Tyco Electronics FIST-GCO2 Series, GCO2-BC6 Series, GCO2-BE6 Series, GCO2-BD6 Series, GCO2-BC16 Series Installation Instruction

...Page 1

FIST-GCO2

INSTALLATION INSTRUCTION

GCO2-BC6/16-XX

GCO2-BD6/16-XX

GCO2-BE6/16-XX

1 Introduction

2 General

2.1 Abbreviation

2.2 Kit Contents

2.3 Elements needed from the FIST

installation kit

2.4 Tools

2.5 Cable preparation table

3 Installation

3.1 Installation of workstand

3.2 Opening the FIST GCO

4 Cable preparation

4.1 Loose buffer tube cable

4.1a Looped cable preparation

4.1b Bracket/strength member

4.1c Loose buffer tube storage

4.1d Fiber storage in trays

4.1e Drop cable preparation

(6 port base)

4.1f Drop cable preparation

(16 port base) single fiber,

ribbon and compact sheet

cable

4.1g Tube preparation

4.2 Central core cable

4.2a Looped cable preparation

4.2b Bracket/strength member

4.2c Mass storage facility and twisted

fibers:(Using Basket)

4.2d Twistfree fibers

4.2e Drop cable preparation (6 port base)

4.2f Drop cable preparation (16 port base)

5 Heatshrink installation

6 Fiber routing

7 Fiber routing on tray

8 Tube holder capacity

9 Cable grounding / shielding

10 Closing the closure

11 Important steps

12 Re-arrangement

Content

1 Introduction

The generic closure FIST-GCO is the environmentally sealed enclosure for the fiber management system that

provides the functions of splicing and passive component integration in the external network. The product can

be tailored to almost any required configuration by adding splicing and/or passive device Sub-Assemblies. The

FIST-GCO has provision for all cable termination and sealing requirements.

To clean FIST components, the use of isopropylalcohol is recommended.

The closure is a single-ended design made of a thermoplastic material.

The base and dome are sealed with a clamp and an O-ring system. One oval entry port for looped (uncut) cable

management and six or sixteen round ports for single cable entry/exit are included in the base. The cable seals

are manufactured from heat-shrinkable material. The Universal Mounting System provides the foundation for

mounting SOSAs and SASAs back to back. The two back to back sides have each a standard capacity of

28, 42 or 58 units. Uncut loose buffer tube storage is available between the two UMS-sides (Universal Mounting

System). Storage of uncut looped ribbons or fibers from central core (or slotted core) cables is available with the

fiber storage basket. Storage of uncut looped ribbons or fibers can be done in individual FIST-trays.

Page 2

2

Dimensions (in mm)

Closure Type GCO2-BC6-XX GCO2-BD6-XX GCO2-BE6-XX

L 488 566 700

D with clamp 285 285 285

Closure Type GCO2-BC6-XX GCO2-BD6-XX GCO2-BE6-XX

Capacity

Primary coated fibers

Single element 336 480 672*

Single circuit 2 112 160 224

Single circuit 4 224 320 448

Ribbon 4

2 ribbons each tray 40 (160 fibercount) 80 (320) 110 (440)

1 ribbon each tray 20 (80 fibercount) 40 (320) 55 (220)

Ribbon 12

1 ribbon each tray 16 (192 fibercount) 28 (336) 36 (432)

* Capacity on FAS can depend on capacity on tubeholder, see for instance the

capacity table for loose tubes later on

According network layout and cable constructions the kit content can

be different from the kit content described in this installation

instruction.

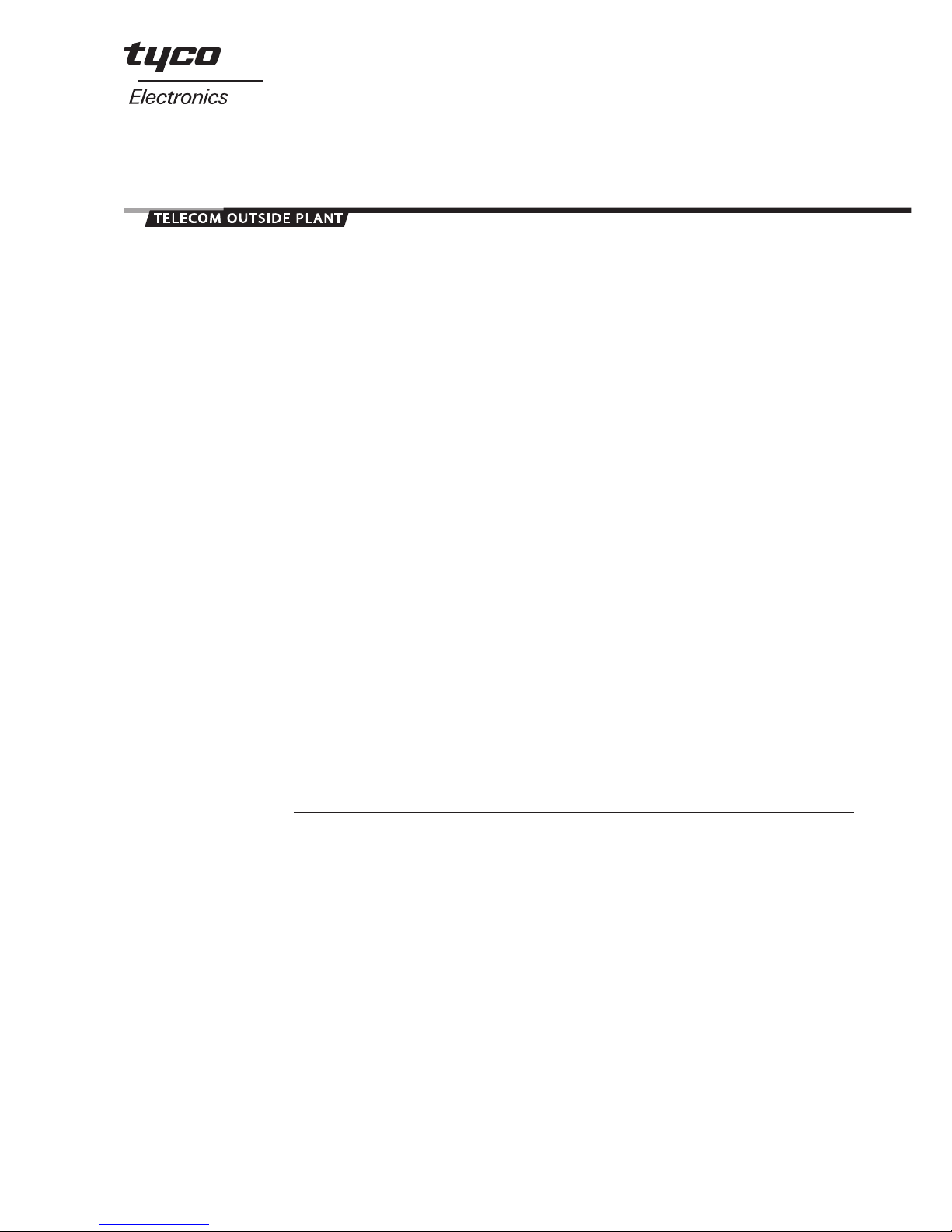

• Dome

• Base including routing block + cover (universal mounting system),

shield mounting bolt, and strength member termination bracket

• Clamp

• O-ring

• 100g Silicagel

• 2 tray covers + fiber guiding pin +tube holder retainers

• 2 tray wedges

• Installation Instruction

2 General

2.1 Abbreviations

Looped Cable Installation Tool LCIT

Universal Mounting System UMS

2.2 Kit contents

Cable diameters in 6 port base

Loose tube loop, 12-25mm drop,(5-30mm)

C.Core loop, 12-25mm drop,(5-25mm)

Cable diameters in 16 port base

Loose tube loop, 12-25mm drop ports 3-10,(5-20mm)

drop ports 11-18,(5-14mm)

C.Core loop, 12-25mm drop ports 3-10,(5-20mm)

drop ports 11-18,(5-14mm)

Page 3

3

2.3 Elements possibly needed from the FIST installation kit

Product Name UOM QTY/UOM Product description

FISTV-E7185-3010 1 RL 50 m Cut wire to open the FIST-GCO ports

FISTV-E7100-1005 1 PK 10x100g Silicagel for inside the closure, to be replaced after each re-entry

FISTV-SPLI-COL 1 PK 30 sets Split identifications collet (2-sizes) till 3.5mm

2.4 Tools

• FIST-LCIT Looped tube insertion tool for oval outlet To insert loose tubes in oval port

• FACC-TUBE-CUTTER-01 Tube cutter To cut spiral tubing

• FACC-TUBE-STRIPPER-02 Tube stripper To strip loose tubes

• FACC-AXIAL-STRIPPER-01 Tube splitter To split buffer tubes 2.0-3.1mm

• FACC-HEAT-GUN-220V Heatgun + Heatgun tip To shrink cable seals

• FIST-WORK-STAND To hold the closure in a vertical position during installation

• FIST-WORK-STAND-H Hinging workstand To hold the closure in any position during installation

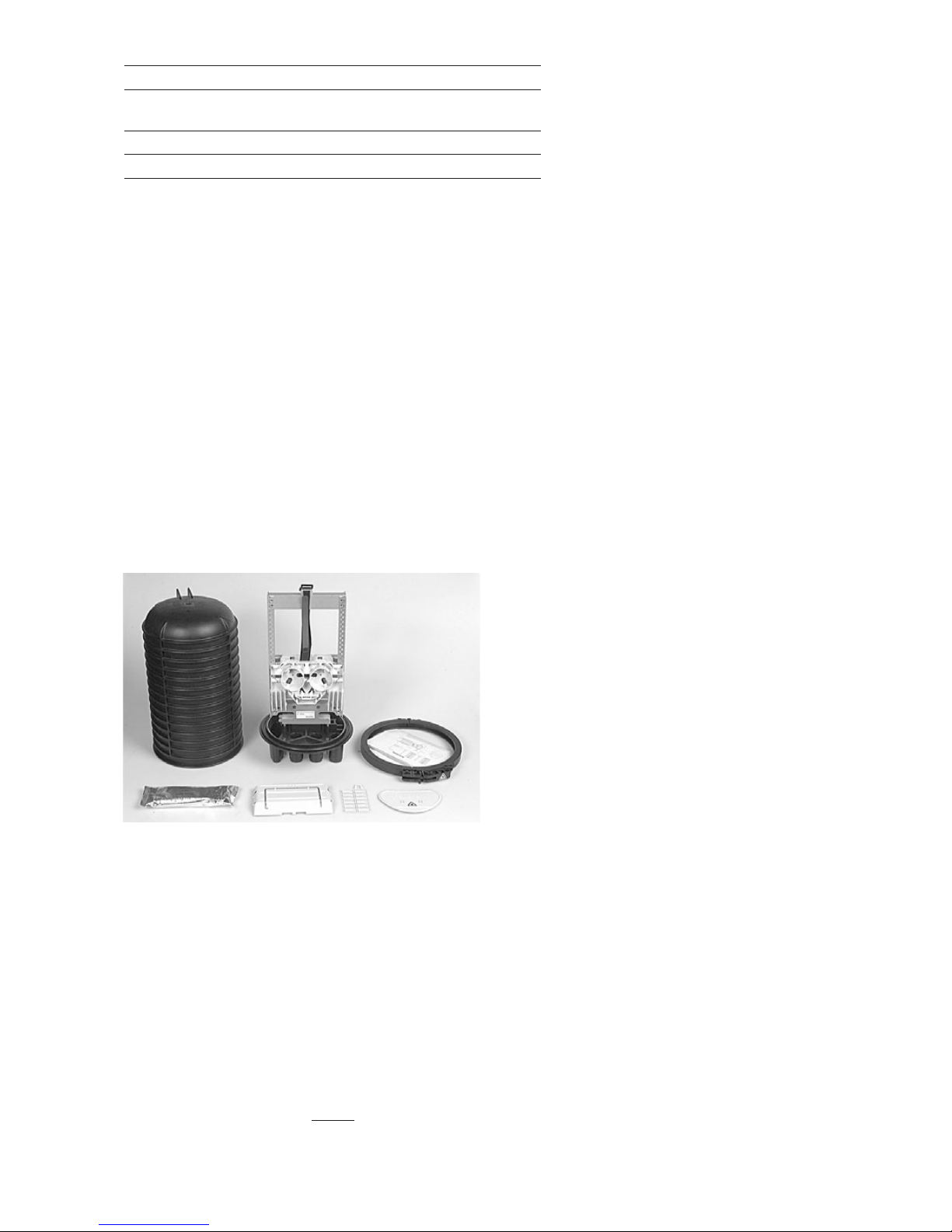

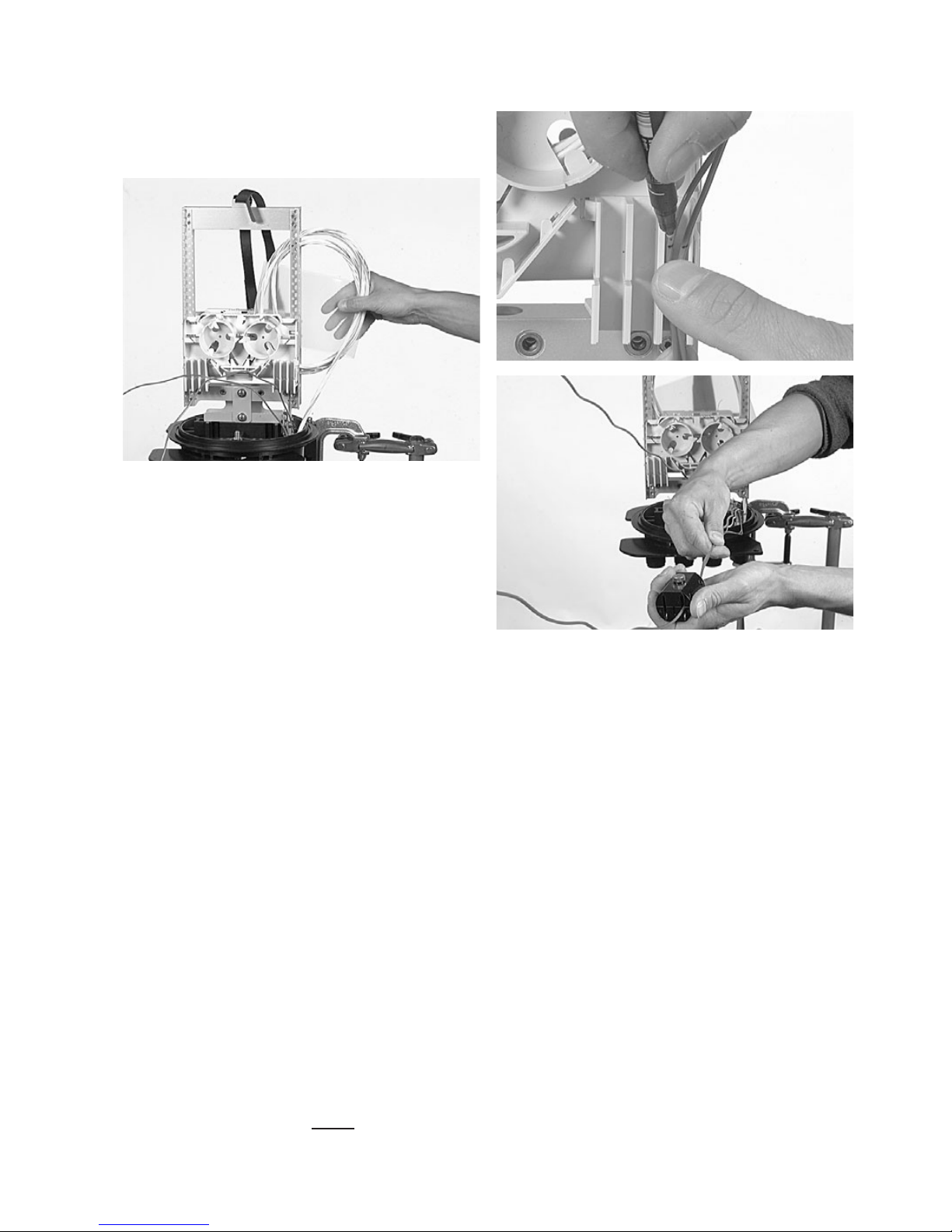

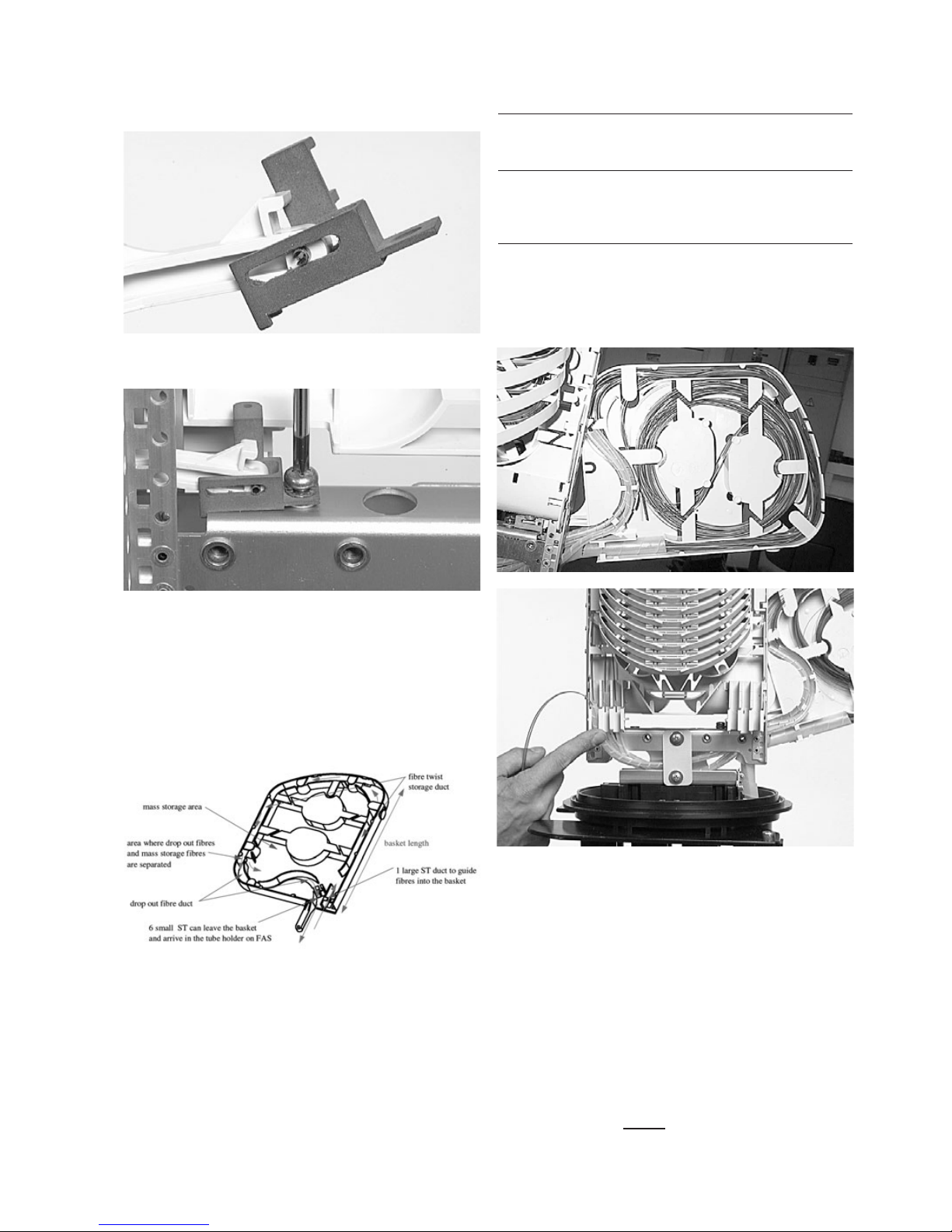

3.1.1 The FIST-GCO will be mounted temporary on the work-stand.

The work-stand is wrap-around, so that the FIST-GCO installed with

cables can be taken away from it.

Fix the FIST-GCO base onto the workstand with the four split-pen.

3 Installation

3.1 Installation of workstand

2.5 Cable preparation table

Window cut drop cable

Loose Tube BC6 or 16 3.5 m 2.2 m

BD6 or 16 3.7 m 2.2 m

BE6 or 16 3.9 m 2.2 m

Twisted C.Core BC6 or 16 5.3 m 2.2 m

(Use Basket) BD6 or 16 5.9 m 2.2 m

BE6 or 16 6.1 m 2.2 m

Untwisted C.Core BC6 or 16 3.5 m 2.2 m

BD6 or 16 3.7 m 2.2 m

BE6 or 16 3.9 m 2.2m

3.1.2 The hingable work stand can be used. It is recommended

when he 16 port base is applied.

Page 4

4.1.7 Insert the strength members of the cable into the universal

strength member connector on the loop bracket (loosen the bolts with

the Allen key if necessary) such that all loose tubes can be routed

without unnecessary crossings. Avoid to twist the loop in the case of a

reversed oscillating cable. Fasten with the Allen key.

4.1b Bracket/ Strength member and cable termination

preparation

4

3.2 Opening the FIST-GCO

4 Single fiber

4.1 Loose buffer tube cable

4.1a Looped cable preparation

4.1.1. S-cable: A window cut of 3m50 is needed for GCO2-BC6-XX,

3m70 for GCO2-BD6-XX and 3m90 for GCO2-BE6-XX.

4.1.2 S-cable: Mark the cable in the middle and mark the cable on

(1.75), (1.85) or (1.95) meters left and right of the first mark. Remove

the cable jacket starting in the middle.

3.2.1 Open and remove the clamp. Remove the dome and the O-ring

Remark: take care with the O-ring and the sealing surfaces on the base

and dome (avoid damaging). Clean only with clear water or with the

cleaning tissue, included in the kit, if needed

4.1.3 Reversed Oscillating cable: Mark the cable in the middle of the

loop and remove cable jacket left and right of the mark over a total

distance of 110cm (little more as the distance between two reversal

points on the cable). Locate the buffer tube reversal point on the cable

and mark the cable on (1.75), (1.85) or (1.95) meters left and right

from this point. Remove further the cable jacket starting from this

point.

Important: make sure that twist position of loose tube is identical in A

and B. This must be done correctly for ease of installation.

4.1.4 Remove the strength member leaving 80mm from the cable

jacket, if shield present leave 15mm of the shield

4.1.5 Clean the loose tubes, remove all grease.

4.1.6 Identify the loose tubes with the split collet rings markers if

necessary. There are different FIST-split-collet-rings depending on

diameter of the loose tube.

A

B

Page 5

5

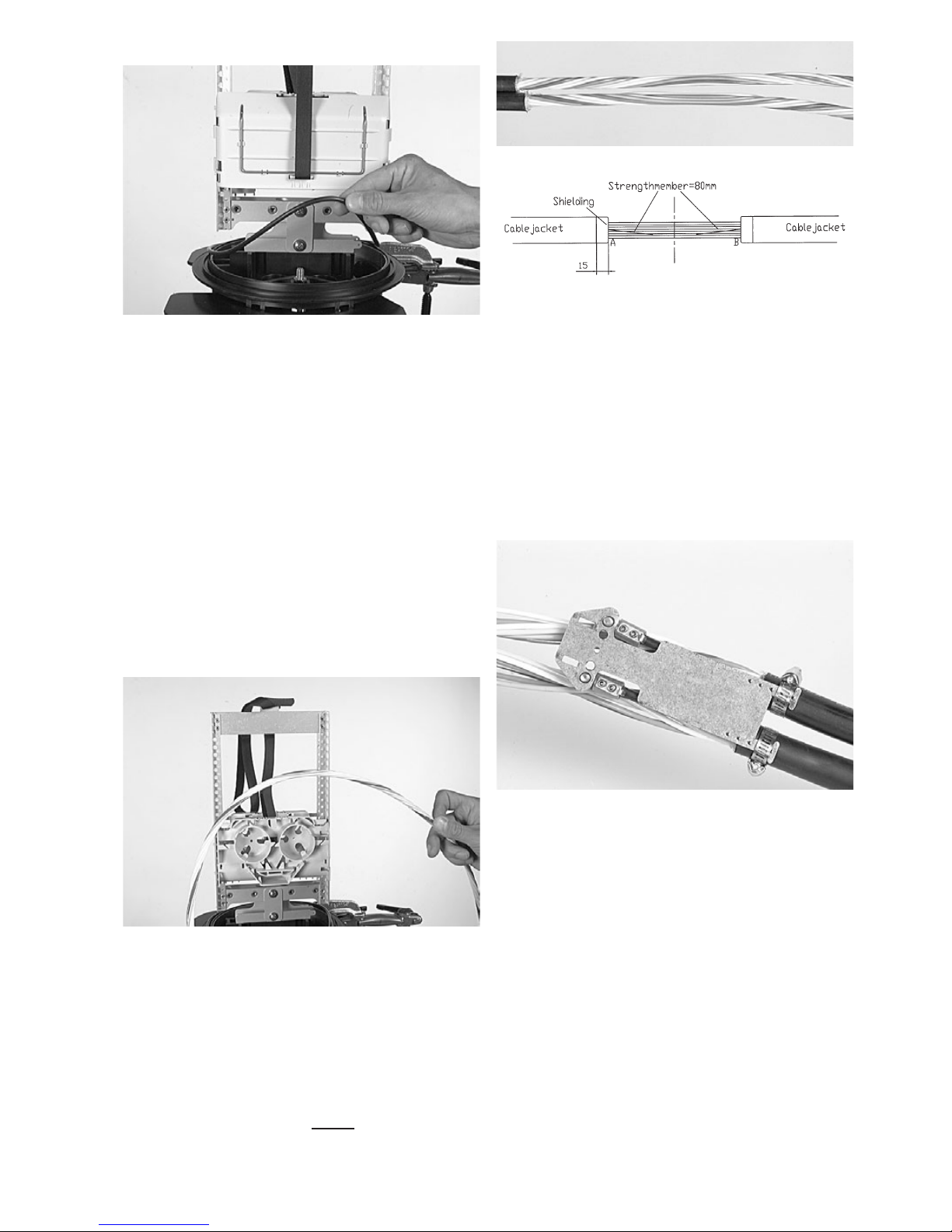

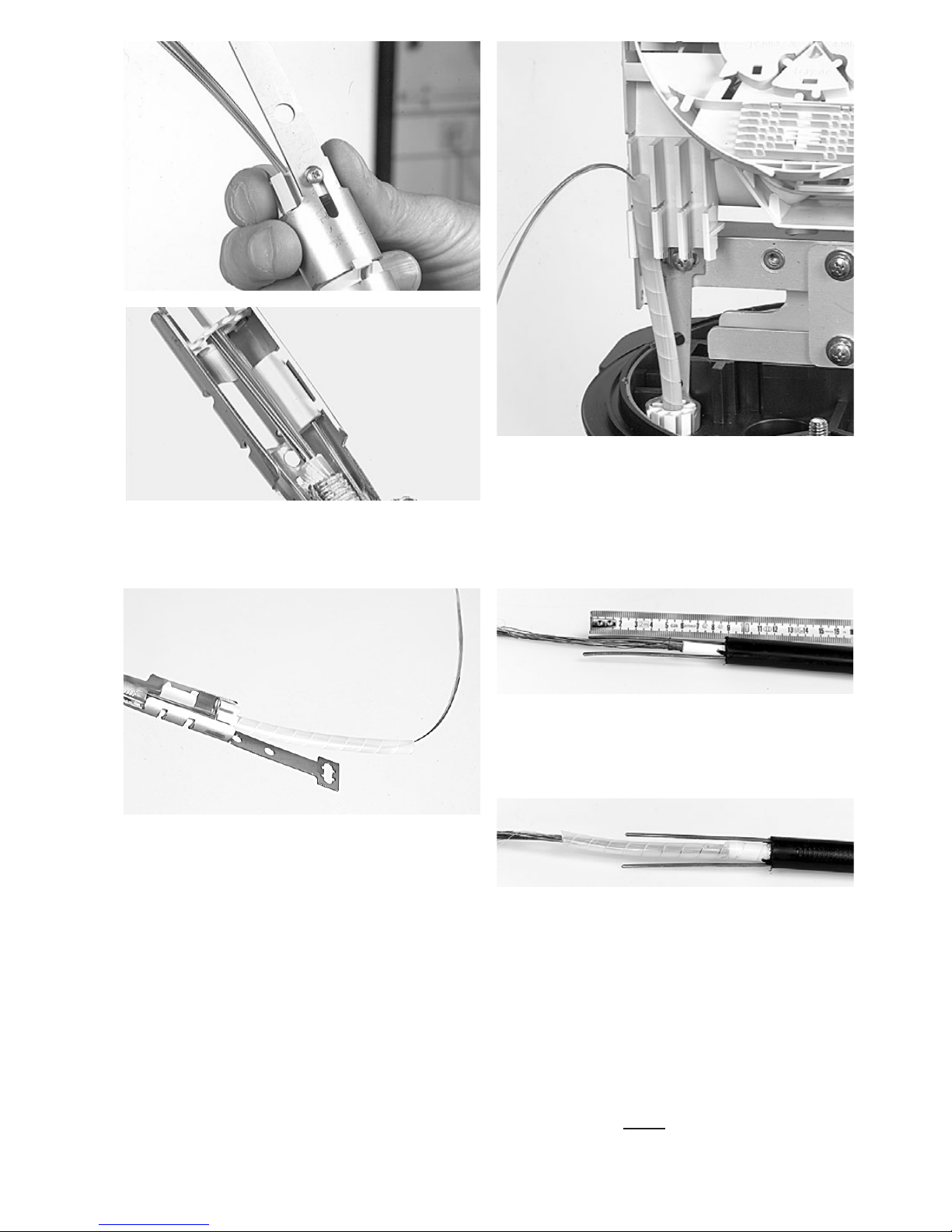

4.1.9 Open the oval port; the cutting wire can be used.

4.1.8 If the cable diameter is more than 8mm Fix the cables with the

hose clamp onto the loop bracket. Wrap a few layers of tape around

the hose clamp.

If the cable diameter is less than 8mm fix the cables with tie wraps.

• When using cables with a diameter smaller than 12mm,bend the

sharp edges on the bottom of the bracket towards the cable and use

some tape around the bracket to protect the heatshrink.

4.1.10 Take the oval sleeve and place the packing bag that has been

opened on both sides in the oval sleeve to prevent the hotmelt inside

the sleeve from dirt and grease. Take the LCIT and bend the loose

tubes gently over it. Push the loose tubes in the sleeve. The non-coated

edge of the sleeve and the arrows should be pointed to the base of the

closure.

4.1.11 Now push the loose tubes (looped around the LCIT) in the oval

port up to the bottom of the bottom bracket.

4.1.12 Remove the LCIT and pull the cable gently in the closure.

Page 6

6

4.1.13 Position the loop bracket in the bottom bracket and lock with

the split pin.

4.1.14 Install heatshrink.

4.1c Loose buffer tube storage

4.1d Fiber storage in trays

4.1.15 Select the loose tube(s) with the fibers that have to be spliced.

4.1.15 Make some loops with the uncut loose tubes, and put these in

the plastic bag (Be careful not to damage the loose tubes!).Two sizes of

bags are available. Use the correct size according the volume of the

loose tubes.

Slide the bag between the UMS. If the capacity of the looped loose

tubes is too much, one puts the loops at one side; in this case fix the

plastic bag with the tubes on the UMS-profiles with tie-wraps. In case

of S-cable cut the loose tube(s) in the middle of the loop for routing

them to the tube holder.

Remark: Loose tubes routed up to the tube holder should be

routed in such a way that one still has complete access of the

stored tubes between UMS profile. This is needed for later

routing of loose tubes from the loops to the tube holders,

without creating crossings and without creating disturbances

on the loose tubes already routed up to the tube holders.

4.1.16 In case of reversed oscillating cable: separate the loose tube(s).

Match the loose tube(s) on the tubeholder and mark both sides

between the two marks. Shave between the two marks with the

appropriate tooling. Clean the fibers and wind some Teflon around the

ends of the tubes and fibers ,to protect the transition from tube to

fibers.

In case of S-cable: cut the loose tube(s) (with fibers that have to be

spliced) in the middle of the loop. Separate the cut loose tube(s) from

the others. Match the loose tube(s) on the tubeholder and mark both

sides. Strip the loose tube(s). Clean the fibers.

- Separate the fibers till the tubeholder and route to single circuit or

single element tray(s).

Page 7

7

4.1.18 In case of Reversed oscillating cable Identify exchange and

customer-side using some Teflon tape around the fibers. One can also

use the FIST-split-collets-rings markers to identify the loose tubes.

4.1.17 Different loops can be put together beneath the same tube

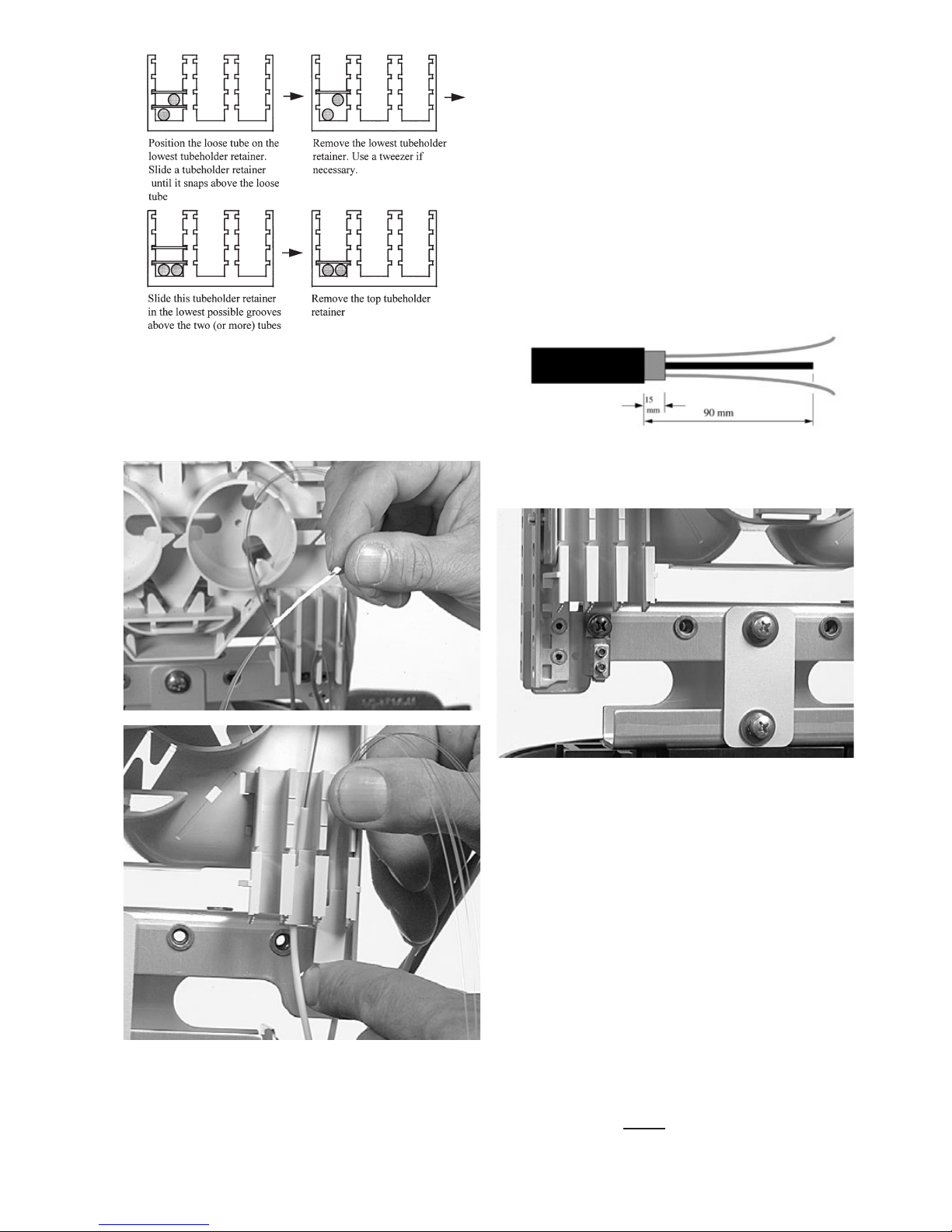

holder retainer. Position one or more loose tubes in the tubeholder and

slide the tube holder retainer with the snap forward in the lowest

possible cavities of the tubeholder above the loose tube(s). The tube

holder retainer must snap.

4.1.19 - If the fibers are ‘twist free’ one can route the fibers separate

to single circuit trays or single element trays. Separate all fiber loops

first till the tubeholder.

If the fibers are not ‘twist free’ select first the fiber(s) that have to be

spliced and cut these fibers in the middle of the loop. Remove these out

of the bundle till the tubeholder. These fibers can be routed to single

circuit trays, others uncut will be routed to a single element tray (never

in dark fiber storage) (See at fiber routing).

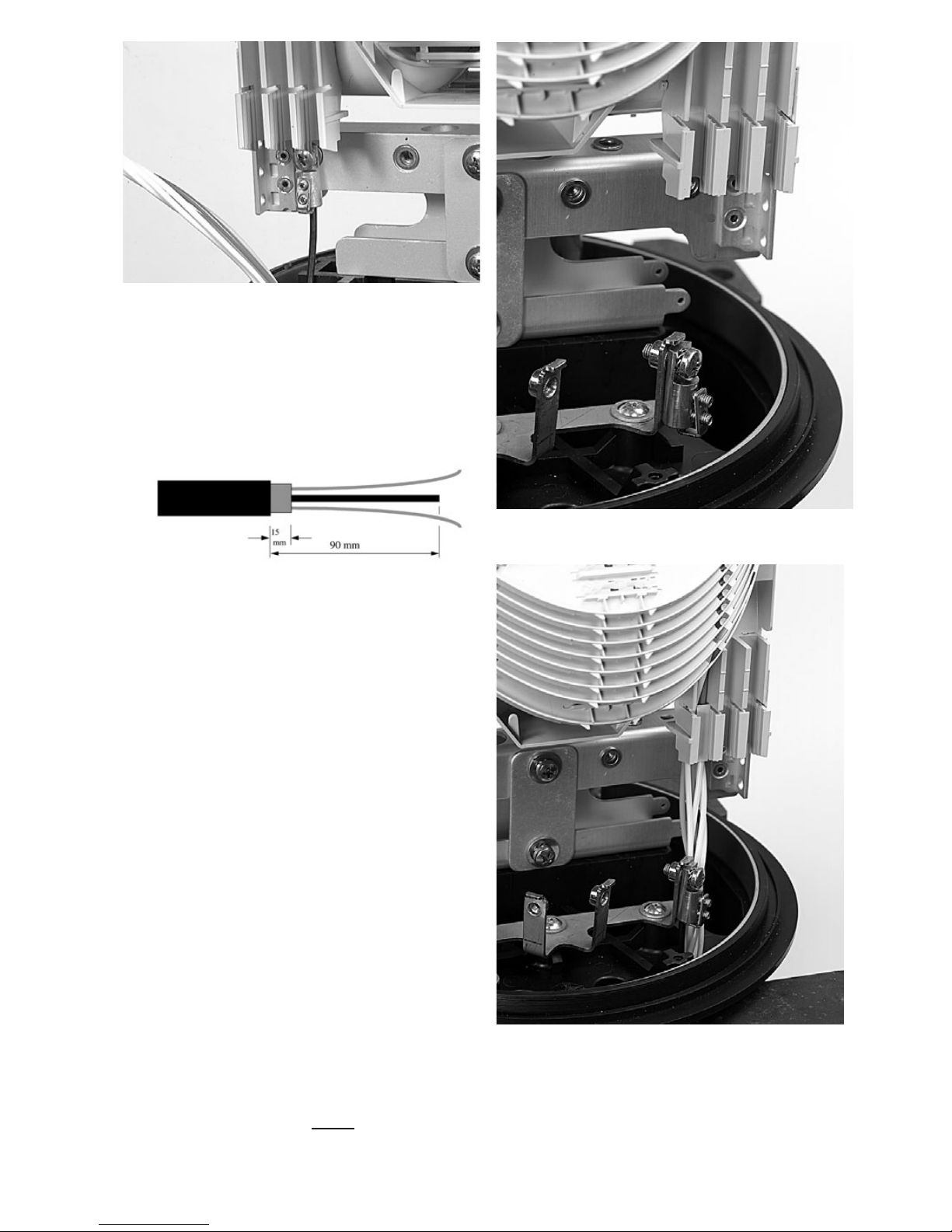

4.1.22 Remove the strength member leaving 90mm from the cable

jacket, if shield present leave 15mm of the shield.

4.1.23 Fix the strength member connector in the closure (on the

bottom bracket )

4.1.24 Take the sleeve and place the packing bag that has been

opened on both sides in the sleeve to prevent the hot melt inside the

sleeve from dirt and grease.. Push the loose tubes in the sleeves. The

non-coated edge of the sleeve and the arrows should be pointed to the

base of the closure (see installation heatshrink).

4.1e Drop cable preparation (6 port base)

4.1.20 Open the round port; the cutting wire can be used

4.1.21 Remove the cable jacket for 2.2m.

Page 8

8

4.1.28 Fix the strength member connector in the closure.

4.1.27 If ports 3-4-5-6-7-8-9-10 are used, cut strength member at 75

mm length. If ports 11-12-13-14-15-16-17 and 18 are used, cut

strength member at 90mm length.

4.1.25 Push the loose tubes in the port and fix the strength member in

the strength member connector. Be sure that all loose tubes are routed

without crossing around the strength member.

4.1f Drop cable preparation (16 port base)

4.1.26 Remove the cable jacket for 2.2m.

4.1.29 Fix the cable in it.

4.1.30 Install the heat shrink.

Page 9

9

4.1.31 Match the loose tube on the tubeholder, mark and strip the

loose tube from this mark. Clean the fibers.

4.1.32 Position one or more loose tubes in the tubeholder according

to the correct position and slide the tube holder retainer with the snap

forward in the lowest possible cavity of the tubeholder above the loose

tube. The tube holder retainer must snap. (see capacity of tubeholders).

4.2 Central Core cable (Single Fiber), ribbon and compact

sheet cable

4.2a Looped cable preparation

4.2.1 Twisted fibers: fibers have to be routed over the BASKET :a

window cut of 5m30 is needed for GCO2-BC6-XX, 5m90 for

GCO2-BD6-XX and 6m10 for GCO2-BE6-XX. Mark the cable in the

middle, and mark the cable on (2.65), (2.95) or (3.05) meters left and

right of the first mark. Remove the cable jacket and the strength

members starting in the middle. For non cut loop storage contact Tyco

Electronics to check if possible

Twistfree fibers or limited twist: direct to tubeholder; a window

cut of 3m50 is needed for GCO2-BC6-XX, 3m70 for GCO2-BD6-XX

and 3m90 for GCO2-BE6-XX. Mark the cable in the middle, and mark

the cable on (1.75),(1.85) or (1.95) meters left and right of the first

mark. Remove the cable jacket and the strength members starting in

the middle.

4.2.3 Remove the jacket for 45mm leaving the strength members.

Be cautious not to damage the strength members.

4.2.4 Remove the central core leaving 20mm from the cable jacket.

Be careful not to loose the ID of the fibers.

In case of metal shield, remove 5 mm from the end.

4.2.5 Clean the fibers.

4.2b Bracket/ Strength member and cable termination

preparation

4.2.6 Slightly loosen the screws of the two strength member stops

on the loopbracket such that one can position the strength members

stops according to the position of the strength members.

4.1g Tube preparation 4.2.2 Mass storage facility: mount the basket (see Basket instruction.

Page 10

10

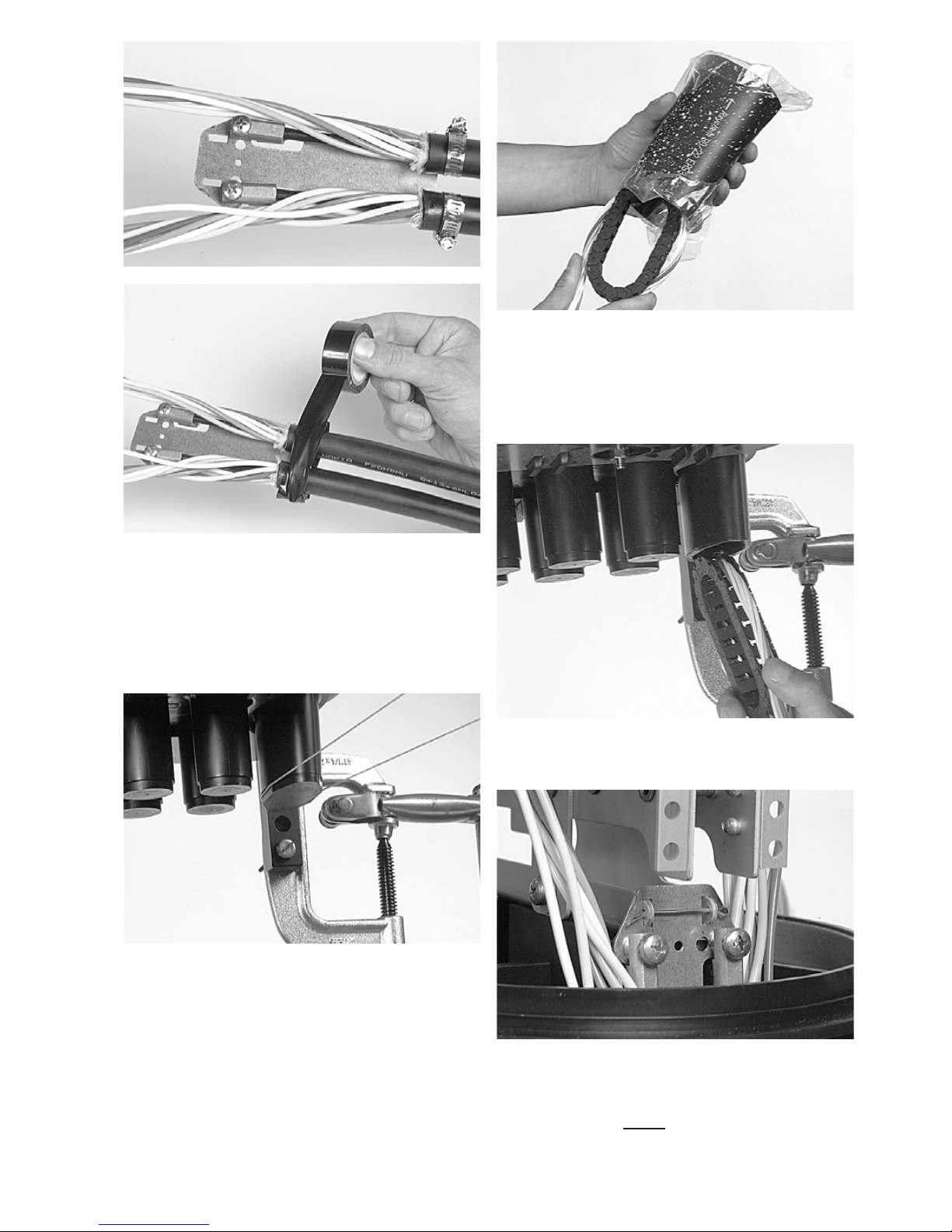

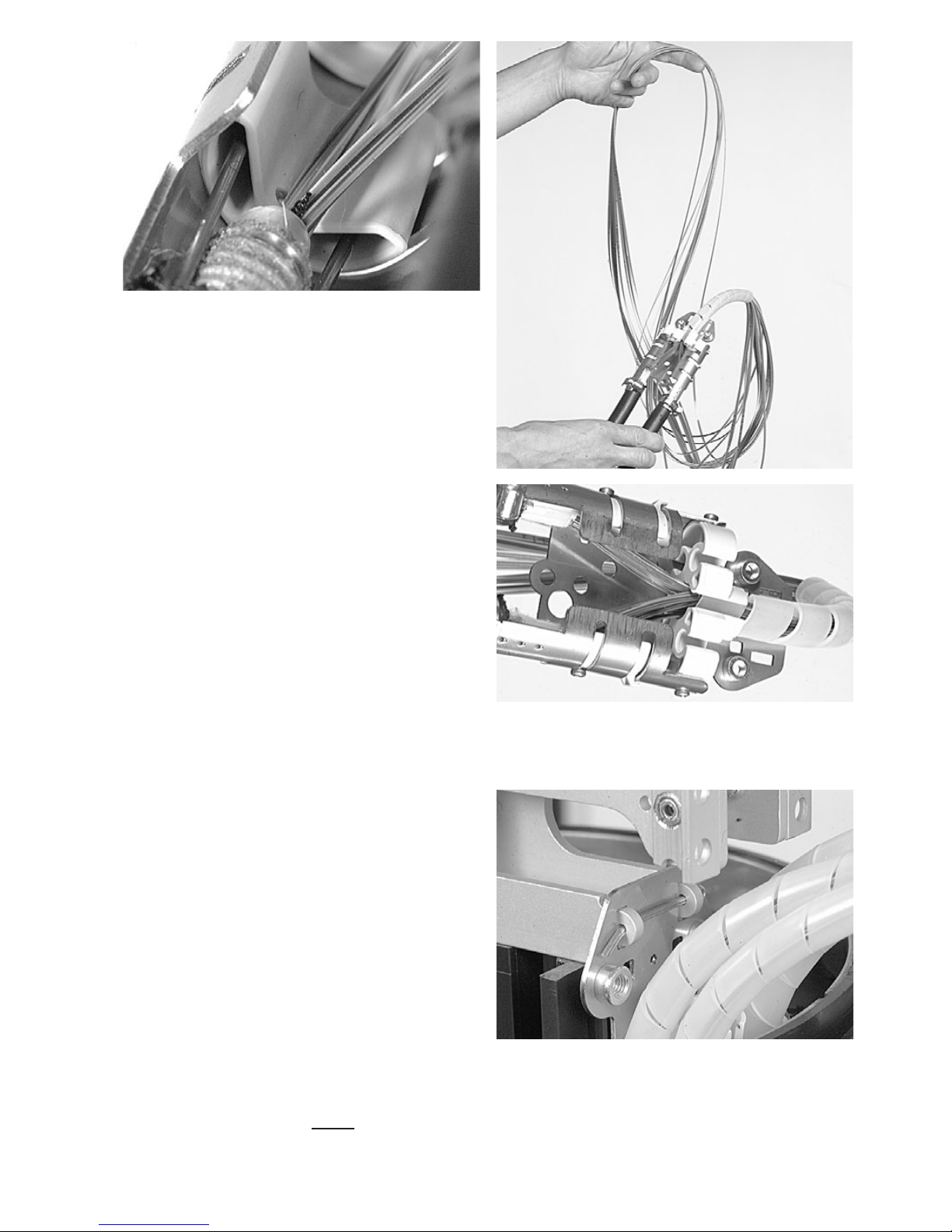

4.2.7 Insert the strength members from the cable into the strength

member stop. In case cable diameter is more than 8mm, Fix the cable

with the hose clamp onto the loopbracket. In case cable diameter is

less than 8mm. Fix the cable with tie wrap onto the loopbracket Fix the

screw of the strength member stop on the loopbracket. Wind a few

layers of tape around the hose clamp.

When using cables with a diameter smaller than 12mm,bend

the sharp edges on the bottom of the bracket towards the

cable and use some tape around the bracket to protect the

heatshrink.

4.2.9 Place the heatshrink and loop bracket in place as described in

loose tube installation.

4.2.8 Take the spiral tube and cut it at 160mm length.

Put the tube over the bundle fibers and insert this in the central cavity

of the loop breakout device.

Page 11

11

4.2.11 Install hinge on basket with pen.

4.2c Mass storage facility and twisted fibers: Using Basket

(single fiber, ribbon and compact cable sheet)

4.2.10 Start with mounting the basket.

4.2.12 Mount hinge on GCO.

4.2.13 Remove the cover by pulling it at the top of the basket (via the

opening). When the top of the cover clicks out of the snaps shove the

cover upward in the basket till it releases.

ST=Spiral tubing

4.2.16 All fibers are placed in the “fiber twist storage duct” as shown

on the figure above. One has to place the fibers as far as

possible at the outside of the path because when closing the

basket some overlength will be pulled out of the basket (risk of loading

fibers when basket is hinged).

4.2.17 At the point of separation, mass storage fibers and fibers to

drop out are separated. This is possible because all cable-twists are

stored in the “fiber twist storage duct”.

4.2.18 The fibers for mass storage are organised in the mass storage

area of the basket, the loop end is placed over one of the islands.

4.2.14 A large ST is wrapped around the twisted fiber bundle and

fixed in the loop bracket in the oval port. The length of the large ST is

given for each application.: 16 cm for loopbracket cc. In the table

below the capacities of this ST are given.

Fiber type Number of cut Numbers of looped

fibers/ribbons fibers/ribbons

in ST 15 OD in ST 15 OS

SF 392+ 196+

R12 36 18

R8 48 24

R4 100 50

4.2.15 This large ST is placed in the right cavity of the basket by

bending the spiral tube and gliding it in its cavity when the basket is in

an almost closed position.

Page 12

12

4.2.19 The fibers that need to be guided to the routing block are

wrapped with a small ST with a length of 37 cm. Make sure you group

the fibers/ribbon going to the OS1 or ES2-side of a closure separately.

Place as many fibers as possible fibers together in one ST to maintain a

high drop out capacity of your basket (see table below). (The addition

of fibers in an occupied ST is not possible without removal of the ST,

causing transients in the optical fibers).

Fiber type Number of cut Numbers of looped

fibers/ribbons fibers/ribbons

in ST 6 OD in ST 6 OS

SF 70 35

R12 6 3

R8 9 4

R4 14 7

A maximum of 6 ST (6 mm OD) can be dropped from the basket.

4.2.20 Guide the ST through the bottom bracket of the closure to the

side of the FAS opposite to the hinge side of the basket to the tube

holder (OS1 and/or ES2). To install the ST in the tube holder one

places the ST in the holder and marks the place where the tube holder

retainer will be. The place is wrapped with a 3 cm long FOAM strip

after the grease is removed from the location with an isopropylalcohol

tissue. One has to make sure the foam strip is under the tube holder

retainer by inserting tube and retainer in one go. After installation of

the tube holder retainer the fibers can be placed in the organiser

system.

4.2.21 Insert the fiber and the ST in the “drop out fiber duct” (as

shown in 4.2.19). Insert the ST in the basket in the way it passes the

top of the bend and end just before the fiber containment lip. Store the

first three STs at the inside of the bend. The next three at the outside.

To pass the fiber containment lip on top of the bend one can enlarge

the space between both lips by bending the outer lip.

4.2.22 Place cover back in place, Make sure the cover is under the lip

of the bottom island. Hinge the basket inbetween the UMS profiles and

make sure the hinge is in the correct position.

4.2.23 Secure the basket by mounting the metal profile on basket and

closure bracket.

Remark: when the basket is closed, check if the large ST is well placed

in the loop breakout device.

Page 13

13

4.2.25 Slide the loop breakout device in the loopbracket and fix the

two screws. Open the oval port as described in loose tube

preparation..Take the oval sleeve and place the packing bag that has

been opened on both sides in the oval sleeve to prevent the hotmelt

inside the sleeve from dirt and grease. as discribed in loose tube

preparation.

4.2d Twistfree fibers or limited twist (single fiber, ribbon

and compact cable sheet)

4.2.24 Divide the fibers according to the position in the loop breakout

device (fig.); in the 4 small cavities and spiral tubes (ST) directly to the

trays in a way that fibers going to the O-side and E-side of the closure

(also marked on the loop breakout device) are divided, divide also the

exchange and customer fibers (avoid unnecessary crossings). Typical a

looped fiber will be put in two spiral tubes going to the same side of the

closure (O- or E-side). Put the spiral tubes over the different bundles of

fibers and insert afterwards the spiral tube with fibers in the loop

breakout device.

4.2.26 Push the fibers in the oval port and position the loopbracket in

the bottom bracket and lock with the split pin.

Page 14

14

4.2e Drop cable preparation (6 port base)

4.2.28 Remove the cable jacket 2.2m.

4.2.29 Remove the jacket for 45mm leaving the strength members.

Be cautious not to damage the strength members.

In case of metal shield, remove 5 mm from the end.

4.2.30 Remove the central core leaving 20mm from the cable jacket.

Be careful not to loose the ID of the fibers.

4.2.31 Clean the fibers.

4.2.32 Loosen a little bit the screws such that one can position the

strength members stop according to the position of the strength

members and remove the break-out part.

4.2.33 Insert the strength members from the cable into the strength

member stop. Fix the cable with the hose clamp in case cable diameter

is more than 8mm. onto the bracket. Fix the cable with tie wrap in case

cable diameter is less than 8mm. onto the bracket. Fix the screw of the

strength member stop on the bracket. Wind a few layers of tape

around the hose clamp.

4.2.27 Match the spiral tube on the tubeholder, mark and cut the

spiral tube from this mark. Remove element per element the ID cords

or compact cable sheet (Microgain™, Compacttube™, ...) till about

10 mm after the spiral tubes; use teflon to bundle the fibers and the ID

cord. Position the small spiral tubes in the respective tubeholders.

Bottom picture shows compact cable sheet.

Page 15

15

4.2.36 Fix the round port cable fixation bracket (using a Phillips

screwdriver) on the bottom bracket.

4.2.f Drop cable preparation (16 port base)

4.2.37 Remove the cable jacket for 2.2m.

4.2.34 Put the fibers in the breakout through the center (put the tube

stop at cable jacket side) and slide the breakout on the bracket and fix

it with the screw.

4.2.35 Insert the ST (spiral tube) over the fibers into the breakout till

the tube stop.

0pen the round port and place the heatshrink as discribed in loose tube

preparation.

4.2.38 If ports 3-4-5-6-7-8-9-10 are used, cut strength member on

75mm length.

If ports 11-12-13-14-15-16-17-18 are used cut strength member on

90mm length and cut the central core at 30 mm from the jacket.

4.2.39 Put the Spiral tube on the cable

Page 16

4.2.43 Remove the ID cords or compact sheet till about 10mm after

the spiral tube; use teflon to bundle the fibers and the ID cord. Position

the spiral tubes in the respective tubeholder. Put the tube holder

retainer.

16

4.2.40 Fix the strength member plates in the closure.

Use FACC-DSCT for dual strength member cables.

4.2.41 Fix the cable in it.

4.2.42 Install the heatshrink (see section 5).

Page 17

17

5 Installation of the heatshrink

5.1 Oval port

5.1.1 Clean by using the cleaning tissue. Abrade the port.

5.1.2 Clean and abrade the cable.

5.1.3 Remove the packing bag out of the seal, push the seal

upwards to the base and mark the cable flush with the seal. Make sure

the non-coated zone butts up against the base.

Page 18

18

5.1.4 Match the blue line of the aluminium protection foil with the

marks on the cables. Wrap aluminium cable protection foil around the

cable (the aluminium foil should not be more than 30 mm inside the

sleeve.

5.1.5 Push the seal against the base and place the clip.

5.1.6 Start heating the seal on the base, and wait one minute and

shrink in spiral movements downwards.

5.1.7 Hold the cable in position. Shrink till the green painting dots

become black, and the hotmelt is visible on the bottom. Postheat the

clip on both sides till the adhesive shows a proper flow on the clip

between the two cables.

Do not move the FIST-GCO or cable during 20 minutes.

Page 19

19

5.2 Round port

5.2.1 Repeat all the steps as discribed in oval port.

5.3 16 port base

5.3.1 It is recommended to use the hingable workstand.

Note: use the appropriate seals for the ports.

Fibers can be routed between OS1, OS2, ES1 and ES2. In case that

fibers have to be routed from SIDE-O (Odd portnumbers) to SIDE-E

(Even portnumbers), use the window (see picture). Select the cable

termination as such, that a minimum of fibers will cross and have to be

routed through the window. Therefore the selection of the ports

according to the cable lay-out is important.

6 Fiber routing

6 PORT BASE: Ports (1+3), (6+8) for cables to (S2). Ports (5+7), (2+4)

for cables to (S1). Verify the position of two cables if they are placed on

the same side (next to each other) because the total amount of loose

tubes in ports (1+3) or (2+4) or (5+7) or (6+8) can never be more than

mentioned in the capacity of the tube holder.

S1 side

S2 side

To E or

O side

Page 20

20

6.3 To remove push the two snapfits at S2 UMS-profile and slide the

wraparound plate towards S1 UMS-profile.

6.1 Remove the VELCRO and routing block cap. To remove the

routing block cap lift the two snaps at one side of the routing block cap.

6.2 Fix the wraparound groove plate on the UMS by putting the

plate with the long protrusions in the S1 UMS-profile and sliding the

plate in the S2 UMS-profile until it snaps. (Do not leave gaps between

groove plates).

6.4 Place a tray in the wraparound groove plate; do this by pushing

the lip on the groove plate (lowest possible position) slightly down with

the tray and move the tray lateral into the hinge-cavities of the groove

plate. To snap the High Capacity Single Element tray (HCSE) in the W/a

single fiber groove plate leave always one hinge facility open between

Fasblock or previous tray and the HCSE-tray.

16 PORT BASE: Ports (1+3+5+11+13), (2+4+6+12+14) for cables to

(S2). Ports (5+7+9+15+17), (6+8+10+16+18) for cables to (S1). Verify

the position of two cables if they are placed on the same side (next to

each other) because the total amount of loose tubes in ports going to

one tubeholder can never be more than mentioned in the capacity of

the tubeholder.

S1

S2

Page 21

21

6.5 To remove the tray put the fiber guiding pin between lip on

wraparound groove plate and tray and move lateral towards S1.

6.6 Identify the tray to be worked on and make it accessible. If the

routing block and trays are in vertical position you will have to support

the trays above the selected one using the tray wedge which fits in the

cavities of the wraparound groove plate. Position the wedge carefully

such that the groove is still accessible for the fibers and be careful not

to push the wedge against fibers. To remove the wedge,use two hands

to pull on both ends (near the groove plate).

6.7 Route the fiber in the grooves of the wraparound groove plates

to the entrance of the identified tray. Fiber must be routed in the

groove below the hinge of the tray!

6.6 Pull gently on the fibers in the tray and make sure that the fibers are

well contained in the routing block and wraparound groove plate.

6.9 Store the fibers temporarily on a tray (picture shows the case

of a loopback).

6.10 Storing dark fibers can be done in different ways.

1) Organise dark fibers into the different trays, following instructions

as described.

2) Organise dark fibers together into the first available tray (i.e. with a

max. of 24cut or 12 loops primary coated fibers in one SE-tray).

Page 22

7.2 SMOUV in SE tray.

7.5 ANT in SC tray.

7.3 SMOUV in SC tray.

7.4 ANT in SE tray.

22

7 Fiber routing on tray

7.1 Take the splice protector and put it centred towards the splice

holder

7.6 Ribbon 4/8 tray.

7.7 Ribbon 12 tray.

Page 23

23

8 Tube holder capacity and tray identification

Number x outer diameter loose tube (mm)

8.1 Use a permanent marker en to write on the tray.

9.1 In case of cable shield termination,connect the shield

continuity wires on the shield mounting bracket

9 Cable grounding/shielding

9.2 In case of grounding,mount grounding wire on the grounding

bolt

Page 24

10 Closing the closure

10.1 Remove the outer bag and place the Silica gel in the closure

(be careful, do not disturb any fiber or tube routing)

10.2 Place the o-ring back on a clean base and place the dome on

top of it.

10.3 Close with clamp.

11 Important steps during installations

• Make sure that grooves on the wraparound groove plate are clean.

• Clean the fibers.

• Be sure that fibers are not stored to tight in the trays, to prevent

stress on the fibers.

• Loose tubes routed up to the tube holder should be routed in such

a way that one still has complete acces of the stored tubes

between UMS profile.This is needed for later routing of loose

tubes from the loops to the tube holders without creating crossings

and without creating disturbtions on the loose tubes allready

routed up to the tube holders.

• Use correct lengths in the tubeholder.

• Make sure not to loose ID.

• Use only 45mm long SMOUV.

• Be secure when preparing window cut on loose tube cable for

storing uncut fibers.

• Avoid in all cases crossings of fibers and loose tubes in the cable

brackets.

• When using cables with a diameter smaller than 12mm in a cable

bracket,bend the sharp edges towards the cable and use some

tape around the bracket to protect the heatshrink.

• Replace the Silica gel each time the closure has been opened.

• Do not place the aluminum protection foil too deep in the

heatshrink.

12 Re-arrangement

Avoid to pull fibers inbetween groove plates.

Avoid fiber movement between tubeholder and first containment lip

on the routing block.

Take special care rearanging fibers from E to O side or reverse.

If accidentaly active fibers are removed from the containment

devices,reposition them carefully.

TC 574/IP/2 07/00

Tyco is a trademark. Teflon is a trademark of E.I. du Pont de Nemours. Velcro is a trademark of Velcro Industries B.V.

The information given herein, including drawings, illustrations and schematics which are intended for illustration purposes only, is

believed to be reliable. However, Tyco Electronics makes no warranties as to its accuracy or completeness and disclaims any liability

in connection with its use. Tyco Electronics’ obligations shall only be as set forth in Tyco Electronics’ Standard Terms and Conditions

of Sale for this product and in no case will Tyco Electronics be liable for any incidental, indirect or consequential damages arising out

of the sale, resale, use or misuse of the product. Users of Tyco Electronics products should make their own evaluation to determine

the suitability of each such product for the specific application.

Tyco Electronics Raychem NV

Telecom Outside Plant

Diestsesteenweg 692

B-3010 Kessel-Lo, Belgium

Tel.: 32-16-351 011

Fax: 32-16-351 697

www.tycoelectronics.com

www.telecomosp.com

Loading...

Loading...