Tyco Electronics T208M-PRINTER, T208M-C-PRINTER, T212M-PRINTER, T212M-C-PRINTER System User's Manual

Page 1

T200 SERIES THERMAL TRANSFER PRINTER

SYSTEM USER’S GUIDE

(T208M-PRINTER, T208M-C-PRINTER, T212M-PRINTER & T212M-C-PRINTER)

Page 2

T200 SERIES THERMAL TRANSFER PRINTER

SYSTEM USER’S GUIDE

(T208M-PRINTER, T208M-C-PRINTER, T212M-PRINTER & T212M-C-PRINTER)

APPROVALS NAME SIGNED DATE

TECHNICAL J. SWIFT

TECHNICAL SUPPORT J. SMITH

30/07/07

30/07/07

PRODUCT MANAGEMENT R. SWIFT

30/07/07

Revision History

Rev No CR No Date Incorporated By

1 Original Issue July 2002 Graham Leat & Mario Appello

2 Merged 4 languages November 2002 Jim Smith

3 Complete update March 2003 Graham Leat

4 Updated for New Model September 2004 Jim Smith

5 Made model have -Printer October 2004 Jim Smith

6 New logo & contents added July 2007 Jim Smith

7

8

9

Page 3

Contents

English .....................................................................................................................1

Forward ......................................................................................................................................2

Important Information!...............................................................................................................3

1.0 Printer Set-up..................................................................................................................4

1.1 Unpacking the Printer.................................................................................................4

1.2 Printer Overview ........................................................................................................5

1.3 Attaching the Power Supply To The Printer..............................................................6

1.4 Connecting the Interface Cable..................................................................................7

2.0 Ribbon Selection ............................................................................................................8

3.0 Loading Ribbon..............................................................................................................8

3.1 Adding a New Ribbon................................................................................................9

3.2 Removing a partially used Ribbon.............................................................................9

4.0 Loading Product...........................................................................................................10

4.1 Loading TMS Marker Sleeves .................................................................................11

4.2 Loading Labels.........................................................................................................12

4.3 Loading Product Cont… ..........................................................................................13

5.0 Calibration....................................................................................................................14

5.1 Alignment For Calibration .......................................................................................15

6.0 Changing Sensor Type .................................................................................................16

6.1 Reflective (Black Mark) Sensor...............................................................................16

6.2 Continuous Sensing Mode........................................................................................16

6.3 Transmissive Sensor.................................................................................................16

7.0 Printer Firmware Versions ...........................................................................................16

8.0 Software........................................................................................................................17

9.0 Print Quality.................................................................................................................17

10.0 Maintenance .................................................................................................................18

10.1 Cleaning the Print Head ...........................................................................................18

10.2 Cleaning the Platen Roller........................................................................................19

11.0 Troubleshooting............................................................................................................20

Appendix A ..............................................................................................................................21

T200 Series with Cutter........................................................................................................21

Clearing the Media Cutter....................................................................................................22

Appendix B...............................................................................................................................23

Interface Cable Wiring.........................................................................................................23

Francàis .................................................................................................................26

Avant-propos............................................................................................................................27

Information importante !..........................................................................................................28

1.0 Installation de l’imprimante .........................................................................................29

1.1 Déballage de l’imprimante.......................................................................................29

1.2 Vue d’ensemble de l’imprimante.............................................................................30

1.3 Branchement de l’adaptateur d’alimentation électrique de l’imprimante................31

1.4 Connexion du câble d’interface................................................................................32

2.0 Choix du ruban.............................................................................................................33

3.0 Chargement du ruban ...................................................................................................33

Page 4

3.1 Insertion d’un ruban neuf.........................................................................................34

3.2 Retrait d’un ruban partiellement usagé ....................................................................34

4.0 Chargement du produit.................................................................................................35

4.1 Chargement des manchons de marquage TMS........................................................36

4.2 Chargement d’étiquettes...........................................................................................37

4.3 Chargement du produit (suite)..................................................................................38

5.0 Calibrage ......................................................................................................................39

5.1 Alignement de calibrage...........................................................................................40

6.0 Changement du type de capteur ...................................................................................41

6.1 Capteur réflectif (marque noire)...............................................................................41

6.2 Mode de détection continue .....................................................................................41

6.3 Capteur transmissif...................................................................................................41

7.0 Versions du micrologiciel de l’imprimante..................................................................41

8.0 Logiciel.........................................................................................................................42

9.0 Qualité d’impression ....................................................................................................42

10.0 Entretien .......................................................................................................................43

10.1 Nettoyage de la tête d’impression ............................................................................43

10.2 Nettoyage du rouleau de la platine...........................................................................44

11.0 Dépannage....................................................................................................................45

Annexe A..................................................................................................................................46

Série T200 avec massicot.....................................................................................................46

Déblocage du massicot de support.......................................................................................47

Annexe B..................................................................................................................................48

Câblage du câble d’interface................................................................................................48

Deutsch...................................................................................................................51

Vorwort ....................................................................................................................................52

Wichtige Information!..............................................................................................................53

1.0 Aufbau des Druckers....................................................................................................54

1.1 Den Drucker auspacken............................................................................................54

1.2 Überblick über den Drucker.....................................................................................55

1.3 Anschluss des Druckers an die Stromversorgung....................................................56

1.4 Anschluss des Interface-Kabels................................................................................57

2.0 Auswahl des Farbbands................................................................................................58

3.0 Einlegen des Farbbands................................................................................................58

3.1 Ein neues Farbband einlegen....................................................................................59

3.2 Entfernen eines teilweise gebrauchten Farbbands ...................................................59

4.0 Einlegen von Druckmedien..........................................................................................60

4.1 Einlegen der TMS Markierungsbanderolen.............................................................61

4.2 Einlegen von Etiketten .............................................................................................62

4.3 Einlegen von Druckmedien Fortsetzung..................................................................63

5.0 Kalibrierung..................................................................................................................64

5.1 Ausrichtung zur Kalibrierung...................................................................................65

6.0 Wechsel des Sensortyps ...............................................................................................66

6.1 Reflektionssensor (schwarze Markierung)...............................................................66

6.2 Endlosdruck-Sensor..................................................................................................66

6.3 Sensor für lichtdurchlässige Druckmedien...............................................................66

Page 5

7.0 Drucker-Firmware-Versionen......................................................................................67

8.0 Software........................................................................................................................67

9.0 Druckqualität................................................................................................................67

10.0 Wartung........................................................................................................................68

10.1 Reinigung des Druckkopfes .....................................................................................68

10.2 Reinigung der Walzenrolle.......................................................................................69

11.0 Fehlerbehebung............................................................................................................70

Anhang A .................................................................................................................................71

T200 Serie mit Schneideinrichtung......................................................................................71

Reinigen der Schneideinrichtung .........................................................................................72

Anhang B..................................................................................................................................73

Interfacekabel-Verdrahtung..................................................................................................73

Español...................................................................................................................76

Objeto.......................................................................................................................................77

Información importante............................................................................................................78

1.0 Configuración de la impresora.....................................................................................79

1.1 Desembalaje de la impresora....................................................................................79

1.2 Visión de conjunto de la impresora..........................................................................80

1.3 Conexión de la impresora a la red eléctrica .............................................................81

1.4 Conexión del cable de interfaz.................................................................................82

2.0 Selección de cinta.........................................................................................................83

3.0 Carga de la cinta...........................................................................................................83

3.1 Adición de una nueva cinta......................................................................................84

3.2 Retirada de una cinta parcialmente usada ................................................................84

4.0 Carga del producto .......................................................................................................85

4.1 Carga de las fundas para marcar TMS .....................................................................86

4.2 Carga de las etiquetas...............................................................................................87

4.3 Carga del producto cont. ..........................................................................................88

5.0 Calibrado......................................................................................................................89

5.1 Alineación para el calibrado.....................................................................................90

6.0 Cambio del tipo de sensor............................................................................................91

6.1 Sensor reflectante (marca negra)..............................................................................91

6.2 Modo de detección continua.....................................................................................91

6.3 Sensor transmisor.....................................................................................................91

7.0 Versiones de microprogramación de la impresora.......................................................91

8.0 Software........................................................................................................................92

9.0 Calidad de impresión....................................................................................................92

10.0 Mantenimiento..............................................................................................................93

10.1 Limpieza del cabezal de impresión ..........................................................................93

10.2 Limpieza del rodillo de platina.................................................................................94

11.0 Resolución de problemas..............................................................................................95

Apéndice A...............................................................................................................................96

Serie T200 con guillotina.....................................................................................................96

Retirada de residuos de la guillotina ....................................................................................97

Apéndice B...............................................................................................................................98

Instalación del cable de interfaz...........................................................................................98

Page 6

English

English

T200 SERIES THERMAL TRANSFER PRINTER

SYSTEM USER’S GUIDE

(T208M-PRINTER, T208M-C-PRINTER,T212M-PRINTER & T212M-C-PRINTER)

EIL/MAN/002: REVISION 6 Date: July 2007 Page 1

Page 7

English

Forward

This manual provides installation and operation information for the T208M-PRINTER (E63660-

000), T208M-C-PRINTER (D82271-000), T212M-PRINTER (E23401-000) and T212M-CPRINTER (A53989-000), manufactured for Tyco Electronics.

Copyright Notice

This document contains information proprietary to Tyco Electronics. This document and

information contained within is copyrighted by Tyco Electronics and may not be duplicated in

full or in part by any person without written approval from Tyco Electronics. While every effort

has been made to keep the information contained within current and accurate as of the date of

publication, no guarantee is given or implied that the document is error-free or that it is accurate

with regard to any specification. Tyco Electronics reserve the right to make changes, for the

purpose of product improvement, at any time.

Trademarks

T208M and T212M are service trademarks of Tyco Electronics. Windows and MS-DOS are

registered trademarks of Microsoft Corp. All other marks are trademarks or registered

trademarks of their respective holders.

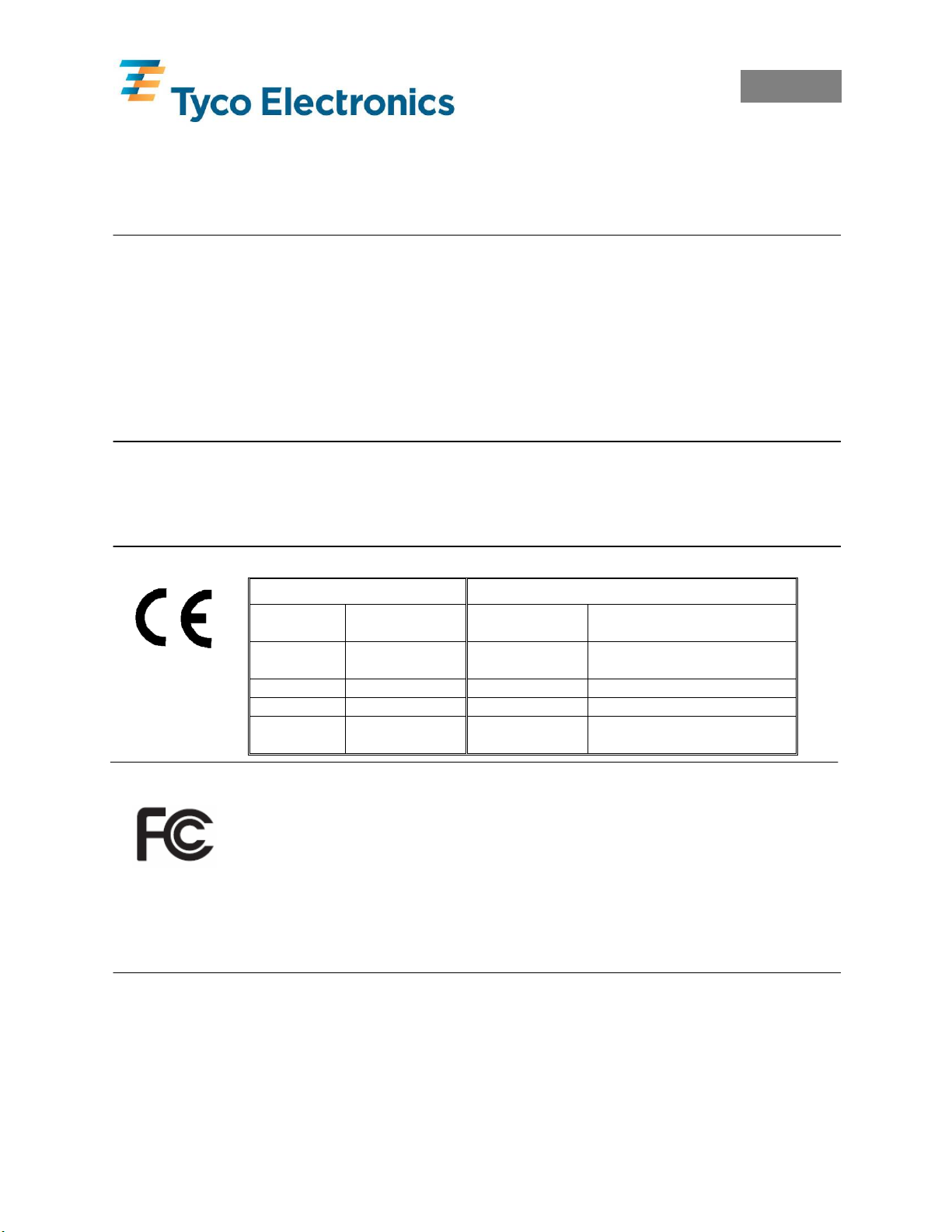

T208M-PRINTER, T208M-C-PRINTER, T212M-PRINTER and T212M-C-PRINTER Thermal Printers

European Council Directive Compliance to Standards

89/336/EEC EMC Directive

EMC Directive EN 55024 1988

92/31/EE EMC Directive EN 61000-3-2 Harmonic Emissions

92/31/EE EMC Directive EN 61000-3-3 Voltage Variation

CB Scheme

FCC – Declaration of Conformity

Models: T208M-PRINTER, T208M-C-PRINTER, T212M-PRINTER and

T212M-C-PRINTER conform to the following specifications: FCC Part 15,

Subpart B, Section 15.107(a) and Section 15.109(a) Class B digital device.

Supplimental Information:

This device complies with part 15 of the FCC Rules. Operation is subject to the following Two Conditions: (1)

This device may not cause harmfull interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

Industry Canada Notice:

This device complies with Industry Canada ICS-003 class B requirements.

Cet equipment est conforme a l’ICS-003 classse B de la norm Industrielle Canadian.

EN 55022-B

1988

EN 60950 1991

A1, A2, A3, A4

RF Emissions control

Immunity to Electro-magnetic

Disturbances

Safety

EIL/MAN/002: REVISION 6 Date: July 2007 Page 2

Page 8

English

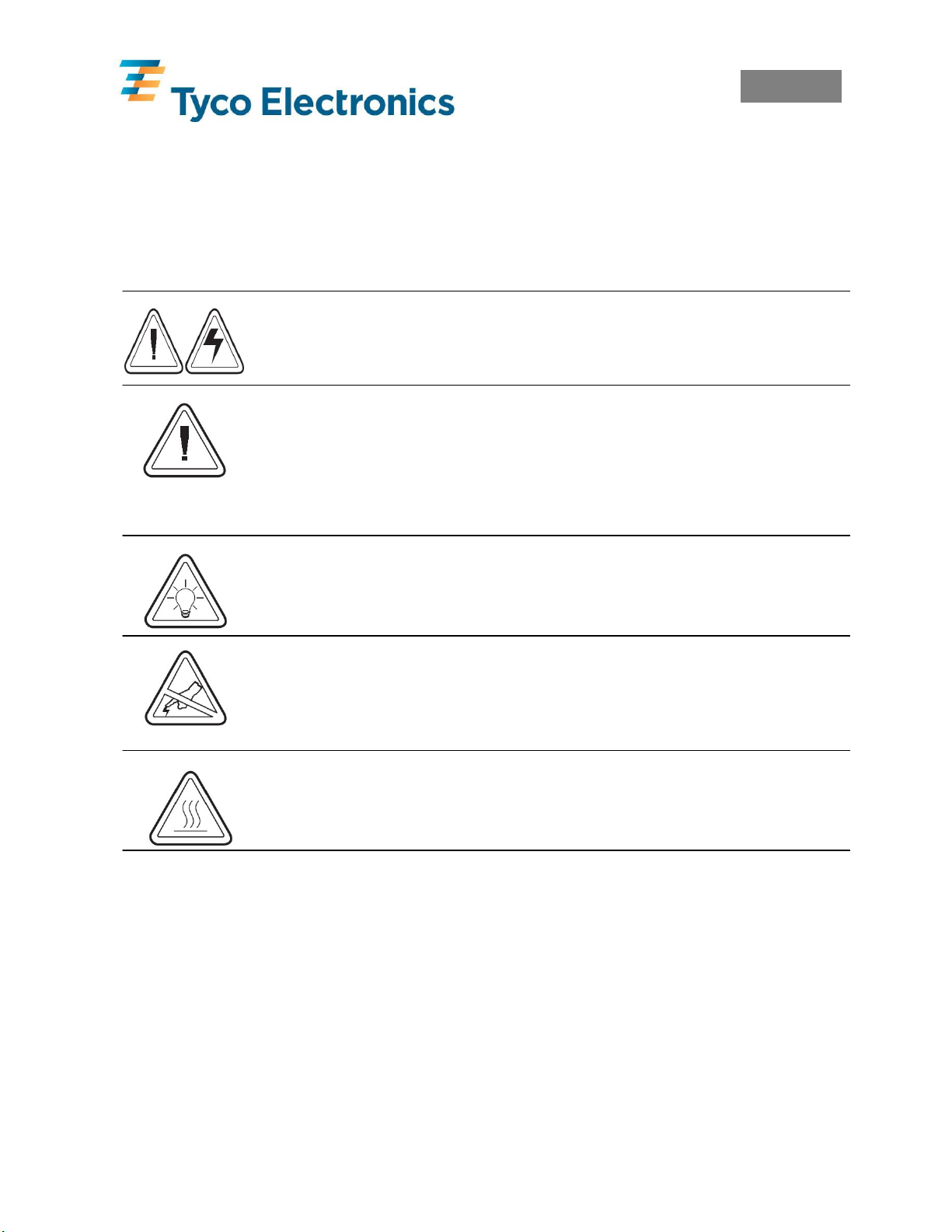

Important Information!

Incorrect use of this equipment can cause injury. It is advised that operators be trained in

the correct use of the equipment and that they read this manual before use.

Maintenance must only be carried out by suitably qualified and trained personnel.

Shock Hazard Warning:

The printer and power supply should never be operated in a location where either one

can get wet. Personal injury could result.

Media and Ribbon Warning:

Always use high quality, approved product and ribbons. If adhesive backed labels are

used the DO NOT lay flat on the backing liner, the exposed edges may stick to the label

guides and rollers inside the printer, causing the label to peel off from the liner and jam

the printer. Permanent damage to the print head may result if a non-approved ribbon is

used as it may be wound incorrectly for the printer or contain chemicals corrosive to the

print head. Approved supplies can be ordered from your dealer.

Reloading Hint:

If labels or ribbon run out while printing, DO NOT turn the power switch OFF (0) while

reloading or data loss may result. The printer automatically restarts after you load a new

label or ribbon roll

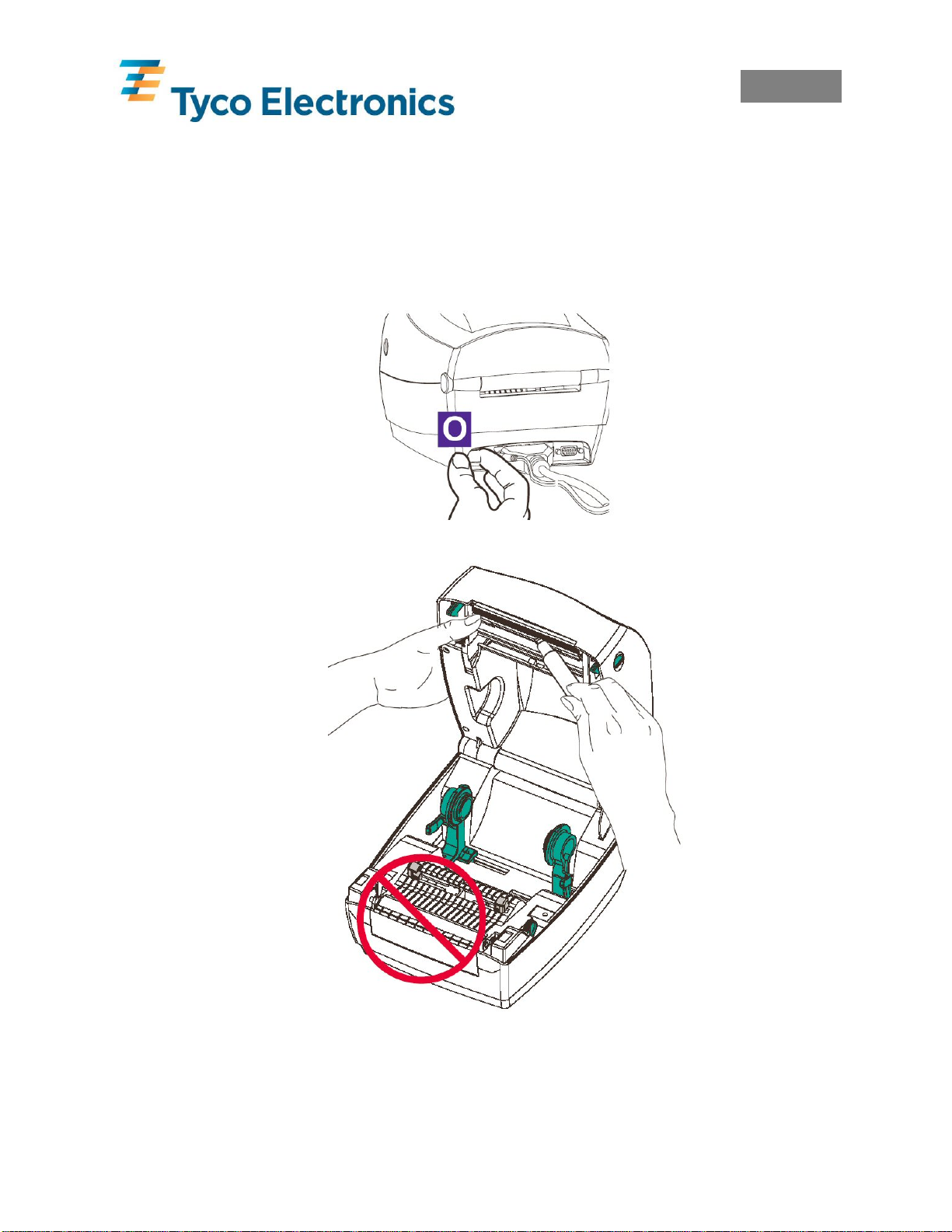

Static Discharge:

The discharge of electrostatic energy that accumulates on the surface of the human body

or other surfaces can damage or destroy the print head or electronic components used in

this device. DO NOT TOUGH the print head or the electronic components under the top

cover.

Thermal Printing:

The print head becomes hot while printing. To protect from damage the print head and

risk of personal injury, avoid touching the print head. Use only the cleaning pen or IPA

wipes to perform maintenance.

Product and Ribbon Storage:

All products and ribbons must be kept in a clean area, free from contamination, dust,

grease and condensation. Image quality and durability may be affected if this is not the

case. Storage conditions and shelf-life are marked on each product container. For

further information please contact Tyco Electronics.

EIL/MAN/002: REVISION 6 Date: July 2007 Page 3

Page 9

English

1.0 Printer Set-up

1.1 Unpacking the Printer

Unpack the printer ensuring that all packaging is retained for future transit. In the unlikely

event of the printer arriving in a less than perfect state, please contact your Tyco Electronics

representative or the shipping agent.

The following should be included with the printer:

• Three power leads: UK, European, US.

• Parallel communications cable.

• Power supply.

• Spare cardboard core (for ribbon take-up).

• Print head cleaning pen.

• Tyco Electronics CD ROM containing…

o Electronic Copy of this User Guide.

o Printer Drivers for Windows 95, 98, Me, NT4, 2K and XP.

o Font Downloader .

o Firmware Downloader – Only to be used when advised by Tyco Electronics.

o Wintotal Demo Software.

o PrintEasy Demo Software.

• Tyco Electronics print contrast scale.

EIL/MAN/002: REVISION 6 Date: July 2007 Page 4

Page 10

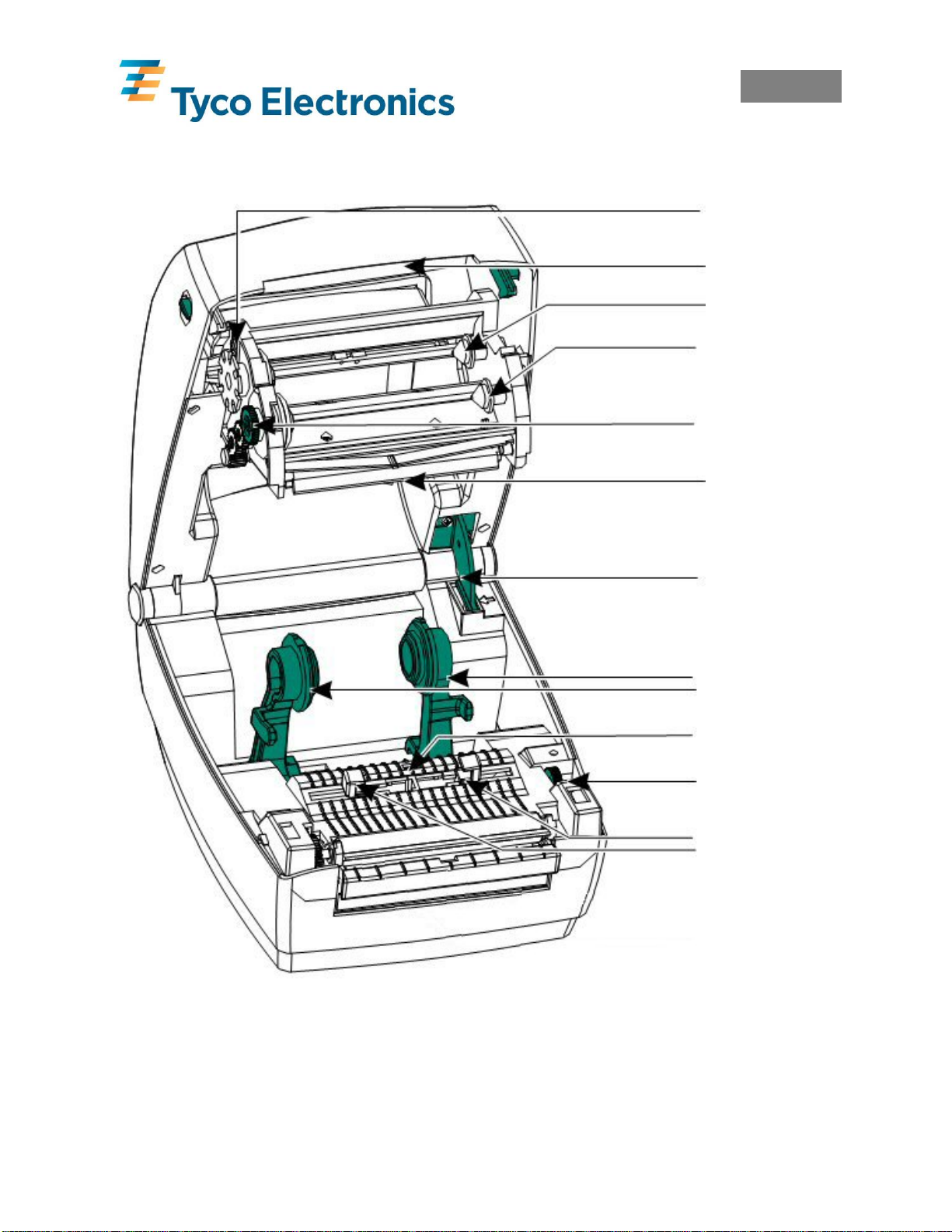

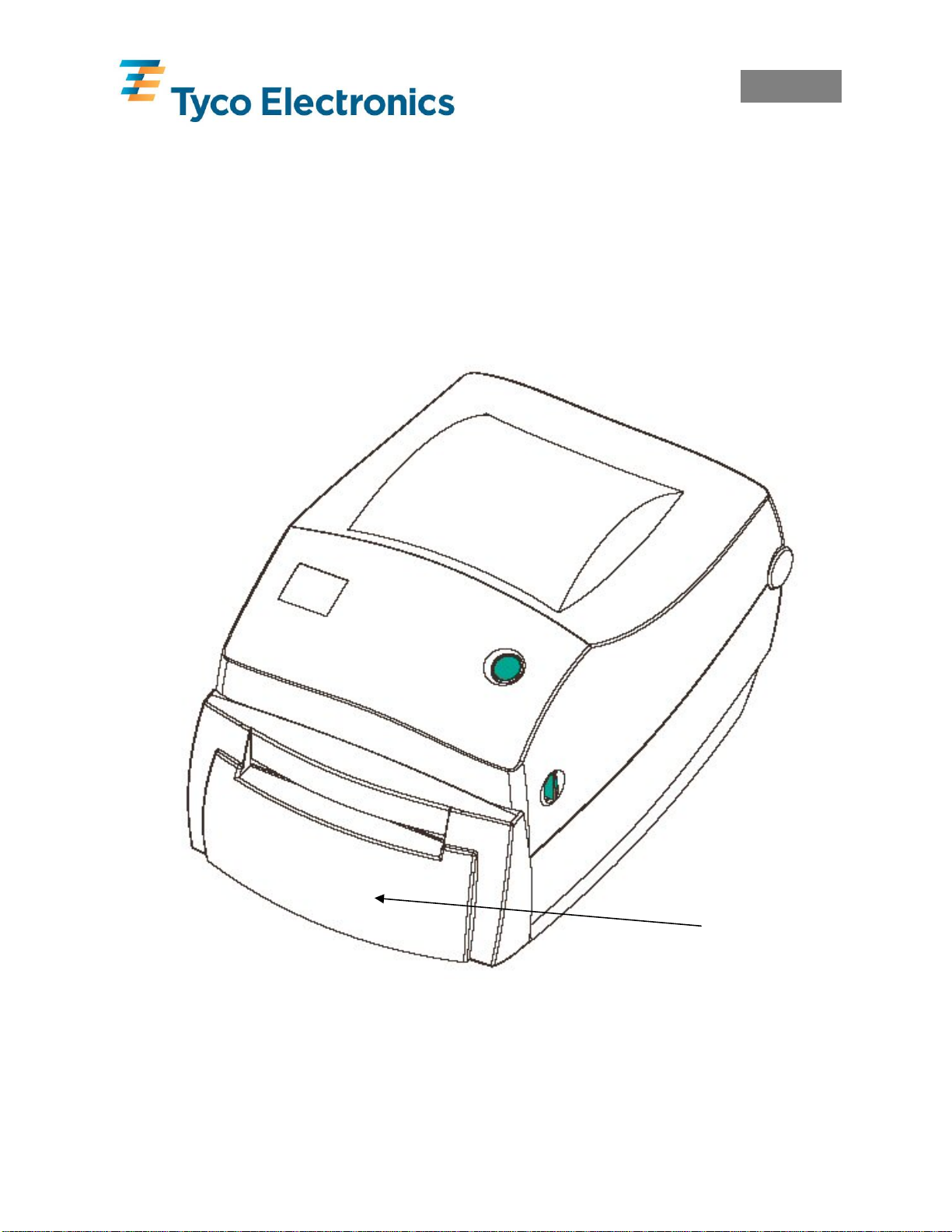

1.2 Printer Overview

English

Supply Ribbon Hub

Take-Up Ribbon Hub

Ribbon Take-Up Gear

Top Cover Lock

Media Roll Holders

Media Sensor

EIL/MAN/002: REVISION 6 Date: July 2007 Page 5

Guides Adjustment

Media Guides

Page 11

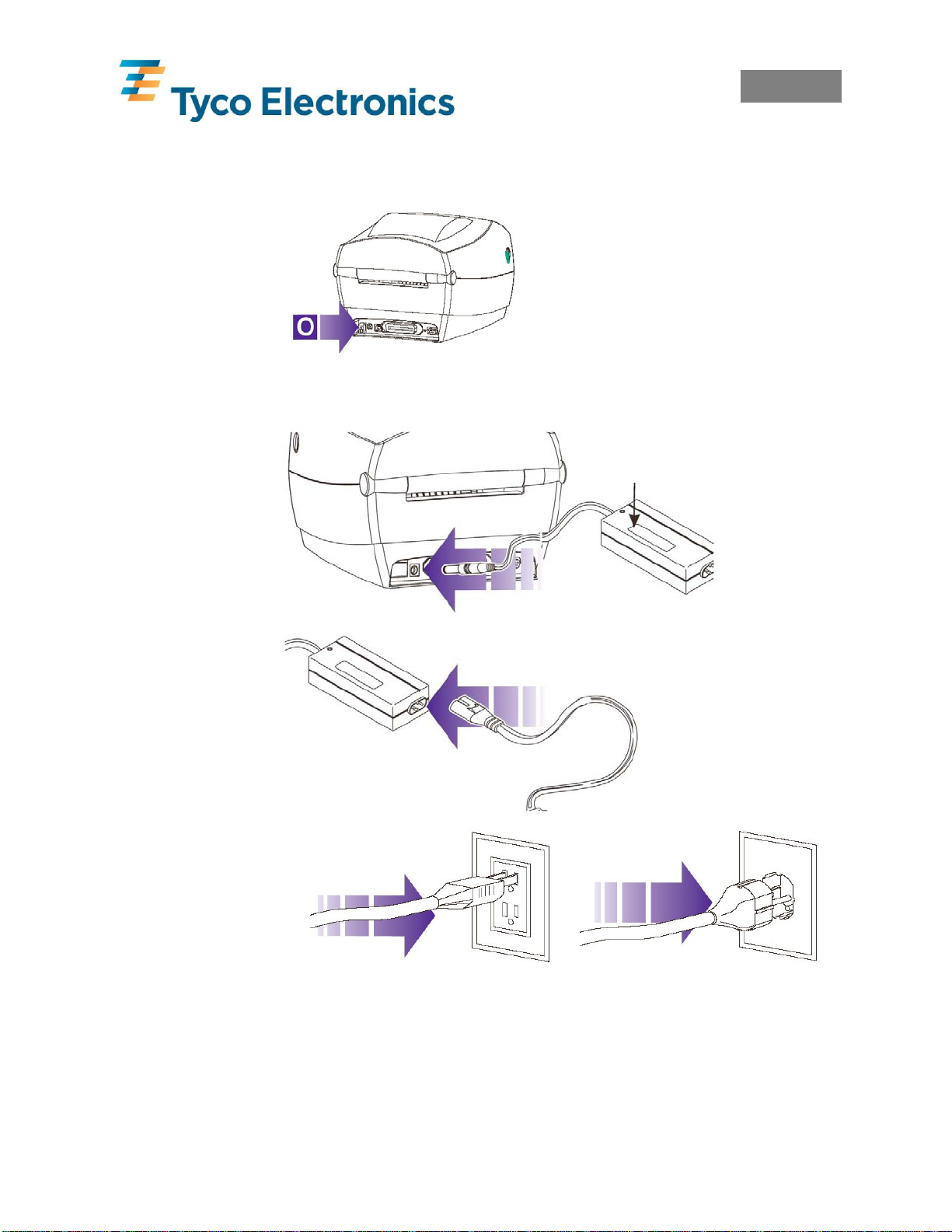

1.3 Attaching the Power Supply To The Printer

Power OFF

Check Voltage

Plug In Power

Module

Plug in Power Cord

Plug Power Cord

into a Suitable AC

Outlet

English

EIL/MAN/002: REVISION 6 Date: July 2007 Page 6

Page 12

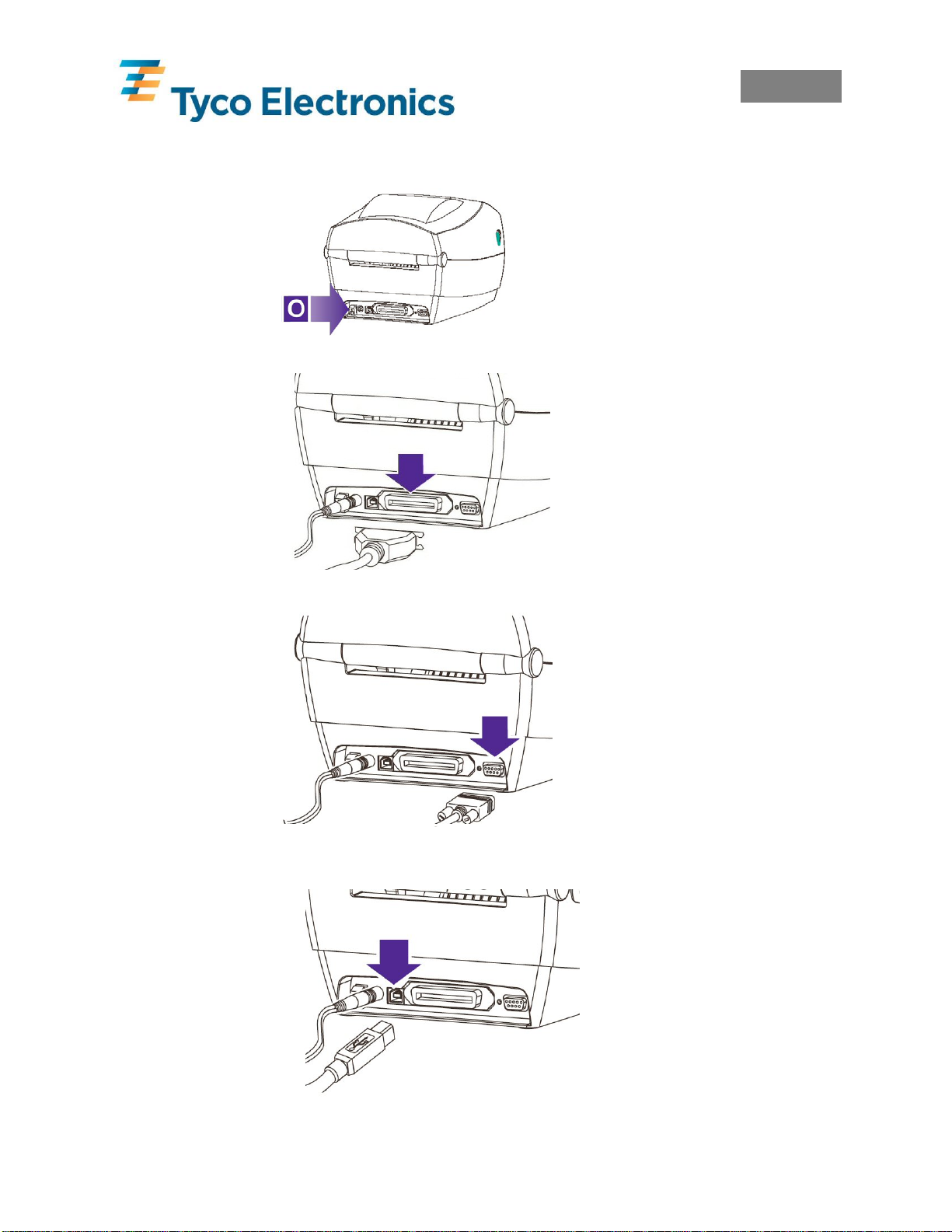

1.4 Connecting the Interface Cable

Power OFF

Parallel

Serial

USB

(Universal

Serial Bus)

English

EIL/MAN/002: REVISION 6 Date: July 2007 Page 7

Page 13

English

2.0 Ribbon Selection

Print quality and permanency on Tyco Electronics Identification products is only guaranteed if

the correct thermal transfer ribbon is used for each product. Please refer to the

“Printer/material/ribbon compatibility cross reference” found at

Tyco Electronics.

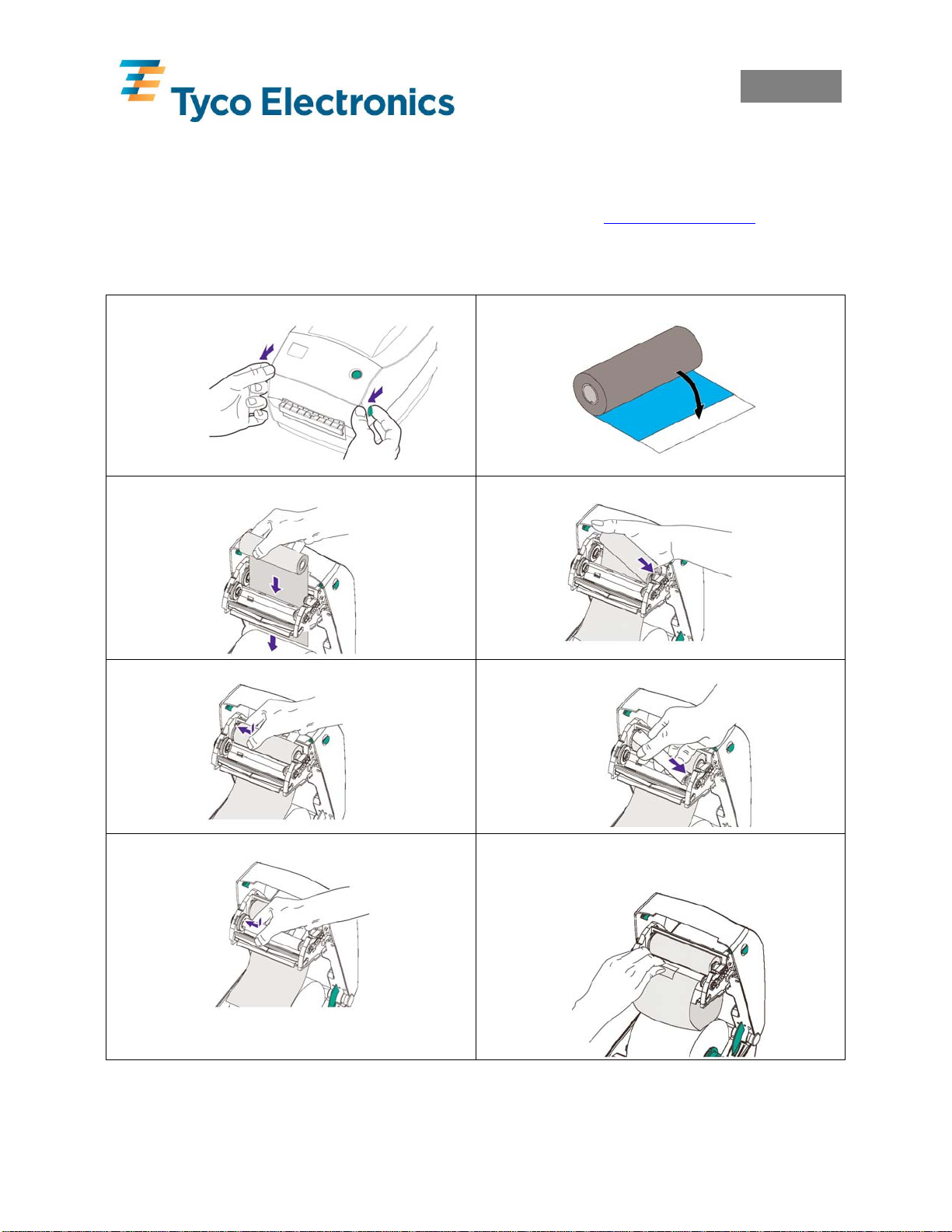

3.0 Loading Ribbon

1. Open Cover.

2. Pull Adhesive Strip Free on ribbon.

www.tycoident.com or contact

3. Thread the ribbon through carriage.

5. Align Notches onto Hub Spokes.

7. Align Notches onto Hub Spokes.

4. Press core onto Hub.

6. Press the take-up core on to the Hub.

8. Attache ribbon to take-up core using

adhesive strip on new ribbons or tape.

EIL/MAN/002: REVISION 6 Date: July 2007 Page 8

Page 14

English

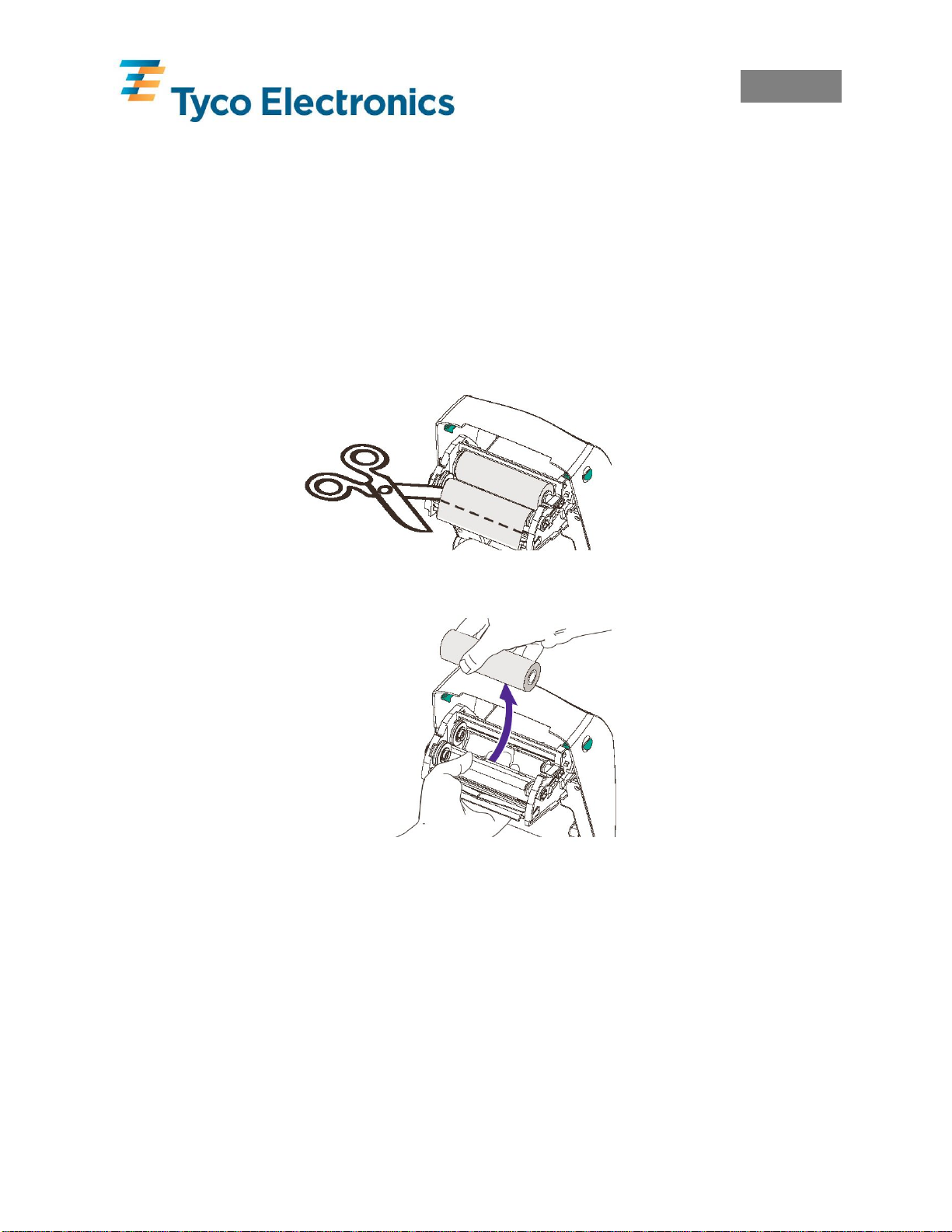

3.1 Adding a New Ribbon

If while printing the ribbon runs out, the indicator lights orange and the printer pauses. Keeping

the power ON, open the top cover. Cut the used ribbon so both cores can be removed. Load the

new ribbon as described in section 3.0 Loading Ribbon. Close the top cover and press the feed

button to restart printing.

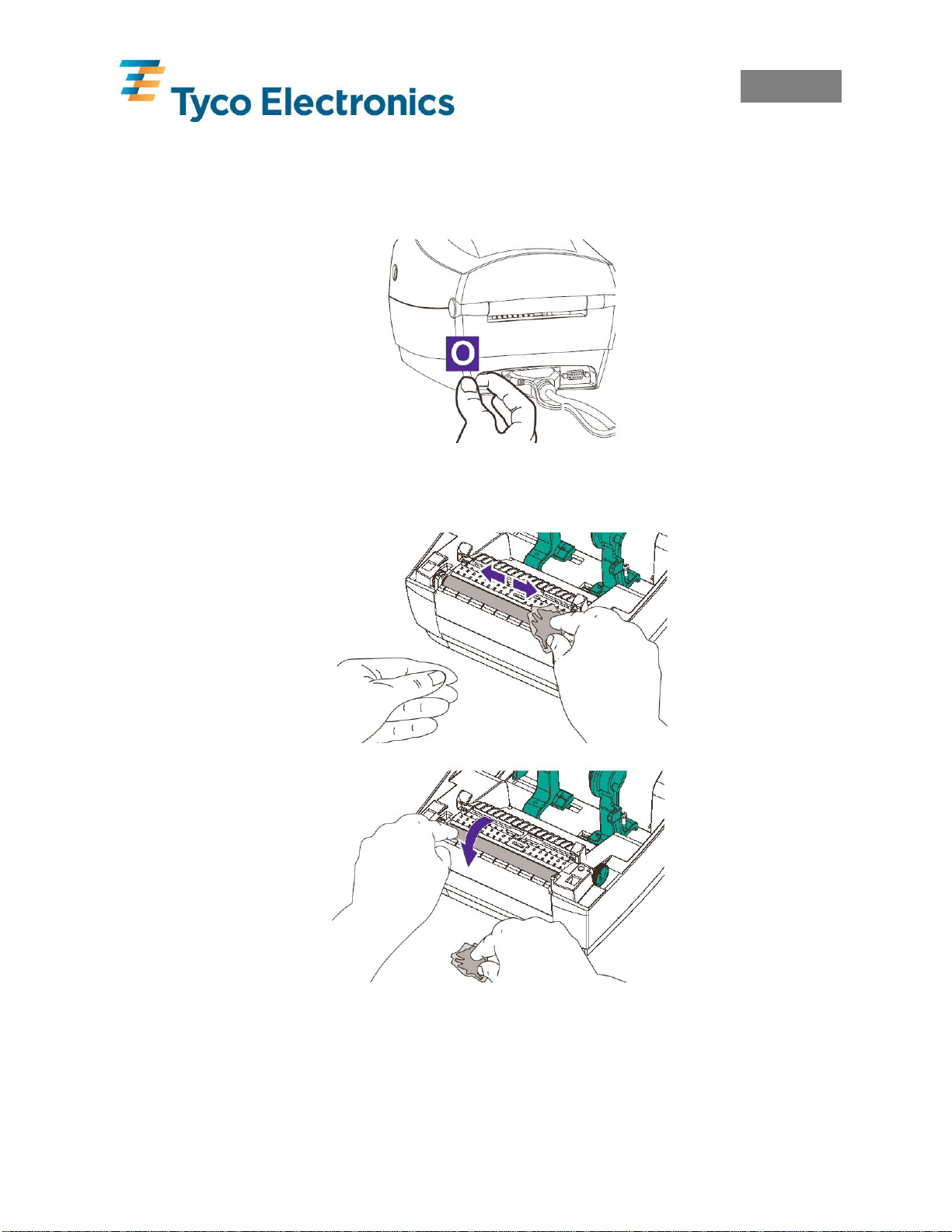

3.2 Removing a partially used Ribbon

To remove a partially used ribbon cut the ribbon from the take-up roll. Remove the take-up roll.

Remove all the used ribbon from the take-up core and keep the empty core for future use.

Remove the supply roll and store in accordance with the ribbons storage conditions.

Cut Used Ribbon from Supply

Push Supply Roll

Out

Important Note: When a complete ribbon has been used, the take-up roll must be replaced with

an empty cardboard roll, or the waste ribbon must be removed from the take-up cardboard core.

Allowing the waste ribbon to build up on the take-up cardboard core can rub against the new

ribbon and jam.

EIL/MAN/002: REVISION 6 Date: July 2007 Page 9

Page 15

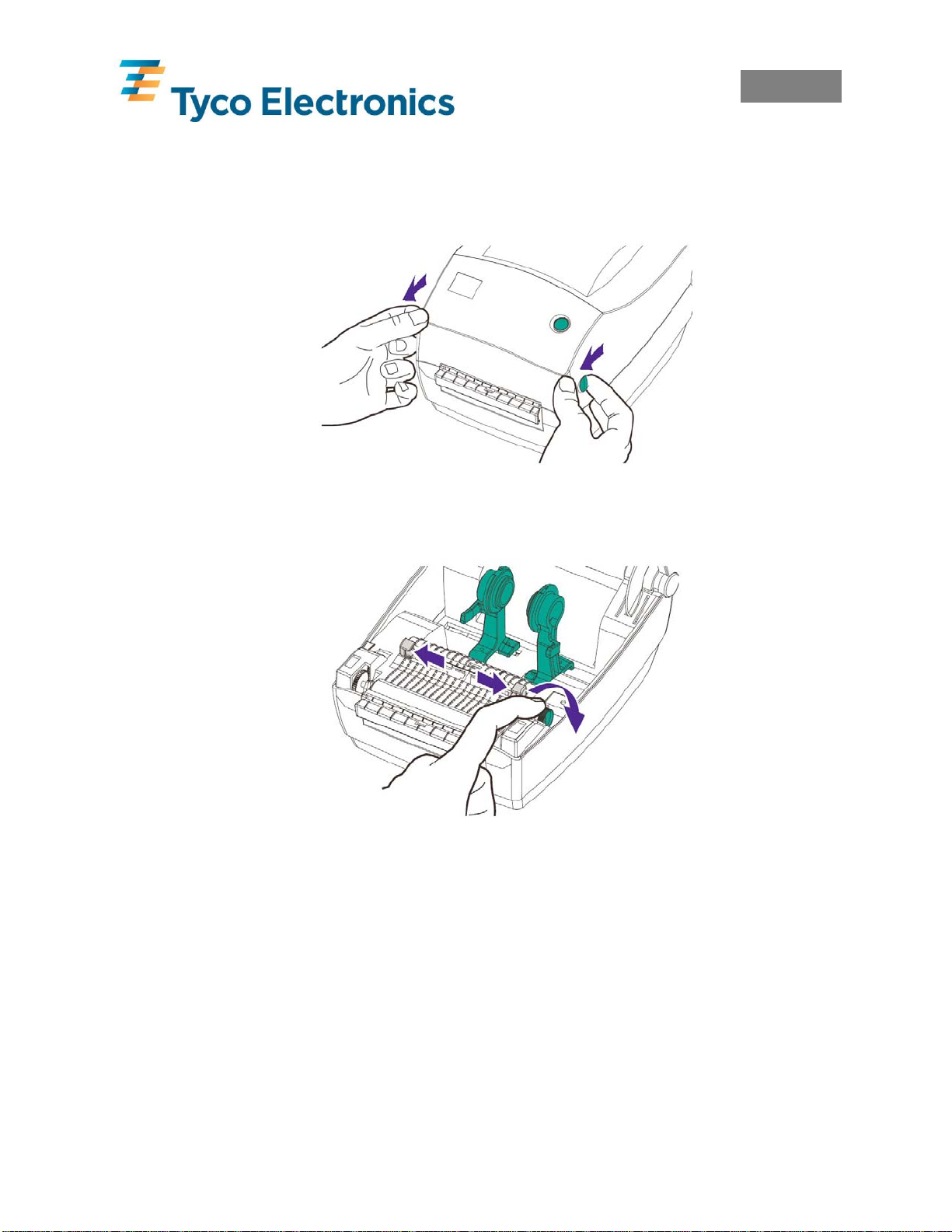

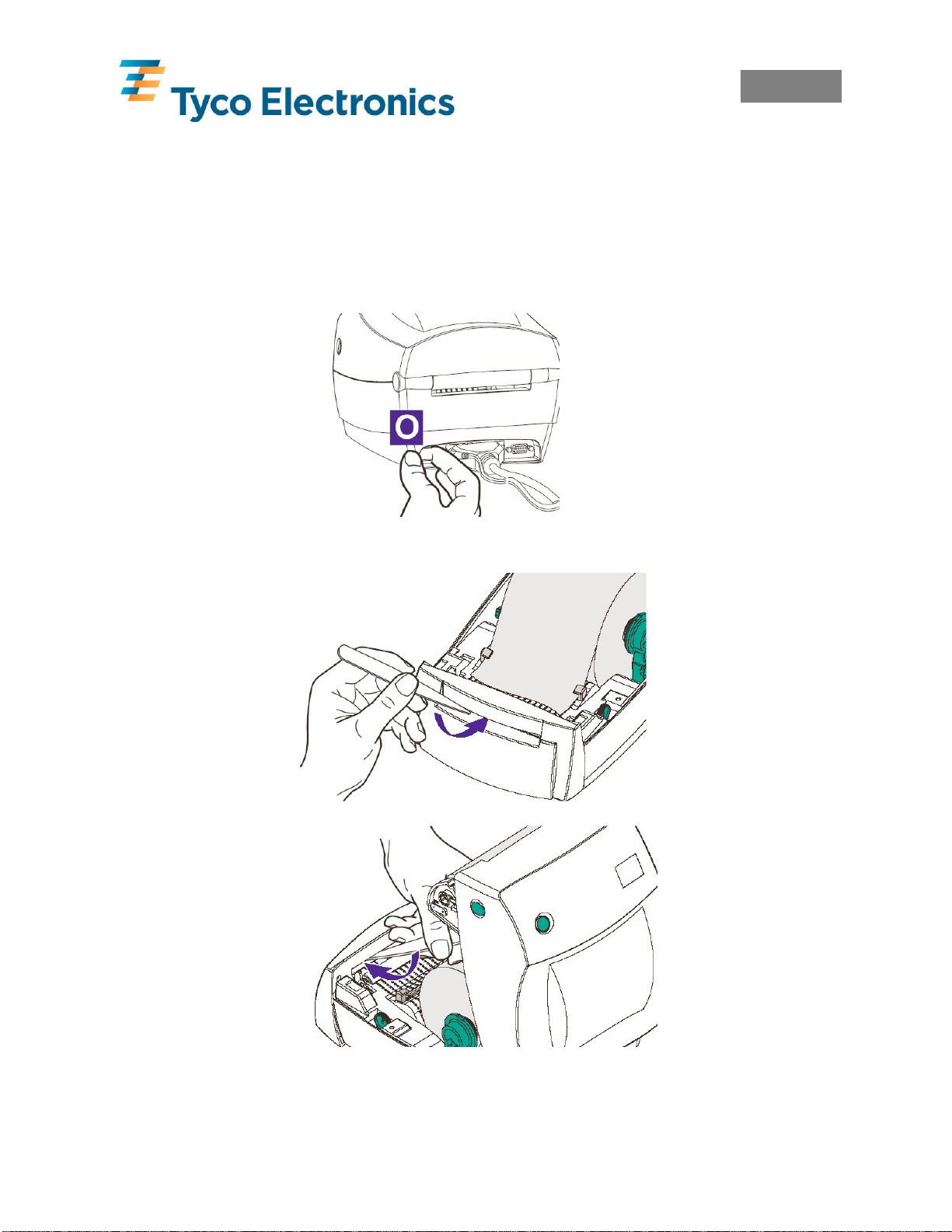

4.0 Loading Product

Open Cover

Open Guides

English

EIL/MAN/002: REVISION 6 Date: July 2007 Page 10

Page 16

English

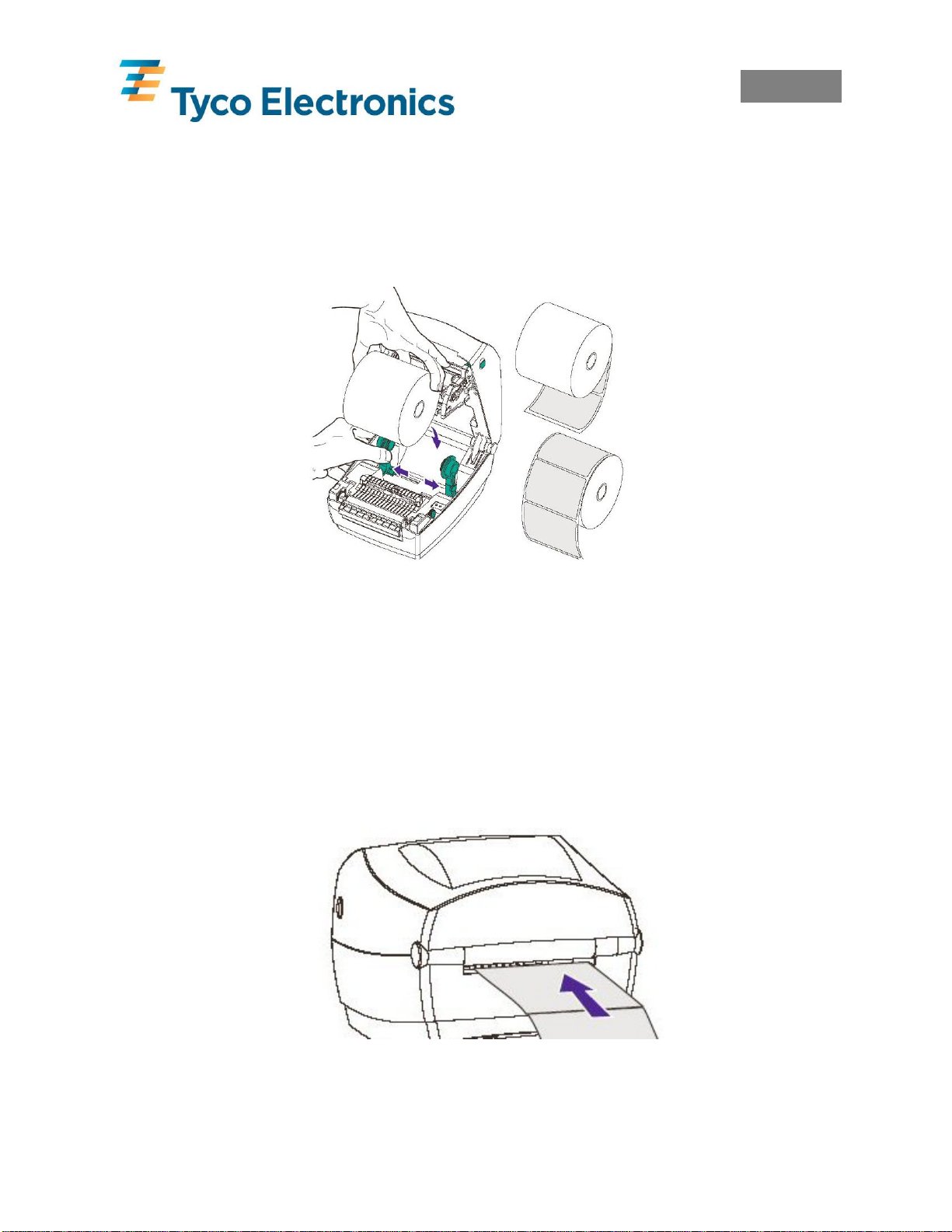

4.1 Loading TMS Marker Sleeves

TMS marker sleeves can be loaded either internally or externally. Both methods require the

Media Roll Holders to be held open and the locking screw tightened using a screwdriver.

4.1.1 TMS Marker Sleeves Internal Loading

Remove all packaging and the large cardboard core and place the product loose into the media

bay of the printer. This is suitable for TMS marker sleeves and some self-adhesive label

products with large cardboard cores.

4.1.2 TMS Marker Sleeves External Loading

Product can be fed into the printer via the rear access slot at the back of the printer. This is

suitable if it is desired to leave TMS marker sleeves in the cardboard box they are shipped in.

EIL/MAN/002: REVISION 6 Date: July 2007 Page 11

Page 17

English

4.2 Loading Labels

Labels can be loaded either internally or externally.

4.2.1 Labels Internal Loading

Labels supplied on small cardboard cores can be held in place by the spring loaded Media Roll

Holders.

Labels that do not fit the Media Roll Holders can be removed from their core and placed loose

in the media bay of the printer. The Media Roll Holders must be locked open for this option,

see section 4.1 Loading TMS Marker Sleeves.

4.2.2 Labels External Loading

Labels can be fed into the printer via the rear access slot at the back of the printer. This is

suitable if the labels do not fit the internal Media Roll Holders. A suitable media holder should

be used. Please contact Tyco Electronics for more details.

EIL/MAN/002: REVISION 6 Date: July 2007 Page 12

Page 18

English

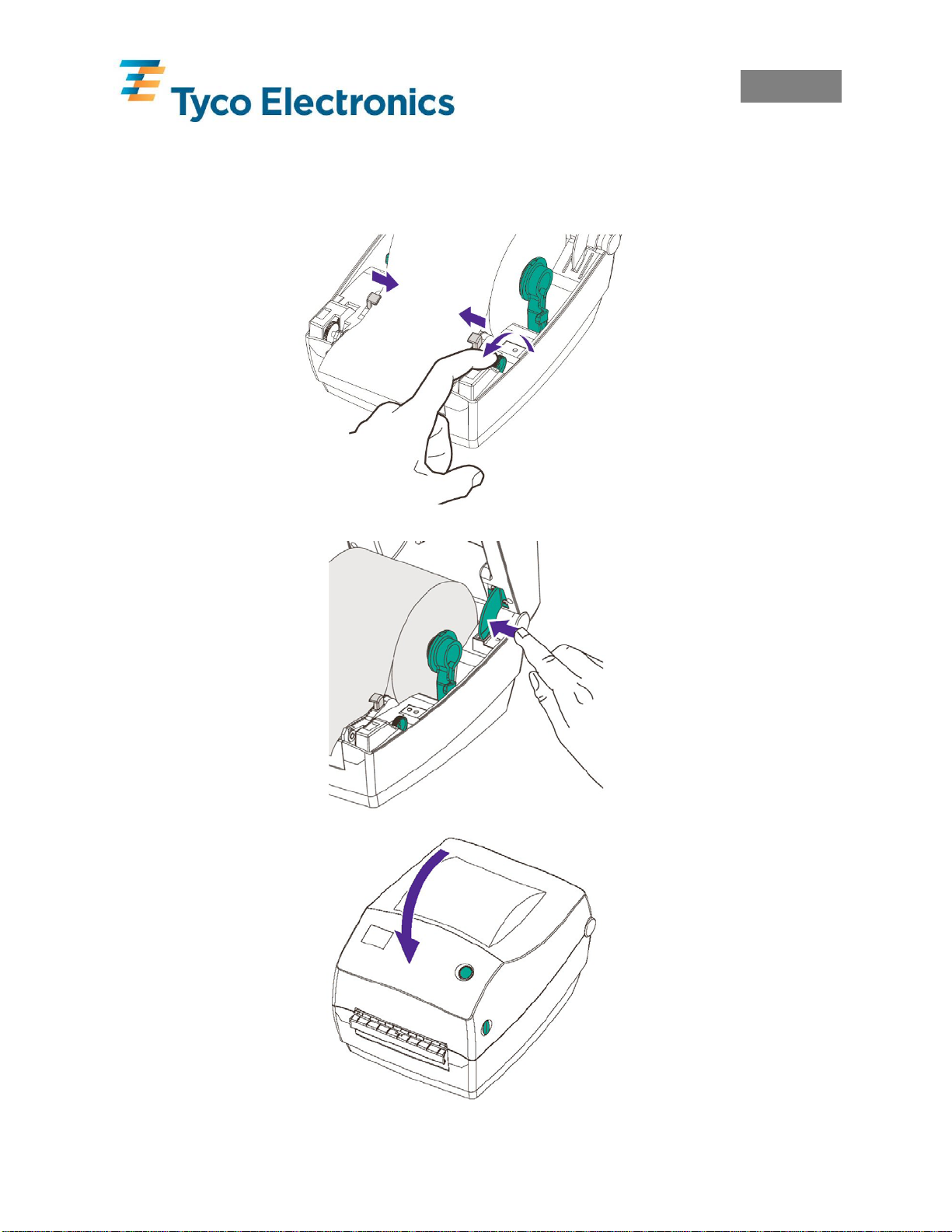

4.3 Loading Product Cont…

The first marker sleeve/label must be positioned on the black rubber pinch roller. Once loaded

close the media guides to lightly grip the product.

Release Cover

Close Cover

EIL/MAN/002: REVISION 6 Date: July 2007 Page 13

Page 19

English

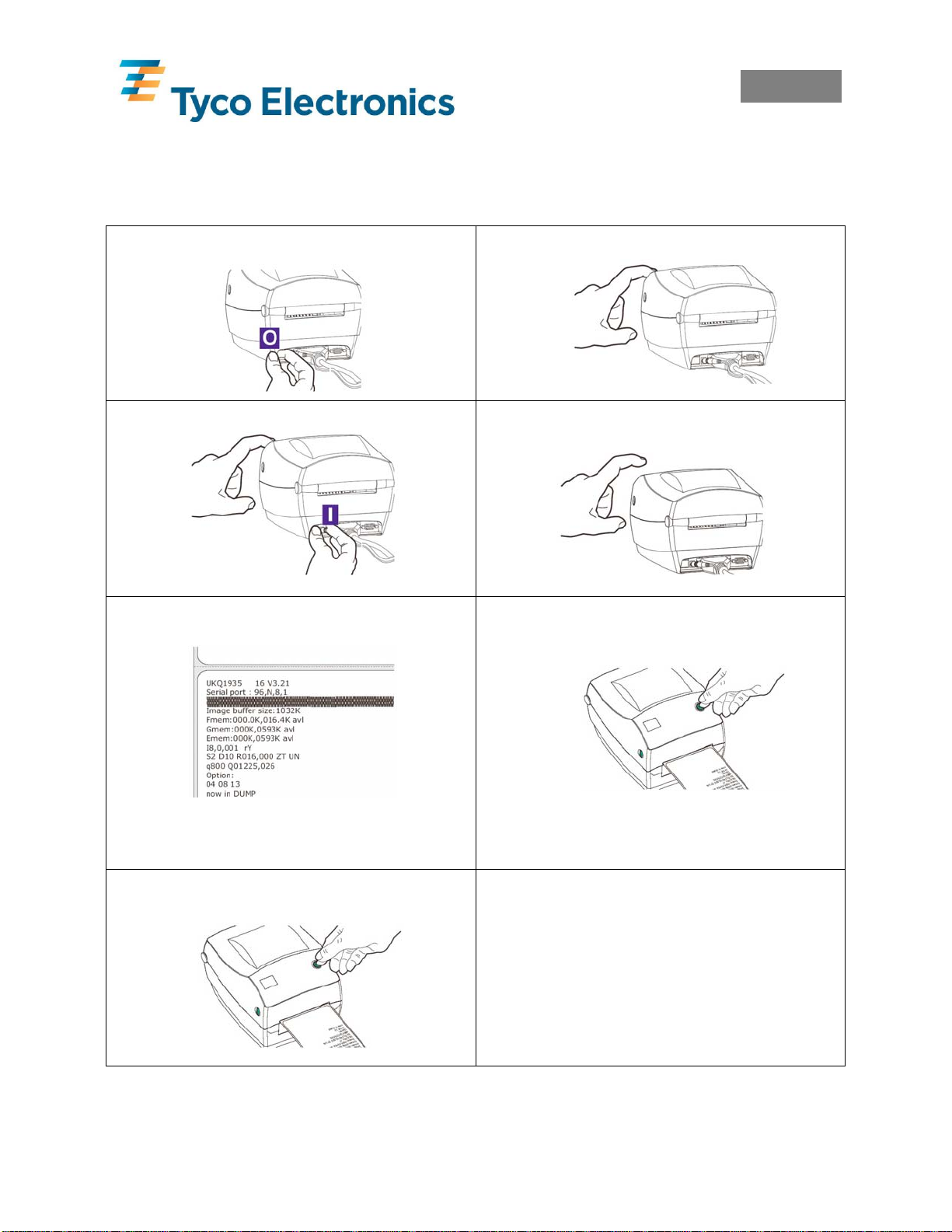

5.0 Calibration

When loading new or changing product types the printer must be calibrated.

Once the product and ribbon are correctly installed, the following procedure must be carried out

1. Power Off.

3. Holding Down Feed Button, Power On.

5. Printer Advances Media and Prints

Status Summary.

Note: Printer is in diagnostic dump mode. The

first line printed on the printout during calibration

will be the firmware version.

7. Each press of the feed button should

then advance one marker sleeve/label.

2. Hold Down Feed Button.

4. Once LED Flashes Red 3 times release

Feed Button.

6. Press Feed Button to Begin Normal

Operation.

Note:

If the printer continuously feeds or feeds more

than one marker sleeve or label at a time, or

the LED remains orange or red then refer

section 5.1 Alignment for Calibration and 11.0

Troubleshooting and then repeat the procedure

calibration procedure .

EIL/MAN/002: REVISION 6 Date: July 2007 Page 14

Page 20

English

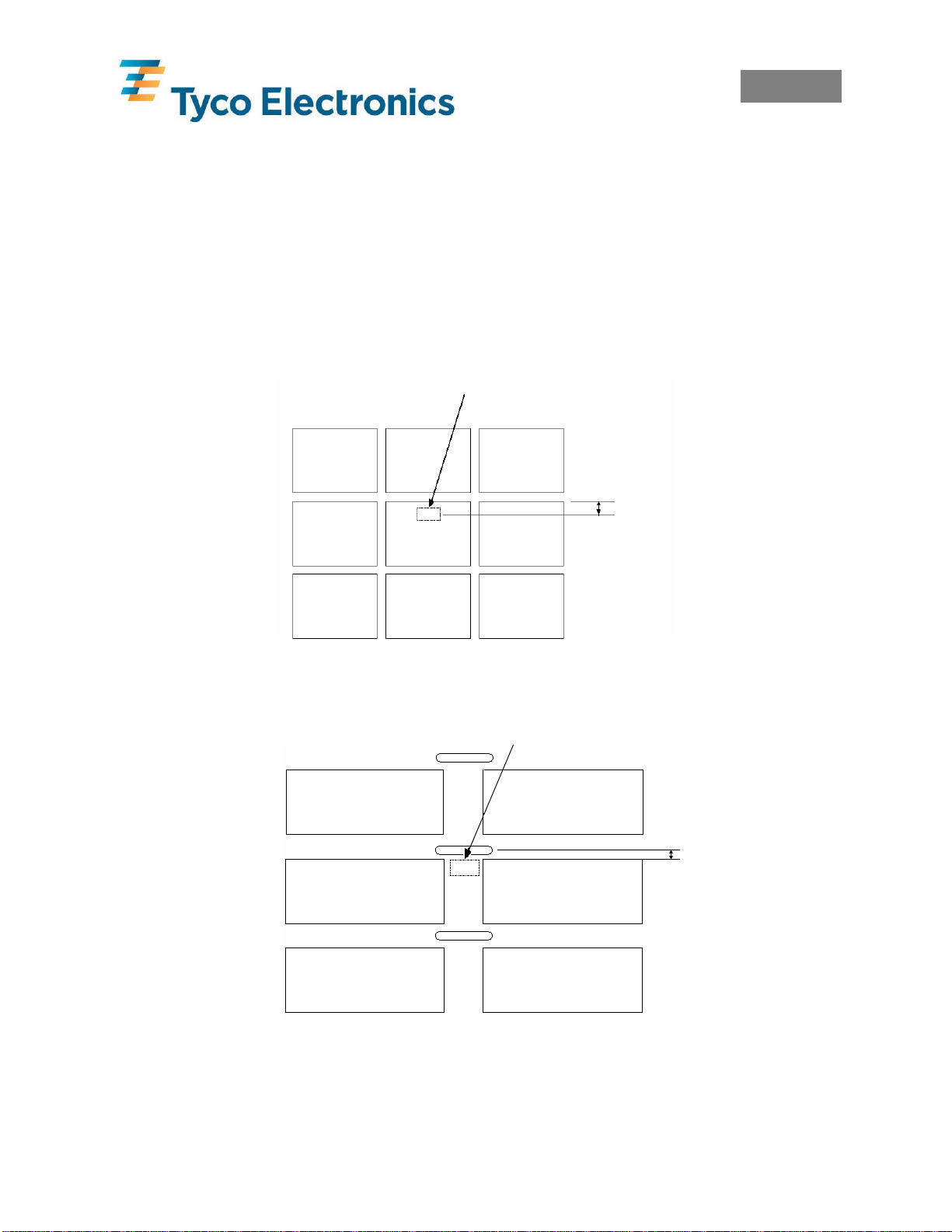

5.1 Alignment For Calibration

Calibration on some products can prove difficult to achieve. This is normally due to the sensor

timing out before the label and backing material contrast has been recognised by the printer’s

sensor.

Reducing the length of time the sensor has to pick up on the difference between the labels and

backing material will result in successful sensor calibrations.

5.1.1 Labels Alignment

Position a label under the T200 sensor with less than approx. 5mm of label travel to occur

before the backing material is picked up by the sensor.

Approx 5mm

5.1.2 Labels With Sensor Holes Alignment

Position a label under the T200 sensor with less than approx. 5mm of media travel to occur

before the sensor hole is picked up by the sensor.

NOTE: Labels will only calibrate if they pass directly under the sensor. Products that do not

have a label directly under the sensor will not calibrate. A sensor hole or black mark is required

to calibrate these products. If the black mark is to be used the default sensor setting must be

changed in the printer, refer to section 6.0 Changing Sensor Type.

AApprox 5mm

EIL/MAN/002: REVISION 6 Date: July 2007 Page 15

Page 21

English

6.0 Changing Sensor Type

The default sensor for the T200 is the Transmissive Sensor (Web) sensor. This should work for

all TMS products and standard labels. If the Reflective (Black Mark) sensor is required or

Continuous mode is required then the relevant procedures must be carried out.

6.1 Reflective (Black Mark) Sensor

To enable the Reflective (Black Mark) sensor a label must be printed to the printer with the

sensor set to Reflective (Black Mark) in either Wintotal via Advanced Label Editing or

PrintEasy’s Windows Printer Driver. Once a label with these settings has been sent to the

printer, the LED will display Red. The printer must then be calibrated on the Reflective (Black

Mark) product.

6.2 Continuous Sensing Mode

To enable continuous products to be printed the printer must be put into continous mode. To

enable this a label must be printed to the printer with the sensor set to Continuous in either

Wintotal via Advanced Label Editing or PrintEasy’s Windows Printer Driver. Once a label

with these settings has been sent to the printer the LED will display Red. The printer must then

be calibrated on the continuous product.

6.3 Transmissive Sensor

To return to the Transmissive (Web) sensor a label must be printed to the printer with the sensor

set to Transmissive (Web) in either Wintotal via Advanced Label Editing or PrintEasy’s

Windows Printer Driver. Once a label with these settings has been sent to the printer, the LED

will display Red. The printer must then be calibrated on the Transmissive (Web) product.

Note: The calibration process is the same for all sensing modes and is described in section 5.0

Calibration.

7.0 Printer Firmware Versions

The printers will come pre-loaded with the correct firmware version:

T208M & T208M-C - firmware version 4.51 or newer.

T212M & T212M-C - firmware version 4.51 or newer.

The firmware version should not be changed or updated without checking with Tyco

Electronics. Not all versions of firmware will allow for the successful printing of Tyco

Electronics identification products.

The firmware version can be checked by undertaking a printer calibration. (see section 5.0

Calibration)

EIL/MAN/002: REVISION 6 Date: July 2007 Page 16

Page 22

English

8.0 Software

The recommended software for printing on the T200 series is either WinTotal for TMS markers

and basic Label design or PrintEasy for Labels. Demonstration versions of both these packages

can be found on the CD.

WinTotal has built in printer drivers.

PrintEasy uses Windows Printer Drivers – they can be installed automatically from the CD.

These drivers will work on Windows 95, 98, Me, NT4, 2K and XP

Both software programs can control all relevant aspects of the printer including Speed and

Darkness. Most products will print successfully with the default settings from either software

package. Increasing the Darkness will normally improve the print quality.

Note: For more details please refer to the software documentation or contact your local Tyco

Electronics representative.

9.0 Print Quality

To ensure that the correct print quality is achieved the printed product should have a minimum

contrast value of 8 (preferably 9-10) on the Tyco Electronics print contrast scale.

EIL/MAN/002: REVISION 6 Date: July 2007 Page 17

Page 23

English

10.0 Maintenance

10.1 Cleaning the Print Head

It is recommended that the print head be cleaned after a roll of ribbon is consumed. This should

be done using the print head cleaning pen shipped with the printer or any standard thermal

transfer print head cleaning product (for example, an IPA wipe).

Turn Printer OFF

Rub Cleaning Pen

Across Dark Area of

Print Head

Do Not Clean Platen

Roller with

Cleaning Pen

EIL/MAN/002: REVISION 6 Date: July 2007 Page 18

Page 24

English

10.2 Cleaning the Platen Roller

Over time the platen picks up adhesive dust which requires occasional cleaning. This can

be done using a clean lint-free cloth lightly moistened with isopropyl alcohol.

Turn Printer OFF

Unplug all power

and interface leads.

Gently wipe top of

platen

Advance platen

One-Sixth (1/6) turn

Repeat steps until

platen is clean

Note: Let the platen dry for at least one minute before loading media.

EIL/MAN/002: REVISION 6 Date: July 2007 Page 19

Page 25

English

11.0 Troubleshooting

Problem Solution or Reason

No LED light after turning printer ON. 1. Check power connections from A.C. outlet to power supply to

printer.

2. Check that media or ribbon is present.

LED Orange. 1. Check the cover is closed and locked.

2. Printer has received partial data or incorrect data. Check the

software program and reboot printer.

LED Blinks Red. 1. Firmware download in process. Indicator lights red, then green.

2. Signal to begin Calibration after turning on printer. Release th e

Feed button.

LED Red. 1. Media or ribbon is out. Reload a new supply.

2. Power-up failure.

3. Printer ready to receive flash programming during firmware

download.

LED is Green but will not print. 1. Check interface cable connections from computer to printer.

2. Ensure the cover is locked closed.

3. Check that the media is loaded correctly.

4. Check that the ribbon is installed correctly and is ink side out (ink

side facing the product)

Printer appears to be working (media is

being fed out) , but nothing is printed.

Or

Printing is faded or poor quality.

Prints only partial labels or skips labels. 1. Calibrate the printer.

Printing stops and LED changes to

Orange or Red.

Wrinkles in ribbon result in missing

print

Cutter cuts through labels instear of liner 1. Check all software settings.

Cutter jammed 1. Unplug power and interface cables. Use tweezers to remove scraps

Cutter not cutting 1. Check software setting.

1. Check correct product/ribbon combination is used and loaded

correctly.

2. Check the cover is closed and locked.

3. Clean the print head with cleaning pen.

4. Adjust the print speed/darkness in software.

5. Check font types/sizes and graphics to ensure they are not too

small.

2. Check product is not getting caught whilst feeding.

3. Ensure the cover is locked closed.

4. Check software settings – especially that the Top Margin setting is

not too high.

1. Calibrate the printer.

2. Check product is not getting caught whilst feeding.

3. Check that data on label is not too large for printer memory.

4. Check all software settings.

1. Check that the ribbon is mounted straight on the take-up core.

from cutter opening.

2. Check for jams.

3. Cutter requires replacing.

For all other issues, including product or software problems, contact your local Tyco Electronics

representative.

EIL/MAN/002: REVISION 6 Date: July 2007 Page 20

Page 26

English

Appendix A

T200 Series with Cutter

The T208M-C-PRINTER and T212M-C-PRINTER have a built in media cutter. This cutter

will cut through continuous label material or the liner between the labels automatically. The

cutter should NOT be used to cut TMS marker sleeves

EIL/MAN/002: REVISION 6 Date: July 2007 Page 21

Page 27

Clearing the Media Cutter

When cutting adhesive from the labels can jam the cutter. To remove the adhesive the

following process should be carried out.

Keep the cutter dry. Never use any solutions or solvents to clean the blade.

Turn Printer OFF

Unplug all power

and interface leads.

Remove all debris

using tweezers.

Once removed plug

the printer in an test

for normal

operation

English

EIL/MAN/002: REVISION 6 Date: July 2007 Page 22

Page 28

English

Appendix B

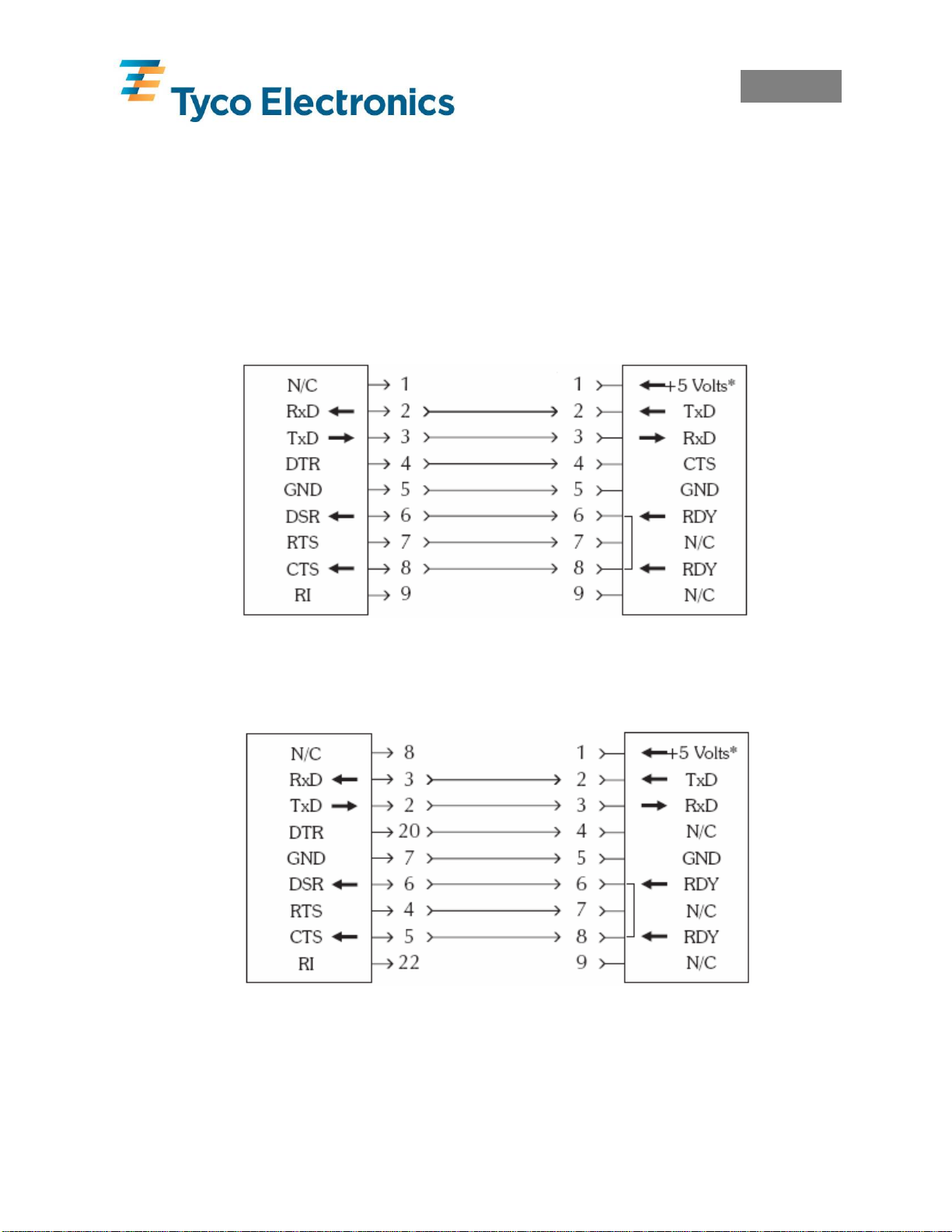

Interface Cable Wiring

Serial Interface Wiring

The figure below displays the cable wiring required to use the printers RS-232 serial interface.

* +5 volts at 150mA for external device (e.g. KDU or scanner)

DB-9

Pin #

Female DB9 to Male DB-9

DB-9

Pin #

Female DB-25 to Male DB-9

DB-9

Pin #

DB-9

Pin #

EIL/MAN/002: REVISION 6 Date: July 2007 Page 23

Page 29

English

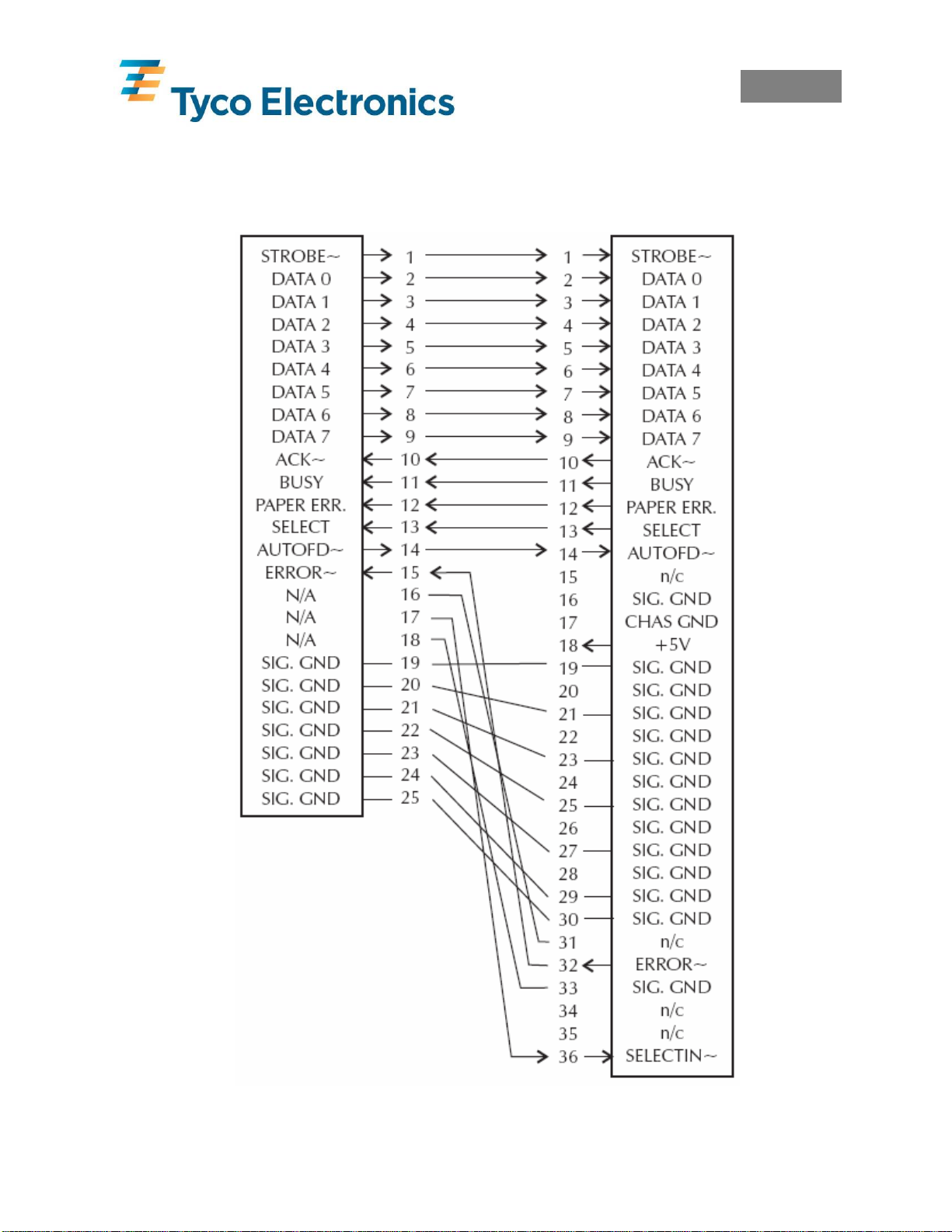

Parallel Interface Wiring

The figure below displays the cable wiring required to use the printers Centronics parallel

interface.

DB-25

Pin #

Male DB-25 to Male Centronics Cable

Centronics

Pin #

+5 Volts at 300mA for external device (e.g. KDU or scanner)

EIL/MAN/002: REVISION 6 Date: July 2007 Page 24

Page 30

English

USB (Universal Serial Bus) Interface Wiring

The table below provides the contact terminating assignments by number and electrical value

for the cable connectors.

Contact Number Signal Name Typical Wiring Assignment

1 VBUS Red

2 D- White

3 D+ Green

4 GND Black

Shell Shield Drain Wire

You can refer to the Universal Serial Bus Specification for details regarding this interface.

EIL/MAN/002: REVISION 6 Date: July 2007 Page 25

Page 31

Francàis

Francàis

IMPRIMANTE À TRANSFERT THERMIQUE

SÉRIE T200

GUIDE DE L’UTILISATEUR DU SYSTÈME

(T208M-PRINTER, T208M-C-PRINTER, T212M-PRINTER et T212M-C-PRINTER)

EIL/MAN/002: REVISION 6 Date: July 2007 Page 26

Page 32

Francàis

Avant-propos

Ce guide contient les instructions d’installation et le mode d’emploi des imprimantes T208MPRINTER(E63660-000), T208M-C-PRINTER (D82271-000), T212M-PRINTER (E23401-000)

et T212M-C-PRINTER (A53989-000), fabriquées pour Tyco Electronics.

Avis de copyright

Ce document contient de l’information propriété de Tyco Electronics. Tyco Electronics en

détient les droits d’auteur. Toute reproduction totale ou partielle sans autorisation écrite de Tyco

Electronics est interdite. Nous avons fait tous les efforts possibles pour que l’information

figurant dans ce guide soit actualisée et exacte à la date de sa publication mais ne pouvons

garantir que ce document ne contienne aucune erreur ni que toutes les spécifications soient

rigoureusement exactes. Tyco Electronics se réserve le droit d’effectuer à tout moment des

modifications dans le but d’améliorer le produit.

Marques de commerce

T208M et T212M sont des marques de services de Tyco Electronics. Windows et MS-DOS sont

des marques déposées de Microsoft Corp. Toutes les autres marques sont des marques de

commerce ou des marques déposées de leurs titulaires respectifs.

Imprimantes thermiques T208M-PRINTER, T208M-C-PRINTER, T212M-PRINTER et T212M-CPRINTER

Directive du Conseil européen Conformité aux normes

89/336/CEE Directive CEM

Directive CEM EN 55024 1988

92/31/CEE Directive CEM EN 61000-3-2 Émissions d’harmoniques

92/31/CEE Directive CEM EN 61000-3-3 Variations de tension

CB Scheme

FCC – Déclaration de conformité

Modèles : les modèles T208M-PRINTER, T208M-C-PRINTER, T212MPRINTER et T212M-C-PRINTER sont conformes aux spécifications

suivantes : Partie 15, Sous-partie B, Articles 15.107(a) et 15.109(a), appareils

numériques de la Classe B, des règles de la FCC.

Information complémentaire :

Cet appareil est conforme à la partie 15 des règles de la FCC. Son fonctionnement doit remplir les deux conditions

suivantes : (1) Cet appareil ne doit pas causer d’interférences dangereuses et (2) cet appareil doit accepter toute

interférence reçue, y compris les interférences pouvant causer un fonctionnement indésirable.

Conformité à la norme canadienne :

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

EN 55022-B

1988

EN 60950 1991

A1, A2, A3, A4

Contrôle des émissions de RF

Immunité contre les

perturbations

électromagnétiques

Sécurité

EIL/MAN/002: REVISION 6 Date: July 2007 Page 27

Page 33

Francàis

Information importante !

Une utilisation impropre de cet appareil peut causer des blessures. Il est recommandé de

former les opérateurs à sa correcte utilisation et de lire ce guide avant d’utiliser l’appareil.

La maintenance ne doit être effectuée que par du personnel qualifié et formé.

Mise en garde contre les risques d’électrocution

L’imprimante et son adaptateur d’alimentation électrique ne doivent jamais être utilisés à

un endroit où l’une ou l’autre puissent prendre l’humidité, au risque de causer des

blessures.

Mise en garde relative aux supports et aux rubans

Toujours utiliser des produits et des rubans homologués de bonne qualité. Si vous

utilisez des étiquettes sur dorsal adhésif qui ne SONT PAS bien à plat sur la doublure

dorsale, les bords exposés risquent de coller aux guides d’étiquettes et aux rouleaux à

l’intérieur de l’imprimante, ce qui décollerait l’étiquette de la doublure et entraînerait un

bourrage dans l’imprimante. L’utilisation d’un ruban non homologué risque

d’endommager irrémédiablement la tête d’impression, si son enroulement ne correspond

pas à cette imprimante ou s’il contient des produits chimiques corrosifs pour la tête

d’impression. Les fournitures homologuées peuvent être commandées chez votre

revendeur.

Conseil de chargement

Si les étiquettes ou le ruban se terminent pendant l’impression, N’ÉTEIGNEZ PAS

l’interrupteur d’alimentation (0) pendant que vous rechargez l’appareil sous peine de

perdre des données. L’imprimante redémarre automatiquement après le chargement de

nouvelles étiquettes ou d’un nouveau rouleau de ruban.

Électricité statique

La décharge d’électricité statique s’accumulant sur le corps humain ou sur d’autres

surfaces peut endommager ou détruire la tête d’impression ou les composants

électroniques utilisés dans cet appareil. NE TOUCHEZ PAS la tête d’impression ni les

composants électroniques placés sous le couvercle supérieur.

Impression thermique

La tête d’impression chauffe pendant l’impression. Pour la protéger et pour vous

protéger contre les blessures, évitez de toucher la tête d’impression. N’utilisez que le

stylo nettoyant ou une lingette imprégnée d’alcool isopropylique pour en effectuer

l’entretien.

Stockage de produits et de rubans

Tous les produits et rubans doivent être conservés dans une zone propre et non polluée,

sans poussière, graisse ni condensation. Leur stockage dans d’autres conditions peut

nuire à la qualité et la durabilité de l’image. Les conditions de stockage et la date de

péremption sont indiquées sur chaque conteneur de produits. Pour plus d’informations,

veuillez contacter Tyco Electronics.

EIL/MAN/002: REVISION 6 Date: July 2007 Page 28

Page 34

Francàis

1.0 Installation de l’imprimante

1.1 Déballage de l’imprimante

Déballez l’imprimante et conservez l’emballage pour de futurs déplacements. Au cas,

improbable, où l’imprimante ne serait pas en parfait état à son arrivée, veuillez contacter votre

représentant Tyco Electronics ou le transitaire.

Les éléments suivants devraient être livrés avec l’imprimante :

• Trois conducteurs d’alimentation : anglais, européen, américain.

• Câble de communication en parallèle.

• Adaptateur d’alimentation électrique.

• Rouleau en carton vide (pour ré-enroulement du ruban).

• Stylo nettoyant de tête d’impression.

• CD-ROM de Tyco Electronics contenant :

o Une copie électronique de ce Guide de l’utilisateur.

o Les pilotes d’imprimante pour Windows 95, 98, ME, NT4, 2000 et XP.

o Un téléchargeur de polices.

o Un téléchargeur de micrologiciels – à n’utiliser que sur indication de Tyco

Electronics.

o Un logiciel de démonstration WinTotal.

o Un logiciel de démonstration PrintEasy.

• L’échelle de contraste d’impression de Tyco Electronics.

EIL/MAN/002: REVISION 6 Date: July 2007 Page 29

Page 35

1.2 Vue d’ensemble de l’imprimante

Francàis

Capteur de ruban

Mandrin d’alimentation

de ruban

Mandrin de ré-enrouleur

de ruban

Engrenage de réenrouleur de ruban

’

Verrou du couvercle

supérieur

Porte-rouleau de

support

Capteur de support

EIL/MAN/002: REVISION 6 Date: July 2007 Page 30

Réglage des guides

Guides du support

Page 36

1.3 Branchement de l’adaptateur d’alimentation électrique de l’imprimante

Éteignez l’appareil

Vérifiez la tension

Branchez

l’adaptateur

d’alimentation

électrique

Branchez le cordon

électrique

Branchez le cordon

électrique dans une

prise CA appropriée

Francàis

EIL/MAN/002: REVISION 6 Date: July 2007 Page 31

Page 37

1.4 Connexion du câble d’interface

Éteignez

l’appareil

Port parallèle

Port série

Port USB

(bus série

universel)

Francàis

EIL/MAN/002: REVISION 6 Date: July 2007 Page 32

Page 38

Francàis

2.0 Choix du ruban

La qualité et la durabilité des impressions avec les produits Identification de Tyco Electronics

ne sont garanties que si le ruban de transfert thermique adéquat est utilisé avec chacun des

produits. Veuillez consulter la page « Printer/material/ribbon compatibility cross reference »

(Références croisées de compatibilité imprimante/matériau/ruban) sur le site

www.tycoident.com ou bien contacter Tyco Electronics.

3.0 Chargement du ruban

1. Ouvrez le couvercle.

2. Tirez sur la languette adhésive du

ruban.

3. Insérez le ruban dans le chariot.

5. Alignez les encoches avec les rayons

du mandrin.

7. Alignez les encoches sur les rayons du

mandrin.

4. Enfoncez le rouleau dans le mandrin.

6. Enfoncez le rouleau ré-enrouleur dans

le mandrin.

8. Fixez le ruban sur le rouleau ré-

enrouleur à l’aide de la languette

adhésive des rubans neufs ou avec du

ruban adhésif.

EIL/MAN/002: REVISION 6 Date: July 2007 Page 33

Page 39

Francàis

3.1 Insertion d’un ruban neuf

Si le ruban se termine en cours d’impression, le voyant s’allume en orange et l’imprimante

s’arrête. Sans éteindre l’imprimante, ouvrez le couvercle supérieur. Coupez le ruban usagé pour

pouvoir enlever les deux rouleaux. Chargez le ruban neuf comme décrit au paragraphe 3.0,

Chargement du ruban. Refermez le couvercle supérieur et appuyez sur le bouton d’alimentation

pour reprendre l’impression.

3.2 Retrait d’un ruban partiellement usagé

Pour enlever un ruban partiellement usagé, découpez la partie usagée sur le rouleau réenrouleur. Retirez le rouleau ré-enrouleur. Retirez tout le ruban usagé du rouleau ré-enrouleur

et conservez le rouleau vide pour une future réutilisation. Retirez le rouleau d’alimentation et

conservez-le dans les conditions de stockage des rubans.

Coupez la partie

usagée du ruban

Poussez sur le

rouleau

d’alimentation pour

le sortir

Remarque importante : Après avoir complètement utilisé le ruban, il faut soit remplacer le

rouleau ré-enrouleur par un rouleau en carton vide, soit retirer le ruban usagé du rouleau réenrouleur en carton. Si le ruban usagé s’accumule sur le rouleau ré-enrouleur en carton, il risque

de frotter contre le ruban neuf et de bloquer.

EIL/MAN/002: REVISION 6 Date: July 2007 Page 34

Page 40

4.0 Chargement du produit

Ouvrez le couvercle.

Séparez les guides.

Francàis

EIL/MAN/002: REVISION 6 Date: July 2007 Page 35

Page 41

Francàis

4.1 Chargement des manchons de marquage TMS

Les manchons de marquage TMS peuvent être chargés de l’intérieur ou de l’extérieur. Les deux

méthodes exigent que le porte-rouleau de support soit maintenu ouvert et que la vis de blocage

soit serrée à l’aide d’un tournevis.

4.1.1 Chargement intérieur des manchons de marquage TMS

Retirez l’emballage et le grand rouleau en carton ; placez le produit libre dans la baie de support

de l’imprimante. Cette méthode est possible avec les manchons de marquage TMS et avec

certaines étiquettes auto-collantes enroulées sur de grands rouleaux en carton.

4.1.2 Chargement extérieur des manchons de marquage TMS

Le produit peut être inséré dans l’imprimante au moyen de la fente qui se trouve à l’arrière de

l’imprimante. Cette méthode convient si l’on souhaite laisser les manchons de marquage TMS

dans la boîte en carton dans laquelle ils sont livrés.

EIL/MAN/002: REVISION 6 Date: July 2007 Page 36

Page 42

Francàis

4.2 Chargement d’étiquettes

Les étiquettes peuvent être chargées par l’intérieur ou par l’extérieur.

4.2.1 Chargement intérieur d’étiquettes

Les étiquettes fournies sur de petits rouleaux en carton peuvent être maintenues en place par le

porte-rouleau de support à ressort.

Les étiquettes ne s’adaptant pas au porte-rouleau peuvent être ôtées de leur rouleau et placées

librement dans la baie de support de l’imprimante. Si l’on choisit cette méthode, le porterouleau de support doit être bloqué sur la position d’ouverture ; voir le chapitre 4.1 Chargement

des manchons de marquage TMS.

4.2.2 Chargement extérieur d’étiquettes

Les étiquettes peuvent être insérées dans l’imprimante au moyen de la fente qui se trouve à

l’arrière de l’imprimante. Cette méthode est applicable si les étiquettes ne rentrent pas dans le

porte-rouleau intérieur de support. Un porte-support adapté doit être utilisé. Veuillez contacter

Tyco Electronics pour plus de détails.

EIL/MAN/002: REVISION 6 Date: July 2007 Page 37

Page 43

Francàis

4.3 Chargement du produit (suite)

Le(la) premier(ère) manchon de marquage/étiquette doivent être placés sur le rouleau presseur

en caoutchouc noir. Une fois chargé(e), refermer les guides-support pour qu’ils agrippent

légèrement le produit.

Dégagez le couvercle

Refermez le couvercle

EIL/MAN/002: REVISION 6 Date: July 2007 Page 38

Page 44

Francàis

5.0 Calibrage

Quand vous changez de type de produit ou que vous en chargez un nouveau, l’imprimante doit

être calibrée.

Après avoir correctement installé le produit et le ruban, procédez comme suit :

1. Éteignez l’appareil.

3. Tout en maintenant la pression sur le

bouton d’alimentation, allumez

l’appareil.

5. L’imprimante fait avancer le support et

imprime un résumé d’état.

2. Appuyez sur le bouton d’alimentation.

4. Attendez que le voyant clignote 3 fois

en rouge et relâchez le bouton

d’alimentation.

6. Appuyez sur le bouton d’alimentation

pour activer le fonctionnement normal.

Remarque : L’imprimante est sur le mode image

de diagnostic. La première ligne imprimée sur le

papier pendant le calibrage correspond à la version

du micrologiciel.

7. À chaque fois que vous appuyez sur le

bouton d’alimentation, le papier doit

avancer d’un manchon de

marquage/étiquette.

EIL/MAN/002: REVISION 6 Date: July 2007 Page 39

Remarque :

Si l’imprimante s’alimente en continu ou fait

avancer plus d’un manchon de marquage ou

d’une étiquette à la fois, ou si le voyant reste

orange ou rouge, reportez-vous au chapitre 5.1

Alignement de calibrage et au chapitre 11.0

Dépannage, puis répétez la procédure de

calibrage.

Page 45

Francàis

5.1 Alignement de calibrage

Le calibrage peut être difficile à réaliser avec certains produits généralement parce que le délai

de retard du capteur est dépassé avant qu’il n’ait pu reconnaître le contraste entre l’étiquette et le

dorsal du support.

La réduction du temps dont dispose le capteur pour détecter la différence entre les étiquettes et

le matériau du dorsal permettra de calibrer correctement le capteur.

5.1.1 Alignement des étiquettes

Placez une étiquette sous le capteur de la T200 de sorte que moins de 5 mm environ d’étiquette

ne se déplace avant que le matériau du dorsal ne soit détecté par le capteur.

Environ 5 mm

5.1.2 Alignement d’étiquettes à perforations pour capteur

Placez une étiquette sous le capteur de la T200 de sorte que moins de 5 mm environ d’étiquette

ne se déplace avant que la perforation pour capteur ne soit détectée par le capteur.

REMARQUE : Les étiquettes ne seront calibrées que si elles passent directement sous le

capteur. Les produits dont les étiquettes ne se trouvent pas directement sous le capteur ne seront

pas calibrés. Une perforation pour capteur ou une marque noire sont nécessaires pour calibrer

ces produits. Si vous utilisez une marque noire, le réglage par défaut du capteur doit être

modifié dans l’imprimante. Reportez-vous au chapitre 6.0 Changement du type de capteur.

Capteur

5 mm environ

EIL/MAN/002: REVISION 6 Date: July 2007 Page 40

Page 46

Francàis

6.0 Changement du type de capteur

Le capteur par défaut de la T200 est un capteur transmissif (bobine) qui devrait fonctionner avec

tous les produits TMS et les étiquettes standard. Si le capteur Réflectif (marque noire) ou le

mode Continu sont requis, procédez comme indiqué ci-après.

6.1 Capteur réflectif (marque noire)

Pour activer le capteur Réflectif (marque noire), imprimez une étiquette avec le capteur réglé sur

« Réflectif (marque noire) » dans « Édition d’étiquettes avancée » de WinTotal ou dans « Pilote

d’imprimante Windows » de PrintEasy. Après l’impression d’une étiquette avec ces paramètres,

le voyant s’allume en rouge. Il faut alors calibrer l’imprimante sur le produit Réflectif (marque

noire).

6.2 Mode de détection continue

Pour imprimer des produits continus, l’imprimante doit être réglée sur le mode continu. Pour ce

faire, imprimez une étiquette avec le capteur réglé sur « Continu » dans « Édition d’étiquettes

avancée » de WinTotal ou dans « Pilote d’imprimante Windows » de PrintEasy. Après

l’impression d’une étiquette avec ces paramètres, le voyant s’allume en rouge. Il faut alors

calibrer l’imprimante sur le produit continu.

6.3 Capteur transmissif

Pour revenir au capteur Transmissif (bobine), imprimez une étiquette avec le capteur réglé sur

« Transmissif (bobine) » dans « Édition d’étiquettes avancée » de WinTotal ou dans « Pilote

d’imprimante Windows » de PrintEasy. Après l’impression d’une étiquette avec ces paramètres,

le voyant s’allume en rouge. Il faut alors calibrer l’imprimante sur le produit transmissif

(bobine).

Remarque : Le procédé de calibrage est le même pour tous les modes de détection et est décrit

au chapitre 5.0 Calibrage.

7.0 Versions du micrologiciel de l’imprimante

La version correcte du micrologiciel est pré-chargée dans les imprimantes :

T208M et T208M-C - version 4.51 ou supérieure du micrologiciel.

T212M et T212M-C - version 4.51 ou supérieure du micrologiciel.

Ne modifiez et n’actualisez pas la version du micrologiciel sans auparavant vérifier auprès de

Tyco Electronics. Toutes les versions du micrologiciel ne permettent pas une impression

réussie des produits d’identification de Tyco Electronics.

Vérifiez la version du micrologiciel en faisant un calibrage de l’imprimante (voir chapitre 5.0

Calibrage).

EIL/MAN/002: REVISION 6 Date: July 2007 Page 41

Page 47

Francàis

8.0 Logiciel

Le logiciel conseillé pour imprimer avec une T200 est soit WinTotal pour les manchons TMS et

le format standard d’étiquettes, soit PrintEasy pour les étiquettes. Des versions de démonstration

de ces deux logiciels sont fournies dans le CD.

WinTotal comporte des pilotes d’imprimante intégrés.

PrintEasy utilise les pilotes d’imprimante Windows qui peuvent être automatiquement installés

à partir du CD. Ces pilotes fonctionnent avec Windows 95, 98, ME, NT4, 2000 et XP.

Ces deux logiciels permettent de contrôler tous les aspects importants de l’imprimante, y

compris la vitesse et le niveau de luminosité. La plupart des produits sont correctement

imprimés avec les paramètres par défaut de l’un ou l’autre des logiciels. L’augmentation du

niveau de luminosité améliore normalement la qualité de l’impression.

Remarque : Pour plus de détails, veuillez consulter la documentation des logiciels ou contacter

votre représentant local Tyco Electronics.

9.0 Qualité d’impression

Pour garantir l’obtention d’une bonne qualité d’impression, le produit imprimé doit avoir une

valeur de contraste d’au moins 8 (et de préférence 9-10) sur l’échelle de contraste d’impression

de Tyco Electronics.

EIL/MAN/002: REVISION 6 Date: July 2007 Page 42

Page 48

Francàis

10.0 Entretien

10.1 Nettoyage de la tête d’impression

Il est recommandé de nettoyer la tête d’impression après consommation d’un rouleau de ruban.

Utilisez pour ce faire le stylo nettoyant qui vous est livré avec l’imprimante ou tout produit

habituel de nettoyage de tête d’impression d’imprimantes à transfert thermique (par exemple,

une lingette imprégnée d’alcool isopropylique).

Éteignez

l’imprimante

Frottez le stylo

nettoyant sur la

surface foncée de la

tête d’impression

Ne nettoyez pas le

rouleau de la platine

avec le stylo

nettoyant

EIL/MAN/002: REVISION 6 Date: July 2007 Page 43

Page 49

Francàis

10.2 Nettoyage du rouleau de la platine

Avec le temps, la poussière d’adhésif encrasse la platine qui doit alors être nettoyée. Utilisez

pour ce faire un chiffon propre non pelucheux légèrement humidifié avec de l’alcool

isopropylique.

Éteignez

l’imprimante.

Débranchez tous les

câbles

d’alimentation et

d’interface.

Essuyez doucement

le dessus de la

platine

Faites avancer la

platine d’un sixième

(1/6) de tour

Répétez les

opérations jusqu’à

ce que la platine soit

propre

Remarque : Laissez la platine sécher pendant au moins une minute avant de charger le support.

EIL/MAN/002: REVISION 6 Date: July 2007 Page 44

Page 50

Francàis

11.0 Dépannage

Problème Solution ou cause

Le voyant ne s’allume pas après

avoir allumé l’imprimante.

Voyant orange. 1. Vérifiez que le couvercle est fermé et verrouillé.

Le voyant clignote en rouge. 1. Le téléchargement du micrologiciel est en cours. Le voyant

Voyant rouge. 1. Fin du support ou du ruban. Réalimentez.

Le voyant est vert mais

l’impression ne se fait pas.

L’imprimante semble fonctionner

(le support en sort) mais rien ne

s’imprime.

Ou

L’impression est trop claire ou de

mauvaise qualité.

N’imprime que partiellement les

étiquettes ou en saute certaines.

L’imprimante s’arrête et le voyant

passe à l’orange ou au rouge.

Des plis du ruban provoquent des

manques dans l’impression.

Le massicot coupe les étiquettes au

lieu de la doublure.

Bourrage dans le massicot. 2. Débranchez les câbles électriques et d’interface. Enlevez les

Le massicot ne coupe pas. 1. Vérifiez les paramètres du logiciel.

1. Vérifiez les branchements électriques entre la prise CA,

l’adaptateur et l’imprimante.

2. Vérifiez que le support ou le ruban sont présents.

2. L’imprimante a reçu des données partielles ou erronées. Vérifiez le

programme du logiciel et réinitialisez l’imprimante.

s’allume en rouge puis en vert.

2. Signal pour commencer le calibrage après avoir allumé

l’imprimante. Relâchez le bouton d’alimentation.

2. Panne d’alimentation.

3. L’imprimante est prête à recevoir une programmation Flash

pendant le téléchargement du micrologiciel.

1. Vérifiez les connexions du câble d’interface entre l’imprimante et

l’ordinateur.

2. Vérifiez que le couvercle est fermé et verrouillé.

3. Vérifiez que le support est correctement chargé.

4. Vérifiez que le ruban est correctement installé et que le côté encré

est dirigé vers l’extérieur (face au produit).

1. Vérifiez que la combinaison produit/ruban utilisée est co rrecte et

que le chargement a été correctement effectué.

2. Vérifiez que le couvercle est fermé et verrouillé.

3. Nettoyez la tête d’impression avec le stylo nettoyant.

4. Réglez la vitesse/luminosité d’impression dans le logiciel.

5. Vérifiez que les types/tailles de polices et les graphiques ne sont pas

trop petits.

1. Calibrez l’imprimante.

2. Vérifiez que le produit ne reste pas coincé pendant l’alimentation.

3. Vérifiez que le couvercle est fermé et verrouillé.

4. Vérifiez les paramètres du logiciel – en particulier que le réglage de

la marge supérieure n’est pas trop élevé.

1. Calibrez l’imprimante.

2. Vérifiez que le produit ne reste pas coincé pendant l’alimentation.

3. Vérifiez que les données de l’étiquette ne sont pas trop lourdes pour

la mémoire de l’imprimante.

4. Vérifiez tous les paramètres du logiciel.

1. Vérifiez que le ruban s’enroule bien droit sur le rouleau ré-

enrouleur.

1. Vérifiez tous les paramètres du logiciel.

morceaux de l’ouverture du massicot à l’aide d’une pince.

2. Recherchez des bourrages.

3. Le massicot doit être remplacé.

Pour tout autre problème, y compris les problèmes de produit ou de logiciel, veuillez contacter

votre représentant Tyco Electronics.

EIL/MAN/002: REVISION 6 Date: July 2007 Page 45

Page 51

Francàis

Annexe A

Série T200 avec massicot

Les imprimantes T208M-C et T212M-C sont équipées d’un massicot de support intégré. Ce

massicot coupe le matériau continu des étiquettes ou la doublure entre les étiquettes de manière

automatique. Le massicot NE DOIT PAS servir à couper les manchons de marquage TMS.

EIL/MAN/002: REVISION 6 Date: July 2007 Page 46

Page 52

Francàis

Déblocage du massicot de support

L’adhésif des étiquettes peut provoquer un bourrage dans le massicot. Pour enlever l’adhésif,

procédez comme indiqué ci-dessous.

Le massicot doit rester sec. N’utilisez aucune solution ni solvant pour nettoyer la lame.

Éteignez

l’imprimante.

Débranchez tous les

câbles

d’alimentation et

d’interface.

Retirez tous les

débris avec une

pince

Rebranchez

l’imprimante et

faites un test de

fonctionnement

EIL/MAN/002: REVISION 6 Date: July 2007 Page 47

Page 53

Francàis

Annexe B

Câblage du câble d’interface

Câbles d’interface en série

La figure ci-dessous montre le câblage requis pour utiliser l’interface d’imprimantes en série

RS-232.

* +5 volts à 150 mA pour appareil externe (par ex., KDU ou scanner)

DB-9

Fiche #

DB9 femelle à DB-9 mâle

DB-9

Fiche #

DB-25 femelle à DB-9 mâle

DB-9

Fiche #

DB-9

Fiche #

EIL/MAN/002: REVISION 6 Date: July 2007 Page 48

Page 54

Francàis

Câblage d’interface en parallèle

La figure ci-dessous montre le câblage requis pour utiliser l’interface d’imprimantes en parallèle

Centronics.

+5 volts à 300 mA pour appareil externe (par ex., KDU ou scanner)

DB-25

Fiche

Male DB-25 to Male Centronics Cable

Centronic

s

EIL/MAN/002: REVISION 6 Date: July 2007 Page 49

Page 55

Francàis

Câblage d’interface USB (bus série universel)

Le tableau ci-dessous indique les attributions de terminaisons de contacts par numéro et valeur

électrique des connecteurs de câbles.

Numéro de contact Nom du signal Attribution habituelle de

câblage

1 VBUS Rouge

2 D- Blanc

3 D+ Vert

4 TERRE Noir

Gaine Blindage Conducteur de drainage

Reportez-vous aux spécifications de l’USB pour plus de détails concernant cette interface.

EIL/MAN/002: REVISION 6 Date: July 2007 Page 50

Page 56

Deutsch

Deutsch

T200 SERIE THERMOTRANSFER-DRUCKERSYSTEM

BENUTZERHANDBUCH

(T208M-PRINTER, T208M-C-PRINTER, T212M-PRINTER und T212M-C-PRINTER)

EIL/MAN/002: REVISION 6 Date: July 2007 Page 51

Page 57

Deutsch

Vorwort

Dieses Handbuch stellt Informationen zur Aufstellung und Inbetriebnahme für die DRUCKER

T208M-PRINTER (E63660-000), T208M-C-PRINTER (D82271-000), T212M-PRINTER

(E23401-000) und T212M-C-PRINTER (A53989-000) bereit, hergestellt für Tyco Electronics.

Copyright-Hinweis

Dieses Dokument enthält Informationen, die Eigentum von Tyco Electronics sind. Dieses

Dokument und die darin enthaltenen Informationen sind für Tyco Electronics geschützt und

dürfen von niemandem weder vollständig noch in Teilen ohne schriftliche Erlaubnis von Tyco

Electronics dupliziert werden. Obwohl jede mögliche Anstrengung unternommen wurde, um die

Informationen darin auf dem Laufenden und so exakt wie möglich zum Tage der

Veröffentlichung zu halten, wird keine Garantie gegeben oder stillschweigend angenommen,

dass das Dokument fehlerfrei ist oder dass es hinsichtlich etwaiger Produktänderungen richtig

ist. Tyco Electronics behält sich das Recht vor, zu jeder Zeit Änderungen zum Zwecke der

Produktverbesserung durchzuführen.

Marken

T208M und T212M sind Handelsmarken von Tyco Electronics. Windows und MS-DOS sind

eingetragene Marken der Microsoft Corp. Alle anderen Marken sind Marken oder eingetragene

Handelsmarken der jeweiligen Firmen.

T208M-PRINTER, T208M-C-PRINTER, T212M-PRINTER und T212M-C-PRINTER Thermodrucker

EU-Richtlinien Richtlinienkonformität

89/336/EW

G

92/31/EWG

92/31/EWG

CB-Schema

FCC – Konformitätserklärung

Die Modelle T208M-PRINTER, T208M-C-PRINTER, T212M-PRINTER und

T212M-C-PRINTER stimmen mit den folgenden Spezifizierungen überein:

FCC Teil 15, Unterabteilung B, Sektion 15.107(a) und Sektion 15.109(a),

Klasse B, Digitalgeräte.

Zusätzliche Information:

Dieses Gerät stimmt mit Teil 15 der FCC-Regelungen überein. Der Betrieb unterliegt den folgenen zwei

Bedingungen: (1) Dieses Gerät darf keine schädlichen Störungen hervorrufen, und (2) dieses Gerät muss alle

Störungen vertragen, einschließlich Störungen, die einen unerwünschten Betrieb hervorrufen.

Hinweis zu Industry Canada:

Dieses Gerät stimmt mit den Anforderungen der Industry Canada ICS-003, Klasse B, überein.

EMC-

Richtlinien

EMC-

Richtlinien

EMC-

Richtlinien

EMC-

Richtlinien

EN 55022-B

1988

EN 55024 1988

EN 61000-3-2 Harmonische Emissionen

EN 61000-3-3 Spannungsschwankungen

EN 60950 1991

A1, A2, A3, A4

RF Emissionskontrolle

Schutz vor elektro-

magnetischen Störungen

Sicherheit

EIL/MAN/002: REVISION 6 Date: July 2007 Page 52

Page 58

Deutsch

Wichtige Information!

Die unkorrekte Benutzung dieses Gerätes kann Verletzungen hervorrufen. Es wird

empfohlen, dass die Benutzer im korrekten Umgang mit dem Gerät geschult werden und

sie dieses Handbuch vor dem Gebrauch lesen.

Die Wartung darf ausschließlich durch dafür geeignetes und geschultes Personal

durchgeführt werden.

Warnung vor Stromschlag:

Der Drucker und die Stromversorgung dürfen niemals in einem Bereich betrieben

werden, in dem sie Nässe ausgesetzt sein können. Dies kann die Verletzung von

Personen zur Folge haben.

Warnung zu Druckmedien und Farbband:

Benutzen Sie immer zugelassene Druckmedien und Farbbänder von hoher Qualität.

Wenn Selbstklebeetiketten benutzt werden, die NICHT flach auf dem Trägerpapier

aufliegen, können die Sticker mit ihren Ecken an den Etiketten- und Rollenführungen

innerhalb des Druckers festkleben, die Ablösung des Etiketts vom Träger hervorrufen

und so den Drucker blockieren. Der Druckkopf kann auf Dauer dadurch zerstört werden,

dass ein nicht zugelassenes Farbband benutzt wird, da es in ungeeigneter Weise

aufgerollt sein oder für den Druckkopf korrosive Chemikalien enthalten kann.

Zugelassene Produkte können von Ihrem Händler geliefert werden.

Hinweis zum Einlegen:

Falls die Etiketten oder das Farbband während des Druckes ausgehen sollten , schalten

Sie beim Einlegen NICHT den Schalter auf AUS (0), da sonst ein Datenverlust die Folge

sein kann. Der Drucker startet automatisch neu, nachdem Sie ein neues Etikett oder eine

neue Farbbandrolle eingelegt haben.

Statische Entladung:

Das Entladen statischer Energie, die sich auf der menschlichen Haut oder auf anderen

Oberflächen gebildet hat, kann den Druckkopf oder in diesem Gerät eingesetzte

elektronische Komponenten beschädigen oder zerstören. BERÜHREN SIE NICHT den

Druckkopf oder andere elektronische Komponenten unter der oberen Abdeckung.

Thermodruck:

Der Druckkopf erhitzt sich während des Druckens. Um den Druckkopf vor Schaden zu

bewahren und Verletzungen von Personen zu verhindern, vermeiden Sie eine Berührung

des Druckkopfes. Benutzen Sie nur den Reinigungsstift oder ein IPA-Tuch, um die

Wartung durchzuführen.

Lagerung von Druckmedien und Farbbändern:

Alle Druckmedien und Farbbänder müssen in einem sauberen Bereich gelagert werden,

der frei von Verschmutzung, Staub, Fett und hoher Luftfeuchtigkeit ist. Ansonsten kann

die Druckqualität und die Lebensdauer leiden. Die Lagerbedingungen und -zeit sind auf

jedem Druckmedienbehälter vermerkt. Wenden Sie sich zu weitergehenden

Informationen bitte an Tyco Electronics.

EIL/MAN/002: REVISION 6 Date: July 2007 Page 53

Page 59

Deutsch

1.0 Aufbau des Druckers

1.1 Den Drucker auspacken

Packen Sie den Drucker aus, und stellen Sie dabei sicher, dass das gesamte

Verpackungsmaterial für einen zukünftigen Transport behalten wird. Sollte der Drucker in dem

unwahrscheinlichen Fall in einem fehlerhaften Zustand sein, so wenden Sie sich bitte an Ihren

Tyco Electronics Vertreter oder an die Transportfirma.

Die folgenden Bestandteile sollten mit dem Drucker mitgeliefert werden:

• Drei Netzkabel für UK, Europa und USA.

• Paralleles Kommunikationskabel.

• Stromversorgung.

• Zusätzliche Pappehülse (für Farbbandaufnahme).

• Druckkopf-Reinigungsstift.

• Tyco Electronics CD-ROM mit folgendem Inhalt…

o Elektronisches Handbuch.

o Druckertreiber für Windows 95, 98, ME, NT4, 2000 und XP.

o Downloadprogramm für Schriften.

o Downloadprogramm für Firmware – nur zu benutzen, wenn durch Tyco

Electronics empfohlen.

o Wintotal Demo-Software.

o PrintEasy Demo-Software.

• Tyco Electronics Druckkontrast-Skala.

EIL/MAN/002: REVISION 6 Date: July 2007 Page 54

Page 60

r

g

r

1.2 Überblick über den Drucker

Deutsch

Farbband-Senso

Abreißbalken

Farbband-

Zuführungs-Rollenhalter

Farbband-

AufnehmerRollenhalte

Farbband-AufnehmerAntrieb

Druckkopf

Sperre obere

Abdeckun

Rollenhalter

Druckmedium

Druckmedium-Sensor

Einstellung Führungen

Druckmediumführung

EIL/MAN/002: REVISION 6 Date: July 2007 Page 55

Page 61

1.3 Anschluss des Druckers an die Stromversorgung

Drucker ausschalten

Prüfen der

Spannung

Strommodul

einstecken

Netzkabel

einstecken

Netzkabel

in geeignete

Steckdose

einstecken

Deutsch

SpannungsAufdruck

EIL/MAN/002: REVISION 6 Date: July 2007 Page 56

Page 62

1.4 Anschluss des Interface-Kabels

Drucker

ausschalten

Parallel

Seriell

USB

(Universal

Serial Bus)

Deutsch

EIL/MAN/002: REVISION 6 Date: July 2007 Page 57

Page 63

Deutsch

2.0 Auswahl des Farbbands

Die Druckqualität und die Lebensdauer von Tyco Electronics Identifikationsprodukten sind nur

gewährleistet, wenn das korrekte Thermotransfer-Farbband für jedes Produkt benutzt wird.

Schauen Sie bitte unter dem Titel „Printer/material/ribbon compatibility cross reference“ nach,

den Sie auf www.tycoident.com finden können, oder wenden Sie sich an Tyco Electronics.

3.0 Einlegen des Farbbands

1. Öffnen Sie die Abdeckung.

3. Führen Sie das Farbband durch die

Durchführung.

2. Ziehen Sie den Klebestreifen ab.

4. Drücken Sie die Farbbandhülse gegen

den Rollenaufnehmer.

5. Rasten Sie die Rollenöffnungen in die

Aufnehmer ein.

7. Rasten Sie die Hülsenöffnungen in die

Aufnehmer ein.

6. Drücken Sie die Leerhülse gegen den

Aufnehmer.

8. Befestigen Sie das Farbband an der

Leerhülse mit Hilfe des Klebestreifens.

EIL/MAN/002: REVISION 6 Date: July 2007 Page 58

Page 64

Deutsch

3.1 Ein neues Farbband einlegen

Falls während des Druckens das Farbband endet, leuchten die Anzeigelampen orange, und der

Drucker hält an. Lassen Sie das Gerät eingeschaltet, öffnen Sie die obere Abdeckung. Schneiden

Sie das gebrauchte Farbband durch, so dass beide Hülsen entfernt werden können. Legen Sie

das neue Farbband wie unter Abschnitt 3.0 „Einlegen des Farbbands“ beschrieben ein.

Schließen Sie die obere Abdeckung, und drücken Sie den Einzugknopf, um das Drucken

fortzusetzen.

3.2 Entfernen eines teilweise gebrauchten Farbbands