PRN800 MX Printer MZX Fire alarm system

© Tyco Fire & Security GmbH, Victor von Bruns-Strasse 21, 8212 Neuhausen

am Rheinfall, Switzerland

www.zettlerfire.com

120.415.535_17A-03-PRN, doc. version 3, 22. March 2017

Subject to change without notice.

Paper roll replacement

1 Undo the two Supadrive™ screws and

remove the printer mechanism front

cover.

2 Pull out the paper drive spindle.

3 Pull out the paper roll retaining bar and

slide off the old paper roll.

4 Put the new paper roll onto the paper roll

retaining bar with the paper feeding from

the rear.

5 Press the paper roll retaining bar back into

its grooves.

6 Feed the paper over the paper drive spin-

dle and press the spindle back into its

retaining grooves.

7 Feed the paper through the printer mecha-

nism front cover slot and refit the retaining

screws.

Ordering information

Fig. 3: Paper change

1 –Paper drive spindle

2 –Paper roll retaining bar

1

2

Item Order Code

Spare paper roll (pk of 5) 557.301.014

Fig. 4: Order codes

MZX Fire alarm system PRN800 MX Printer

Fixing Instructions Doc. version 3 1/4

PRN800 MX Printer

Part No. 557.202.024

The PRN800 is fitted to the front cover of the

MX /T2000 battery housing/MX2 Expansion box housing and is powered from the

panel PSU830 Power Supply via an FB800

fuse board. The use of a thermal printer mechanism ensures high reliability, only the paper

roll requires replacement periodically.

Installation instructions

The installation instructions are as follows:

1 Open the battery/expansion housing

and loosen or remove the relevant

blanking strips holding the top blanking plate onto the front door.

Fig. 1: PRN800 MX printer kit

1 –Paper feed button

1

NOTICE

The PRN800 Printer kit is

designed for use within the MX/

T2000 battery housing and MX2

Expansion box housing.

CAUTION

The printer assembly must be

powered via a FB800 fuse board

using a 0.5 A time delay fuse.

A free cable entry hole is required

in both the controller and battery/

expansion housings.

Any cable runs must be protected

by conduit or trunking.

2/4 Fixing Instructions Doc. version 3

PRN800 MX Printer MZX Fire alarm system

2 Remove the blanking plate and fit the

printer assembly.

3 Re-tighten blanking strips to secure

printer assembly.

4 Locate a spare cable entry gland into

the housing. If none is available, then

a knockout must be removed.

5 To remove a knockout, remove any

fouling PCBs (or wiring) to prevent

swarf or metal filings damaging them.

6 Holes for the cable entry gland must

be drilled in the T2000/T2000 battery

housing gland plates.

7 Connect data lead to printer assem-

bly. Data cable should be connected

to COM1 on FIM inside the MX/

T2000/MX2 housing.

8 Locate a spare 24V fused output on

the FB800 fuseboard. Remove 0.5A

fuse. Connect red and black wires of

power cable assembly to +24V and 0V

respectively.

– Connect power lead to 24V dc fused

supply input TB1 (See Item 6 in

Fig. 2) of printer assembly.

Note: At TB1, connect +24V to the

pin VM and -0V to the pin 0V respectively.

– Power and data cables may be run

together if required through an

appropriate conduit and should be

separated from other field wiring of

the MX/T2000 panel.

9 Fit the paper roll to printer mecha-

nism, as described in Paper Roll

Replacement.

10 Replace the 0.5A fuse taken from the

FB800 fuseboard.

11 Check that the jumper links are cor-

rectly fitted on the Printed Circuit

Board.

– Configure the jumper links as indi-

cated in Fig. 2.

12 Configure the printer using MZX CON-

SYS as follows:

– In the Printers dialog box:

Printer Address - COM1, tick Enabled

Printer Name - PRINTER

Paper Width -Narrow (40)

Printer Type - Standard Printer

Quiescent Logging - tick if required

Default Printer - tick

– In the Communication Ports dialog

box:

Set the Baud Rate to 9600

13 Save the printer configuration, then

download the new configuration.

14 The PRN800 is now installed.

NOTICE

All necessary precautions

must be taken to protect

wiring and PCBs.

MZX Fire alarm system PRN800 MX Printer

Fixing Instructions Doc. version 3 3/4

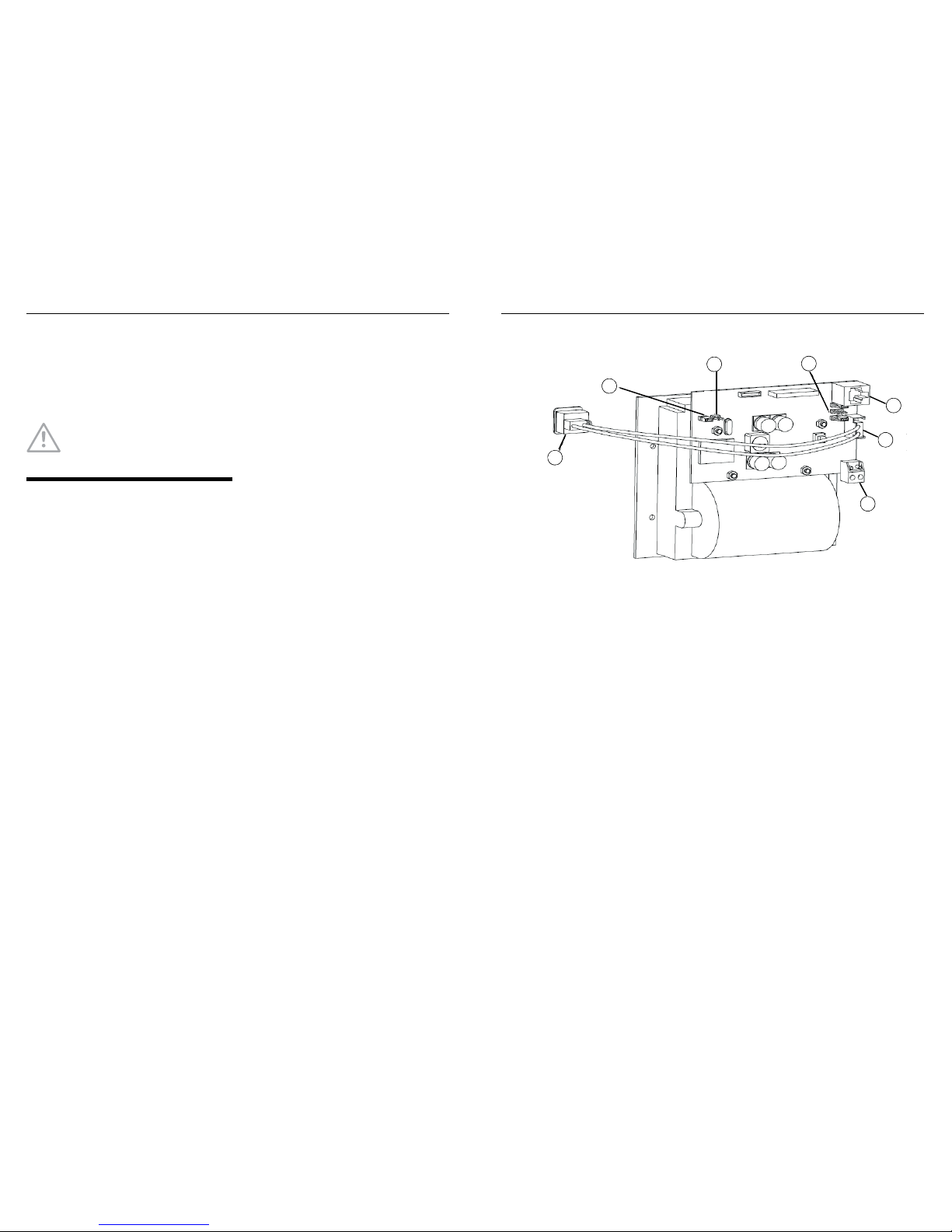

Fig. 2: Printer configuration - Jumper setting (1-3) and wiring connections (4-7)

1 –LK6 ON

2 –LK5 OFF

3 –LK1 RIGHT, LK2 OFF, LK4 RIGHT

4 –Printer connector for RS232

5 –Cable to paper feed button

6 –Printer hea der connector for power supply cable

7 –Connection t o paper feed button

1

2

3

4

5

6

7

PRN800 MX-Drucker MZX-Brandmeldeanlage

© Tyco Fire & Security GmbH, Victor von Bruns-Strasse 21, 8212 Neuhausen

am Rheinfall, Schweiz

www.zettlerfire.com

120.415.535_17A-03-PRN-DEU, Dok.-Version 3, 6. April 2017

Änderungen vorbehalten.

Wechseln der Papierrolle

1 Lösen Sie die beiden Supadrive™-Schrau-

ben und nehmen Sie die vordere Abdec-

kung des Druckerwerks ab.

2 Ziehen Sie die Papiervorschubrolle her-

aus.

3 Ziehen Sie den Haltestift der Papierrolle

heraus und schieben Sie die alte Papier-

rolle herunter.

4 Setzen Sie die neue Papierrolle auf den

Haltestift und führen Sie dabei das Ende

des Papierstreifens von hinten nach vorne.

5 Drücken Sie den Haltestift wieder in die

Kerben.

6 Führen Sie das Papier über die Papiervor-

schubrolle und drücken Sie die Rolle wie-

der in die Haltekerben.

7 Fädeln Sie das Papier durch den Schlitz in

der vorderen Abdeckung des Druckerwerks und bringen Sie die Befestigungsschrauben wieder an.

Bestellinformationen

Abb. 3: Papierwechsel

1 –Papiervorschubrolle

2 –Haltestift für Papierrolle

1

2

Komponente Bestellnum-

mer

Ersatzpapierrolle (5er

Pack):

557.301.014

Abb. 4: Bestellnummern

MZX-Brandmeldeanlage PRN800 MX-Drucker

Montagehinweis Dok.-Version 3 1/4

PRN800 MX-Drucker

Teilenr. 557.202.024

Der PRN800 wird an der Vordertür des MZX/

T2000-Batteriegehäuses bzw. MX2-Universalgehäuses montiert und durch die Energieversorgung PSU830 über die Sicherungsplatte FB800 mit Strom gespeist. Durch das

Thermo-Druckverfahren wird eine hohe

Zuverlässigkeit des Druckers erreicht. Lediglich die Papierrolle muss regelmäßig gewechselt werden.

Abb. 1: PRN800 MX-Druckerkit

1 –Papierzufuhrtaste

1

HINWEIS

Das PRN800-Druckerkit ist für die

Verwendung mit dem MZX/

T2000-Batteriegehäuse und

dem MX2-Universalgehäuse

vorgesehen.

VORSICHT

Die Stromversorgung des

Druckermoduls muss über eine

FB800-Sicherungsplatte unter

Verwendung einer trägen 0,5-ASicherung erfolgen.

Sowohl im Zentralen- als auch im

Batterie-/Erweiterungsgehäuse

muss eine freie

Kabeleinführungsöffnung

vorhanden sein.

Alle Kabelwege müssen durch

geeignete Maßnahmen

mechanisch geschützt werden.

2/4 Montagehinweis Dok.-Version 3

PRN800 MX-Drucker MZX-Brandmeldeanlage

Installations- und Montageanleitung

Gehen Sie zur Installation wie folgt vor:

1 Öffnen Sie das Batterie-/Erweite-

rungsgehäuse und lösen oder entfer-

nen Sie die entsprechenden Leisten,

mit denen die obere Blindplatte an der

Vordertür befestigt ist.

2 Nehmen Sie die Blindplatte ab und

setzen Sie das Druckermodul ein.

3 Bringen Sie die Blindleisten wieder

fest an, um das Druckermodul zu

sichern.

4 Suchen Sie nach einer freien Kabel-

verschraubung im Gehäuse. Wenn

keine vorhanden ist, muss eine Öff-

nung gebohrt werden.

5 Entfernen Sie zum Bohren der Öff-

nung alle angrenzenden Leiterplatten

(oder Kabel), sodass diese nicht durch

Bohrspäne oder Metallstaub beschä-

digt werden.

6 Die Öffnung für die Kabelverschrau-

bung muss in die dafür vorgesehene

Platte des MZX/T2000-Batteriegehäu-

ses gebohrt werden.

7 Verbinden Sie das Datenkabel mit

dem Druckermodul. Das Datenkabel

muss an COM1 auf der FIM-Hauptpla-

tine im Inneren des MZX/T2000/MX2Gehäuses angeschlossen werden.

8 Suchen Sie einen freien gesicherten

24-V-Ausgang auf der FB800-Sicherungsplatte. Bauen Sie die 0,5-ASicherung aus. Schließen Sie die

roten und schwarzen Leitungen des

Kabelsatzes an +24 V bzw. 0 V an.

– Schließen Sie die Leitung für die

Spannungsversorgung an den gesicherten 24-VDC-Eingang TB1 (siehe

Komponente 6 in Abb. 2) des Druckermoduls an.

Hinweis: Verbinden Sie an TB1

+24 V mit Pin VM und -0 V mit

Pin 0V.

– Das Netz- und Datenkabel können

bei Bedarf zusammen in einem

geeigneten Kabelkanal verlegt werden und sollten von anderen Feldverdrahtungen der MZX/T2000-Zentrale

getrennt werden.

9 Setzen Sie die Papierrolle in das Druc-

kerwerk, wie unter „Wechseln der

Papierrolle“ beschrieben.

10 Setzen Sie die aus der FB800-Siche-

rungsplatte ausgebaute 0,5-A-Sicherung wieder ein.

11 Überprüfen Sie, dass die Steckbrüc-

ken richtig auf der Leiterplatte eingesetzt sind.

– Konfigurieren Sie die Steckbrücken

wie in Abb. 2 dargestellt.

12 Konfigurieren Sie den Drucker über

MZX CONSYS wie folgt:

– Im Dialogfeld „Drucker“:

Wählen Sie unter „Druckeradresse

– COM1“ die Option „Aktiviert“

aus

Druckername – DRUCKER

HINWEIS

Es müssen alle notwendigen

Maßnahmen zum Schutz der

Kabel und Leiterplatten

getroffen werden.

MZX-Brandmeldeanlage PRN800 MX-Drucker

Montagehinweis Dok.-Version 3 3/4

Papierbreite – Narrow (40)

Druckertyp – Standarddrucker

Protokollierung im Ruhezustand –

bei Bedarf aktivieren

Standard-Drucker – aktivieren

– Im Dialogfeld „Kommunikations-

ports“:

Stellen Sie die Baudrate auf 9600

ein

13 Speichern Sie die Druckerkonfigura-

tion und laden Sie anschließend die

neue Konfiguration herunter.

14 Der PRN800 ist nun installiert.

Abb. 2: Druckerkonfiguration – Steckbrückeneinstellung (1-3) und Verdrahtungsverbindungen (4-7)

1 –LK6 ON

2 –LK5 OFF

3 –LK1 RECHTS, LK2 OFF, LK4 RECHTS

4 –Druckerverbindung für RS232

5 –Kabel zur Papierzufuhrtaste

6 –Verbindung der Druckersteckbrücke für das Stromversorgungskabel

7 –Anschluss zur Papierzufuhrtaste

1

2

3

4

5

6

7

Loading...

Loading...