Tyco Safety Canada 00NB912 Installation guide

WLS912L

Glassbreak Detector

INSTALLATION INSTRUCTIONS

The WLS912L is a battery-operated glassbreak sensor, designed to detect the

sound produced by the shattering of framed glass. Equipped with an RF transmitter, the WLS912L establishes a supervised, one–way communications link with the

system controller.

The WLS912L uses Dynamic Signal Processing* to provide accurate detection of

plate, laminated, wired and tempered glass types, while rejecting common false

alarm sounds.

*Protected under US Patent 5,675,320

Specifications

Operating Voltage ................. 3.0V (two 3V Lithium EL123AP Batteries)

Operating Temperature .......... 0o C - 50oC (32o F- 122oF)

Operating Humidity ............... 5% – 95% RH, non-condensing

Maximum detection range

Glass Type Thickness Minimum Glass

Plate/

Tempered

Wired/

Laminated

1/8" – 1/4"

3 – 6mm

1/4"

6mm

Size (L X W)

12" X 12"

30cm X 30cm

18"X18"

46cmX46cm

Level 1 Setting Level 2 Setting

20ft

6m

20ft

6m

10ft

3m

DO NOT USE

Battery Guidelines and Installation

• Use fresh batteries. Most batteries have a “best before” date printed on their

packaging or on the batteries themselves. Buy batteries that have a “best

before” date of two years or more from your purchase date

• When disposing of used batteries, follow the instructions and precautions

printed on the batteries. Many cities and communities have collection sites or

services for used household batteries. Contact your municipal offices for

information on the disposal of used batteries

• Do not mix old and new batteries

NOTE: Use only Energizer Lithium EL123AP batteries.

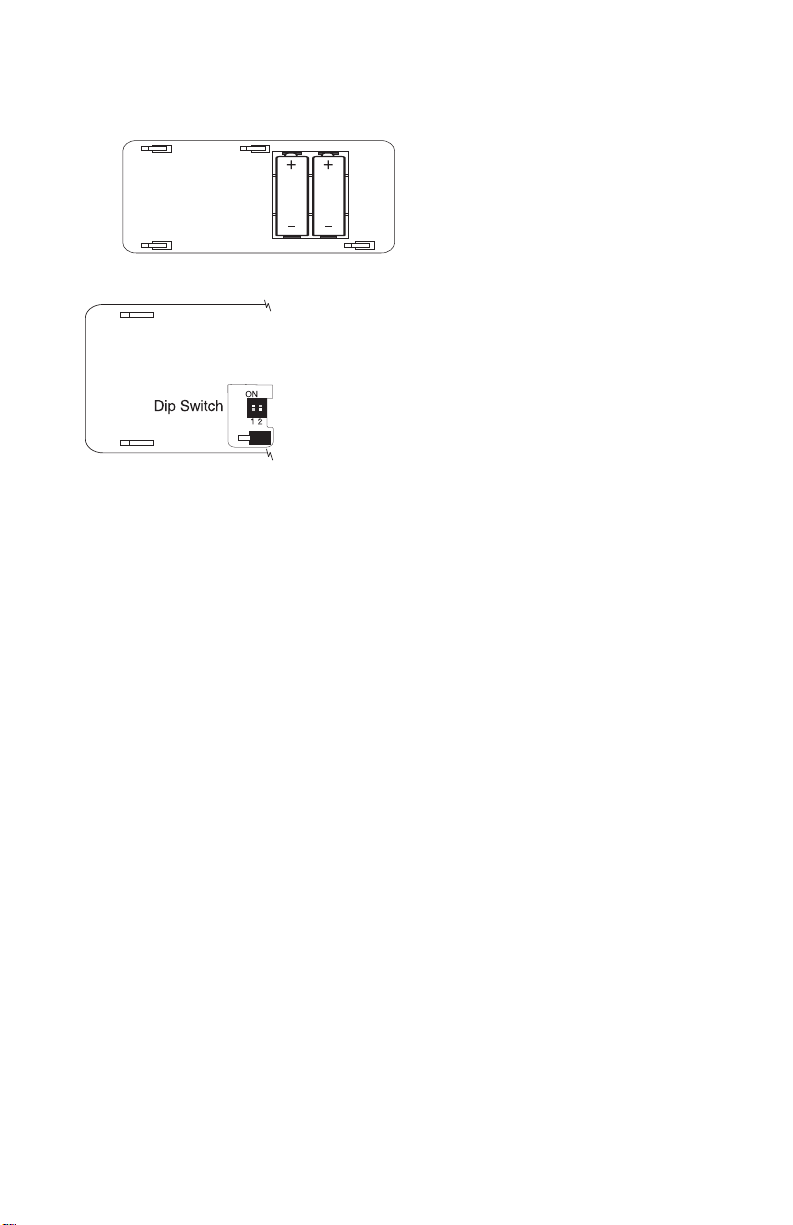

To install batteries:

1. Remove the detector from its mounting plate:

If unmounted, hold the detector by its sides and push down

on the top end of the mounting plate, as shown at right.

If mounted, press the detector in the direction shown below.

2. Install the batteries positive (+) side first, with the correct polarity, as shown

below.

Setting the Dip Switches

The detector has user-selectable dip switch settings as

shown.

Dip Switch 1– Not Used

Dip Switch 2– Level 1/Level 2 Detection

This is a sensitivity selection dip switch which may be

used to optimize false alarm immunity for certain

acoustic environments.

Switch 2 = OFF). This is the highest sensitivity setting for the detector, and will be

suitable for most applications.

For rooms which are smaller, and contain a significant number of sound-reflective

surfaces (such as bathrooms, kitchens, entrances, etc.), Level 2 detection (Dip

Switch 2=ON) provides a reduced sensitivity setting which may be more appropriate.

The detector is factory set for Level 1 detection (Dip

Selecting a Mounting Location

The detector is omnidirectional, providing 360 degree coverage. Coverage is

measured from the center of the detector to the point on the glass farthest from

the detector.

Guidelines for optimizing detection and avoiding false alarms

• For optimum protection, the detector should have a direct line of sight to the

protected glass.

• Window coverings will absorb sound from the shattering glass. In these

cases, mount the detector as close as possible to the protected glass, either

on an adjacent wall, the ceiling, or behind the window covering if possible.

• The detector should be mounted at least 1.8m (6 feet) off the ground.

• Do not mount the detector on the same wall as the protected glass.

• Avoid installation near noise sources, such as speakers or other objects

which produce sounds continuously.

• Do not install the detector beyond the maximum recommended range, even

if the AFT–100 simulator shows additional range - future changes in room

acoustics could reduce the range.

• Application on 24 hour loops should be avoided unless the location is

unoccupied.

• Test false alarm immunity by creating any sounds in the room which will

likely occur when the alarm system is armed.

Note: T est the detec tor tho roug hl y f or pr oper plac ement u sing the AFT-100

Glassbreak Simulator. Other simulators may trip the unit, but will not provide accurate test results.

Loading...

Loading...