TYROLIT Hydrostress DME22SU Series Operating Instructions Manual

Operating Instructions

DME22SU

Index 000

Original operating instructions

10993155 en / 16.10.2012

Page 2

DME22SU

TYROLIT Hydrostress AG

Witzbergstrasse 18

CH-8330 Pfäkon

Switzerland

Tel. 0041 (0) 44 952 18 18

Fax 0041 (0) 44 952 18 00

Congratulations!

With a Hydrostress unit from TYROLIT you have chosen a tried and tested piece of equipment

designed and built to the highest technical standards. Only genuine TYROLIT Hydrostress replacement parts can guarantee quality and interchangeability. If maintenance work is neglected or carried out inexpertly we will be unable to honour our warranty obligations. Any repair

work must be carried out by trained personnel only.

Our after-sales service is available to help ensure that your TYROLIT Hydrostress units remain in

perfect working order.

We hope that working with your TYROLIT unit will be a satisfying and fault-free experience.

TYROLIT Hydrostress

Copyright © TYROLIT Hydrostress

TYROLIT Hydrostress AG

Page 3

DME22SU

Table of contents

Page

1. Concerning these instructions .................................................... 4

2. Safety ........................................................................... 5

3. Product description .............................................................. 8

4. Design and Function .............................................................. 11

5. Assembly / Disassembly .......................................................... 13

6. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7. Servicing and Maintenance ....................................................... 17

8. EC Declaration of Conformity ..................................................... 18

TYROLIT Hydrostress AG

Page 4

DME22SU

Concerning these instructions

These instructions are just one part of the documentation which is supplied together with the

electric tool.

These instructions go together with the “Core Drills Safety Manual / System Description” to form

a complete set of documentation.

These instructions, together with the “Core Drills Safety Manual / System Description”, are a constituent of the equipment. They describe how to use the equipment safely and properly in all

phases of operation.

• Read the instructions carefully before use, particularly the safety instructions.

• Keep the instructions for the entire service life of the equipment.

•Ensure that the instructions are available to the operator and the service engineers at all

times.

• Pass the instructions on to all subsequent owners or users of the equipment.

• Update instructions with all supplements received from the manufacturer.

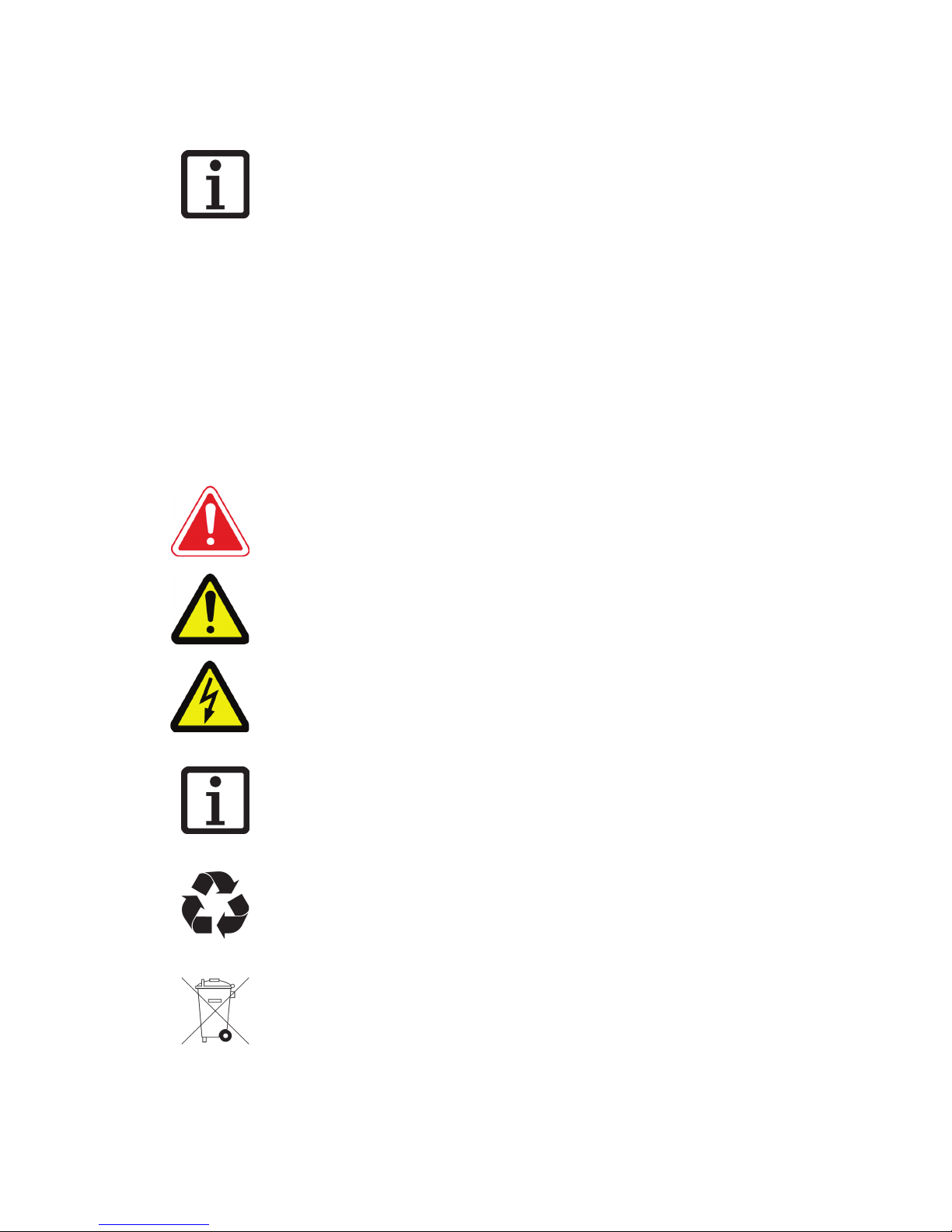

Symbols in these instructions

DANGER

Warning of danger, where failure to comply could lead to death or serious injury.

WARNING

Warning of danger, where failure to comply could lead to injuries or damage to property.

WARNING

Warning - dangerous electrical voltage.

Before working in an area identied in this way, the installation or device must be fully disconnected from the power (voltage) and secured against being accidentally powered up again.

INFORMATION

Information for optimum use of equipment. Failure to take note of this information may mean

that the performance information shown in the technical data can no longer be guaranteed.

RECYCLING

Take waste for recycling.

DISPOSAL

The normal national and regional rules and guidelines must be observed during disposal.

1.

1.1

TYROLIT Hydrostress AG

Page 5

DME22SU

Safety

Core drilling systems may only be operated by authorised persons. Information about authorised persons can be found in the “Core Drills Safety Manual / System Description”.

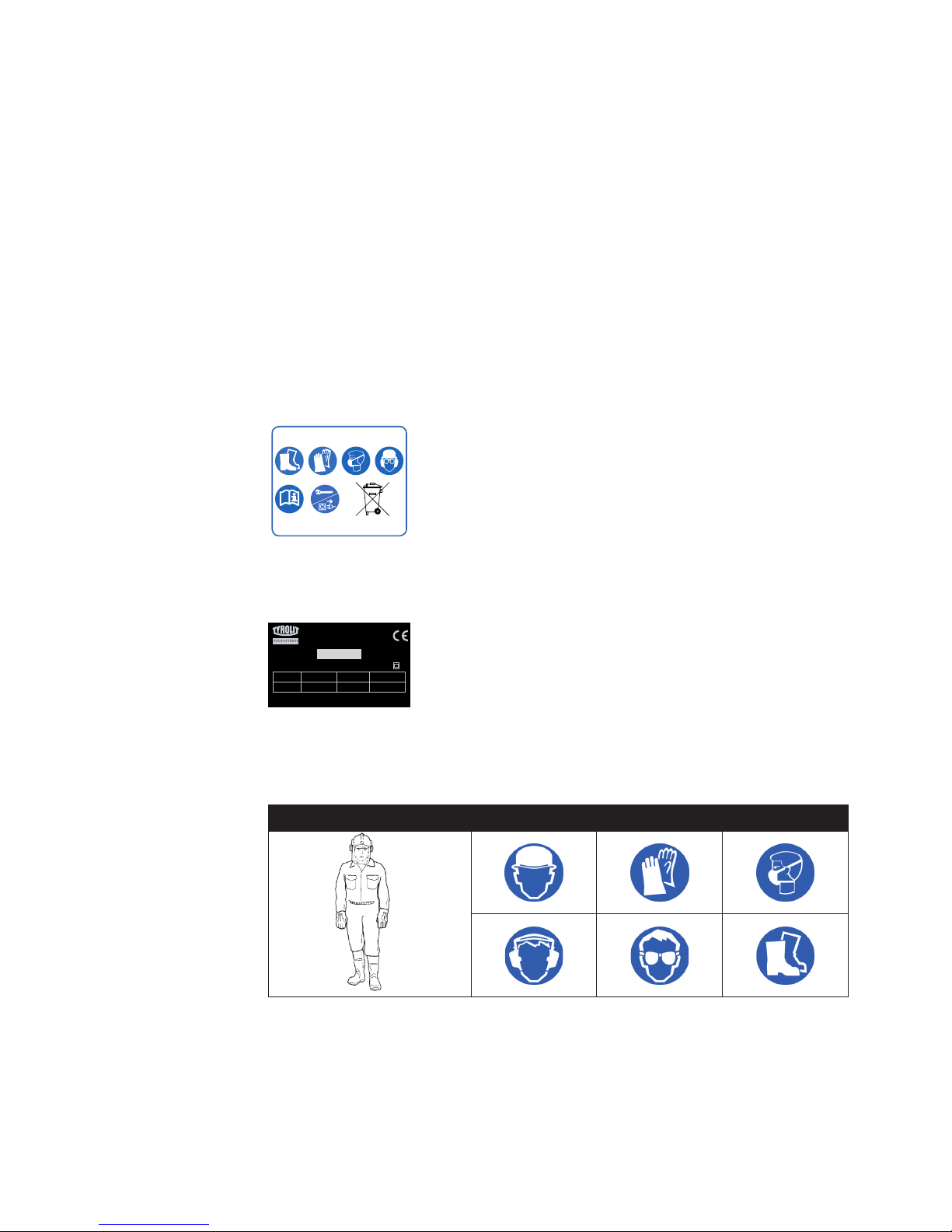

Protective devices and signs on the equipment

Protective devices

Protective devices may only be removed if the equipment has been switched o, disconnected

from the mains and is at a standstill. Safety components in particular should only be removed

and retted by authorised personnel.

Before switching the equipment back on again, check that the safety elements are operating

correctly.

Signs on the equipment

Safety sign

1 Wear safety shoes 3 Wear a breathing mask 5 Read the instructions

2 Wear gloves 4 Wear a helmet, goggles and

hearing protection

6 Before working on the equipment

unplug mains

Name plate

Safety clothing

Anyone working with and on core drilling systems is strictly required to wear individual protective equipment.

Safety clothing

Safety clothing

Spare parts and modications

Only original spare parts from TYROLIT Hydrostress must be used. Otherwise damage may be

caused to the equipment or to other property and persons. No additions or modications must

be made to the equipment without written permission from TYROLIT Hydrostress.

2.

2.1

2.1.1

1 2 3 4

5 6

DME22SU

10993027 No. 2012

2200 W 230 V-240V~ 50-60 Hz

RPM 400 750 1550

Ø max.

180 120 60

TYROLIT Hydrostress AG | CH-8330 Pfäkon ZH

2.1.2

2.2

TYROLIT Hydrostress AG

Page 6

DME22SU

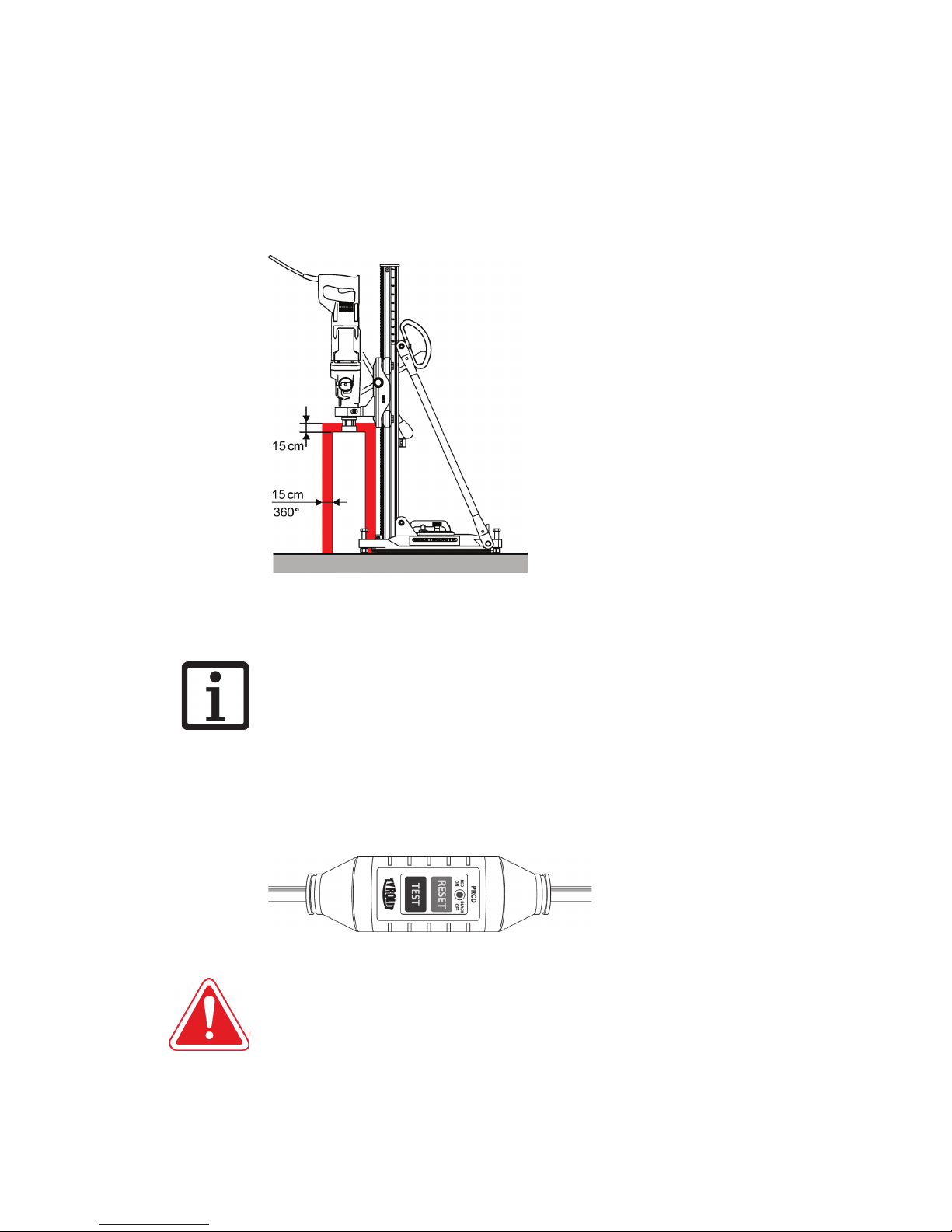

Danger and working area

Danger zone at electrical tool

The marked area on the drawing denes the danger zone of the electrical and cutting tool.

The minimum clearance of 15 cm must be maintained during operation.

Danger zone at electrical tool

Danger zone at workplace

Information about the danger zone at the workplace can be found in the “Core Drills Safety

Manual / System Manual”.

Product-specic dangers

Personal protection device (PRDC, GFCI)

Only ever work if a serviceable current-operated personal protection device is present (PRCD,

GFCI).

Personal protection device

DANGER

Failure to comply will result in a risk of death or serious injuries

X Keep your electrical tool away from rain and moisture. Water penetrating an electrical tool

increases the risk of electric shocks.

Overhead drilling

X Overhead drilling is not permitted in wet conditions.

2.3

2.3.1

2.3.2

2.4

2.4.1

2.4.2

Loading...

Loading...