Tyco Safety Canada 06RFK55XX4 User Manual

Installation Instructions, Instructions d’Installation, Installatiehandleiding, Asennusohjeet

PK55XX/RFK55XX-433

English, Français, Nederlands, Suomi

123

456

78

9

0

#

*

PK5500

RFK5500

WARN ING: Pl ease refer to the System Installation Manual for information on li mitat i ons regarding product use and function a nd i nfor ma tion on t he l imit atio ns as t o li abil ity of t he manuf acturer.

NOTE: These instructions shall be used in conjunction with the system Installation Manual of t he Con trol Panel with which this equipment is intended to be used.

ATTENTION: Ce manuel contient des informations sur les restrictions concernant le fonctionnement et l’utilisation du produit et des informations sur les restrictions en ce qui concerne la responsabilité du fabri-

cant. La totalité du manuel doit être lu attentivement.

NOTE: Ce manuel doit être utilisé en conjonction avec le Manuel d'installation du Panneau de contrôle.

WAARSCHUWING: Raadpleeg de installatiehandleiding van het systeem voor informatie over beperkingen m.b.t. productgebruik en functie en informatie ov er de beperkingen m.b.t. aansprakelijkheid van de fabrikant.

OPMERKING: Deze instructies dienen te worden gebruikt in combinatie met de installatiehandleiding van het systeem van de centrale waarmee deze app ara tuur gebruikt wordt.

ADVARSEL: Vennligst se manualen for installasjon av systemet for i nform as jon om beg rensningene angående bruk og funksjon av produktet og inform as jon om begrensningene hva angår produsentens ansvar.

LEGG MERKE TIL: Disse instruksene skal brukes sammen med manualen til kontrollpanelet for installasjon av systemet som dette utstyret er ment å brukes med.

123

456

78

9

0

#

*

PK5501

RFK5501

123

456

78

9

0

#

*

PK5508

RFK5508

123

456

78

9

0

#

*

PK5516

RFK5516

English

Disasembling

(Free-standing)

1. Insert the screwdriver into

slot at an angle and push

3. Repeat steps

1. and 2. for

left side

2. Rotate 90°

Installation Instructions

The PK55XX\RFK55XX keypads can be used on security systems with

up to 64 zones. These keypads are compatible with the following DSC

security systems:

•PC580 •PC585 •PC1555MX •PC1565

•PC1616 •PC1832 •PC1864 •PC5005

•PC5008 •PC5010 •PC5015 •PC5016

•PC5020

The RFK55XX keypads combine a wireless receiver with the respective

PK55XX keypad.

Specifications

• Temperature range: -10°C to +55°C (14°F to 131°F), Tempera-

ture range for UL/ULC: 0°C to +49°C (32°F to 120°F)

• Humidity (MAX): 93%R.H.

• Plastic enclosure protection degree: IP30, IK04

• Voltage rating: 12V

• Connects to control panel via 4-wire Keybus

• 1 keypad zone input/PGM output*

• PK55XX Current draw: 50mA (standby)/125mA (maximum)

• RFK55XX Current draw: 75mA (standby)/135mA (maximum)

• Wall mount tamper

• 5 programmable function keys

• Ready (Green LED), Armed (Red LED), Trouble (Yellow LED), AC

(Green LED)

• Low temperature sensor

• Frequency: 433.92MHz

• Up to 32 wireless zones (RFK55XX Only)

NOTE: * Zone not to be programmed as Fire type or 24h type.

Unpacking

The Power keypad package includes the following parts:

•One Power keypad •Keypad inner door labels

•Four mounting screws •1 tamper switch

•2 end-of-line resistors •Installation Instructions

Mounting

You should mount the keypad where it is accessible to designated

points of entry and exit. Once you have selected a dry and secure location, perform the following steps to mount the keypad.

Disassemble Keypad

1. Removing the keypad from the backplate for the first time.

(a) Position the keypad as indicated, insert screwdriver and rotate.

DC nominal

(RFK55XX-433 Only)

2. Removing the keypad from backplate once mounted.

(a) Open door, holding it 90° to the keypad, as shown below.

(b) Insert screwdriver into slot located under the door hinge and

rotate the screwdriver.

Disasembling

(Wall-Mounted)

3. Repeat steps 1.

and 2. for right side

1. Insert the screwdriver into

slot at an angle and push

Mount and Wire Keypad

Knock Out

Knock Out

Wiring Slot

Hooks

2. Rotate 90°

Knock Out

1.

3.

1. Secure Keypad to wall using mounting holes. Use all 4 screws provided unless mounting on a single gang box.

2. Place keypad into hooks on the backplate and swing down to

engage.

3. Run wire through wiring slot or knockouts. Connect Keybus and

PGM/Zone wiring to keypad. Place tamper switch into tamper hole

on backplate.

4. Remove keypad from hooks. Place keypad into backplate, ensure

the wire is pushed back into the wall as much as possible. Route the

wire inside the keypad ensuring high components are avoided. Snap

the front assembly closed, ensuring that there is no pressure to the

keypad from the wire below.

NOTE: If any tension found between the front keypad assembly and wiring,

please open the keypad reroute the wire and close again. Repeat these

steps until the keypad is closed properly.

Wiring

1. Before wiring the unit, ensure that all power (AC transformer and

battery) is disconnected from the control panel.

2. Connect the four Keybus wires from the

control panel (red, black, yellow and

green) to the keypad terminals. Refer to

diagram:

3. If programmed as an input, you can

connect a device - such as a door contact

Tamper

- to the ‘P/Z’ terminal of the keypad.

This eliminates the need to run wires back to the control panel for

the device. To connect the zone, run one wire from the device to the

‘P/Z’ terminal and the other wire from the device to the B (black)

terminal. For powered devices, run the red wire to the R (positive)

Hooks

Tamper

2.

4.

Swing

to engage

Press to snap

PK55XX\RFK55XX

RED

BLK

YEL

GRN

To zone or

P/Z

PGM output

R

B

Y

G

terminal and the black wire to the B (negative) terminal. When

41

Toggle Option

1 _ _ 4 _ _ _ _

using end of line supervision, connect the zone according to one of

the configurations outlined in your system’s Installation Manual.

4. If the ‘P/Z’ terminal is programmed as an output, the output follows

the PGM programmed in Section [080]. A small relay, buzzer or

other DC operated device may be connected between the positive

supply voltage and the ‘P/Z’ terminal (maximum load is 50mA).

Applying Power

Once all wiring is complete, and the equipment is secured to the building structure with at least two screws apply power to the control panel:

1. Connect the battery leads to the battery.

2. Connect the AC transformer.

For more information on control panel power specifications, see the

control panel Installation Manual.

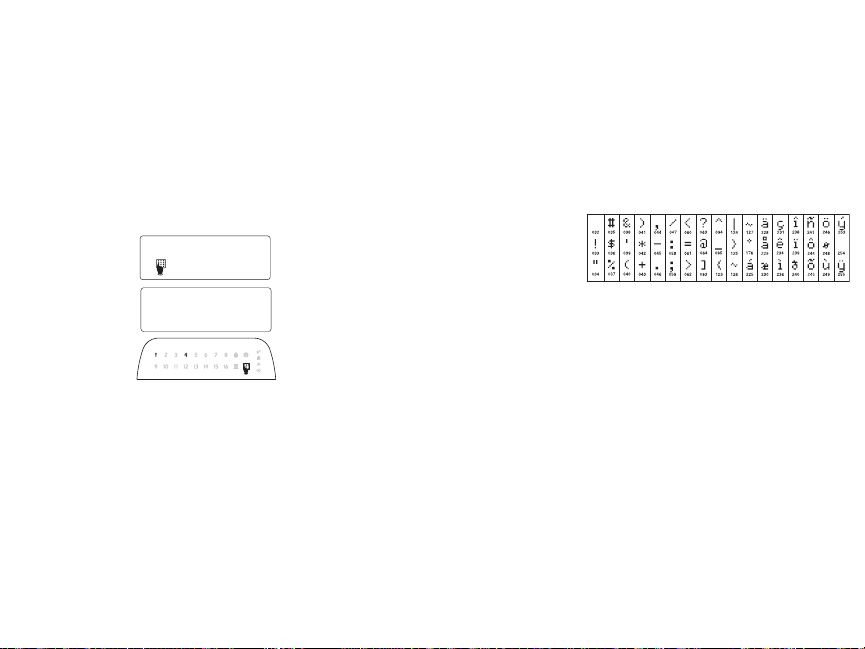

Programming the Keypad

There are several programming options available for the

keypad. These are described

below. Programming the keypad is similar to programming

the rest of the system. When

you are in the keypad programming sections, the keypad will display which options

are turned on along the top of

the display. To turn an option

on or off, press the number corresponding to the opt ion on the number

pad. The numbers of the options that are currently turned ON will be

displayed. For example, if options 1 and 4 are on, the display will

look like this on the different keypad displays:

For information on programming the rest of your security system,

please refer to your system’s Installation Manual.

Broadcasting LCD Labels

All LCD programming is done per keypad. If more than one LCD keypad is present on the system, labels programmed at one keypad can

be broadcast to all other LCD keypads. Perform the following procedure

in order to broadcast labels:

Step 1 - Program one LCD keypad completely.

Step 2 - Make sure all LCD keypads are connected to the Keybus.

Step 3 - Enter keypad programming by pressing [,][8][Installer

Code][,], then enter section [998] at the keypad that was programmed. The keypad will now broadcast all the information programmed to all the other LC D keypads on the system.

Step 4 - When the keypad is finished press the [#] key to exit.

NOTE: Label broadcast from this keypad is only compatible with other

PK5500 and RFK5500 Keypads.

Language Programming

(PK5500\RFK5500 Only)

Hold (<>) keys for 2 seconds to enter language programming,

scroll to the desired language and Press [

NOTE: If section [077] option 4 is OFF, language programming

can only be performed while in installers programming.

Enrolling the Keypad

The keypad will need to be assigned to a partition and slot if supervision or keypad zones are being used. Keypad assignments and keypad option programming must be done at each keypad individually.

The 1st digit of keypad assignment is used to determine partition

assignment (1 to 8). If partitioning is not used, enter [1]. For Global

Keypads, enter [0].

NOTE: LED and ICON keypads cannot be programmed as Global Keypads

The 2nd digit of keypad assignment is used to determine slot assignment for keypad supervision. Each keypad will be assigned a different

slot number from 1 to 8. PK5500 and RFK5500 LCD keypads come

defaulted in slot 8. If LCD keypads are used one LCD keypad must

remain in slot 8.

NOTE: The RFK55XX enrolls as two modules:

Light 1 = keypad section of the RFK55XX

Light 17 = receiver section of the RFK55XX

NOTE: Deleting all wireless devices from the RFK55XX or defaulting the

RFK55XX will cause a supervisory fault.

Enter the following at each keypad installed on the system:

1. Enter Installer Programming by pressing [,][8][Installer ’s Code]

2. Press [000] for Keypad Programming

3. Press [0] for Partition and Slot Assignment

4. Enter the 1st digit (0 to 8 for partition assignment)

5. Enter the 2nd digit (1 to 8 for slot assignment supervision)

6. Press the [#] key twice to ex it programming.

7. After assigning all keypads, perform a supervisory reset by entering

[,][8][Installer’s Code][902] and wait for 60 seconds.

8. Press the [#] key to exit programming after 60 seconds.

Programming Labels

(PK5500\RFK5500 Only)

1. Enter keypad programming by pressing [,][8][Installer Code][,].

Enter the 3-digit section number for the label to be programmed.

2. Use the arrow keys (<>) to move the underline bar underneath

the letter to be changed.

,] to select.

3. Press the number keys [1] to [9] corresponding to the letter you

require. The first time you press the number the first letter will

appear. Pressing the number key again will display the next le tter.

[1] - A, B, C , 1 [4] - J, K, L, 4 [7] - S, T, U, 7 [0] - Space

[2] - D, E, F, 2 [5] - M, N, O, 5 [8] - V, W, X, 8

[3] - G, H, I, 3 [6] - P, Q, R, 6 [9] - Y, Z, 9,0

4. When the required letter or number is displayed use the arrow keys

(<>) to scroll to the next letter.

5. When you are finished programming the Zone Label, press the [

key, scroll to “Save,” then press [

6. Continue from Step 2 un til all Labels are programmed.

NOTE: Label Programming can also be accessed from the [,][6] User

Functions Menu

ASCII Characters

Changing Brightness/Contrast

LCD Keypads

1. Press [,][6][Master code].

2. Use the [<][>] keys to scroll to either Brightness Control or Contrast Control.

3. Press [,] to select the setting you want to adjust.

4. a) ‘Brightness Control’: There are multiple backlighting levels. Use the [<][>]

keys to scroll to the desired level.

5. b) ‘Contrast Control’: There are 10 different display contrast levels. Use the

[<][>] keys to scroll to the desired contrast level.

6. To exit, press [#].

LED/ICON Keypads

1. Press [,][6][Master Code].

2. Use the [>] key to move through the 4 different backlighting levels.

3. The level is automatically saved when you press [#] to exit.

Changing the Buzzer Level

LCD Keypads

1. Press [,][6][Master Code].

2. Use the [<][>] keys to scroll to Buzzer Control.

3. There are 21 different levels, use the [<][>] keys to scroll to the desired level.

4. To exit, press [#].

LED/ICON Keypads

1. Press [,][6][Master Code].

2. Use the [<] key to move through the 21 different buzzer levels.

3. The level is automatically saved when you press [#] to exit.

,].

,]

Loading...

Loading...