Tyco Safety Canada 18PG9312 Users manual

PGx312

DRAFT SEP 11 (2)

PowerG 2-Way WirelessM agnetic Contact Device

with Hard-Wired Input Installation Instructions.

Introduction

The PGx312 is a two-way wireless PowerG magnetic

contact device. The device has thefollowing features:

l Weatherproof, water-resistant outdoor transceiver

l Flat and curvedsurface installation

l Battery pull tab for auto enrollment

l Functions at extreme temperatures (-40 °C to

66 °C / -40°F to 151 °F) and is IP66 certified

Note:ULtesting temperatures:-35°C to 66 °C

(-31 °F to 151 °F)

l Battery life of up to5years (wi th typical

commerical use)

l Integrated magnetic sensor

l Maximum magnetic gapof 44.5m m ( 1.75in.) on

woodand 31.8 mm (1.25i n.) on metal

l Magnetic sensor toggleif the auxiliary input only is

required

l Separate transmissions from sensor and auxiliary

input that trigger the same RF transmitter.

l Front and back tamper protection (back tamper not

available in USmarket)

l Automatic periodic supervision at r egular intervals

l PowerG two-way FHSS TDMA technology

l Anti-maskingprotection, based on panel software

version

l Auxiliary hard-wired input, programmable as

either normally open (N O), normally closed (NC),

end of line (EOL, or double end of li ne (DEOL) for

use with additional device. DEOLfunctionality is

based on panel version software.

l Supports temperature level reports according to

PowerG panel software version

l Paintable using non-metallic paint. Recommended

paints i nclude Krylon 'Fusion for Plastic', Rust-

Oleum ' Plastic', and D upli-Color 'Vinyl & Fabric

Coating'.

Enrolling th e PGx312

1. Enter into the installer menu andselect 02: ZONES

/ D EVICES.

2. Select ADD NEW DEVICES.

3. Beginthe auto-enrollment process by pulling the

tab, i nsertingthe batteries, or entering the device

ID.

4. Select the desiredzonenumber.

5. Configure the l ocation, zonetype, and chime parameters.

6. Configure the detector.

Note:

l If the magnetic contact device i s already enrolled,

configure the magnetic contact device parameters

usingthe M odify Devices option – see step 2.

l To configure thedeviceparameters, select the

Device Settings option andrefer to Configuring the

Device Parameters.

l To enroll the device, power on the device by pulling

thebattery tab or insert the batteries. Bothmethods

will activate the auto-enrollment process. Alternatively, enter the ID:107-XXXX ( the number of the

device printed on thelabel).

l If the device was not automatically enrolled, press

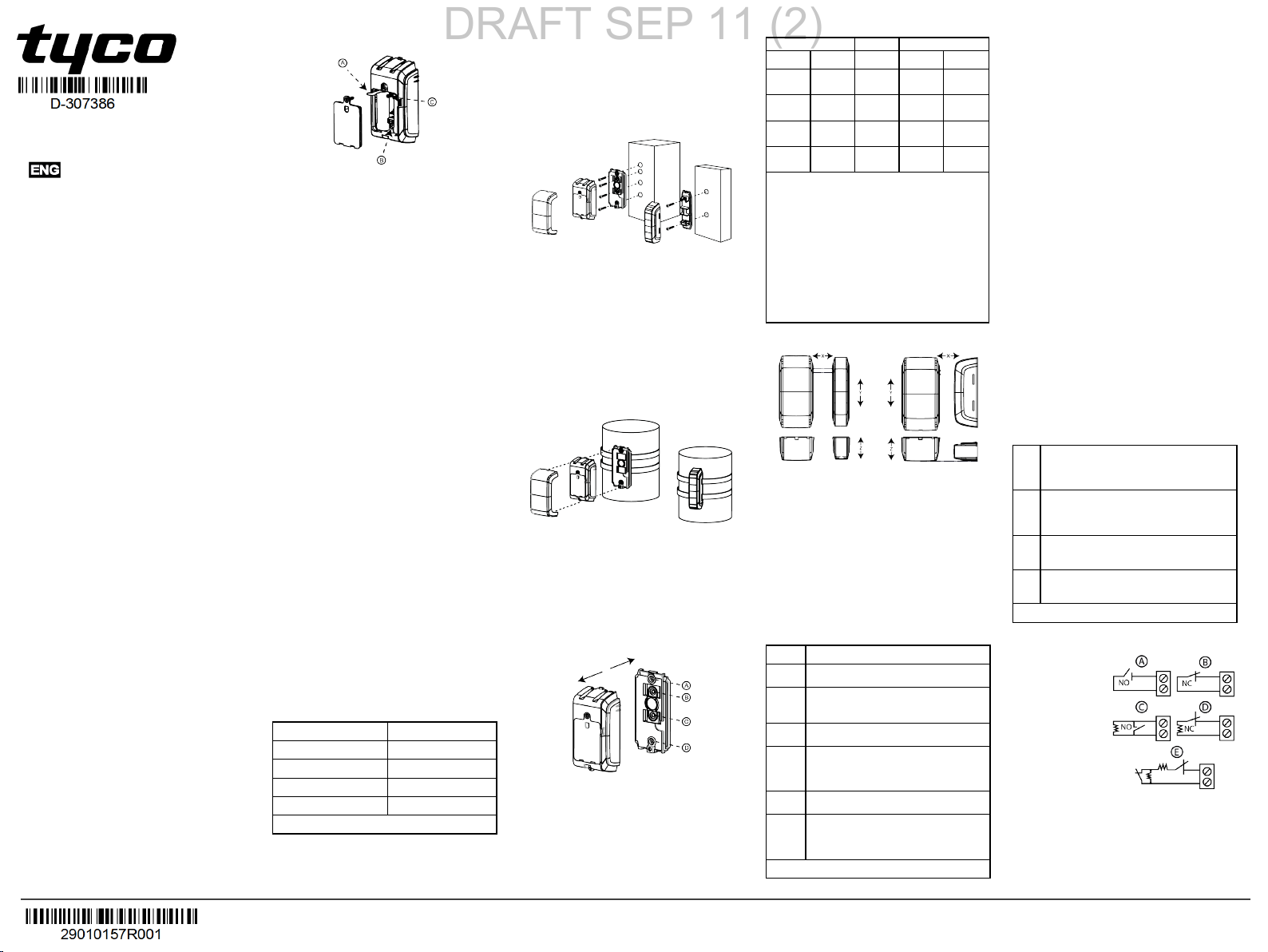

theenrollment button as seenin F igure 1 B.

A: Enrollmen t tab B: Enrollmen t bu tton

C: Tamp er switch

Figure 1 : Enrollment options

Installation

This equipment i s designedto be installed by qualified

service persons only. Place the device abovethe door

or window on the fixed frame and the magnet on the

movable part of the door or window. Do not place the

magnet more than44.5 mm (1.75 in) from the marked

side of the device.

To m onitor outdoor areas, you can m ount the PGx312

on a curved surface, such as a fencepole or si milar.

Note:

l Oncethe battery cover is removed, a tamper mes-

sage i s transmittedto the panel. Subsequent

removal of the battery prevents transmission of the

TAMPER R ESTORE alert, leaving the receiver in

permanent alert. To avoid this, press the tamper

switch w henyou remove the battery.

l It is recommended to wait about 1 minute after bat-

tery r emoval before insertingthe new batteries.

Caution! Risk of explosion if the battery is replacedby

an incorrect type. Dispose of theusedbattery according

to the manufacturer’s instructions.

Attention! Some m odels havea back tamper switch

behind the device. As longas the device is seatedfir mly

within the bracket, the switch lever will be pressed

against a special break-away bracket segment that is

loosely connected to thebracket. Be sure to fasten the

break-away segment to the wall. If the detector unit is

forcibly r emovedfrom thew all, this segment will break

away from the bracket, causing the tamper switch to

open.

Local diagnosticst est

A local diagnostic test establishes thesignal strength of

a device in its currentposition during the installation process. To perform this mandatory test, completethe following:

1. Separatethedecorative cover from thedevice and

unscrew the battery cover. See steps 1 to 3 of

Mounting the PGx312.

2. Press thetamper switch onceandr elease it.

3. Openthe door or window and verify thatdetection

is indicated by a r ed LED flash.

After two seconds, the LED flashes three times in

one of three colors to indicatethe si gnal strength.

LEDresponse Reception

Green LEDflas hes Strong

Yellow LED flas hes Good

Red LEDflas hes Poor

No fl ashes No c ommunication

Table 1: LEDreception response

Important! Reliable r eception must be assured. There-

fore, "poor" signal strength is not acceptable. If you

receive a "poor" signal from thedetector, relocateit and

re-test until a "good" or "strong" signal strength is

received( in regions requiring UL-compliant installation,

only “strong” signal strength is permitted).

Note:

l For UL, only strong signal strength is acceptable.

l For detailed diagnostics test instructions, refer to

thecontrol panel Installer Guide.

l After this step, r eattach the battery cover.

l The LED l ight is off in normal conditions.

Mount ing the PGx312

Figure 2 : Mounting on a fla t surfac e

1. Insert a flat-head screwdriver into the slot provided

and push upward to r emove the decorative cover.

2. Unscrew the lower screw from the device cover.

3. Separatethedevice from the bracket.

4. Mark and drill the requirednumber of holes in the

mounting surface.

5. Screw in the bracketwith four screws provided.

6. Reattach the device to the bracket.

7. Mount the magnet base with two supplied screws

to an adjacent surface and attach the magnet to the

magnet bracket.

Figure 3 : Mounting on a c urve d sur face with s traps

To m ount the device on a curved surface, use straps

(not included)as seen in Figure 3.

Note:

l Use holes A and D i n Figure 4 for standard m ount-

ing. Addholes B and C in Figure 4 for tamper protection.

l Align the device andmagnet accordingto the spe-

cifications in Range CoverageDirections.

A: Standa rd mo unting

C: Tamp er prote ction

Figure 4 : Dev ice and bra cke t s epar ation

B: Tamp er prote ction

D: Standa rd mo unting

Range coverage directions

Non-metallic surface Supports Metallic surface

Open Close Direction Open Close

71 mm

52 mm

(2.8 in.)

(2.0 in.)

40 mm

33 mm

(1.6 in.)

(1.3 in.)

22 mm

17 mm

(0.9 in.)

(0.7 in.)

85 mm

55 mm

(3.3 in.)

(2.2 in.)

Table 2 - Range coverage directions

Note:

l The values stated abovem ay vary by up to

10%.For steel installations, the gaps cannot be

less than 3.2 mm (0.1 in.).

l For roller shutter assembly, the magnet needs to

be mounted 25 mm to 35 mm ( 1.0 in. to 1.4 in.)

from the devices (on the X plane). For all other

installations, a m inimum gap of 5 mm (0.2 in.) i s

needed.

l When mounting on a slide door, refer to X. W hen

mounting on a roller shutter, refer to Y. W hen

mounting on a normal door, refer to Z.

Parallelm ag net Perpendicularm ag net

Figure 5 : Range cover age direc tions

Note:

l For UL commercial installations, the maximum

opening to activate i s 50.8m m (2 in.).

l Y ( up) r efers to theupper half of the Y plane. Y

(down) refers to thebottom half of the device on

theY plane.

l When mounting the magnet perpendicular to the

device, align themagnet with the face of the device

as seen in the perpendicular magnet im age.

Configuring the device parameters

Enter thecontrol panel D EVICE SETTINGS menu and

follow the configurationi nstructions for the PGx312 m agnetic contact device as describedin Table 3.

Option Configuration instructions

Magnetic

Determine whether to enable or dis able the

sensor

magnetic sens or.

Optional s ettings: Enable (default) or Dis-

X

Y (up)

Y(down)

Z

48 mm

(1.9 in.)

32 mm

(1.3 in.)

17 mm

(0.7 in.)

80 mm

(3.1 in.)

35 mm

(1.4 in.)

25 mm

(1.0 in.)

8 mm

(0.3 in.)

60 mm

(2.4 in.)

abled.

Define the external input acc ording to the

Input #1

installer's requirements.

Optional s ettings:Disabled (default), N O,

NC,EOL, or DEOL.

Note:DEOL s upport is dependent on panel

software versi on.

Anti-

Determine whether to enable or dis able the

mask

anti-masking.

Optional s ettings: D isabled (default) or

Enabled(default).

Note: This feature is dependent on panel soft-

ware version.

Table 3 - Magnetic device parameters

Wiring the auxiliary input

Note:

l For UL installations, the device connected to the i ni-

tiatingcircuit must be located in the same r oom as

thetr ansmitter.

l For UL installations, connect to U L listed res-

idential burglar alarm accessories only.

l For ULC installations, connect ULC listed products

only to theauxiliary wiring input.

l An alarm message transmits once the loop is

opened or short ci rcuited.

To connect this device wi th another nearby device by

auxiliary i nput, complete the following steps:

1. Remove the jacket at the endof the cable to

expose the wir es w ithin.

2. Perforate the sil icon gasketwith a 0.8 mm

(1/32i n.) pin.

3. Pass each wir e throughan entry hole and out the

oppositesi de.

4. Remove the insulationfrom theendof eachwire.

5. Connect each wir e to the relevantterminal, referencing Auxiliary Wi ring Options.

6. Screw the terminal closedusing a flat head screwdriver.

Note:

l Use a 22 AWG AUX cable (3.0mm, 0.12 in. j acket

diameter) for this installation.

l Use a cable shorter than 3 m (10 ft) for theAUX

connection.

l Seal the auxiliary wiri ng gasket w ith R TV Silicone

adhesive sealant.

Auxiliary wiring options

Youcan addm ore devices to the circuit of the PGx312

for NC, NO, EOL, or DEOL applications. Eachapplicationtype is as follows:

NC Excl usiv ely use series connected NC sensor con-

tacts i f the auxil iary i nput of the PGx312 i s

defined as a normally closed (NC)ty pe. An EOL

resistor is not required.

NO Exclus ivel y us e parallel c onnected NO sensor

contacts i f the auxi liary i nput of the PGx 312 is

defined as NO ty pe. An EOL resi stor is not

required.

EOL For EOL supervisi on, NCor NOsensor contacts

can be used. A 5.6k Ω EO L resistor must be wired

at the far end of the zone l oop.

DEOL For DEOL s upervision, onl y N.C. contacts should

be used. A 5.6kΩ EOL resistor must be wired at

the far end of the zone l oop.

Table 4:Auxiliary w iring options

Note:Figure 6 E illustrates a D EOL resistor setup that

is available dependent on panel software version.

A: N.O. switch

B: N.C. switch

C: EOL ; N .O. switch ;

use 5.6 kΩ resistor

D: EOL ; N .C. switch ;

use 5.6 kΩ resistor

E: DEOL ; N.C. swi tch

only ; use 5.6 kΩ

resistor

Figure 6 :Auxili ary wiring options

Calibrating the anti-mask

The anti-mask feature enables the detectionof attemptedsabotage, for example, sensor obstruction.

Note:

©2018 Tyco Security Products, Toronto, Canada www.dsc.com

Tech. Support: 1-800-387-3630

D-307386Rev.0 (09/18)

l This feature is dependenton panel software ver-

DRAFT SEP 11 (2)

sion.

l Begin the anti-mask calibrationprocess w henthe

device andm agnet are i n the final installation position. This must be the shortest distance between

them agnet and the device.

l For the proper operationof the AM function, align

them agnet with the sensor decorative cover during

calibration. See Figure 5 for parallel and perpendicular magnet i nstallation.

Pre-requisites:

l To r eceive an alert for m agnet interference, enable

theanti-masking configurationon the device settings menu.

l Completethe anti-masking learning process after

enrollment ( see Enrolling the PGx312) andwith the

device andm agnet in the final installationposition.

To enable the anti-mask feature, completethefollowing

steps:

1. Positionthedevice and magnet pointers to face

each other wi th referenceto RangeCoverage Dir-

ections.

2. Ensure thedeviceandm agnet are placed no more

than 5 mm apart on the Z plane. SeeR ange Cover-

age D irections.

Note: During the anti-mask learning process, the

sensor andthe m agnet must be stable for 10

seconds.

3. Press andhold the enroll button for 6-8 seconds to

start the anti-mask learning process.

Note: Do not r elease the enrollment button while

theyellow LED is l it. Releasethe button after the

green LED lights at 6 seconds andbefore 8

seconds.

If successful, the greenLED flashes three times. If

unsuccessful, the r ed LED flashes three times.

Note: If the door is open while the enroll buttoni s

pressed, the anti-mask l earning process is ignored.

Miscellaneous comments

DSC wir eless systems are very reliable and are tested

to high standards. However, due to low transmitting

power and limited range( requiredby FCC and other

regulatory authorities), there are some limitations to be

consideredas follows:

A. Receivers m ay be blocked by radio signals occurring on or near their operating frequencies, regardless of

thedigital codeused.

B. A receiver responds only to one transmitted signal at

a time.

C. Wir eless devices should be tested r egularly to

determine whether there are sources of interference and

to protectagainst faults.

Specifications

Frequency Band (MHz) :Europe and rest of world:

433-434, 868-869. USA:912-919

Maximum TxPower:

10dBm ( 10mW)@433MHz

14dBm ( 25mW) @868MHz

15dBm ( 30mW) @915MHz

Alarm input:One internal andoneauxiliary

Supervision:Signalling at 4-minute intervals

Tamper alert:Report whena tamper event occurs

Communication prot ocol:PowerG

Power supply: Tyce C

Battery type: 2 x 1.5 VAA Ul timate Lithium Energizer

battery only

Battery life expectancy: 5 years with typical commercial transmissions per day (not testedby UL)

Low battery t hreshold: 3.0 V

Battery supervision: Automatic transmission of bat-

tery conditiondata as part of the periodic status r eport

and i mmediately upon low battery detection.

Operating Temperature:-40 °C to 66 °C (-40°F to

151 °F)

Note:UL testingtemperatures: - 35 °C to 66 °C

(-31 °F to 151 °F)

Relative Humidity (R H): Average relative humidity of

approximately 75% non-condensing. For 30 days per

year relativehumidity may vary between 85% and 95%

noncondensing.

Note:For UL installations, relative humidity is 93%.

Dimensions ( LxWxD): 105m m x 52 mm x 35 mm

(4.1 in. x 2.0 in. x 1.4in.)

Device weight (including battery): 154 g ( 5.4 oz)

Color: Dark grey

UL/ULC n otes

TheP G9312 has been listedby UL for co mmercial and r esidentialburglar y applicationsand by ULC forr esidentialbur glary applications in acc ordanc e withthe

requirements inthe S tandardsUL 634 an d ULC/ORDC634 for Door and Window

Contact.For UL/ULC installationsus e thisd evice only in conjunction withc ompatibleDS C wireless receiv ers: HSM2HOST9, HS 2LCDRF(P )9,H S2ICNRF(P )

9,P G9920,WS 900-19, and WS900 -29.

Europe: CE /EN (E N50131-2- 6 GRADE 2, CLAS S IV,

EN50131- 6 Type C) listedP G8312:868 MHz PG4312: 433

MHz.Accor ding toE N 50131-1, this equipmentcan be applied in

installedsy stems up toan d including Sec urity Grade 2, Envir onmentalClass IV. UK :The P G8312 is suitable for use in sy stemsinstalled toc onformto PD6662 atGrade 2 and

environmentalclas s IV B S8243.

SIMPLIFIED EU DECLARATION OF CONFORMITY

Hereby, Tyco Safety Produc ts Canada Ltd declares thatthe radio equipmenttype

is in compliance withD irective 2014/53/E U.The full textof theE U declar ationof

conformity is av ailablea tthe followinginternetaddr ess: www .dsc.com

PG4312: http://dsc.com/pdf/1808001

PG8312: http://dsc.com/pdf/1808002

Frequency Bands Maximum Power

868.0MHz - 868.6 MHz 14dBm (25mW)

868.7MHz - 869.2MHz 14dBm (25mW)

433.22MHz - 434.64MHz 10dBm (10mW)

European single pointof contact:Tyc o Safety Pr oducts, Voltaweg 20,6101 XK

Echt,N etherlands.

FCC C OMPLIANCE STATEMENT

WARNING!Changes or modifications to thisunit note xpres sly appr oved by the

party respo nsible for compliance could vo idthe us er’s authority tooper atethe

equipment.

This device has been tested and found toc omplyw iththe limits for a Class B digital

device, pursua ntto Par t15 of the FCC Rules. These limits are d esigned to provide

reasonable pr otectionagainst harmfulinterference in res identialinstallations. This

equipmentgenerates use s and c an radiate radio frequency energy an d,if not

installedand us ed in acc ordance w iththe instructions,may c ause har mfulinterference tor adio and television rec eption.

However ,there is no guarantee thatinterference willnot occ ur in a par ticular installation.Ifthisdev ice does cause such interference,which c an be v erifiedby turning

thedev ice offand on, the user is encouraged toeliminatethe interference by one

or more ofthe followingmeasur es:

– Re-orient or re -locate ther eceiving antenna.

– Increase the distance between the devic e and the receiver .

– Connect the device to an outleton a c ircuit different fromthe one thatsupplies

power to ther eceiver .

– Consult thedealer or an ex perienced r adio/TVtechnician.

FCC ID:F5318PG9312

Innovation Scienc e and Economic Dev elopment Ca nada

(ISED) Statement

This equipmentcomplies withFCC a nd ISED C anada RF radiation exposur e limits

set forthfor an uncontrolled enviro nment.

This device c ompliesw ithFCC Rules Part 15 and w ithISED Canada licenc eexemptRSS standard(s ). Operationis subject tothe followingtwo c onditions:

(1) This dev ice may not cause harmfulinterference,and ( 2) this devic e must

accept any interferencethat may be receiv ed or thatmay c ause undes ired operation.

Le present appareil es tc onformeaux CNR d'ISE D Canada app licables aux

appareils radio ex emptsde licenc e.L 'exploitation est autorisee aux deu x conditionss uivantes :(1) l'appareil ne doit pas produire de brouillage,et (2) l'utilisateur

de l'appareil doitacc epter toutbrouillage radioelectrique sub i,memesi le br ouillage est susc eptibled'en c ompromettre lefonctionnement.

W arrant y

(a) NO WA RRA NTY - D SC P ROVIDES THE SOFTWARE “AS IS” WITHOUT

WARRA NTY. DSC DOES NOT WARRA NT THAT THE SOFTWAREWILL

MEET YOUR REQUIREMEN TS OR THAT OP ERA TIONOF THE

SOFTWAREWILL B E UNINTER RUPTE D OR ER ROR-FREE .

(b) CHA NGES IN OPE RATING ENV IRONMENT- DSC shall notb e respons ible

forpr oblems caused by cha nges in the operating charac teristics ofthe

HARD WARE ,or forpr oblems in theinteraction ofthe SOFTWARE PR ODUCT

withnon-D SC- SOFTWARE or HA RDWAR E P RODUCTS.

(c) L IMITATION OFL IABILITY;WARR ANTY REFLEC TS ALL OCATIONOF

RISK - INA NY EV ENT, IFANY S TATUTE IMPLIES WA RRAN TIES OR

CONDITIONS NOT S TATED IN THIS LICENS E A GREE MENT,D SC’S ENTIRE

LIABILITYU NDER ANY PROV ISIONOF THIS LICENS E A GREE MENT

SHA LL BE LIMITED TO THE GRE ATER OFTHE AMOUNT ACTUA LLY PA ID

BY YOU TO LICENS E THE SOFTWARE PRODU CT AND FIVE CAN ADIAN

DOLLARS (CA D$5.00).B EC AUS E S OME JURISD ICTIONS DO NOT A LLOW

THE E XCLUS IONOR LIMITATION OF LIABILITYFOR CONS EQUE NTIAL OR

INCIDENTAL DA MAGES, THE AB OVE L IMITATION MAY N OTA PP LY TO

YOU.

(d) DISCLA IMER OFWA RRA NTIES - THISWA RRA NTY CONTA INS THE

ENTIRE WA RRAN TY AN D SH ALL B E IN LIEU OF AN Y A ND A LL OTHER

WARRA NTIES, WHETHE R E XP RES SE D OR IMPLIED (INCLUDING ALL

IMPLIED WA RRA NTIES OF MERCHA NTAB ILITY OR FITNESS FOR A

PA RTICULAR P URPOS E) AND OF A LL OTHER OB LIGATIONS OR

LIABILITIES ON THE P ART OF DSC .DS C MAK ES NO OTHER

WARRA NTIES. DSC NEITHER A SS UMES NOR AU THORIZES ANY OTHER

PE RSON P URP ORTINGTO ACT ON ITS BE HA LF TOMODIFY OR TO

CHAN GE THIS WAR RANTY ,NOR TO A SS UME FOR ITA NY OTHE R

WARRA NTY OR LIAB ILITYCONC ERNING THIS SOFTWARE PR ODUCT.

(e) E XCLU SIVE REMEDY AN D LIMITATIONOF WARR ANTY - UNDE R NO

CIRCUMSTANCE S S HAL L DSC BE LIABLE FOR ANY SP ECIAL,

INCIDENTAL,C ONSE QUENTIAL OR INDIRECT DA MAGES BA SE D UP ON

BRE ACH OFWA RRA NTY, BRE ACH OFCONTRA CT,NE GLIGENCE,

STRICTLIAB ILITY,OR ANY OTHER LEGAL THEORY. SU CH DA MAGES

INCLUDE, BUT A RE NOTLIMITEDTO,L OSS OF P ROFITS, LOSS OFTHE

SOFTWARE PRODUC TOR A NY AS SOCIATED EQUIPMENT, COST OF

CAP ITAL,COST OF SU BS TITUTE OR RE PLA CE MENT EQUIPMENT,

FACILITIES OR S ER VICES ,DOWN TIME,P URCH AS ERS TIME,THE

CLAIMS OFTHIRD P ARTIES ,INCLUDING CUS TOMERS, AND INJURY TO

PROP ERTY. WAR NING:

DSC r ecommends thatthe entires ystem be completelytested on a regu lar basis.

However ,des pitefrequent testing,and due to,but notlimitedto,cr iminaltampering

or electrical disrup tion,itis pos sible for thisS OFTWARE P RODUCT to failto performas ex pected.The term ICbe forethe radio c ertification number signifiesthat the

Industry Canada technical s pecificationsw ere met.This Class B digitalappara tus

complies withCanadian ICE S-003. This dev ice complies with RSS -247 of

Industry Canada. Operationis subject tothe followingtwo co nditions:(1) this

device may not caus e interference,and (2) this devic e mustac cept any interference,inc ludinginterference that may cause u ndesired oper ationof thedev ice.

Cetappar eilnu mériquede lac lasse B es tco nformeà la norme NMB- 003 du

Canada.C e dispositifsatisfaitaux exigences d’IndustrieCanad a,pres crites dans

ledo cumentCNR -247. son utilisationest autorisée seu lementaux con ditions

suivantes: (1) il ne doit pas prod uire de brouillage et (2) l’utilisateurdu dispos itifdoit

êtrepr êtà a ccepter toutbr ouillager adioélectriquer eçu, mêmesi c e brouillage est

susc eptiblede c ompromettrele fonctionnementdu dispos itif.

©2018 Tyco Security Products, Toronto, Canada www.dsc.com

Tech. Support: 1-800-387-3630

D-307386Rev.0 (09/18)

Loading...

Loading...