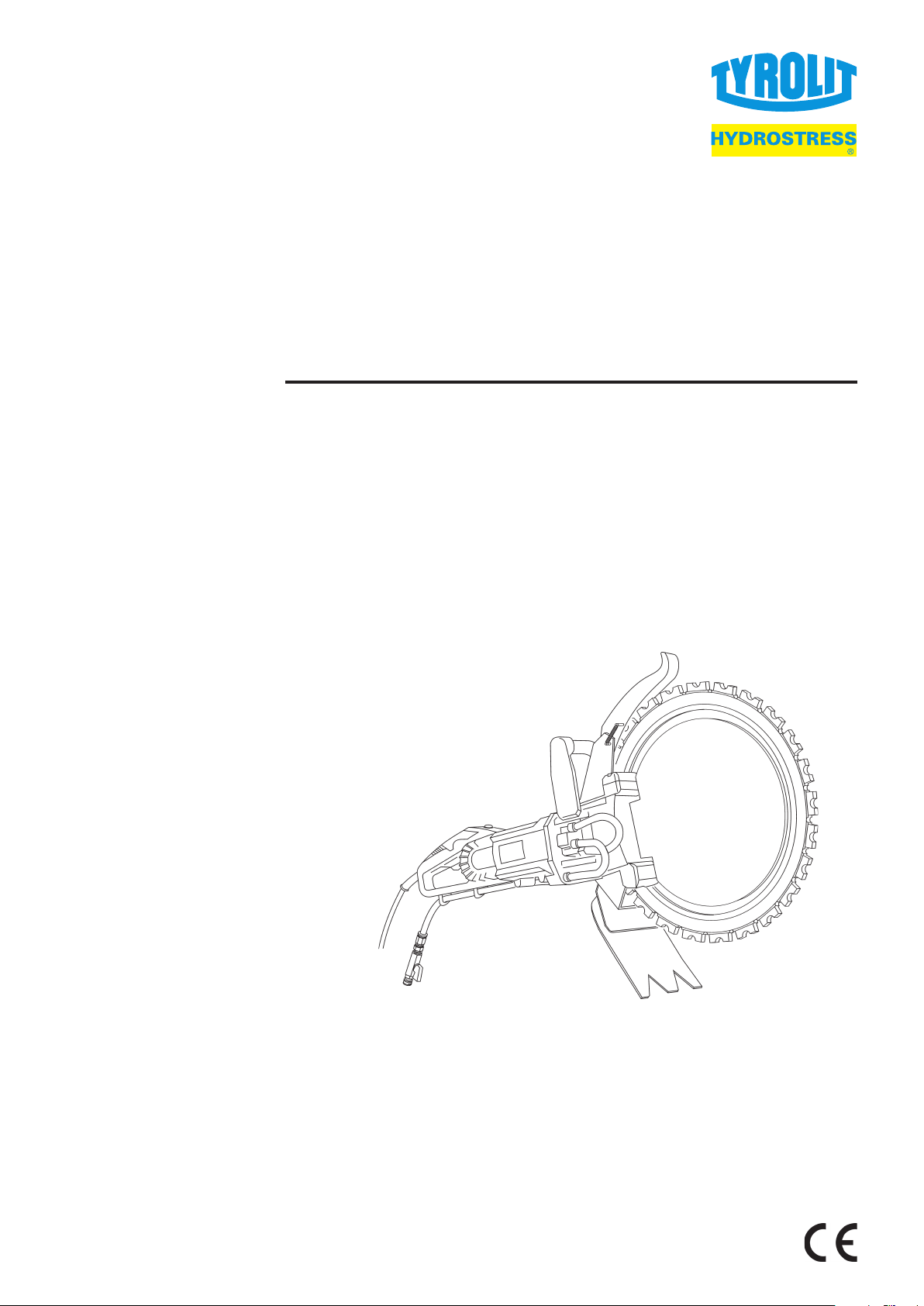

TYROLIT Hydrostress HRE400 Operating Instructions Manual

Operating Instructions

Ring saw HRE400

Index 000

Original operating instructions

10996848 en/21/04/2016

Congratulations!

You have decided to purchase a tried-and-tested TYROLIT Hydrostress unit and have thus acquired a highly sophisticated and reliable state-of-the-art device. Only genuine TYROLIT Hydrostress replacement parts can guarantee quality and interchangeability. If maintenance work

is neglected or carried out inexpertly, we will be unable to honour our warranty obligations. All

repairs must be carried out by trained personnel only.

Our after-sales service is available to help ensure that your TYROLIT Hydrostress units remain in

perfect working order.

We hope that working with your TYROLIT unit will be a satisfying and fault-free experience.

TYROLIT Hydrostress

Copyright © TYROLIT Hydrostress

TYROLIT Hydrostress AG

Witzbergstrasse 18

CH-8330 Pfäkon

Switzerland

Tel. 0041 (0) 44 952 18 18

Fax 0041 (0) 44 952 18 00

Page 2

Ring saw HRE400

TYROLIT Hydrostress AG

Table of contents

Page

1. Concerning these instructions .................................................... 4

2. Safety ........................................................................... 5

3. Product description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4. Preparatory operations ........................................................... 17

5. Assembly / Disassembly .......................................................... 18

6. Operation ........................................................................ 22

7 Maintenance ..................................................................... 26

8. Faults ............................................................................ 27

9. Technical data ................................................................... 29

10. EC Declaration of Conformity ..................................................... 31

Ring saw HRE400

Page 3

TYROLIT Hydrostress AG

1

Concerning these instructions

These instructions are a part of the electrical tool. They describe how to use the equipment

safely and properly in all phases of operation.

• Read the instructions carefully before use, particularly the safety instructions.

• Keep the instructions for the entire service life of the electrical tool.

• Ensure that the instructions are available to the operator and the service engineers at all

times.

• Pass the instructions on to all subsequent owners or users of the electrical tool.

• Update instructions with all supplements received from the manufacturer.

1.1

Danger symbols in these instructions

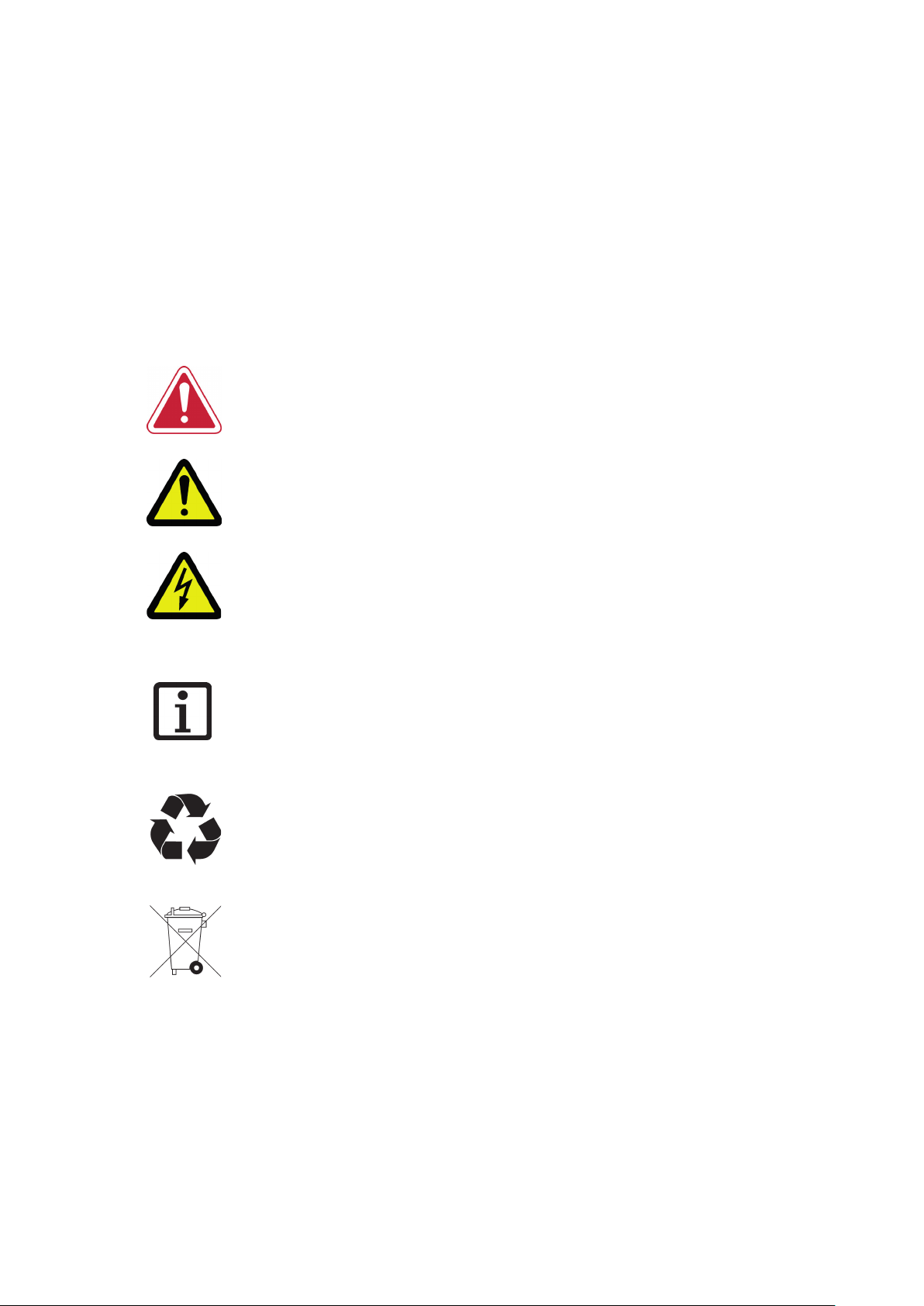

DANGER

Warning of danger, where failure to comply could lead to death or serious injury.

WARNING

Warning of danger, where failure to comply could lead to injuries or damage to property.

WARNING

Warning - dangerous electrical voltage.

Before working in an area identied in this way, ensure the installation or electrical tool is fully

isolated from the power (voltage) and secured to prevent it being accidentally powered up

again.

INFORMATION

Information for optimum use of electrical tool. Failure to take note of this information may

mean it is not possible to guarantee the performance stated in the technical data.

RECYCLING

Take waste for recycling.

DISPOSAL

Observer country-specic national and regional laws and guidelines when disposing of the

electrical tool.

Page 4

Ring saw HRE400

TYROLIT Hydrostress AG

2

Safety

Electrical tools must be operated by authorised personnel only. Information regarding

authorised personnel is available in “Chapter 2.4”.

2.1

2.1.1

2.1.2

General safety information

WARNING

Read all safety information and instructions. Any failure to observe the safety information

and instructions can result in electric shock, re and/or serious injuries.

Retain all safety information and instructions for future reference.

The term electrical tool used in the safety instructions pertains to the mains-operated electrical

tool (with a mains cable) and battery-operated electrical tool (without a mains cable).

Workplace safety

• Keep your place of work clean and well illuminated. Untidy or non-illuminated work areas

can lead to accidents.

• Do not use the electrical tool in potentially explosive areas in which ammable liquids,

gases or dust are present. Electrical tools create sparks that can ignite dust or vapours.

• Ensure children and other people kept at a safe distance when using the electrical tool. If

you are distracted, you may lose control of the tool.

Electrical safety

• The electric plug of the electrical tool must t into the socket outlet. Do not modify

the plug in any way. Do not use adapter plugs together with earthed electrical tools.

Unmodied plugs and matching socket outlets reduce the risk of electric shock.

• Avoid body contact with earthed surfaces such as pipes, heaters, ovens and

refrigerators. There is an increased risk of electric shock if your body is earthed.

• Protect your electrical tool from rain and moisture. Water ingressing an electrical tool

increases the risk of electric shock.

• Do not use the cable to carry or hang up the electrical tool or to pull the plug out of the

socket outlet. Keep the cable away from heat, oil, sharp edges and moving tool parts.

Damaged or tangled cables increase the risk of electric shock.

• When using an electrical tool outdoors, use an extension lead that is suitable for use in

outdoor areas. Using an extension lead suitable for use in outdoor areas reduces the risk of

electric shock.

• If it is not possible to avoid operating the electrical tool in a damp environment, ensure

a residual current protective device is installed. Using a residual current protective device

reduces the risk of electric shock.

Ring saw HRE400

Page 5

TYROLIT Hydrostress AG

2.1.3

Safety of persons

• Remain alert, be aware of what you are doing and use common sense when working

with the electrical tool. Do not use the electrical tool when you are tired or under the

inuence of drugs, alcohol or medication. A eeting moment of carelessness when using

the electrical tool can lead to serious injuries.

• Wear Personal Protective Equipment and always wear safety goggles. Wearing

appropriate personal protective equipment according to the prevailing conditions, such as

a dust mask, non-slip safety shoes, hard hat and/or hearing protection will reduce the risk of

injuries.

• Avoid starting the electrical tool unintentionally. Ensure the electrical tool is switched

o before you pick up, carry or connect the electrical tool to the power supply and/or

connect the rechargeable battery. Carrying the electrical tool with your nger on the switch

or the tool is switched on when you connect it to the power supply can lead to accidents.

• Remove adjusting tools and spanners before switching on the electrical tool. Never work

from a ladder. A tool or key attached to the rotating tool may cause injuries.

• Avoid abnormal postures. Ensure that you have rm footing, and keep your balance

at all times. That will ensure you are able to better control the electrical tool in unexpected

situations.

• Wear suitable clothing. Do not wear loose tting clothing or jewellery. Keep your hair,

clothing and gloves away from moving parts. Loose tting clothing, jewellery and long hair

can get caught up in moving parts.

2.1.4

• If there is an option to t dust extraction and collection devices, ensure they are

correctly connected and used properly. Using a dust extraction device can reduce risks

associated with dust.

Using and caring for the electrical tool

• Do not overload the tool. Use the correct electrical tool for your work. Using the correct

electrical tool will enable you to carry out your work better and more safely in the specied

power range.

• Do not use any electrical tool if the switch is faulty. Any electrical tool that can no longer

be switched on and o is dangerous and must be repaired.

• Remove the plug from the socket outlet and/or remove the rechargeable battery before

adjusting the tool, changing accessories or putting the tool away. These cautionary

measures prevent the electrical tool starting up unintentionally.

• When not in use store the electrical tool out of reach of children. Do not allow anybody

to use the tool not familiar with the tool or have not read these instructions. Electrical

tools are dangerous in the hands of untrained users.

• Care for electrical tools appropriately. Check moving parts function awlessly and do

not jam; check if any parts are broken or damaged and impair the proper function of

the electrical tool. Ensure damaged parts are repaired before using the tool. Poorly

maintained electrical tools are the cause of many accidents.

• Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp edges jam

less often and are easier to use.

Page 6

• Observe these instructions when using the electrical tool, accessories and tool bits.

Be aware of the working conditions and the task at hand. Using electrical tools for any

application other than for what they were designed can lead to hazardous situations.

Ring saw HRE400

TYROLIT Hydrostress AG

2.1.5

2.1.6

2.2

Service

• Allow only qualied and skilled personnel to repair your tool using only original spare

parts. That guarantees the safety of the electrical tool is maintained.

Safety information for hand saws

• Wear hearing protection when using hand saws. The eect of noise can lead to a loss of

hearing.

• Use the handles tted to the tool. Losing control of the machine can lead to injuries.

• Hold the tool using the insulated gripping surfaces when carrying out work that risks

the tool being used coming into contact with concealed power cables or its own mains

cable. Contact with a live conductor can cause metal parts to become live and result in an

electric shock.

Pay attention to the safety instructions

Do not work with the electrical tool unless you have read and understood the safety

instructions.

The electrical tool has been inspected before being shipped and is delivered in perfect

condition. TYROLIT Hydrostress does not accept liability for damage caused by failing to follow

these instructions. This applies in particular to the following damage:

• Damage caused by improper use and operator error

• Damage caused by failure to observe the safety-related information in these instructions or

the warning signs on the electrical tool

• Damage caused by substandard maintenance work

2.3

Intended use

The electrical tool is used by trained personnel to cut concrete, masonry and stone.

Incorrect use:

• Working without protective equipment or inadequate protective equipment

• Cutting other materials

• Removing protective devices

• Cutting in potentially explosive areas

• Cutting loose parts

• Incorrect or absence of waste water disposal (sawing sludge)

Ring saw HRE400

Page 7

TYROLIT Hydrostress AG

2.4

2.4.1

2.4.2

2.4.3

Target groups and responsibility

Authorised personnel

Work on or with machines or systems from TYROLIT Hydrostress must be carried out by

authorised personnel only. Personnel are considered to be authorised if they meet the

necessary training and know-how requirements and have been assigned a precisely dened

task.

Manufacturer

Manufacturers of products supplied by TYROLIT Hydrostress are:

• TYROLITHydrostress

• A company explicitly named by TYROLIT Hydrostress

Within the context of an integrated quality assurance and safety control system, the

manufacturer is entitled to request from the operating company information about the

products.

Operating company

The operating company named by TYROLITHydrostress is the primary, legal entity responsible

for the correct use of the product and for the training and assignment of authorised personnel.

The operating company sets out the skills and level of training of authorised personnel.

Personnel qualications

• A person with technical qualications in a management position

• Relevant experience in personnel management and risk assessment

• Has read and understood the safety instructions

2.4.4

2.4.5

Operator (user)

User is the term employed by TYROLIT Hydrostress to designate a person who performs the

following work without direct supervision:

• Setting up the machines and systems from TYROLIT Hydrostress within the scope of their

intended use

• Performs and monitors work without direct supervision

• Localises faults and organises troubleshooting and fault correction without direct

supervision

• Maintenance

• Veries safety devices are functioning correctly

Personnel qualications

• Completed vocational training as a concrete tradesman or relevant occupational experience

• Introduction (basic training) in the operation of the electrical tool by a service engineer

Service engineer

A service engineer is the term applied by TYROLIT Hydrostress to a person who performs the

following work without direct supervision:

• Installs TYROLIT Hydrostress machines and systems

• Makes adjustments to machines and systems for which certain access rights are required

• Complex service and repair work

Personnel qualications

• Specialist vocational training (mechanical / electrical engineering)

• Product-specic training at TYROLIT Hydrostress

Page 8

Ring saw HRE400

TYROLIT Hydrostress AG

2.5

2.5.1

2.5.2

2.5.3

Organisational measures

Product monitoring obligation

Operate the electrical tool only when it is in a perfect and undamaged condition. Operating

personnel must immediately notify a responsible person or the manufacturer of changes in the

operational behaviour or to safety-related components of the tool.

The maintenance intervals must be adhered to. Faults that aect safety must be remedied

immediately.

Location of these instructions

Keep a copy of these instructions available to personnel at the place of use of the electrical tool

at all times.

Workplace

X Provide sucient space to carry out work safely.

X Ensure that the workplace is suciently illuminated.

X Cordon o the danger area in a highly visible manner so nobody can enter the danger area

during sawing.

Ring saw HRE400

Page 9

TYROLIT Hydrostress AG

2.6

2.6.1

2.6.2

Protective devices and signs on the electrical tool

Protective devices

Protective devices may only be removed if the electrical tool has been switched o and is at a

standstill. Safety components in particular should only be removed and retted by authorised

personnel.

Before switching the electrical tool back on again, check that the safety elements are operating

correctly.

Signs on the electrical tool

Safety label “Kick-Back”

2.7

Name plate

HRE400

10996672

2800 W 220 V - 240V~ / 50-60 Hz

V 40 m / s

Blade

406 mm

Ø max.

TYROLIT Hydrostress AG | CH-8330 Pfäkon ZH

Made in Canada

Spare parts and modications

Only original spare parts from TYROLITHydrostress must be used. Otherwise damage may be

caused to the electrical tool or to other property and personal injuries.

Do not ax any attachments or make any modications to the electrical tool without prior

written permission from TYROLIT Hydrostress.

Page 10

Ring saw HRE400

Loading...

Loading...