Page 1

Operating Instructions

Wall saw DZ-S2

Index 001

10987273 EN /25.07.2007

Page 2

Page 2

Wall saw DZ-S2

TYROLIT Hydrostress AG

Witzbergstrasse 18

CH-8330 Pfäkon

Switzerland

Tel. 0041 (0) 44 952 18 18

Fax 0041 (0) 44 952 18 00

Congratulations!

With a Hydrostress unit from TYROLIT, you have chosen a tried and tested piece of equipment

which has been designed and built to leading technical standards. Only genuine TYROLIT Hy-

drostress replacement parts can guarantee quality and interchangeability. We are unable to ful-

l our warranty obligations if maintenance work is neglected or carried out unprofessionally.

Any repair work must be carried out by trained personnel only.

Our aftersales service is available to help ensure that your TYROLIT Hydrostress units remain in

perfect working order.

We hope that you enjoy untroubled and fault-free working with your TYROLIT unit.

TYROLIT Hydrostress

Copyright © TYROLIT Hydrostress

Page 3

TYROLIT Hydrostress AG

Page 3

Wall saw DZ-S2

Safety

These instructions are just one part of the documentation which is supplied together with the

wall saw. These instructions go together with the «Safety Manual / System Description for Wall

Saws» to form a complete set of documentation.

DANGER

Failure to comply with the safety instructions in the «Safety Manual / System Manual» may result in serious injury or even death.

Please ensure that the «Safety Manual / System Description for Wall Saws» has been read and

understood in full.

DANGER

Cuts from the saw blade.

Always wear protective gloves when working on the wall saw, particularly when working on

the saw blade.

Always use the blade guard when operating the wall saw.

DANGER

Serious injury or material damage as a result of uncontrolled movements of the wall saw.

Never connect or disconnect hoses while the drive unit is running.

1

Page 4

TYROLIT Hydrostress AG

Page 4 Wall saw DZ-S2

Description

Wall saw system

The layout and functions of the wall saw systems are described in the «Safety Manual / System

Description for Wall Saws».

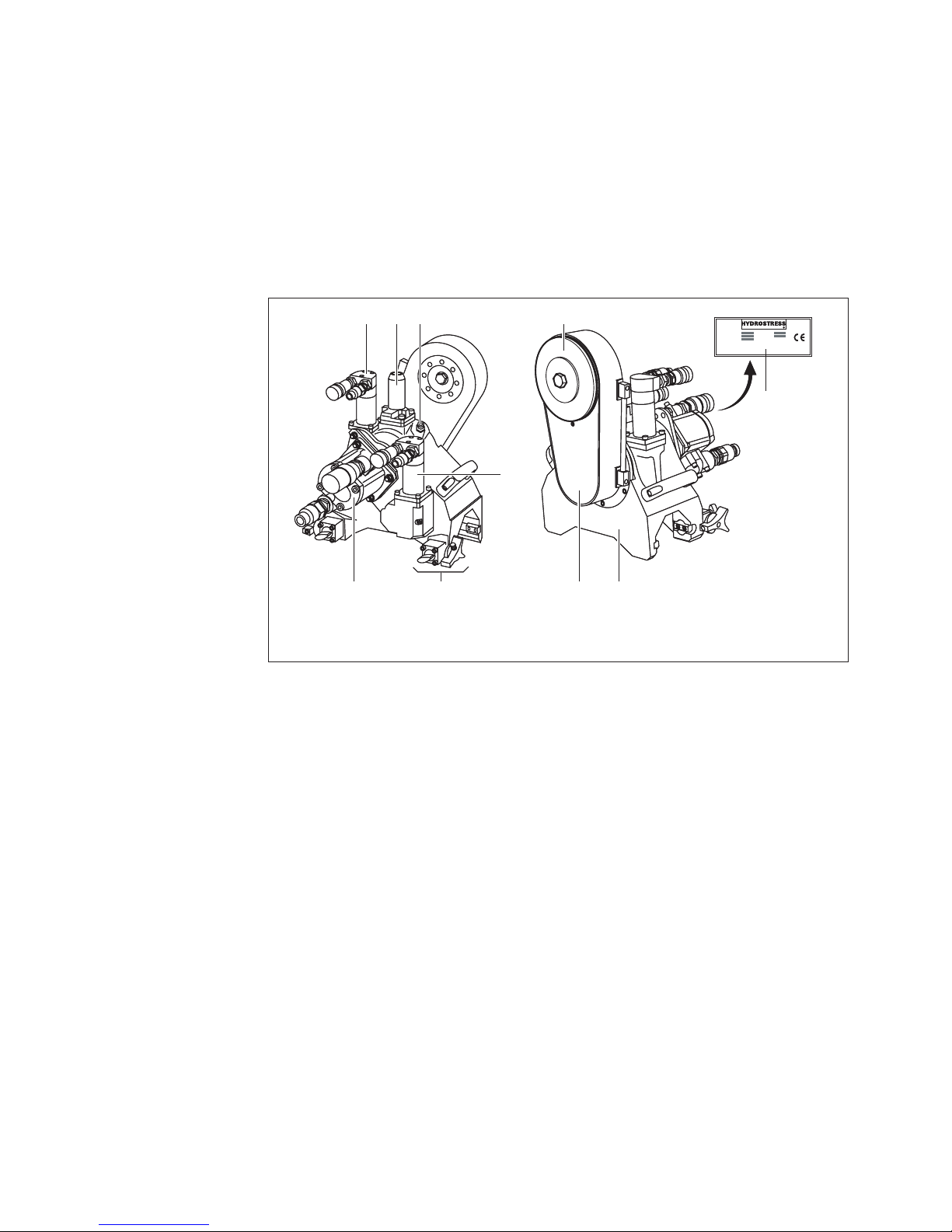

Wall saw

Components

1 Feed motor, swivel 6 Blade drive motor

2 Blade guard holder 7 Saw blade holder

3 Water connection 8 Name plate

4 Feed motor, travel 9 Chassis

5 Lock unit 10 Belt swivel arm

2

10 9

8

Typ

Masch.- Nr.

Gewicht.

Index

Baujahr

CH-8330 Pfäffikon ZH Made in Switzerland

31

56

4

72

10 9

8

Typ

Masch.- Nr.

Gewicht.

Index

Baujahr

CH-8330 Pfäffikon ZH Made in Switzerland

31

56

4

7

2

2.1

2.2

Page 5

TYROLIT Hydrostress AG

Page 5Wall saw DZ-S2

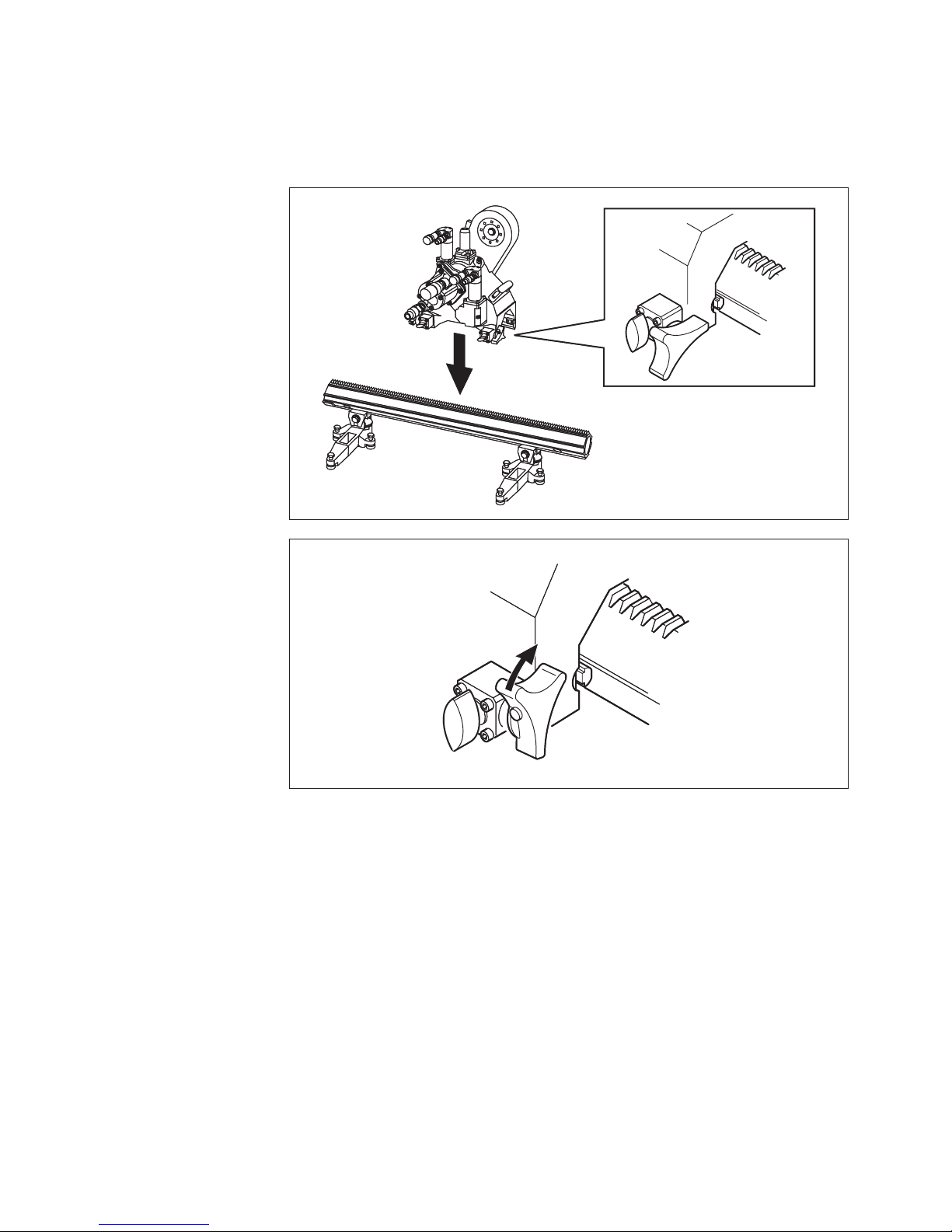

Assembly / disassembly

Place the wall saw on the guide rail

1.

2.

3

3.1

Page 6

TYROLIT Hydrostress AG

Page 6 Wall saw DZ-S2

Adjustment of the closure

A: Rotate as far as the stop.

B: Rotate back two notch positions.

Release the closure

Perform the remaining assembly steps in reverse order.

1.

2.

click

click

A

B

click

click

A

B

3.2

3.3

Page 7

TYROLIT Hydrostress AG

Page 7Wall saw DZ-S2

Mount the drive motor

Mount the saw blade

DANGER

It can cause death or serious injury if the saw blade ies away.

Only use original screws and bolts from TYROLIT Hydrostress AG.

DANGER

Serious injury can be caused by sudden start-up of the saw blade.

Switch o the drive unit before working on the saw blade.

Depressurize the hoses.

Fixing saw blade in position

The direction of rotation of the saw blade must match the direction of rotation of the machine.

Correct alignment: Countersinking of the fastening bores against the blade cover.

For normal cuts

A

C

B

A

C

B

A

B

C

A

B

C

3.4

3.5

3.5.1

Page 8

TYROLIT Hydrostress AG

Page 8 Wall saw DZ-S2

For ush cuts

Mount the blade guard

Mount the blade guard according to the instruction leaet.

C

D

6x

A

B

6x

C

D

6x

A

B

6x

3.6

Page 9

TYROLIT Hydrostress AG

Page 9Wall saw DZ-S2

Connecting the wall saw to the drive unit

The drive unit is isolated from the power supply.

Couplings are clean.

Hoses are undamaged.

3.7

Page 10

TYROLIT Hydrostress AG

Page 10 Wall saw DZ-S2

Servicing and maintenance

Lubricate lock unit

1 Grease nipple

11

4

Maintenance and servicing table

Before every

commissioning

At end of work

Weekly

Yearly

After faults

After damage

Wall saw Retighten loose bolts, screws and nuts

(refer to the tightening torque specications)

X X X

Prism guides Check for wear

X

Replace before the anchoring screws

of the guide prisms touch the rail or

the chassis touches the rail

X

Y-guides Apply 2-3 applications of grease to

the lubricating nipples

X

Couplings Check for leak-tightness and damage

and replace as required

X

Swivel arm Clean with water

X

Check the saw blade uptake for wear

X X X

Feed motor Check cleanliness and leak-tightness

X X X X

Drive motor Check cleanliness and leak-tightness

X X X X

Water economy Check water line for cleanliness and

leak-tightness

X X X

Blow out water

X

Saw blade Clean with water

X

Check for wear

X X X X

Service To be performed by TYROLIT Hydros-

tress AG or an authorised workshop

After 100 / 300 / 500 / 700 hours

4.1

Page 11

TYROLIT Hydrostress AG

Page 11Wall saw DZ-S2

Technical data

Dimensions

Dimensions (* with ush cutting ange)

Design

Design

Parameter Value

Construction Cast aluminium / steel

Rotatable swivel arm 360°

Power transmission toothed belt

Blade drive transmission 1:2

Lock unit Low-wearing, suitable for all VS and VAS rails

Rail mounting Locking and securing function at the prism guide

Blade drive motor Secured by means of quick-release device (hydraulic motor size 2)

Feed motor Gerotor

Flush cutting Special ange (+15 mm)

Normal cutting: Standard blade hub with blade cover

Water Water connection on chassis

360°

360

560

240 (255)*

140 (155)*

460

600

455

195290

360°

360

560

240 (255)*

140 (155)*

460

600

455

195290

5

5.1

5.2

Page 12

TYROLIT Hydrostress AG

Page 12 Wall saw DZ-S2

Weight

Weight

Parameter Value

Wall saw head, incl. feed motors without blade drive motor

27 kg

Blade drive motor, size 2

5.5 kg

Blade drive motor

Blade drive motor

Parameter Value

Hydraulic motors 1100 to 3333 rpm.

Size 2

Absorption volume 12 to 30 cm

3

Transmission ratio 1:2

Operating pressure max. 260 bar

Type External geared motor

Rotational speeds, hydraulic motors for wall saws

cm

3

12

cm

3

16

cm

3

18

cm

3

22

cm

3

26

cm

3

30

l/min 33 2750 2063 1833 1500 1269 1100

l/min 40 3333 2500 2222 1818 1538 1333

l/min 45 3750 2813 2500 2045 1731 1500

l/min 50 4167 3125 2778 2273 1923 1667

l/min 60 5000 3750 3333 2727 2308 2000

Operation possible Operation not possible

5.3

5.4

Page 13

TYROLIT Hydrostress AG

Page 13Wall saw DZ-S2

Feed motor, travel

Feed motor, travel

Parameter Value

Hydraulic motors 187 rpm

Type Gerotor

Operating pressure max. 120 bar

Output torque 50 Nm

Feed force 6,000 N

Feed Toothed wheel on rail

Feed motor, swivel

Feed motor, swivel

Parameter Value

Hydraulic motors 187 rpm

Type Gerotor

Operating pressure max. 120 bar

Output torque 50 Nm»

Swivel range (swivel arm) 360°

Feed force 3,000 N

Saw blades

Saw blades

Parameter Value

Saw blade max. Ø 1,200 mm

Fully detachable saw blade Ø 900 mm

Blade holder Ø 60 mm

Blade ange mounting at wall saw xed

Saw blade xing on blade ange central screw

Saw blade xing (ush cuts) 6 countersunk head screws

reference circle 130 mm

Blade cover mounting on blade ange 1 hexagonal bolt

Blade ange Ø 165 mm

Cutting depth Ø 800 mm 310 mm

Ø 900 mm 360 mm

Ø 1000 mm 410 mm

Ø 1200 mm 510 mm

5.5

5.6

5.7

Page 14

TYROLIT Hydrostress AG

Page 14 Wall saw DZ-S2

Lubricants, uids and sealants

Lubricants, uids and sealants

Parameter Value

Lubricating grease (lock unit) Penetration 265 to 295

NLGI 2

Connectable drive units

The wall saw must only be operated with the coordinated drive units from TYROLIT Hydrostress.

Drive unit power requirements:

Parameter Value

Minimum output: 12 kW (max. operating pressure 260 bar)

Maximum performance 20 kW (max. operating pressure 260 bar)

Water connection

Parameter Value

Pressure 2 to 6 bar

Quantity At least 6 l/min

Max. temperature 25 °C

5.8

5.9

Page 15

TYROLIT Hydrostress AG

Page 15Wall saw DZ-S2

EC Declaration of Conformity

Description Wall saw

Type designation DZ-S2

Year of construction 2002

We declare under our own liability that this product complies with the following directives and

standards:

Directive applied

Machinery Directives 2006/42/EC

Standards applied

EN 12100-1

EN 12100-2

Safety of machines – Basic concepts, general design principles

EN 294 Safety of machinery – Safety distances to prevent upper limbs

reaching danger areas

EN 349 Safety of machinery – Safety distances to avoid crushing of body

parts

EN 982 Safety of machinery – Safety requirements for safety systems and

their components - hydraulics

Page 16

Loading...

Loading...