TYROLIT Hydrostress HBH534 series Safety & Operator Manual

Safety & Operator Manual Hydraulic Hand Saw HBH534***

1 10984829 EN / 28.08.2007

Safety & Operator Manual

System Description

Hydraulic hand saw HBH534***

Index / Indice 000

Safety & Operator Manual Hydraulic Hand Saw HBH534***

2 10984829 EN / 28.08.2007

Overview

Page

0 Introduction

0.1 Scope of the Safety Manual 3

0.2 Document structure 3

0.3 Terms 3

1 Technical data

1.1 Recommended ambient temperature 4

1.2 Water connection 4

1.3 Cutting speed 4

1.4 Vibration level 4

1.5 Sound level 4

1.6 Specification for oils 4

1.7 Dimensions 4

1.8 Weight 4

2 Safety instructions

2.1 General 5

2.2 Safety principles 7

2.4 General safety rules 8

2.5 Responsibility 9

3 Start-up

3.1 Putting into operation 11

4 Operation

4.1 General 11

4.2 Safety-related operator’s controls 11

4.3 Operation 11

5 Maintenance

5.1 General 17

5.2 Inspection 17

5.3 Maintenance 17

5.4 Servicing 17

5.5 Maintenance record sheet 18

Safety & Operator Manual Hydraulic Hand Saw HBH534***

3 10984829 EN / 28.08.2007

0 Introduction

0.1 Scope of the Safety Manual

The Safety Manual contains a description of how to safely operate this hydraulic hand

saw machine. It contains all the safety instructions that must be followed when working

with and on the system and must be strictly adhered to.

0.2 Document structure

The hydraulic hand saw doc umentation is structured as follows:

General system: Safety Manual with the following contents:

(Technical Data, Safety Instructions, Start-up, Operation,

Maintenance)

Components: Instruction leaflet with the following contents: (Exploded view

with part numbers, important instructions on use)

0.3 Terms

0.3.1 General Terms

Operating Instructions

The Operating Instructions are an essential document accompanying the product. They

contain all the information that is necessary to operate the product safely and to be able

to maintain it.

0.3.2 Terms related to hydraulic hand sawing

Term Definition

Saw: The saw contains the hydraulic motor, blade guard, handles and

machine components.

Cutting tool: The saw blade (diamond blade) is referred to as the cutting tool.

Drive: The drive (power pack) provides the power (hydraulic oil pressure and

flow for the hydraulic motor.

Motors: The hydraulic motor drives the pulley for the belt

Blade guard: The blade guard is a safety device that prevents accidental contact with

the tool, intercepts flying parts and at the same time acts as a spray

guard.

Safety & Operator Manual Hydraulic Hand Saw HBH534***

4 10984829 EN / 28.08.2007

1 Technical data

1.1 Recommended ambient temperature

Storage: between 5 °C and 35 °C

Usage: from 0 °C to 50 °C

1.2 Water connection

Pressure: min. 2 bar to max. 6 bar at max. 25 °C

Quantity: min. 6 l/min.

1.3 Cutting speed

This must be selected according to the nature of the material. The recommended values

in m/sec. are:

• Max. permitted blade diameter 534 mm

• Max. rotation speed 2862 rpm

• Max. peripheral speed 80 m/s

1.4 Vibration level

front handle 1,4 m/s

2

rear handle 3,7 m/s

2

1.5 Sound level

Sound pressur level L

PA

95 dB

Sound power level L

WA

104 dB

1.6 Specification for oils

1.4.1 Oils

Hydraulic oil: HLP / ISO VG46

1.4.2 Pressure

Hydraulic performance to be set at 35-40 l/min @ 140 bar

1.7 Dimensions

1.8 Weight

Weight 13.5 kg

Safety & Operator Manual Hydraulic Hand Saw HBH534***

5 10984829 EN / 28.08.2007

2 Safety instructions

2.1 General

2.1.1 Target audience

This chapter describes the safety instructions that are essential to follow when using the

hydraulic hand saw. All persons who work on and with the hydraulic hand saw have a

duty to read and understand the chapters of the Safety Manual relevant to their particular

activities. This applies in particular to the “Safety instructions” chapter which is mandatory

for all persons and activities.

2.1.2 Design Purpose

This saw was designed to be operated with:

• Hydraulic power packs, with hose length 10metres

• Hydraulic power output 40 l/min / 140bar

• Max blade rpm not to exceed 2862 rpm. When using power packs fitted with flow

control valves, it is the operator’s responsibility to ensure the correct flow has

been selected and the max blade rpm are not exceeded!

This saw was designed to perform:

• Straight cuts in concrete or fixed solid structures.

• Cuts on flat surfaces, not curved (pipes)

This saw needs to be operated:

• With both hands on both handles at all times

• With consideration of kick back when saw blade is jammed, therefore head must

not be in line with saw blade/guard.

• Never for overhead cutting or cutting above shoulder height.

• Never kneeling or on ladders

• Never forced.

• Never without a blade guard.

2.1.3 Saw blade

• A witness cut or precut must be made with a standard saw to a depth of 125mm.

Only then use the hydraulic hand saw with the 534mm saw blade.

• Always ensure the saw blade has enough clearance from the diamond

segments. The minimum side clearance should be 0.5 – 0.8mm both side and a

segment width of no less than 3.2mm.

• Only use diamond saw blades designed for this machine from TYROLIT.

• Only use laser welded saw blades.

2.1.4 Observance of the safety instructions

No work must be performed on or with the hydraulic hand saw before the safety

Instructions contained in the Safety Manual and in the Operating Instructions (Chapter 2)

have been read and understood. The Safety Manual and the Operating Instructions are

Safety & Operator Manual Hydraulic Hand Saw HBH534***

6 10984829 EN / 28.08.2007

the mandatory references for all work – Instruction leaflets are of an informative nature

and contain certain instruct io n s only co nc ernin g co rre c t us e.

The hydraulic hand saw has been inspected before being shipped and are delivered in

perfect condition. TYROLIT Hydrostress AG does not accept any liability for damage

caused by the failure to observe the instructions and information provided in the Safety

Manual and in the Operating Instructions.

This applies in particular to:

• Damage caused by improper use and operator error.

• Damage caused by improperly installed third-party components.

• Damage caused by failure to observe safety-related information in the Safety Manual

or shown on the warning signs fitted to the machine.

• Damage caused by defective or absence of maintenance work.

• Damage caused by cutting unauthorized material.

• Independently performed conversions and alterations may affect safety and are not

permitted.

Warning

Danger of allergic reactions if skin comes into contact with hydraulic oil.

Persons who have an allergic reaction to hydraulic oil must wear protective gloves and

goggles when carrying out work where they come into contact with hydraulic oil. Any

areas of the skin affected must be rinsed immediately with copious amounts of water.

Failure to adhere to this regulation may result in allergic reactions or injuries to the eyes.

Safety & Operator Manual Hydraulic Hand Saw HBH534***

7 10984829 EN / 28.08.2007

2.2 Safety principles

2.2.1 Safety measures (organisational)

2.2.1.1 Product monitoring obligation

Operating personnel must notify change s in operational behaviour or of safety-related

parts to a responsible person or the manufacturer immediately.

2.2.1.2 Location of the Safety Manual

A copy of the Safety Manual must be available at all times to staff at the place of use of

the apparatus.

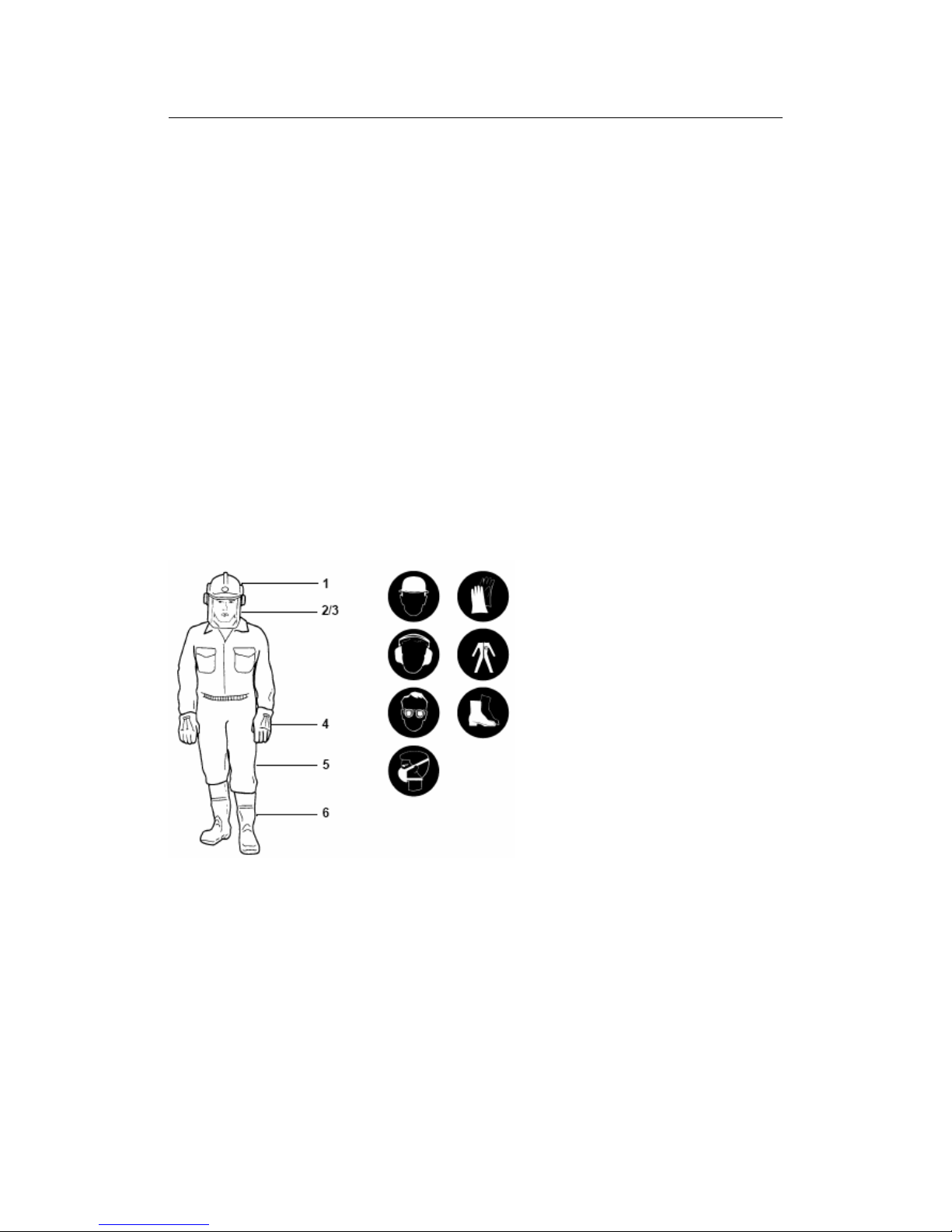

2.3.1 Safety measures (personnel)

2.3.1.1 Individual protective equipment

Anyone working with and on the hydraulic hand saw is required to wear individual

protective equipment.

The individual protective equipment comprises the following:

Fig. 1 Individual protective equipment

1. Helmet with ear protectors

2. Visor or goggles

3. Breathing mask

4. Safety gloves

5. Close-fitting, sturdy, comfortable clothing

6.

Work boots with steel toecaps and non-slip soles

Safety & Operator Manual Hydraulic Hand Saw HBH534***

8 10984829 EN / 28.08.2007

2.4 General safety rules

2.4.1 Statutory provisions

The generally applicable national and local safety and accident prevention provisions and

the supplementary operator regulations must be followed and complied with.

2.4.2 Warranty

TYROLIT warrants that the hydraulic hand saw will operate correctly and safely on

condition that all the directions, working instructions and maintenance instructions

contained in this Safety Manual and in the Operating Instructions are strictly followed and

observed.

TYROLIT will not entertain claims for liabilities, any damages or warranty Claims for

damage that has arisen as a result of improper or inappropriate handling.

2.4.3 Inspection and maintenance obligation

The operator is under an obligation to only use the hydraulic hand saw when in perfect

and undamaged condition. The maintenance intervals shown in the Safety M anual must

be strictly observed and documented in this hand book. Malfunctions and mechanical

damage must be rectified without delay. Prior every use inspect the following:

• Shaft arm for fatigue or damage

• Shaft / spindle for fatigue or damage

• Inner and outer flange for fatigue or damage (replace flanges when worn)

• Diamond saw blade for any faulty or damaged segment weld, mounting screws

and bolt for any damage.

2.4.4 Spare parts

Only original spare parts should be used. Otherwise damage may be caused to the

machine or damage to other property and personal injury may result.

2.4.5 Modifications

No technical alterations should be made independently to the equipment and installation

components in the form of additions or conversions without the written consent of

TYROLIT. This concerns all additions and conversions that are not provided for by the

system design.

2.4.6 Safety instructions in the individual chapters

The chapters of this Safety Manual and of the Operating Instructions contain additional

safety instructions. These make reference to specific potential dangers (residual

dangers). The instructions must be followed closely and require that the actions or

sequences of actions described are taken.

2.4.7 Correct application

The hydraulic hand saw is designed and built for the following application:

• Cutting of concrete (including reinf orc ed ) and na tu ra l stone.

• Cutting of parting cuts, flush cuts, cross-cuts and joints.

Safety & Operator Manual Hydraulic Hand Saw HBH534***

9 10984829 EN / 28.08.2007

• Only tools with the original hole pattern must be used.

• If the hydraulic hand saw is operated in an enclosed area, the exhaust gases from

combustion motor of the power pack must be discharged into the open air.

2.4.8 Abuse or misuse

Any use other than for the intended purpose (see Chapter 2.4.8, 2-5.5.2), constitutes

improper use or misuse. Since improper use or misuse can sometimes results in

considerable danger, details are given here of what we believe constitutes improper use

or misuse.

The following applications are prohibited:

• Cutting wood, glass and plastics.

• Cutting of loose material or loose-detached steel reinforcing (including in concrete)

• Operation in explosion-protected areas

• Cutting without system and tool cooling

• Cutting without the safety devices provided

• Incorrect or absence of waste water disposal (saw sludge)

2.4.9 Making the workplace safe

Before starting work enough s pac e sh ould be created to ensure working w it hout dang er.

The workplace must be adequately lit.

Danger areas must be visibly cordoned off so that no-one can enter the danger areas

during sawing.

The front, underneath and rear of the sawing area must be protected so that persons or

equipment cannot be harmed by falling parts or sawing sludge. Lumps of concrete that

have been loosened must be secured against falling.

Breathing in the water fog/mist that is created is a health hazard. Ensure adequate

ventilation in sealed-off areas.

The sludge resulting from cutting is very greasy. Suitable steps must be taken (removal

or cordoning off) so that persons do not slip and injure themselves.

2.5 Responsibility

2.5.1 Authorised personnel

Work on or with hydraulic hand saw should only be performed by authorized persons.

Personnel are considered to be authorised if they meet the necessary training and knowhow requirements and they have been assigned a precise functional role.

The personnel qualifications for the corresponding work are defined in the introduction

under “General” of the respective chapters.

2.5.2 Delimitation of authority (functional roles)

2.5.2.1 Manufacturer

TYROLIT or its local agents are deemed to be the manufacturer of equipment

components supplied by TYROLIT. The manufacturer is entitled to request from the

operator information on its hydraulic hand saw machine.

Safety & Operator Manual Hydraulic Hand Saw HBH534***

10 10984829 EN / 28.08.2007

2.5.2.2 Operator

As the primary legal entity, the operator is responsible for the correct use of the product

and for the training and use of the authorised personnel. He sets out the mandatory skills

and level of training of the authorised personnel for his company.

2.5.3 User (operative)

• Sets up the hydraulic hand saw for the material to be cut or the material thickness.

• Performs sawing tasks independently and monitors these.

• Locates malfunctions and initiates or performs troubleshooting.

• Carries out servicing and simple maintenance.

• Monitors the correct functioning of the safety devices.

• Makes the site safe.

2.5.4 Service engineers

The service engineer is an employee of TYROLIT Hydrostress AG or a person

authorised by TYROLIT Hydrostress AG .

• Makes adjustments to the system.

• Performs repairs, complex service work and maintenance work.

2.5.5 Qualification and training Operator

• Trained building expert in a specialist role

• Has extensive experience in personnel training and danger assessment.

• Has read and understood the “Safety instructions” chapter.

2.5.5.1 User

• Has attended user training at TYROLIT Hydrostress AG or corresponding technical

courses at regional professional associations and federations.

• Has received an introduction (basic training) to the operation of the hydraulic hand

saw machine from the manufacturer.

2.5.5.2 Service engineers

• Specialist professional training (mechanical / hydraulically).

• Has attended specialist courses at TYROLIT Hydrostress AG.

Safety & Operator Manual Hydraulic Hand Saw HBH534***

11 10984829 EN / 28.08.2007

3 Start-up

3.1 Putting into operation

Each time that the hydraulic hand saw is put into operation it must be checked to ensure

that it is free of defects. Putting into operation of the individual system parts (machines

and components) is described in the corresponding Operating Instructions or instruction

leaflets.

4 Operation

4.1 General

Before proceeding read Chapter 2 “Safety instructions”, 2-1 in this Safety Manual. Be

sure also to take note of all the danger information given here and follow the instructions

on how to avoid physical injury and damage to property.

4.1.1 Safety instructions

It is essential to observe the following safety instructions, in particular in relation to the

operation of the hydraulic hand saw.

4.1.2 Personnel qualifications

The hydraulic hand saw should not be operated by unauthorised persons.

Personnel are only authorised where they meet the following requirements:

• Have successfully completed user training at TYROLIT Hydrostress AG or

corresponding technical courses at regional professional associations and

federations.

• The Safety instructions in Chapter 2 must have been read and understood.

• Are familiar with all the general rules of architecture

4.2 Safety-related operator’s controls

4.2.1 Blade guard

The blade guard is a safety device. It provides protection from accidental contact with the

cutting tool and from flying parts and at the same time acts as a spray guard. Working

without the blade guard is prohibited.

4.3 Operation

In order to guarantee that all work is carried out in complete safety, it is essential to

perform the activities described in this Safety Manual.

Safety & Operator Manual Hydraulic Hand Saw HBH534***

12 10984829 EN / 28.08.2007

Sawing Information:

This checklist is intended solely to provide a better overview of the sequence in which the stages

of the work should be carried out. It is merely information for general cutting. It is the operator’s

responsibility to be familiar with the proper action to saw concrete and solid structures in general.

4.3.1 Process checklist

1. Approval from the supervision of works

Before any work commences the approval of the supervision of works must be

obtained. The following points must be clarified:

• Are their static concerns about the building structure?

• Are electrical lines laid in the wall or ceiling (floor)?

• Are sanitation lines laid in the wall or ceiling (floor)?

• Have loose parts been left in the wall or ceiling (floor)?

• At what depth are any longitudinally running reinforcements?

2. Mark out cut

The cut to be made must be marked out. In doing so the size and/or the weight

of the structural blocks must be taken into account.

3. Determine cutting sequence

In principle, for a wall cutting for example, first the bottom, then the side and

only at the end the top, cuts must be performed.

4. Secure danger area

Before starting work the danger areas must be secured

5. Secure structural blocks

Before sawing work commences the structural blocks must be correctly

secured from the structural engineering point of view. It must be ensured that

the structural blocks neither overturn nor fall out or down and that they cannot

displace.

6. Carry out a pre-cut / guide cut

Before the cut itself a pre-cut / guide cut should be made. This will ensure that

the cutting tool (saw blade) does not drift.

7. Sawing, etc.

Now the cuts must be performed in the order envisaged. For each new cut

steps 4 to 9 must be repeated. If necessary, steel wedges are used to secure

the cut concrete.

8. Removal of the structural blocks

Removal of the structural blocks is dangerous and therefore particular care is

called for. It must in particular be ensured that no persons remain in the danger

areas and the securing and suspension or crane apparatus are adequately

designed for the load to be held or lifted.

9. Disposal of sawing sludge

If necessary the sawing sludge must be disposed of according to the normal

local environmental regulations. The sawing sludge contains all the materials

that have been sawn through.

Loading...

Loading...