Tyco Safety Canada 02WLS916NB User Manual

WLS916-433 Series

T

Wireless Smoke Detector

Installation and Operating Instructions

Read this instruction sheet thoroughly

before installation and use of the

WLS916-433 Wireless Smoke Detector

Introduction

The WLS916-433 is a wireless photoelectric smoke detector with a

fixed temperature heat detector and an internal piezoelectric

alarm. Three version are available: US version (UL), Canadian version (ULC) and an International version (EU).

LED /Test Bu tto n

Piezo Sounder

Align ment Mark s

Operation

Approximately every 7 to 8 seconds the unit tests for a smoke or

heat alarm condition. During this sequence the unit also performs

self diagnostics, and checks for tampers and faults. During normal

operation the LED will flash every 48 seconds and the sounder will

not sound.

Smoke Alarm

The smoke detector has a nominal fixed alarm sensitivity of

approximately 2.5%/ft. obscuration. The smoke detector will go

into alarm when the signal level exceeds the 'alarm' threshold and

automatically restore when the signal level falls below the alarm

'restore' threshold. During an alarm the LED will flash 1/second

and the sounder will sound the the evacuation temporal pattern

(UL, EU) or continuous beeps (ULC).

The smoke detector has a preset warning threshold at 75% of the

alarm threshold. If the signal level stays above this threshold, but

below the alarm threshold, for more than 120 seconds, the detector will go into the 'warning' state. If the signal level falls below

the early warning 'restore' threshold, the detector will restore to its

normal state automatically. If the signal level rises above the alarm

threshold, the detector will go into alarm. The LED will flash and

the sounder will chirp every 48 seconds when in the warning state.

Note: This feature is intended to provide a warning if the environment is persistently close to the alarm threshold and provide more

time to investigate and either escape or correct the situation.

Smoke - Drift Compensation

The detector automatically compensates for long-term environmentally induced changes to maintain a constant smoke sensitivity.

When the drift compensation has reached its high or low limit of

adjustment, the detector will go into the trouble state.

Heat Alarm

The heat detector will go into alarm when the heat signal level

exceeds the heat alarm threshold (135ºF/57.22ºC); and will automatically restore when the heat signal level falls below the heat

alarm threshold (restore). During an alarm the LED will flash 1/second and the sounder will sound the the evacuation temporal pattern (UL, EU) or continuous beeps (ULC).

Batteries

The WLS916-433 is powered by two, 3 V

Do NOT use batteries other than those listed.

The low battery threshold is set so that the batteries will provide

not less than 14 days of operation and at that point the detector

will send a 'low battery' signal. If the battery is still low 7 days after

falling through the low battery threshold, the horn will 'chirp' once

every 48 seconds until battery failure. During the first 7 days after

low battery detection, (non-chirp period), if the detector is tested

or goes into alarm, the horn will 'chirp' once the test or alarm is

restored and remain 'chirping' until battery failure.

Tamper

The removal of the detector from the mounting plate initiates a

'tamper' transmission. The tamper condition is restored after the

detector is mounted on the plate.

Wireless Transmissions

A supervisory message is transmitted at 64 minute intervals (12

minutes in EU models) to the control panel. If the signal is not

received the control panel determines that the detector is missing.

The detector transmits the following:

• Alarm / Alarm Restore - (heat or smoke alarm). Transmitted

at time of occurrence.

• Tamper / Tamper Restore - (tamper switch activated) 10

second maximum delay on restore before transmission.

• Low Battery - (battery voltage falls below threshold). The

batteries are tested & transmitted at the time of a supervisory

or other transmissions.

• Trouble - (detector fault or sensor compensation limit

reached). Troubles are transmitted at the time of occurrence

(one trouble per supervisory interval).

DC lithium batteries.

F

A

R

D

Installation Instructions

1 Smoke Detector Placement

On smooth ceilings, detectors may be spaced 9.1M (30 feet) apart

as a guide. Other spacing may be required depending on ceiling

height, air movement, the presence of joists, uninsulated ceilings,

etc. Consult National Fire Alarm Code NFPA 72, CAN/ULS-S553M86 or other appropriate national standards for installation recommendations.

Do NOT locate smoke detectors at the top of peaked or gabled

ceilings; the dead air space in these locations may prevent the unit

from detecting smoke.

Avoid areas with turbulent air flow, such as near doors, fans or

windows. Rapid air movement around the detector may prevent

smoke from entering the unit.

Do NOT locate detectors in areas of high humidity.

Do NOT locate detectors in areas where the temperature rises

above 38ºC (100ºF) or falls below 5ºC (41ºF).

Install Smoke detectors in accordance

with paragraph 2.1.1.1 of NFPA 72,

Chapter 2.

“2-2.1.1.1 Smoke detectors shall be

installed outside of each sleeping area in

the immediate vicinity of the bedrooms and

on each additional story of the family living

unit, including basements and excluding

crawl spaces and unfinished attics. In new

construction, a smoke detector also shall be

installed in each sleeping room.”

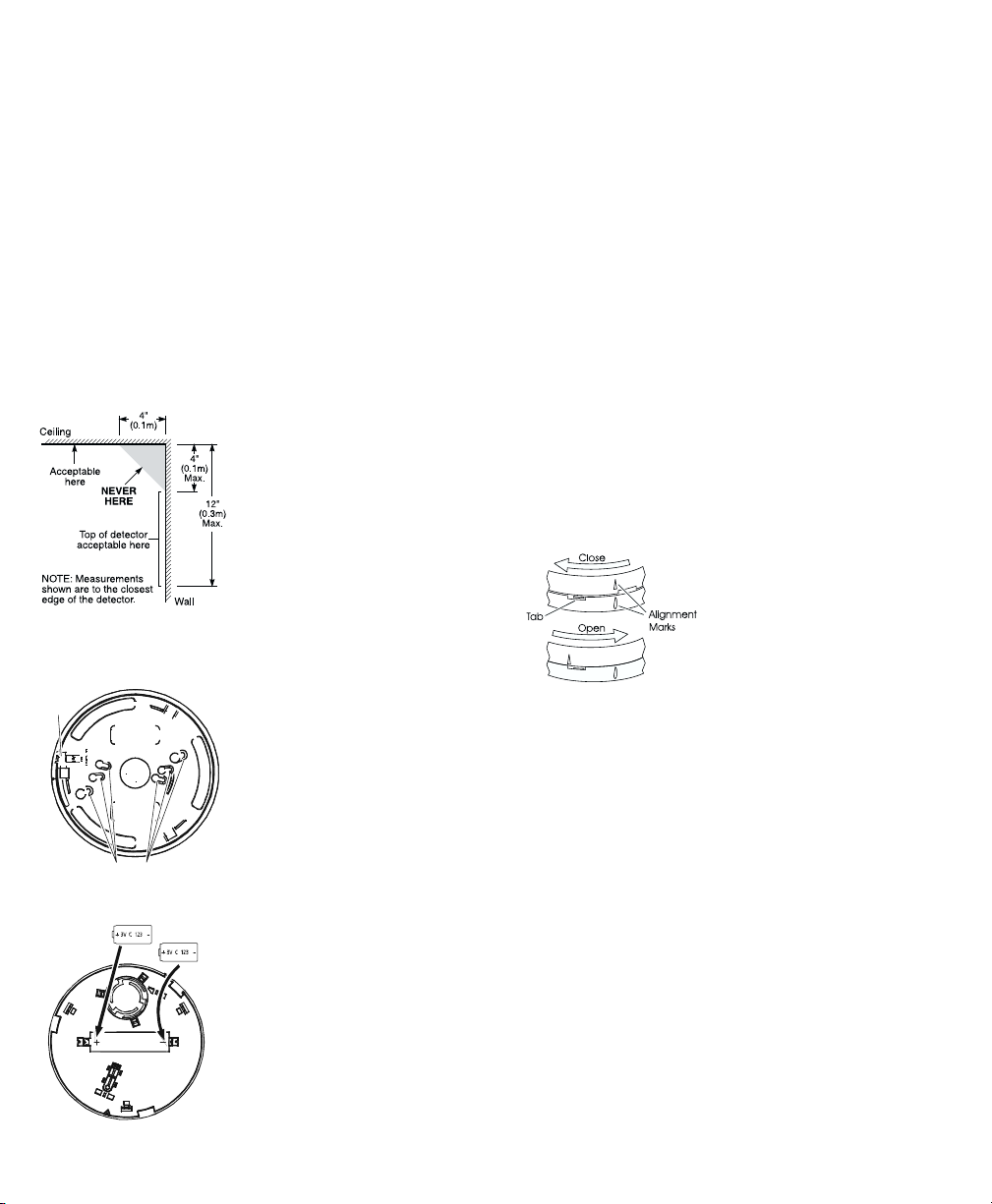

2 Mount Smoke Detector Backplate

Locking

Tab

Mounting Hol es

2 Install Batteries

Insert

Last

Secure backplate to the mounting

surface using the screws provided.

Note: Avoid mounting on uneven surfaces or electrical boxes. Warping of

the backplate can result in a tamper.

Install batteries in the sequence indicated. Use only 3 V

ies from the following approved

Insert

First

sources:

DC CR123A batter-

• Tekcell

• Ever Ready

• Panasonic

4 Test Unit

The test can be initiated by pressing the test button or activating

the internal reed switch with a magnet for a minimum of 5 seconds. Alarm activation will be indicated by the flashing LED, The

Sounder, and transmission of the alarm reporting code to the central station. The detector will restore to normal after the test button is released or the magnet removed.

Note: Allow a minimum of 20 seconds between test activations

Note: If the detector is in one of the following states when a test is

initiated; it will not enter an alarm state.

1. Tamper, (detector not installed on mounting plate).

2. Compensation Trouble.

3. Failure of Heat or Smoke detector.

4. Other internal faults that could prevent a smoke or heat alarm

Device Enrollment

The 6 digit serial number located on the back of the smoke detector housing must be enrolled into the alarm control panel with

Installer programming. Refer to the receiver Installation Manual

for details.

Mounting

Detector Installation:

Position the detector on to the base

plate using the detector and base

plate alignment marks. Press the

detector gently in place while rotating

the detector clockwise until the detector snaps into place. Remove the side

tab from the locking tab to lock in

place.

Removal:

Depress tab with a small slotted

screwdriver. Rotate detector counterclockwise until the alignment marks

line up. Remove detector.

Compensation Reset

Cleaning, replacement of the smoke sensor, or other environmental changes may change the background signal/noise of the detector; this requires the drift compensation be reset. Compensation

trouble is one of the faults indicated when the LED indicator is OFF

while the sounder is chirping.

1. Remove batteries

2. Power up unit while pressing the test button.

The tamper switch must not be pressed.

3. The LED will flash when 5 seconds has elapsed. Release the

test button within 2 seconds of the LED flash.

4. The LED will flash every 2 seconds for 1 minute. During this

period, the detector must be mounted.

Allow an additional 2 minutes for the detector to make

background level checks

5. Test the detector to verify normal operation.

Loading...

Loading...