Tyco Healthcare AG 6325 User manual

Operation

&

Service

MODEL

Manual

6325

COMPRESSION

#YCO

KENDALL

SYSTEM

/

Healthcare

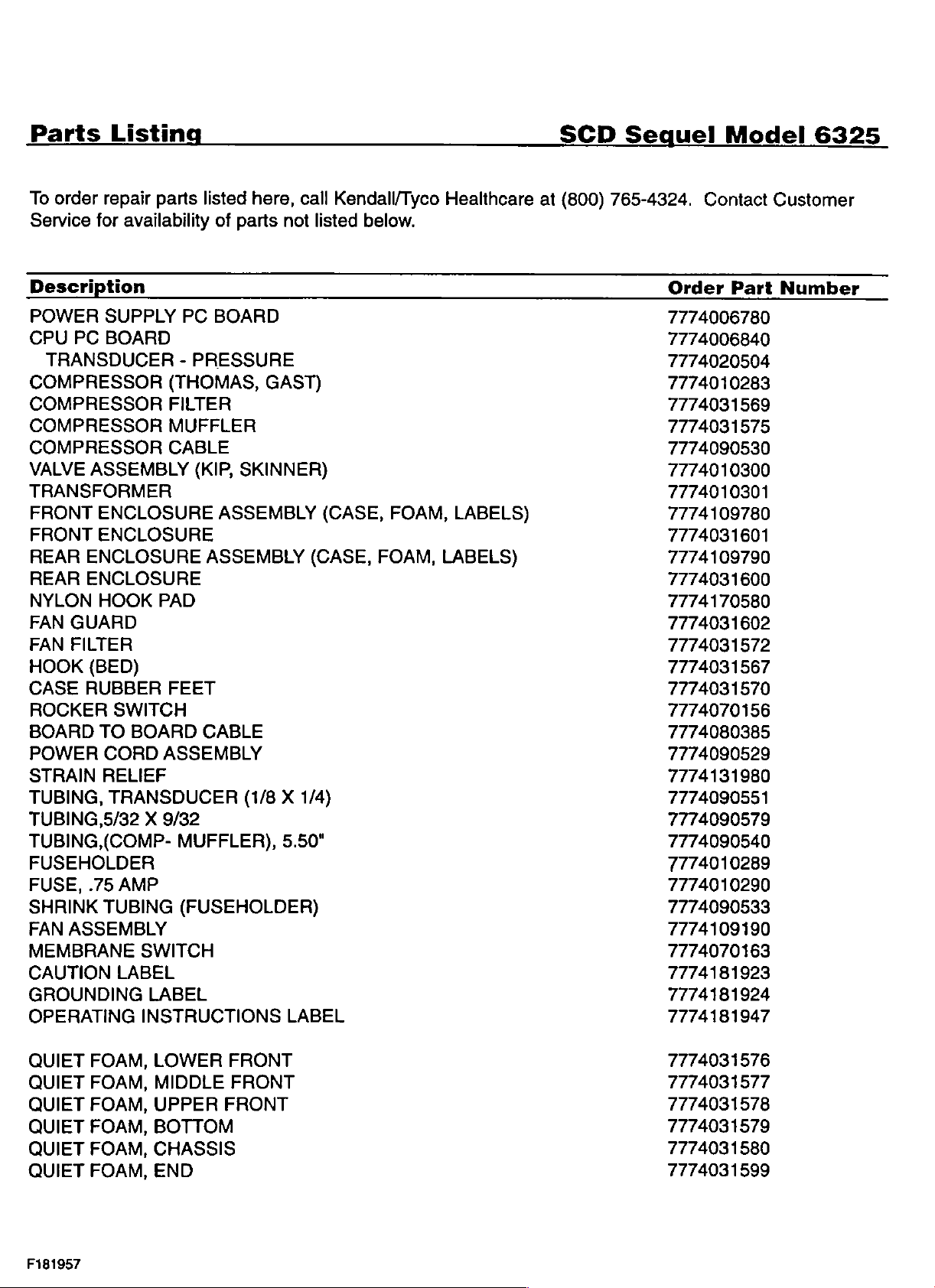

Parts

To

order

Service

Description

POWER

CPU

TRANSDUCER

COMPRESSOR

COMPRESSOR

COMPRESSOR

COMPRESSOR

VALVE

Listing

repair

for

availability

SUPPLY

PC

BOARD

ASSEMBLY

parts

PC

-

(THOMAS,

FILTER

MUFFLER

CABLE

TRANSFORMER

FRONT

FRONT

REAR

REAR

NYLON

FAN

FAN

HOOK

CASE

ROCKER

BOARD

POWER

STRAIN

TUBING,

ENCLOSURE

ENCLOSURE

ENCLOSURE

ENCLOSURE

HOOK

GUARD

FILTER

(BED)

RUBBER

SWITCH

TO

BOARD

CORD

RELIEF

TRANSDUCER

PAD

FEET

ASSEMBLY

TUBING,5/32 X 9/32

TUBING,(COMP-

MUFFLER),

FUSEHOLDER

FUSE,

SHRINK

FAN

MEMBRANE

CAUTION

GROUNDING

OPERATING

.75

AMP

TUBING

ASSEMBLY

LABEL

(FUSEHOLDER)

SWITCH

LABEL

INSTRUCTIONS

listed

of

here,

parts

BOARD

PRESSURE

(KIP,

SKINNER)

ASSEMBLY

ASSEMBLY

CABLE

(1/8 X 1/4)

call

not

GAST)

5.50"

LABEL

Kendall/Tyco

listed

(CASE,

below.

(CASE,

FOAM,

FOAM,

Healthcare

LABELS)

LABELS)

SCD

at

(800)

Sequel

765-4324.

Order

7774006780

7774006840

7774020504

7774010283

7774031569

7774031575

7774090530

7774010300

7774010301

7774109780

7774031601

7774109790

7774031600

7774170580

7774031602

7774031572

7774031567

7774031570

7774070156

7774080385

7774090529

7774131980

7774090551

7774090579

7774090540

7774010289

7774010290

7774090533

7774109190

7774070163

7774181923

7774181924

7774181947

Model

Contact

Part

6325

Customer

Number

QUIET FOAM,

QUIET

QUIET

QUIET

QUIET

QUIET

F181957

FOAM,

FOAM,

FOAM,

FOAM,

FOAM,

LOWER

MIDDLE

FRONT

FRONT

UPPER FRONT

BOTTOM

CHASSIS

END

7774031576

7774031577

7774031578

7774031579

7774031580

7774031599

Operation

&

Service

Manual

M

GENERAL

e

Pre-Operation

*

Use

+

Operation

e

Cycle

©

Comfort

+

Power

+

Sleeve

M

FAULT

MODEL

Table

OPERATING

Check

of

Bed

Hook............................................

....................................,..,.,,,,,4.

Monitor

Cord

Compatibility

CONDITIONS

..........................,,..................

Cooling

Storage

6325

of

Contents

INSTRUCTIONS

.......................................

...................................,........

........................................

........................................

1

1

1

1

1

1

1

e

Fault

Messages

ㆍ

Watchdog

M

CONTRAINDICATIONS

M

CAUTIONS

E

SERVICE

slntroduction.............................

e

Warranty

+

Maintenance

e

Ventilation

efFuses.................................

+

Electrical

e

Cleaning

*

Electrical/Electronics

e

Pneumatic

e

Portidentity

»

System

+

Pressure

Circuit

.............................,.,....,..........,.,.

AND

and

Safety

.................................,...............

Start-Up

Monitoring

.................................,..,..,..

.........................................1

...........................,.............

MAINTENANCE

Factory

.........................................,....

.................................................

Description

............................................

Service

............................................

Description

...............................:

Routine

........................................

...............................

...........................

....................................

eee

eee

Fer

24

4

5

5

6

6

6-7

7

7

7

7

7

8

8

8

8

(Continued

on

next

page}

Operation

&

Service

Manual

MODEL

Table

M

CALIBRATION/TEST

.latroduction..............................

*

Calibration

.CalibrationProcedure.....................................

e

General

+

Procedure

Ш

DISASSEMBLY/REASSEMBLY

»eCaseRemoval

Verification

Function

.....................,..........................

.............................................

of

(CONTINUED)

METHODS

Procedure

Test

......................................

6325

Contents

1...

eee

...........................

9

9

9-10

10

10

1

eCircuitBoardRemoval......................................

+

Circuit

+

Compressor..........................................,.....

+

Solenoid

«

Case

画

SPEEIFICATIONS

HE

QUALITY

E

FIGURE

@

FIGURE

@

FIGURE

M

FIGURE

E

FIGURE

Ш

FIGURE

BB

FIGURE

Board

Reassembly

SPECIFICATIONS

1:

2:

3:

4:

5:

6:

7:

Installation

Valves

...................,...,.,.......,..........

..........................................

...................................

..................................

Diagram

System — View

Diagram

Pneumatics

System — Exploded

of

Bed

of

of

Power

Schematic

Hook

Controls & Indicators

Cord

View

Pneumatics & Electrical

Electrical

Schematic

ων

νε

νο

ων κκ

νε

κκ

Use

...........................

.............

Storage

.............................

Circuits

...............................

.....................

...........................

....................

1

1

1

12

12

18

、.4

15

16

7

18

19

20

2

General

The

SCD

SEQUEL

limbs

to

prevent

M

PRE-OPERATION

Before

using

the

patient,

©

©

©

©

©

Ш

The

hook.

the

away

NOTE:

that

not

E

Turn

the

check

at

normal

location

NOTE:

will

while

illuminate

In

appropriate

will

verify

The

Tubing

the

Sleeves.

System

connect

plastic

There

The

for

The

receptacle

No

USE

footboard

interfere

can

bag.

are

left

free

air

System

flammable

OF

SCD

SEQUEL

This

feature

from

the

After

the

System

the

and

BED

placing

OPERATION

the

power

System).

the

upon

top

The

start-up.

of

operation

of

each

When

be

off.

To

the

machine

when

the

case

of a fault

fault

shut

down.

Operating

Compression

deep

SCD

that:

Set

is

Both

only

second

no

kinks

right

flow.

power

of

the

anesthetic

HOOK

may

of

the

patient

is

securely

with

patient

switch

System

the

display

with

control

the

System

activate

the

code

vein

thrombosis

System

Model

in

patients

CHECK

SEQUEL

properly

Sleeves

be

or

sides

cord

correct

Compression

hospital

(see

the

on

The

ankle

is

option

condition,

Compression

connected

must

used

on

sleeve

but

sharp

bends

of

the

is

plugged

voltage.

gases

be

used

by

bed

Figure

System

held

care.

on

by

(located

performs a self-diagnosis

LED

segments

panel.

The

inflation.

and

indicator.

is

turned

Cooling,

press

operating.

is

on.

the

will

be

displayed

to

the

be

connected.

one

leg

(e.g.,

leave

it

packaged

in

the

System

on

are

into a grounded

are

present.

System

placing

with

1).

the

the

on, the

The

features a bed

the

footboard,

footboard,

the

lower

illuminate,

System

See

Figure 2 for

Sleeve

the

Cooling

Cooling

alarm

will

and

Instructions

6325

is

at

risk.

System

Tubing

the

System

on

the

System

unobstructed

right

then

and

If

the

amputee),

in

its

Set.

AC

System

on

facing

confirm

and

does

side

of

and

LED

starting

begins

the

Cooling

Button

LED

will

sound.

The

the

System

designed

to

apply

M

CYCLE

The

SCD

Monitor,

System’s

two

INFLATE

sions

INFLATE

part

off,

which

compression

back-lit

and

of

one

and

of

the

the

compressor

AUTOMATIC

The

SCD

SEQUEL

processor

feature

maintains

changes

After

display

Controller

the

the

Within

and

“45”

NOTE:

the

order

MW

Power

System

the

E

The

with

controlled

automatically

this

position.

the

start-up

45mmHg.

initial

setting

45

will

five

47mmHg

displayed.

Even

System

to

maintain

POWER

cord

is

provided

bed

hook.

SLEEVE

SCD

SEQUEL

SCD

Sleeve

5336.

sequential

MONITOR

SEQUEL

panels

VENT.

VENT

cycle

set

will

display

cycles

and

after

will

CORD

storage

This

COMPATIBILITY

gradient

Compression

continuously

sequence.

which,

These

represent

complete

the

lights

will

system

will

shut

cycle.

is

PRESSURE

Compression

automatic

sets

the

pressure

sequence,

During

adjust

period

the

the

continue

the

itself

the

“.45.”

the

System

decimal

initial

45mmHg.

even

the

the

to

decimal

45mmHg

to

STORAGE

for

the

by

wrapping

is

shown

Compression

Reorder

in

#5330,

compression

System

displays

The

Monitor

when

illuminate

in.

off

the

During

If

the

during

illuminated,

the

ADJUSTMENT

System

pressure

pressure

when

the

System

first

few

inflation

meet

the

45mmHg.

points

will

stabilize

points

will

pressure

make

small

SCD

SEQUEL

the

power

Figure

3.

System

is

5329,

to

the

has a Cycle

the

status

of

consists

two

major

operation,

to

indicate

Sleeve

Vent

features

adjustment.

to

45mmHg

patient

will

on

turn

adjustments

designed

5480,

which

Cooling

Cycle.

micro-

moves

set

itself

cycles

During

each

side

between

off,

leaving

is

reached,

Compression

cord

around

for

5345,

lower

the

of

read

divi-

the

is

This

and

or

and

the

of

43

in

use

and

Model

6325

Fault

Fault

CODE

SL

Conditions

Messages

FAULT

System

TYPE

Low

”

DESCRIPTION

There

is

less

the

end

of

two

POTENTIAL

*

Tubing

*

There

CORRECTIVE

©

Ensure

*

Turn

the

Set

is a leak

proper

the

System

unit

requires

than

8mmHg

consecutive

CAUSES

is

not

properly

inside

ACTIONS

Tubing

off

and

servicing.

pressure

cycles

the

System.

connections.

restart.

at

thereafter.

connected.

If

the

the

end

System

of

the

first

displays

inflation

the

same

cycle

fault,

or

at

Lo

SH

(1)

When

deactivates

active

Low

System

the

microprocessor

all

valves,

until

the

System

The

tive

POTENTIAL

*

*

CORRECTIVE

*

*

High

detects a fault

displays a fault

power

switch

Pressure

*

*

code,

is

System

cycles.

is

unable

The

pressure

CAUSES

Tubing

Sleeves

Ensure

Apply

the

Turn

the

On

is

not

are too

proper

Sleeves

patients

the

unit

first

leg.

System

requires

has

exceeded

cycle,

properly

loose.

ACTIONS

Tubing

so

off

servicing.

System

appropriately.

On

subsequent

display

turned

this

condition,

and

sounds

off.

cycles,

code.

it

interrupts

an

to

bring

in

the

connected.

connections.

that

only

two

and

restart.

90mmHg

will

switch

Systern

the

audible

the

pressure

Sleeves

fingers

If

the

after

to

will

normal

alarm.

up

above

is

consistently

fit

snugly

System

1.2

seconds

vent

mode

switch

to

(Continued

operation

This

alarm

43mmHg

below

between

displays

the

of the

will

the

of

thigh

and

adjust

fault

mode

on

next

controller,

remain

for

five

the

set

each

Sleeve

same

fault,

cycle:

flow

control

and

page)

consecu-

pressure.

and

Segue

Fault

CODE

SH

HI

Conditions

FAULT

TYPE

System

High

High

(continued)

comwe

DESCRIPTION

POTENTIAL

©

Tubing

©

Sleeves

CORRECTIVE

*

Straighten

+

Apply

the

e

Tum

the

The

consecutive

set

POTENTIAL

*

Sleeves

Set

are

the

patients

the

System

unit

requires

System

is

pressure.

are

CAUSES

is

kinked.

too

tight.

ACTIONS

out

kinked

Sleeves

so

leg.

off

servicing.

unable

cycles.

The

CAUSES

too

tight.

Tubing

that

two

and

restart.

to

bring

pressure

Set.

fingers

If

the

the

pressure

in

the

can

fit

snugly

System

down

Sleeves

between

displays

is

the

below

47mmH

consistently

each

same

above

Sleeve

fault,

for

five

the

and

CORRECTIVE

+

Apply

the

the

patients

*

Turn

the

System

the

unit

reguires

The

SP

System

Pressure

System

POTENTIAL

+

Sleeves

are

CORRECTIVE

+

Apply

the

the

patients

e

Turn

the

System

the

unit

reguires

If

the

di

internal

Diagnostic

One

solenoid

condition,

The

shut

System

ACTIONS

Sleeves

leg.

off

servicing.

has

not

CAUSES

too

tight.

ACTIONS

Sleeves

leg.

off

servicing.

valve

the

should

so

that

two

and

restart.

controlled

so

that

and

stays

System

be

returned

to

two

restart.

open,

off,

and

|

fingers

If

the

can

System

35 - 55mmHg

fingers

to

can

If

the

System

the

microprocessor

display

the

manufacturer

fit

snugly

displays

fit

snugly

displays

this

code.

between

the

for

12

consecutive

between

the

will

for

repair.

each

same

each

same

detect

Sleeve

fault,

cycles.

Sleeve

fault,

this

and

and

Model

6325

Fault

CODE

d2

d3,

d4

ds

Conditions

FAULT

TYPE

Internal

Diagnostic

Diagnostic

Diagnostic

Two

Internal

Three,

Four

Internal

Five

commun

DESCRIPTION

Upon

start-up,

to

pass

all

of

these

The

System

These

occur

The

System

This

The

Compressor

cleaned.

the

manufacturer

faults

during

fault

is

If

should

are

normal

should

indicated

fault

the

microprocessor

tests,

it

will

be

returned

indicated

Outlet

reoccurs

for

only

operation.

be

returned

if

the

Filter

after

repair.

performs

not

start

to

the

manufacturer

during

pump

should

replacement,

special

to

the

manufacturer

speed

be

diagnostic

and

this

test

is

not

what

replaced

the

tests.

fault

code

for

repair.

conditions

for

repair.

is

expected.

or

the

Muffler

System

should

If

the

will

be

and

be

System

displayed.

should

should

not

be

returned

fails

to

d7 - d9

de

internal

Diagnostic

Internal

Diagnostic

Eight,

Six

Seven,

Nine

WATCHDOG

CIRCUIT

This

fault

is

of

the

vent

cycle.

The

System

These codes

They

have

been

If

the

Microprocessor

circuit

will

trip.

operation.

If

the

cause

attempt

If

pulse,

the

to

reset,

cause

the

System

detected

should

have

be

not

reserved

This

causes

of

the

disruption

which

of

the

disruption

will

if

the

pressure

returned

been

implemented.

for

future

cannot

the

will

cause

restart

exceeds

to

the

use.

continue

System

is

still

the

was

transient,

with

the

25

mmHg

manufacturer

normal

to

present,

alarm

COOLING

go

to

function,

into

reset

the

sound

such

OFF.

after

for

repair.

the

and

restart

unit

will

once

every

as a high

54

seconds

watchdog

normal

continue

second.

energy

to

RF

Loading...

Loading...