instructions

7-2 PPH25RR*** / 000

The hydraulic oil is cloudy, light in

colour and the tank overflows

Defective oil cooler Inform TYROLIT Hydrostress AG

after-sales service

Warning: Do not continue operating

the unit, otherwise hydraulic elements could be damaged

Coupling leaks - Defective seal

- Defective coupling

- Replace seal

- Replace coupling

The drive unit stops suddenly Power supply interrupted because

electric motor or thermal relay has

overheated.

Reasons:

- Undervoltage at the power supply

- Overvoltage at the power supply

- Cross section of power supply

cable too small

- Water supply not correct

Check power supply,

see "Chapter 1" 1.9.1, 1-6

Check power supply,

see "Chapter 1" 1.9.1, 1-6

Use mains cable with correct cross

section, see "Chapter 5" 5.3.1, 5-2

Check water circuit,

see "Chapter 1" 1.10, 1-7

Defective plug connection Check plug connection

No radio connection - Replace the battery

- Work with cable insert

Main motor potentiometer does not

work

Defective potentiometer Note:

see "Chapter 5" 5.4.2, 5-7

TYROLIT Hydrostress AG

Inform the after-sales service

Defective proportional valve Inform TYROLIT Hydrostress AG

after-sales service

Defective pump Inform TYROLIT Hydrostress AG

after-sales service

No pressure build-up in feed circuit Defective potentiometer Inform TYROLIT Hydrostress AG

after-sales service

Defective proportional valve Inform TYROLIT Hydrostress AG

after-sales service

Defective pump Inform TYROLIT Hydrostress AG

after-sales service

Fault Possible cause Solution

Operating Instructions Corrective maintenance

PPH25RR*** / 000 7-3

If you are unable to remedy a fault, please call our service centre (see manufacturer's address on the reverse of the title page).

To guarantee a rapid and professional solution to the problem, it is important that you have prepared as follows before calling:

• Try to describe the fault as accurately as possible

• Note the type and index designation of your unit (name plate)

• Have the Operating Instructions close to hand

Fig. 7-1 Name plate

No water emerging Water line is blocked Clean the water line

Water valve on feed line is closed Open water valve

Insufficient water pressure Check water circuit,

see "Chapter 1" 1.10, 1-7

Defective water valve Inform TYROLIT Hydrostress AG

after-sales service

Water filter is blocked Clean the filter or inform

TYROLIT Hydrostress AG

after sales service

Fault Possible cause Solution

Corrective maintenance Operating Instructions

7-4 PPH25RR*** / 000

7.2 Storage

The Drive Unit PPH25RR*** consists partially of material which can corrode. If you take the unit out of service for an extended period, proceed as

follows:

• Blow out the water from the water lines

• Lightly oil the unit

• Store in a dry location

Operating Instructions Transport

PPH25RR*** / 000 8-1

8 Transport

8.1 Transport

The Drive Unit PPH25RR*** is a high-quality, technical device. Protect it

against transport damage:

• Do not place any parts on or against the Drive Unit PPH25RR***

• Protect the Drive Unit PPH25RR*** from impacts

• The Drive Unit PPH25RR*** must be secured against rolling away during transport

8.2 Safety instructions

It is essential to observe the following safety instructions, especially in relation to taking the Drive Unit PPH25RR*** out of service.

Danger

Danger from incorrect crane transport

Crane transport should only be carried out using the crane shackles provided.

Only undertake crane transport with serviceable building and mobile cranes.

Failure to observe this regulation may lead to serious physical injury, possibly even death, and to property damage.

Warning

Danger from the lifting of heavy loads.

Units which weight more than 30 kg must not be lifted without suitable equipment.

For transport, use the handles provided. Always keep handles

clean and free of grease.

Failure to adhere to this regulation may result in physical injury and

damage to property.

Transport Operating Instructions

8-2 PPH25RR*** / 000

8.3 Crane shackles and transport handles

Fig. 8-1 Crane shackles and transport handles

1 Crane shackles

2 Transport handles with hose bracket

Danger

Danger of falling parts.

When crane transport is used, the Drive Unit PPH25RR*** must be

transported alone, without the radio remote control and hoses.

Failure to observe this regulation may lead to serious physical injury, possibly even death, and to property damage.

1

2

Operating Instructions Disposal

PPH25RR*** / 000 9-1

9 Disposal

9.1 General

The operator can recycle or dispose of the Drive Unit PPH25RR*** himself

provided that he observes the statutory provisions. In order to dismantle

the unit correctly and to properly separate the materials, some knowledge

of mechanical procedures and knowledge about the differentiation of waste

materials is necessary.

Before proceeding, first of all read Chapter 2 "Safety instructions", 2-1 in

these Operating Instructions. Be sure also to observe all the danger information given here and follow the instructions on how to prevent personal

injury and damage to property.

9.1.1 Safety instructions

It is essential to observe the following safety instructions, especially in relation to disposal of the Drive Unit PPH25RR***.

9.1.2 Personnel qualifications

Personnel who carry out the work described in this chapter must meet the

following conditions:

• Have read and understood the safety instructions in "Chapter 2".

• Have completed their technical training (mechanical/electrotechnical)

and are in a position to differentiate the various mate r ial gr ou ps .

Danger

Danger of falling heavy parts.

When performing the types of work described in this chapter, it is

absolutely essential to wear the following personal protective

equipment: goggles, protective gloves and safety shoes.

It is essential to ensure that the work instructions and p rocedur es

described in this safety manual are followed.

Failure to observe this regulation may lead to serious physical injury, possibly even death, and to property damage.

Disposal Operating Instructions

9-2 PPH25RR*** / 000

9.2 Disposal regulations

The usual national and regional regulations and directives must be observed when disposing of the Drive Unit PPH25RR***.

9.3 Disposal of the Drive Unit PPH25RR***

To allow proper disposal, the components of the Drive Unit PPH25RR***

must be dismantled. This is performed by the client's personnel.

The dismantled parts of the device are sorted by material type and sent

separately to the appropriate collection points. Ensure, above all, that the

following parts are correctly disposed of.

The Drive Unit PPH25RR*** consists of the following materials:

Cast aluminium Rolled aluminium products

Copper Steel

Rubber Rubber / nylon fabric

Synthetic grease Hydraulic oil

Plastic

Loading...

Loading...