Utilities Catalog

Utilities Catalog

PC-U2008, February, 2008

Tyler Utilities • 11910 CR. 492 • Tyler, Texas 75706 • (800) 527-8478

Union Foundry Company • Box 309 • Anniston, Alabama 3602 • (800) 226-7601

TABLE OF CONTENTS

Item Page Item Page

Pressure Pipe Fittings:

Flanged C110 .................................. 28-35

Mechanical Joint C110 ..................... 11-21

Mechanical Joint C153 ......................... 1-8

Swivel Hydrant Fittings ............. 3-5, 20, 21

Tapping Sleeves, MJ ...............................10

Union-Tite Push-On C153 ................ 22-27

Sample Specifications:

Flanged C110 ........................................28

Mechanical Joint C110 ...........................11

Mechanical Joint C153 .............................1

Union-Tite Push-On C153 ......................22

Special Information:

Terms and Conditions of Sale ........... 48-49

Adapter Flange Assembly .......................50

Flange Data ..................................... 34-35

Questions Frequently Asked ............. 53-54

Tap Locations for Flanged Fittings ...........35

Tapping Sleeves, Excavation ...................55

Cutting-In Sleeve, Installation ...................8

MJ Gasket ..............................................56

MJ Transition Gasket ..............................56

Offsets ...................................................51

Pipe O.D.'s .............................................52

Retainer Gland Data ....................8, 20, 50

MJ Nuts and Bolt ....................................54

SUBMITTALS:

MJ Field Lok ..................................... 55-56

22U - C110 Full Body .............................57

23U - C153 MJ Compact ........................58

26U - Union-Tite ....................................59

28U - C110 Flange Fittings ................... BC

Municipal Castings:

Boxes:

Service Screw Type ............................36

Valve

Adjustable, O-Ring ...................... 43-44

Two-Piece (Screw Type) ................ 37-38

Two-Piece (Slip Type) ........................ 39-40

Three-Piece (Screw Type) ..................41-42

Lids

Drop & MWW ....................................45

Covers

Meter Box .........................................47

Risers .....................................................46

Wrenches ...................................36, 45, 47

NOTE: Flanged ductile-iron fittings in 24-in.

(610 mm) and smaller sizes may be rated for 350

psi (2,413 kPa) with the use of special gaskets.

( +.06)

( - .06)

Flange Thickness of SSB D.I. Class 350

MJxFlange Fittings

Size T Size T

3 .60 14 .87

4 .63 16 .90

6 .63 18 .93

8 .70 20 .96

10 .75 24 1.00

12 .81

NOTICE: Weights published in this catalog are for shipping purposes only. Actual weights may

vary because some fittings are produced in both foundries. All meet the AWWA standards to

which they are designed.

For weights of specific fittings, please contact Tyler Pipe or Union Foundry Company.

Tyler Utilities Division • 11910 CR 492 • Tyler, Texas 75706 • (800) 527-8478

Union Foundry Company • Box 309 • Anniston, Alabama 36202 • (800) 226-7601 02/01/08

TUF Lock

B E T T E R B Y D E S I G N

Advantages of the TUF Lock™ mechanical joint restraint:

● UL Listed and FM approved for PVC and Ductile Iron

Pipe sizes 4 - 12 inch.

● PVC TUF Lock conforms to ASTM 1674.

● Eliminates cumbersome thrust blocks.

● Currently available to restrain PVC and Ductile Iron

Pipe from 3 - 24 inches.

● Proven joint restraint technology utilizes fewer

wedges in frequently applied diameters.

● Cast with tested and traceable ASTM A536

compliant 65-45-12 ductile iron.

● Wedges and bolts are E-coated for corrosion

resistance.

● Color-coded red for PVC or black for Ductile Iron

applications.

● Restrain IPS PVC pipe, standard PVC Pipe and

Ductile Iron Pipe.

● PVC wedge design maintains pipe hoop strength

integrity.

● Accommodate out-of-round pipe.

● Ductile and PVC TUF Lock™ rated for a 2:1 safety

factor based on pipe pressure rating.

● Suitable for potable water and wastewater

applications.

● Allows disassembly just like a standard mechanical

joint.

TUF Lock™ Ductile Iron TLD

● Restrain any class of Ductile Iron Pipe.

● Reduce time in the trench utilizing proven joint

restraint technology.

TUF Lock™ PVC TLP

● Restrain any class of AWWA C900/905 PVC pipe.

● One restraint accommodates IPS and C900 PVC

pipe w/o removing a washer.

● Single tooth design provides superior restraint

technology.

Featuring a new

product line . . .

™

MJ TUF LockTM Restraints

MJ TUF LockTM TLD

Tyler Utilities Division • 11910 CR 492 • Tyler, Texas 75706 • (800) 527-8478

02/01/08 Union Foundry Company • Box 309 • Anniston, Alabama 36202 • (800) 226-7601 i

MJ TUF LockTM TLP

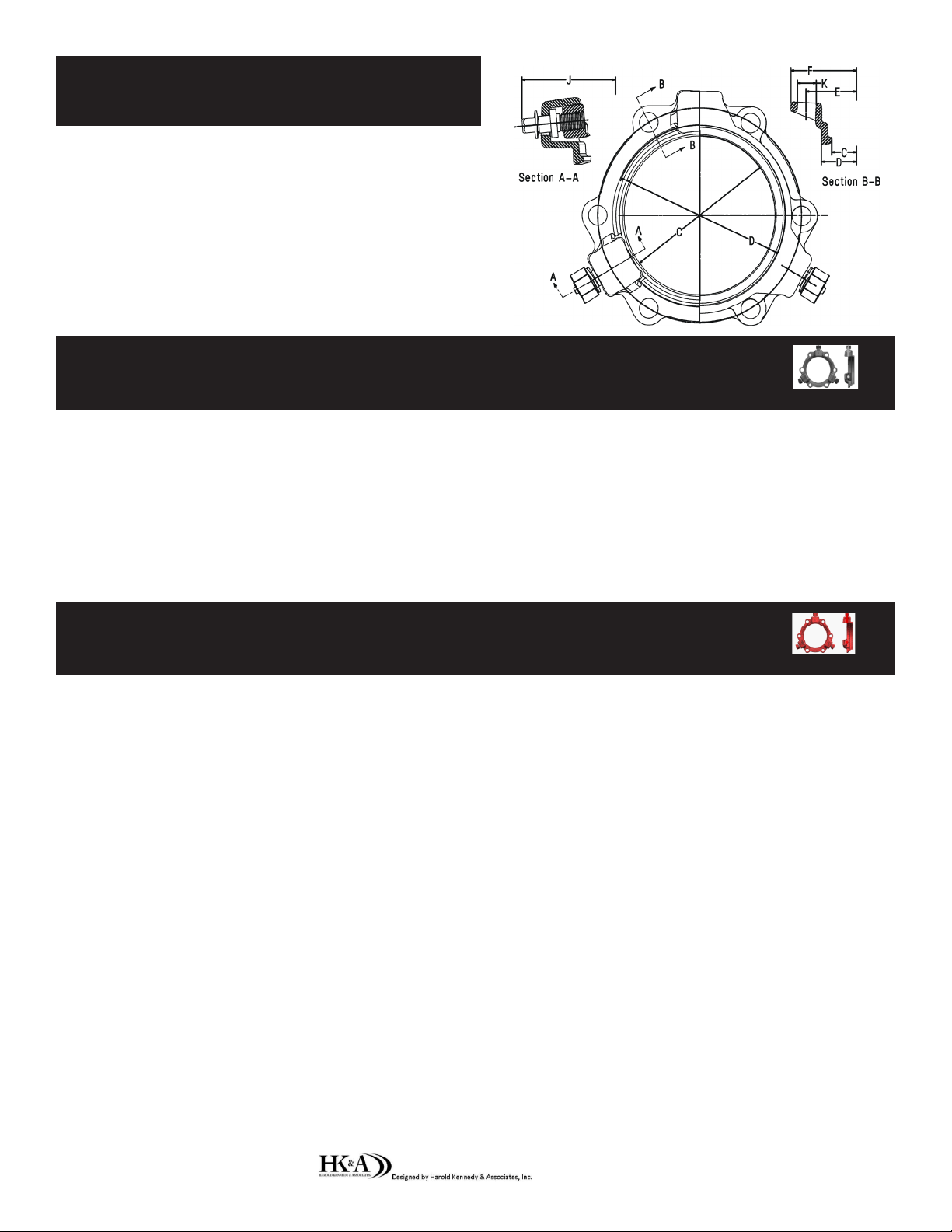

TUF Lock™ MJ Restraint Dimensions

Size

(inches) C D E F J K

3 4.08 4.88 6.19 7.67 9.82 3/4

4 4.93 5.92 7.50 8.98 10.67 7/8

6 7.03 8.02 9.50 10.98 12.77 7/8

8 9.18 10.17 11.75 13.23 14.92 7/8

10 11.23 12.22 14.00 15.70 16.97 7/8

12 13.33 14.32 16.25 17.95 19.07 7/8

14 15.44 16.40 18.75 20.43 21.18 7/8

16 17.54 18.50 21.00 22.88 23.28 7/8

18 19.64 20.60 23.25 25.43 25.38 7/8

20 21.74 22.70 25.50 27.50 27.48 7/8

24 25.94 26.90 30.00 32.00 31.68 7/8

Ductile TUF™ Lock Application Chart

Size Part Wedge T-Bolt Weight Weight Pressure

(inches) Number Quantity Quantity (lbs) (w/ Acc.) Rating (psi) Pipe OD

3 TLD-3 2 4 7.0 10.1 350 3.96

4 TLD-4 2 4 7.8 10.9 350 4.80

6 TLD-6 3 6 11.2 17.8 350 6.90

8 TLD-8 3 6 13.1 20.3 350 9.05

10 TLD-10 6 8 26.0 32.5 350 11.10

12 TLD-12 8 8 31.5 40.4 350 13.20

14 TLD-14 10 10 43.3 53.6 350 15.30

16 TLD-16 12 12 54.1 66.3 350 17.40

18 TLD-18 12 12 59.8 72.2 250 19.50

20 TLD-20 14 14 69.8 83.8 250 21.60

24 TLD-24 16 16 90.4 106.9 250 25.80

PVC TUF™ Lock Application Chart

Size Part Wedge T-Bolt Weight Weight Pressure

(inches) Number Quantity Quantity (lbs) (w/ Acc.) Rating (psi) Pipe OD

3 TLP-3 2 4 7.1 10.2 305 3.50

4 TLP-4 2 4 8.3 11.0 305 4.50-4.80

6 TLP-6 3 6 12.4 18.3 305 6.63-6.90

8 TLP-8 3 6 14.9 20.8 305 8.63-9.05

10 TLP-10 6 8 25.7 33.4 305 10.75-11.10

12 TLP-12 8 8 34.1 42.0 305 12.75-13.20

14 TLP-14 10 10 45.1 55.4 235 15.30

16 TLP-16 12 12 56.2 68.4 235 17.40

18 TLP-18 12 12 62.4 74.8 235 19.50

20 TLP-20 14 14 72.9 86.9 235 21.60

24 TLP-24 16 16 93.2 109.8 235 25.80

Suggested Specications: Bold Italicized language applies to Ductile and PVC TUF Lock™

Restraint glands shall be designed for use with and conform to the applicable requirements of ANSI / AWWA

C111.A21.11. Restraint gland product identication shall have traceability. Restraint glands shall have a minimum safety factor of 2:1. Restraint glands shall employ a single tooth wedge design and utilize torque limiting

nutsrequiring no more than 60 ft-lbs of torque to actuate wedges. Restraint devices shall accept out of round

pipe. Restraint devices shall not utilize stops, shall have a bolt and threaded wedge that can not be removed prior

to assembly. Mechanical Joint restraints shall be listed by Underwriters Laboratories in sizes 4”- 12”, and have

Factory Mutual approval in sizes 4” -12”. Specialty tools will not be required for installation. Restraint glands

shall be Tyler Union TUF Lock™ or approved equal.

Ductile TUF Lock™ will restrain pipe conforming to the requirements of ANSI/AWWA/C151/A21.51. Ductile Iron Pipegripping wedges shall be heat treated and hardened to a BHN range of 370-470.

PVC TUF Lock™ will restrain pipe manufactured to AWWA C900 / C905 and have working pressure ratings equal to the

pressure rating of the pipe on which they are used. Restraint glands shall accommodate 3”- 12” IPS pipe without the

removal of spacers or other modication of the device and conform to the requirements of ASTM 1674.

MECHANICAL JOINT C153 DUCTILE IRON

COMPACT FITTINGS

Sizes 3" thru 12" UL Listed For Fire Main Equipment

SAMPLE SPECIFICATIONS

Mechanical Joint watermain fittings with accessories, 3" through 48" shall be manufactured from Ductile Iron in

accordance with and meet all applicable terms and provisions of standards ANSI/AWWA C153/A21.53 ANSI/

AWWA C111/A21.11 (current revisions). Ductile Iron Mechanical Joint Fittings 3" through 24" shall be rated for

350 PSI working pressure. 30" through 48" shall be rated for 250 psi working pressure. Flanged ductile-iron

fittings in 24-in. (610 mm) and smaller sizes may be rated for 350 psi (2,413 kPa) with the use of special gaskets.

All coated fittings meet requirements of NSF-61.

NOTE - EXCEPTIONS: Mechanical Joint Fittings with flanged branches are rated for water pressure of 250 PSI.

NOTE: Fittings are CEMENT LINED and seal coated in accordance with ANSI/AWWA C104/A

21. 4

; also available

double cement-lined, bare or epoxy coated.

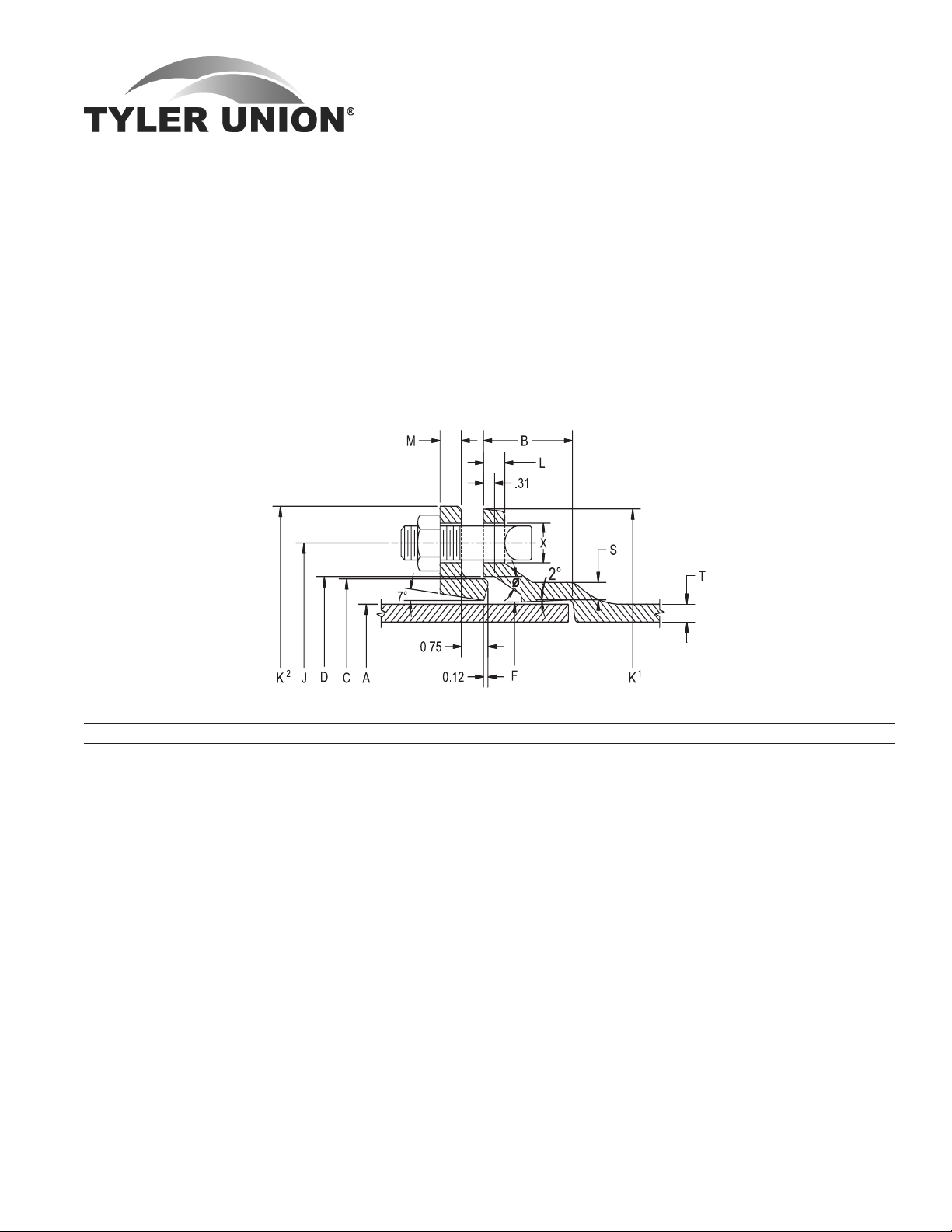

JOINT DIMENSIONS IN INCHES BOLTS

Size A Dia. B C Dia. D Dia. F Dia. J Dia. K 1 Dia. K2 Dia. L M S T X Size No.

3 3.96 2.50 4.84 4.94 4.06 6.19 7.62 7.69 .58 .62 .39 .33 ¾ Á x3 4

4 4.80 2.50 5.92 6.02 4.90 7.50 9.06 9.12 .60 .75 .39 .34 Â ¾x3½ 4

6 6.90 2.50 8.02 8.12 7.00 9.50 11.06 11.12 .63 .88 .43 .36 Â ¾x3½ 6

8 9.05 2.50 10.17 10.27 9.15 11.75 13.31 13.37 .66 1.00 .45 .38 Â ¾x3½ 6

10 11.10 2.50 12.22 12.34 11.20 14.00 15.62 15.62 .70 1.00 .47 .40 Â ¾x3½ 8

12 13.20 2.50 14.32 14.44 13.30 16.25 17.88 17.88 .73 1.00 .49 .42 Â ¾x3½ 8

14 15.30 3.50 16.40 16.54 15.44 18.75 20.31 20.25 .79 1.25 .56 .47 Â ¾x4 10

16 17.40 3.50 18.50 18.64 17.54 21.00 22.56 22.50 .85 1.31 .57 .50 Â ¾x4 12

18 19.50 3.50 20.60 20.74 19.64 23.25 24.83 24.75 1.00 1.38 .68 .54 Â ¾x4 12

20 21.60 3.50 22.70 22.84 21.74 25.50 27.08 27.00 1.02 1.44 .69 .57 Â ¾x4 14

24 25.80 3.50 26.90 27.04 25.94 30.00 31.58 31.50 1.02 1.56 .75 .61 Â ¾x4½ 16

30 32.00 4.00 33.29 33.46 32.17 36.88 39.12 39.12 1.31 2.00 .82 .66 1¿ 1 x5½ 20

36 38.30 4.00 39.59 39.76 38.47 43.75 46.00 46.00 1.45 2.00 1.00 .74 1¿ 1 x5½ 24

42 44.50 4.00 45.79 45.96 44.67 50.62 53.12 53.12 1.45 2.00 1.25 .82 1À 1¼x6½ 28

48 50.80 4.00 52.09 52.26 50.97 57.50 60.00 60.00 1.45 2.00 1.35 .90 1À 1¼x6½ 32

Tyler Utilities Division • 11910 CR 492 • Tyler, Texas 75706 • (800) 527-8478

02/01/08 Union Foundry Company • Box 309 • Anniston, Alabama 36202 • (800) 226-7601 1

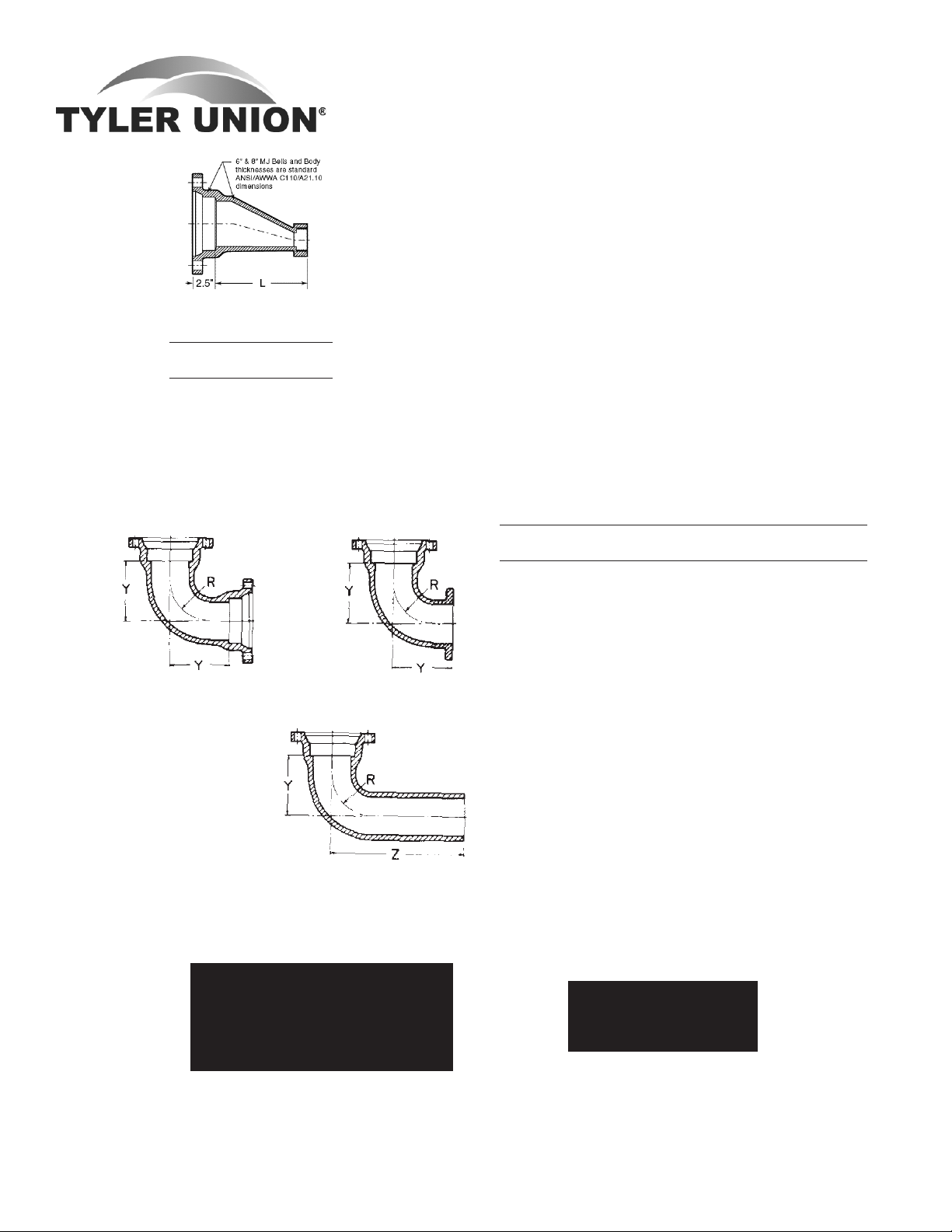

MECHANICAL JOINT C153 DUCTILE IRON

COMPACT FITTINGS

Sizes 3" thru 12" UL Listed For Fire Main Equipment

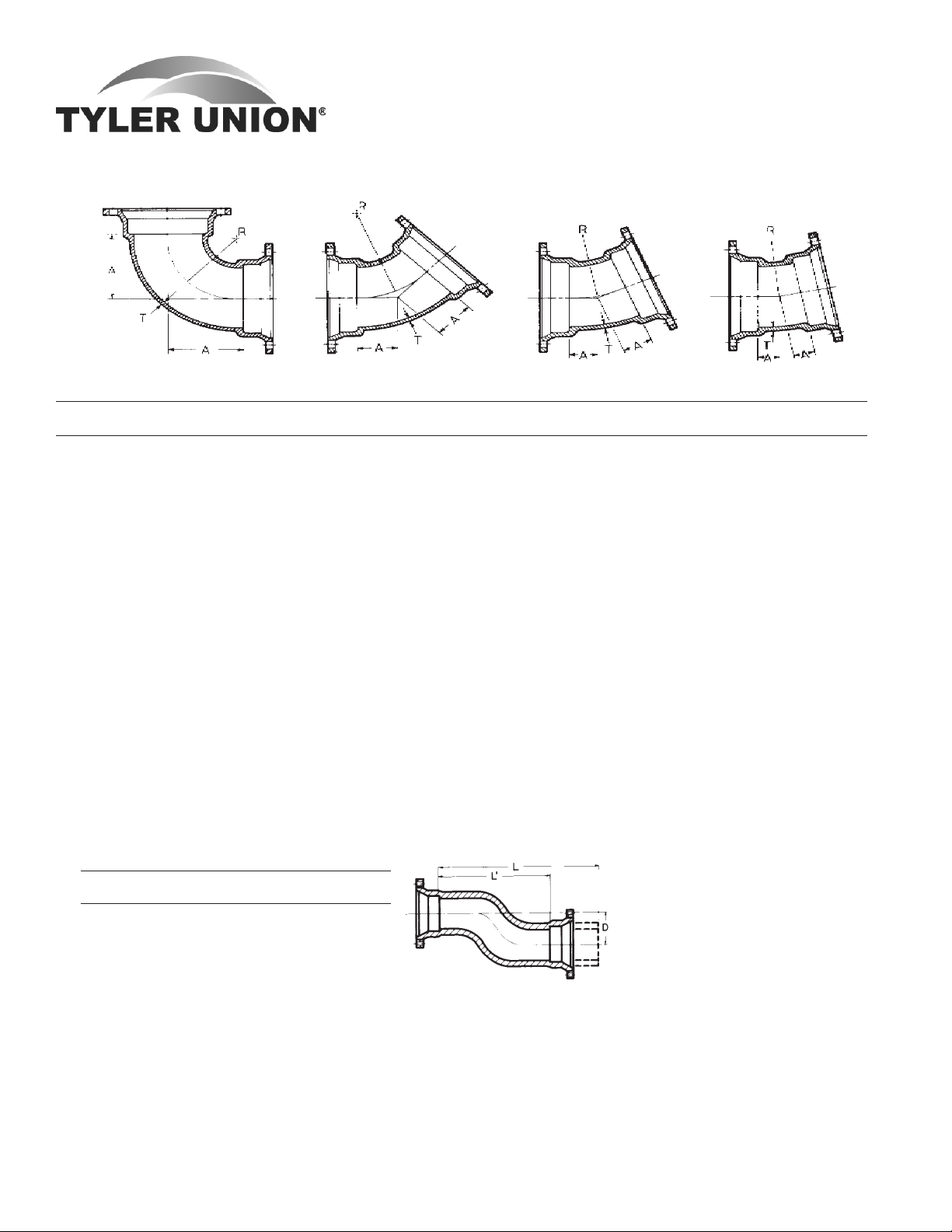

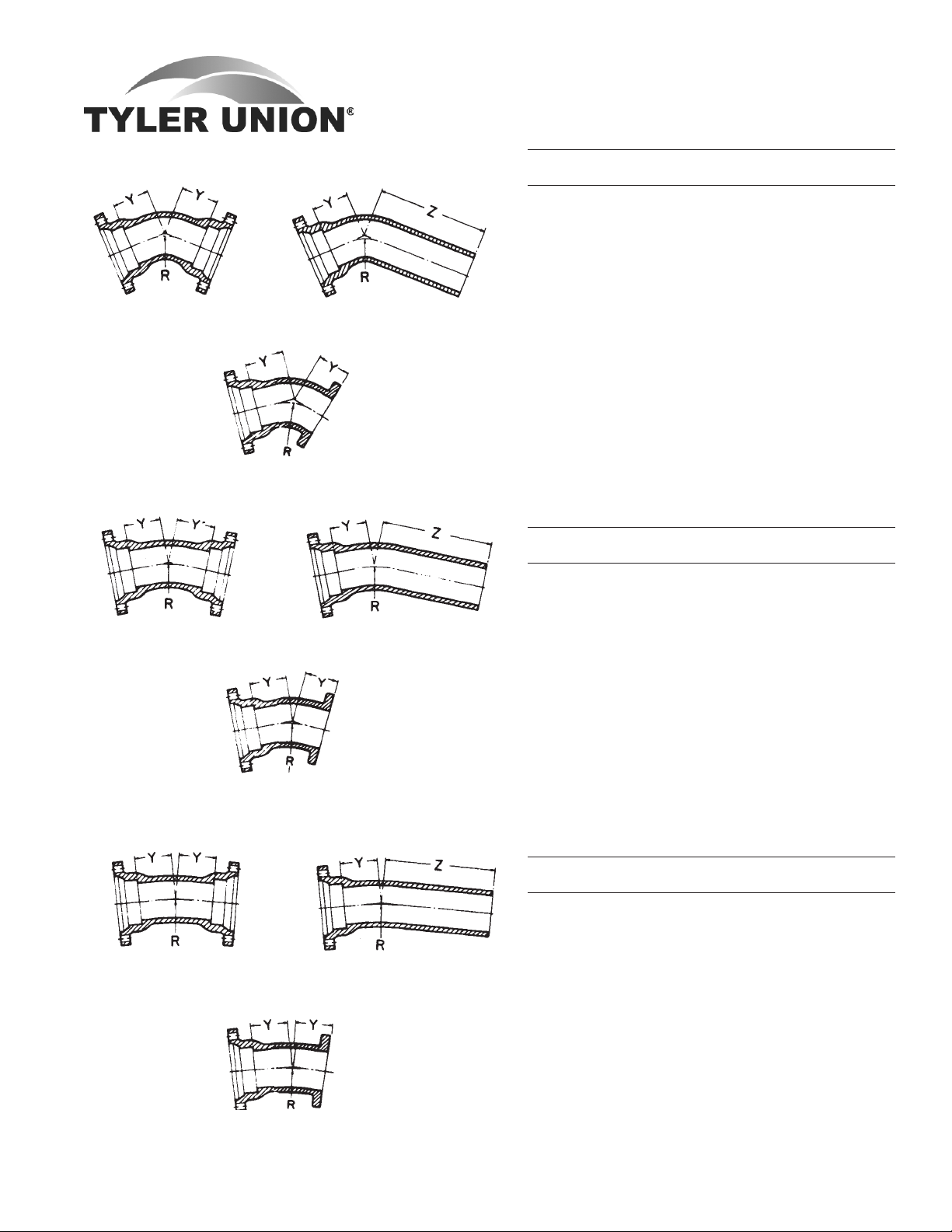

BENDS

90° Bends (1/4) 45° Bends (1/8) 22½° Bends (1/16) 11¼° (1/32)

Dimensions Dimensions Dimensions Dimensions

Size T A R Weight A R Weight A R Weight A R Weight

3 .34 3.5 2.5 19 2.00 2.41 17 1.50 2.51 15 1.25 2.53 16

4 .35 4.0 3.0 26 2.50 3.56 22 1.75 3.81 20 1.50 5.12 20

6 .37 6.5 6.0 49 3.50 7.25 39 2.25 6.35 31 1.50 5.12 29

8 .39 7.5 7.0 64 4.00 8.44 56 2.85 11.80 50 2.06 15.80 45

10 .41 9.5 9.0 102 5.01 10.88 78 3.35 14.35 66 2.32 18.36 59

12 .43 10.5 10.0 129 5.98 13.25 102 3.86 16.90 87 2.56 20.90 82

14 .51 12.0 11.5 214 5.50 12.06 155 3.93 17.25 142 2.59 21.25 136

16 .52 13.0 12.5 273 5.98 13.25 204 3.98 17.50 178 2.62 21.50 157

18 .59 15.5 14.0 411 6.50 12.36 292 7.50 30.19 286 3.00 60.84 283

20 .60 17.0 15.5 519 7.00 13.59 372 8.50 35.19 376 3.50 71.07 374

24 .62 17.0 15.5 721 7.50 14.89 490 9.00 37.69 512 3.50 76.12 487

30 .66 21.50 19.0 930 10.50 9.31 716 6.75 21.36 665 4.75 22.84 600

36 .74 24.50 22.0 1450 11.50 21.73 1110 7.75 26.39 960 5.00 25.38 820

42 .82 29.25 26.7 2205 14.00 27.76 1610 9.00 32.68 1350 6.00 35.54 1180

48 .90 33.25 30.75 2990 15.00 30.17 2090 10.00 27.70 1760 6.50 40.61 1475

*OFFSETS

MJ x MJ MJ x PE

Dimensions Weights

Size D L1 L MJxMJ MJxPE

4 6 10 -- 45 --

4 12 16 -- 55 - 4 18 22 -- 65 - 4 24 28 -- 75 - 6 6 12 17.5 41 54

6 12 18 -- 65 - 6 18 24 -- 75 - 6 24 30 -- 85 - 8 6 13 -- 84 - 8 12 19 -- 90 - 8 18 25 -- 100 --

* Not included in AWWA C153.

Tyler Utilities Division • 11910 CR 492 • Tyler, Texas 75706 • (800) 527-8478

2 Union Foundry Company • Box 309 • Anniston, Alabama 36202 • (800) 226-7601 02/01/08

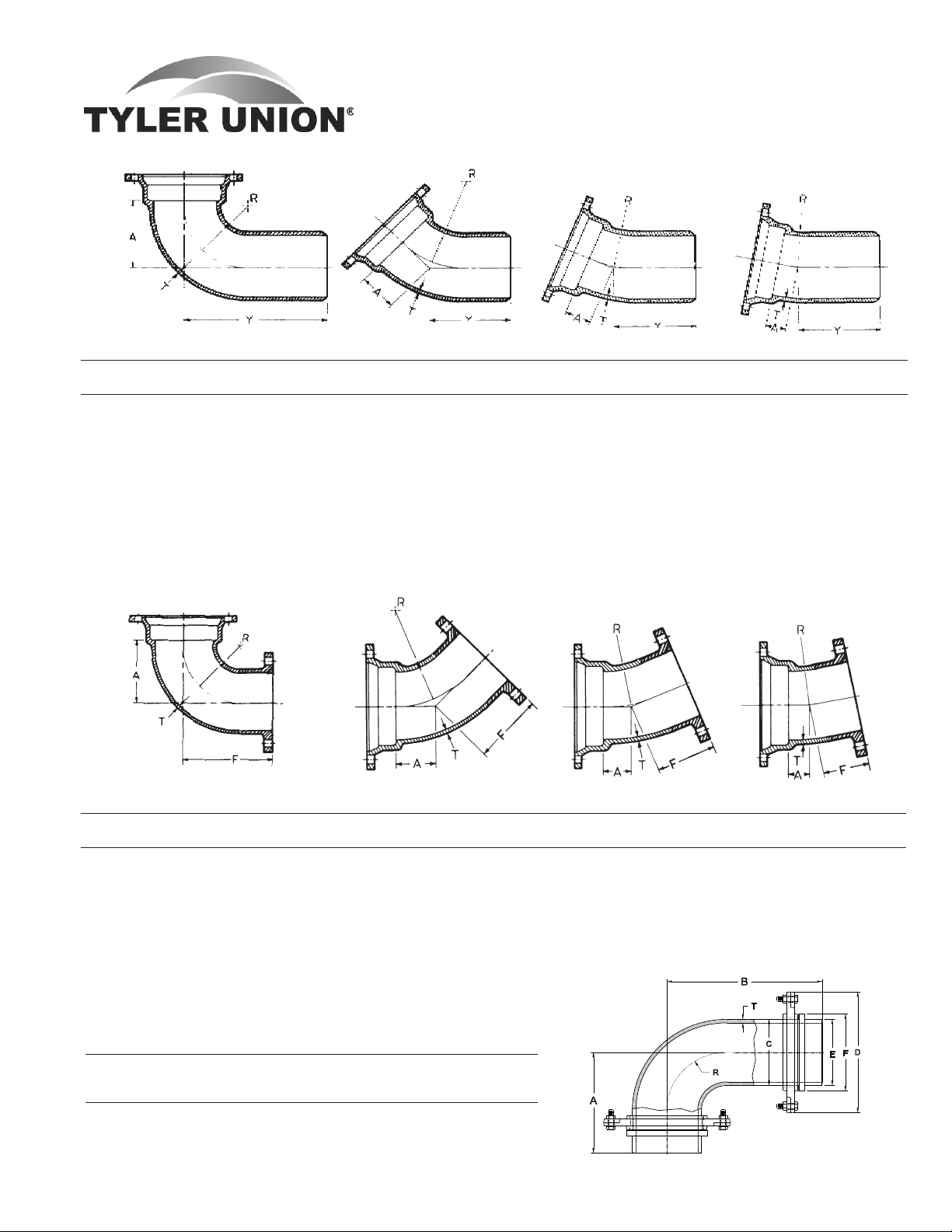

MECHANICAL JOINT C153 DUCTILE IRON

COMPACT FITTINGS

Sizes 3" thru 12" UL Listed For Fire Main Equipment

BENDS

90° Bend MJ x PE (1/4) 45° Bend MJ x PE (1/8) 22½° Bend MJ x PE (1/16) 11¼° Bend MJ x PE (1/32)

Dimensions Dimensions Dimensions Dimensions

Size T A Y R Weight A Y R Weight A Y R Weight A Y R Weight

3 .34 3.5 9.0 2.5 18 2.0 7.5 2.41 17 1.50 7.00 2.51 19 1.25 6.75 7.62 15

4 .35 4.0 9.5 3.0 26 2.5 8.0 3.56 22 1.75 7.25 3.81 20 1.50 7.00 5.12 20

6 .37 6.0 11.5 5.0 45 3.2 8.7 5.49 38 2.25 7.75 6.35 33 1.50 7.00 5.12 32

8 .39 7.5 13.0 7.0 64 4.0 9.5 8.44 55 2.84 8.34 11.80 51 2.05 7.55 15.80 44

10 .41 9.5 15.0 9.0 108 5.0 10.5 10.88 78 3.35 8.85 14.35 66 2.31 7.81 18.36 60

12 .43 9.0 14.4 6.0 114 6.0 11.5 13.25 104 3.50 9.00 12.70 89 2.56 8.06 20.90 79

14 .51 12.0 20.0 11.5 219 5.5 13.4 10.85 165 3.93 11.93 17.25 152 2.59 10.59 21.25 137

16 .52 13.0 21.0 12.5 254 6.0 14.0 13.25 206 3.98 11.98 17.50 181 2.62 10.62 21.50 161

24 .62 17.0 25.0 15.5 710 7.5 16.6 14.69 460 9.00 17.66 37.69 455 9.00 26.12 12.00 475

30 .68 21.5 30.5 -- 865 10.5 19.5 -- 715 6.75 15.75 -- 600 -- -- -- --

90° Bend MJ x Flange 45° Bend MJ x Flange 22½° Bend MJ x Flange 11¼° Bend MJ x Flange

(1/4) (1/8) (1/16) (1/32)

Dimensions Dimensions Dimensions Dimensions

Size T A R F Weight A R F Weight A R F Weight A R F Weight

3 .34 3.5 2.5 5.5 21 ... ... .. .. ... ... .. .. ... ... .. ..

4 .35 4.0 3.0 6.5 28 2.50 3.56 4.0 34 1.75 3.81 4.0 34 1.50 5.12 4.0 19

6 .37 6.0 5.0 8.0 45 3.25 5.49 5.0 57 2.25 5.35 5.0 57 1.50 5.12 5.0 30

8 .39 7.5 7.0 9.0 73 4.25 7.93 5.5 83 2.50 7.62 5.5 83 1.75 7.70 5.5 50

10 .41 9.5 9.0 11.0 113 5.00 9.76 6.5 122 3.00 10.16 6.5 122 2.00 10.25 6.5 75

12 .43 10.5 10.0 12.0 141 6.00 12.19 7.5 159 3.50 12.70 7.5 159 2.25 12.82 7.5 88

14 .51 12.0 11.5 14.0 217 5.50 10.85 8.5 207

16 .52 13.0 12.5 15.0 280 6.00 12.02 9.5 290

90° Swivel x Swivel Hydrant Ell

Dimensions

Size T A B C D E F R

*Weight

6 .37 10.5 15.5 6.90 11.2 6.81 7.98 6.0 74

* Weight includes two swivel glands.

Tyler Utilities Division • 11910 CR 492 • Tyler, Texas 75706 • (800) 527-8478

02/01/08 Union Foundry Company • Box 309 • Anniston, Alabama 36202 • (800) 226-7601 3

MECHANICAL JOINT C153 DUCTILE IRON

COMPACT FITTINGS

Sizes 3" thru 12" UL Listed For Fire Main Equipment

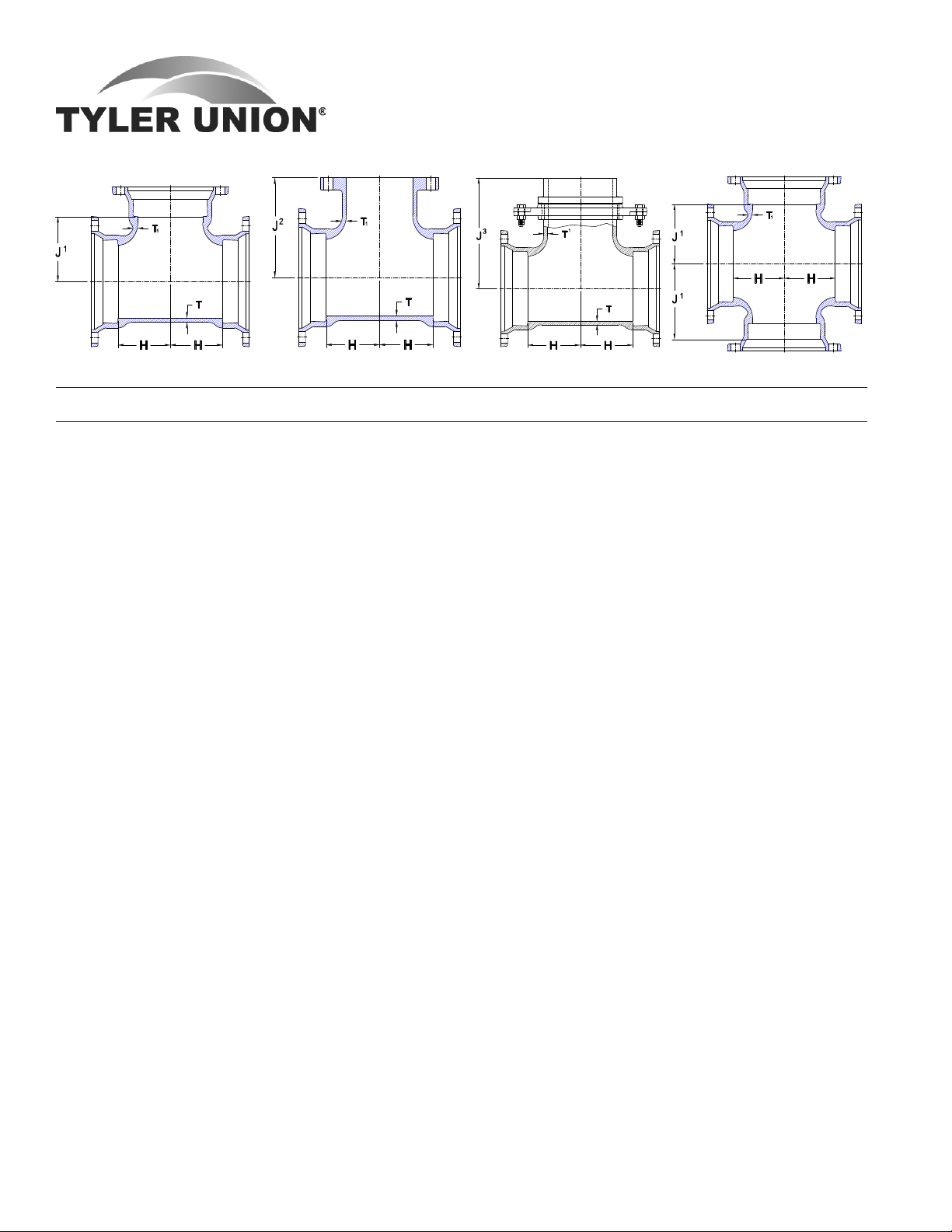

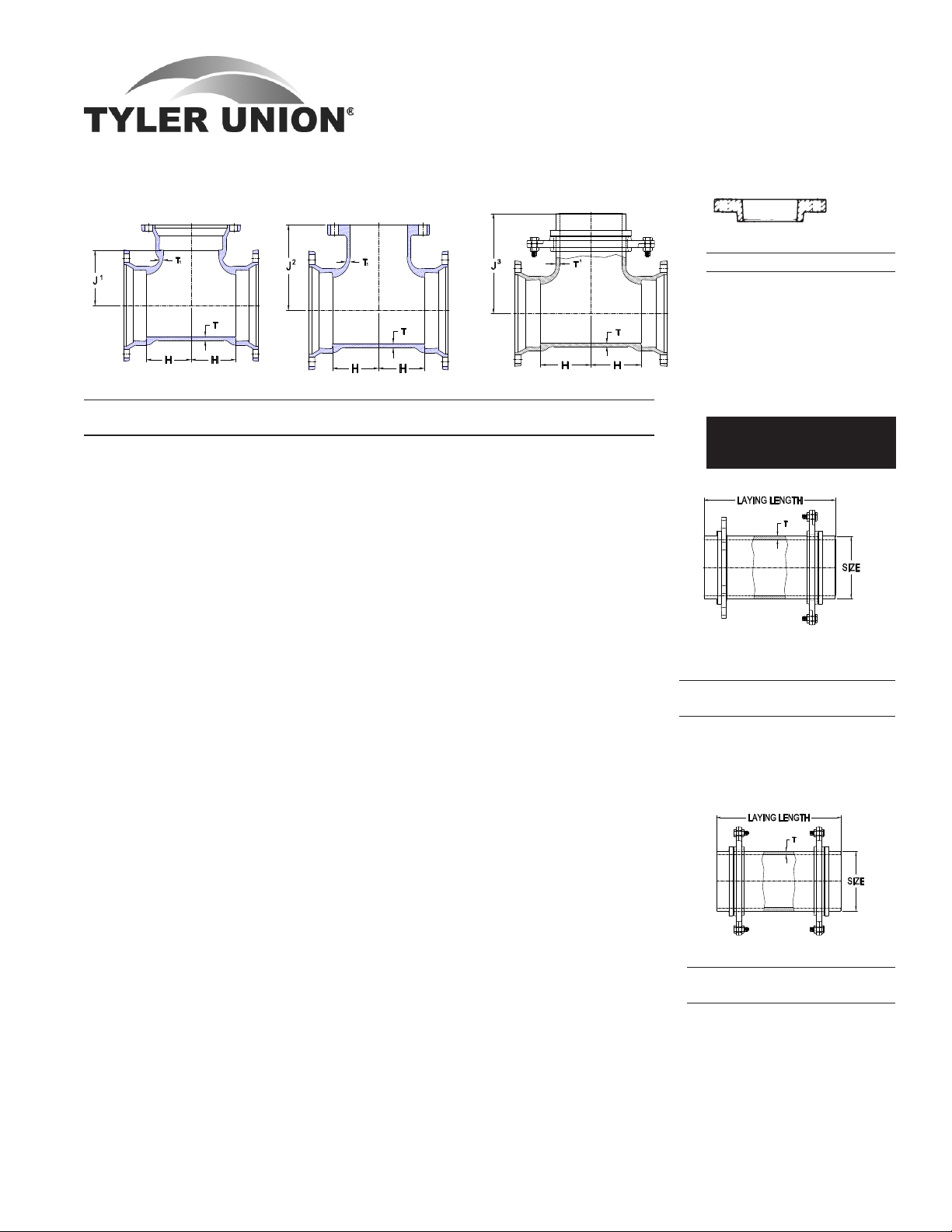

TEES

MJ Tee MJ x FE Tee MJ x Swivel Tee Cross

Dimensions Weights

Size T T1 H J1 J2 J3 MJ MJxFE †MJxS Cross

3 .34 .34 3.5 3.50 5.5 ... 26 29 ... 31

4x3 .35 .34 3.5 4.00 6.5 ... 35 34 ... 39

4 .35 .35 4.0 4.00 6.5 ... 36 39 ... 45

6x3 .37 .34 4.0 4.00 6.5 ... 51 54 ... ...

6x4 .37 .35 4.0 5.00 8.0 ... 52 57 ... 62

6 .37 .37 5.0 5.00 8.0 10.50 66 68 77 79

8x3 .39 .34 4.0 6.50 9.0 ... 56 ... ... ...

8x4 .39 .35 4.5 6.50 9.0 ... 72 82 ... 84

8x6 .39 .37 5.5 6.50 9.0 11.50 79 81 105 98

8 .39 .39 6.5 6.50 9.0 11.50 90 101 116 112

10x3 .41 .34 4.0 7.50 11.0 ... 80 ... ... ...

10x4 .41 .35 4.5 7.50 11.0 ... 82 92 ... 98

10x6 .41 .37 5.5 7.50 11.0 13.00 99 116 114 121

10x8 .41 .39 6.5 7.50 11.0 13.00 116 128 138 135

10 .41 .41 7.5 7.50 11.0 ... 132 144 ... 156

12x3 .43 .34 4.0 8.75 12.0 ... 99 ... ... ...

12x4 .43 .35 4.5 8.75 12.0 ... 108 118 ... 119

12x6 .43 .37 5.5 8.75 12.0 14.25 119 133 132 138

12x8 .43 .39 6.5 8.75 12.0 14.25 126 146 149 149

12x10 .43 .41 7.5 8.75 12.0 ... 159 174 ... 187

12 .43 .43 8.75 8.75 12.0 ... 171 198 ... 202

14x6 .51 .44 6.5 10.50 14.0 16.00 183 205 211 210

14x8 .51 .45 7.5 10.50 14.0 ... 211 ... ... 231

14x10 .51 .46 8.5 10.50 14.0 ... 229 244 ... 255

14x12 .51 .47 9.5 10.50 14.0 ... 245 284 ... 269

14 .51 .51 10.5 10.50 14.0 ... 281 291 ... 299

16x6 .52 .45 6.5 11.50 15.0 17.00 222 230 243 250

16x8 .52 .46 7.5 11.50 15.0 ... 245 248 ... 264

16x10 .52 .47 8.5 11.50 15.0 ... 265 287 ... 286

16x12 .52 .48 9.5 11.50 15.0 ... 277 312 ... 312

16x14 .52 .51 10.5 11.50 15.0 ... 317 348 ... ...

16 .52 .52 11.5 11.50 15.0 ... 337 324 ... 457

30 .66 .66 22.0 22.00 ... ... ... ... ... 1840

36 .74 .74 26.0 26.0 ... ... ... ... ... 2655

† Weights include swivel gland

CROSS

Tyler Utilities Division • 11910 CR 492 • Tyler, Texas 75706 • (800) 527-8478

4 Union Foundry Company • Box 309 • Anniston, Alabama 36202 • (800) 226-7601 02/01/08

MECHANICAL JOINT C153 DUCTILE IRON

COMPACT FITTINGS

Sizes 3" thru 12" UL Listed For Fire Main Equipment

TEES (Continued)

MJ Tee MJ x FE Tee MJ x Swivel Tee

Dimensions Weights

Size T T1 H J1 J2 J3 MJ MJxFE †MJxS

18x6 .59 .44 6.5 14.5 15.5 18.0 275 261 279

18x8 .59 .45 7.5 14.5 14.5 ... 280 351 ...

18x10 .59 .47 8.5 12.5 ... ... 286 ... ...

18x12 .59 .49 9.5 12.5 ... ... 372 ... ...

18x14 .59 .56 10.5 12.5 ... ... 415 ... ...

18x16 .59 .57 11.5 12.5 ... ... 445 ... ...

18 .59 .59 13.0 12.5 ... ... 490 ... ...

20x6 .60 .44 7.0 16.0 17.0 19.5 335 362 358

20x8 .60 .45 8.0 14.0 ... ... 390 ... ...

20x10 .60 .47 9.0 14.0 ... ... 417 ... ...

20x12 .60 .49 10.0 14.0 ... ... 460 ... ...

20x14 .60 .56 11.0 14.0 ... ... 475 ... ...

20x16 .60 .57 12.0 14.0 ... ... 530 ... ...

20x18 .60 .59 13.0 14.0 ... ... 560 ... ...

20 .60 .60 14.0 14.0 ... ... 605 ... ...

24x6 .62 .44 7.0 18.0 19.0 21.5 465 451 457

24x8 .62 .45 8.0 16.0 ... ... 475 ... ...

24x10 .62 .47 9.0 16.0 ... ... 516 ... ...

24x12 .62 .49 10.0 18.0 ... ... 549 580 ...

24x14 .62 .56 11.0 16.0 ... ... 585 ... ...

24x16 .62 .57 12.0 19.5 ... ... 625 744 ...

24x18 .62 .59 13.0 16.0 ... ... 675 ... ...

24x20 .62 .60 15.0 17.0 ... ... 740 ... ...

24 .62 .62 17.0 17.0 ... ... 844 ... ...

30x6 .66 .36 7.00 20.0 ... ... 700 ... ...

30x8 .66 .38 8.50 20.0 ... ... 739 ... ...

30x12 .66 .42 10.0 20.0 ... ... 739 ... ...

30x16 .66 .50 12.5 20.0 ... ... 959 ... ...

30x20 .66 .57 15.0 20.0 ... ... 995 ... ...

30x24 .66 .61 16.0 20.0 ... ... 1160 ... ...

30 .66 .66 20.0 20.0 ... ... 1323 ... ...

36x16 .74 .50 12.5 23.5 ... ... 1350 ... ...

36x24 .74 .61 16.0 23.5 ... ... 1498 ... ...

36x30 .74 .66 20.0 23.5 ... ... 1555 ... ...

36 .74 .74 23.5 23.5 ... ... 1900 ... ...

42 .82 .82 30.0 30.0 ... ... 3175 ... ...

† Weights include swivel gland.

MJ GLANDS

Glands

Size Weight Size Weight

3 3 12 10

4 4 14 17

6 5 16 21

8 6 18 22

10 9 20 32

24 37

Swivel Glands, page 19-20

Retainer Glands, page 7

Swivel x Solid Adapter

with Swivel Gland

Size by Wall

Laying Length Thickness Weight

6x13 .37 52

6x18 .37 65

6x24 .37 69

8x12 .39 52

Swivel x Swivel Adapter

Size by Wall

Laying Length Thickness Weight

6x12 .37 28

6x18 .37 49

6x24 .37 52

Tyler Utilities Division • 11910 CR 492 • Tyler, Texas 75706 • (800) 527-8478

02/01/08 Union Foundry Company • Box 309 • Anniston, Alabama 36202 • (800) 226-7601 5

MECHANICAL JOINT C153 DUCTILE IRON

COMPACT FITTINGS

Sizes 3" thru 12" UL Listed For Fire Main Equipment

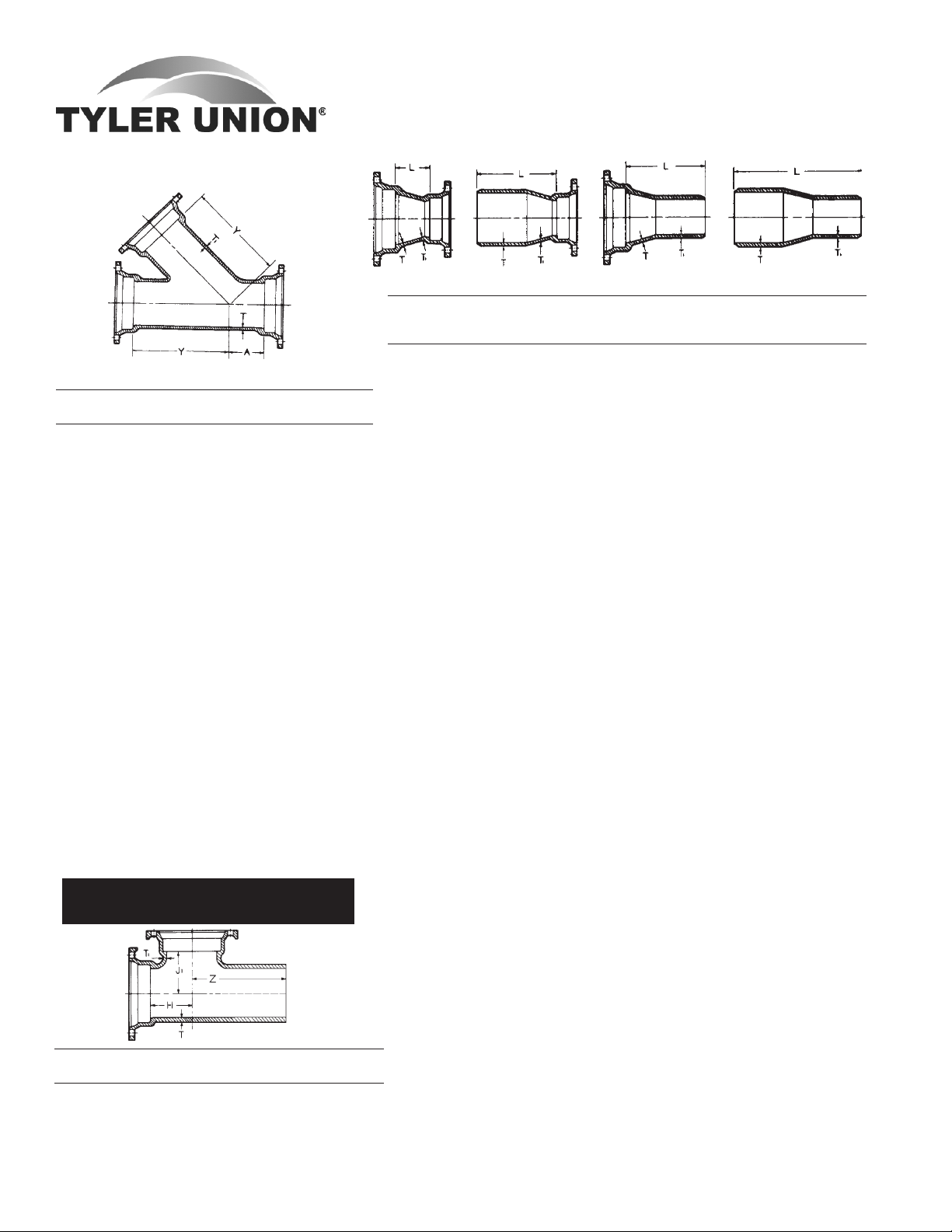

WYES/LATERAL

REDUCERS

MJ x MJ MJSEBxPE MJLEBxPE PE x PE

Dimensions

MJ SEB LEB PE Weights

Size T T1 L L L L MJ SEB LEB PE

4x3 .35 .34 3.0 8.5 8.5 14.0 18 17 17 18

*Wyes

Dimensions

Size A Y T T1 Weights

3 2.5 7.5 .34 .34 36

4x3 2.0 8.5 .35 .34 39

4 2.5 8.5 .35 .35 45

6x4 1.5 11.0 .37 .35 67

6 3.0 13.0 .37 .37 85

8x4 0.5 13.0 .39 .35 86

8x6 2.0 14.5 .39 .37 109

8 3.5 16.0 .39 .39 117

10x4 0.0 15.0 .41 .35 112

10x6 1.0 16.0 .41 .37 129

10x8 2.5 17.0 .41 .39 162

10 3.5 19.0 .41 .41 199

12x4 0.0 16.5 .43 .35 141

12x6 1.5 18.5 .43 .37 170

12x8 1.5 18.5 .43 .39 177

12x10 3.0 20.0 .43 .41 216

12 4.5 22.5 .43 .43 269

14 6.0 25.0 .51 .51 476

†

16x6 0.0 21.0 .52 .45 300

16x8 0.5 22.5 .52 .46 349

16x12 3.5 25.0 .52 .48 471

†

16 6.5 28.0 .52 .52 635

†

* Not included in AWWA C153.

† Rated at 250 psi.

MJ x FE Flange Dimensions are on inside

front cover.

6x3 .37 .34 5.0 10.5 10.5 16.0 28 25 27 20

6x4 .37 .35 4.0 9.5 9.5 15.0 28 26 27 26

8x4 .39 .35 5.0 10.5 10.5 16.0 36 34 36 33

8x6 .39 .37 4.0 9.5 9.5 15.0 39 38 39 30

10x4 .41 .35 7.0 12.5 12.5 18.0 53 46 51 ...

10x6 .41 .37 5.0 10.5 10.5 16.0 59 48 52 49

10x8 .41 .39 4.0 9.5 9.5 15.0 54 52 52 47

12x4 .43 .35 9.0 14.5 14.5 20.0 67 61 68 60

12x6 .43 .37 7.0 12.5 12.5 18.0 64 58 66 54

12x8 .43 .39 5.0 10.5 10.5 16.0 57 62 65 60

12x10 .43 .41 4.0 9.5 9.5 15.0 63 61 65 57

14x6 .51 .44 9.0 17.0 14.5 22.5 104 107 112 ...

14x8 .51 .45 7.0 15.0 12.5 20.5 104 107 108 ...

14x10 .51 .46 5.0 13.0 10.5 18.5 100 102 100 ...

14x12 .51 .47 4.0 12.0 9.5 17.5 100 101 100 100

16x6 .52 .45 11.0 19.0 16.5 24.5 132 131 141 128

16x8 .52 .46 9.0 17.0 14.5 22.5 136 128 136 136

16x10 .52 .47 7.0 15.0 12.5 20.5 128 124 128 123

16x12 .52 .48 5.0 13.0 10.5 18.5 120 123 119 113

16x14 .52 .51 4.0 12.0 12.0 20.0 140 139 138 133

18x8 .59 .45 14.0 22.0 19.5 27.5 201 180 195 ...

18x10 .59 .47 12.0 20.0 17.5 25.5 196 180 185 ...

18x12 .59 .49 10.0 18.0 15.5 23.5 175 170 190 ...

18x14 .59 .56 8.0 16.0 16.0 24.0 180 181 200 ...

18x16 .59 .57 7.0 15.0 15.0 23.0 194 180 190 ...

20x10 .60 .47 14.0 22.0 19.4 27.5 225 210 210 ...

20x12 .60 .49 12.0 20.0 17.5 25.5 214 208 210 ...

20x14 .60 .56 10.0 18.0 17.8 26.0 208 198 205 ...

20x16 .60 .57 8.0 16.0 15.8 24.0 225 215 222 ...

20x18 .60 .59 7.0 15.0 15.0 23.0 233 220 ... ...

24x12 .62 .49 16.0 24.0 21.4 29.5 320 302 300 ...

24x14 .62 .56 14.0 22.0 21.8 30.0 314 325 322 ...

24x16 .62 .57 12.0 20.0 19.8 28.0 325 319 340 ...

24x18 .62 .59 10.0 18.0 18.0 26.0 325 310 ... ...

24x20 .62 .60 8.0 16.0 16.0 24.0 315 305 ... ...

30x16 .66 .50 30.0 39.0 ... ... 475 565 ... ...

30x18 .66 .54 28.0 37.0 ... ... 495 590 ... ...

30x20 .66 .57 24.0 33.0 ... ... 525 560 ... ...

MJ x PE x MJ Tee

Dimensions

Size T T

1

H J

1

Z Weights

6 .37 .37 5.0 5.0 11.5 57

8x6 .39 .37 5.5 6.5 11.5 79

8 .39 .39 6.5 6.5 12.5 83

10 .41 .41 7.5 7.5 13.0 133

Tyler Utilities Division • 11910 CR 492 • Tyler, Texas 75706 • (800) 527-8478

6 Union Foundry Company • Box 309 • Anniston, Alabama 36202 • (800) 226-7601 02/01/08

30x24 .66 .61 10.0 24.5 ... ... 478 495 ... ...

36x16 .74 .50 ... ... ... ... ... 890 ... ,,,

36x20 .74 .57 ... 45.0 ... ... ... 874 ... ...

36x24 .74 .61 19.0 33.0 ... ... 770 746 ... ...

36x30 .74 .66 ... 24.5 ... ... ... 725 ... ...

42x30 .82 .66 20.0 ... ... ... 1185 ... ... ...

48x30 .90 .66 40.0 ... ... ... 1505 ... ... ...

MECHANICAL JOINT C153 DUCTILE IRON

COMPACT FITTINGS

Sizes 3" thru 12" UL Listed For Fire Main Equipment

SOLID & TAPPED PLUGS & CAPS

3"-12" 14"-24" 3"-12" 14"-24"

MJ Plug MJ Cap

Dimensions Max. Weights

Size T Tap Plugs Caps

3 .46 2 9 8

4 .46 2 9 10

6 .46 2 18 18

8 .46 2 25 26

10 .56 2 36 32

12 .56 2 47 46

14 .62 2 76 85

16 .62 2 98 94

18 .65 2 138 121

20 .66 2 158 149

24 .68 2 223 210

30 .66 2 355 345

36 .74 2 688 626

MJ x FE Flange

TAPPED TEE

Dimensions are

on inside front

cover.

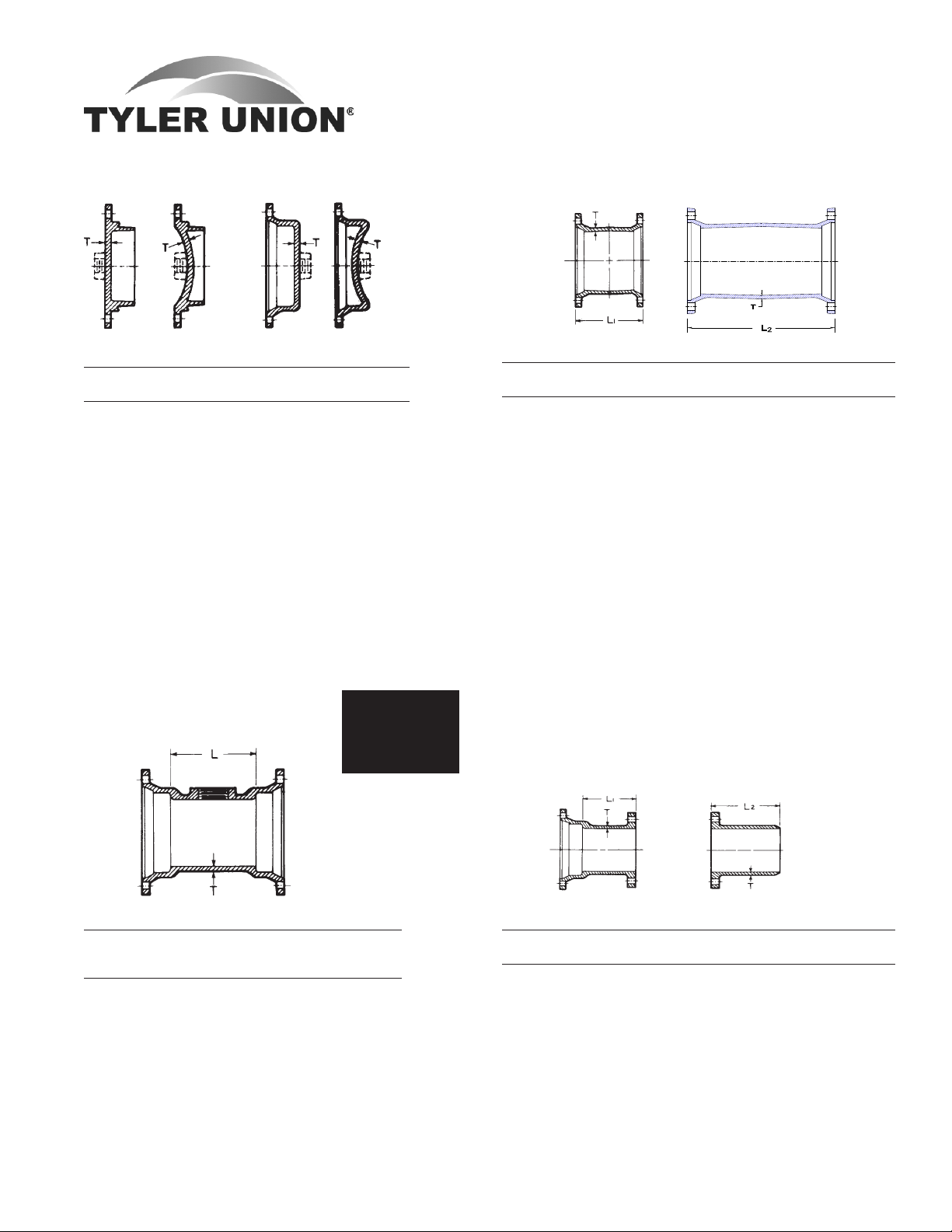

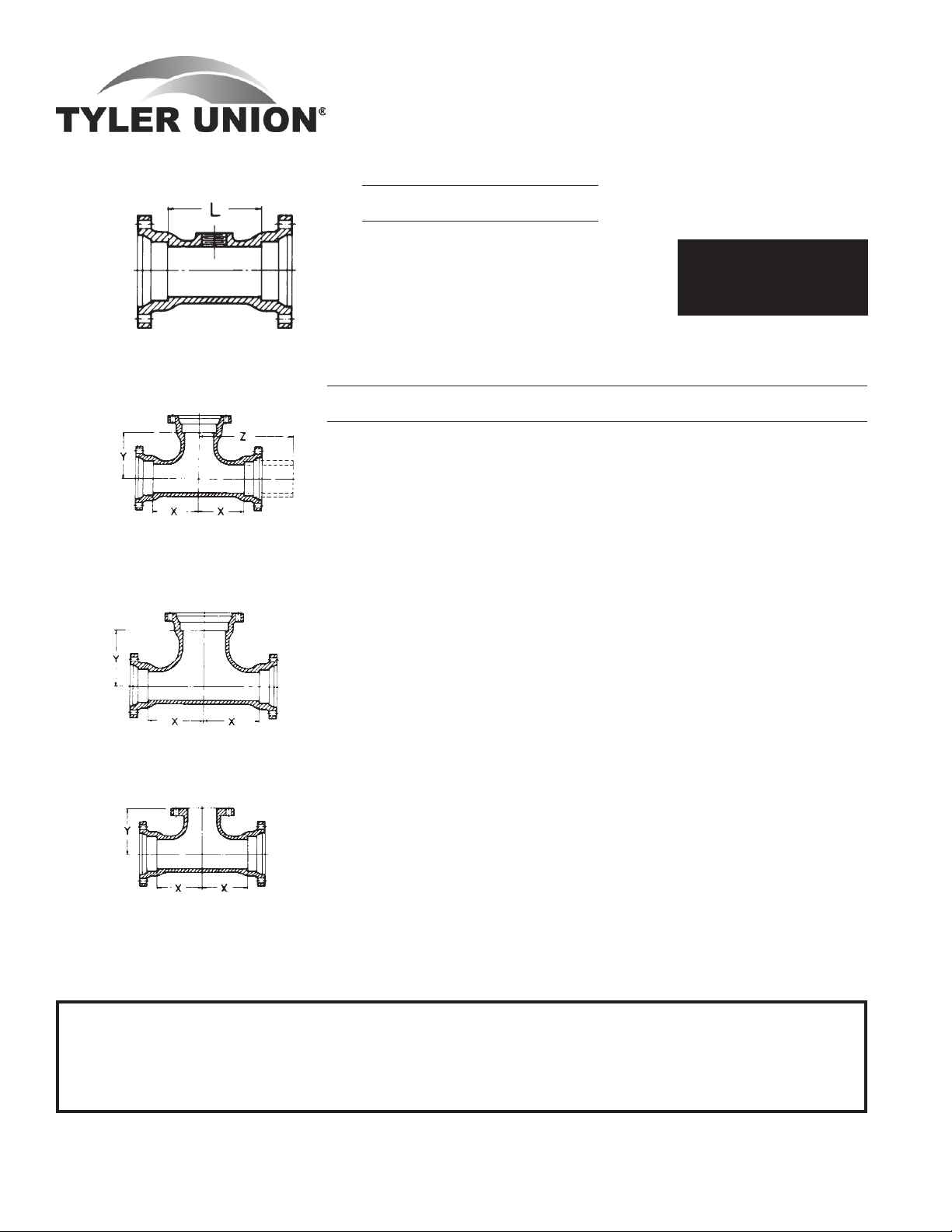

SOLID SLEEVES

Short Long

Dimensions Weights

Size T L1 L2 Short Long

3 .34 7.5 12 13 22

4 .35 7.5 12 19 25

6 .37 7.5 12 28 39

8 .39 7.5 12 38 55

10 .41 7.5 12 48 68

12 .43 7.5 12 62 81

14 .56 9.5 15 116 146

16 .57 9.5 15 138 174

18 .68 9.5 15 160 230

20 .69 9.5 15 212 269

24 .75 9.5 15 272 380

30 .66 15.0 15 500 ...

30 .66 ... 24 ... 640

36 .74 15.0 15 725 ...

36 .74 ... 24 ... 925

42 .82 ... 24 ... 1146

48 .90 ... 24 ... 1455

ADAPTERS

MJ Tapped Tee (2" Tap)

Dimensions

Size T L Max. Tap Weights

3 .34 6 2 19

4 .35 6 2 23

6 .37 6 2 35

8 .39 6 2 54

10 .41 6 2 68

12 .43 6 2 88

16 .52 6 2 164

Tyler Utilities Division • 11910 CR 492 • Tyler, Texas 75706 • (800) 527-8478

02/01/08 Union Foundry Company • Box 309 • Anniston, Alabama 36202 • (800) 226-7601 7

MJ x FE FE x PE

Dimensions Weights

Size T L1 L2 MJxFE FExPE

3 .34 6 12 18 ...

4 .35 6 12 26 23

6 .37 6 12 36 35

8 .39 6 12 50 50

10 .41 6 12 60 69

12 .43 6 12 88 88

14 .51 6 12 127 ...

16 .52 6 12 155 149

20 .60 6 ... 275 ...

30 .66 7 ... 470 ...

36 .74 8 ... 750 ...

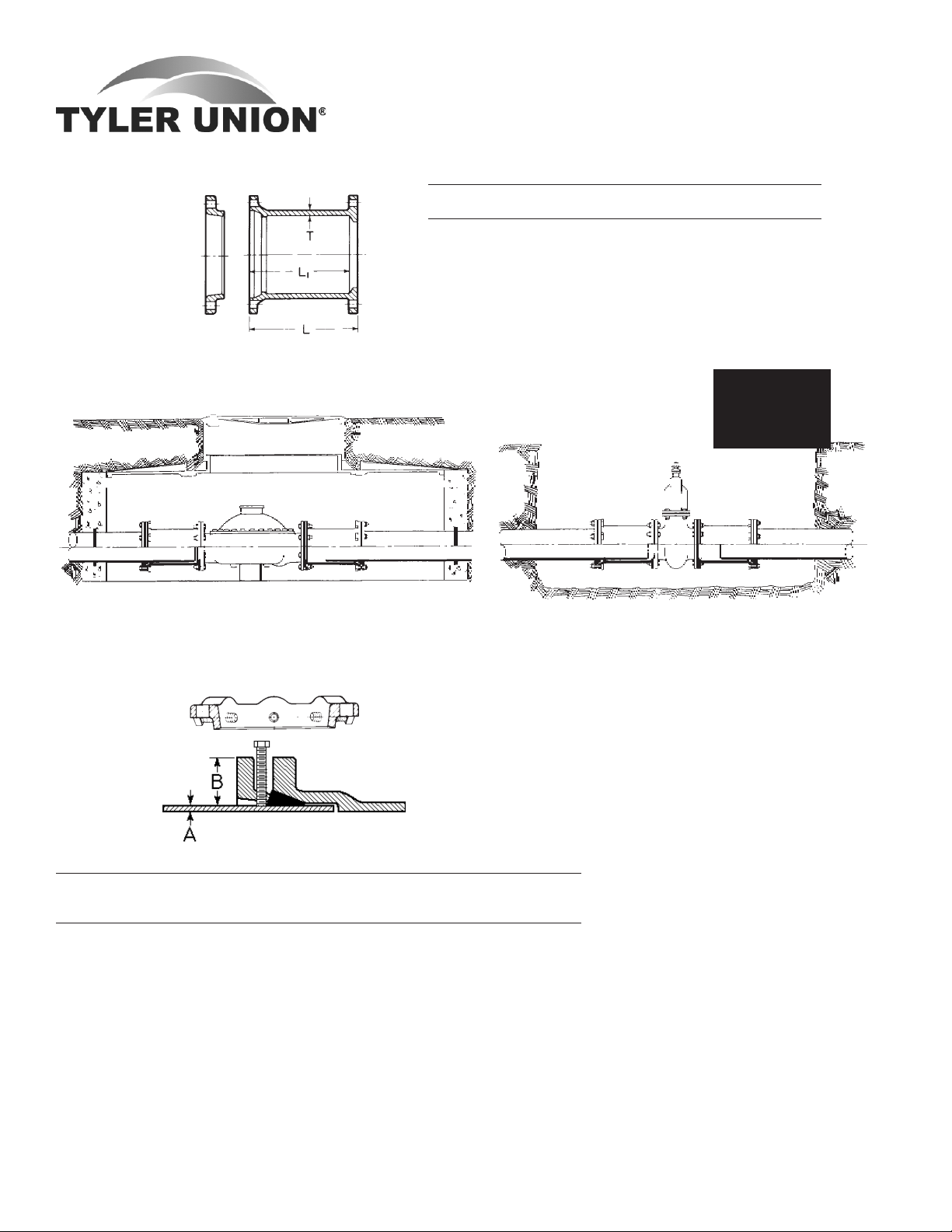

MECHANICAL JOINT C153 DUCTILE IRON

COMPACT FITTINGS

Sizes 3" thru 12" UL Listed For Fire Main Equipment

DUAL PURPOSE CUTTING-IN SLEEVE

Flanged ends are faced and drilled per ANSI/AWWA C110/A21.10. Mechanical joint ends are designed to receive both standard and oversize gray or ductile iron pipe as shown above.

TYPICAL CUTTING-IN SLEEVE INSTALLATIONS

METER SETTINGS

MJ x FE

Cutting-In Sleeve with Dual Purpose Accessories

Dimensions Shipping Wt.

Size For Pipe Size L L1 T Assembled

4 4.80-5.00 O.D. 10 9.5 .35 33

6 6.90-7.10 O.D. 10 9.5 .37 50

8 9.05-9.30 O.D. 10 9.5 .39 67

10 11.10-11.40 O.D. 10 9.5 .41 122

12 13.20-13.50 O.D. 10 9.5 .43 157

MJ x FE Flange

Dimensions are

VALVE

INSTALLATIONS

on inside front

cover.

Pipe Wall Thickness:

*RETAINER GLAND ASSEMBLY

Sizes 3"-12" are recommended for ductile

iron pipe class 50 thru 56. Sizes 14" thru 24"

are recommended for ductile iron pipe class

53 thru 56.

DUCTILE IRON RETAINER

GLANDS

Mechanical Joint Retainer Glands are

designed to provide a method for restraining mechanical joint pipe and fittings

and other standardized mechanical joints

See Installations Instructions ........................................................ Page 50

Pressure Gland Pipe O.D. D.I. Pipe No of Size of

Rating, O.D. O.D. Wall Set Set Gland Weight

Size psi B A Class Screws Screws Weight w/Acces.

3 350 7.69 3.96 50-56 4 Á x2 5 7

4 350 9.12 4.80 50-56 4 Á x2 6 13

6 350 11.12 6.90 50-56 6 Á x2 11 20

8 250 13.37 9.05 50-56 9 Á x2 13 25

10 250 15.62 11.10 50-56 12 Á x2 18 33

12 150 17.88 13.20 50-56 16 Á x2 23 38

14 250 20.25 15.30 53-56 20 Á x2½ 44 55

16 200 22.50 17.40 53-56 24 Á x2½ 51 64

18 200 24.75 19.50 53-56 24 Á x2½ 62 72

20 200 27.00 21.60 53-56 28 Á x3 73 91

24 150 31.50 25.80 53-56 32 Á x3 93 118

* Not included in AWWA C110

Tyler Utilities Division • 11910 CR 492 • Tyler, Texas 75706 • (800) 527-8478

8 Union Foundry Company • Box 309 • Anniston, Alabama 36202 • (800) 226-7601 02/01/08

against possible joint separation, rupture

or blow-out caused by internal water pressure.

The set screws are square-headed

with Type C knurled cup points, and are

shipped already assembled in the Glands.

They are manufactured of 4140 grade

alloy steel, and are heat treated to a Rockwall “C” 45/53 case hardness. Tee-head

bolts and gaskets are not included, but

may be ordered separately. Recommended torque for set screws is 75 foot pounds,

and set screws on opposite sides of the

glands should be tightened alternately.

Tee-head bolt hole size and spacing are equal to MJ Glands as shown in

AWWA C-111. Standard mechanical Joint

gaskets as shown in C-111 should be

used.

4" Size

MECHANICAL JOINT DUCTILE IRON

COMPACT SPLIT REPAIR GLANDS

6"-8"-10"-12" Sizes

MJ Compact Split Repair Glands

Inside Diameter Bolt Circle Weight

Size (+.07-.03) (+-.06) Lbs.

4 4.90 7.50 4.0

6 7.00 9.50 5.0

8 9.15 11.75 6.0

10 11.20 14.00 7.7

12 13.50 16.25 10.2

Split glands work with standard MJ gaskets and standard

T-head bolts. Glands are shipped in halves and do not need

separate bolts. T-head bolts alone hold the halves together.

Tyler Utilities Division • 11910 CR 492 • Tyler, Texas 75706 • (800) 527-8478

02/01/08 Union Foundry Company • Box 309 • Anniston, Alabama 36202 • (800) 226-7601 9

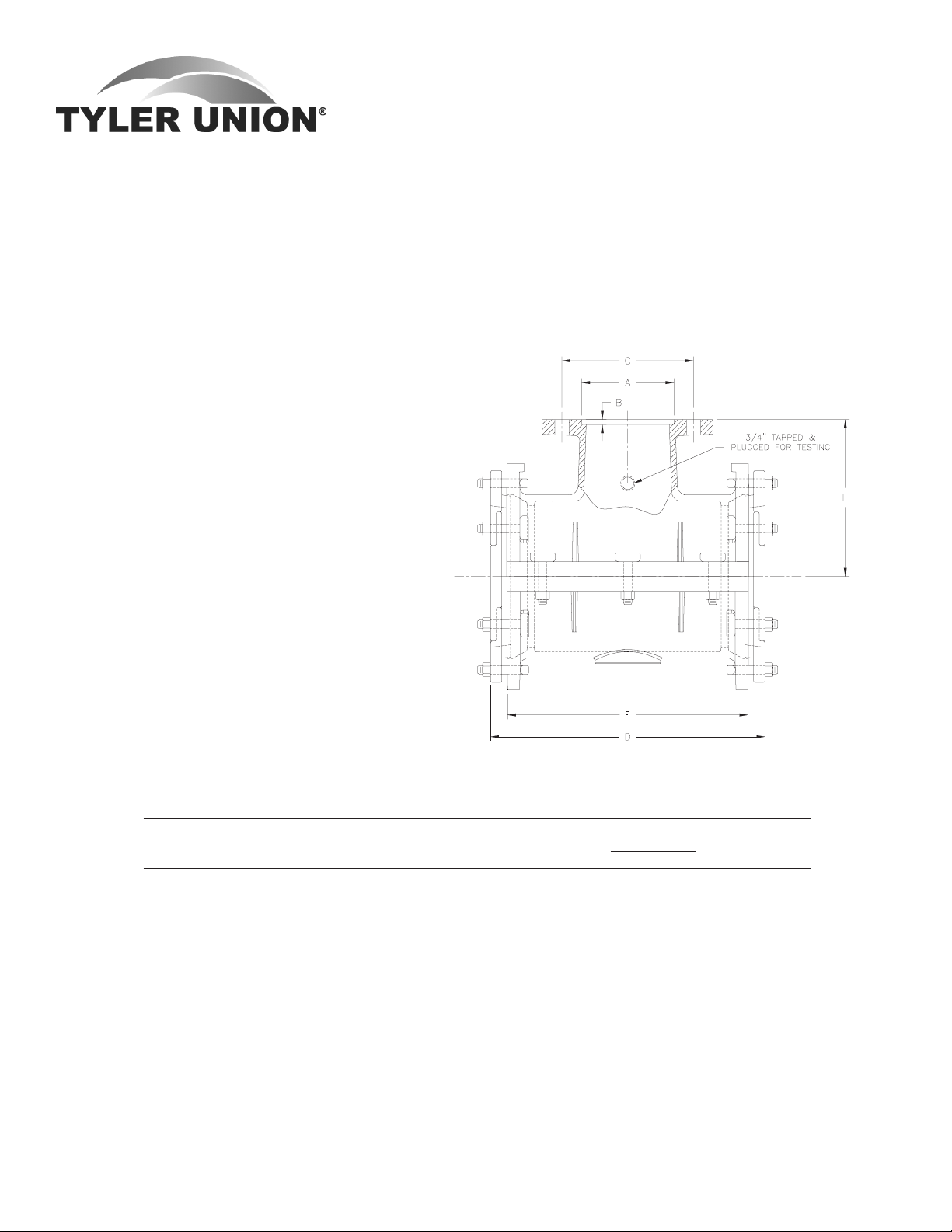

COMPACT

DUCTILE IRON MJ TAPPING SLEEVES

SAMPLE SPECIFICATION

Ductile Iron Mechanical Joint Tapping Sleeves furnished by Tyler Pipe Company, Tyler, Texas are produced in accordance with manufacturer's standards. Chemical and physical properties of the ductile iron are in accordance

with the requirements of ANSI/AWWA C110/A21.10-82.

Recess dimensions are per Manufacturer's Standardization Society standard practice SP-60.

General Installation Instructions for Tyler MJ Tapping Sleeves

1. Clean pipe - insert side gasket into back half of gasket grooves. Make sure ends are flush with or slightly protrude into the end gasket seating area.

2. Bolt sleeve halves together and trim side gaskets as necessary. MAKE SURE SLEEVE WILL ROTATE FREELY ON

PIPE.

3. Install end gaskets, locating cut ends 90° from

side gasket. If pipe is maximum OD, stretch

gasket to make certain cut ends match with no

gap in between.

4. Install glands and bolts - rotate sleeve to desired

position. Be sure pipe is centered inside the sleeve.

5. Tighten gland bolts alternately, using 80 to 90

foot pounds.

6. After assembly, PRESSURE TEST ALL JOINTS BEFORE TAPPING. If additional tightening is

required, release pressure and relax tension on

gland bolts before tightening side bolts.

For Cast Iron or Ductile Iron Pipe

Mechanical joint tapping sleeves - for 6" through

12" cast iron or ductile iron pipe.

• Outlet flange per ANSI/AWWA C110/A21.10

• Gaskets furnished.

• Working pressure-200 p.s.i.

Tapping Sleeve for

Cast Iron/Ductile Iron

O.D. Range

Dimensions DI Weight

Size A B C D E F Min. Max. DI

6x4 5.016 .250 7.50 15.75 8.00 12.75 6.85 7.15 104

6 7.016 .312 9.50 15.75 8.00 12.75 6.85 7.15 108

8x4 5.016 .250 7.50 16.50 9.00 13.50 9.00 9.35 134

8x6 7.016 .312 9.50 16.50 9.00 13.50 9.00 9.35 140

8 9.016 .312 11.75 16.50 9.00 13.50 9.00 9.35 148

10x4 5.016 .250 7.50 24.00 11.00 20.75 11.04 11.45 236

10x6 7.016 .312 9.50 24.00 11.00 20.75 11.04 11.45 240

10x8 9.016 .312 11.75 24.00 11.00 20.75 11.04 11.45 246

10 11.016 .312 14.25 24.00 11.00 20.75 11.04 11.45 257

12x4 5.016 .250 7.50 26.50 12.00 23.25 13.14 13.56 273

12x6 7.016 .312 9.50 26.50 12.00 23.25 13.14 13.56 286

12x8 9.016 .312 11.75 26.50 12.00 23.25 13.14 13.56 292

12x10 11.016 .312 14.25 26.50 12.00 23.25 13.14 13.56 303

12 13.016 .312 17.00 26.50 12.00 23.25 13.14 13.56 320

Tyler Utilities Division • 11910 CR 492 • Tyler, Texas 75706 • (800) 527-8478

10 Union Foundry Company • Box 309 • Anniston, Alabama 36202 • (800) 226-7601 02/01/08

DUCTILE IRON C110 FULL BODY

MECHANICAL JOINT DIMENSIONS

SAMPLE SPECIFICATION

Mechanical Joint watermain fittings with accessories, 2" through 48" shall be produced of Ductile Iron in accordance with and

meet all applicable terms and provisions of standards ANSI/AWWA C110/A21.10 ANSI/AWWA C111/A21.11 (current revisions). Ductile Iron Mechanical Joint Fittings 3" through 24" shall be rated for 350 PSI working pressure. All Ductile Iron Mechanical Joint Fittings 30" through 48" shall be rated for 250 PSI working pressure. Flanged ductile-iron fittings in 24-in. (610

mm) and smaller sizes may be rated for 350 psi (2,413 kPa) with the use of special gaskets.

NOTE - EXCEPTIONS: Mechanical Joint Fittings with flanged branches and 14" and larger caps and plugs are rated for water

pressure of 250 PSI.

NOTE: Fittings are CEMENT-LINED and seal coated in accordance with ANSI/AWWA C104/A21.4; also available double

cement-lined, bare or epoxy coated. All coated fittings meet requirements of NSF-61.

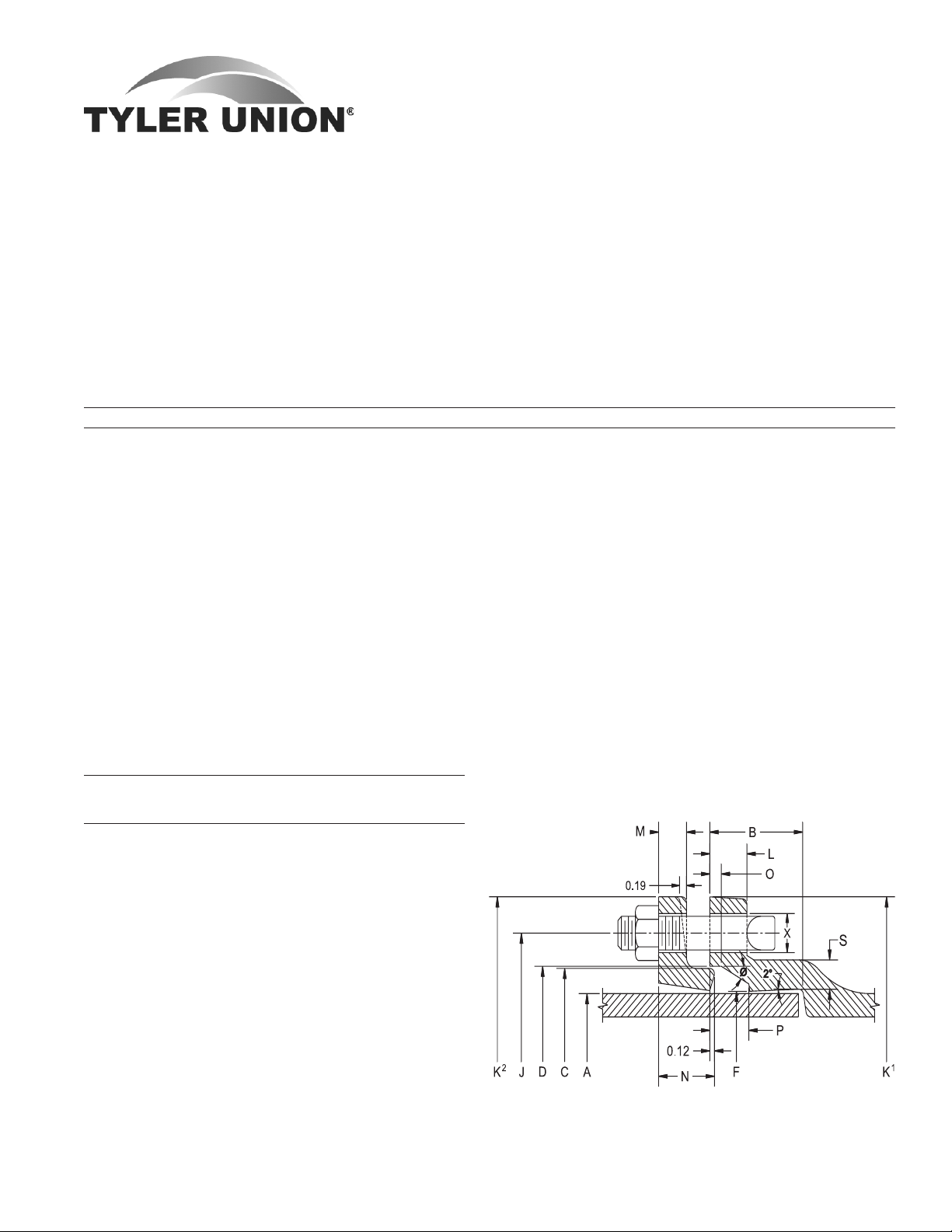

JOINT DIMENSIONS IN INCHES FOR MECHANICAL JOINT FITTINGS

DIMENSIONS IN INCHES

Size A B C D F Ø X J K1 K2 L M N O P S

*2 2.50 2.50 3.39 3.50 2.61 28° ¾ 4.75 6.25 6.25 .75 .62 ... .31 .63 .44

3 3.96 2.50 4.84 4.94 4.06 28° ¾ 6.19 7.69 7.69 .94 .62 1.37 .31 .63 .52

4 4.80 2.50 5.92 6.02 4.90 28° Â 7.50 9.12 9.12 1.00 .75 1.50 .31 .75 .65

6 6.90 2.50 8.02 8.12 7.00 28° Â 9.50 11.12 11.12 1.06 .88 1.63 .31 .75 .70

8 9.05 2.50 10.17 10.27 9.15 28° Â 11.75 13.37 13.37 1.12 1.00 1.75 .31 .75 .75

10 11.10 2.50 12.22 12.34 11.20 28° Â 14.00 15.69 15.62 1.19 1.00 1.75 .31 .75 .80

12 13.20 2.50 14.32 14.44 13.30 28° Â 16.25 17.94 17.88 1.25 1.00 1.75 .31 .75 .85

14 15.30 3.50 16.40 16.54 15.44 28° Â 18.75 20.31 20.25 1.31 1.25 2.00 .31 .75 .89

16 17.40 3.50 18.50 18.64 17.54 28° Â 21.00 22.56 22.50 1.38 1.31 2.06 .31 .75 .97

18 19.50 3.50 20.60 20.74 19.64 28° Â 23.25 24.83 24.75 1.44 1.38 2.13 .31 .75 1.05

20 21.60 3.50 22.70 22.84 21.74 28° Â 25.50 27.08 27.00 1.50 1.44 2.19 .31 .75 1.12

24 25.80 3.50 26.90 27.04 25.94 28° Â 30.00 31.58 31.50 1.62 1.56 2.31 .31 .75 1.22

30 32.00 4.00 33.29 33.46 32.17 20° 1¿ 36.88 39.12 39.12 1.81 2.00 2.75 .38 1.00 1.50

36 38.30 4.00 39.59 39.76 38.47 20° 1¿ 43.75 46.00 46.00 2.00 2.00 2.75 .38 1.00 1.80

42 44.50 4.00 45.79 45.96 44.67 20° 1À 50.62 53.12 53.12 2.00 2.00 2.75 .38 1.00 1.95

48 50.80 4.00 52.09 52.26 50.97 20° 1À 57.50 60.00 60.00 2.00 2.00 2.75 .38 1.00 2.20

* Not included in AWWA C110.

ACCESSORIES AND WEIGHTS

Wt. of Gland, Pipe

Bolt Bolt Bolt Torque Bolts and Barrel

Size No. Size Length Ft/Lbs. Gasket, Lbs. O.D.

*2 2 Á 3 45-60 5 2.50

3 4 Á 3 45-60 7 3.96

4 4 ¾ 3½ 75-90 10 4.80

6 6 ¾ 4 75-90 16 6.90

8 6 ¾ 4 75-90 25 9.05

10 8 ¾ 4 75-90 30 11.10

12 8 ¾ 4 75-90 40 13.20

14 10 ¾ 4½ 75-90 45 15.30

16 12 ¾ 4½ 75-90 55 17.40

18 12 ¾ 4½ 75-90 65 19.50

20 14 ¾ 4½ 75-90 85 21.60

24 16 ¾ 5 75-90 105 25.80

30 20 1 6 100-120 220 32.00

36 24 1 6 100-120 301 38.30

42 28 1¼ 6½ 120-150 389 44.50

48 32 1¼ 6½ 120-150 477 50.80

* Not included in AWWA C110.

ANSI/AWWA C110/A21.10, ANSI/AWWA C111/A21.11

Tyler Utilities Division • 11910 CR 492 • Tyler, Texas 75706 • (800) 527-8478

02/01/08 Union Foundry Company • Box 309 • Anniston, Alabama 36202 • (800) 226-7601 11

14" THRU 48"

GLANDS MAY

BE TAPERED

BENDS

MJ x FIPT ECCENTRIC

REDUCER

Dimensions

Size L Weights

6x2 13 51

8x2 15 71

90° MJ x MJ (1/4)

90° MJ x PE (1/4)

90° MJ x FE (1/4)

DUCTILE IRON C110 FULL BODY

MECHANICAL JOINT FITTINGS

90° Bends (1/4)

Dimensions Weights

Size R Y Z MJxMJ MJxPE MJxFE

*2 2.25 3.25 ... 16 ... ...

3 4.0 5.5 13.5 26 36 ...

4 4.5 6.5 14.5 56 53 51

6 6.0 8.0 16.0 88 80 75

8 7.0 9.0 17.0 123 119 118

10 9.0 11.0 19.0 189 181 168

12 10.0 12.0 20.0 268 252 288

14 11.5 14.0 22.0 380 ... ...

16 12.5 15.0 23.0 552 470 465

18 14.0 16.5 24.5 625 600 577

20 15.5 18.0 26.0 862 775 ...

24 18.5 22.0 30.0 1423 1301 1150

30 21.5 25.0 33.0 1942 1920 ...

36 24.5 28.0 36.0 2629 2310 ...

42 27.5 31.0 3410 ... ...

48 30.5 34.0 4595 ... ...

Mechanical Joint weights

do not include Glands,

Nuts, Bolts and Gaskets.

For sizes not found in this

section check MJ-SSB DI

fittings, pages 1 thru 8.

See Joint Accessories.

ANSI/AWWA C110/A21.10, ANSI/AWWA C111/A21.11

Tyler Utilities Division • 11910 CR 492 • Tyler, Texas 75706 • (800) 527-8478

12 Union Foundry Company • Box 309 • Anniston, Alabama 36202 • (800) 226-7601 02/01/08

BENDS

45° MJ (1/8)

45° MJ x FE (1/8)

22½° MJ (1/16) 22½° MJ x PE (1/16)

22½° MJ x FE (1/16)

45° MJ x PE (1/8)

DUCTILE IRON C110 FULL BODY

MECHANICAL JOINT FITTINGS

45° Bends (1/8)

Dimensions Weights

Size R Y Z MJ MJxFE* MJxPE

*2 1.96 1.8 ... 16 ... ...

3 3.62 3.0 11.0 30 ... ...

4 4.81 4.0 12.0 53 48 45

6 7.25 5.0 13.0 77 60 69

8 8.44 5.5 13.5 110 107 111

10 10.88 6.5 14.5 172 168 167

12 13.25 7.5 15.5 222 215 218

14 12.06 7.5 15.5 311 ... ...

16 13.25 8.0 16.0 364 360 360

18 14.50 8.5 16.5 531 430 455

20 16.88 9.5 17.5 655 543 664

24 18.12 11.0 19.0 865 1099 825

30 27.75 15.0 23.0 1447 ... 1510

36 35.00 18.0 26.0 2435 ... 1930

42 42.25 21.0 2955 ... ...

48 49.50 24.0 4080 ... ...

* Not included in AWWA C110.

22½° Bends (1/16)

Dimensions Weights

Size R Y Z MJ MJxFE* MJxPE

3 7.56 3.0 11.0 30 ... ...

4 10.06 4.0 12.0 52 ... ...

6 15.06 5.0 13.0 77 71 70

8 17.62 5.5 13.5 110 107 109

10 22.62 6.5 14.5 156 155 163

12 27.62 7.5 15.5 221 215 224

14 25.12 7.5 15.5 300 ... ...

16 27.62 8.0 16.0 391 315 365

18 30.19 8.5 16.5 527 422 455

20 35.19 9.5 17.5 611 ... 575

24 37.69 11.0 19.0 986 800 930

30 57.81 15.0 23.0 1898 ... 1540

36 72.88 18.0 26.0 2372 ... 1970

42 88.00 21.0 3020 ... ...

48 103.06 24.0 4170 ... ...

11¼° Bends (1/32)

Dimensions Weights

Size R Y Z MJ MJxFE* MJxPE

3 15.25 3.0 11.0 30 ... ...

4 20.31 4.0 12.0 52 ... ...

6 30.50 5.0 13.0 65 71 ...

11¼° MJ (1/32)

11¼° MJ x PE (1/32)

8 35.50 5.5 13.5 104 105 ...

10 45.69 6.5 14.5 171 ... ...

12 55.81 7.5 15.5 221 215 ...

14 50.75 7.5 15.5 305 ... ...

16 55.81 8.0 16.0 391 367 ...

18 60.94 8.5 16.5 525 422 ...

20 71.06 9.5 17.5 605 ... ...

24 76.12 11.0 19.0 996 800 972

30 116.75 15.0 23.0 1410 ... 1305

36 147.25 18.0 26.0 2397 ... 2185

11¼° MJ x FE (1/32)

42 177.69 21.0 3035 ... ...

48 208.12 24.0 4190 ... ...

Tyler Utilities Division • 11910 CR 492 • Tyler, Texas 75706 • (800) 527-8478

02/01/08 Union Foundry Company • Box 309 • Anniston, Alabama 36202 • (800) 226-7601 13

ANSI/AWWA C110/A21.10, ANSI/AWWA C111/A21.11

DUCTILE IRON C110 FULL BODY

MECHANICAL JOINT FITTINGS

TEES

MJ TAPPED TEE

Straight Tees and

Reducing on Branch Tees

Bullhead

MJxMJxFE

MJ Tapped Tee (2"Tap)

Dimensions

Size L Max. Tap Weights

3 8 2 40

4 8 2 51

6 8 2 73

8 8 2 104

10 8 2 130

12 8 2 180

Size Dimensions Weights

Run Run Branch X Y Z MJ **MJxPExMJ **MJxMJxFE

*2 2 2 3.25 3.25 ... 21 ... ...

*3 3 2 3.25 3.25 ... 45 ... ...

3 3 3 5.5 5.5 13.5 58 ... ...

*4 4 2 4.8 4.8 14.5 68 ... 49

4 4 3 6.5 6.5 14.5 77 ... ...

4 4 4 6.5 6.5 14.5 78 75 76

4 4 6 8.0 8.0 ... 112 ... ...

*6 6 2 8.0 8.0 ... 78 ... ...

6 6 3 8.0 8.0 16.0 112 ... ...

6 6 4 8.0 8.0 16.0 110 ... 109

6 6 6 8.0 8.0 16.0 119 120 141

6 6 8 9.0 9.0 ... 158 ... ...

8 8 3 9.0 9.0 17.0 155 ... ...

8 8 4 9.0 9.0 17.0 157 ... 150

8 8 6 9.0 9.0 17.0 175 170 182

8 8 8 9.0 9.0 17.0 199 180 194

10 10 4 11.0 11.0 19.0 ... ... 229

10 10 6 11.0 11.0 19.0 258 ... 264

10 10 8 11.0 11.0 19.0 268 ... 245

10 10 10 11.0 11.0 19.0 300 250 ...

12 12 4 12.0 12.0 20.0 318 315 323

12 12 6 12.0 12.0 20.0 325 325 335

12 12 8 12.0 12.0 20.0 335 335 372

12 12 10 12.0 12.0 20.0 392 390 ...

12 12 12 12.0 12.0 20.0 396 396 476

*16 16 4 15.0 15.0 ... 600 ... 575

16 16 6 15.0 15.0 ... 656 ... 605

16 16 8 15.0 15.0 ... 625 ... 615

16 16 10 15.0 15.0 ... 645 ... ...

16 16 12 15.0 15.0 ... 715 ... 651

16 16 16 15.0 15.0 ... 780 ... 730

For sizes not found in this

section check MJ-SSB DI

fittings, pages 1 thru 8.

* Not included in AWWA C110

** Made to order only. Not Returnable

NOTICE: Weights published in this catalog are for shipping purposes only. Actual weights may vary

because some fittings are produced in both foundries. All fittings meet the AWWA standards to which they

are designed.

For weights of specific fittings, please contact Tyler Pipe or Union Foundry Company.

ANSI/AWWA C110/A21.10, ANSI/AWWA C111/A21.11

Tyler Utilities Division • 11910 CR 492 • Tyler, Texas 75706 • (800) 527-8478

14 Union Foundry Company • Box 309 • Anniston, Alabama 36202 • (800) 226-7601 02/01/08

DUCTILE IRON C110 FULL BODY

MECHANICAL JOINT FITTINGS

TEES (Con't)

Straight Tees and

Reducing on Branch Tees

Bullhead

MJxMJxFE

Size Dimensions Weights

Run Run Branch X Y Z MJ **MJxPExMJ **MJxMJxFE

18 18 6 13.0 15.5 ... 710 ... 707

18 18 8 13.0 15.5 ... 674 ... 675

18 18 12 13.0 15.5 ... 749 ... 733

18 18 18 16.5 16.5 ... 945 ... 953

20 20 6 14.0 17.0 ... 849 ... ...

20 20 8 14.0 17.0 ... 892 ... 859

20 20 12 14.0 17.0 ... 896 ... ...

20 20 16 18.0 18.0 ... 1095 ... ...

20 20 20 18.0 18.0 ... 1258 ... 1168

24 24 6 15.0 19.0 ... 1233 ... 1228

24 24 8 15.0 19.0 ... 1234 ... 1242

24 24 12 15.0 19.0 ... 1256 ... 1165

24 24 14 15.0 19.0 ... 1220 ... ...

24 24 16 15.0 19.0 ... 1245 ... ...

24 24 18 22.0 22.0 ... 1735 ... ...

24 24 20 22.0 22.0 ... 1720 ... ...

24 24 24 22.0 22.0 ... 1947 ... 1795

30 30 6 18.0 23.0 ... 2050 ... ...

30 30 8 18.0 23.0 ... 2060 ... ...

30 30 10 18.0 23.0 ... 2075 ... ...

30 30 12 18.0 23.0 ... 2090 .... ...

30 30 16 18.0 23.0 ... 2145 ... ...

30 30 18 18.0 23.0 ... 2170 ... ...

30 30 20 18.0 23.0 ... 2205 ... ...

30 30 24 25.0 25.0 ... 2880 ... ...

30 30 30 25.0 25.0 ... 2275 ... 3080

36 36 6 20.0 26.0 ... 2439 ... 2430

36 36 8 20.0 26.0 ... 2444 ... ...

36 36 10 20.0 26.0 ... 2535 ... ...

36 36 12 20.0 26.0 ... 2541 ... 2550

36 36 14 20.0 26.0 ... 2570 ... ...

36 36 16 20.0 26.0 ... 2585 ... 2450

36 36 18 20.0 26.0 ... 2610 ... ...

36 36 20 20.0 26.0 ... 2635 ... ...

36 36 24 20.0 26.0 ... 2792 ... 2660

36 36 30 28.0 28.0 ... 3545 ... ...

36 36 36 28.0 28.0 ... 3450 ... ...

42 24 42 23.0 30.0 ... 3690 ... ...

42 30 42 31.0 31.0 ... 4650 ... ...

42 36 42 31.0 31.0 ... 4880 ... ...

42 42 42 31.0 31.0 ... 6320 ... ...

48 24 48 26.0 34.0 ... 4995 ... ...

48 30 48 26.0 34.0 ... 5140 ... ...

48 36 48 34.0 34.0 ... 6280 ... ...

48 42 48 34.0 34.0 ... 8130 ... ...

48 48 48 34.0 34.0 ... 8420 ... ...

* Not included in AWWA C110 ** Made to order only. Not Returnable

ANSI/AWWA C110/A21.10, ANSI/AWWA C111/A21.11

Tyler Utilities Division • 11910 CR 492 • Tyler, Texas 75706 • (800) 527-8478

02/01/08 Union Foundry Company • Box 309 • Anniston, Alabama 36202 • (800) 226-7601 15

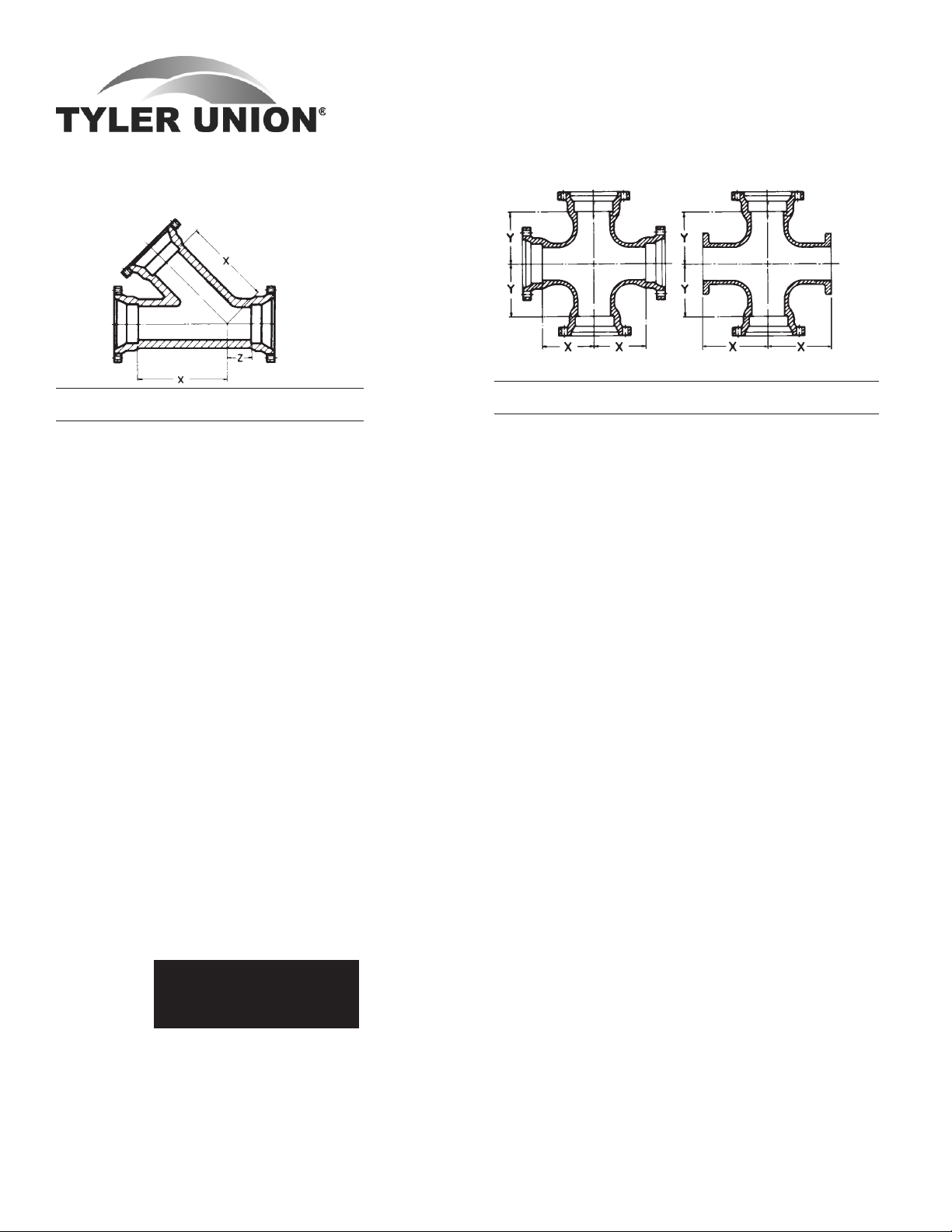

DUCTILE IRON C110 FULL BODY

MECHANICAL JOINT FITTINGS

WYES/LATERAL

( Not included in AWWA C110.)

Size Dimensions

Run Branch X Z Weights

3 3 10.0 3.0 60

4 4 12.0 3.0 90

6 4 14.5 3.5 130

6 6 14.5 3.5 145

8 4 17.5 4.5 190

8 6 17.5 4.5 205

8 8 17.5 4.5 230

10 6 20.5 5.0 330

10 8 20.5 5.0 310

10 10 20.5 5.5 435

12 8 24.5 5.5 505

12 12 24.5 5.5 490

14 6 27.0 6.0 626

16 16 30.0 6.5 1079

18 8 32.0 7.0 1073

18 10 32.0 7.0 975

18 12 32.0 7.0 1015

18 16 32.0 7.0 1135

18 18 32.0 7.0 1130

20 10 35.0 8.0 1220

20 12 35.0 8.0 1260

20 16 35.0 8.0 1375

20 20 35.0 8.0 1525

24 24 40.5 9.0 2372

30 30 49.0 10.0 3670

For sizes not found in this

section check MJ-SSB DI

fittings, pages 1 thru 8.

CROSSES

ALL MJ

Size Dimensions Weights

Run Branch X Y MJ *MJxFE

6 6 8.0 8.0 160 141

8 4 9.0 9.0 185 ...

8 6 9.0 9.0 205 182

8 8 9.0 9.0 255 245

10 6 11.0 11.0 285 ...

10 8 11.0 11.0 310 ...

10 10 11.0 11.0 380 360

12 6 12.0 12.0 361 367

12 8 12.0 12.0 371 373

12 12 12.0 12.0 486 487

14 8 14.0 14.0 550 ...

14 14 14.0 14.0 779 ...

16 6 15.0 15.0 650 ...

16 8 15.0 15.0 675 655

16 16 15.0 15.0 895 875

18 8 13.0 15.5 775 ...

18 10 13.0 15.5 760 ...

18 12 13.0 15.5 860 ...

18 18 16.5 16.5 1140 ...

20 8 14.0 17.0 951 ...

20 12 14.0 17.0 977 ...

20 16 18.0 18.0 1245 ...

20 20 18.0 18.0 1448 ...

24 8 15.0 19.0 1244 ...

24 12 15.0 19.0 1326 ...

24 16 15.0 19.0 1479 ...

24 20 22.0 22.0 1965 ...

24 24 22.0 22.0 2192 ...

30 6 18.0 23.0 2085 ...

30 12 18.0 23.0 2165 ...

30 24 25.0 25.0 3180 ...

30 30 25.0 25.0 3640 ...

36 36 28.0 28.0 4370 ...

* Not included in AWWA C110.

*MJ x MJ x FE x FE

ANSI/AWWA C110/A21.10, ANSI/AWWA C111/A21.11

Tyler Utilities Division • 11910 CR 492 • Tyler, Texas 75706 • (800) 527-8478

16 Union Foundry Company • Box 309 • Anniston, Alabama 36202 • (800) 226-7601 02/01/08

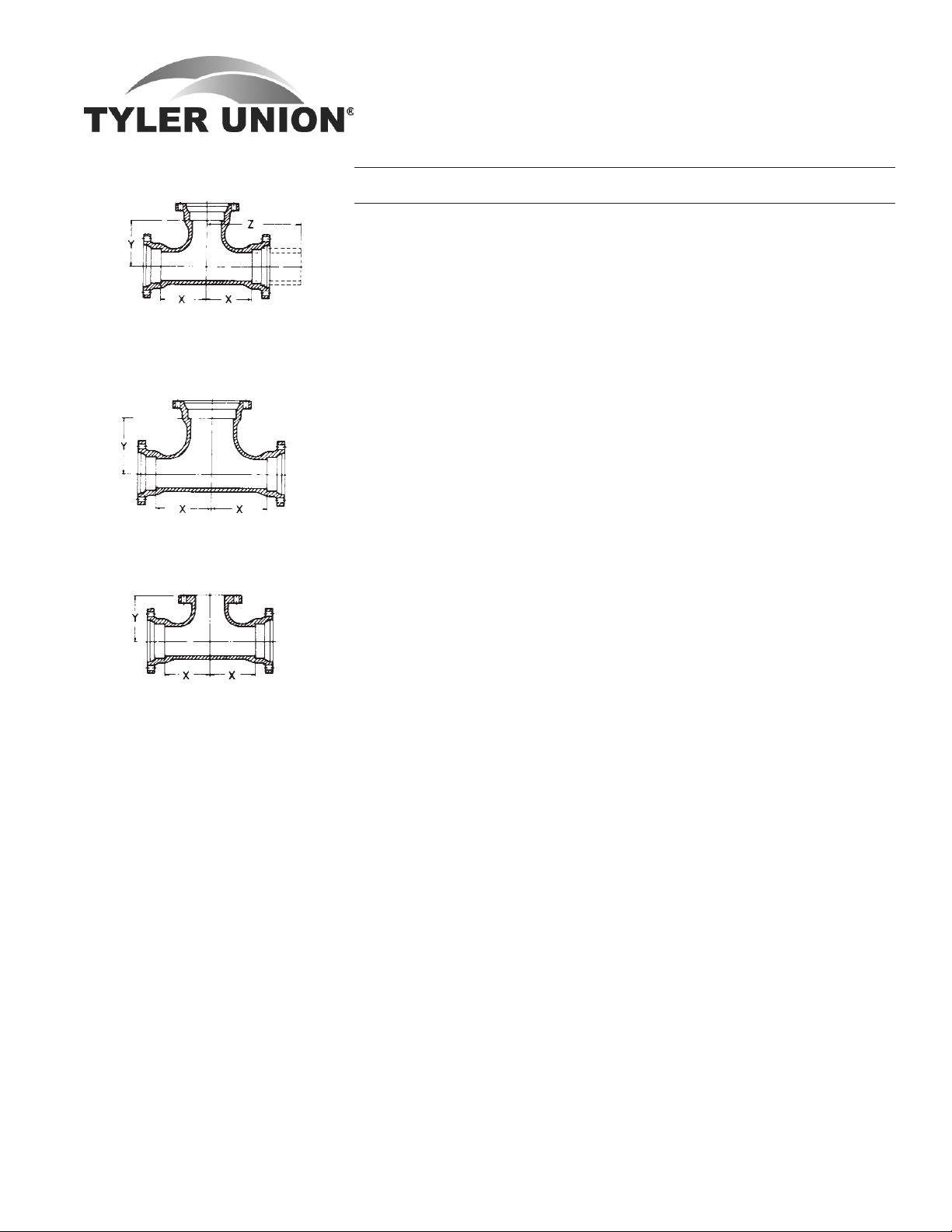

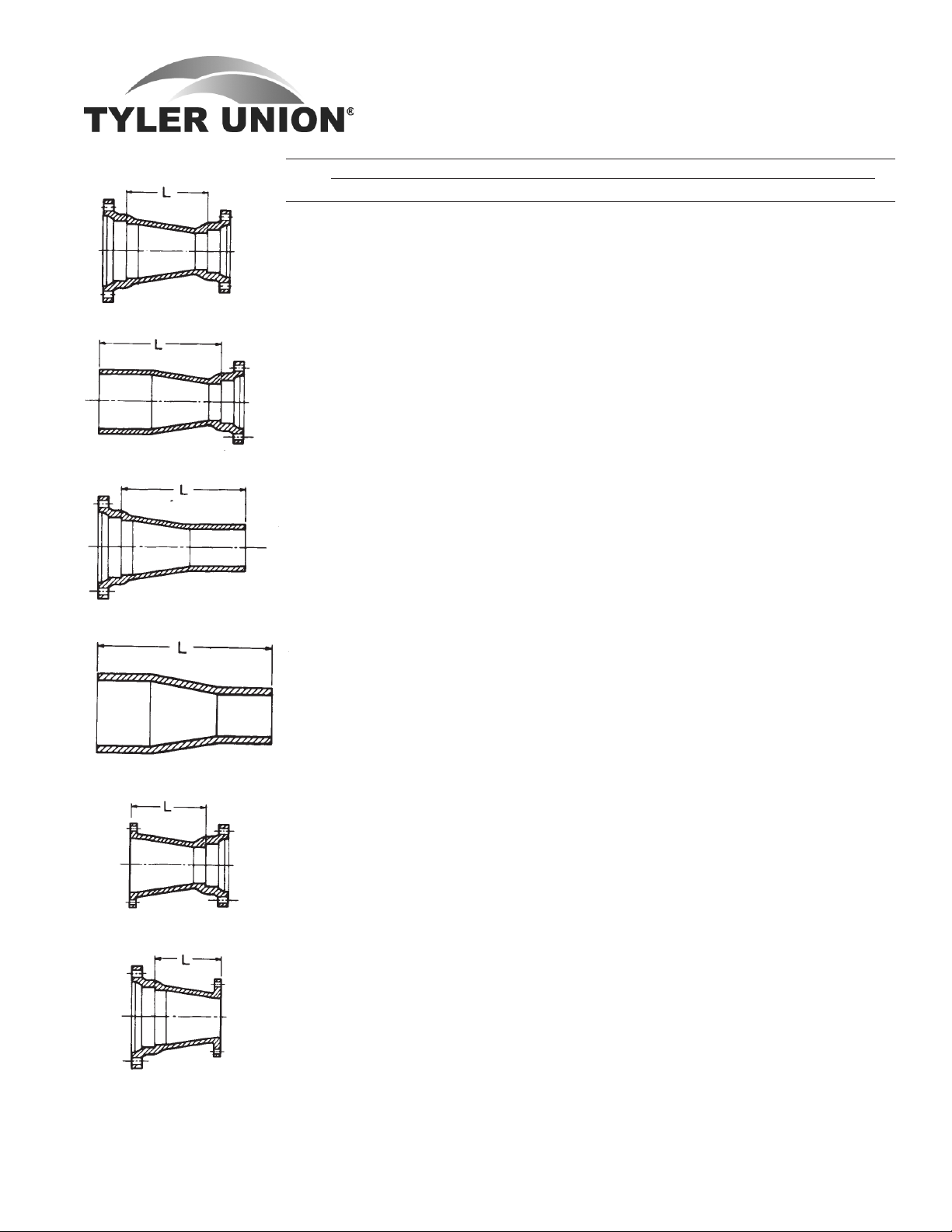

DUCTILE IRON C110 FULL BODY

MECHANICAL JOINT FITTINGS

REDUCERS

MJ Reducer

MJ Small End Bell Reducer

MJ Large End Bell Reducer

Plain End-Plain End Reducer

FExMJ Reducer

Laying Lengths (L) Weights

Size MJ MJ-SEB MJ-LEB PExPE FExMJ MJxFE MJ MJ-SEB MJ-LEB PExPE FExMJ MJxFE

* 3x2 6 14 14 ... ... ... 24 24 24 ... ... ...

* 4x2 7 15 15 ... ... ... 31 30 31 ... ... ...

4x3 7 15 15 23 7 7 37 38 37 34 34 35

* 6x2 9 17 17 ... ... ... 46 43 47 ... ... ...

6x3 9 17 17 ... ... 9 55 50 55 ... ... 50

6x4 9 17 17 25 9 9 56 60 59 57 53 62

8x3 11 19 19 ... ... ... 84 77 70 ... ... ...

8x4 11 19 19 ... 11 11 84 82 84 ... 73 75

8x6 11 19 19 27 11 11 94 90 93 96 84 80

10x6 12 20 20 ... 12 12 115 116 117 ... 100 105

10x8 12 20 20 28 12 12 142 135 130 135 130 130

12x4 14 22 22 ... ... ... 139 131 ... ... ... ...

12x6 14 22 22 ... 14 12 148 150 153 ... 145 130

12x8 14 22 22 30 14 12 173 168 165 168 170 175

12x10 14 22 22 30 14 12 194 190 178 185 188 190

14x6 ... ... ... ... ... 16 ... ... ... ... ... 195

14x8 ... ... ... ... ... 16 ... ... ... ... ... 215

14x12 ... ... ... ... ... 16 ... ... ... ... ... 270

16x6 18 ... ... ... ... ... 250 ... ... ... ... ...

16x8 18 26 ... ... ... ... 288 248 ... ... ... ...

16x10 18 ... ... ... ... ... 300 ... ... ... ... ...

16x12 18 26 26 ... 18 18 330 304 325 ... 305 325

16x14 18 ... ... ... ... ... 370 ... ... ... ... ...

18x8 19 ... ... ... ... 19 320 ... ... ... ... 300

18x10 19 ... ... ... ... ... 388 ... ... ... ... ...

18x12 19 27 ... ... ... 19 380 355 ... ... ... 405

18x14 19 ... ... ... ... ... 450 ... ... ... ... ...

18x16 19 ... ... ... ... 19 476 ... ... ... ... 445

20x10 20 ... ... ... ... ... 410 ... ... ... ... ...

20x12 20 28 ... ... ... ... 515 420 ... ... ... ...

20x16 20 28 28 ... ... 20 578 525 510 ... ... 510

20x18 20 ... ... ... ... ... 575 ... ... ... ... ...

24x12 24 32 ... ... ... 24 610 570 ... ... ... 455

24x16 24 32 32 ... ... ... 705 665 753 ... ... ...

24x18 24 32 ... ... ... ... 789 720 ... ... ... ...

24x20 24 32 32 ... ... ... 815 775 804 ... ... ...

*30x16 30 38 ... 46 ... ... 1150 1040 ... 1015 ... ...

30x18 30 38 ... 46 ... ... 1160 1050 ... 1025 ... ...

30x20 30 38 ... 46 ... ... 1225 1120 ... 1090 ... ...

30x24 30 38 38 46 ... ... 1360 1255 1320 1215 ... ...

36x20 36 ... 44 ... ... ... 1495 ... 1466 ... ... ...

36x24 36 ... 44 52 ... ... 1580 ... 1535 1389 ... ...

36x30 36 44 ... 52 ... ... 1919 1721 ... 1585 ... ...

42x24 42 ... ... ... ... ... 2060 ... ... ... ... ...

42x30 42 ... ... ... ... ... 2370 ... ... ... ... ...

42x36 42 ... ... ... ... ... 2695 ... ... ... ... ...

48x30 48 ... ... ... ... ... 3005 ... ... ... ... ...

48x36 48 ... ... ... ... ... 3370 ... ... ... ... ...

48x42 48 ... ... ... ... ... 3750 ... ... ... ... ...

* Not included in AWWA C110

MJxFE Reducer

ANSI/AWWA C110/A21.10, ANSI/AWWA C111/A21.11

Tyler Utilities Division • 11910 CR 492 • Tyler, Texas 75706 • (800) 527-8478

02/01/08 Union Foundry Company • Box 309 • Anniston, Alabama 36202 • (800) 226-7601 17

SOLID SLEEVES

DUCTILE IRON C110 FULL BODY

MECHANICAL JOINT FITTINGS

Standard

Pipe Short Long

Size O.D. L Weight L Weight

*2 2.50 8.0 13 12 18

3 3.96 7.5 ... 12 36

4 4.80 7.5 35 12 47

6 6.90 7.5 45 12 65

8 9.05 7.5 65 12 90

10 11.10 7.5 85 12 115

12 13.20 7.5 120 12 136

16 17.40 9.5 206 15 281

18 19.50 9.5 246 15 362

20 21.60 9.5 275 15 404

24 25.80 9.5 360 15 540

30 32.00 15.0 745 24 1085

36 38.30 15.0 1047 24 1502

42 44.50 ... ... 24 1550

48 50.8 ... ... 24 1940

* Not included in AWWA C110

* Dual Purpose †

Pipe Short Long

Size O.D. L Weight L Weight

4 4.80/5.00 7.5 33 12 44

6 6.90/7.10 7.5 46 12 63

8 9.05/9.30 7.5 65 12 88

10 11.10/11.40 ... ... 12 111

†12 13.20/13.50 ... ... 12 221

†16 17.40/17.80 ... ... 15 385

All Sizes Use MJ Dual Purpose Gland

* Not included in AWWA C110

† 12" & 16" are sold assembled

NOTE: Sizes 4-10" use standard MJ Gaskets;

* MJ x PE DUAL-PURPOSE CUTTING-IN SLEEVE

With Dual-Purpose Accessories

(NOTES: Gland with cup-joint set screws available at extra cost

when specified. NOT FOR RESTRAINT.)

Currently, Tyler and Union Dual Purpose Glands are NOT

interchangeable.

Cutting-In

Sleeve & Gland

Weight

For Use Gland Gland

Size On Pipe O.D. L L1 D Only & Sleeve

4 4.80 - 5.00 12 8 4.80 6.0 72

6 6.90 - 7.10 12 8 6.90 10.0 94

8 9.05 - 9.30 12 8 9.05 16.0 122

10 11.10 - 11.40 12 8 11.10 25.0 175

12 13.20 - 13.50 12 8 13.20 30.0 235

* Not included in AWWA C110.

12" and 16" require special duo gaskets.

ADAPTERS

MJ x FE

Dimensions

Size L Weights

3 8 30

4 8 42

6 8 62

8 8 88

10 8 120

12 8 150

16 8 257

18 8 324

20 8 365

24 8 528

30 10 760

36 10 1070

ANSI/AWWA C110/A21.10, ANSI/AWWA C111/A21.11

Tyler Utilities Division • 11910 CR 492 • Tyler, Texas 75706 • (800) 527-8478

18 Union Foundry Company • Box 309 • Anniston, Alabama 36202 • (800) 226-7601 02/01/08

DUCTILE IRON C110 FULL BODY

MECHANICAL JOINT FITTINGS

PLUGS

Solid or Tapped

Weight

Size Tap Solid Tapped

*2 2 5 5

3 2 9 9

4 2 13 14

6 2 15 15

8 2 45 45

10 2 66 66

12 2 79 79

14 2 120 120

16 2 147 147

†18 2 192 190

†20 2 220 219

†24 2 338 338

†30 2 660 660

†36 2 838 838

42 .. 1180 ...

48 .. 1455 ...

† Dished – Not flat as shown.

* Not included in

AWWA C110.

CAPS

Solid or Tapped

Weight

Size Tap Solid Tapped

*2 2 6 ...

3 2 10 10

4 2 18 13

6 2 34 30

8 2 46 45

10 2 58 54

12 2 86 80

16 2 178 175

†18 2 215 215

†20 2 250 249

†24 2 370 370

†30 2 680 680

†36 2 850 850

42 .. 1180 ...

48 .. 1595 ...

† Dished – Not flat as shown.

* Not included in

AWWA C110.

OFFSETS

MJ x MJ MJ x PE

Dimensions Weights

Size D L1 L MJxMJ MJxPE

4 6 19 27 ... 82

4 12 22 30 85 80

4 18 30 38 105 ...

* 4 24 26 34 126 125

6 6 20 28 114 105

6 12 26 34 148 143

6 18 33 41 188 176

* 6 24 24 32 182 160

8 6 21 29 177 155

8 12 28 36 231 195

8 18 35 43 287 282

* 8 24 36 44 280 285

10 12 30 38 347 280

10 18 38 46 340 340

10 24 38 46 420 ...

12 12 37 45 420 420

12 18 48 56 520 520

*12 24 48 56 649 630

16 12 40 48 715 ...

16 18 50 58 850 830

*20 12 40 48 1025 ...

*20 18 48 60 1362 ...

* Not included in AWWA C110.

TYTON® Plug**

Solid or Tapped

Size Tap T Weight*

4 2 .60 18

6 2 .65 25

8 2 .70 46

10 2 .75 70

12 2 .75 95

* Weights do not include accessories

** Not included in AWWA C110.

TYTON® is a registured trademark

of U.S. Pipe and Foundry Company.

Tyler Utilities Division • 11910 CR 492 • Tyler, Texas 75706 • (800) 527-8478

02/01/08 Union Foundry Company • Box 309 • Anniston, Alabama 36202 • (800) 226-7601 19

Solid Tapped

Push-In Plug with Ears

(To be used with all push-in

pipe and fittings)

Size Tap Weight

14 2.0 101

16 2.0 137

18 2.0 177

†20 2.0 239

†24 2.0 311

† Dished - Not flat as shown

NOTE: Blocking still required–

ears for assembly only.

ANSI/AWWA C110/A21.10, ANSI/AWWA C111/A21.11

*RETAINER GLAND ASSEMBLY

See Installations Instructions ........................................................ Page 50

Pressure Gland Pipe O.D. D.I. Pipe No of Size of

Rating, O.D. O.D. Wall Set Set Gland Weight

Size psi B A Class Screws Screws Weight w/Acces.

3 350 7.69 3.96 50-56 4 Á x2 4 8

4 350 9.12 4.80 50-56 4 Á x2 5 11

6 350 11.12 6.90 50-56 6 Á x2 9 16

8 250 13.37 9.05 50-56 9 Á x2 13 21

10 250 15.62 11.10 50-56 12 Á x2 17 26

12 150 17.88 13.20 50-56 16 Á x2 20 28

14 250 20.25 15.30 53-56 20 Á x2½ 44 55

16 200 22.50 17.40 53-56 24 Á x2½ 54 64

18 200 24.75 19.50 53-56 24 Á x2½ 62 72

20 200 27.00 21.60 53-56 28 Á x3 76 91

24 150 31.50 25.80 53-56 32 Á x3 103 118

* Not included in AWWA C110

DUCTILE IRON C110 FULL BODY

MECHANICAL JOINT FITTINGS

Pipe Wall Thickness:

Sizes 3"-12" are recommended for ductile

iron pipe class 50 thru 56. Sizes 14" thru

24" are recommended for ductile iron pipe

class 53 thru 56.

DUCTILE IRON RETAINER

GLANDS

Mechanical Joint Retainer Glands are

designed to provide a method for restraining mechanical joint pipe and fittings

and other standardized mechanical joints

against possible joint separation, rupture

or blow-out caused by internal water pressure.

The set screws are square-headed

with Type C knurled cup points, and are

shipped already assembled in the Glands.

They are manufactured of 4140 grade

alloy steel, and are heat treated to a Rockwall “C” 45/53 case hardness. Tee-head

bolts and gaskets are not included, but

may be ordered separately. Recommended torque for set screws is 75 foot pounds,

and set screws on opposite sides of the

glands should be tightened alternately.

Tee-head bolt hole size and spacing are equal to MJ Glands as shown in

AWWA C-111. Standard mechanical Joint

gaskets as shown in C-111 should be

used.

TEES

MJ x MJ x Swivel

Dimensions

Size X Y Weight

6 8.0 10.5 150

8x6 9.0 11.5 199

8 9.0 11.5 210

10x6 11.0 13.5 267

12x6 12.0 14.5 346

16x6 15.0 17.5 619

16x8 15.0 17.5 649

30x6 18.0 24.5 2070

All weights shown include the Swivel Gland

ANSI/AWWA C110/A21.10, ANSI/AWWA C111/A21.11

Tyler Utilities Division • 11910 CR 492 • Tyler, Texas 75706 • (800) 527-8478

20 Union Foundry Company • Box 309 • Anniston, Alabama 36202 • (800) 226-7601 02/01/08

MJ GLAND

Gland Weight

Size Wt. Pack Gland Only

2 5 3

3 7 4

4 10 6

6 16 10

8 25 16

10 30 19

12 40 26

14 45 34

16 55 54

18 65 52

20 85 73

24 105 91

30 220 90

36 301 127

ADAPTERS

ELLS

Swivel x Solid Adapter

Size by Wall

Laying Length Thickness Weight*

4x13 .52 52

6x12 .55 84

6x18 .55 91

6x24 .55 105

6x36 .55 156

8x13 .60 126

12x13 .75 186

* Weights with Gland.

DUCTILE IRON C110 FULL BODY

MECHANICAL JOINT ELLS, ADAPTERS

AND GLANDS

For Valve and Hydrant Connections

Other Swivel Hydrant

Fittings, Pages 3, 4 and 5.

*90° Swivel x Swivel Ell

(Not Included In AWWA C110)

Wall Dimensions

Size Thickness A B C D E F R *Weight

6 .55 10.5 15.5 7.10 11.12 6.90 8.02 6.0 106

8 .60 11.5 16.5 9.20 13.37 9.05 10.17 7.0 156

* With 2 Swivel Glands

SWIVEL GLAND ASSEMBLY

Used with swivel fittings, the TYLER Swivel Gland, with its rotating feature, permits the installer to meet any grade requirements regardless of bolt-hole alignment. In addition, the system permits stiff connections without braces, blocking or strapping.

Swivel Glands**

Size Weight

12 30

** Not included in

AWWA C110.

NOTE: When ordering glands

separately,

(1) Specify TYLER UPCode

Number,

(2) Description, and

(3) Size of fitting to be joined.

ANSI/AWWA C110/A21.10, ANSI/AWWA C111/A21.11

Tyler Utilities Division • 11910 CR 492 • Tyler, Texas 75706 • (800) 527-8478

02/01/08 Union Foundry Company • Box 309 • Anniston, Alabama 36202 • (800) 226-7601 21

UNION-TITE DUCTILE IRON

C153 COMPACT FITTINGS

SAMPLE SPECIFICATIONS

4"through24"Push-OnJointDuctileIronFittingsshallbeproducedinaccordancewithallapplicabletermsandprovisions

ofANSI/AWWAC153/A21.53.Fittingsarecement-linedandseal-coatedinaccordancewithANSI/AWWAC104/A21.4.Joints

shallbeinaccordancewithANSI/AWWAC111/A21.11withbellsocketsdesignedtoreceivepressurepipeO.D.'sasspecified

inANSI/AWWAC151/A21.51andAWWAC900TABLE2.Theworkingpressureratingshallbe350PSI,exceptforwyesand

flanged-branchfittings.NOTE:FittingsareCEMENT-LINEDandsealcoatedinaccordancewithANSI/AWWAC104/A21.4,also

availablebareorepoxycoated.Doublecementlinedavailableinnon-domesticonly.Allcoatedfittingsmeetrequirementsof

NSF-61.

Thicknessesanddimensionsofbellsocketsandgasketsshallbeinaccordancewiththemanufacturer'sdesign.Rubberrings

shallbefurnishedbythemanufacturer.Workingpressuresapplytofittingsonlyanddonotapplytorestraininglugsorexternal

restrainingdevices.

NOTE: Restraining lugs are provided on sizes 4" through 12" ONLy.

NOTE - EXCEPTIONS: Union-Tite Fittings with flanged branches are rated for water pressure of 250 PSI.

ADVANTAGESANDFEATURES

• Push-ongasketjointusesTYTON

®

or SURE 350® STOPgaskets

• ForusewithDuctileIronpipe,C-900plasticpipe,and4-12"pressureratedIPSdiameterplasticpipe

usingtransitiongaskets

• Deepstabjointdesignaccommodatestaperonplasticpipes

• SlipjointinstallationeliminatesT-boltsandnuts:MJglandsnotneeded

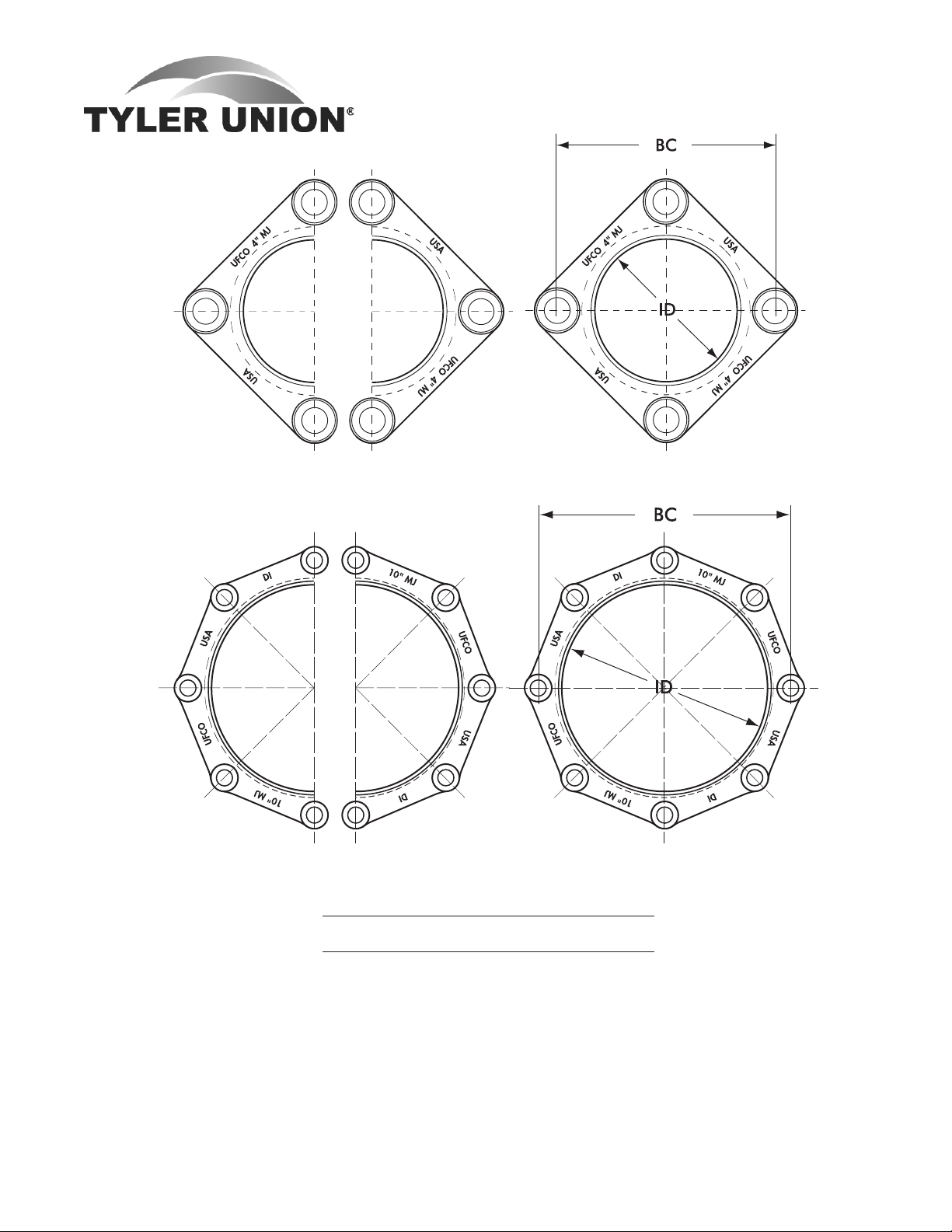

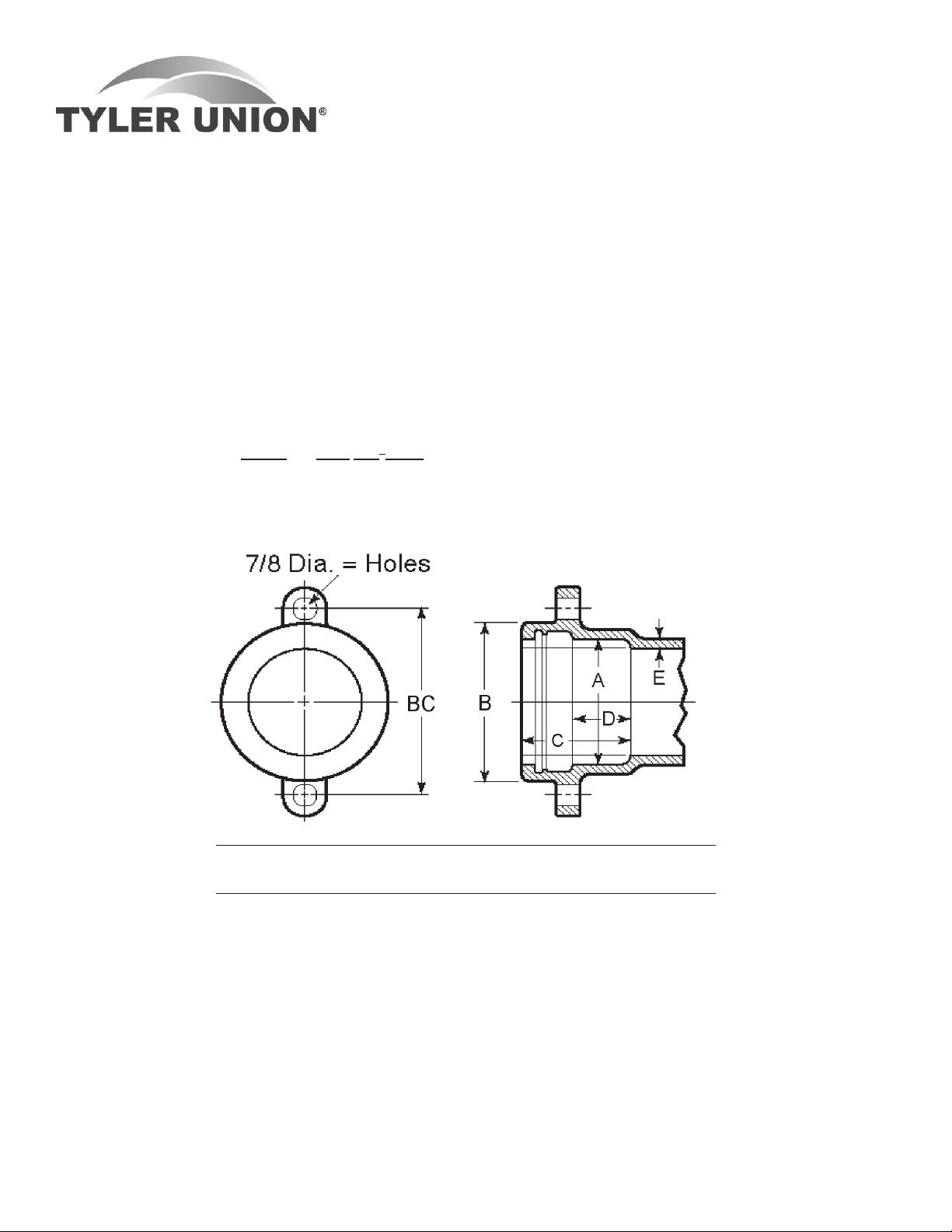

BELL DIMENSIONS IN INCHES FOR UNION-TITE FITTINGS

Pipe

Size A B B.C. C D E

4 5.04 6.38 7.88 4.16 2.25 .35

6 7.14 8.52 10.50 4.29 2.25 .37

8 9.32 10.90 12.88 4.78 2.25 .39

10 11.37 12.91 14.69 4.98 2.25 .41

12 13.47 15.12 17.19 4.98 2.25 .43

14 15.64 18.12 ... 5.40 2.25 .51

16 17.74 20.32 ... 5.40 2.25 .52

18 19.83 22.52 ... 5.40 2.25 .59

20 21.94 24.29 ... 5.40 2.25 .60

24 26.14 29.14 ... 5.65 2.50 .62

TYTON®andFIELD-LOK®areregisteredtrademarksofU.S.PipeandFoundryCompany.

Maximumdeflectionis5°.

TylerUtilitiesDivision•11910CR492•Tyler,Texas75706•(800)527-8478

22 UnionFoundryCompany•Box309•Anniston,Alabama36202•(800)226-7601 02/01/08

UNION-TITE DUCTILE IRON

C153 COMPACT FITTINGS

BENDS

90° (1/4) UT Bends 45° (1/8) UT Bends 22½° (1/16) UT Bends 11¼° (1/32) UT Bends

Dimensions Dimensions Dimensions Dimensions

Size T A R Weight A R Weight A R Weight A R Weight

4 .35 4.5 3.87 24 2.0 3.31 26 1.50 4.38 18 1.25 6.77 18

6 .37 6.0 5.37 51 3.0 5.72 42 2.25 8.16 39 1.50 9.38 40

8 .39 7.0 6.37 80 3.5 6.93 66 2.50 9.40 64 1.75 11.48 60

10 .41 9.0 8.36 121 4.5 9.34 101 3.00 13.17 67 2.00 13.95 77

12 .43 10.0 9.36 151 5.5 11.75 128 3.50 14.42 111 2.25 16.50 94

14 .51 12.0 10.98 254 5.5 10.85 143 3.75 13.82 162 2.60 14.26 113

16 .52 13.0 12.00 328 6.0 12.02 225 4.00 14.97 195 2.60 15.23 172

18 .59 15.5 14.00 482 6.5 12.36 209 7.50 30.19 209 3.00 60.94 209

20 .60 17.0 15.50 340 7.0 13.59 397 8.50 35.19 414 3.50 71.07 265

24 .62 17.0 15.59 674 7.5 14.69 492 9.00 37.69 596 ... ... ...

90° (1/4) 45° (1/8) 22½° (1/16) 11¼° (1/32)

UT x Flange Bends UT x Flange Bends UT x Flange Bends UT x Flange Bends

Dimensions Dimensions Dimensions Dimensions

Size T A B R Weight A B R Weight A B R Weight A B R Weight

4 .35 4.5 6.5 3.87 31 2.0 4.0 3.31 21 1.50 3.5 4.38 25 1.25 3.30 6.77 24

6 .37 6.0 7.0 5.37 49 3.0 5.0 5.72 42 2.25 4.3 8.16 44 1.50 3.50 9.38 30

8 .39 7.0 9.0 6.37 74 3.5 5.5 6.93 60 2.50 4.5 9.40 64 1.75 3.75 11.48 61

10 .41 9.0 10.0 8.36 130 4.5 6.5 9.34 93 3.00 5.3 13.17 90 2.00 4.00 13.95 80

12 .43 10.0 12.0 9.36 158 5.5 7.5 11.75 122 3.50 5.5 14.42 112 2.25 4.30 16.50 94

14 .51 12.0 15.5 10.98 231 5.5 8.5 10.85 162 3.75 6.8 13.82 174 2.60 5.75 14.26 170

16 .52 13.0 16.5 12.00 233 6.0 9.5 12.02 275 4.00 7.5 14.97 228 2.60 6.10 15.23 228

Tyler Utilities Division • 11910 CR 492 • Tyler, Texas 75706 • (800) 527-8478

02/01/08 Union Foundry Company • Box 309 • Anniston, Alabama 36202 • (800) 226-7601 23

UNION-TITE DUCTILE IRON

C153 COMPACT FITTINGS

BENDS

90° (1/4) 45° (1/8) 22½° (1/16) 11¼° (1/32)

UT x PE Bends UT x PE Bends UT x PE Bends UT x PE Bends

Dimensions Dimensions Dimensions Dimensions

Size T A B R Weight A B R Weight A B R Weight A B R

Weight

4 .35 4.5 10.5 3.87 35 2.0 8.0 3.31 21 ... ... ... .. ... ... ... ..

6 .37 6.0 12.0 5.37 70 3.0 9.0 5.72 38 2.25 8.08 8.16 35 1.50 7.30 9.38 36

8 .39 ... ... ... .. 3.5 9.5 6.93 60 2.50 8.34 9.40 57 1.75 7.55 11.48 55

TEES

UT x UT x PE Tees

Size Dimensions

Run Branch T T1 H J3 Weight

6 6 .37 .37 6.0 11.5 60

8 6 .39 .37 6.0 12.5 80

12 6 .43 .37 7.0 15.5 140

Tyler Utilities Division • 11910 CR 492 • Tyler, Texas 75706 • (800) 527-8478

24 Union Foundry Company • Box 309 • Anniston, Alabama 36202 • (800) 226-7601 02/01/08

UNION-TITE DUCTILE IRON

C153 COMPACT FITTINGS

TEES

UT x UT Tees UT x Flange Tees UT x Swivel Tees

Dimensions Weights

Size T T1 H J1 J2 J3 UT x UT UT xFlange UT x Swivel

4 .35 .35 4.5 4.5 6.5 ... 44 45 ...

6x4 .37 .35 5.0 6.0 8.0 ... 68 56 ...

6 .37 .37 6.0 6.0 8.0 9.5 69 71 65

8x4 .39 .35 5.0 7.0 9.0 ... 73 89 ...

8x6 .39 .37 6.0 7.0 9.0 10.5 96 101 100

8 .39 .39 7.0 7.0 9.0 10.5 116 117 110

10x4 .41 .35 6.0 9.0 11.0 ... 102 115 ...

10x6 .41 .37 7.0 9.0 11.0 12.5 113 128 130

10x8 .41 .39 8.0 9.0 11.0 12.5 145 145 156

10 .41 .41 9.0 9.0 11.0 ... 155 158 ...

12x4 .43 .35 6.0 10.0 12.0 ... 119 138 ...

12x6 .43 .37 7.0 10.0 12.0 13.5 141 148 162

12x8 .43 .39 8.0 10.0 12.0 13.5 177 170 158

12x10 .43 .41 9.0 10.0 12.0 ... 160 162 ...

12 .43 .43 10.0 10.0 12.0 ... 217 183 ...

14x6 .51 .44 6.5 10.5 12.5 14.0 176 212 202

14x10 .51 .46 8.5 10.5 12.5 ... 195 246 ...

14x12 .51 .47 9.5 10.5 12.5 ... 196 296 ...

14 .51 .51 10.5 10.5 14.0 ... 209 321 ...

16x6 .52 .45 6.5 11.5 13.5 15.0 266 160 229

16x8 .52 .46 7.5 11.5 13.5 15.0 292 270 292

16x10 .52 .47 8.5 11.5 13.5 ... 232 330 ...

16x12 .52 .48 9.5 11.5 13.5 ... 239 321 ...

16x14 .52 .51 10.5 11.5 15.0 ... 349 342 ...

16 .52 .52 11.5 11.5 15.0 ... 261 355 ...

18x6 .59 .44 6.5 12.5 14.5 16.13 348 301 348

18x8 .59 .45 7.5 12.5 14.5 16.13 325 319 324

18x10 .59 .47 8.5 12.5 14.5 ... 344 337 ...

18x14 .59 .56 10.5 12.5 16.0 ... 342 393 ...

18x16 .59 .57 11.5 12.5 16.0 ... 362 420 ...

20x6 .60 .44 7.0 14.0 16.0 17.5 355 341 400

20x10 .60 .47 9.0 14.0 16.0 ... 369 420 ...

20x14 .60 .56 11.0 14.0 17.5 ... 484 474 ...

20x16 .60 .57 12.0 14.0 17.5 ... 610 498 ...

20x18 .60 .59 13.0 14.0 17.5 ... 539 ... ...

24x6 .62 .44 7.0 16.0 18.0 19.5 385 512 525

24x10 .62 .47 9.0 16.0 18.0 ... 478 468 ...

24x12 .62 .49 10.0 16.0 18.0 ... 663 503 ...

24x14 .62 .56 11.0 16.0 19.5 ... 542 531 ...

24x16 .62 .57 12.0 16.0 19.5 ... 566 555 ...

24x18 .62 .59 13.0 16.0 ... ... 593 ...

24x20 .62 .60 15.0 17.0 ... ... 628 ... ...

24 .62 .62 17.0 17.0 ... ... 884 ... ...

Tyler Utilities Division • 11910 CR 492 • Tyler, Texas 75706 • (800) 527-8478

02/01/08 Union Foundry Company • Box 309 • Anniston, Alabama 36202 • (800) 226-7601 25

REDUCERS

UT x UT Reducers UT x Flange Reducers

Dimensions Weights

Size T T1 L G UT x UT UT xFlange

6x4 .37 .35 4.0 6.0 32 32

8x4 .39 .35 5.0 7.0 46 46

8x6 .39 .37 4.0 6.0 49 47

10x4 .41 .35 7.0 9.0 47 55

10x6 .41 .37 5.0 7.0 47 59

10x8 .41 .39 4.0 6.0 53 61

12x4 .43 .35 9.0 11.0 74 78

12x6 .43 .37 7.0 9.0 58 75

12x8 .43 .39 5.0 7.0 74 74

12x10 .43 .41 4.0 6.0 82 95

14x6 .51 .44 9.0 11.0 84 121

14x8 .51 .45 7.0 9.0 85 128

14x10 .51 .46 5.0 7.0 87 127

14x12 .51 .47 4.0 6.0 104 144

16x6 .52 .45 11.0 13.0 94 133

16x8 .52 .46 9.0 11.0 104 141

16x10 .52 .47 7.0 9.0 130 158

16x12 .52 .48 5.0 7.0 152 172

16x14 .52 .51 4.0 6.0 139 196

18x8 .59 .45 14.0 16.0 142 157

18x10 .59 .47 12.0 14.0 151 175

18x12 .59 .49 10.0 12.0 167 215

18x14 .59 .56 8.0 11.5 217 234

18x16 .59 .57 7.0 10.5 202 246

20x10 .60 .47 14.0 16.0 180 234

20x12 .60 .49 12.0 ... 205 ...

20x14 .60 .56 10.0 13.5 233 249

20x16 .60 .57 8.0 11.5 250 272

20x18 .60 .59 7.0 ... 248 ...

24x12 .62 .49 16.0 18.0 246 262

24x14 .62 .56 14.0 17.5 281 315

24x16 .62 .57 12.0 15.5 380 328

24x18 .62 .59 10.0 ... 390 ...

24x20 .62 .60 8.0 ... 421 ...

UNION-TITE DUCTILE IRON

C153 COMPACT FITTINGS

TAPPED TEE/CROSS

UT x Tapped Tee/Crosses

Dimensions

Size T Max Tap L Weight

4 .35 3.0 6.0 27

6 .37 3.5 6.0 38

8 .39 3.5 6.0 59

10 .41 3.5 6.0 72

12 .43 3.5 6.0 92

CAPS AND PLUGS

Solid Cap Solid Plug

UT x Flange Adaptor

Dimensions

Size T L Weight

4 .35 6.0 28

6 .37 6.0 36

8 .39 6.0 54

10 .41 6.0 71

12 .43 6.0 102

14 .51 7.0 113

16 .52 7.0 115

20 .60 6.0 295

Tyler Utilities Division • 11910 CR 492 • Tyler, Texas 75706 • (800) 527-8478

26 Union Foundry Company • Box 309 • Anniston, Alabama 36202 • (800) 226-7601 02/01/08

2" Tapt Cap 2" Tapt Plug

UT Caps and Plugs*

Dimensions Weights

Size T1 T2 L Cap Plug

4 .48 .50 5.25 15 8

6 .48 .50 5.25 20 23

8 .51 .53 5.25 35 32

10 .53 .56 5.25 50 38

12 .55 .62 5.25 75 49

*Restraining lugs (ears) available.

UNION-TITE DUCTILE IRON

C153 COMPACT FITTINGS

WYES CROSSES

UT Wyes

Dimensions

Size T T1 P N Weights

8x4 .39 .35 13.5 .0 89

10x4 .41 .35 15.0 .0 141

10x6 .41 .37 16.0 1.0 151

10x8 .41 .39 17.0 2.5 175

10 .41 .41 18.0 4.0 200

12x4 .43 .35 16.5 .0 178

12x6 .43 .37 18.5 1.5 201

12x8 .43 .39 18.5 1.5 224

12x10 .43 .41 20.0 3.0 240

12 .43 .43 20.0 5.0 289

14x6 .51 .44 19.5 .0 236

14x8 .51 .45 21.0 1.5 255

14x10 .51 .46 22.5 3.0 325

14 .51 .51 25.0 6.0 475

16x6 .52 .45 21.0 .0 281

16x8 .52 .46 22.5 0.5 304

16x12 .52 .48 25.0 3.5 346

16 .52 .52 28.0 6.5 380

TYTON® GASKETS

TYTON® JOINT IPS Transition and Regular Gasket

Dimensions

Transition (IPS) Regular (Ductile)

Size A B(±1%) B* C

4 5.74 4.18 4.68 1.00

6 7.86 6.31 6.73 1.10

8 10.15 8.32 8.85 1.29

10 12.10 10.30 10.87 1.36

12 14.31 12.70 12.95 1.45

TYTON® is a registered trademark of

U.S. Pipe and Foundry Company.

UT Crosses

Dimensions

Size T1 H J Weights

6 .37 6.0 6.0 88

8x6 .37 6.0 7.0 117

8 .39 7.0 7.0 156

10x4 .35 6.0 9.0 116

12x8 .39 8.0 10.0 240

12 .43 10.0 10.0 241

14x6 .44 6.5 10.5 189

14x8 .45 7.5 10.5 204

14x10 .46 8.5 10.5 222

14x12 .47 9.5 10.5 239

14 .51 10.5 10.5 270

16x6 .45 6.5 11.5 234

16x8 .46 7.5 11.5 323

16x10 .47 8.5 11.5 268

16x12 .48 9.5 11.5 274

16x14 .51 10.5 11.5 322

16 .52 11.5 11.5 317

NOTICE: Weights published in this

catalog are for shipping purposes only.

Actual weights may vary because some

fittings are produced in both foundries.

All fittings are made in the USA and meet

the AWWA standards to which they are

designed.

For weights of specific fittings, please

contact Tyler Pipe or Union Foundry

Company.

Tyler Utilities Division • 11910 CR 492 • Tyler, Texas 75706 • (800) 527-8478

02/01/08 Union Foundry Company • Box 309 • Anniston, Alabama 36202 • (800) 226-7601 27

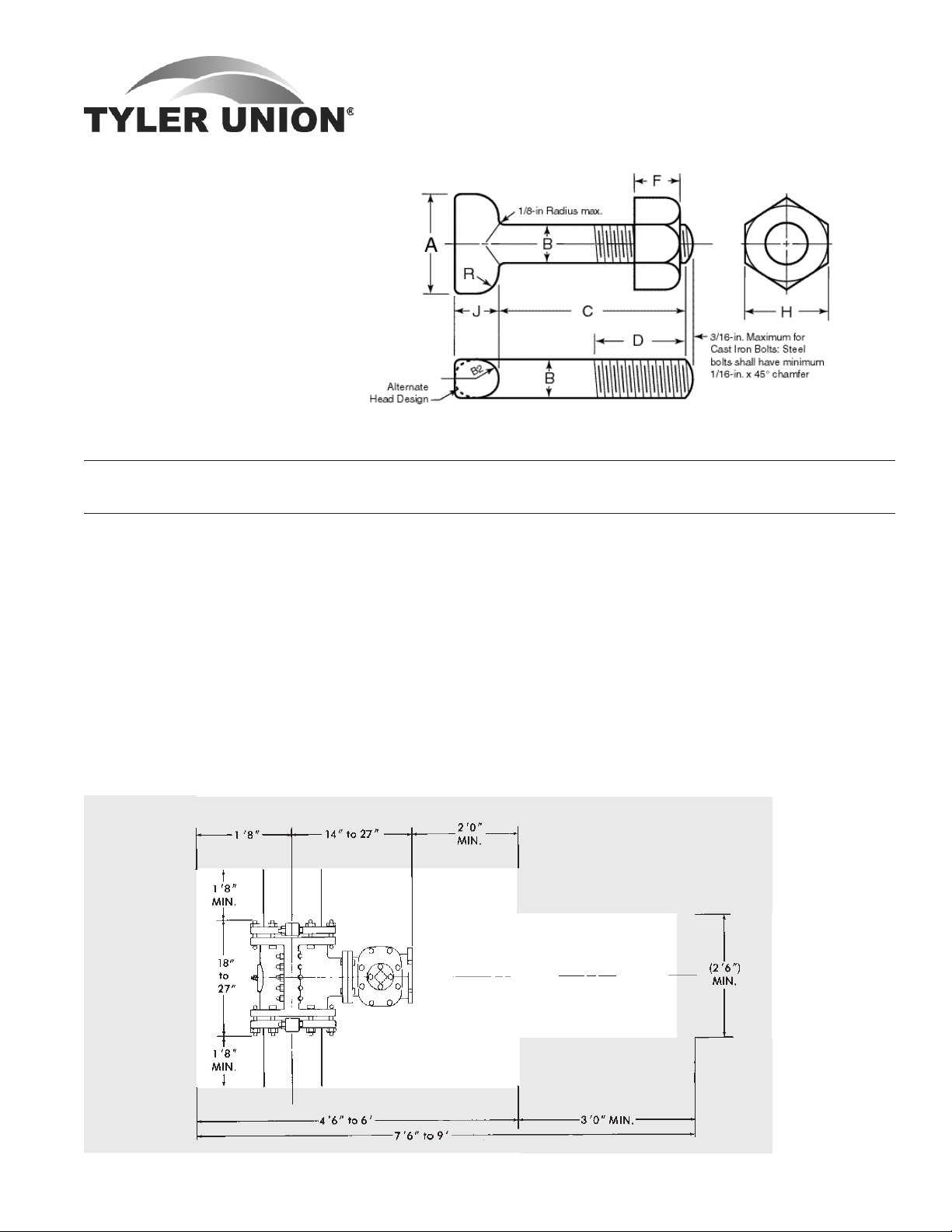

DUCTILE IRON C110

FLANGED FITTINGS

Sizes 3" thru 12" UL Listed for Fire Main Equipment

SAMPLE SPECIFICATION

Flanged Fittings, 2" through 48" shall be manufactured of Ductile Iron in accordance with all applicable terms and provisions of

standards ANSI/AWWA C110/A21.10 (current revisions). Flange surface shall be faced and drilled in accordance with ANSI Class

125 B16.1. All Ductile Iron Flanged Fittings shall be rated for water pressure of 250 PSI. Flanged ductile-iron fittings in 24-in. (610

mm) and smaller sizes may be rated for 350 psi (2,413 kPa) with the use of special gaskets. NOTE: Fittings are CEMENT-LINED

and seal coated in accordance with ANSI/AWWA C104/A21.4, also available prime coated, bare or epoxy coated. All coated fittings

meet requirements of NSF-61. Interiors shall be lined and seal coated in accordance with ANSI/AWWA C104/A21.04, “Cement-

mortor Lining for Ductile Iron Pipe and Fittings for Water” unless otherwise specified.

FLANGE DETAILS

Nominal Dia. of Flange

Pipe Size Flange Bolt Thickness Bolt Hole Number Bolt Dia.

Inch O.D. Circle T Diameter of Bolts and Lengths

2 6 4.75 .62 .75 4 Á x 2¼

3 7.5 6 .75 .75 4 Á x 2½

4 9 7.5 .94 .75 8 Á x 3

6 11 9.5 1.00 .875 8 ¾ x 3½

8 13.5 11.75 1.12 .875 8 ¾ x 3½

10 16 14.25 1.19 1.00 12 Â x 4

12 19 17 1.25 1.00 12 Â x 4

14 21 18.75 1.38 1.125 12 1 x 4½

16 23.5 21.25 1.44 1.125 16 1 x 4½

18 25 22.75 1.56 1.25 16 1¿ x 5

20 27.5 25 1.69 1.25 20 1¿ x 5

24 32 29.5 1.88 1.375 20 1¼ x 5½

NOTE: No flange joint

material furnished.

30 38.75 36 2.12 1.375 28 1¼ x 6½

36 46 42.75 2.38 1.675 32 1½ x 7

42 53 49.50 2.62 1.625 36 1½ x 7½

48 59.50 56.00 2.75 1.625 44 1½ x 8

NOTE: Drilling templates are in multiples of four, so that fittings may be made to face in any

quarter. Bolt holes shall straddle the center line.

Tyler Utilities Division • 11910 CR 492 • Tyler, Texas 75706 • (800) 527-8478

28 Union Foundry Company • Box 309 • Anniston, Alabama 36202 • (800) 226-7601 02/01/08

Sizes 3" thru 12" UL Listed for Fire Main Equipment

BENDS

Note: Base Bends are on page 33 and 34, reducing and long radius 90° bends are on page 33.

DUCTILE IRON C110

FLANGED FITTINGS

90° Bends (1/4) 45° Bends (1/8) 221/2° Bends (1/16) 111/4° Bends (1/32)

Dimensions Dimensions Dimensions Dimensions

Size R A Weight R A Weight R A Weight R A Weight

2 3.0 4.5 14 ... ... ... ... ... ... ... ... ...

3 4 5.5 26 3.62 3 20 7.56 3 22 15.25 3 20

4 4.5 6.5 44 4.81 4 36 10.06 4 35 20.31 4 40

6 6 8 67 7.25 5 57 15.06 5 64 30.5 5 56

8 7 9 115 8.44 5.5 105 17.62 5.5 90 35.5 5.5 90

10 9 11 164 10.88 6.5 131 22.62 6.5 130 45.69 6.5 130

12 10 12 236 13.25 7.5 196 27.67 7.5 194 55.81 7.5 193

14 11.5 14 330 12.06 7.5 245 25.12 7.5 250 50.75 7.5 245

16 12.5 15 478 13.25 8 315 27.62 8 315 55.81 8 315

18 14 16.5 527 14.5 8.5 422 30.19 8.5 402 60.94 8.5 385

20 15.5 18 878 16.88 9.5 485 35.19 9.5 505 71.06 9.5 505

24 18.5 22 1085 18.12 11 730 37.69 11 528 76.12 11 760

30 21.5 25 1755 27.75 15 1355 57.81 15 1385 116.75 15 1395

36 24.5 28 2135 35.00 18 1755 72.88 18 1790 147.25 18 1805

42 27.5 31 3055 42.25 21 2600 88.00 21 2665 177.69 21 2680

48 30.5 34 4095 49.50 24 3580 103.06 24 3665 208.12 24 3695

Tyler Utilities Division • 11910 CR 492 • Tyler, Texas 75706 • (800) 527-8478

02/01/08 Union Foundry Company • Box 309 • Anniston, Alabama 36202 • (800) 226-7601 29

DUCTILE IRON C110

FLANGED FITTINGS

TEES, REDUCING TEES, CROSSES

Straight Tees, Reducing *Reducing *Reducing on *Bullhead Straight and

on Branch Tees on Run Run and Branch Tees Reducing Crosses

Size Dimensions Weights

Run Run Branch H J Tee Cross

2 2 2 4.5 4.5 20

3 3 2 5.5 5.5 35 ...

3 3 3 5.5 5.5 42 51

4 3 3 6.5 5.5 53 ...

*4 4 2 6.5 6.5 55 ...

4 4 3 6.5 6.5 54 76

4 4 4 6.5 6.5 60 87

*4 4 6 8.0 8.0 88 ...

*6 4 4 8.0 8.0 96 ...

*6 4 6 8.0 8.0 100 ...

*6 6 2 8.0 8.0 85 ...

6 6 3 8.0 8.0 85 96

6 6 4 8.0 8.0 90 112

6 6 6 8.0 8.0 98 141

6 6 8 9.0 9.0 138 ...

*8 6 4 9.0 9.0 130 ...

*8 6 6 9.0 9.0 148 ...

*8 6 8 9.0 9.0 154 ...

8 8 3 9.0 9.0 128 140

8 8 4 9.0 9.0 155 155

8 8 6 9.0 9.0 148 172

8 8 8 9.0 9.0 179 195

*8 8 10 11.0 11.0 225 ...

*8 8 12 12.0 12.0 277 ...

*†10 6 6 13.0 13.0 278 ...

*†10 6 10 13.0 13.0 308 ...

*†10 8 6 13.0 13.0 298 ...

*†10 8 8 13.0 13.0 278 ...

*†10 8 10 13.0 13.0 325 ...

10 10 4 11.0 11.0 239 220

10 10 6 11.0 11.0 215 242

10 10 8 11.0 11.0 254 294

10 10 10 11.0 11.0 265 330

10 10 12 12.0 12.0 337 ...

* †12 6 6 14.0 14.0 346 ...

*†12 6 8 14.0 14.0 362 ...

*†12 8 6 14.0 14.0 355 ...

Size Dimensions Weights

Run Run Branch H J Tee Cross

*12 8 8 12.0 12.0 375 ...

*12 8 12 12.0 12.0 420 ...

*†12 10 6 14.0 14.0 390 ...

12 10 8 12.0 12.0 400 ...

12 10 10 12.0 12.0 420 ...

12 10 12 12.0 12.0 440 ...

12 12 4 12.0 12.0 322 310

12 12 6 12.0 12.0 297 326

12 12 8 12.0 12.0 346 351

12 12 10 12.0 12.0 394 415

12 12 12 12.0 12.0 369 438

*14 14 4 14.0 14.0 410 ...

14 14 6 14.0 14.0 420 450

14 14 8 14.0 14.0 435 475

14 14 10 14.0 14.0 450 ...

14 14 12 14.0 14.0 470 555

14 14 14 14.0 14.0 500 595

*16 16 4 15.0 15.0 525 ...

16 16 6 15.0 15.0 573 565

16 16 8 15.0 15.0 555 590

16 16 10 15.0 15.0 565 620

16 16 12 15.0 15.0 590 665

16 16 14 15.0 15.0 610 ...

16 16 16 15.0 15.0 635 755

18 18 6 13.0 15.5 780 ...

18 18 8 13.0 15.5 609 ...

18 18 10 13.0 15.5 585 ...

18 18 12 13.0 15.5 638 706

18 18 14 16.5 16.5 808 ...

18 18 16 16.5 16.5 760 ...

18 18 18 16.5 16.5 865 915

* Not included in AWWA C110

† H and J dimensions are two-inches longer than straight

tees.

Tyler Utilities Division • 11910 CR 492 • Tyler, Texas 75706 • (800) 527-8478

30 Union Foundry Company • Box 309 • Anniston, Alabama 36202 • (800) 226-7601 02/01/08

DUCTILE IRON C110

FLANGED FITTINGS

TEES, REDUCING TEES, CROSSES (Con't)

Size Dimensions Weights

Run Run Branch H J Tee Cross

20 20 6 14.0 17.0 773 ...

20 20 8 14.0 17.0 720 ...

20 20 10 14.0 17.0 735 ...

20 20 12 14.0 17.0 816 820

20 20 14 14.0 17.0 770 ...

20 20 16 18.0 18.0 950 1065

20 20 18 18.0 18.0 965 ...

20 20 20 18.0 18.0 1005 1175

24 24 6 15.0 19.0 1089 ...

24 24 8 15.0 19.0 1060 ...

24 24 10 15.0 19.0 1020 ...

24 24 12 15.0 19.0 1125 1100

24 24 14 15.0 19.0 1050 1125

24 24 16 15.0 19.0 1070 1160

24 24 18 22.0 22.0 1534 ...

24 24 20 22.0 22.0 1510 1695

24 24 24 22.0 22.0 1685 1850

*30 30 6 18.0 23.0 1725 ...