Tycor-UPS Ty-Borealis Series Operator's Manual

Ty-Borealis Series

Three Phase ELI System

8 KW – 48 KW

Operators Manual

M4102 Ty-Borealis 8-48KW Operators Manual v1.0 2013-08-14

i

M4102 Ty-Borealis 8-48KW Operators Manual v1.0 2013-08-14

Dear Customer,

Thank you for selecting our emergency lighting inverter (ELI). We are

pleased to include you as one of our valued Tycor UPS customers!

We are confident that this emergency lighting inverter system, developed

and satisfaction you demand.

Please read this installation manual carefully as it contains the necessary

information required to install the ELI properly.

Thank you for choosing Tycor UPS.

ii

NOTE

The instructions contained in this manual are not intended to cover all of the

details or variations in equipment, or to provide for every possible contingency

to be met in connection with installation, operation, or maintenance. Should

further information be desired or should particular problems arise which are not

covered sufficiently for the purchaser’s purposes, the matter should be referred

directly to Tycor UPS.

Any electrical or mechanical modifications to this equipment, without prior

written consent of Tycor UPS, will void all warranties and may void UL/cUL

listing. Unauthorized modifications may also result in personal injury, death,

and damage to the equipment.

and manufactured in our ISO 9001 certified facilities, will provide the quality

M4102 Ty-Borealis 8-48KW Operators Manual v1.0 2013-08-14

Preface

Congratulations on your choice of our emergency lighting inverter (ELI).

This equipment has been manufactured and tested using methods and procedures

UL 924.

This manual describes the recommended procedures for installing the ELI.

While every effort has been made to ensure the completeness and accuracy of this manual,

the use of the information contained in this document.

We recommend that this manual be kept with the ELI for future reference. If any problems

Centre before proceeding.

This document may not be copied or reproduced without the explicit written permission of

Tycor U P S .

Due to technical advancements and improvements, some of the information contained in

this manual may be changed or modified without prior notice.

iii

equivalent to

Tycor U P S assumes no responsibility or liability for any losses or damages resulting from

WARNING: This manual is intended to provide installation instructions

only. The information contained in this manual is to be used as a guideline

and recommendation only. Only qualified personnel should perform

installation and maintenance. Factory authorized personnel shall inspect

installation prior to start up and commissioning to validate warranty.

Failure to follow this directive will void the warranty.

are encountered with the procedures contained in this manual, please contact our Service

M4102 Ty-Borealis 8-48KW Operators Manual v1.0 2013-08-14

Symbols

Warning Information

Electrical Hazard

Electrical Symbols

Protective grounding terminal; a terminal that must be connected to ground prior to

making any other connection to the equipment.

A terminal to/from which an alternating current or voltage may be applied/supplied.

A terminal to/from which a direct current or voltage may be applied/supplied.

This symbol indicates the word “phase”.

iv

The following symbols are used through out this manual.

This symbol alerts you to important information.

This symbol indicates an electrical hazard may be present.

M4102 Ty-Borealis 8-48KW Operators Manual v1.0 2013-08-14

Safety Instructions

READ AND FOLLOW ALL SAFETY INSTRUCTIONS.

SAVE THESE INSTRUCTIONS.

This manual contains important safety instructions that should be followed during installation

process

operators

to

protect themselves and the equipment being installed.

GENERAL

Move the ELI in an upright position, in its original packaging, to its final destination.

and

be

Do not use this equipment for other than intended use.

-

-

-

-

- - -

-

-

-

-

-

-

v

and maintenance of the ELI system and optional packages. Before the installation

begins, we recommend that the installer read through the safety precautions,

manual and the option installation instructions, taking all necessary safety precautions

-

To lift the cabinets, use a forklift or lifting belts with spreader bars.

-

Check for sufficient floor and elevator loading capacity.

-

Check the integrity of the ELI equipment carefully.

If visible damage is evident, do not attempt to install or start the ELI. Contact the

transport delivery company immediately, file a claim with the transport company

inform Tycor UPS directly.

Do not use outdoors.

The use of accessory equipment not recommended by Tycor UPS may cause an unsafe

condition

WARNING! RISK OF ELECTRICAL SHOCK: use extreme caution when removing

covers.

All maintenance and service work should be performed by qualified and trained service

personnel. The ELI may contain its own energy source, (batteries) which can

dangerous to the untrained person. This ELI contains potentially hazardous voltages

The field-wiring terminals may be electrically live, even when the ELI is not connected to

the utility.

Use caution when servicing batteries. A battery can present a risk of electrical shock,

burn from high short-current. Battery acid can cause burns to skin and eyes. If acid is

spilled on skin or in eyes, flush with fresh water and contact physician immediately.

When replacing batteries use the same number and type (sealed-cell lead acid).

Proper disposal of batteries is required. Refer to your local codes for disposal

requirements.

Dangerous voltages may be present during battery operation. The batteries must be

disconnected during maintenance or service work. (Open battery breaker or fuses)

Be aware that the inverter can restart automatically after the utility voltage is restored.

M4102 Ty-Borealis 8-48KW Operators Manual v1.0 2013-08-14

INSTALLATION

This ELI is intended for use in a controlled indoor environment free of conductive

Avoid locations in direct sunlight or near heat sources (gas or electric heaters).

-

-

- - -

- - -

STORAGE

Store the ELI in a dry location free of contaminants;

periodically (time depending on storage temperature).

WARNING!

IS

S

DEATH.

QUALIFIED TO DO SO. AN INSTALLER SHOULD NEVER WORK ALONE.

WARNING!

CAPACITORS TO DISCHARGE BEFORE WORKING ON THE EQUIPMENT.

CAUTION!

necessary to correct the interference.

CAUTION!

cables.

vi

contaminants and protected against any type of intrusion.

Do not install the ELI in an excessively humid environment or near water.

-

Avoid spilling liquids and/or dropping any foreign object(s) onto the ELI.

The unit must be placed in a sufficiently ventilated area; the ambient temperature should

not exceed 40°C (104°F).

Optimal battery life is obtained if the ambient temperature does not exceed 25°C (77°F).

HIGH GROUND LEAKAGE CURRENT: ground connection completed before connecting

the AC voltage wires on the input!

Switching OFF the ELI does not isolate the ELI from the utility as the utility supply is still

HOT at the input terminal strip. Supply breaker needs to be opened.

It is important that air can move freely around and through the unit. Do not block the air

vents.

-

-

Storage temperature must be within -25°C (-13°F) to 55°C (131°F).

-

If the unit is stored for a period exceeding 3 months, the batteries must be recharged

LETHAL VOLTAGES MAY BE PRESENT WITHIN THIS UNIT EVEN WHEN IT

APPARENTLY NOT OPERATING. OBSERVE ALL CAUTIONS AND WARNINGS IN THI

MANUAL. FAILURE TO DO SO COULD RESULT IN SERIOUS INJURY OR

REFER UNIT TO QUALIFIED SERVICE PERSONNEL IF MAINTENANCE IS REQUIRED.

NO ONE SHOULD WORK ON THIS EQUIPMENT UNLESS THEY ARE FULLY

WHEN REMOVING POWER FROM THE ELI, ALLOW FIVE MINUTES

This equipment complies with the requirements in Part 15 of FCC rules for a Class A

computing device. Operation of this equipment in a residential area may cause

interference to radio and TV reception, requiring the operator to take whatever steps

Do not put option control wiring in the same conduit as the ELI input or output power

FOR

M4102 Ty-Borealis 8-48KW Operators Manual v1.0 2013-08-14

THIS SAFETY NOTICE IS ADDRESSED TO THE TYCOR UPS

Electrical Safety

•

Maintenance work to be performed by a factory trained customer engineers, or

boards and working inside the unit.

• • • • •

READ AND FOLLOW ALL SAFETY INSTRUCTIONS.

SAVE THESE INSTRUCTIONS.

vii

CUSTOMER ENGINEERS WHO PERFORM MAINTENANCE OF THE

UNINTERRUPTIBLE POWER SUPPLY (ELI) SYSTEMS.

qualified personnel. Extremely dangerous voltage levels can exist within the ELI

system. Extreme caution must be used.

Ensure system is in maintenance bypass mode or external wrap-around bypass

mode before work is started.

This manual is designed as an aid tool in diagnosing problems that may arise.

Tycor U P S does not assume responsibility if information causes injuries.

Apart from the front door, do not open any other part of the ELI without consulting the

factory first. Before removing the protection screens, be sure that the unit is

completely powered off.

Be aware that dangerous voltage can be supplied by the internal battery or

electrolytic capacitors.

When system is in bypass mode and all fuses have been opened dangerous

voltages may exist within the ELI system. Use extreme caution when exchanging

M4102 Ty-Borealis 8-48KW Operators Manual v1.0 2013-08-14

1

Introduction ........................................................................................................................................................... 1

1.1

1.3

Overview............................................................................................................................................................................... 1

Definitions............................................................................................................................................................................ 2

2

Theory of Operation............................................................................................................................................. 3

2.1

2.10

General Topology............................................................................................................................................................... 3

Manual Bypass Switch.....................................................................................................................................................10

3

5

Inter-PCB Diagram ............................................................................................................................................. 12

Installation ........................................................................................................................................................... 16

5.1

5.3

Site & Environmental Conditions..................................................................................................................................16

Terminal Strip Connections............................................................................................................................................19

6

7

Front Panel........................................................................................................................................................... 20

Operation.............................................................................................................................................................. 25

7.1

7.6

Switch On Procedure (Authorized Trained Personnel Only) .................................................................................25

Battery Condition Test.....................................................................................................................................................28

8

The LCD Display ................................................................................................................................................. 29

8.1

8.5

Menu 0 – Main Menu.........................................................................................................................................................29

Menu 4 – Historical Event Menu ....................................................................................................................................34

viii

TABLE OF CONTENTS

1.2

Features................................................................................................................................................................................ 1

2.2

Normal Operation Mode ................................................................................................................................................... 4

2.3

Backup Mode ...................................................................................................................................................................... 4

2.4

Reserve Mode ..................................................................................................................................................................... 5

2.5

Manual Bypass Mode ........................................................................................................................................................ 5

2.6

Features and Advantages ................................................................................................................................................ 6

Rectifier ................................................................................................................................................................................ 8

2.7

2.8

Inverter.................................................................................................................................................................................. 9

Static Switch.......................................................................................................................................................................10

2.9

4

Physical Topology ............................................................................................................................................. 13

5.2

Cable Selection..................................................................................................................................................................18

7.2

Shutdown Procedure .......................................................................................................................................................26

7.3

From Inverter To Manual Bypass Procedure .............................................................................................................27

From Manual Bypass to Inverter Procedure ..............................................................................................................28

7.4

Manual Battery Test..........................................................................................................................................................28

7.5

8.2

Menu 1 – Select Menu ......................................................................................................................................................30

Menu 2 – Status Warning Menu.....................................................................................................................................30

8.3

8.4

Menu 3 – Real Time Data Menu .....................................................................................................................................32

M4102 Ty-Borealis 8-48KW Operators Manual v1.0 2013-08-14

9 INTERFACE CONNECTIONS ........................................................................................................................... 36

9.1

9.6

Dry Contacts.......................................................................................................................................................................36

Emergency Lighting Notification ..................................................................................................................................38

10

Battery Backup Units (BBU) ............................................................................................................................ 39

10.1 Run Time Charts................................................................................................................................................................41

Options ................................................................................................................................................................. 45

11

11.1

11.5

Emergency Stop Switch ..................................................................................................................................................45

Normally Off Function......................................................................................................................................................45

12

13

Technical Specifications .................................................................................................................................. 46

Contact Information........................................................................................................................................... 50

ix

9.2

Software for PC Monitoring ............................................................................................................................................37

9.3

Emergency Power off Connection ................................................................................................................................37

9.4

DB9 Connectors ................................................................................................................................................................37

9.5

Web Monitoring Module (SNMP Module) ....................................................................................................................37

10.2 BBU Configurations .........................................................................................................................................................43

11.2

Remote Display Panel ......................................................................................................................................................45

12 Pulse Rectifier ..............................................................................................................................................................45

11.3

11.4

External Wrap Around Bypass ......................................................................................................................................45

M4102 Ty-Borealis 8-48KW Operators Manual v1.0 2013-08-14

Congratulations on your choice of the Ty-Borealis On-Line Emergency Lighting Inverter

1.1

Overview

required.

1.2

Features

the LCD screen displays critical system information including:

•

•

Percent Load

Internal ELI temperature.

A manual test switch has been incorporated into the input/test breaker that makes

ELI to be performed without interruption of power to the load.

The communications port, in conjunction with multi-platform monitoring and control

Other communications options include:

•

An SNMP adapter to remotely control and monitor the unit via a network or

environments.

•

1

1 Introduction

(ELI). This ELI features the latest top of the line microprocessor technology and IGBT

transistors

sine wave

and provides clean, highly regulated and pulse width modulated (PWM) true

power.

This ELI is designed for installation between your AC power supply (utility or

generator) and your lighting equipment. It provides power to your equipment during

major power events such as blackouts and brownouts, over-voltage and undervoltage conditions. The ELI provides a consistent supply of regulated AC power

during these power events, allowing you to ensure safety and lighting for the period

This ELI provides full time self-diagnostics as well as two levels of audible alarms

when the unit is operating in battery mode. Along with the current mode of operation,

•

•

•

•

•

testing a simple procedure. The internal bypass switch allows maintenance on the

Remaining battery capacity, battery voltage

Input voltage,

Output voltage,

Input frequency,

Output frequency and

software, enables the unit to be connected to a local or networked computer system.

Detailed operating information including voltages, currents, and alarm status is

available to the monitoring system.

the Internet.

An AS-400 interface to allow for relay communications in PLC or dry contact

M4102 Ty-Borealis 8-48KW Operators Manual v1.0 2013-08-14

1.3

Definitions

•

Critical Load

Emergency Power Off.

• • • • •

•

• • • • • • •

2

These are loads that require clean, regulated and continuous AC power and

which are connected to the output of the ELI module

ELI Module

The portion of the ELI system that contains one or more of: the rectifier /

DFC, charger, inverter, static bypass switch, maintenance bypass switch,

controls, monitoring, and indicators.

Rectifier / DFC

Contained in the ELI module. Responsible for converting the normal AC input

power to DC power and supplying the inverter with DC power.

Charger

Contained in the ELI module. Responsible for recharging the batteries.

Inverter

Contained in the ELI module. Responsible for converting DC power (supplied

by the rectifier) to regulated and filtered AC power that is then supplied to the

critical loads.

Static Bypass Switch

Contained in the ELI module. Responsible for automatically transferring the

attached load, without interruption, from the inverter AC output to the bypass

AC power source in the event of an overload or degradation of the inverter’s

performance.

Maintenance Bypass Switch:

Contained in the ELI module. Used to transferring the attached load, without

interruption, from the inverter AC output to the bypass AC power source while

electrically isolating the static bypass switch, rectifier / DFC, charger and

inverter. Used for maintenance purposes.

Battery

The battery system provides DC power to the inverter input when the normal

AC input power to the ELI fails.

IGBT

Isolated Gate Bipolar Transistor.

PWM

Pulse Width Modulation.

ELI

Emergency Lighting Inverter.

BBU

Battery Backup Unit.

PFC

Power Factor Correction.

EPO

M4102 Ty-Borealis 8-48KW Operators Manual v1.0 2013-08-14

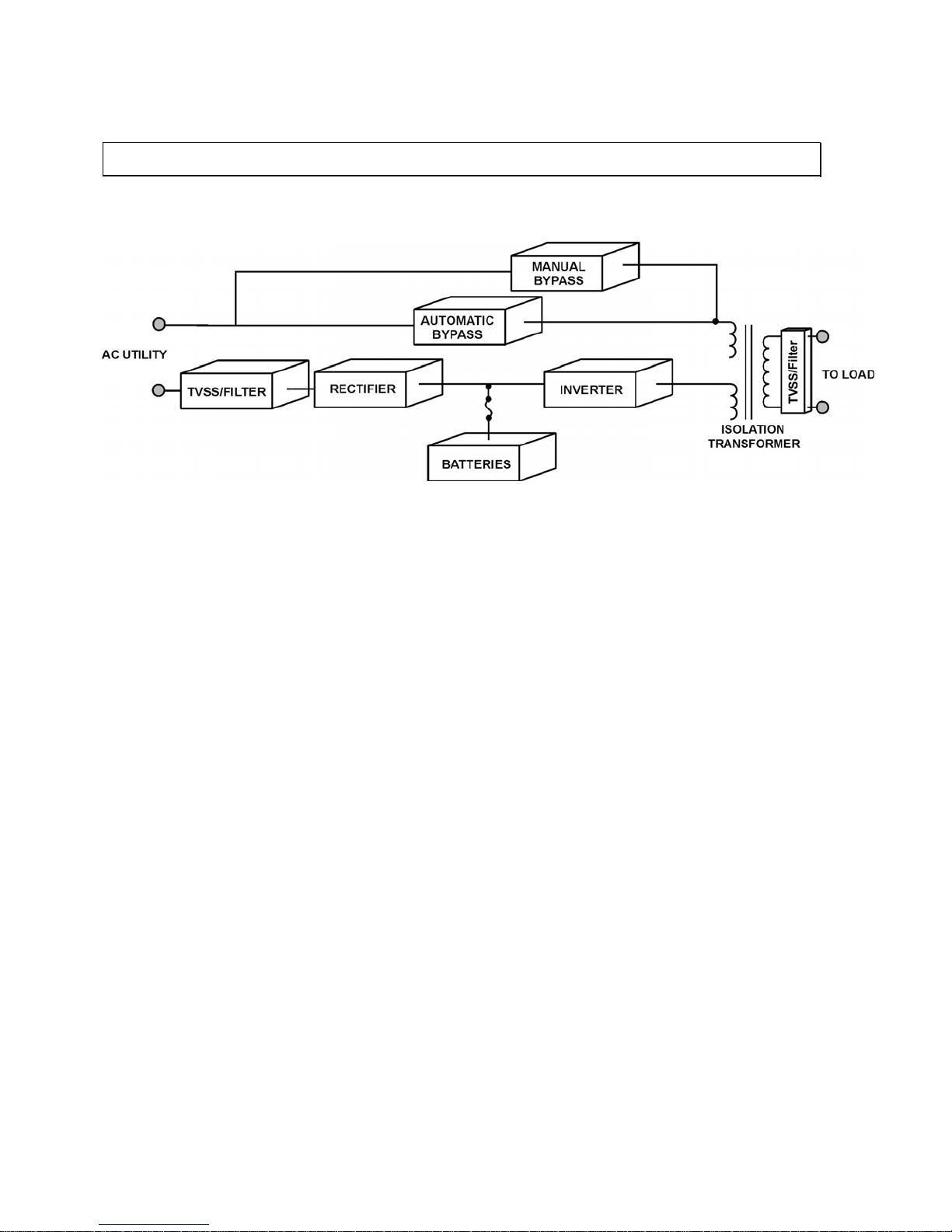

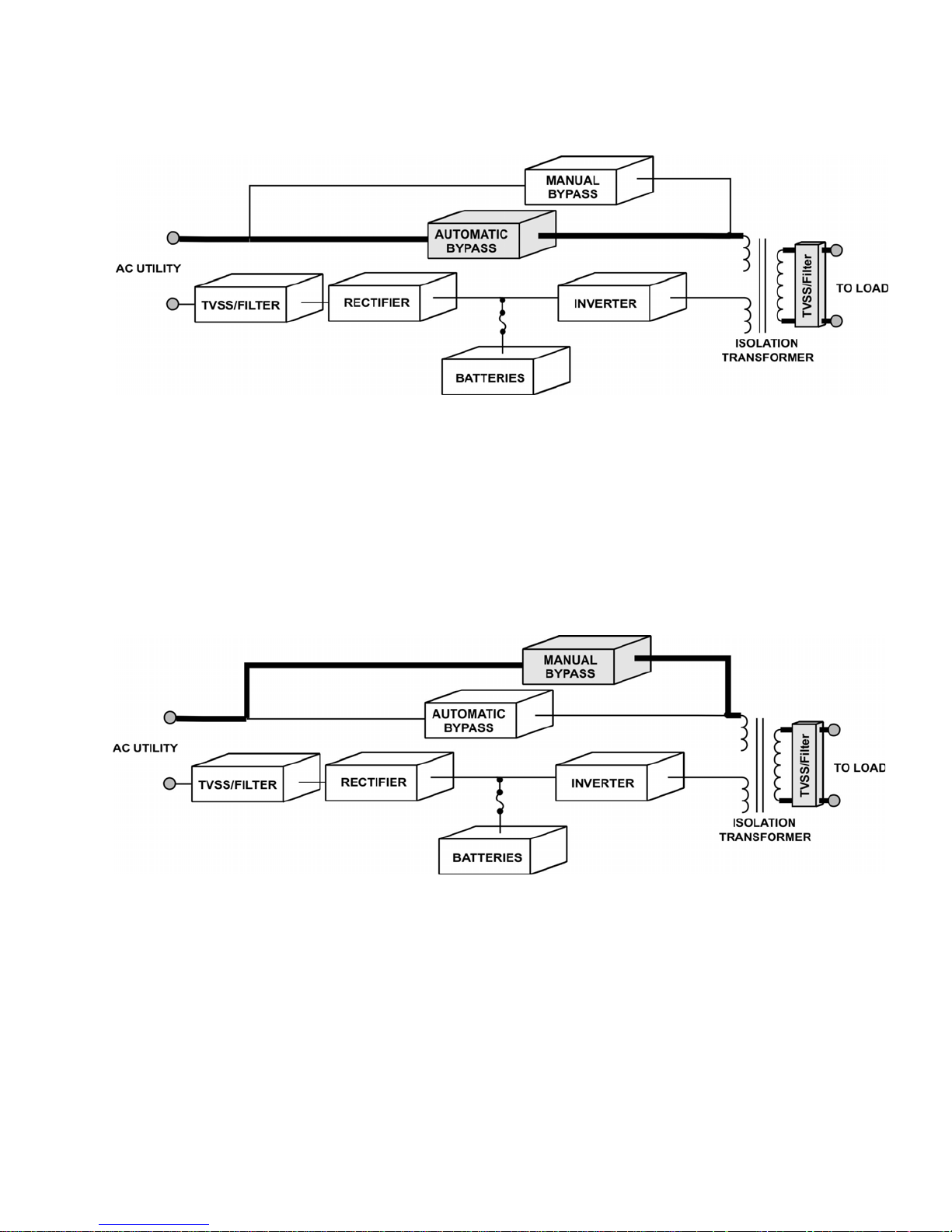

2.1

General Topology

Figure 2.1

General Block Diagram

ELI Module Components:

components:

The ELI module consists of the following major

-

-

Input, Reserve and Bypass circuit breakers

Optional Features:

-

-

12-pulse rectifier and harmonic filter to reduce input harmonic content.

Isolated parallel redundant operation (IPRO)

-

-

Generally, there are four modes of operation for an ELI system, NORMAL MODE,

MODE.

3

2 Theory of Operation

-

Rectifier / Charger

-

Inverter

Microprocessor controlled logic and control panel with alarm indicators and digital

metering display

External battery connection

-

Static bypass

-

Full maintenance bypass

-

Emergency power off (EPO) connection

-

Communications interface

-

SNMP Adapter for network communications and monitoring

-

Input power walk-in

-

Front cable connections

-

Output isolation transformer

-

Additional battery modules for extended runtime

-

Top cable entry

-

Remote display panel

-

Emergency power off switch

-

External maintenance bypass cabinet

BACK-UP (BATTERY) MODE, RESERVE MODE and MAINTENANCE BYPASS

M4102 Ty-Borealis 8-48KW Operators Manual v1.0 2013-08-14

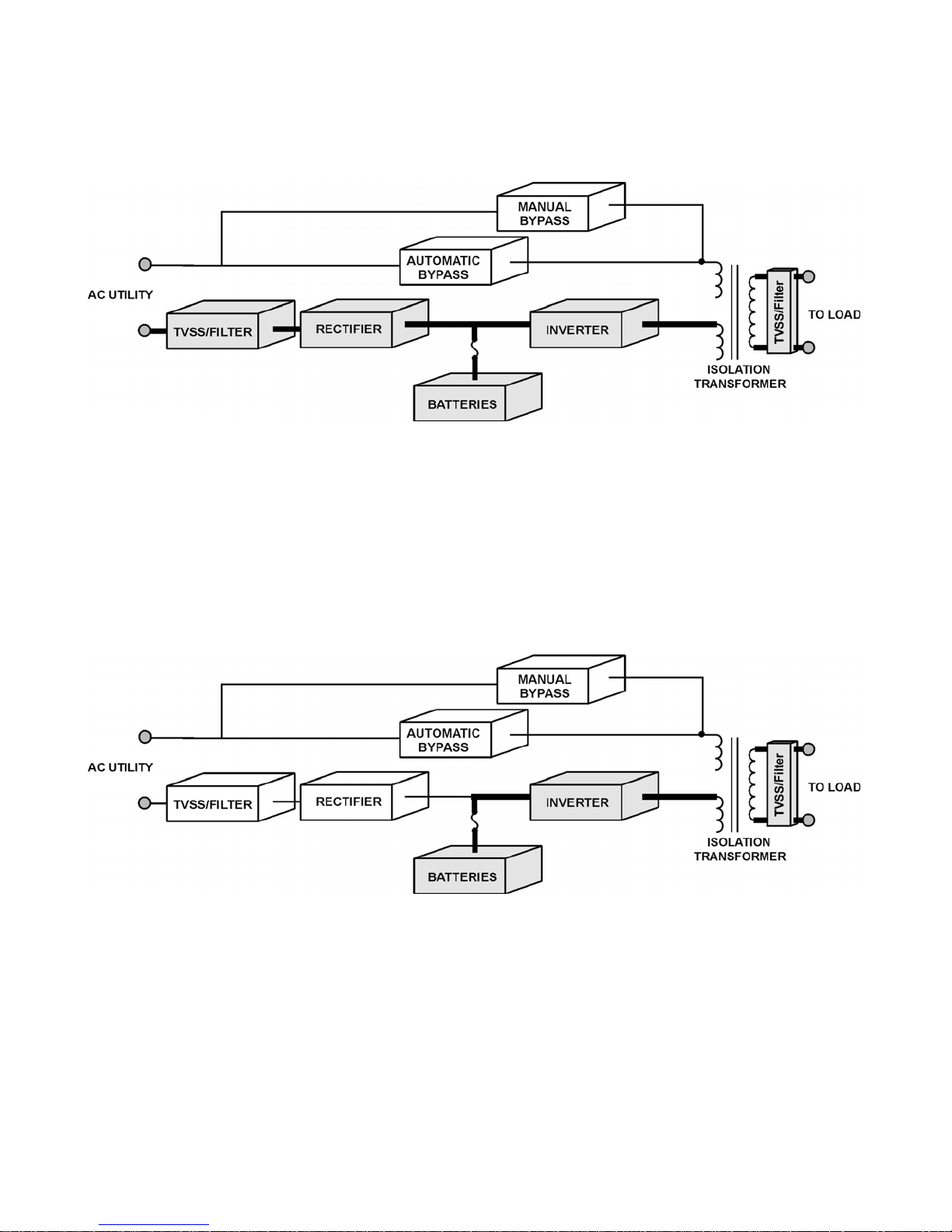

Normal Operation Mode

2.2

Figure 2.2

Normal Mode Operation

The rectifier/charger converts the supplied AC power into DC (bus) power that is

then

is

source is within the specified frequency range.

Backup Mode

2.3

Figure 2.3

n

Upon

power to the inverter and the battery charger to replenish the batteries.

4

then supplied to the inverter and the battery charger. The DC to AC inverter

supplies continuous, noise free AC power to the critical loads. The inverter output

synchronized with the bypass AC power source provided that the bypass AC power

Back-up Mode Operation

As the batteries are connected to the DC bus they supply energy to the inverter via

this DC bus, the AC power will remain constant and continuous without interruptio

to the loads when the AC fails or falls out side of the operating parameters.

return of the supplied AC input power the ELI. The rectifier will aut omat ically assume

the DC load (charger, inverter) from the batteries. The ELI will simultaneously supply

M4102 Ty-Borealis 8-48KW Operators Manual v1.0 2013-08-14

Reserve Mode

2.4

Figure 2.4

Reserve Mode Operation

If the inverter is placed into an abnormal condition, such as over temperature,

to

interruption of the AC output.

Manual Bypass Mode

2.5

Figure 2.5

Manual Bypass Mode Operation

During ELI service procedures or battery replacement, the loads cannot be

close

the loads.

5

short circuit, abnormal output voltage or is overloaded for a period which

exceeds the inverter’s limits, the inverter will automatically shutdown in order

protect itself. If the AC utility power is within the normal parameters, the static

switch will automatically transfer the load to the reserve (utility) source without

interrupted, and as such the technician needs to turn off the inverter switch,

the bypass breaker and then open the rectifier and reserve (utility) breakers. The

ELI is now running in Manual By-pass mode supplying utility AC to the loads. The

AC output will not be interrupted during the manual bypass transfer procedure

because the manual bypass switch is designed to supply continuous power to

M4102 Ty-Borealis 8-48KW Operators Manual v1.0 2013-08-14

Features and Advantages

2.6

a.

Reliable input protection: Circuit breakers are in each input loop to ensure

caused by abnormal conditions in either the rectifier or the load.

b.

Input surge protection: Input surge protection is added at the input to

s

that are being turned on and/or off.

c.

EMI suppression: An EMI filter is added to meet the international EMC limits

connected to the same AC source.

d.

Ruggedness: The rectifier employs phase control technology to regulate the

PFC circuit also assist in maintaining the input waveform.

e.

High frequency design: The inverter design incorporates high frequency,

DC

acoustic noise, size and weight.

f.

True galvanic isolation: The isolation transformer addresses ground

mode of operation.

g.

PNP modular design: The circuit boards are designed into several modules,

easy replacement in the field when necessary and eliminate field diagnostics.

h.

Cold start function: The ELI can be started without the utility AC supply

designed

ELI on battery DC power.

i.

Multi-CPU design: Several CPU’s are designed into the control circuit.

reliability and up-times by eliminating field problems.

6

power can continue through the other loops in the event of a breaker trip

provide enhanced protection to both the ELI and the load and also protect

against lightning effects and/or surges caused by large cycling loads or those

to ensure that No noise will effect or interfere with other equipment

DC bus voltage allowing the batteries to be charged while supplying DC

power to the inverter. This has been proven to be the most efficient method

to control and regulate the charge on the batteries. The SCR technology and

highly efficiency Insulated Gate Bi-polar Transistors (IGBT). A PWM wave,

synchronized to the bypass input, triggers the IGBT’s, which invert the

into AC power required by the loads. This design decreases the number of

required components, increases reliability and performance while decreasing

differentials between the input and output, and prevents ground leakage

current problems, common mode and normal mode noise. This transformer is

located on the output side of the ELI system providing isolation under every

which are plugged into slots in the ELI. These plug-able modules allow for

being activated. Or present at the input terminal strip because our

system is designed with current limiting circuitry, which allows Startup of the

These critical functions are designed with multi-level redundancy increasing

M4102 Ty-Borealis 8-48KW Operators Manual v1.0 2013-08-14

j.

Protection against possible operator error: The ELI is designed with

causing possible damage.

k.

Wide input range: The components are overrated by design to handle high

Tycor

today’s market.

l.

Harsh environment: Each component of the ELI is chosen with the highest

specifications related to temperature, humidity, altitude, surge or noise.

m.

Intelligent charger: The ELI will automatically recharge (boost charge) the

begins.

n.

Intelligent battery test: The batteries are tested after every boost charge

be informed immediately through alarms on the ELI system.

o.

Charging rate: The charging rate is selectable (L/M/H) according to Ah

banks without adding an additional charger (up to 8hr. back-up).

p.

MTBF of cooling fans: Long cycling fans will operate at variable speeds

increasing the life expectancy of the fan motors.

q.

Redundant power supply: Redundant power supplies have been installed

to allow for worry free operation of the system.

r.

Intelligent interface: One rem ote control panel (or one PC) can monitor and

transmitted to external modules through four RS-485 ports.

s.

Data log capability: All abnormal conditions will be stored within the ELI

abnormal

for servicing.

7

breaker on/off sensors and power supply sensors. These sensors prevent

potential operational mistakes from interfering with the start –up operation

input voltages and currents without harm to the s ystem, ensuring that

UPS ELI’s remain one of the most reliable ELI Systems available in

degree of safety margins allowing for wider environmental parameters and

batteries when the battery voltage level decreases to approximately 2V/Cell

or to a user specified level. To prevent the over-charging of the battery, the

boost charge will stop when batteries achieve a 90% charged level or the

ambient temperature reaches 35oC (95oF) at which point the float charging

whether the charge has been initiated by a battery discharge state (2V/Cell)

or by the regular battery test performed by the ELI (monthly test). When an

abnormal condition (low charge rating, or bad battery) is found the user will

ratings of the batteries. The charger is designed to charge the larger battery

necessary which is d e pendent on the ambient temperature of th e E LI syst em

control up to ninety-nine ELI’s. The communication allows for N+1

redundancy, whereby if one system encounters an emergency or fault

condition, it will warn the user immediately and the load is automatically

transferred to the other ELI systems. The ELI status, data or commands are

control interface board for further reference by the user. Each

condition is time and date stamped (real-time clock) as the event occurs. This

history is stored and cannot be removed even if or when the ELI is turned off

M4102 Ty-Borealis 8-48KW Operators Manual v1.0 2013-08-14

t.

Convenient front panel design: The LCD display and control switches are

is password protected.

u.

Emergency stop: In the event of an emergency the ELI can be shutdown

detector signal (optional).

Rectifier

2.7

The main function of a rectifier is to convert the AC input power to DC power. The

supplies the inverter.

Figure 2.6

Rectifier Function

The rectifier design used in the 8KW to 48KW ELI’s include a 6-pulse full

affecting any part of the ELI system.

Additionally, over and under-voltage protection is added to improve reliability and

to

handle extreme ranges of high voltage and high current (–25% to +25%).

8

accessible through the up, down, and enter switches below the front panel

window. All the viewable parameters can be read without opening the front

door. The inverter on/off switch is protected from accidental operation by

being located behind the locked front door although the inverter can still be

switched on and off via the control switches on the front panel but this feature

(no AC at the output) either through a switch (optional) or through a smoke

DC power is then used to charge the batteries, supply the DC bus, which in turn

controlled rectifier. Power Factor Correction (PFC) has been added to maintain a

high input power factor, independent of the load power factor. This 6 pulse

rectifier smoothes the current waveform and reduces the harmonic content

reflected back to the utility. The control circuit regulates the DC bus to within 1%

of the nominal voltage. Soft walk-in circuitry (approximately 20 seconds) and

current limiting circuitry are used to prevent over current or surge currents from

to shutdown the rectifier in the event of abnormal conditions. The DC bus is

adjustable to allow for different types and capacities of batteries. The power

components used within the rectifier are specially designed and selected

M4102 Ty-Borealis 8-48KW Operators Manual v1.0 2013-08-14

Inverter

2.8

Figure 2.7

well above the human audible range.

The Voltage regulating circuitry limits the output voltage variation to within 1% of

to

loads

are connected.

The system is designed to incorporate an independent inverter per phase. These

100% unbalanced load situation.

The IGBT is operated in its optimal condition to obtain maximum efficiency,

keeping electrical costs to a minimum.

Usually, most ELI failures are a result of inverter failures. To prevent this

added a high efficiency filter designed to suppress the spikes and noise that can

be reflected from the attached loads back into the ELI system.

allowing for good ventilation systems within further increase reliability.

Specifying

fuses and

9

Inverter Layout

The inverter is composed of IGBT’s, inductors, capacitors, highly efficient filters,

control circuitry and protection circuitry. This inverter inverts the DC power

received on the DC bus to isolated, noise-free AC power, which is then supplied

to the critical loads. Our PWM wave generator is switching at a higher frequency

the nominal voltage and special compensation circuitry has been added

eliminate output distortion. Every component is oversized to accept a wide DC

input range (from 285 to 420VDC), allowing the output waveform to remain

sinusoidal throughout the entire range. With the aid of dynamic feedback loop

circuits the inverter maintains a true sine wave output, even if non-linear

inverters are totally independent of each other preventing the possibility of

cascading failures. This allows the user to connect loads to adjacent inverters

without affecting the other inverters providing high-end voltage regulation under a

occurrence, Tycor UPS has included redundant protection circuitry to protect the

inverter and increase its reliability. To enhance this protection we have also

oversized and high quality components, additional semi-conductor

M4102 Ty-Borealis 8-48KW Operators Manual v1.0 2013-08-14

Loading...

Loading...