TYPICAL GC0303, GC0303CX OPERATION INSTRUCTION

GC0303

UPPER AND LOWER FEED LOCKSTITCH SEWING

MACHINE FOR MEDIUM AND HEAVY DUTY

GC0303CX

UPPER AND LOWER FEED

MACHINE FOR HEAVY DUTY WITH THICK THREAD

OPERATION INSTRUCTION / PARTS MANUAL

LOCKSTITCH SEWING

Please don't adjust and repair the machine by non-professionals,except adjusting stitch.

Specifications subject to change without notice

TYPICAL SEWING MACHINE WANPING MACHINERY CO.,LTD.

ADD: WANPING TOWN, WUJIANG CITY, JIANGSU

PROVINCE, CHINA

TEL: +86-512-63391278

FAX: +86-512-63391371

POST. CODE: 215223

Http://www.typicalwpchina.com

E-mail:export@typicalwpchina.com

Operation Instruction

CONTENT

1. Main technical specifications

2. Operation preparation

3. Installing the motor

4. Connecting the clutch lever to the pedal

5. Installing belt guard

6. Installing the bobbin winder

7. Lubrication

8. Trial run

9. Hook oil amount adjustment

10. Oil pump supply adjustment

11. Installing the needle

12. Coordination among needle 、thread and sewing materials

13. Threading the needle thread

14. Winding adjustment

15. Setting the stitch length and controlling the reverse sewing

16. Setting the position of presser bar

17. Adjusting the pressure of presser foot

18. Adjusting the thread tension

19. Adjusting the thread take-up spring

20. Adjusting the tension of needle thread and bobbin thread

21. Timing adjustment between the needle and the rotating hook

22. Installing and removing rotating hook

23. Installing feed dog

24. Feed dog horizontal adjustment

25. Stitch length error adjustment

26. Feed timing adjustment

27. Adjusting the tension releasing mechanism

28. Upper feed adjustment

29. Adjusting presser foot alternate lift mechanism

30. Adjusting the lift amount of presser foot with walking presser foot

31. Adjusting the clearance between presser foot and walking presser foot

32. Periodical cleaning

1

1

1

1

2

2

2

3

3

3

4

4

4

5

6

6

6

7

7

8

9

10

10

11

11

12

13

14

14

15

15

15 16~

Parts Catalogue

1. Arm and bed

2. Arm shaft vertical shaft Needle bar and thread take-up

3. Feed dog lift and thread looping

4. Feed adjustment

5. Presser foot

6. Upper feed

7. Oil pump

8. Oil reservoir and accessories

17~18

19 20~

21 22~

23 24~

25 26~

27 28~

29 30~

31 32~

Operation instruction

Notice:

1. Parts design is subject to change without notice.

2. Only the professional can adjust and repair the machine except adjusting stitch

length.

1.Main techanical specifications

2.Preparation

Model

Application

Max. Sewing Speed

Max. Stitch length

Max. Sewing Capacity

Alternate presser foot lift volume

Needle

Presser

foot lift

Hook

Lubrication

Motor power

By hand

By knee

GC0303

Medium and heavy duty

2000spm

8mm 12mm

3.5-5.5mm

DP×17(20#~23#) DP×17(25#)

8mm

16mm

Auto-lubricating big rotating hook

Auto lubrication

GC0303CX

1800spm

8mm

370W

(1)Cleaning machine

Clean off the grease and dusts on the Surface of machine with gasoline and soft cloth.

(2)Inspection

Before use a thorough inspection should be done upon

the machine. Turn balance wheel slowly to see if there is

any obstacle , collision and uneven resistance between

parts. If there is , adjustment should be done before

operation.

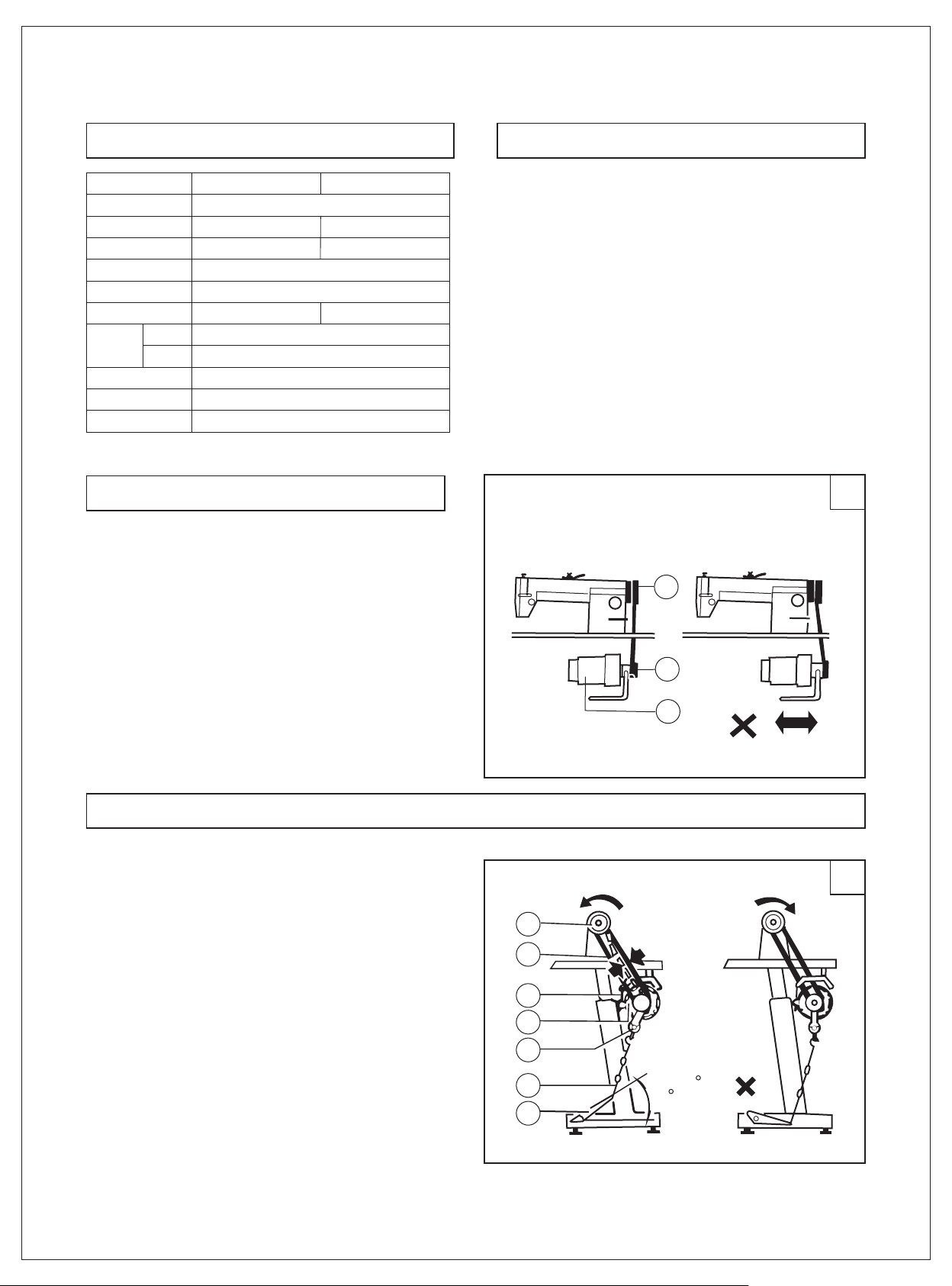

3.Installing the motor(Fig.1)

Align machine balance wheel belt groove (A)

with motor pulley belt groove (B) by moving the

motor(C) leftward or rightward. Be sure the belt is

not touch with table.

1

A

B

C

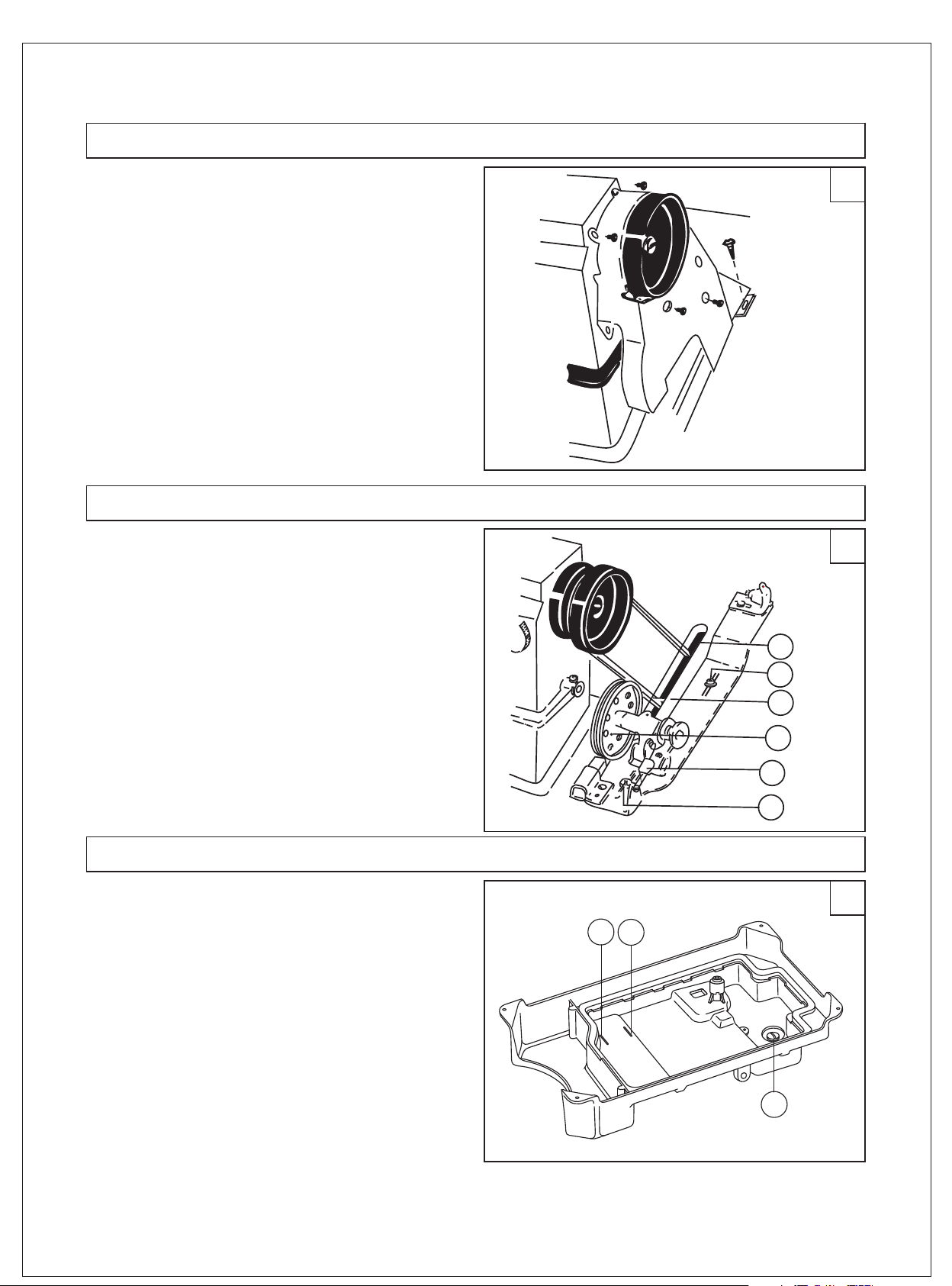

4.Connecting the clutch lever to the pedal(Fig.2)

a. The optimum tilt angle of pedal with floor is

approx 15 degree.

b. Adjust the clutch of the motor so that clutch

lever (C) and draw bar (B) run in line as Fig. 6, the

machine would have stable motion and long using.

c. The machine balance wheel should rotate

conter clockwise for normal sewing when view

from opposite side of the balance wheel. The motor

rotates in the same direction. The rotation can be

reversed by reversing (turn over 180 deg.) the plug of

the motor.

d. Adjust the tension of V-belt F by moving

the motor vertically. The proper tension of V-belt

is a slack of 10~12mm when the belt is depressed

(at the belt pan) by finger.

G

F

E

D

C

B

A

10 - 12 mm

20~30

2

-1-

5.Installing belt guard(Fig 3)

The belt guard should be installed for safety.

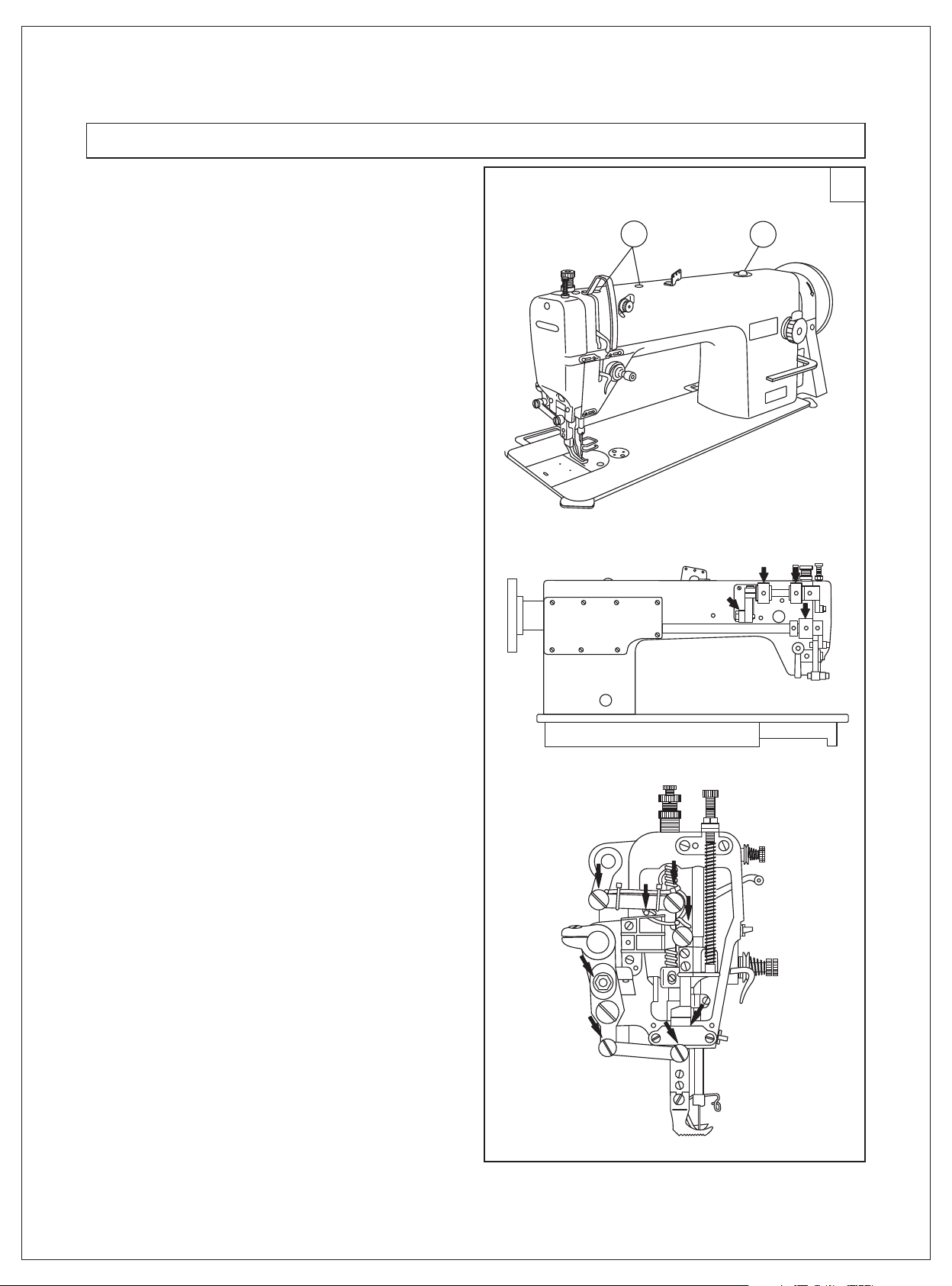

6.Installing the bobbin winder (Fig 4)

Align pulley (B) of the bobbin winder with the

outside of the belt , and there should be a proper

clearness between them , so that pulley (B) can be

contacted with the belt when stop latch thumb lever (A) is depressed, thereby the belt drives prlley

(B) white the machine running , the bobbin winder

should be parallel with belt slit (E) of the table,

the fasten with two wood screw (D).

E

D

C

3

4

7.Lubrication (Fig 5)

A. Oil amount

Oil amount must be oiled according to the

mark of drip pan. Mark (A) is the highest situation,

Mark (B) is the lowest situation , Note that oil

amount couldn t the lower than mark (B), otherwise

all parts of machine will appear heat and dead

point for not gaining oil.

b. Oiling

In lubruation, HA-8 sewing machine oil or HJ-7

machine oil must be used. Before running, the machine must be oiled at the mark (A).

c.Changing

Turn off the screw plugs (C), clean up the dirty

oil and the dust of drip pan, then fasten the screw

plugs (C), add fresh oil

,

B

A

D

5

A

B

L

I

O

L

H

C

-2-

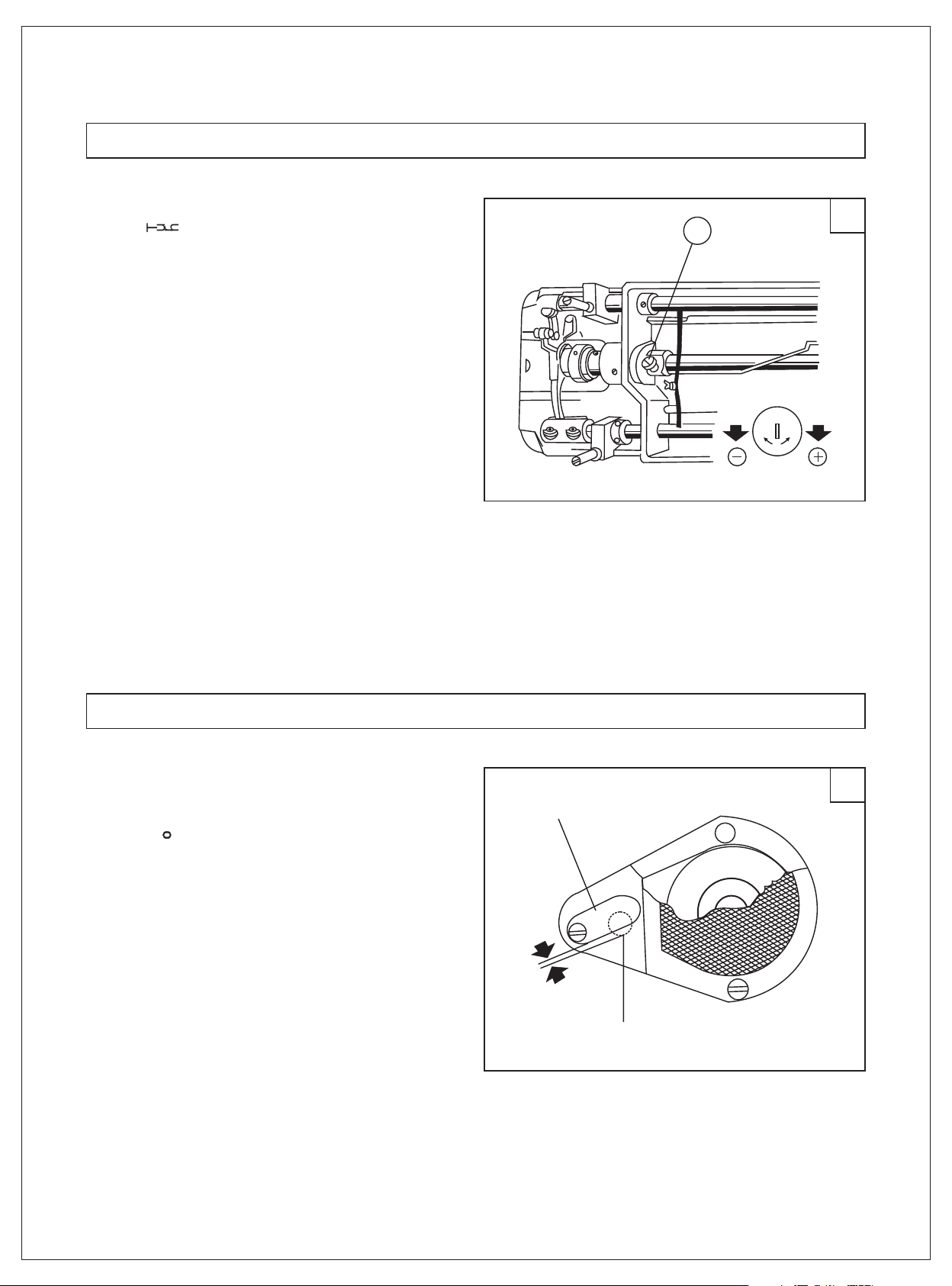

8. Trial run (Fig 6)

When the machine left out of operation for a quite

long time and used again, remove the red rubber plug on

top of the machine head, oil it thoroughly, the lift the

presser foot and run at a low speed of 1000 ~ 1500spm,

observe the sparkling condition through oil window (c),

as the lubrication is well, keep the running test at the low

speed about 30 minutes, then increase the speed gradually,

after months running to perfect its performance, then

'

increase up to proper sewing speed. .

6

A

C

-3-

9. Rotating hook oil amount adjustment (Fig 7)

The hook oil amount can be adjusted by Screw

(A). it clockwise ("+") to increase amount;

counter-clockwise ("-") to decrease. The oil amount

is adjusted in the range of five turns of Screw(A): Tightning

for more; Loosening for less.

nruT

A

.

7

10. Oil pump supply adjustment (Fig 8)

Generally no adjustment is for oil pump. When the machine

is running at a low speed, observe the oil screen. If no oil

splashing, clse the clearance.

o

.

Adjusting plate

Standard clearance

0.5-1.0

By-pass oil hole

8

-4-

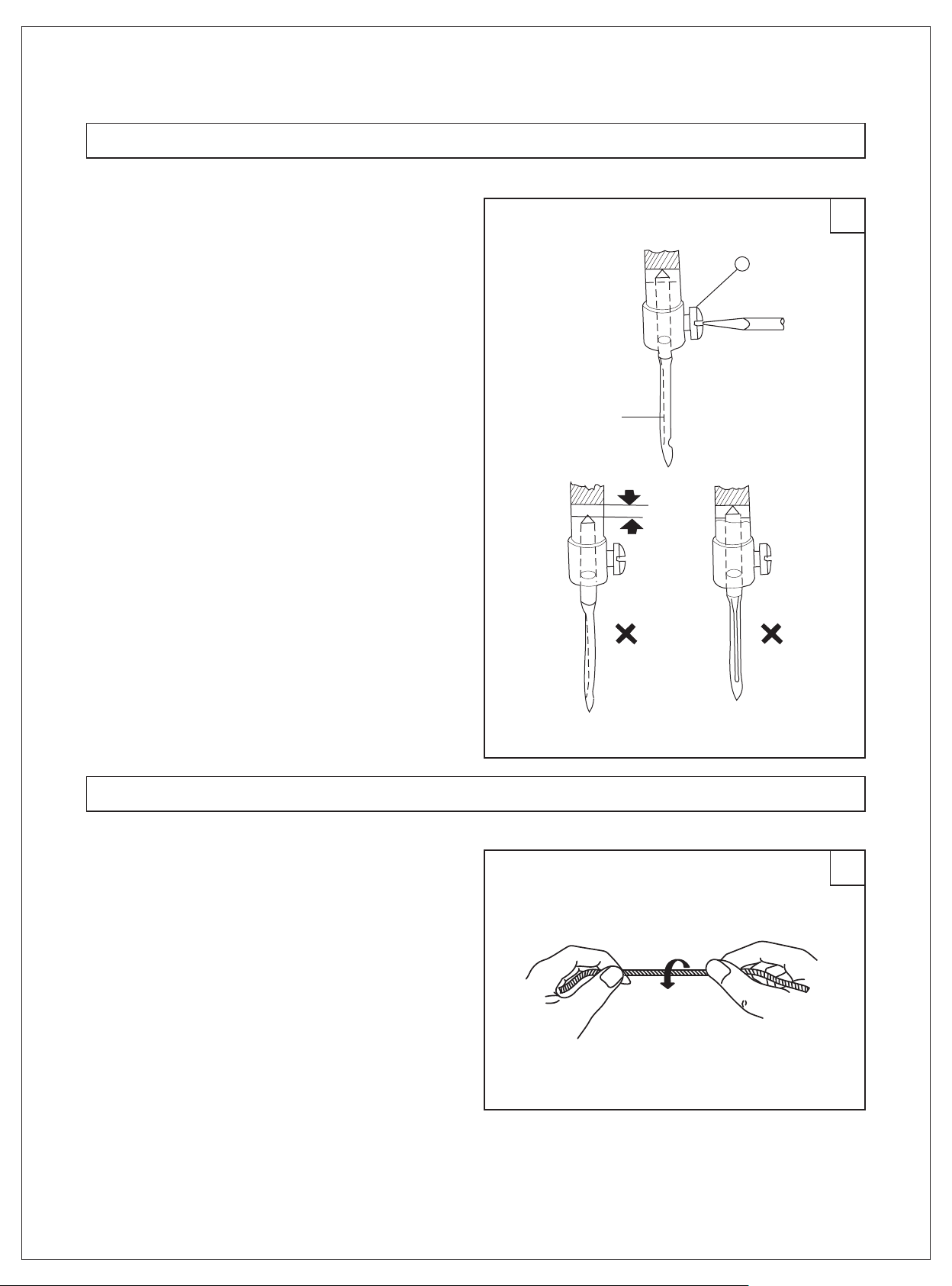

11.Installing the needle (Fig 9)

Turn the balance wheel to lift the needle bar to

its highest point, loosen needle set screw l, making

the needle groove turn to the left side of an opera-

tor, fully insert the needle shank up to the bottom

of needle socket, then tighten needle set screw l.

Note: Fig.12(b) insufficient insertion

Fig.12(C) Wrong direction of groove ..

Long groove leftward

a

Clearance

9

1

b c

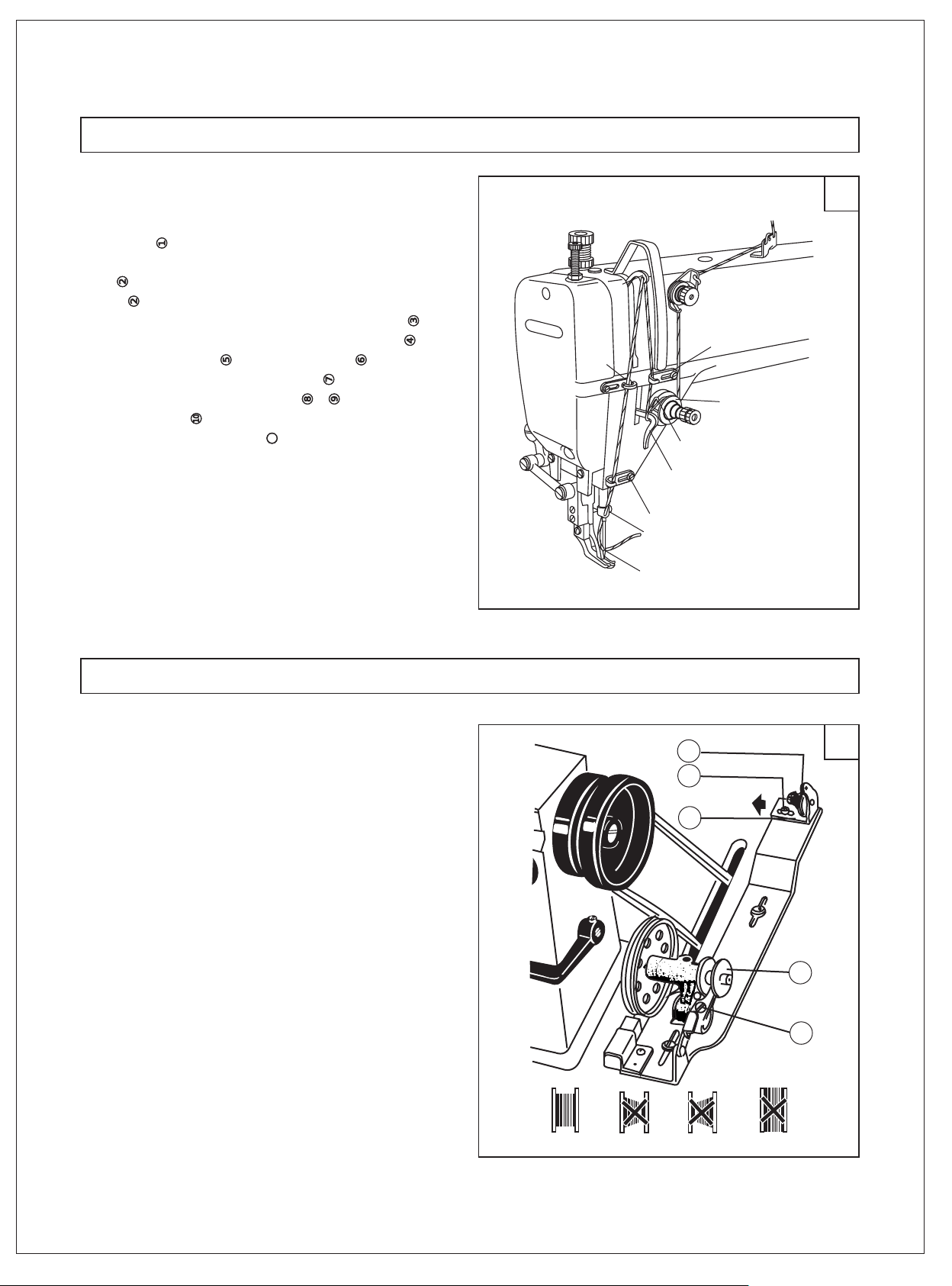

12.Coordination among the needle、 the thread and the material(Fig 10)

The needle thread is le t-twisted, the bobbin

thread is left or right-twisted.Holding the thread,

twist it with right hand in the direction of arrow

shown in Fig 10, if it is tight, it is left-twisted,con-

trarily, it is right-twisted.

The Needle is DP× 17 20#~24# (GC0303CX

DP×17 25#), the needle number must be fitted for the

materials. Sewing too heavy the weight of materials, the

needle would be breaking and skipping stitch and thread

breaking for its too thin, if the needle is too thick, it

would damage the clothes for its large needel hole.

Therefor, the selection of needle and thread must be fit-

ted to the materials.

f

10

.

.

-5-

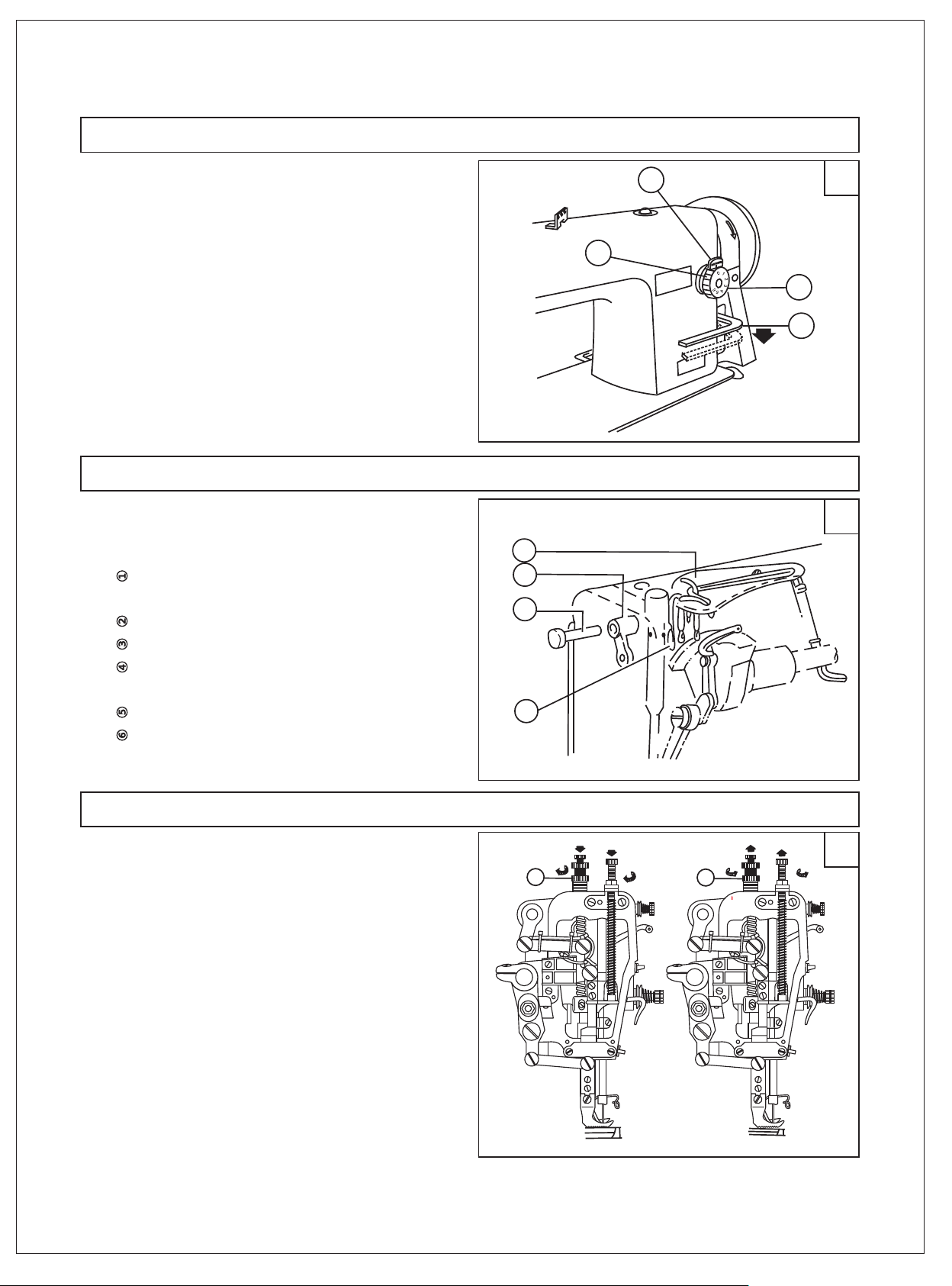

13.Threading the needle thread (Fig 11)

When threading the needle thread, raise the needle

bar to its highest position, lead the thread from the spool

and pass it in the order instructed.

(1) Lead the thread down through the three-eye

thread guide on the top.

(2) Pass down thru the left hole of thread retainer , then down thru the lower hole of thread

retainer .

(3)Pass down thru between the two tension disc

(4)Pass up thru the hook of thread take-up spring .

thru thread regulator , thru thread guide and up

thru the hole of thread take-up lever

(5) Down thru thread guide , , and needle

bar thread guide , then pass the thread from the

left thru the eye of needle , draw out the thread

approx 100mm from the needle eye.

When drawing the bobbin thread, hold the tip

of the needle thread by hand, turn the balance

wheel to lower the needle bar and then to lift it to

its highest position. Pull the needle thread and then

the bobbin thread is drawn up. put the tips of the

needle and bobbin thread toward front under the

presser foot.

①

②

②

⑤

⑧

⑩

○

11

⑥

⑦

.

⑨

.

.

.

③

④

.

.

.

1

7

2

6

8

3

4

5

9

10

11

11

14.Winding adjustment (Fig 12)

The wound bobbin thread should be neat and

tight. If not, adjust the thread tension by turning

tension stud thumb nut of the bobbin winder tension

bracket (A). If the wound bobbin is not neat, tension

bracket(C)can be moved to be adjusted. When adjusting,

loosen screw(B)first, then move the bracket leftward or

rightward if the thread is wound to one side as shown in

Fig.15(6), move the tension bracket rightward, while if

the thread is wound to one side as shown in Fig.15(C),

move the tension bracket leftward until the thread is

wound neatly as shown in Fig.15(a),tighten screw(B).

Note: Nylon or polyester thread should be

wound with light tension. otherwise bobbin (D) might be

.

.

a b c d

broken or deformed.

Don't overfill the bobbin, because it make its

thread loosening down from the bobbin. The

optimum capacity of thread will fill about 80% of

bobbin outside diameter, and this can be adjusted by

stop latch screw(E).

A

B

C

12

D

E

-6-

15.Setting the stitch length and controlling the reverse sewing (Fig 13)

Stitch length can be set by turning stitch

length regulating dial(A). The figures on the stitch

length regulation dial plate (B) indicate the stitch

length.

Reverse sewing can be obtained when feed re-

verse lever (C) is depressed and forward sewing can

be restored automatically when feed reverse lever

(C) is released.

.

.

A

D

16.Thread take-up oiling (Fig 14)

Thread take-up section adopts woolen thread

oiling. after long time of use, its function lost, so re-

place with a new one.

①

Open the face plate, remove the pressure

screw, lock nut and presser bar.

②

Renove Hinge(A) and Lever(B)

③

Draw out Oil Wick(C).

④

Loosen the wick fix screw on the arm top,

and take out Set Plate(D).

⑤

Replace with a new one.

⑥

Installing is a reverse sequence.

D

B

A

C

13

B

C

14

17.Adjusting the pressure of presser foot (Fig 15.)

15

Pressure on presser foot is to be adjusted in

accordance with materials to be sewn. Loosen lock

nut (A). If heavy materials to be sewn, turn pres-

sure regulating thumb screw clockwise as shown

Fig.20 (a) to increase the pressure .While light mate-

rials to be sewn, turn the pressure regulating thumb

screw counter clockwise as shown in Fig. 20 (b) to

decrease the pressure on presser foot, then tighten

lock nut (A).

The pressure of presser foot is proper as the

sewing materials can be fed normally. .

A

.

a b

-7-

A

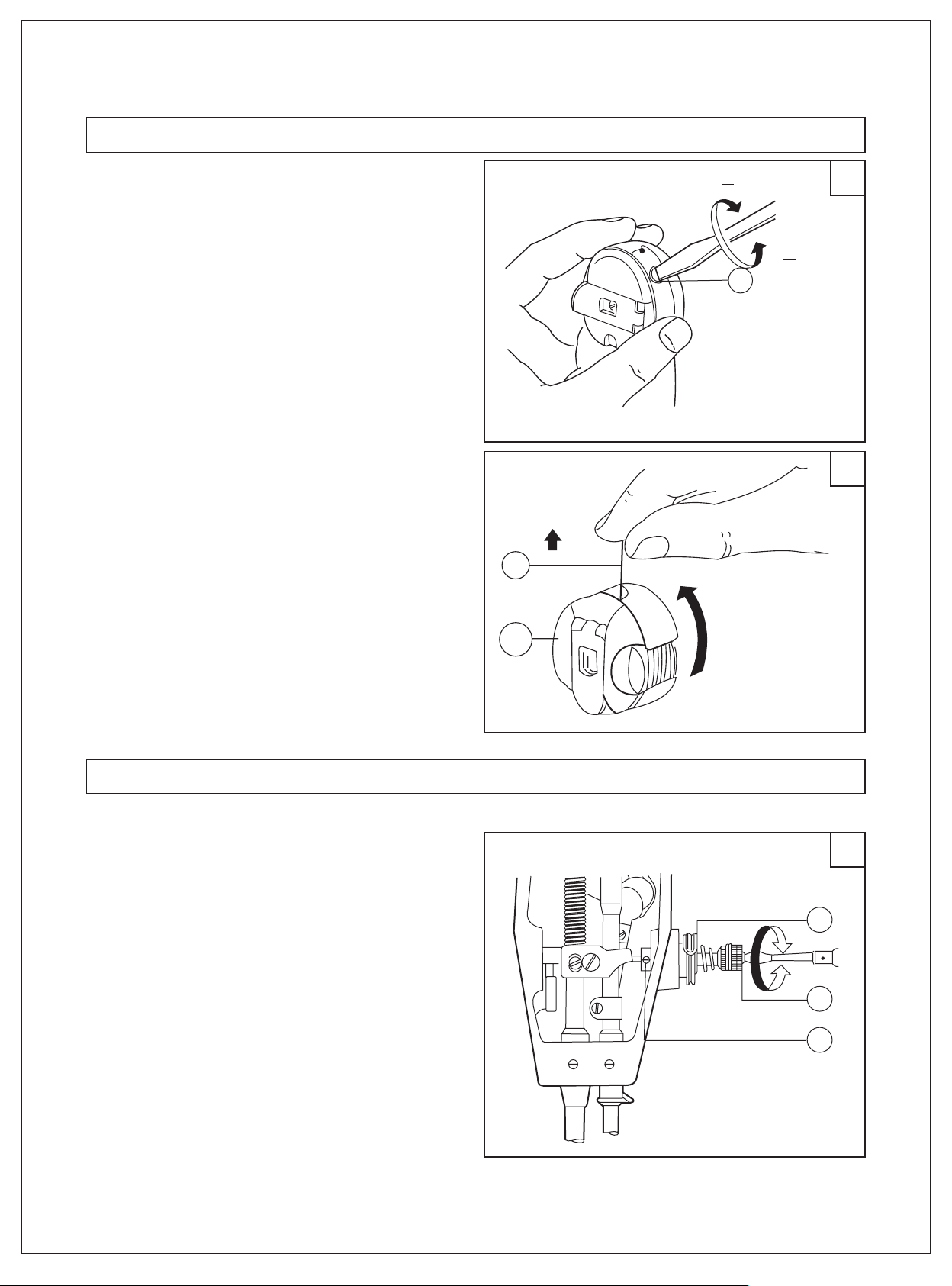

18.Adjusting the thread tension(Fig 16、17)

In general, the thread tension is to be adjusted

in accordance with materials thread and others.

In practice, the thread tension is adjusted ac-

cording to the stitches resulted to get the normal

stitches.

When adjusting the bobbin thread tension,

turn bobbin case tension spring screw (A) clock-

wise for more tension or turn the screw counter

clockwise for less tension.

It is a common practice to check the bobbin

thread tension. In case of polyester thread 50=,

hold the end of the thread. If the bobbin case falls

down slowly, the proper tension is obtained.

The needle thread tension should be ad-

justed with referance to the bobbin thread ten-

sion. The needle thread tension can be adjusted by

changing tension of the thread take-up spring ,sew-

ing range of the thread take-up spring, tension of

tension disc, and the position of thread guide.

.

.

.

.

.

16

A

17

A

B

19.Adjusting the thread take-up spring (Fig 18、19)

The normal sewing range of thread take-up sping

is 5~8mm. For sewing light weight materials( short

stitch), weaken the spring tension and widen the

sewing range of spring, while for sewing heavy

weight materials, strengthen the spring tension and

shorten the sewing range of spring .

1) Adjusting the thread take-up spring tension

(Fig.18) .

Loosen tension stud set screw (A), turn ten-

sion stud (B) clockwise to make the spring get

more tension, or turn the tension stud counter

clockwise to make the spring get less tension, After

adjustment, Be sure to tight tension stud set screw (A).

The method of adjustment:

Loose set screw (A) first, then to turn tension

stud(B) counter clockwise to release the tension of

.

.

:

18

C

B

A

-8-

Loading...

Loading...