Page 1

10987477 en / 07.11.2008

Operating Instructions

Floor Saw FSG620

Index 001

Page 2

Congratulations!

You have decided to purchase a tried and tested TYROLIT-Hydrostress unit and have thus

acquired a highly sophisticated and reliable state-of-the-art unit. The exclusive use of only

TYROLIT Hydrostress spare parts ensures quality and interchangeability. If maintenance work is

neglected or carried out inexpertly we will be unable to honour our warranty obligations. Any

repair work must be carried out by trained personnel only.

Should you need more details concerning your TYROLIT Hydrostress unit in order to keep it in

perfect condition, please contact our after-sales service for further information.

We hope that you enjoy untroubled and fault-free working with your TYROLIT unit.

TYROLIT Hydrostress

Copyright © TYROLIT Hydrostress

TYROLIT Hydrostress AG

Witzbergstrasse 18

CH-8330 Pfäffikon

Switzerland

Tel. 0041 (0) 44 952 18 18

Fax 0041 (0) 44 952 18 00

Page 2 Floor Saw FSG620

Page 3

TYROLIT Hydrostress AG

1 Safety

These instructions are just one part of the documentation which is supplied together with the

floor saw. These instructions go together with the "Safety Manual / System Description for Floor

Saws" to form a complete set of documentation.

DANGER

Failure to comply with the safety instructions in the "Safety Manual / System Description" may

result in serious injury or death.

► Please ensure that the "Safety Manual / System Description for Floor saws" has been read

and understood in full.

Floor Saw FSG620 Page 3

Page 4

TYROLIT Hydrostress AG

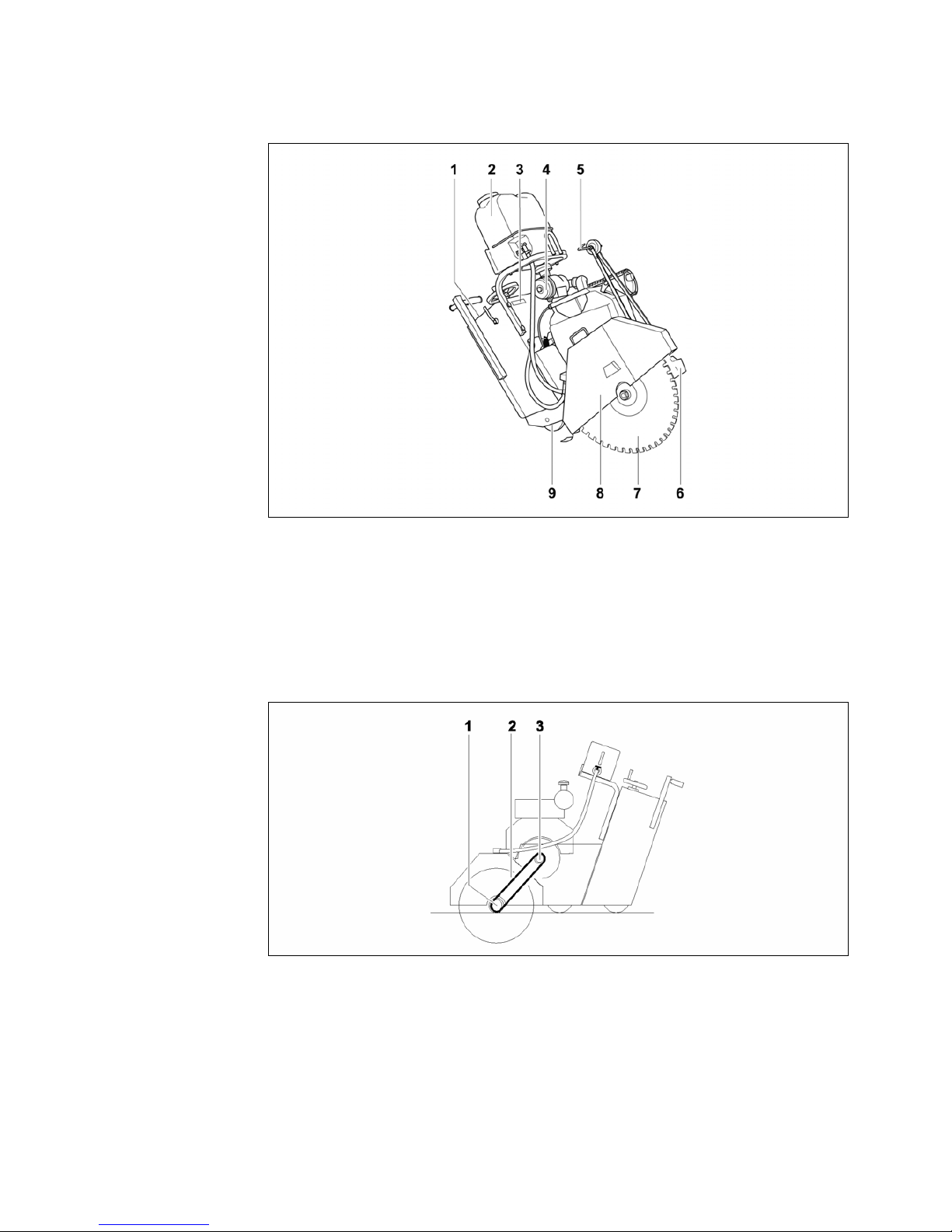

2 Design

Components

1 Operating console

2 Water tank

3 Name plate

4 Main motor

5 Cut guide

6 Shaft cover

7 Saw blade

8 Blade guard

9 Drive wheel

2.1 Saw blade drive

Saw blade drive (schematic)

1 Blade drive shaft

2 Drive belt

3 Main motor drive shaft

Page 4 Floor Saw FSG620

Page 5

TYROLIT Hydrostress AG

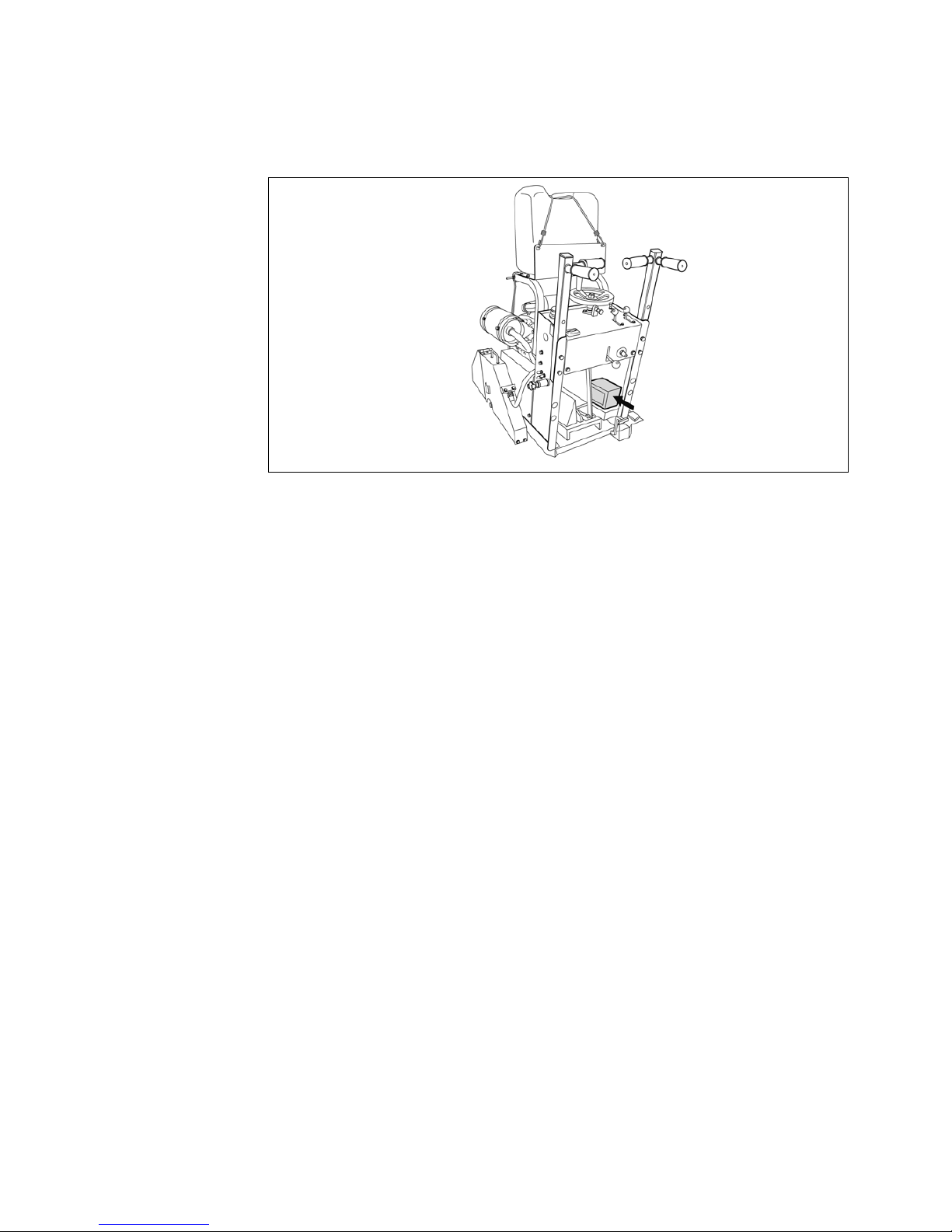

2.2 Lift drive

Lift drive (schematic)

1 Movable spindle

2.3 Travel drive

Travel drive (schematic)

1 Drive shaft (main motor)

2 Hydrostat drive belt

3 Hydrostatic motors

4 Drive chain

5 Wheel drive shaft

6 Drive wheel

Floor Saw FSG620 Page 5

Page 6

TYROLIT Hydrostress AG

3 Transpor t

DANGER

Inexpert transport may result in death or serious injury.

► Floor saws must only be transported with the main motor switched off.

► Only transport vehicles, lifting tools and load suspension devices with sufficient load-

bearing capacity must be used.

► Floor saws must only be hitched by the hitching points provided.

► Appoint an expert marshaller.

► When transporting by crane do not stand underneath suspended load.

► Always have the floor saw in your line of vision while it is being transported.

3.1 Hitching points

Hitching points

1 Crane hitching device

Page 6 Floor Saw FSG620

Page 7

TYROLIT Hydrostress AG

4 Initial start-up

4.1 Fitting battery

► Fit battery (for type see Technical Data).

Floor Saw FSG620 Page 7

Page 8

TYROLIT Hydrostress AG

5 Assembly / Set-up

5.1 Mounting grip

►

5.2 Mounting saw blade

1. Apply footbrake

Page 8 Floor Saw FSG620

Page 9

TYROLIT Hydrostress AG

2.

DANGER

Parts that fly off (segments, concrete splinters, saw blade, etc.) may cause serious injury

or even death.

► Floor saws must only be operated with a blade guard.

► When assembling the saw blade on the right-hand side use the anchoring screw with the

left-hand thread.

When assembling the saw blade on the left-hand side, use the anchoring screw with the

right-hand thread.

► Note the direction or rotation arrows on the saw blade.

3.

1 Anchoring screw

*Note the direction of rotation

Floor Saw FSG620 Page 9

Page 10

TYROLIT Hydrostress AG

4.

C: To prevent the saw blade rotating while being tightened, carefully place the saw blade on the floor.

5.3 Mounting saw blade on the other side

5.3.1 Disassemble the blade guard

►

Page 10 Floor Saw FSG620

Page 11

TYROLIT Hydrostress AG

5.3.2 Disassemble the shaft cover

►

5.3.3 Assembling the blade guard and shaft cover on the other side

Assembly of the blade guard and the shaft cover is performed in the opposite order to

disassembly.

5.4 Connecting water line

The water tank should also always be full when an external water supply is used. This ensures

that the joint cutter exerts sufficient weight on the cutting material.

►

Floor Saw FSG620 Page 11

Page 12

TYROLIT Hydrostress AG

6 Operation

6.1 Overview of operating elements

Operating elements

1 Raise / lower hand wheel

2 Choke

3 Ignition key

4 Feed adjuster (forward /

backward travel)

5 Speed governor

6 EMERGENCY STOP switch

7 Foot brake

8 Battery main switch

9 Feed gears coupling lever

10 Operating hours meter

6.2 Checking oil level

► Note the details from the motor manufacturer.

Page 12 Floor Saw FSG620

Page 13

TYROLIT Hydrostress AG

6.3 Checking the fuel level

► Check the tank display (1) and top up with ROZ 95 petrol as necessary.

6.4 Positioning the floor saw

1. Release footbrake

2. Slide floor saw into the working position.

3. Fit the cutting guides to the floor saw.

6.5 Connecting the water supply

►

Floor Saw FSG620 Page 13

Page 14

TYROLIT Hydrostress AG

6.6 Switch on motor

Symbol Significance

Coupling lever in coupled position

Coupling lever in uncoupled position

9 Coupling lever (5) is in the uncoupled position

9 EMERGENCY STOP switch (3) has been released

1. Pull out choke (1) according to temperature.

2. Start motor with ignition key (2).

3. Push choke (1) back in.

4. Set motor speed with speed governor (4).

Page 14 Floor Saw FSG620

Page 15

TYROLIT Hydrostress AG

6.7 Lowering / raising saw blade

Symbol Significance

Raising / lowering saw blade

1. Lower joint cutter with the hand wheel (1) to the desired cutting depth.

2. Engage locking pin (2)

Floor Saw FSG620 Page 15

Page 16

TYROLIT Hydrostress AG

6.8 Adjusting the feed

Symbol Significance

Coupling lever in coupled position

Coupling lever in uncoupled position

Feed adjuster in the forwards direction of travel

Feed adjuster in the backwards direction of travel

9 Feed adjuster (1) is in the neutral position

9 Footbrake (2) is released

1. Place coupling lever (3) in the coupled position.

2. Using the feed adjuster (1), set the direction of travel and speed.

Page 16 Floor Saw FSG620

Page 17

TYROLIT Hydrostress AG

7 Maintenance

When? What?

Daily ► Check oil level.

► Perform a visual check for damage.

Weekly ► Check belt and chain tension and adjust as

necessary.

Every 50 hours of operation ► Lubricate grease nipples.

Annually or every 100 operating hours ► Arrange a major service by TYROLIT

Hydrostress AG or an authorised

representative.

According to the information from the motor

manufacturer

► Carry out all necessary measures in

accordance with the operating instructions of

the motor manufacturer.

7.1 Grease nipples

Position of grease nipples

1 Blade drive shaft: 2 items

2 Wheel drive shaft bearing: 2 items

Floor Saw FSG620 Page 17

Page 18

TYROLIT Hydrostress AG

7.2 Tensioning chain on travel drive

►

Tensioning chain

1 Chain

Page 18 Floor Saw FSG620

Page 19

TYROLIT Hydrostress AG

8 Malfunctions

Malfunction Possible cause Solution

Floor saw does not operate

EMERGENCY STOP switch has been pressed. ► Release EMERGENCY STOP switch.

Saw blade jammed Saw blade is jammed in the cutting material ► Reverse the floor saw.

► If necessary release the saw blade by

rocking.

► If necessary stop the motor, disassemble

the saw blade and release this

individually from the cutting material.

Belt tension too slack ► Tension or replace belt. Saw blade does not rotate even

though the motor is running

Pulling pin on the anchoring flange has

sheared off

► Mount new anchoring flange.

Operation of the control rods impaired ► Check control rods and repair as

necessary.

Defective hydrostat ► Check hydrostat and if necessary have

this repaired by a TYROLIT Hydrostress

engineer.

Defective chain ► Have the chain replaced by a TYROLIT

Hydrostress engineer.

Feed not working

Main motor belt slipping ► Check belt for wear and if necessary

have this replaced by a TYROLIT

Hydrostress engineer.

► Increase belt tension as necessary.

Wrong fuel ► Switch off motor immediately and

change fuel.

Motor running off centre

Oil filter blocked ► Have oil filter changed.

Floor Saw FSG620 Page 19

Page 20

TYROLIT Hydrostress AG

9 Technical data

9.1 Dimensions

Parameter Value

Weight 200 kg

Cutting depth (max.) 230 mm

Blade uptake diameter 25.4 mm

Max. saw blade diameter

600 mm

Dimensions (transport dimensions with blade

guard folded up)

L: 990 mm

W: 570 mm

H: 1,070 mm

9.2 Motor

Parameter Value

Type Honda

Power 20 PS

Rated speed According to operating instructions from motor

manufacturer

Oil content According to operating instructions from motor

manufacturer

Tank content 7.6 l

Fuel Petrol

Cooling Air cooling

9.3 Lift drive

Parameter Value

Drive type mechanical via spindle

9.4 Travel drive

Parameter Value

Drive type Hydraulic

Oil grade ATF Dexron II D

Cooling Air cooling by means of cooling ribs

Page 20 Floor Saw FSG620

Page 21

TYROLIT Hydrostress AG

9.5 Noise level and vibrations

Parameter Value

Noise level at the ear of the user (Leq) 87.9 dB(A)*

Noise level at workplace (LPA) 89.1 dB(A)*

Sound power level in accordance with ISO 3744

(LwA)

109.1 dB(A)*

Vibrations DIN EN ISO 5349-2 < 2.5 m/s

*Value applies under the following condition: Travel drive is switched off and the saw blade is not

engaged. The measurement is performed with the motor under full load with the saw blade dia. 600 mm.

Higher noise levels may be generated in cutting operation.

9.6 Battery

Parameter Value

Description Battery 12-Volt, Group Size U1

DP battery part number 2500584

Length 196 mm

Width 130 mm

Height 165 mm

Capacity 300 Amps

Manufacturer's reference 53030

ETN 530 030 030

Special feature Clamping shoe

Floor Saw FSG620 Page 21

Page 22

TYROLIT Hydrostress AG

EC declaration of conformity

Description Floor Saw

Type designation FSG620

Year of construction 2007

Manufacturer TYROLIT Hydrostress AG

We declare under our own liability that this product complies with the following directives and standards:

Directive applied

Machine Directive 2006/42/EC

Noise Emission 2000/14/EC

Electricity Directives 93/68/EEC

Electromagnetic Compatibility 89/336/EEC

2002/95/EC Restriction of the use of certain hazardous substances in

electrical and electronic equipment

2002/95/EC

Waste Directive 2002/96/EC

Vibration Directive 2002/44/EC

Standards

EN 12100-1

Safety of machinery – Basic concepts, general design principles.

EN 12100-2 Safety of machinery - Basic concepts and general principles for design.

EN ISO 14121 Safety of machinery - Principles of risk assessment.

EN 294 Safety of machinery – Safety distances to prevent upper limbs reaching

danger areas.

IEC 60204-1 Safety of machinery – Electrical equipment of machines, General

Requirements.

IEC 6100-6-3 Electromagnetic Compatibility

EN 13862 Floor cutting-off machines. Safety.

EN 349 Safety of machinery – Safety distances to avoid crushing of body parts.

EN 982 Safety of machinery

Safety requirements for safety systems and their components –

hydraulics.

EN ISO 3744 Acoustics - Determination of sound power levels of noise sources using

sound pressure

Page 22 Floor Saw FSG620

Loading...

Loading...