Tykma Zetalase General Manual

L AS E R S F O R M A R K I N G

General Manual

L AS E R S F O R M A R K I N G

Copyright © 2013 TYKMA™ Inc. All rights reserved.

This document contents information covered by copyright.

Any information contained in this manual may be subject to change without prior

notice. All product or program names mentioned in this document are registered

trademarks owned by the respective companies. Windows™ and Windows™XP are

trademarks of the Microsoft Corporation. They are only used in this document for

editorial purposes.

All information and contents in this document are property of TYKMA Inc. and

cannot be shown, distributed, modified and/or reproduced through electronic,

mechanical or any other way, without written consent from TYKMA Inc.

Originally Published: January, 2013

TYKMA Technologies

P.O. Box 917

931 E Water Street

Chillicothe, OH 45601

Toll Free: 877-318-9562

Fax: 740-779-9910

www.permanentmarking.com

Zetalase™

General Manual SE 1

2

Contents

1)

Contents

2)

Technical Specifications

3)

Laser Safety

4)

Introduction

5)

Machine Overview

6)

System Setup

7)

Operator Pendant

8)

System Operation

9)

Maintenance

L AS E R S F O R M A R K I N G

Page

3

4

5

14

15

16

18

20

24

Zetalase™

General Manual SE 1

3

L AS E R S F O R M A R K I N G

Technical Specifications

Your Zetalase™ Laser Marking System is available in different laser models, options,

and accessories depending on marking application and customer specifications.

Please reference your Sales Order for system details.

Zetalase™ Laser Marking System

* Electrically powered Z-Axis for focal length adjustment

* Large Operator Sliding Part Loading Door

* Fully Opening Service Door for 180 degree work access

* Auto/Manual Mode for Part Marking Cycle Start

* T-Slotted 18" X 24" Aluminum Work Surface

* Full Size Viewing Window with Laser Safety Glass

* Front Panel Mounted Operator Control Panel with Safety Key

Lock/Shutter/Start/E-stop

* Operator HMI for Quick Program Select and Part Changeover

* 10" Touch Screen Integrated Monitor

* External Keyboard/Mouse/USB/Network/Monitor Ports

* Integrated Focus Finder

* Class 1 Safety Interlocking

* 100-240V one plug operation

* Laser programming software included

* Air-Cooling

* Max part height - 9.5" with FL160 (S) lens / 5.5" with FL254 (S) lens

* Dimensions 40"W x 26"D x 35"H

* Total System Weight - 306 Lbs.

--Laser Specifications:

* Laser Source - Solid State Fiber

* Wavelength 1060-1080nm

* Average Power 10, 20, or 30W(+/- 10%) Depending on Model

* Frequency Range 1-200K (10-20W), 1-1000K (30W)

* Red Pointing laser, wavelength 635 nm, Class 2M

* Focusing lense: FL 160mm (Optional FL100, 254S, and 254L)

* Marking field: 100 mm x 100 mm with FL160

Zetalase™

General Manual SE 1

4

Laser Safety

L AS E R S F O R M A R K I N G

The Zetalase™

accordance with EC directives, DIN EN 60825-1, ANSI Z136.1, and Complies with FDA Performance

Standards for Laser Products.

Class I laser systems are completely safe for operators to use under normal working conditions.

However, it may be possible during machine maintenance or physical modification to be exposed to

direct and/or scattered laser radiation. The following section describes laser basics and potential

safety hazards they may produce in these unlikely circumstances.

The word laser is an acronym for Light Amplification by Stimulated Emission of Radiation. In this

document, the word laser will be limited to electromagnetic radiation-emitting devices using light

amplification by stimulated emission of radiation at wavelengths from 180 nanometers to 1 millimeter.

The electromagnetic spectrum includes energy ranging from gamma rays to electricity. Figure 1

illustrates the total electromagnetic spectrum and wavelengths of the various regions.

is a Class 1 laser marking system designed, developed, and manufactured in

Figure 1. Electromagnetic Spectrum

The primary wavelengths for lasers include the ultraviolet, visible and infrared regions of the

spectrum. Ultraviolet radiation for lasers consists of wavelengths between 180 and 400 nanometers

(nm). The visible region consists of radiation with wavelengths between 400 and 700 nm. This is the

portion we call visible light. The infrared region of the spectrum consists of radiation with

wavelengths between 700 nm and 1 mm.

The color or wavelength of light being emitted depends on the type of lasing material being used.

For example, if a Neodymium:Yttrium Aluminum Garnet (Nd:YAG) crystal is used as the lasing

material, light with a wavelength of 1064 nm will be emitted. Table 1 illustrates various types of

material currently used for lasing and the wavelengths that are emitted by that type of laser. Note

that certain materials and gases are capable of emitting more than one wavelength. The wavelength

of the light emitted in this case is dependent on the optical configuration of the laser.

While not strictly adopted by OSHA, the ANSI standard, Z136.1-2000, “Safe Use of Lasers”, is

considered an appropriate guideline for ensuring a safe environment where lasers are present. The

ANSI standard requires that companies using Class IV lasers have a designated Laser Safety Officer

(LSO). The LSO is one who has authority to monitor and enforce the control of laser hazards.

Typically the Industrial Hygiene department or the company Safety Specialist oversees the

implementation of laser safety.

Zetalase™

General Manual SE 1

5

L AS E R S F O R M A R K I N G

Laser Safety

OSHA information concerning laser hazards can be assessed through the following link:

http://www.osha-slc.gov/dts/osta/otm/otm_iii_6.html

Common Laser Hazards

Other than the light that is emitted, lasers generate the same hazards as many other types of

equipment. Common hazards are high voltage, compressed gases and intense radio frequency

energy. The presence of these hazards depends upon the specific laser technology employed. For

example, pulsed CO2 lasers can generate internal voltages in excess of 25,000 volts and often

contain large capacitors capable of delivering over 200 Joules of energy. These lasers have

interlocked enclosures, which should not be defeated. When opening the enclosures of these lasers,

capacitive discharge procedures should be understood and strictly followed.

Pulsed lasers also typically use a flowing gas design, requiring connection to a cylinder of

compressed gas. While most laser gases are very safe, pressurized cylinders can be hazardous and

must be properly restrained during use and transportation.

Radio frequency energy can cause severe burns. Only trained personnel should service laser

equipment employing RF generators (like sealed CO2 lasers). Connections carrying RF energy

should never be touched during operation.

Often materials being marked give off fumes and gases. Sometimes these gases are noxious or even

toxic. Fumes from laser marking should be controlled with an adequate fume extraction system.

When in doubt, a chemical analysis of the fumes is suggested to determine if any fume hazards exist.

Light Hazards

Laser systems are typically designed to prevent a beam from directly contacting a person. Risks,

therefore, are more a result of unintentional reflected light. Reflected light falls into two categories,

diffuse and specular. Diffuse reflections result when reflective surface irregularities scatter light in all

directions. Diffuse reflections are typically much safer as the energy is split into many directions.

Specular reflections are mirror-like reflections and can reflect close to 100% of the incident light.

Because such a large percentage of the energy can be redirected, specular reflections are more

hazardous. Note that as the diameter of the laser beam increases, the ability to cause damage

decreases. Laser intensity is measured in power or energy over a measured area (W/cm2). While

focused laser beams produce a very small spot size (and very intense energy) at the mark point, they

are typically safer than unfocused beams because the laser beam size spreads out much more

rapidly as the distance from the mark point increases.

While specular reflections are more hazardous, they are much less common. Most laser marking

systems can be designed to eliminate specular reflective surfaces in the beam path.

Zetalase™

General Manual SE 1

6

L AS E R S F O R M A R K I N G

Laser Safety

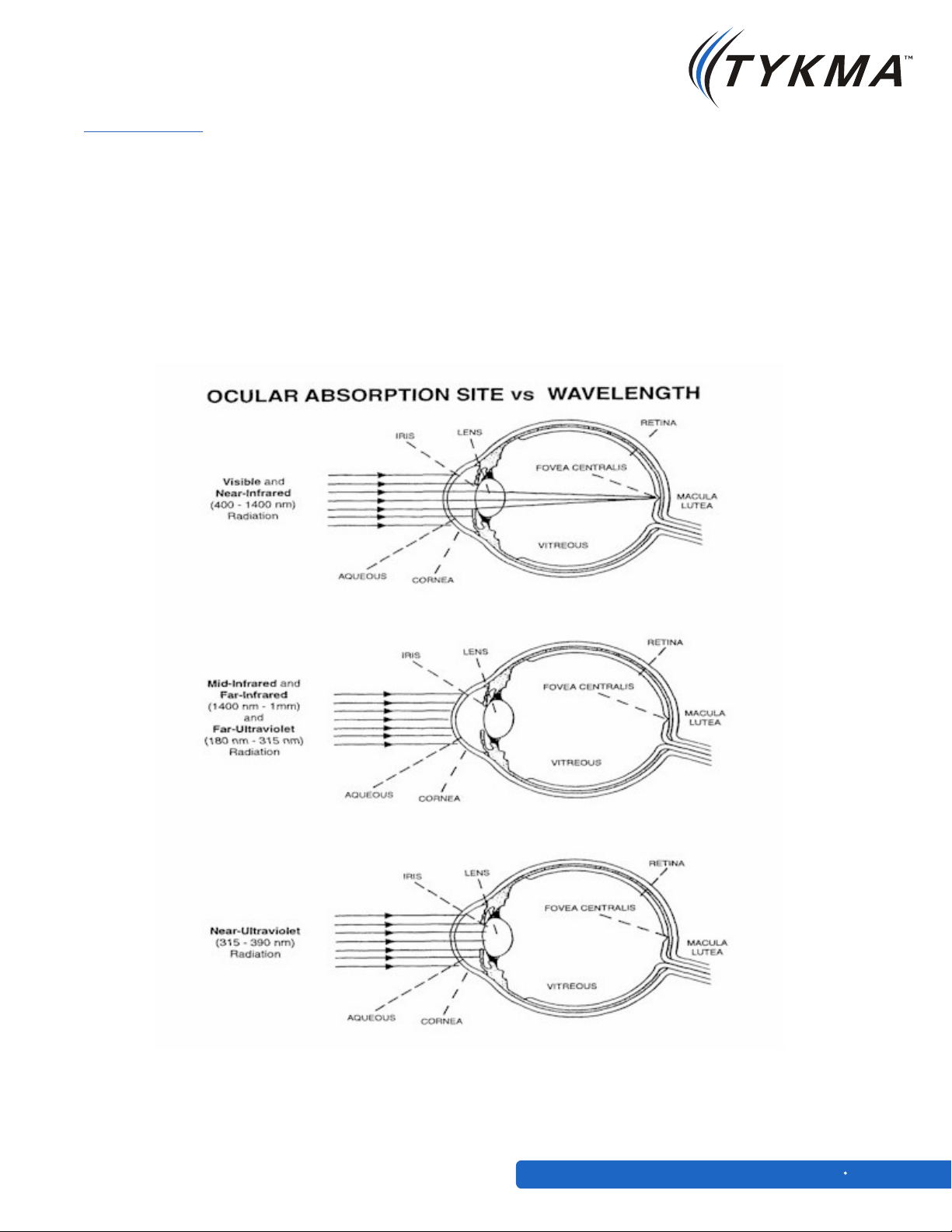

Laser Radiation Effects on the Eye - Visible Light and Infrared-A (400-1400 nm)

The marking laser most commonly used in this category is the Q-switched Nd:YAG laser, which

operates at a typical wavelength of 1,064 nm. Eye exposure to this laser beam is more hazardous

since at this wavelength the laser beam is transmitted through the eye and focused onto the retina.

Exposure may initially go undetected because the beam is invisible and the retina lacks pain sensory

nerves. Visual disorientation due to retinal damage may not be apparent to the operator until

considerable thermal absorption has occurred. Since the energy is concentrated by the eye's lens,

the strength of the laser beam that is required to damage the eye is significantly less. Figure 2.

shows various laser wavelengths and their effect on the eye.

Figure 2.

Zetalase™

General Manual SE 1

7

L AS E R S F O R M A R K I N G

Laser Safety

While specular reflections are more hazardous, they are much less common. Most laser marking

systems can be designed to eliminate specular reflective surfaces in the beam path.

Visible Light and Infrared-A (400-1400 nm)

The marking laser most commonly used in this category is the Q-switched Nd:YAG laser, which

operates at a typical wavelength of 1,064 nm. Eye exposure to this laser beam is more hazardous

since at this wavelength the laser beam is transmitted through the eye and focused onto the retina.

Exposure may initially go undetected because the beam is invisible and the retina lacks pain sensory

nerves. Visual disorientation due to retinal damage may not be apparent to the operator until

considerable thermal absorption has occurred. Since the energy is concentrated by the eye's lens,

the strength of the laser beam that is required to damage the eye is significantly less.

Laser Radiation Effects on Skin

Skin effects are generally considered of secondary importance with lasers used for most marking

applications. High power infrared lasers, like those used in cutting and welding applications, pose a

larger skin effect hazard. Lasers emitting radiation in the visible and infrared regions produce effects

that vary from mild reddening to blisters and charring. These conditions are usually repairable or

reversible. However, de-pigmentation, ulceration, scarring of the skin and damage to underlying

organs may occur from extremely high powered lasers.

Maximum Permissible Exposure (MPE)

The MPE is defined in ANSI Z-136.1-1993 as “The level of laser radiation to which a person may be

exposed without hazardous effect or adverse biological changes in the eye or skin.” The MPE is not

a distinct line between safe and hazardous exposures. Instead they are general maximum levels to

which various experts agree should be occupationally safe for repeated exposures. The biological

effects of laser radiation are dependent on the wavelength and exposure duration. The goal of any

control measures is to ensure that any laser radiation contacting a person is below the MPE.

Nominal Hazard Zone (NHZ)

In many marking applications, and most packaging applications, it is not practical to fully enclose the

area where the laser beam is delivered onto the product. In these instances, it is necessary to define

an area of potentially hazardous laser radiation. This area is called the Nominal Hazard Zone (NHZ).

The NHZ is the space within which the level of direct, scattered or reflected laser radiation exceeds

the MPE. The purpose of a NHZ is to define an area in which control measures are required. The

Laser Safety Officer should determine the NHZ and the control measures to protect the laser worker

from exposure to radiation above the MPE.

Zetalase™

General Manual SE 1

8

L AS E R S F O R M A R K I N G

Laser Safety

To quote the OSHA Technical Manual, Section III, Chapter 3: “This (NHZ), is an important factor since,

as the scope of laser uses has expanded, controlling lasers by total enclosure in a protective housing

or interlocked room is limiting and in many instances an expensive overreaction to the real hazards.”

Carefully designed guarding can eliminate any real light hazards associated with laser radiation

during equipment operation. This guarding can often be of very simple design. For example, the

infrared emissions from a CO2 laser can be blocked by clear polycarbonate (lexan) sheet. Often a

simple tunnel through which the product passes while being marked provides reliable, adequate

protection, preventing unsafe exposure from the direct beam or any diffuse reflections.

Control Measures

Certain control measures need to be in place wherever there are lasers in use. The extent of the

control measures is a function of the type of equipment installed, the nature of any shielding, and any

maintenance procedures that may be undertaken. These control measures include:

Engineering Controls

Engineering controls include proper shield interlock designs (when required), and safe system

operation controls, as in situations where the laser will be integrated into another control system.

Electrical Hazards

The use of lasers or laser systems can present an electric shock hazard. This may occur from contact

with exposed utility power utilization, device control, and power supply conductors operating at

potentials of 50 volts or more. These exposures can occur during laser set-up or installation,

maintenance and service, where equipment protective covers are often removed to allow access to

active components as required for those activities. The effect can range from a minor tingle to

serious personal injury or death. Protection against accidental contact with energized conductors by

means of a barrier system is the primary methodology to prevent electrical shock.

Additional electrical safety requirements are imposed upon laser devices, systems and those who

work with them by the federal Occupational Safety and Health Administration (OSHA), the National

Electric Code and related state and local regulations. Individuals who repair or maintain lasers may

require specialized electric safety-related work practices training.

Zetalase™

General Manual SE 1

9

Loading...

Loading...