TYROLIT Hydrostress HYCON HRS 5806 Operating Manual

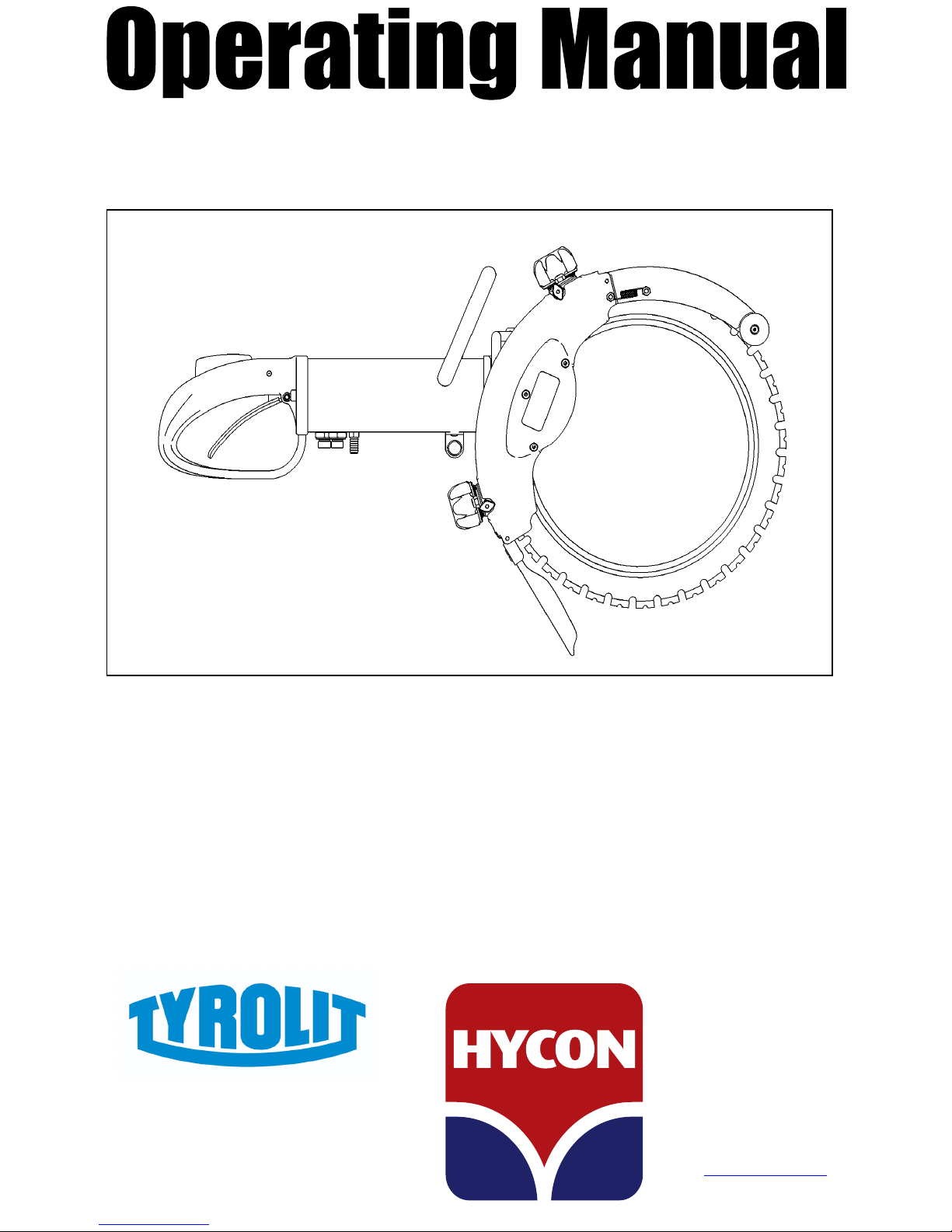

HYCON HRS RING SAW

Operating Manual

www.tyrolit.com.au

info.au@tyrolit.com

1300 TYROLIT

(897 654)

A Company within the SWAROVSKI Group

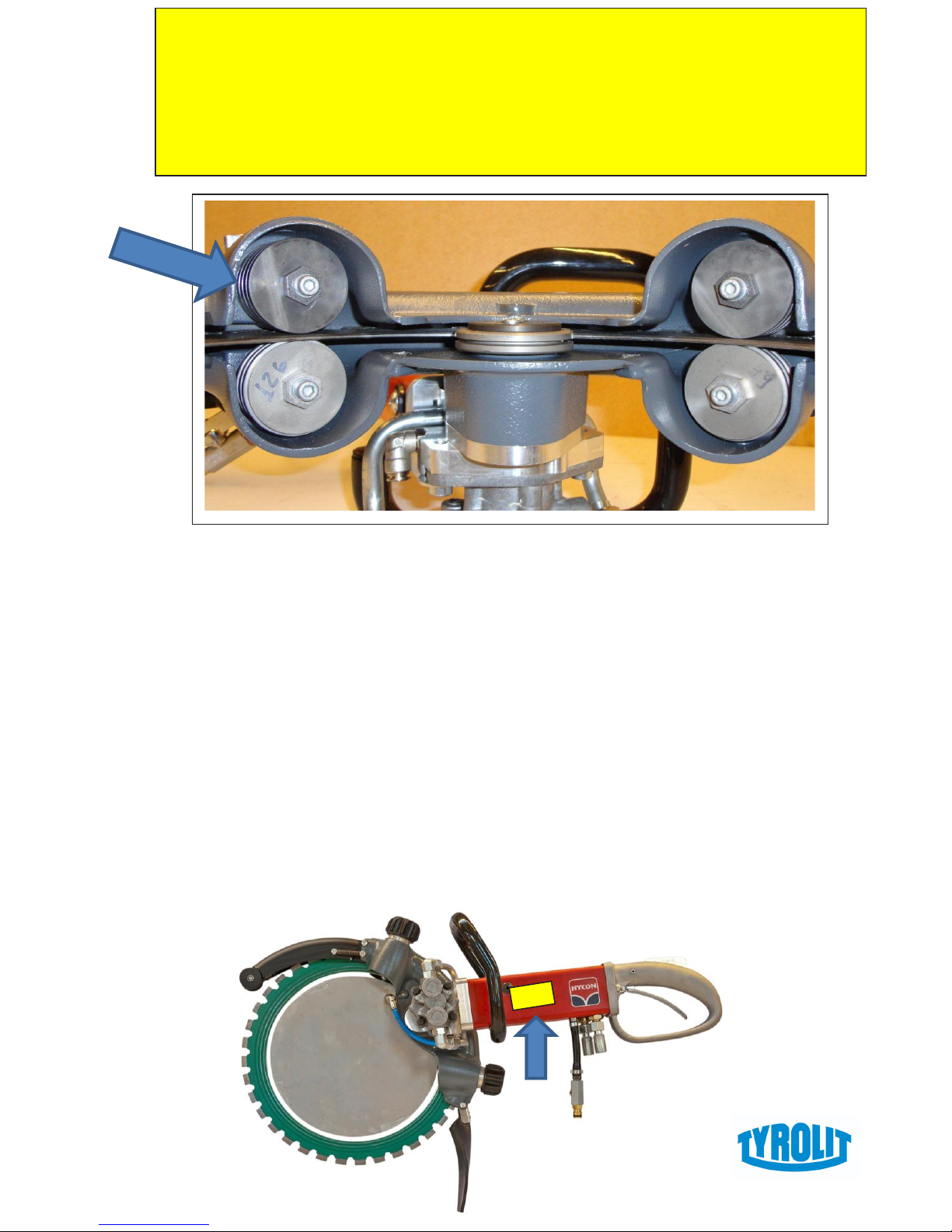

DURING OPERATION WATER AND SLURRY CAN GET INTO THE HOUSING WHERE

THE ROLLERS ARE – THEREFORE TO ENSURE YOUR RING SAW WILL WORK EVERY

DAY TO YOUR SATISFACTION IT IS VITAL THAT YOU:

* LET THE RINGBLADE SPIN FREE IN THE AIR FOR MINIMUM 30 SECONDS AFTER

EACH USE > THIS WILL FLUSH CLEAN WATER AROUND THE ROLLERS.

* CLEAN THE ROLLERS AND THE HOUSING VERY CAREFULLY WITH THE WATER

HOSE EVERY DAY AFTER USE AND SPRAY ALL PARTS WITH WD40

* THE GUIDE ROLLER ADJUSTMENT SHOULD EVERY DAY AFTER USE BE TURNED

ANTI CLOCKWISE TO PROTECT THE ADJUSTMENT FUNCTION

Important

Clean after use

HYCON A/S

Juelstrupparken 11

DK-9530 Støvring

Denmark

Tel: +45 9647 5200

Fax: +45 9647 5201

Mail hycon@hycon.dk

www.hycon.dk

TYROLIT Australia

9 Tarlington Place

Smithels, NSW 2164

P:1300 TYROLIT (897 654)

F:1300 235 689

E: info.au@tyrolit.com

HYCON HRS Ring Saw

HYCON A/S • Juelstrupparken 11 • DK-9530 Støvring • Tel +45 9647 5200

1

Prior to Operation

We thank you for choosing a HYCON

HRS ring saw.

To ensure smooth operation and longlasting performance of your new ring

saw, we recommend you to study this

operating manual carefully and pay

special attention to the chapters about

Safety and Service

Precautions

We hope you will be satisfied with your

new HYCON ring saw.

Best regards

HYCON A/S.

Table of Content

Prior to Operation .................................................................... 1

Specifications ........................................................................... 2

Safety Precautions ............................................................... 2+3

HRS Hydraulic Ring Saw Overall Dimensions ........................... 4

Operation ................................................................................. 5

General Working Instructions .................................................. 5

Cold Weather Operation ......................................................... 5

Equipment Protection and Care .............................................. 5

Starting Instructions ................................................................ 6

Use of HRS Ring Saw Discs ....................................................... 6

Service and Maintenance ........................................................ 6

Oil Types .................................................................................. 6

Length of Hoses ....................................................................... 6

Use of Hydraulic Power Sources .............................................. 6

Useful Information regarding use of HRS Ring Saw ................. 7

Replacement/Adjustment of Disc ............................................ 8

Adjustment of Support Rollers ................................................ 8

Dismounting of Front Cover and Water Blade ........................ 9

Replacement of Drive Wheel ................................................... 9

Replacement of Disc .............................................................. 10

Replacement of Support and Guide Rollers .......................... 10

Trouble Shooting ................................................................... 11

HYCON HRS Ring Saw

HYCON A/S • Juelstrupparken 11 • DK-9530 Støvring • Tel +45 9647 5200

2

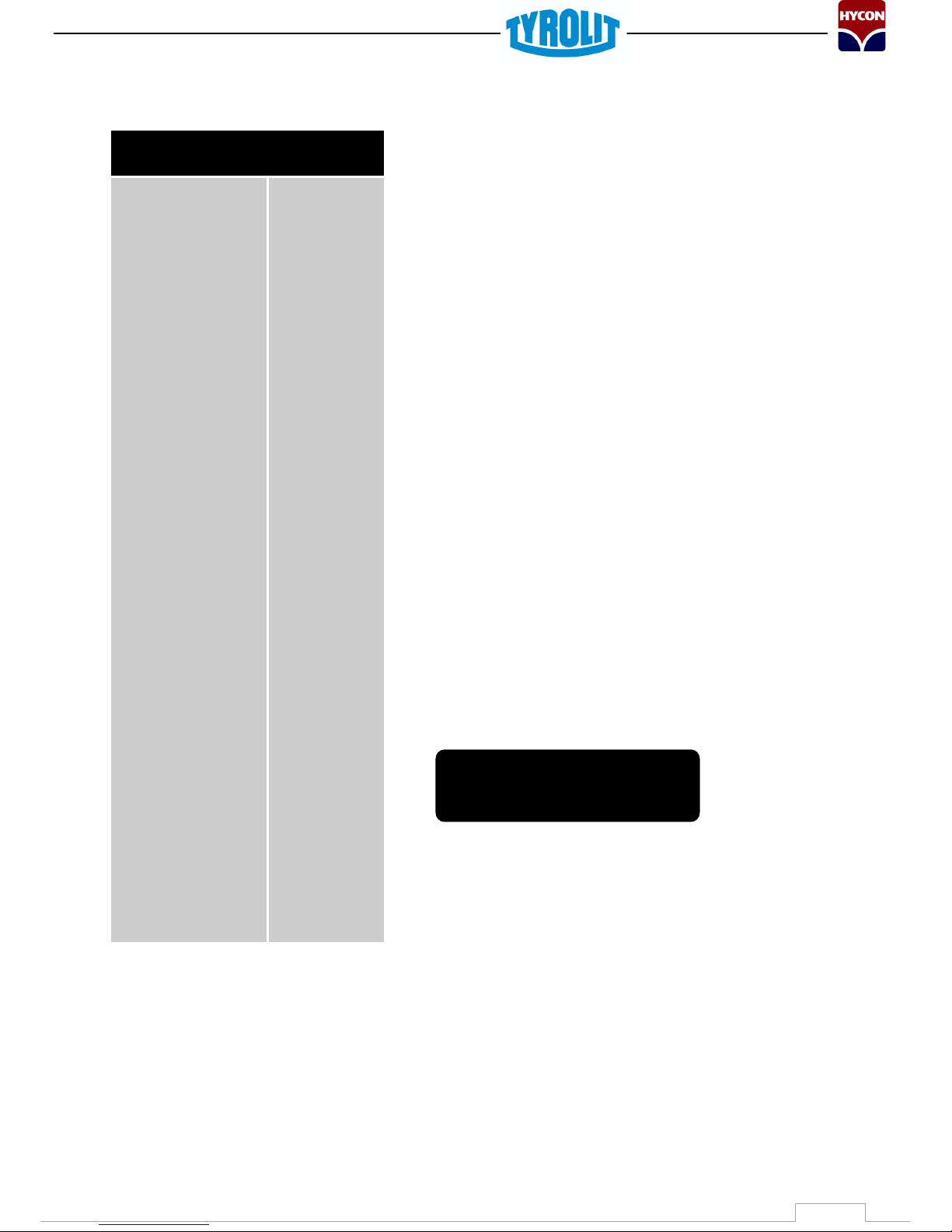

Specifications

HRS Ring Saw

Weight w/o hoses

and disc

10.9 kg

Oil flow

30-40 l.p.m.

Recom

mended water

supply

4 l.p.m. / 2 bar

Working pressure

nominal

160 bar

Pressure relief valve in

power source

Max. 250 bar

Max. return pressure

40 bar

Max. oil temperature

80°C

Disc diameter

400 mm

Max. cutting depth

300 mm

Circumferential speed

37–49 m/s

Vibration level

<2.5m/s²

Sound pressure level

1 m LPA

109 dB(A)

Sound Power level LWA

98 dB(A)

Necessary cooling

capacity on power

source

1 kW

Power

4.7 kW

Safety Precautions

• Read the HRS ring saw and power source operating manuals prior to use.

• Only use the HRS ring saw in accordance with the local working regulations

on allowed working time

• Check the oil flow to the HRS ring saw. The oil flow may not exceed 40

l.p.m. A too high oil supply can result in the speed of the diamond disc

being too high, causing the disc to break.

• Make sure that the diamond disc is mounted correctly and firmly fastened.

• Always use diamond discs approved for handheld cutting and for the

material to be cut.

• Always use discs that are in good condition.

• From the factory, the HRS ring saw is mounted with a safety trigger, which

may never be disturbed or dismounted.

• The HRS ring saw has an automatic integrated security that makes the saw

stop if the diamond disc jams. However, in case of jamming, always loosen

the disc from the material, before you start cutting again.

• Start the HRS ring saw just before you start cutting, and stop it again once

the cutting is done. Do not let the HRS ring saw run freely in the air without

water supply.

• In case of horizontal cutting or cutting above the head, always be aware of

material falling down.

• A fine jet of oil at pressure can penetrate the skin. It is therefore important

never to use your fingers to check for oil leaks and never to hold your face

close to suspected leaks – use a piece of cardboard instead. If oil has

penetrated the skin, you should get medical treatment immediately.

• Never leave the HRS ring saw when connected to the powerpack.

• Always use approved hoses. Contact your dealer, if necessary. Mount the

hoses correctly so that the HRS ring saw rotates in the right direction. The

hydraulic motor will be destroyed if pressure is set to the wrong connection.

(T)

• The operator must pay extra attention and show caution when working in

difficult working areas, such as slopes and other dangerous nature of the

ground. Do not reach too far with the HRS ring saw, but always maintain a

good footing and keep your balance.

• The operator must be properly trained in using the HRS ring saw or under

supervision of a qualified instructor.

• The operator must always use protective goggles, earplugs, hard hat and

shoes when operating the HRS ring saw.

Loading...

Loading...