Installation && SService

Manual

NSSD

This manual has been designed to be used in conjunction with the General

(UL/NSF) Installation & Service Manual.

Save the Instructions in Both Manuals for Future Reference!!

This merchandiser conforms to the American National Standard Institute & NSF International Health and Sanitation standard ANSI/NSF 7 - 1999.

PRINTED IN Specifications subject to REPLACES ISSUE PART

IN U.S.A. change without notice. EDITION

3/02 DATE 10/02 NO. 9037171 REV. A

Tyler Refrigeration Corporation * Niles, Michigan 49120

THREE DECK MEAT/DELI/CRITICAL TEMP

PRODUCE MERCHANDISERS WITH CURVED FRONT GLASS

Medium Temperature Self Serve Display Cases

S P E C I A L T Y

P R O D U C T S

CONTENTS

NSSD Tyler Refrigeration

Page 2 March, 2002

Page

Specifications

NSSD Specification Sheets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Line Sizing Requirements . . . . . . (See General-UL/NSF I&S Manual)

Pre-Installation Responsibilities . . . . . (See General-UL/NSF I&S Manual)

Installation Procedures

Carpentry Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Case Pull-Up Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Plumbing Procedures . . . . . . . . (See General-UL/NSF I&S Manual)

Refrigeration Procedures . . . . . (See General-UL/NSF I&S Manual)

Electrical Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Electrical Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Defrost Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Defrost Control Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation Procedure Check Lists (See Gen.-UL/NSF I&S Manual)

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

NSSD Domestic & Export (50Hz) Case Circuits . . . . . . . . . . . . . 8

Cleaning and Sanitation

Component Removal and Installation Instructions for Cleaning 12

Shelves and Shelf Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Bottom Trays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Front Air Ducts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Rear Duct Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Discharge Air Honeycomb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Front Lower Cladding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Front Upper Cladding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installation & Service Manual NSSD

Page 3March, 2002

Page

General Information

NSF Product Thermometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Radiant Heat Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Radiant Heat Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Display Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Service Instructions

Preventive Maintenance . . . . . . (See General-UL/NSF I&S Manual)

Light Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Ballast and Lighting Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Ballast Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Defrost Heater Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Fan Blade and Motor Replacement (See Gen.-UL/NSF I&S Manual)

Color Band and Bumper Replacement (See Gen.-UL/NSF I&S Man.)

Anti-Sweat Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Top Light Channel Anti-Sweat Replacement . . . . . . . . . . . . . . . . . 16

Front Curved Plexiglas Replacement . . . . . . . . . . . . . . . . . . . . 16

Parts Information

Operational Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Cladding and Trim Parts Lists . . . . . . . . . . . . . . . . . . . . . . . . . . 18

TYLER Warranty . . . . . . . . . . . . . . . . . (See General-UL/NSF I&S Manual)

The following Medium Temperature, Top Display Meat, Deli and Critical Temp Produce

Merchandiser models are covered in this manual:

MODEL DESCRIPTION

NSSD 6’, 8’ & 12’ CURVED GLASS FRONT 3-DECK MEAT/DELI

MERCHANDISER

NSSD Tyler Refrigeration

Page 4 October, 2002

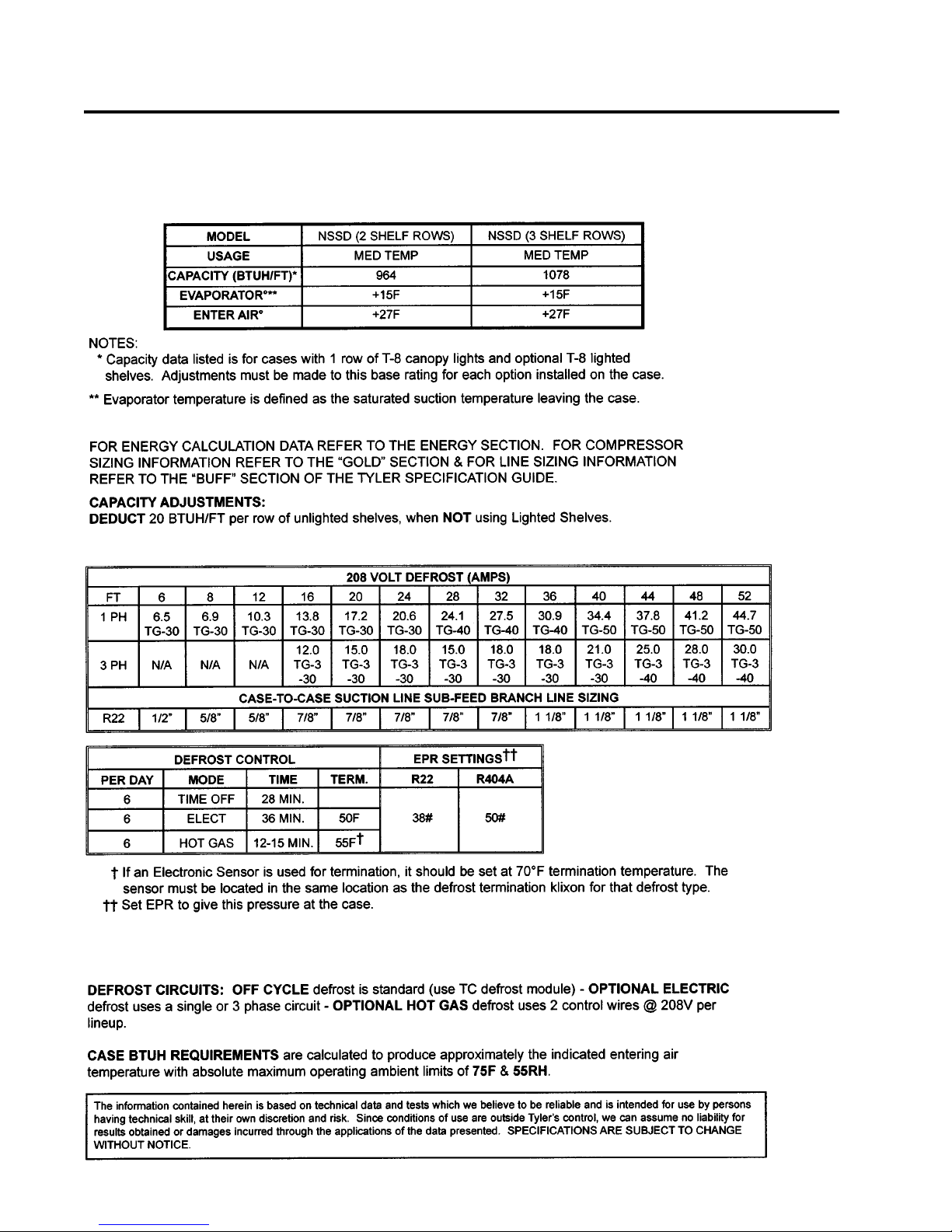

SPECIFICATIONS

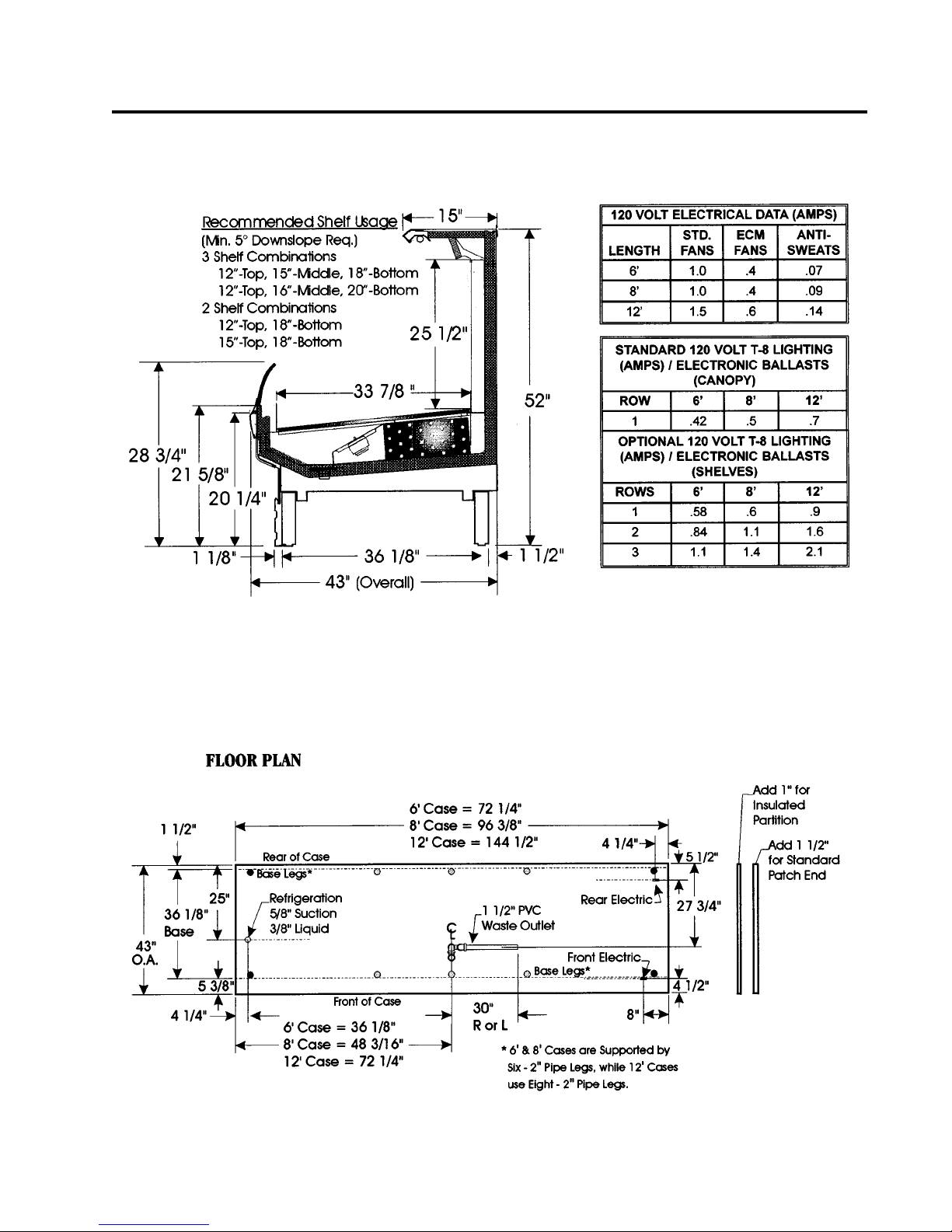

NSSD Three Deck Meat/Deli/Critical Temp Produce Merchandisers

Installation & Service Manual NSSD

Page 5

October, 2002

NSSD Three Deck Meat/Deli/Critical Temp Produce Merchandisers

NSSD Tyler Refrigeration

Page 6 March, 2002

INSTALLATION PROCEDURES

Carpentry Procedures

Case Line-Up

NOTE

The NSSD cases are shipped on casters that

are replaced with adjustable legs during

case line-up and installation.

See the “General-UL/NSF I&S Manual” for

the proper case line-up procedures.

Case Pull-Up Locations

All NSSD models have four pull-ups at each

end of the case. Pull-ups A, B, C and D are

located as shown and should be installed and

tightend starting with A and finishing with D.

See “General-UL/NSF I&S Manual” for lineup assembly instructions.

Electrical Procedures

Electrical Considerations

CA

UTION

Make sure all electrical connections at components and terminal blocks are tight. This

prevents burning of electrical terminals

and/or premature component failure.

NOTE

The NSSD has two raceway locations that

can house the electrical wiring, components

and terminal blocks. All components and

wiring can be located in either the lower

front or the lower rear of the case.

Case Fan Circuit

This circuit is to be supplied by an uninterrupted, protected 120V circuit. The case fan circuit

is not cycled, except when equipped for gas

defrost. On gas defrost cases the fan circuit is

controlled by a 50/40 klixon.

NOTE

With gas defrost, the fans will not start until

the coil temperature reaches 40°F at the fan

delay thermostat.

Fluorescent Lamp Circuit

Case lighting is supplied by T-8 electronic

ballast lights. It is controlled by a light switch

in each case. The standard lighting is 1-row of

T-8 canopy lights. NSSD models also offer up

to 3 rows of optional T-8 shelf lights.

Anti-Sweat Heater Circuit

NSSD cases have three anti-sweat heaters.

One in the top light assembly, one in the front

glass trim rail and one in the front glass retainer. All anti-sweat heaters are wired directly to

the main power supply so they can operate at

all times.

Installation & Service Manual NSSD

March, 2002 Page 7

Defrost Information

See “General-UL/NSF I&S Manual” for

operational descriptions for each type of

defrost control.

Defrost Control Chart

Defrost

Defrost Defrosts Duration Term.

T

ype Per Day (Min) Temp.

Off Time 6 28 ---Electric 6 36 50°F

Gas 6 12-15 55°F

E = Electric Defrost Termination

G = Gas Defrost (Fan Delay)

F/S = Electric Defrost Failsafe (Opt.)

NOTE

The termination klixon for gas defrost is

located at the bypass check valve at the

left end of the evaporator coil.

Most klixons are located on the right end of

the evaporator coil. The diagram shows the

location for each defrost type that uses a

klixon.

CAUTION

If electronic sensors are used in place of

the klixons, the sensors must be located in

the same location as the klixons for that

defrost type. Any other locations will

effect the refrigeration efficiency of the

case.

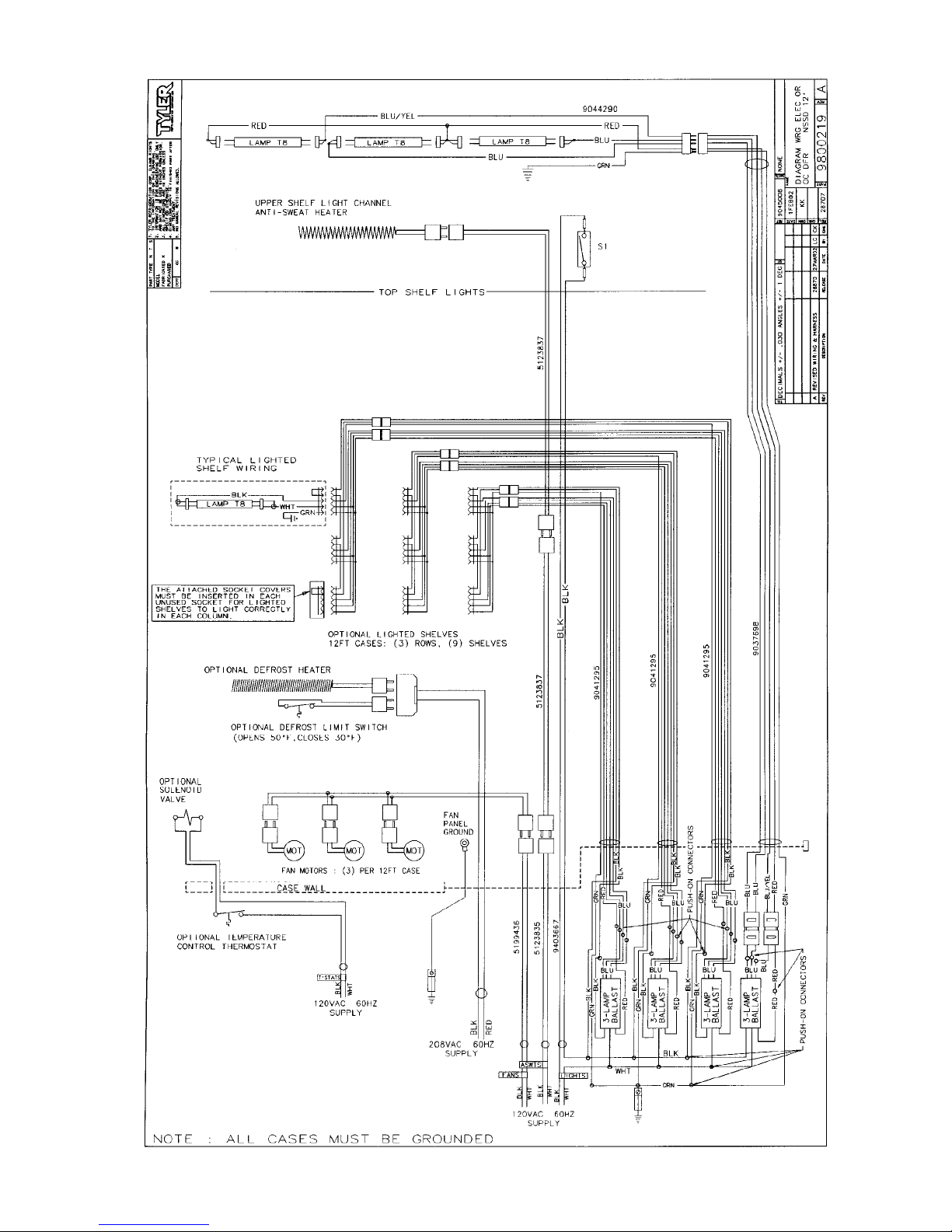

WIRING DIAGRAMS

ELECTRICIAN NOTE - OVERCURRENT

PROTECTION

120V circuits should be protected by 15 or 20 Amp

devices per the requirements noted on the cabinet

nameplate or the National Electrical Code, Canadian

Electrical Code - Part 1, Section 28. 208V defrost

circuits employ No. 12 AWG field wire leads for field

connections. On remote cases intended for end to

end line-ups, bonding for ground may rely upon the

pull-up bolts.

The following wiring diagrams on pages 8

thru 11 will cover the NSSD case circuits

including all defrost and lighting wiring

circuits.

Page 8 March, 2002

NSSD Domestic & Export (50Hz) Case Circuits (6’, 8’ & 12’ Cases)

March, 2002 Page 9

Page 10 March, 2002

March, 2002 Page 11

NSSD Tyler Refrigeration

Page 12 March, 2002

CLEANING AND SANITATION

Component Removal and

Installation Instructions for

Cleaning

Shelves and Shelf Brackets

1. Remove product from shelves.

2. If shelf has a light, unplug the light cord

from the socket in the rear duct panel.

Completely insert socket cover in the light

socket to protect the receptacle.

3. Push shelves back and then lift up and

out to remove them from the shelf

brackets.

4. Remove shelf brackets from slots in rear

uprights.

5. After cleaning, replace in reverse order.

Bottom Trays

1. Remove product from bottom of case.

2. Grasp and lift out each of the bottom

trays from the case interior.

3. After cleaning, replace in reverse order.

Front Air Ducts

1. Remove lower trays, see this page.

2. Lift out front air duct sections.

3. After cleaning, replace in reverse order.

Rear Duct Panels

(w/o Shelf Light Sockets)

1. Remove shelves and bottom trays, see

above.

2. Remove mounting screws and rear duct

panels from case.

3. After cleaning, replace and secure rear

duct panels in reverse order.

(with Shelf Light Sockets)

1. Remove shelves and bottom trays, see

above.

2. Remove mounting screws from rear duct

panel.

3. Slowly lift out rear duct panel until the

shelf harness connector near the top of

the panel can be accessed.

4. Disconnect shelf harness connector and

complete removing the rear duct panel.

WWAARRNNIINNGG

Rear duct panels with electrical receptacles can be cleaned without removing the

electrical receptacles. Do not get moisture

on electrical wires when cleaning under

this cover. Moisture on wires could cause

premature product failure and/or personal

injury or death from electrical shock.

5. After cleaning, reconnect the shelf harness connector and replace and secure

rear duct panels in reverse order.

Discharge Air Honeycomb

1. Loosen screws securing rear retainer

plate.

NOTE

Note position of the honeycomb grid during removal so it can be reinstalled the

same way.

2. Slide rear retainer plate back until the

honeycomb grid sections can be removed

from the top duct.

CAUTION

Improper installation of the honeycomb

grid section could result in improper air

flow and/or poor refrigeration.

3. After cleaning, replace honeycomb grid

sections as they were removed and

secure with the rear retainer plate and

screws.

Front Lower Cladding

1. Remove front kickplate.

2. Lift and pull out front lower cladding until

rear tabs clear holes in front of frame

assembly. After rear tabs are clear, pull

down on cladding to clear upper tabs

from slots in bottom of upper front

cladding and remove cladding from case.

Installation & Service Manual NSSD

March, 2002 Page 13

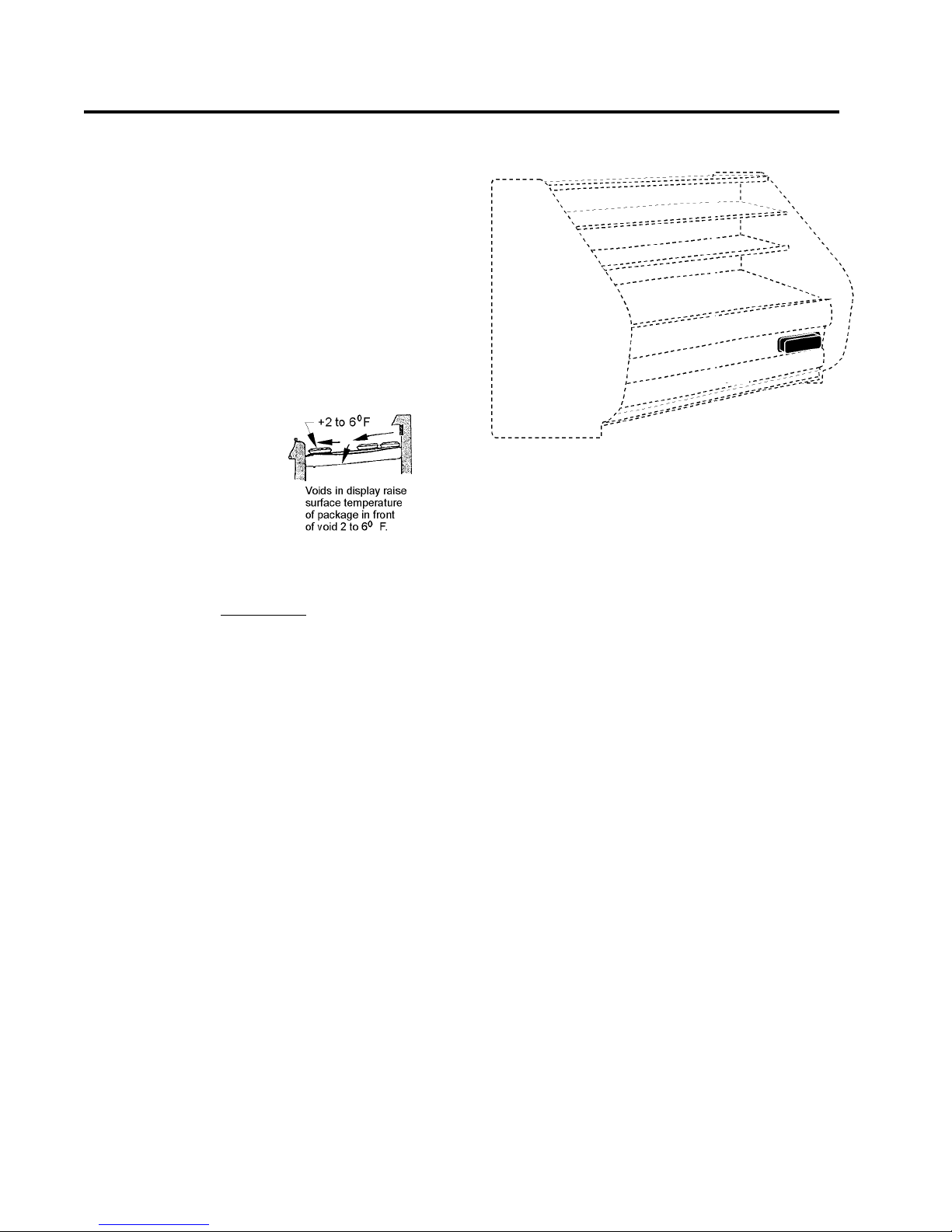

Radiant Heat Information

A wide temperature range is shown for each

type of lighting. This data does not show all

situations. Many situations will have higher

package warm-up figures than indicated.

It is generally known that the temperature of

displayed meat in refrigerated cases will run

higher than the circulated air temperature of

the cases. A dial thermometer stuck into the

center of a piece of meat compared with one

in the air stream quickly confirms this fact.

Another fact is that the surface temperature

of the meat will be higher than the center

temperature due to radiant heat. TYLER’s

ongoing research identifies sources of

radiant heat and accurately measures and

records it. These charts were developed

from the information gathered during this

research. Two major sources of radiant heat

are from display lights and ceiling surfaces.

Additional heat sources come from bad

display practices which either overload the

case with product or allow voids in the

product display. Poor display practices

impair the efficiency of the refrigeration,

adding to the surface temperature of the

meat. Bacteria and molds grow when surface

Front Upper Cladding

1. Remove plexiglas from plexiglas retainer.

Remove screws and plexiglas retainer from

top of bumper retainer

1. Remove color band, bumper and bumper

retainer from the case. (See GeneralUL/NSF I&S Manual.)

2. Remove front kickplate.

3. Remove screws and front lower cladding.

See page 12.

4. Remove screws from top and bottom of

upper cladding and remove front upper

cladding.

5. After cleaning, replace front upper

cladding and remaining front components

in the reverse order.

GENERAL INFORMATION

NSF Product Thermometer

Installation

1. Unwrap the thermometer and bracket

assembly shipped loose with the case.

2. Remove left front return air duct.

3. Position bracket 1” in from left edge and

just under the bottom return air duct holes.

4. Mount the bracket to the return air duct

with two self-tapping screws.

5. Replace the front return air duct.

NSSD Tyler Refrigeration

Page 14 March, 2002

temperatures rise above 45°F. This prematurely discolors displayed meats and causes

unnecessary meat department losses.

Radiant Heat Measurement

Place two accurate dial thermometers side by

side in a case. Cover one of the thermometer

stems with black friction tape. The temperature difference is the approximate amount of

radiant heat. A change in display lighting

or a reduction of high ceiling temperatures

(over 80°F) could reduce the radiant heat in

the case.

Display Practices

Encourage butchers

to maintain all meat

below the case load

lines and to eliminate

product voids. Case

screens could be covered in some instances

to keep the refrigerated air over the display.

CAUTION

The quality damage done to meat products

by high temperatures and/or contamination

during delivery, cooler storage, cutting and

wrapping cannot be repaired by placing

the products into properly operating display cases.

SERVICE INSTRUCTIONS

Light Servicing

See “General-UL/NSF I&S Manual” for T-8

lamp, fan blade and motor, and color band

and bumper replacement instructions.

Ballast and Lighting Locations

All NSSD light ballasts are located either in the

front raceway behind the lower front cladding,

or in the rear raceway behind the rear rail

cover. This includes remote ballasts for

optional shelf lights. The canopy light(s) are

under the canopy light channel in the top of

the case. The optional shelf lights are mounted in separate light fixtures under the front of

each shelf section.

In order to retain safety approval with

Underwriters Laboratory and the Canadian

Standards Association, the mounting of

electrical components and interconnecting

wires must not deviate from the following

instructions. Only qualified personnel are

authorized to install the accessory items.

TYLER Refrigeration recommends you order

all component parts from its Service Parts

Department.

Installation & Service Manual NSSD

March, 2002 Page 15

1. Remove bottom trays (1) from case (2).

2. Unclip and lift up fan plenum (3).

3. Disconnect and remove defrost heater (4)

from mounting clips (5) and case (2).

4. Install new defrost heater (4) in reverse

order.

5. Restore electrical power to case.

Rear Ballast Location Replacement

1. Remove screws (1) and rear rail cover (2)

from rear of case.

NOTE

If tappit screws are not available, a starwasher should be used between the ballast and the heads of the screws.

2. Install required number of ballasts (3) in

rear electrical raceway (4) with two

screws (5) each.

3. Identify and connect required wiring harnesses (upper, lower, etc...) to the ballast

connectors (6).

4. Replace rear rail cover (2) and secure

with screws (1).

Defrost Heater Replacement

WWAARRNNIINNGG

Always shut off electricity to case before

replacing a defrost heater. Automatic

cycling of fans or electrical power to wire

ends could cause personal injury and/or

death.

NSSD Tyler Refrigeration

Page 16 March, 2002

Anti-Sweat Replacement

WARNING

Shut off or disconnect power supply to

case before changing an anti-sweat.

Electrical power from wire ends could

damage other components and/or cause

personal injury or death.

Top Light Channel Anti-Sweat

Replacement

1. Remove screws (1) and lower the top

light channel assembly (2) from top of the

case (3).

2. Disconnect or cut the defective anti-sweat

wires (4) from the case wires.

3. Remove and replace the aluminum tape

(5) and defective anti-sweat wire (4) from

the back of the top light channel assembly (2).

4. Position new anti-sweat wire (4) in case )

and secure with new aluminum tape (5).

5. Reconnect the new anti-sweat wires (4) to

case wires and reinstall the top light

channel assembly (2) with screws (1).

6. Restore electrical power to the case.

Front Curved Plexiglas

Replacement

1. Remove two screw (1) and plexiglas joint

trim (2) from both joints of the damaged

plexiglas (3).

2. Remove damaged plexiglas (3) from plexiglas retainer (4).

3. Position new plexiglas (3) in plexiglas

retainer (4).

4. Install plexiglas joint trim (2) with screw

(1) over the joint areas of plexiglas (3).

Installation & Service Manual NSSD

March, 2002 Page 17

PARTS INFORMATION

Operational Parts List

Case Usage Domestic

Electrical Circuit 115 Volt 60 Hertz

Case Size 6’ 8’ 12’

Fan Motor 5243498 5243498 5243498

9 Watt 9 Watt 9 Watt

Fan Motor Brackets 5962268 5962268 5962268

Fan Bracket Plate 9041077 9041077 9041077

Fan Blades (7” 35° 5B) 9044934 9044934 9044934

Opt. ECM Fan Motor 9025002 9025002 9025002

8 Watt 8 Watt 8 Watt

Opt. ECM Fan Motor Brackets 9025005 9025005 9025005

Opt. ECM Fan Blades (7” 35° 5B) 9044934 9044934 9044934

T-8 Ballast (canopy & shelf)

(canopy / 1-row) 5991029 5991029 5991030

(opt. shelf / 2-row or 3-row) 5991030 5991030 5991030

T-8 Lampholder (canopy or shelf) 9041897 9041897 9041897

Anti-Sweat Heater Wire (top light) 9043426 9043427 9043428

Opt. Elec. Def. Heater 5125153 5124521 5124522

Opt. Elec. Def. Limit Klixon 5125211 5125211 5125211

Opt. Gas Def. Fan Delay Klixon 9023503 9023503 9023503

Opt. Gas Def. Term. Klixon 9023508 9023508 9023508

NSF Product Thermometer 5967100 5967100 5967100

For information on operational parts not listed above contact the TYLER Service Parts

Department.

NSSD Tyler Refrigeration

Page 18 March, 2002

Cladding and Trim Parts Lists

NSSD

Item Description 6’ 8’ 12’

1 Screw (per cover) 5100217 (2) 5100217 (2) 5100217 (2)

2 Joint Trim, Rear Riser 5932659 5932659 5932659

3 Plexiglas, Curved 9800193 9800194 9800193 (2)

RH Plexiglas Trim Assy. 9800225 9800225 9800225

LH Plexiglas Trim Assy. 9800226 9800226 9800226

CTR Plexiglas Trim Assy. ----- ----- 9800211

Plexglas Retainer 9800203 9800204 9800203 (2)

4 Plexiglas Joint Trim 9800211 9800211 9800211

5 Screw 5100217 (2) 5100217 (2) 5100217 (2)

6 Bumper Retainer ----------- color per order -----------7 Color Band, Ptd. 9023796 9023799 9023801

8 Color Band Backer, Ptd. 9040223 9040223 9040223

9 Bumper Backer ----------- color per order -----------10 Bumper End Trim ----------- color per order -----------11 Bumper ----------- color per order -----------12 Upper Front Cladding, Ptd. 9800000 9800003 9800006

Screw 5183536 (8) 5183536 (10) 5183536 (12)

13 Upr. Frt. Cladding Joint Trim 9800021 9800021 9800021

Screw 9024814 (2) 9024814 (2) 9024814 (2)

14 Shoulder Screw, Bumper Ret. 9025833 (12) 9025833 (16) 9025833 (24)

15 Lwr. Frt. Cladding, Ptd. 9800212 9045243 9037941

16 Lwr. Frt. Cladding Joint Trim 9800024 9800024 9800024

Screw 9024814 (2) 9024814 (2) 9024814 (2)

17 Frt. Kickplate Assembly 9024937 9024938 9024939

18 Kickplate Joint Trim 9043816 9043816 9043816

Screw 5619204 (4) 5619204 (4) 5619204 (4)

19 Pipe Leg (2” X 7.25”) 9045242 (6) 9045242 (6) 9045242 (8)

20 Horizontal End Trim 5964733 5964733 5964733

21 End Close-off, Ptd. 9037922 9037922 9037922

(per patch end)

22 Opt. Rear Base Close-off ----- 9037907 9037908

23 Rear Rail Cover, Ptd. 9024929 9024928 (2) 9024929 (2)

Screw 9043080 (16) 9043080 (24) 9043080 (32)

Installation & Service Manual NSSD

March, 2002 Page 19

Loading...

Loading...