TYROLIT Hydrostress HRG500 Operating Instructions Manual

Operating Instructions

Ring saw HRG500

Index 000

10992852 en /17.04.2012

Page 2

Ring saw HRG500

TYROLIT Hydrostress AG

Witzbergstrasse 18

CH-8330 Pfäkon

Switzerland

Tel. 0041 (0) 44 952 18 18

Fax 0041 (0) 44 952 18 00

Congratulations!

You have decided to purchase a tried and tested TYROLIT Hydrostress unit and have thus ac-

quired a highly sophisticated and reliable state-of-the-art unit. Only genuine TYROLIT Hydro-

stress replacement parts can guarantee quality and interchangeability. If maintenance work is

neglected or carried out inexpertly we will be unable to honour our warranty obligations. Any

repair work must be carried out by trained personnel only.

Should you need more details concerning your TYROLIT Hydrostress unit in order to keep it in

perfect condition, please contact our after-sales service for further information.

We hope that working with your TYROLIT unit will be a satisfying and fault-free experience.

TYROLIT Hydrostress

Copyright © TYROLIT Hydrostress

TYROLIT Hydrostress AG

Page 3

Ring saw HRG500

Concerning these instructions

These instructions are a constituent of the unit. They describe how to use the equipment safely

and properly in all phases of operation.

• Read the instructions carefully before use, particularly the safety instructions.

• Keep the instructions for the entire service life of the equipment.

• Ensure that the instructions are available to the operator and the service engineers at all

times.

• Pass the instructions on to all subsequent owners or users of the equipment.

• Update instructions with all supplements received from the manufacturer.

Danger symbols in these instructions

DANGER

Warning of danger, where failure to comply could lead to death or serious injury.

WARNING

Warning of danger, where failure to comply could lead to injuries or damage to property.

Information for optimum use of equipment. Failure to take note of this information may mean

that the performance information shown in the technical data can no longer be guaranteed.

1

1.1

TYROLIT Hydrostress AG

Page 4

Ring saw HRG500

Safety instructions

Please pay attention to the safety instructions

Do not work with the unit unless you have read and understood the safety instructions.

The unit has been inspected before being shipped and is delivered in perfect condition.

TYROLIT Hydrostress does not accept liability for damage caused by failing to follow these

instructions. This applies in particular to the following damage:

• Damage caused by improper use and operator error

• Damage caused by failure to observe the safety-related information in these instructions or

the warning signs on the unit.

• Damage caused by substandard maintenance work

Use for correct purpose

The ring saw is used by trained personnel for cutting concrete, masonry and stone.

Incorrect use:

• Working without protective equipment or inadequate protective equipment

• Cutting other materials

• Removal of protective devices

• Cutting in potentially explosive areas

• Cutting loose parts

• Incorrect or absence of waste water disposal (sawing sludge)

Target groups and responsibility

Authorised personnel

Work on or with machines or systems from TYROLIT Hydrostress may only be carried out by

authorised persons. Personnel are considered to be authorised if they meet the necessary

training and know-how requirements and they have been assigned an exact functional role.

Manufacturer

The following are considered to be manufacturers of products that are supplied by TYROLIT

Hydrostress:

• TYROLIT Hydrostress

• A company explicitly nominated by TYROLIT Hydrostress

Within the context of an integrated quality assurance and safety control system, the manufacturer is entitled to request from the operator information about the products.

Operator

The operator named by TYROLITHydrostress is the primary, legal entity responsible for the correct use of the product and for the training and assignment of the authorised personnel. The

operator sets out the skills and level of training of the authorised personnel.

Personnel qualications

• A technical trained person in a management position.

• Relevant experience in personnel management and risk assessment

• Has read and understood the safety instructions

2

2.1

2.2

2.3

2.3.1

2.3.2

2.3.3

TYROLIT Hydrostress AG

Page 5

Ring saw HRG500

Operator (user)

User is the term employed by TYROLIT Hydrostress to designate a person who independently

performs the following work:

• Setting up the machines and systems of TYROLIT Hydrostress within the scope of correct

purpose of use

• Independent performance and monitoring of work

• Localisation of faults and organisation of troubleshooting and independent fault remedying

• Maintenance

• Testing the correct operation of safety equipment

Personnel qualications

• Completed training as a concrete expert or relevant professional experience

• Introduction (basic training) to the operation of the unit by a service engineer

Service engineer

A service engineer is the term employed by TYROLIT Hydrostress to designate a person who independently performs the following work:

• Installs TYROLIT Hydrostress machines and systems

• Makes adjustments to machines and systems for which certain access rights are required.

• Complex service and repair work

Personnel qualications

• Specialist professional training (mechanical / electrotechnical)

• Product-specic training at TYROLIT Hydrostress

Organisational measures

Product monitoring obligation

The unit may only be operated in perfect and undamaged condition. Operating personnel must

notify changes in operational behaviour or safety-related components to a responsible person

or the manufacturer, immediately.

The maintenance intervals must be adhered to. Faults that aect safety must be remedied immediately

Location of these instructions

A copy of these instructions must be available to personnel at the place of use of the unit at all

times.

Workplace

X Provide sucient space to carry out work safely.

X Ensure that the workplace is suciently illuminated.

X Cordon o the danger area in a clearly noticeable way so that no person can enter the dan-

ger area during sawing.

2.3.4

2.3.5

2.4

2.4.1

2.4.2

2.4.3

TYROLIT Hydrostress AG

Page 6

Ring saw HRG500

Protective devices and signs on the equipment

Protective devices

Protective devices may only be removed if the equipment has been switched o and is at a

standstill. Safety components in particular should only be removed and retted by authorised

personnel.

Before switching the equipment back on again, check that the safety elements are operating

correctly.

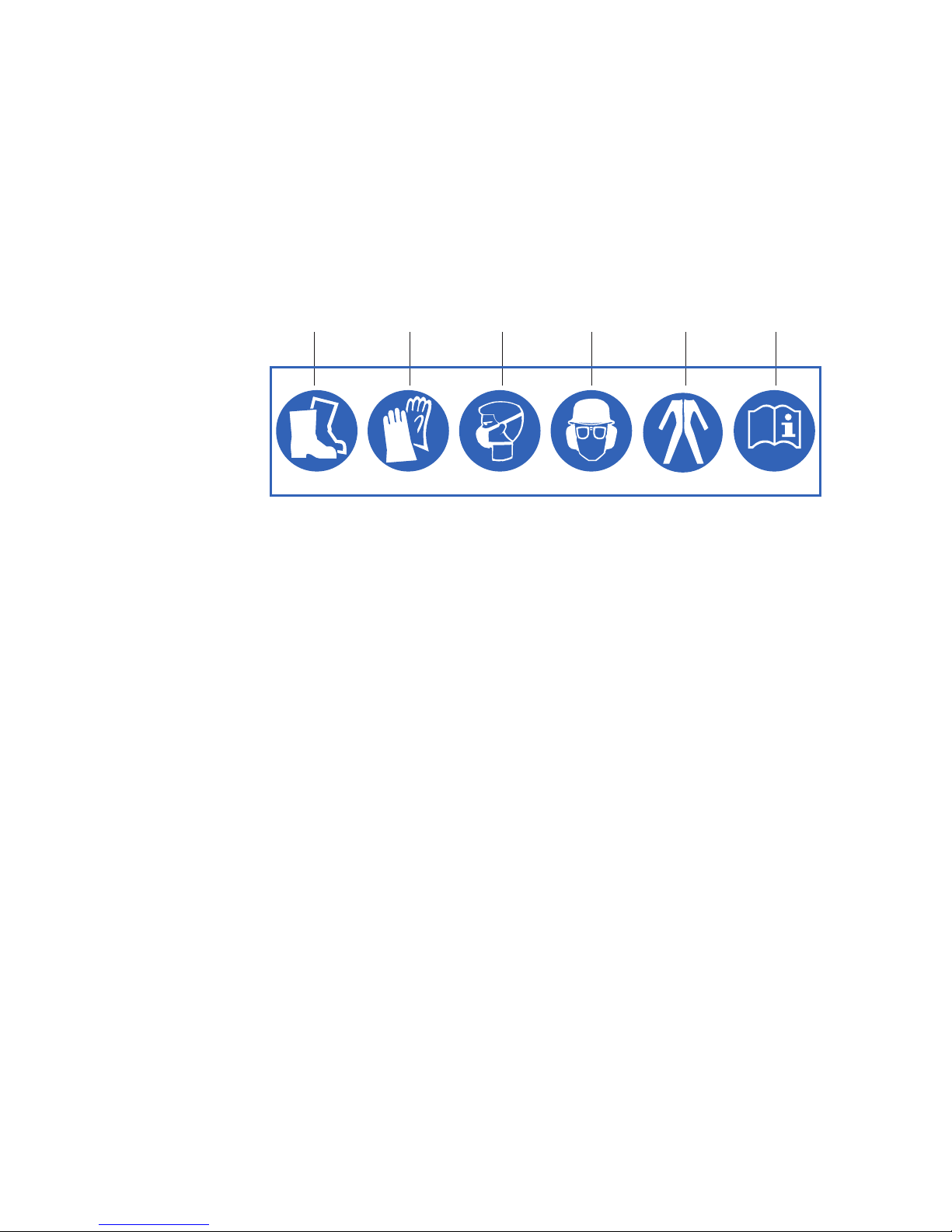

Signs on the equipment

1 Wear safety shoes 4 Wear a helmet, goggles and hearing protection

2 Wear gloves 5 Wear safety clothing

3 Wear a breathing mask 6 Read the instructions

Spare parts and modications

Only original spare parts from TYROLIT Hydrostress must be used. Otherwise damage may be

caused to the unit or to other property and persons.

No additions or modications must be made to the unit without written permission from

TYROLIT Hydrostress.

2.5

2.5.1

2.5.2

1 5432 6

2.6

TYROLIT Hydrostress AG

Page 7

Ring saw HRG500

Safety clothing

Safety clothing

Residual risks

Risk of serious injuries from the residual risks described in the chapters that follow.

Sharp edges

Risk of serious lacerations if the tool is touched.

X Do not touch the tool during operation

X Always wear gloves when handling the stationary tool.

Diamond segments ying o

X Before use, always ensure that the ring guard is correctly tted and undamaged.

X Do not start sawing if any other persons are in the danger zone.

X Ensure that a safety distance of 15 m is maintained from the ring saw.

X Replace the disk grinding ring if diamond segments start to break o.

Recoil

Erroneous positioning of the disk grinding ring or cutting the wrong materials can make the

ring saw recoil and seriously injure the operator.

X Only cut materials that are permitted within the scope of the correct purpose of use.

X Do not apply disk grinding ring above the middle of a workpiece edge.

Unintentional start-up

X Before starting up, please ensure that:

– The control handle with lock is working correctly.

– There are no other persons in the danger zone.

Vibration

Vibration can cause circulation problems and/or nerve damage.

Consult a doctor in the event of symptoms.

2.7

2.8

2.8.1

2.8.2

2.8.3

2.8.4

2.8.5

TYROLIT Hydrostress AG

Page 8

Ring saw HRG500

Uncontrolled movements and vibration

X Always hold ring saw by the handles with both hands during operation. Thumbs and ngers

must be closed around the handles.

X Keep the handles clean.

X Never saw above shoulder height.

X Never stand on ladder when sawing.

X Guide the motor saw in such a way that no part of your body is inside the extension of the

disk grinding ring of the saw.

A loose disk grinding ring can cause uncontrolled ring saw vibration.

X Ensure that the drive rolls are correctly mounted.

Catching and winding in

Items of clothing or long hair can be caught by the rotating disk grinding ring.

X Always work with the protective covers tted.

X Do not wear loose items of clothing at work.

X Wear a hair net if you have long hair.

Particles ying o

Flying particles can cause eye injuries.

X Wear safety goggles or a visor.

X Ensure that danger area is properly cordoned o.

Falling parts

Falling parts can cause serious head and foot injuries.

X Wear helmet and safety shoes with steel toecaps.

X Lumps of concrete that have been cut loose must be secured against falling.

X Safeguard front, underneath and rear of sawing area from falling parts or sawing sludge.

People must not be injured or equipment damaged.

Noise

Noise can damage the hearing.

X Wear hearing protection.

Damaging vapours and aerosols

Inhaling damaging vapours and/or aerosols can cause breathing problems.

Breathing in the water fog and exhaust that is emitted is a health hazard.

X Wear a breathing mask.

X Provide adequate ventilation in conned spaces.

Risk of slipping

X Do not work on uneven surfaces.

X Wear safety shoes with non-slip soles.

The sludge resulting from cutting is very greasy.

X Remove sludge or ensure that people cannot slip in it.

Risk of ring saw restart in the event of an accident

X Ensure that the ring saw can be stopped quickly.

2.8.6

2.8.7

2.8.8

2.8.9

2.8.10

2.8.11

2.8.12

2.8.13

TYROLIT Hydrostress AG

Page 9

Ring saw HRG500

Physical condition

X Do not work whilst under the inuence of alcohol, drugs or medication.

X Do not work when you are overtired.

X Do not allow children or adolescents below the age of 18 to operate the motor saw.

Adolescents aged 16 and over are excepted from this ban is they are under the supervision

of an expert for training purposes.

Reduced cutting ring quality

X Do not use damaged disk grinding rings.

X Check disk grinding ring for damage before installation.

X Do not equip disk grinding ring with new diamond segments.

Fuel / refuelling

Contact with petrol and oil can cause allergic reactions.

X Wear protective gloves.

X If petrol or oil come into contact with skin, wash aected areas immediately with plenty of

water.

Refuelling

X Switch motor o when refuelling the motor saw.

X Smoking and naked ames are prohibited.

X Allow machine to cool before refuelling.

X Fuel can contain substances similar to solvents. Avoid skin and eye contact with mineral oil

products. Wear gloves when refuelling. Change and clean protective clothing at frequent

intervals. Do not inhale fuel vapour. Breathing in fuel vapour can cause physical injury.

X Do not spill fuel or oil. If fuel or oil is spilled, clean motor saw immediately. Do not allow fuel

to come into contact with clothing. If clothing comes into contact with fuel, replace clothing

immediately!

X Ensure that no fuel or oil gets into the soil (environmental protection). Use a suitable surface.

X Do not refuel in conned spaces. Fuel vapour accumulates at oor level (risk of explosion).

X Ensure that screw plugs of fuel tank and oil tank are closed properly.

X Change location before starting the motor saw (at least 3 metres away from refuelling sta-

tion).

X Fuel has a limited storage time. Only buy as much as you intend to use within a foreseeable

time.

X Always transport and store fuel and oil in approved and marked canisters.

Keep children away from fuel and oil.

Explosion hazard

Starting of res and smoking in the immediate vicinity of the ring saw is strictly prohibited.

Transport

X Never transport the motor saw while it is running!

X Always carry motor saw with the bow-type handle.

2.8.14

2.8.15

2.8.16

2.8.17

2.8.18

Loading...

Loading...