Tyler Refrigeration TLM, TLD, TLF User Manual

Installation & Service

Manual

TLM, TLF, TLD

PRINTED IN Specifications subject to REPLACES ISSUE PART

IN U.S.A. change without notice. EDITION

11/05 DATE 4/07 NO. 9037179 REV. E

Tyler Refrigeration * Niles, Michigan 49120

This manual has been designed to be used in conjunction with the

General (UL/NSF) Installation & Service Manual.

Save the Instructions in Both Manuals for Future Reference!

This merchandiser conforms to the American National Standard Institute & NSF International Health and Sanitation standard ANSI/NSF - 7 2003.

LIFT FRONT STRAIGHT GLASS MEAT/SEAFOOD/DELI MERCHANDISERS

Medium Temperature Service Display Cases

CONTENTS

Page

Specifications

TLD/TLM/TLF Specification Sheets . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Line Sizing Requirements . . . . . . (See General-UL/NSF I&S Manual)

Pre-Installation Responsibilities . . . . . (See General-UL/NSF I&S Manual)

Pre-Installation Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Carpentry Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Case Line-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Lift Front Glass Leveling Instructions . . . . . . . . . . . . . . . . . . . . . . . . . 9

Rear Rail Cover and Close-off Installation . . . . . . . . . . . . . . . . . . . . 10

Bumper and Color Band Adjustment . . (See Gen.-UL/NSF I&S Man.)

Optional 2” Bumper Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Plumbing Procedures . . . . . . . . (See General-UL/NSF I&S Manual)

Refrigeration Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Temperature Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Setting the Electronic Thermostat (TLM/TLD/TLF) . . . . . . . . . . . . . 12

Electrical Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Electrical Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Defrost Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Defrost Control Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installation Procedure Check Lists (See Gen.-UL/NSF I&S Manual)

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

TLM/TLF Case Circuits (4’, 6’, 8’ & 12’ Cases) . . . . . . . . . . . . . . . . 14

TLD Case Circuits (4’, 6’, 8’ & 12’ Cases) . . . . . . . . . . . . . . . . . . . . 18

Cleaning and Sanitation

Component Removal and Installation Instructions for Cleaning

Lower Trays and Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Front Air Ducts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Rear Air Ducts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Mullion Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

End Coil Cover (TLM/TLF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Refrigeration Line Cover (TLM Only) . . . . . . . . . . . . . . . . . . . . . . . . 22

Electrical Cover (TLM Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Front Lower Cladding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Front Upper Cladding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Cleaning Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Stainless Steel Cleaning Method . . . . . . . . . . . . . . . . . . . . . . . . . . 23

TLM, TLF, TLD

Page 2 April, 2007

Installation & Service Manual TLM, TLF, TLD

April, 2007 Page 3

Page

General Information

Rear Sliding Door Removal and Installation . . . . . . . . . . . . . . . 25

Mezzanine Shelving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Top Mounted Scale Shelf Installation . . . . . . . . . . . . . . . . . . . . 26

Service Instructions

Preventive Maintenance . . . . . . (See General-UL/NSF I&S Manual)

Fan Blade & Motor Replacement . (See Gen.-UL/NSF I&S Manual)

Connecting the Refrigeration Piping and Components . . . . . . . 27

Light Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Ballast and Lighting Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Light Shield Anti-Sweat Replacement . . . . . . . . . . . . . . . . . . . . . . . 28

Front Glass Anti-Fogging System Service . . . . . . . . . . . . . . . . 28

Front Glass Anti-Sweat Replacement . . . . . . . . . . . . . . . . . . . . . . . 28

Front Glass Anti-Fog Fan Replacement . . . . . . . . . . . . . . . . . . . . . 29

Lift-Glass Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Lift-Glass Gas Piston Replacement . . . . . . . . . . . . . . . . . . . . . . . 30

Color Band, Bumper and Bumper Retainer Replacement . . . . 31

Anti-Sweat Heater Wire Deflector Kit Replacement (TLD) . . . . 32

Parts Information

Operational Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Cladding and Trim Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

TYLER Warranty . . . . . . . . . . . . . . . . . (See General-UL/NSF I&S Manual)

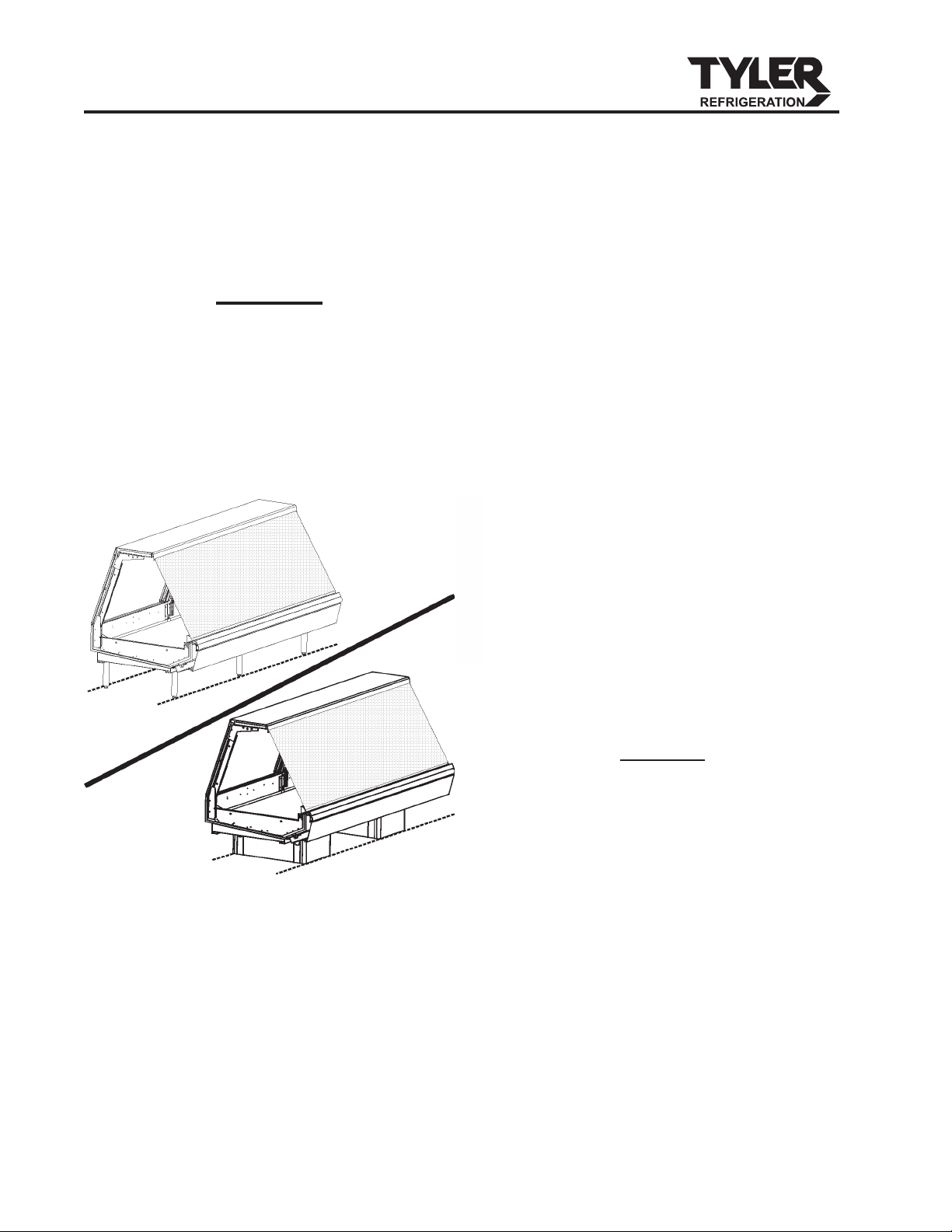

The following Medium Temperature Lift Front Straight Glass Meat/Seafood/Deli Service

Merchandiser models are covered in this manual:

MODEL DESCRIPTION

TLM 4’, 6’, 8’ & 12’ LIFT GLASS GRAVITY COIL MEAT SERVICE

MERCHANDISERS

TLF 4’, 6’, 8’ & 12’ LIFT GLASS GRAVITY COIL SEAFOOD SERVICE

MERCHANDISERS

TLD 4’, 6’, 8’ & 12’ LIFT GLASS FORCED AIR COIL DELI SERVICE

MERCHANDISERS

TLM, TLF, TLD

Page 4

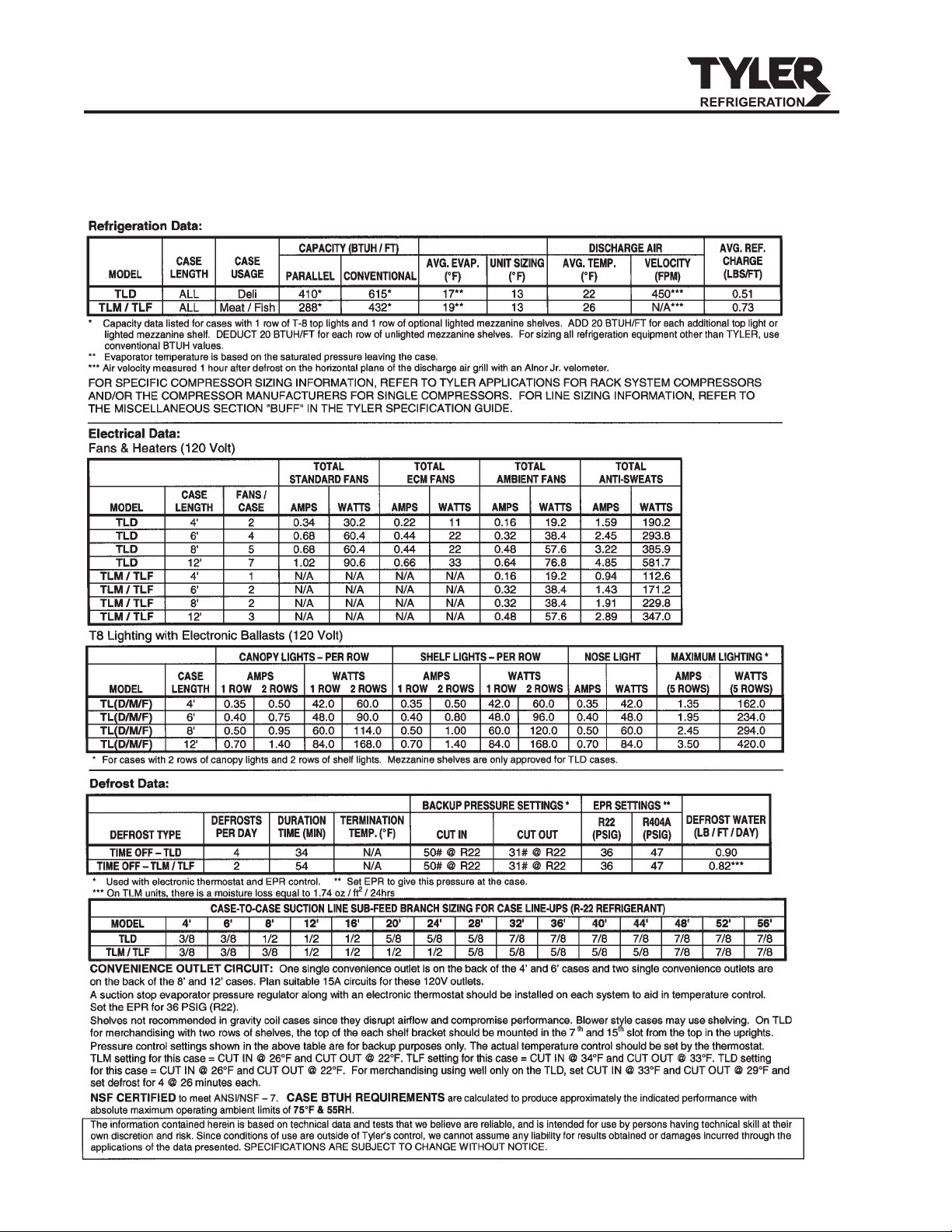

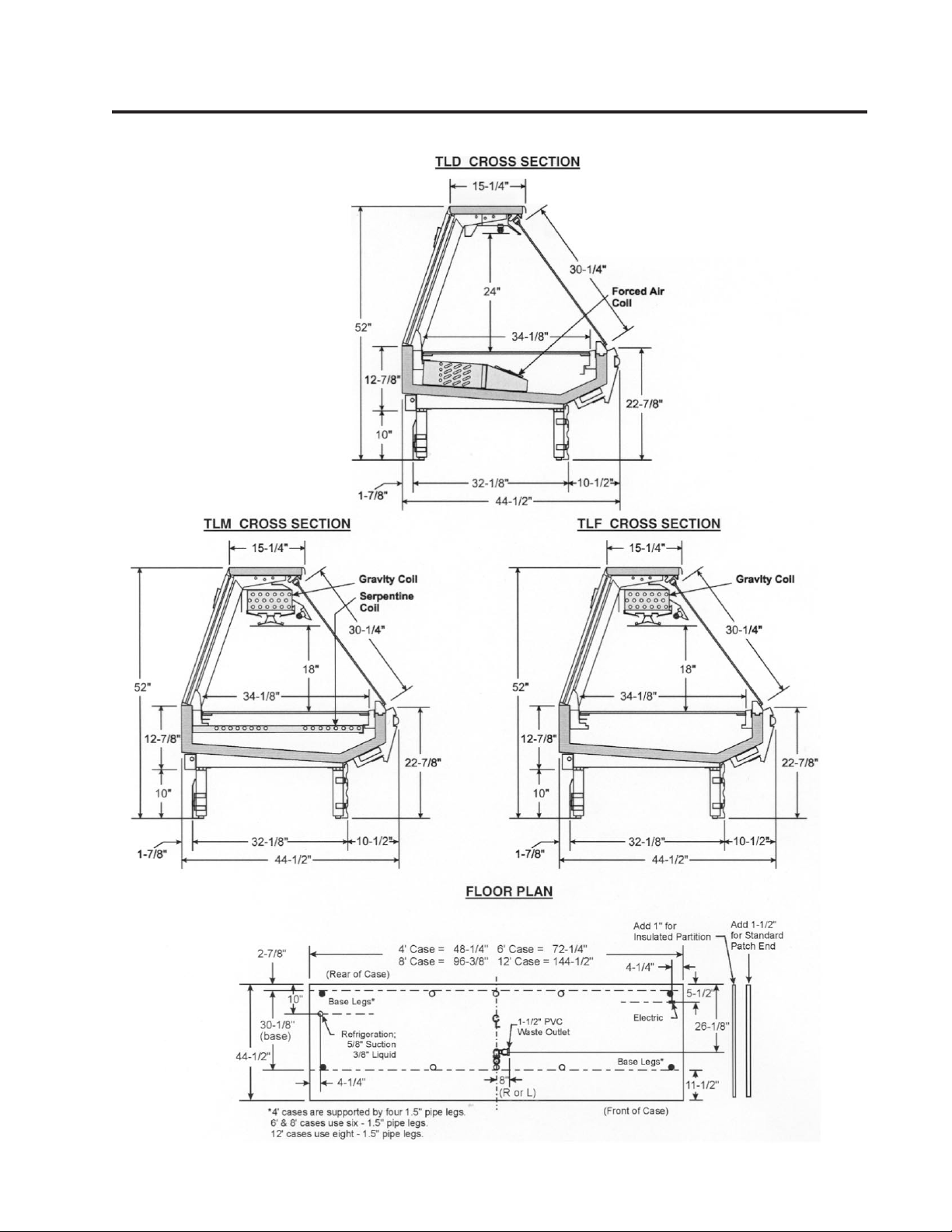

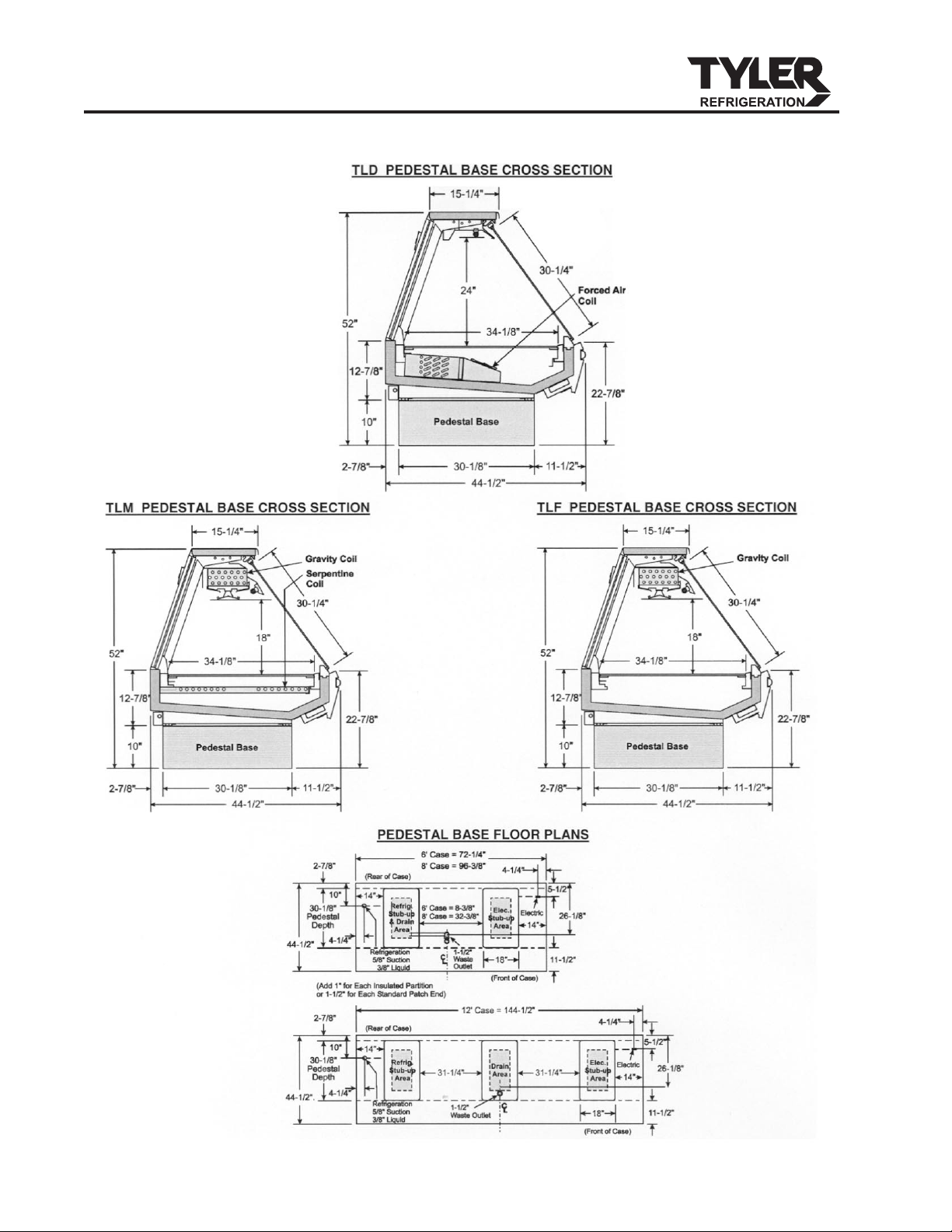

SPECIFICATIONS

TLD Lift Front Straight Glass Blower Service Merchandisers

TLM/TLF Lift Front Straight Glass Gravity Service Merchandisers

April, 2007

Installation & Service Manual TLM, TLF, TLD

Page 5April, 2007

TLM, TLF, TLD

Page 6 April, 2007

Installation & Service Manual TLM, TLF, TLD

Page 7

INSTALLATION PROCEDURES

WARNING

The raised front glass projects in front of

the case and could cause personal injury

to workers, operators and/or customers.

• Do not remove orange warning tags

from front edge of lift glass.

• Do not leave lift glass raised and

unattended.

• Know where the front edge of the

raised glass is when working near it.

This case is designed so the front glass can

be raised for cleaning and merchandising

only. It is recommended that any cleaning

or merchandising be done when the store is

closed. If this is not possible, it should be

done at a time when customer traffic is low.

The raised glass should not be left unattended

and should be lowered whenever leaving the

case.

The glass front is marked with orange warning

tags to make it noticeable when in the raised

position. Do not remove the orange tags.

Pre-Installation Check List

WARNING

These cases are very heavy and require

two or more people to unload, move,

position and/or install them. Improper

handling of these cases could result in

personal injury.

NOTE:

Cases with legs or pedestals are shipped

to stores on skids under the base frame.

Cases should be unloaded and moved by

one of the conventional methods

All cases containing glass MUST be stored

and installed on level surfaces to avoid

possible product damage and/or glass

breakage.

1. Check for hidden damage while

unloading and unpacking of the case.

2. Check the “shipped loose” parts for any

items; such as legs, pedestals, shelves,

nuts and bolts, caulking, access doors,

etc.

3. Check the equipment - remove the screws

used to hold down the deck pans during

shipping. Remove the pans and check

the following, if applicable:

4. Remove all packing material.

5. Check all flare nut connections for

tightness.

6. Check all fan bracket bolts for tightness.

7. Check all electrical plug-in connections

for positive seal.

8. Make sure the expansion valve feeler bulb

is securely attached to the suction line.

9. All field wiring and plumbing MUST

conform to national, state, and local

codes.

10. Do not remove plugs (from flare nuts) or

caps (from threaded connections) until

the unit is ready for final hook-up. All

coils are pressurized and have a Schrader

Valve access fitting. If pressure has been

lost, check for leaks.

September, 2004

TLM, TLF, TLD

Page 8

Carpentry Procedures

Case Line-Up

Before starting the case line-up, review the

store layout floorplans and survey the areas

where case line-ups are going to be installed.

WARNING

• These cases are very heavy and require

two or more people to move, position

and/or install them.

• Do not walk on the tops of these cases.

Tops of cases are not designed to

support the weight of a human being.

Improper handling of these cases could

result in personal injury.

1. Snap chalk lines where the front and rear of

the case legs or pedestals are to be located

for the entire line-up.

NOTE

Front and rear edges of legs or pedestals

should always be used to line-up cases.

Cases with legs have built-in leveling

adjustment capabilities. Cases with

pedestals use 6” shims to make leveling

adjustments.

2. Cases are shipped on skids. Using a

proper lifting devise, lift case off skid and

position case where it is to be installed.

While the case is properly supported,

install legs into threaded holes in base.

Make sure all legs are completely

threaded into the base to properly

secure them. Carefully lower case until

it is supported by the legs or pedestals.

Thread out bottom leg insert, up to 1 1/2”,

to level the case.

If case has pedestals, locate highest

point on chalk lines as a reference for

determining the number of shims to be

placed under case pedestals. Position

first case at the highest point on the

chalk lines and shim case pedestals as

required.

Check leveling across the top of the case

and on top of the front cladding.

CAUTION

If the base of this case is not sitting evenly

on the floor, the case could warp when

loaded and possibly break the lift glass.

NOTE

A foam gasket is factory installed on one

end of the case. This gasket fits into a

groove on the adjoining case when cases

are pulled together. Do not depend on the

foam gasket alone to make a good seal!

April, 2007

Installation & Service Manual TLM, TLF, TLD

Page 9

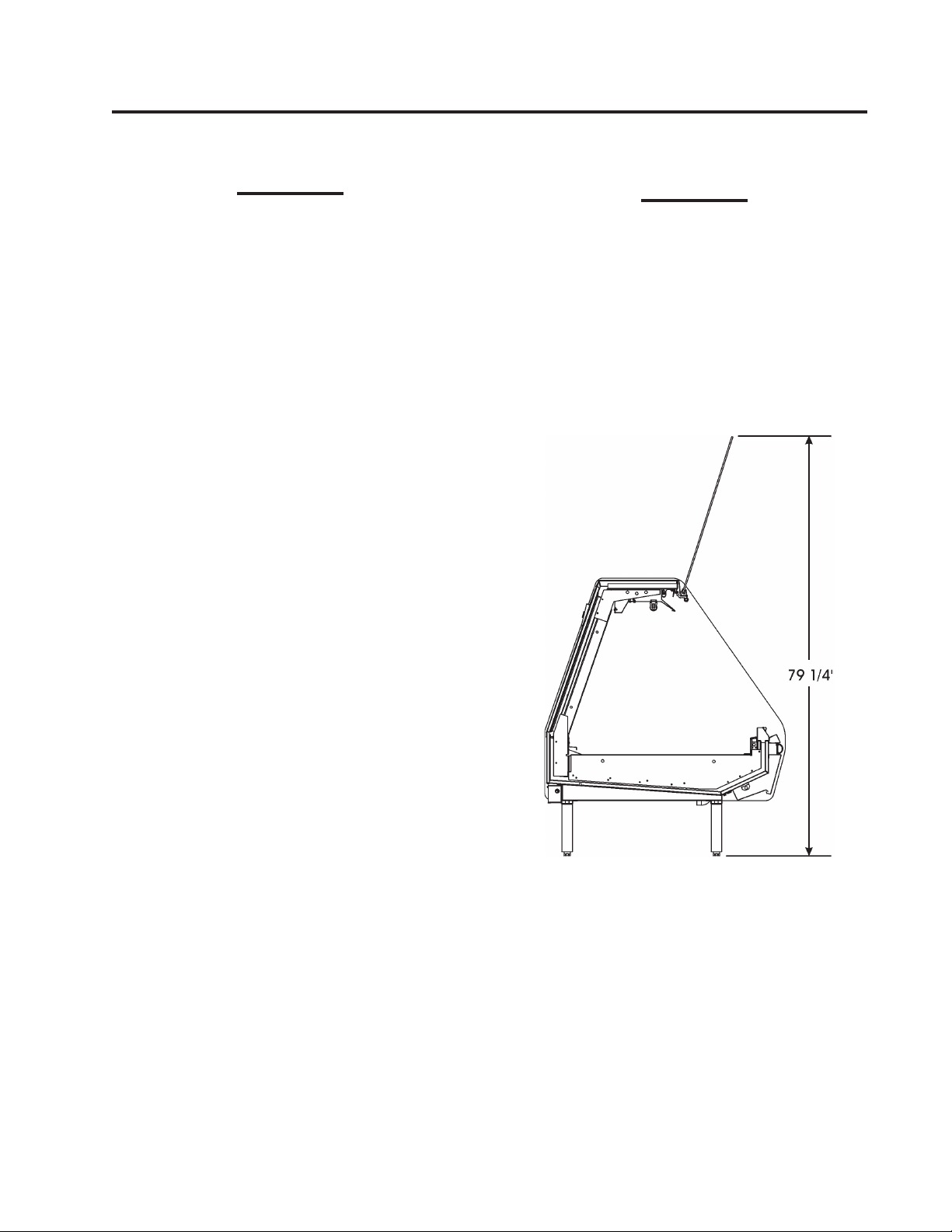

Lift Front Glass Leveling Instructions

Accurate leveling is critical for the proper

operation of the lift glass on this case.

In some instances, setting the case on an

apparently level floor can cause the lift glass

to fit improperly. If there is any twist in the

body, it could cause the lift glass not to fit

or work properly.

The emphasis when leveling this case must

be on making sure the lift glass works and

seals properly.

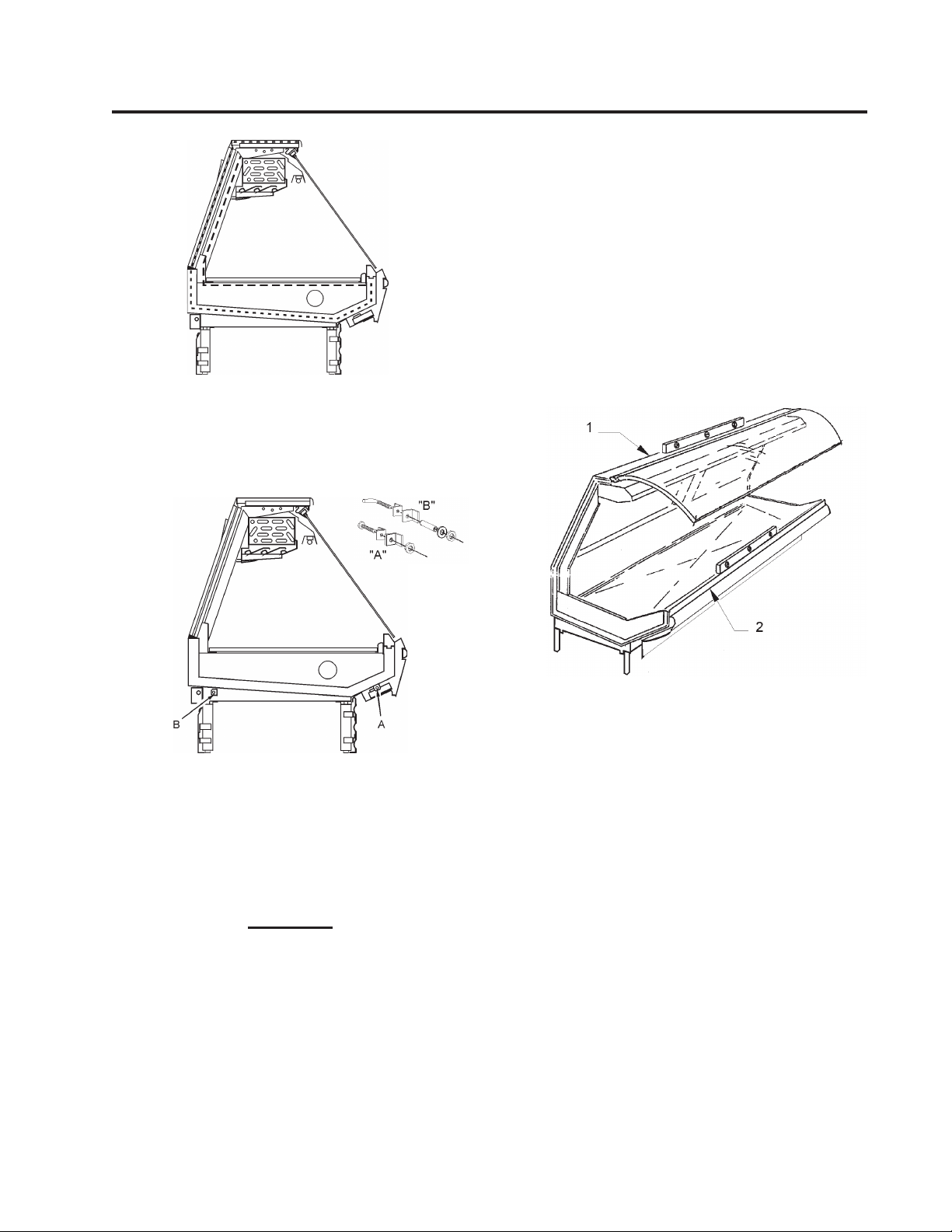

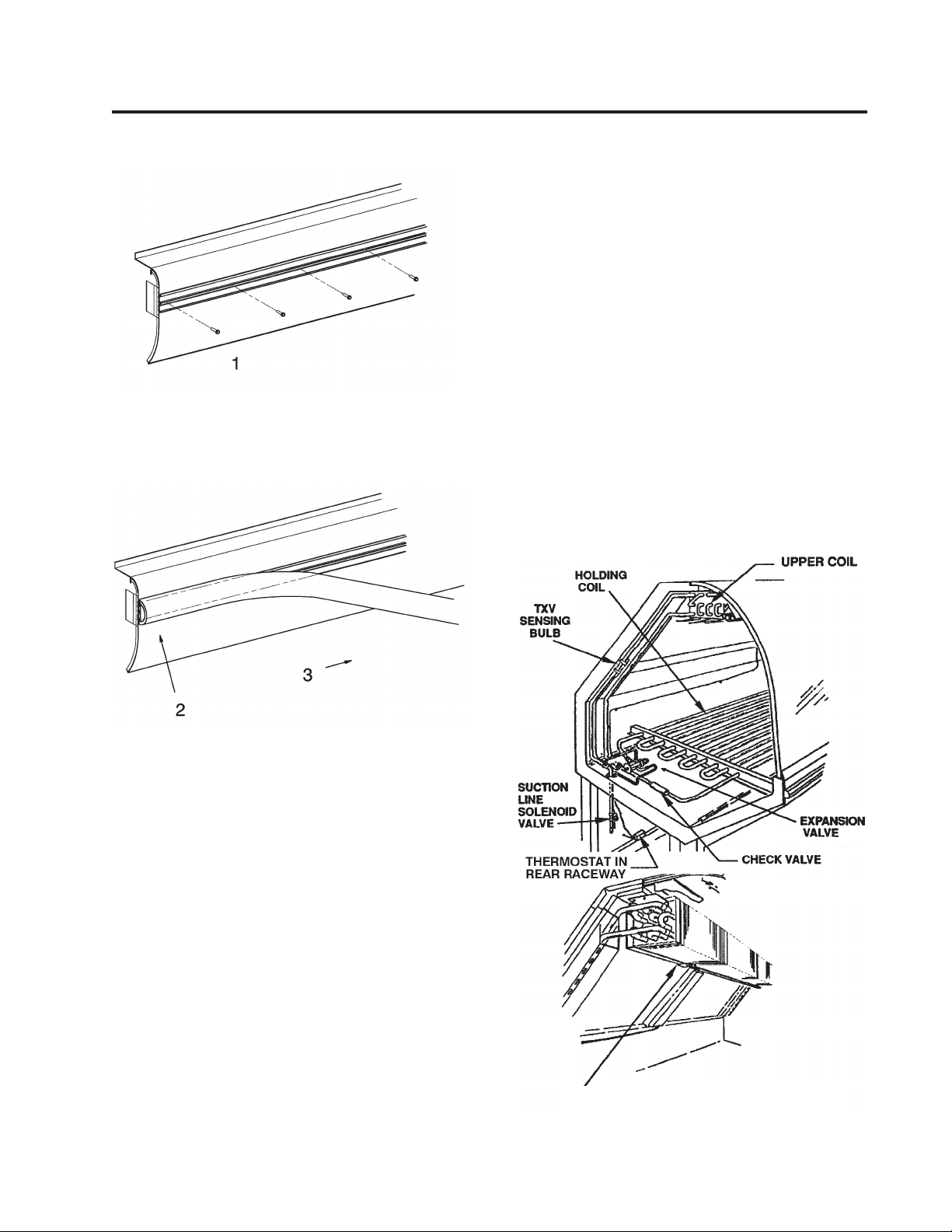

The case should be leveled across the top (1),

close to the hinge, and on the top of the front

cladding (2). A 4 foot level is recommended,

and both places should be level! This will

enable the lift glass to fit and work properly.

If the lift glass still doesn’t close or line-up

properly, adjust the legs at the case corners

or shimm the pedestals. Leg adjustment or

shimming will ensure proper operation and

alignment of the lift glass.

The handle on the lift glass must rest evenly

on the front cladding. Proper lift glass sealing

is essential for good product refrigeration.

NOTE

Do not anchor the base to the floor or

enclose the case until the lift glass is

fitting properly and working correctly.

3. Apply two heavy beads of caulking

compound from the Filler Kit to the end

of case at dotted (. . .) and dashed (- - -)

lines. Proper caulking provides good

case refrigeration and sanitation.

4. Push cases tightly together making sure

the pull-ups are aligned.

5. Adjust legs or add shims under the end

pedestals, as required. Check leveling at

top of the case and on top of the front

cladding.

CAUTION

Do not drill or use other holes through the

case end for pull-ups. This may deform

the case end and could cause joint leaks

and/or poor refrigeration.

6. Position pull-up bolts and mounting hardware at pull-up locations (A and B). Do

not tighten any pull-up hardware until all

of it has been installed. Tighten all pull-up

hardware equally starting at point A and

finishing at point B. Do not overtighten.

September, 2004

TLM, TLF, TLD

Page 10

Rear Rail Cover & Close-off Installation

(Cases with Pipe Legs)

Position rear rail cover (1) over rear raceway

opening and secure with screws in every

hole.

Bottom and End Close-off Installation

Kickplate, optional rear bottom and end

close-offs have spring clips on their back

sides that secure to the pipe legs.

NOTE

Optional rear bottom close-offs do not

require joint trim.

1. Before installing kickplates on a multiple

case lineup, snap a joint trim (2) over

the top and bottom of one of each

kickplate (3).

2. Lineup each kickplate (3) and/or optional

rear bottom close-off (4) and push to

secure the spring clips to the legs (5).

3. Slide joint rrims (2) over the case-to-case

joints.

4. Position end close-offs (6) over the end

of the kickplate (3) and/or optional rear

bottom close-off (4) and push until the

spring clips secure to the legs.

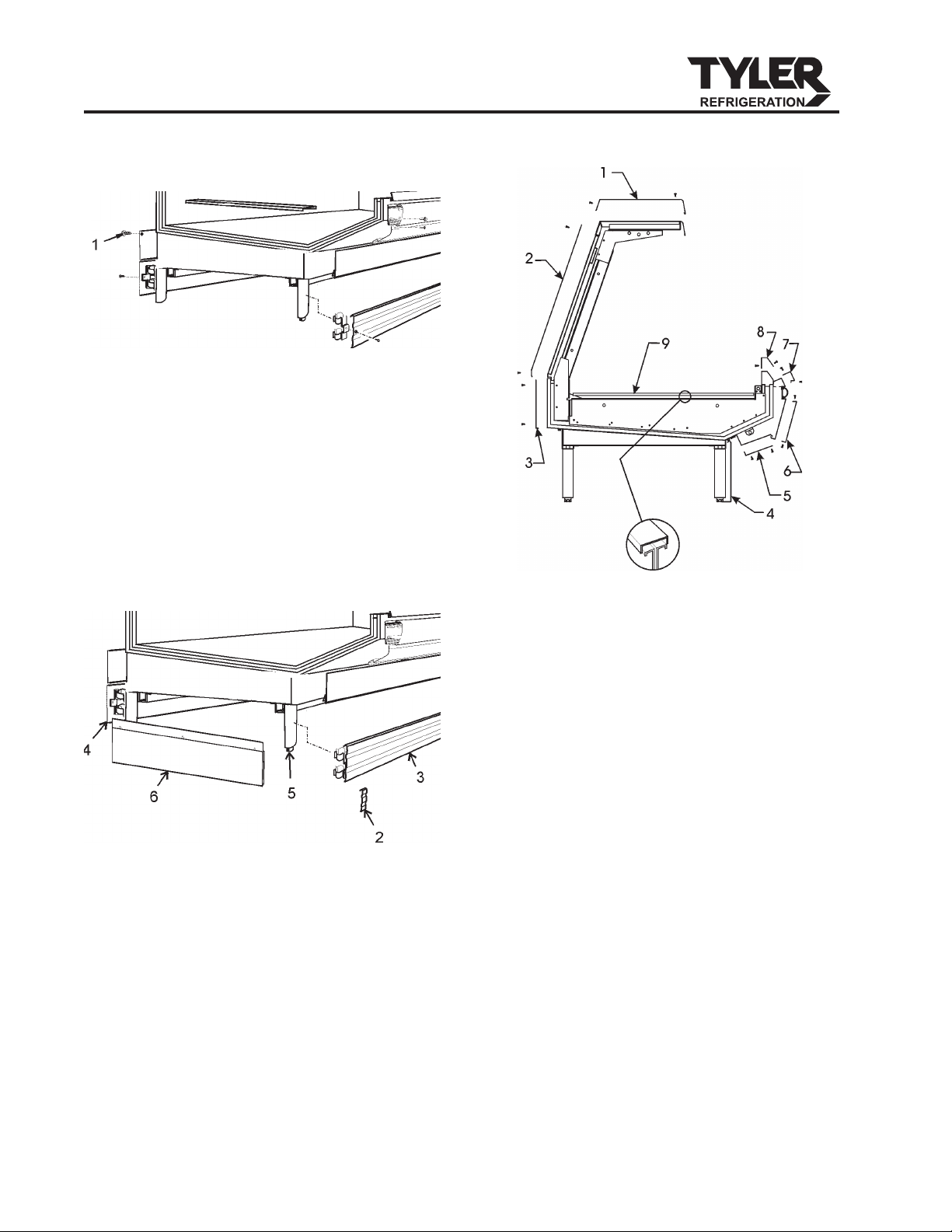

Trim Installation

The joint trim and mounting hardware are

shipped loose. Trim includes top joint trim

(1), rear upper joint trim (2), rear lower joint

trim (3), front kickplate joint trim (4), front

lower cladding joint trim (5) and front upper

cladding joint trim (6), color band backer (7),

glass stop joint trim (8) and horizontal joint

trim (9).

Horizontal joint trim covers gaps between the

cases. The trim is glued onto the shipping

cardboard. If trim has a notched side, apply

trim with notched side towards front of case,

after running beads of caulking on the edges

of the cases. Sheet metal screws can be

used for additional securing.

Patch end trim is shipped factory installed. If

field installation is required, be sure the patch

end is pulled up enough to fit snuggly against

the sealing tubing on the inside of the case.

The patch end must seal tightly against the

lift glass wiper to ensure proper operating

temperatures.

April, 2007

Installation & Service Manual TLM, TLF, TLD

Page 11

Optional 2” Bumper Installation

1. Install bumper retaining track on cladding

with screws, if required, using same

alignment as old bumper track.

2. Cut vinyl bumper slightly longer than

overall length of case line-up. Starting

at either end of the case, snap end of

bumper onto the bumper retainer track.

3. Curve the bumper back as illustrated.

This will open the bumper and allow it

to snap onto the retainer track. Working

in one direction, “roll” the bumper onto

the retainer track. Just before reaching

the opposite end, final cut the bumper

(approx. 1/8”) longer than the bumper

retainer. The additional 1/8” length will

allow for normal shrinkage from case

cooling.

NOTE

Bumper unevenness may be remedied by

striking with a mallet and straight board

along the length of the installation.

See “General (UL/NSF) I&S Manual” for

Plumbing Procedures.

Refrigeration Procedures

Refrigeration system and superheat

instructions can be found in the “General

(UL/NSF) I&S Manual”. Service case

temperature control information is listed

below.

Temperature Control

The temperature of each case is controlled

with a thermostat and suction line solenoid.

One thermostat and one solenoid are

required for up to three cases.

The TLM, TLF and TLD cases use an

electronic thermostat for improved

temperature control.

Typical Service Case with Gravity Coil

THERMOSTAT BULB MOUNTED

UNDERNEATH COIL

September, 2004

Loading...

Loading...