Page 1

TYCO ELECTRONIC PRODUCT GROUP PAGE 1 OF 1

F08 INSTALLATION & PROGRAMMING MANUAL

DOCUMENT DATA SHEET

DO NOT PRINT

Document Number LT0082

Document Title F08 Installation & Programming Manual

Manual Volume 1

Word Processor Word 2000

File Name

G:\CH_TSP_All Staff\VIGDOCS\MANUALS\F08\LT0082 Iss 3.04.DOC

Printer HP Laserjet 4M Plus

Current Issue Issue 3.04, 24 March 2006

LT0082 Issue 3.0 Amendment 0

Prefix

Chapter 1 : Introduction

Chapter 2 : FIP Installation

Chapter 3 : Placing into Operation

Chapter 4 : Programming

Chapter 5 : Application Considerations

Appendix A1 : Compatible Batteries

Appendix A2 : Compatible Actuating Devices

Appendix A3 : Installation Drawings

Zone Designation Label

PRINTING SPECIFICATIONS

1. Paper Type: 80gsm Bond White

2. Manual Size: A4

3. Place in 4-ring binder

Front and spine inserts to be fitted with labels stating:

LT0082

TYCO F08

INSTALLATION & PROGRAMMING

5. All pages are double sided, except for the diagrams at the end of the manual.

Chapter 0

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Chapter 5

Appendix A1-3

6

4

34

8

24

14

6

=

=

=

=

=

=

=

3

2

17

4

12

7

3

double-sided

double-sided

double-sided

double-sided

double-sided

double-sided

double-sided

96 48

Drawings + 5 single-sided

Page 2

F08 Installation & Programming Manual Document No: LT0082

THIS PAGE INTENTIONALLY LEFT BLANK

Page ii 24 March 2006 Issue 3.04

Page 3

F08

INSTALLATION & PROGRAMMING

MANUAL

F08 PRODUCT MANUAL

DOCUMENT: LT0082

Issue 3.04; 24 March 2006

The F08 Fire Indicator Panel is manufactured for

Tyco Services Fire & Safety

47 Gilby Road

Mt Waverley

VIC 3149

AUSTRALIA

Tel : +61-3-9538 7220

Fax : +61-3-9538 7255

COPYRIGHT (C) 2002

Information contained in this document is copyright, and shall not be reproduced in any form whatsoever,

or its contents disclosed to any third party, without the written consent of Tyco Services Fire & Safety (The

Company). Information contained in this document is believed to be accurate and reliable, however the

company reserves the right to change the content without prior notice.

Page 4

F08 Installation & Programming Manual Document No: LT0082

NON-DISCLOSURE AGREEMENT

Tyco Services Fire & Safety (THE COMPANY) and the User of this/these document(s)

desire to share proprietary technical information concerning electronic systems.

For this reason the company is disclosing to the User information in the form of this/these

document(s). In as much as the company considers this information to be proprietary and

desires that it be maintained in confidence, it is hereby agreed by the User that such

information shall be maintained in confidence by the User for a period of TEN YEARS after

the issue date and only be used for the purpose for which it was supplied.

During this period, the User shall not divulge such information to any third party without the

prior written consent of the company and shall take reasonable efforts to prevent any

unauthorised disclosure by its employees. However, the User shall not be required to keep

such information in confidence if it was in their possession prior to its receipt from the

company; if it is or becomes public knowledge without the fault of the User; or the

information becomes available on an unrestricted basis from a third party having a legal right

to disclose such information.

The User's receipt and retention of this information constitutes acceptance of these terms.

This information is copyright and shall not be reproduced in any form whatsoever.

END USER LIABILITY DISCLAIMER

The F08 Fire Indicator Panel provides a configuration programming facility which may be

accessed via a programming push-button. Because this programming facility allows the user

to define in detail the operation of the F08 System, changes may be made by the user that

prevent an installation from meeting statutory requirements.

The Company, therefore cannot accept any responsibility as to the suitability of the functions

generated by the user using the programming facility of the F08.

* * WARNING * *

The F08 is approved to AS/NZ 3548 Class A.

In a domestic environment it may cause radio interference, in which case the user

may be required to take adequate measures.

Page ii 24 March 2006 Issue 3.04

Page 5

Document No: LT0082 F08 Installation & Programming Manual

TABLE OF CONTENTS

NON-DISCLOSURE AGREEMENT......................................................................................ii

END USER LIABILITY DISCLAIMER...................................................................................ii

AMENDMENT LOG..............................................................................................................v

1. INTRODUCTION ............................................................................................................. 1-1

1.1 USING THIS MANUAL............................................................................................. 1-2

1.2 ASSOCIATED DOCUMENTATION.......................................................................... 1-3

1.3 TERMINOLOGY ....................................................................................................... 1-4

2. FIP INSTALLATION........................................................................................................ 2-1

2.1 OVERVIEW............................................................................................................... 2-2

2.2 CABINET INSTALLATION....................................................................................... 2-3

2.3 MAINS WIRING ........................................................................................................2-6

2.4 MAIN BOARD........................................................................................................... 2-8

2.5 BATTERY INSTALLATION.................................................................................... 2-11

2.6 FIP MCP WIRING ................................................................................................... 2-12

2.7 ALARM ZONE WIRING & CIRCUIT TYPES.......................................................... 2-13

2.8 BELL OUTPUT WIRING......................................................................................... 2-18

2.9 ANCILLARY RELAY OUTPUT WIRING................................................................ 2-26

2.10 AUXILIARY OUTPUT WIRING........................................................................... 2-28

2.11 DOOR HOLDER WIRING ................................................................................... 2-29

2.12 BRIGADE INTERFACE RELAYS....................................................................... 2-30

2.13 DISPLAY & ZONE LABELLING......................................................................... 2-34

2.14 DOCUMENTATION............................................................................................. 2-35

3. PLACING INTO OPERATION......................................................................................... 3-1

3.1 GENERAL................................................................................................................. 3-2

3.2 MAINS ISOLATE SWITCH....................................................................................... 3-2

3.3 POWER UP............................................................................................................... 3-4

Issue 3.04 24 March 2006 Page iii

Page 6

F08 Installation & Programming Manual Document No: LT0082

3.4

COMMISSIONING CHECKLIST............................................................................... 3-6

4. PROGRAMMING............................................................................................................. 4-1

4.1 PROGRAMMING FEATURES.................................................................................. 4-2

4.2 ENTERING PROGRAMMING MODE....................................................................... 4-5

4.3 EXITING PROGRAMMING MODE........................................................................... 4-6

4.4 RESET TO DEFAULT PARAMETERS .................................................................... 4-7

4.5 PROGRAMME ZONE TO OUTPUT MAPPING........................................................ 4-8

4.6 PROGRAMMING ZONES AS LATCHING OR NON-LATCHING.......................... 4-12

4.7 PROGRAMMING ZONE INPUT TYPE................................................................... 4-14

4.8 ENABLING OR DISABLING ZONES..................................................................... 4-16

4.9 PROGRAMMING ANCILLARY RELAY SUPERVISION........................................ 4-18

4.10 PROGRAMMING ZONE AUXILIARY OUTPUT MODE...................................... 4-20

4.11 EXIT PROGRAMMING CHECKLIST.................................................................. 4-22

4.12 TROUBLE SHOOTING IN PROGRAMMING MODE.......................................... 4-23

5. APPLICATION CONSIDERATIONS............................................................................... 5-1

5.1 SUB-PANEL WIRING............................................................................................... 5-2

5.2 FIRE DETECTION IN HAZARDOUS AREAS.......................................................... 5-5

5.3 PREVENTION OF NON “FIRE” ALARMS............................................................. 5-10

5.4 TROUBLE SHOOTING........................................................................................... 5-11

APPENDIX A1 - COMPATIBLE BATTERIES.................................................................. A1-1

APPENDIX A2 - COMPATIBLE ACTUATING DEVICES................................................A2-1

APPENDIX A3 - INSTALLATION DRAWINGS ............................................................... A3-1

Page iv 24 March 2006 Issue 3.04

Page 7

Document No: LT0082 F08 Installation & Programming Manual

AMENDMENT LOG

ISSUE DATE AMENDMENT ECN

1 10 Oct 89 Original with two versions:

- Document 696-005 -> Installation

- Document 696-004 Issue 1 -> Programming

Amendment: 1 December 14, 1989

2 11 Apr 92 Combined Installation, Programming and Brigade Kit

Documentation.

28 May 98 Converted to Word 95 document.

3 27 Oct 98 For V3.00 F08 software, additional input types,

RAD/SAD, etc, 15V MCP, Resistor EOL.

2769

3.01

31 Jul 02 Prefix, Pages 2-6, 2-7, 2-27, 5-6….5-12, Appendix A

revised.

3322

3.02 1 Mar 05 Fig 2.12 had Ext Def- directly driving the detector

circuit.

Appendix A2 - add 614CH, 614I & 614P

3524

3635

3.03 28 Oct 05 Added System Sensor detector 885WP-B to

Appendix A.

ECS

1181

3.04 24 Mar 06 Appendix A2 – added 614T 3731

Issue 3.04 24 March 2006 Page v

Page 8

F08 Installation & Programming Manual Document No: LT0082

THIS PAGE INTENTIONALLY LEFT BLANK

Page vi 24 March 2006 Issue 3.04

Page 9

Document No: LT0082 F08 Installation & Programming Manual

Introduction

1. INTRODUCTION

Issue 3.04 24 March 2006 Page 1-1

Page 10

F08 Installation & Programming Manual Document No: LT0082

Introduction

1.1 USING THIS MANUAL

This Manual provides information for personnel engaged in the installation, programming

and commissioning of the F08 Fire Alarm Panel. It is available only to bonafide installation

and maintenance organisations.

The structure of this manual is as follows:

Chapter 1, Introduction, describes the manual, explains the format and terminology used

in this manual, and lists associated F08 product manuals.

Chapter 2, FIP Installation, describes the installation of the F08 FIP; mains wiring; battery

installation; detector, ancillary, auxiliary, bell and brigade output wiring; and other related

wiring.

Chapter 3, Placing Into Operation, describes the procedures for placing an F08 into

operation. A commissioning checklist is included.

Chapter 4, Programming An F08, describes the steps necessary in programming an F08

FIP ready for a particular installation.

Chapter 5, Application Considerations, describes some aspects of special applications,

such as remote panel operation, false alarm minimization and trouble shooting.

Appendix A1, Compatible Batteries, gives a list of compatible batteries.

Appendix A2, Compatible Detectors, gives a list of detectors compatible with the F08.

Appendix A3, Installation Drawings, Includes wiring diagrams for the various brigade

interfaces and provides a place for system installation drawings to be inserted.

Page 1-2 24 March 2006 Issue 3.04

Page 11

Document No: LT0082 F08 Installation & Programming Manual

Introduction

1.2 ASSOCIATED DOCUMENTATION

1.2.1 PRODUCT RELATED

The following F08 manuals are available:

Volume 1 F08 Operator's Manual, provides a complete guide to the operation and

maintenance of the F08 FIP, according to Australian Standards AS1603 Part

4. This manual is provided as standard with F08 FIP panels. It is available in

a bound A5 format (LT0054) and in an A4 loose-leaf format (LT0078).

Volume 2 F08 Technical Manual, provides complete technical details on the F08

system and Hardware/Software components, according to Australian

Standards AS1603 Part 4, for servicing purposes. (LT0081)

Volume 3 F08 Installation & Programming Manual, provides complete details for

correctly installing, wiring, programming and placing into operation the F08

FIP. (LT0082)

1.2.2 STANDARD RELATED

AS1603.1,2,3 Automatic Fire Detection and Alarm Systems -Detectors Parts 1, 2,

& 3 (Heat, Smoke, & Flame)

AS1603.4 Automatic Fire Detection and Alarm Systems

Part 4 - Control and Indicating Equipment

AS1603.5 Automatic Fire Detection and Alarm Systems

Part 5 - Manual Call Points

AS1603.6 Automatic Fire Detection and Alarm Systems

Part 6 - Fire Alarm Bells and Bell Simulators

AS1670.1 Automatic Fire Detection and Alarm Systems -

System Design, Installation, and Commissioning.

AS1851.8 Automatic Fire Detection and Alarm Systems.

Part 8 - Maintenance of Fire Protection Equipment

Issue 3.04 24 March 2006 Page 1-3

Page 12

F08 Installation & Programming Manual Document No: LT0082

Introduction

1.3 TERMINOLOGY

The following abbreviations and terminology are used in this manual.

A/C : Air Conditioning

"ACVD" : Display abbreviation for ACTIVATED

"ALM" : Display abbreviation for ALARM

Ancillary Equipment : Equipment external to Fire Alarm system

Ancillary Relay : Relay in FIP which operates Ancillary equipment

Auto-Reset : Mode for one man testing of detectors

Auxiliary Output : Output for driving additional outputs

AZC : Alarm Zone Circuit, or Detection Zone

AZF : Alarm Zone Facility, or Group

AVF : Alarm Verification Facility, or Check Alarm

COM : COMMON relay contact

Control Key : Key on FIP Display panel for operator control

Control Output : Output from FIP to other equipment

DETECTOR : Alarm Detec tion Device

DETECTOR CIRCUIT : Detectors electrically connected to FIP

EEPROM : Electrically Eraseable Programmable Read Only

Memory

EOL : End Of Line (device)

ELV : Extra Low Voltage

FIRE CONTROL STATION : Fire Brigade Authority, or any other authority which

receives the FIP alarm signals.

FIP : Fire Indicator Panel

"FLT" : Display abbreviation for FAULT

FRC : Flat Ribbon Cable

GLOBAL : No F08 zone/output/battery selected. (i.e. all "SEL"

LED indicators are OFF)

"ISO" : Display abbreviation for ISOLATED

LED : Light Emitting Diode

MAPPING : Programming AZCs to control outputs

MCP : Manual Call Point (Break Glass Switch)

MOV : Metal Oxide Varistor (Used for Surge Protection)

NC : Normally Closed

NO : Normally Open

PCB : Printed Circuit Board

PTC : Positive Temperature Co-efficient (Thermistor)

RAM : Random Access Memory

ROM : Read Only Memory

"SEL" : Display abbreviation for SELECT

U18.6 : IC U18 pin 6

VB : Battery Backed Voltage.

VNB : Non Battery Backed Voltage.

ZONE : Fire searchable area of building

Page 1-4 24 March 2006 Issue 3.04

Page 13

Document No: LT0082 F08 Installation & Programming Manual

FIP Installation

2. FIP INSTALLATION

Issue 3.04 24 March 2006 Page 2-1

Page 14

F08 Installation & Programming Manual Document No: LT0082

FIP Installation

2.1 OVERVIEW

This chapter describes in detail the following FIP installation procedures:

Cabinet Installation

Mains Wiring

Battery Installation

MCP Wiring

Alarm Zone Wiring & Circuit Types

Bell Output Wiring

Supervised Ancillary Relay Output Wiring

Auxiliary Output Wiring

Door Holder Wiring

Brigade Interface Relays

Zone Labelling.

* * WARNING * *

PLEASE ENSURE THAT THE SYSTEM HAS BEEN THOROUGHLY TESTED BEFORE

THE CONNECTION OF BATTERIES AND EXTERNAL WIRING.

Page 2-2 24 March 2006 Issue 3.04

Page 15

Document No: LT0082 F08 Installation & Programming Manual

FIP Installation

2.2 CABINET INSTALLATION

The location of the F08 FIP is determined by the FIRE AUTHORITY and the OWNER or

OWNERS' REPRESENTATIVE in accordance with the current Australian Standard

AS1670.1.

The cabinet is normally fixed to a wall with four (4) 6 mm screws or bolts. The drilling details

are shown in Figure 2.1.

The following points must be observed.

(a) Dry Area, 50°C maximum ambient temperature.

(b) Not exposed to direct sunlight or external environments without suitable

protection.

(c) Indicators and controls must not be higher than 1850 mm and not lower than

750 mm above finished floor level (see Figure 2.1).

(e) Clear access; easy Fire-Fighter's access and observation.

(f) For unhampered installation and maintenance, at least 1 metre free space

must be provided to the front and sides of the F08 FIP. (see Figure 2.2)

(g) Must not be installed in hazardous areas as defined in AS3000.

(h) If recessed into a wall cavity, allow for the door to open by at least 145° and

prevent water entering the cabinet. Seal unused knockouts and any top cable

entries. Preferably use bottom cable entry, with cables going down 100 mm

below cabinet before rising.

* * WARNING * *

1. It is not necessary to remove the Main Board Electronics when installing the cabinet.

However, if drilling or filing holes in the cabinet, remove the Main board first, and

clean out any swarf before replacing. Refer to Section 2.4.3 for the correct procedure

for removing and refitting the Main Board.

2. Use ANTI-STATIC precautions when handling any PCBs.

Issue 3.04 24 March 2006 Page 2-3

Page 16

F08 Installation & Programming Manual Document No: LT0082

FIP Installation

300

│───────────────────────────────────│

│ │

┌───────────────────────────────────────────┐ ───

│ │ │ │ │ 50

│ │ │ │ │

───────────────│── o ───────────────────────────────── o ──│────

│ │ │6.5 6.5│ │

│ │ │ │ │ │

│ │ │ │ │ │

│ │ │ │ │ │

│ │ │ │ │ │

│ │ │ │ │ │

│ │ │ │ │ │

│ │ │ │ │ │

│ │ │ │ │ │

│ │ │ │ │ │

│ │ │ │ │ │450

│ │ │ │ │ │

│ │ │ │ │ │

│ │ │ │ │ │

│ │ │ │ │ │

│ │ │ │ │ │

│ │ │ │ │ │

│ │ │ │ │ │

│ │ │ │ │ │

│ │ │ │ │ │

│ │ o ───────────────────────────────── o ──│────

│ │ 6.5 6.5 │

│ 1870 (MAX) │ │

│ └───────────────────────────────────────────────┘

│ 870 (MIN)

│

│

│

│

│

│

│

│ ALL DIMENSIONS IN MILLIMETRES

│

│

│

│

│ FINISHED FLOOR LEVEL

▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄

/ / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / /

Figure 2.1

F08 Cabinet Mounting Details

Page 2-4 24 March 2006 Issue 3.04

Page 17

Document No: LT0082 F08 Installation & Programming Manual

FIP Installation

▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄▄

│ │

│ │

│ 0.5m │ F08 FIP │ 0.5m │

│ │ │ │

───── ┌──────────── └┬┬──────────────────────┘ ───────────┐

│░░░░░░░░░░░░░░││░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░│

│░░░░░░░░░░░░░░││░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░│

│░░░░░░░░░░░░░░││░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░│

│░░░░░░░░░░░░░░││░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░│

│░░░░░░░░░░░░░░││░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░│

│░░░░░░░░░░░░░░││░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░│

1m │░░░░░░░░░░░░░░││░░░░░░░░░ AS1670 CLEAR AREA ░░░░░░░│

│░░░░░░░░░░░░░░││░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░│

│░░░░░░░░░░░░░░││░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░│

│░░░░░░░░░░░░░░││░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░│

│░░░░░░░░░░░░░░││░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░│

│░░░░░░░░░░░░░░└┘░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░│

│░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░░│

───── └───────────────────────────────────────────────────┘

Figure 2.2

FIP Cabinet Clearance

Issue 3.04 24 March 2006 Page 2-5

Page 18

F08 Installation & Programming Manual Document No: LT0082

FIP Installation

2.3 MAINS WIRING

Mains wiring must be done in accordance with AS1670.1 and AS3000 Wiring Regulations.

* * WARNING * *

Ensure mains is isolated at Distribution Board before connecting or inspecting mains wiring.

The mains wiring should be fixed firmly to the 3 way screw terminal block under the Mains

switch.

Check that safety earths to cabinet doors, Main Board, and mains switch cover are still

connected firmly to the earth studs.

* * NOTES * *

1. Mains supply must be 240 VAC (+6% -10%), at 50 Hz, and terminated as described.

2. All other wiring coming into the panel, including all relay wiring, must only be ELV.

Page 2-6 24 March 2006 Issue 3.04

Page 19

Document No: LT0082 F08 Installation & Programming Manual

FIP Installation

THIS PAGE INTENTIONALLY LEFT BLANK

Issue 3.04 24 March 2006 Page 2-7

Page 20

F08 Installation & Programming Manual Document No: LT0082

FIP Installation

2.4 MAIN BOARD

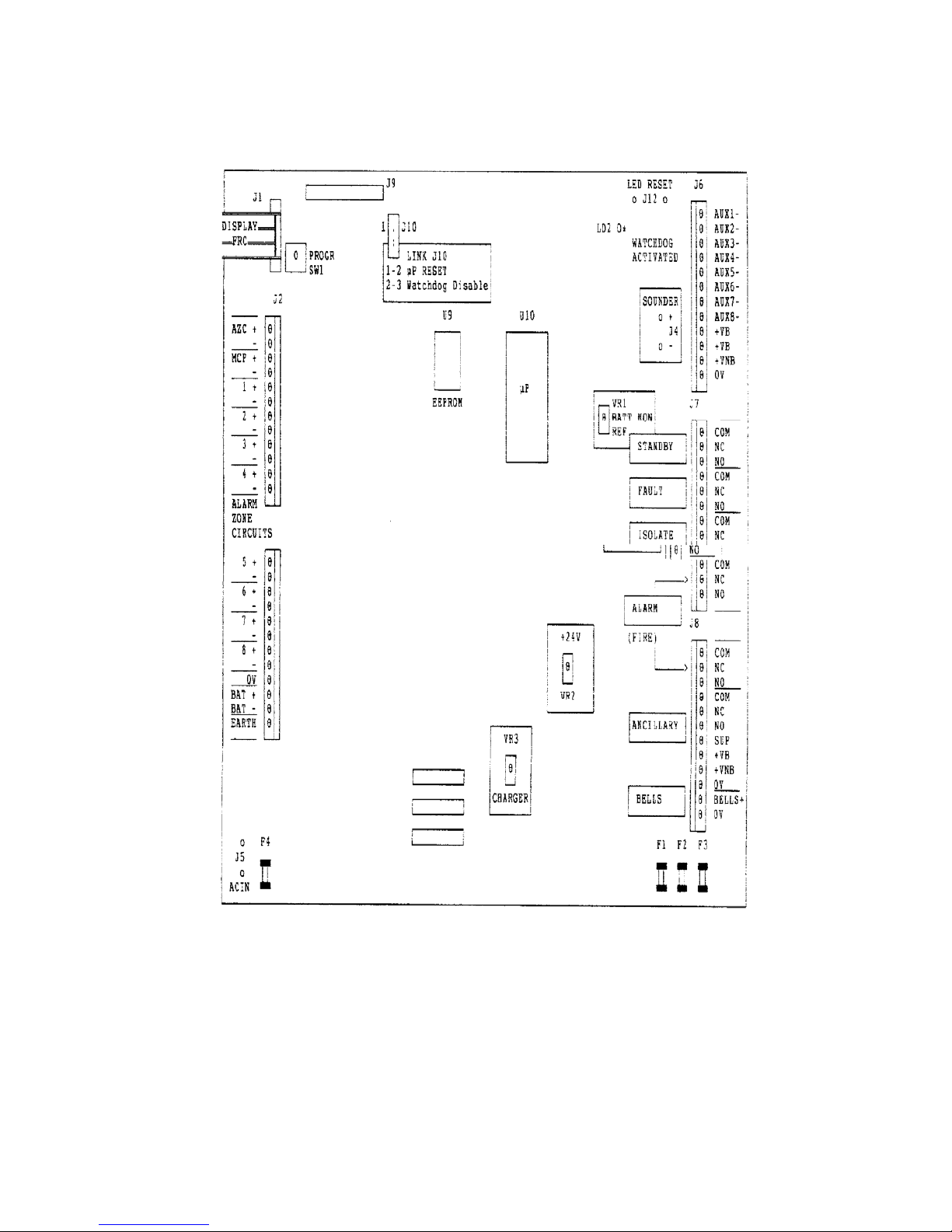

Figure 2.4 shows the basic layout of the F08 FIP Main Board.

2.4.1 TERMINALS

The following terminals and connectors are provided:

J1 - Display FRC Output Connector.

J2 - 12 Way Screw Input Terminal for MCP AZC, MCP, AZC1, AZC2 and AZC3.

J3 - 12 Way Screw Terminal for AZC4, AZC5, AZC6, AZC7, AZC8, 0V,

BATTERY, and EARTH.

J4 - Sounder Output Connector.

J5 - AC IN - 31 VAC Input Connector.

J6 - 12 Way Screw Terminal for AUX1- to AUX8-, VB, VNB, and 0V.

J7 - 12 Way Screw Terminal for Brigade Relays; Standby, Fault, Isolate and

Alarm.

J8 - 12 Way Screw Terminal for Alarm Relay, Ancillary Relay & Supervision and

Bells.

J9 - Reserved for future MODEM socket.

J10 - Link 1-2 for Microprocessor RESET

Link 2-3 for Watchdog DISABLE.

J12 - Reset Watchdog Activated LED.

2.4.2 FUSES

The following fuses are located on the Main Board:

F1 BELLS Rated 1.6 Amp

F2 VB Rated 1.6 Amp

F3 VNB Rated 1.6 Amp

F4 AC IN 31VAC Rated 5.0 Amp

2.4.3 REMOVAL & INSTALLATION

The Main Bd should be removed carefully as it is a delicate piece of electronic equipment.

An electrostatic earth lead should be worn at all times when working on the bd.

Disconnect all field wiring, battery leads, MCP wiring, AC leads, earth wires and the Display

Bd FRC from the Main Bd. Undo the 3 nuts that secure the heatsink to the cabinet case.

Push back the barbs on the plastic standoffs and carefully pull the Main Bd away from the

cabinet.

DO NOT separate the heatsink from the Main Bd as this will weaken the components on the

heatsink and increase any repair cost.

Installation is just the reverse of the removal.

Thoroughly check the wiring before applying power and check all functions after power is

connected.

Page 2-8 24 March 2006 Issue 3.04

Page 21

Document No: LT0082 F08 Installation & Programming Manual

FIP Installation

Figure 2.4

F08 Main Board Layout

Issue 3.04 24 March 2006 Page 2-9

Page 22

F08 Installation & Programming Manual Document No: LT0082

FIP Installation

2.4.4 FIELD SUPPLY CONNECTIONS

The F08 FIP Main Board provides two types of fused power outputs.

(a) Terminals labelled "+VB" provide 27.3 VDC supply output, which is battery backed.

"+VB" terminals are fused by F2.

(b) Terminals labelled "+VNB" provided a non-battery backed 27.9 VDC supply output.

"+VNB" terminals are fused by F3.

The total load current available from "+VB" and "+VNB" is 1.5 Amps. This excludes the panel

and battery charging currents.

A block diagram of the fused power outputs is shown in Figure 2.5.

FUSE

┌──────┐

┌──────────────┤ F3 ├──────── VNB

│ └──────┘ 27.9 VDC

────────────┐ │ 1.5A

30 VAC │ │

─────────┐ │ │

│ │ │

┌─────┴──┴─────┐ │ FUSE

│ │ │ ┌──────┐

│ REGULATOR ├────┴───┤ ├───┬───┤ F2 ├──────── VB

│ │ │ └──────┘ 27.3 VDC

└──────────────┘ │ 1.5A

2A CURRENT │

LIMITED │

│

│

│

┌──────────────┐ │

│ │ │

│BATTERY 24 VDC├───────────────┘

│ │

└──────────────┘

Figure 2.5

Block Diagram of F08 Power Supply

Page 2-10 24 March 2006 Issue 3.04

Page 23

Document No: LT0082 F08 Installation & Programming Manual

FIP Installation

2.5 BATTERY INSTALLATION

Install only compatible batteries (refer Appendix A) in the bottom of the FIP cabinet. Using

the battery cables supplied, connect wiring as shown in Figure 2.6.

* * NOTES * *

(a) The F08 system should be system tested before connecting the batteries.

(b) If the batteries are located remotely from the F08, a battery protection device

(> 3 Amps) must be located at the batteries.

(c) USE ONLY THE BATT+ & BATT- TERMINALS PROVIDED. PARALLEL

CONNECTION OF BATTERIES IS NOT PERMITTED.

PLEASE OBSERVE POLARITY

│ │Q││ 0V │

│ ├─┤│ │

╔═══╪════╡Q││ BATT + │

║ │ ├─┤│ │

╔══════════╡Q││ BATT - │

║ ║ │ ├─┤│ │

║ ║ │ │Q││ EARTH │

║ ║ │ └─┴┘ F08 MAIN BOARD │

║ ║ ────────────────────────────────────────────────────────────┘

║ ║ ────────────────────────────────────────────────────────────┐

║ ║ │ │

║ ║ │ HEATSINK │

║ ║ │ │

║ ╚════════════════════════════════════════════════════════════════╗

║ ║

║ ┌─────────────┐ ┌───────────┐ ║

║BLACK │ │ │ │ RED║

║ │ │ │ │ ║

║ │ │ │ │ ║

║ │ TRANSFORMER │ │ MAINS │ ║

║ │ │ │ SWITCH │ ║

║ ┌──────────────┐ │ │ │ │ ┌──────────────┐ ║

║ │ ┌─┐ ┌─┐ │ │ │ │ │ │ ┌─┐ ┌─┐ │ ║

║ │ ███ - + ███ │ │ │ │ │ │ ███ - + ███ │ ║

║ │ ███ ███ │ └─────────────┘ └───────────┘ │ ███ ███ │ ║

║ │ ║ ║ │ │ ║ ║ │ ║

║ │ ║ ║ │ │ ║ ║ │ ║

║ │ ║ ║ │ │ ║ ║ │ ║

╚════╝ ╚══════════════════════════════════════╝ ╚════╝

│ │ │ │

│ │ │ │

│ │ │ │

│ BATTERY │ │ BATTERY │

│ 12V │ │ 12V │

│ │ │ │

└──────────────┘ └──────────────┘

════════════════════════════════════════════════════════════════════

Figure 2.6

Battery Connections

Issue 3.04 24 March 2006 Page 2-11

Page 24

F08 Installation & Programming Manual Document No: LT0082

FIP Installation

2.6 FIP MCP WIRING

The front door manual call point is factory connected by four wires to the "MCP" connector

J2, located at the top left hand side of the Main Board, and to ZONE 1 (AZC1).

If required by Customer specifications, the MCP can be wired to any other Alarm Zone

Circuit. This is done by shifting the MCP return wires from AZC1 to another AZC, but

MAINTAIN THE CORRECT POLARITY.

Figure 2.7 shows an example of the MCP wired to AZC4.

NOTE 1: The MCP becomes the first "DETECTOR" on the particular AZC used. The

field cabling to the next detector on that AZC is connected to the terminals

(J2; 1 & 2) labelled AZC.

NOTE 2: MCPs can be used only on AZCs programmed as zone input type 1 or

type 2. Refer to Section 2.7.2 for a description of the ten different zone input

types.

FIELD

┌─┐ ┌──────┐ ┌──────┐ │

│E╞═══╪o+ +o╪═══════════╪o+ +o╪════════════════╗┌──────────────

│O│ │OUT IN│ │OUT IN│ │ ║│

│L╞═══╪o -═o╪═══════════╪o- -o╪═══════════╗ ║│

└─┘ └──────┘ └──────┘ │ ║ ║│ F08 MAIN

LAST SECOND ║ ║│ BOARD

└──── DETECTOR ────┘ ║ ║│

─ ── ── ── ── ── ── ── ── ── ─┘ ║ ║│

║ ║│ J2

║ ║│ ┌─┬┐

┌── ── ── ── ── ── ── ── ── ── ──┐ ║ ╚══════╡Q││ +

│ F08 FIP FRONT DOOR │ ║ │AZC ├─┤│

┌───────────┐ ╚═══════════╡Q││ -

│ │ ┌─┐ ┌─┐ │ ORANGE │ │ ├─┤│

╔═════════╡Q│ │Q╞═════════════════════════════════════╡Q││ +

│ ║ │ ├─┤ ├─┤ │ WHITE │ │MCP ├─┤│

║ ╔════╡Q│ │Q╞═════════════════════════════════════╡Q││ -

│ ║ ║ │ ├─┤ ├─┤ │ │ │ ├─┤│

║ ║ │ │Q│ │Q│ │ │ │Q││ +

│ ║ ║ │ └─┘ └─┘ │ │ │AZC1 ├─┤│

║ ║ └───────────┘ │ │Q││ -

│ ║ ║ MCP = FIRST DEVICE ON AZC4 │ │ ├─┤│

└──║ ── ║── ── ── ── ── ── ── ── ──┘ │ │Q││ +

║ ║ │ACZ2 ├─┤│

║ ║ │ │Q││ -

║ ║ │ ├─┤│

║ ║ │ │Q││ +

║ ║ │ACZ3 ├─┤│

║ ║ │ │Q││ -

║ ║ │ └─┴┘

║ ║ │ J3

║ ║ ORANGE ┌─┬┐

╚═══════════════════════════════════════════════════════╡Q││ +

║ WHITE ACZ4 ├─┤│

╚══════════════════════════════════════════════════╡Q││ -

│ ├─┤│

│ │Q││ +

│ACZ5 ├─┤│

│ │Q││ │/\/\/\/\/\/\/\

Figure 2.7

Example of MCP Wired to Zone 4

Page 2-12 24 March 2006 Issue 3.04

Page 25

Document No: LT0082 F08 Installation & Programming Manual

FIP Installation

2.7 ALARM ZONE WIRING & CIRCUIT TYPES

2.7.1 CIRCUIT WIRING

The following rules MUST be observed when wiring ALARM ZONE CIRCUITS:

1) Detector TYPES and NUMBER per AZC MUST COMPLY WITH THOSE STATED IN

THE OPERATOR'S MANUAL.

2) Detector positioning, installation and wiring must conform with AS1670.1 and

detector manufacturer's instructions.

3) The F08 EOL resistor (2k7 1%) must be fitted to the base of the last detector/MCP on

each AZC. If the circuit is disabled the resistor may be left off to reduce current

consumption.

4) Alarm Zone Circuit (detector circuit) wiring is terminated on the F08 Main board

screw terminals marked "AZC1" to "AZC8", except the F08’s MCP zone which is

terminated at "AZC".

5) Observe circuit polarity. "+" to "+", "-" to "-".

6) Detectors are wired across the AZC (+ to -) with a series link to give an open circuit

(Fault) if the detector is unplugged.

7) Observe "IN" and "OUT" wiring of detectors;

- "IN" is from previous detector / Fire Panel.

- "OUT" is to next detector / EOL.

9) If in doubt, refer to detector information for specific detail.

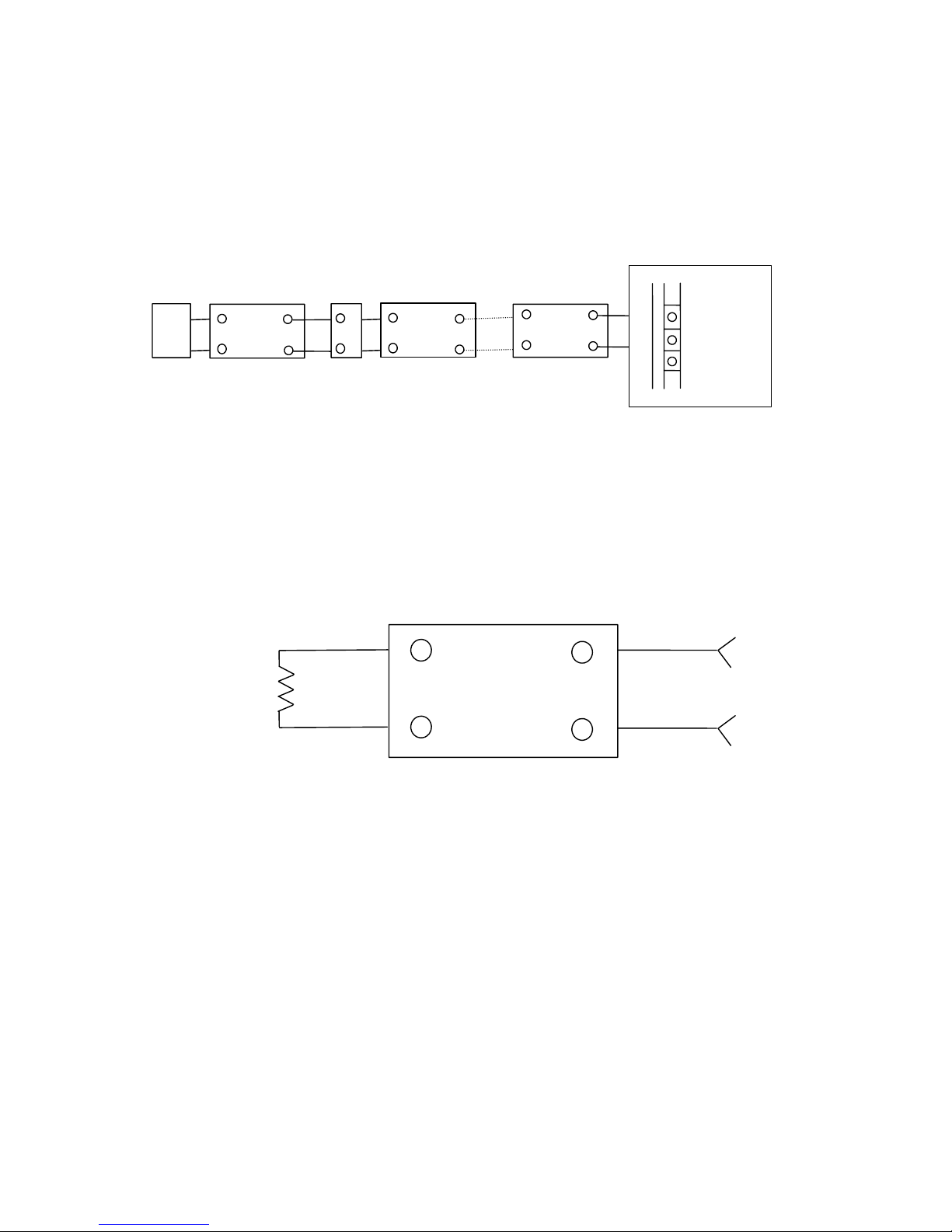

10) Figure 2.8 shows the correct way to wire an AZC with detectors and/or MCPs. The

MCPs and detectors may be in any order. The MCPs however must be the correct

type for 15V operation.

11) Figure 2.9 shows the correct way to wire the EOL resistor.

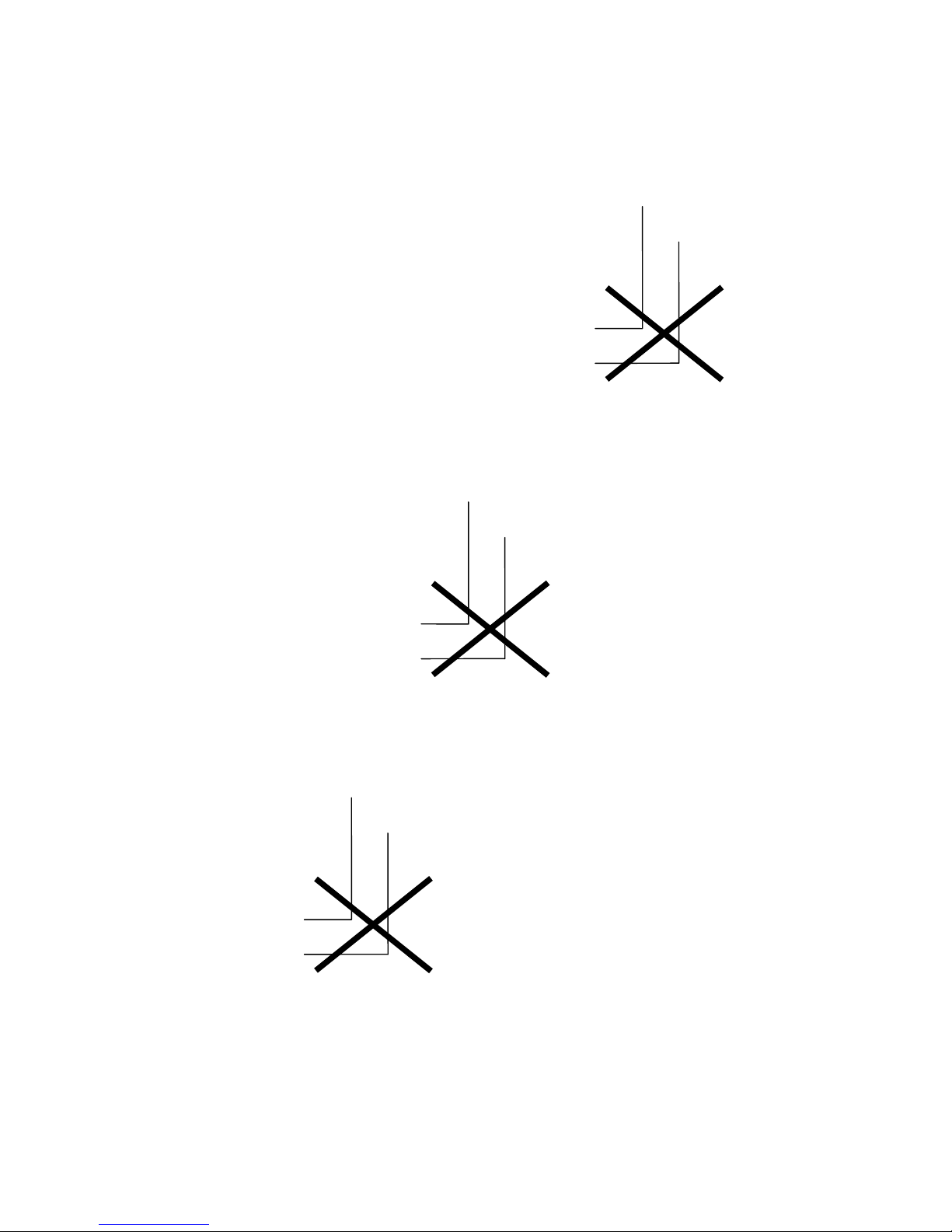

12) Figure 2.10 shows examples of INCORRECT AZC wiring.

13) When operating, circuit voltages at AZC terminals "+" and "-", should be as follows :

i. Between 23 and 24 VDC -> Fault (EOL open)

ii. Between 18 and 23 VDC -> Normal (EOL connected)

iii. Between 13 and 17 VDC -> MCP alarm (programmable)

iv. Less than 13 VDC -> Detector operated (programmable)

Interpretation of the 13-17 volt band and

0-13 volt band depends on the

programming of the circuit type as

described in Section 2.7.2.

Issue 3.04 24 March 2006 Page 2-13

Page 26

F08 Installation & Programming Manual Document No: LT0082

FIP Installation

+

-

AZC#

+

-

OUT

+

-

IN

+

-

OUT

+

-

IN

Detecto

r

+

-

MCP

+

-

OUT

+

-

IN

Detector

EOL

Figure 2.8

Example of Correct AZC Detector/MCP Wiring

+

-

OUT

+

-

IN

2k7 1% EOL

Resisto

r

Last Detector on

A

larm Zone Circuit

Figure 2.9

Correct EOL Wiring

Page 2-14 24 March 2006 Issue 3.04

Page 27

Document No: LT0082 F08 Installation & Programming Manual

FIP Installation

┌─┐ ┌──────┐ ┌──────┐ ┌──────┐ │ ├─┤

│E├───┼o+ +o┼──┼o+ +o┼── ─ ─ ─ ─ ─┼o+ +o┼───────────────┤O│ +

│O│ │OUT IN│ │OUT IN│ │OUT IN│ │ ├─┤AZC

│L├───┼o- -o┼──┼o- -o┼── ─ ─ ─ ─ ─┼o- -o┼───────────────┤O│ └─┘ └──────┘ └──────┘ └──────┘ │ ├─┤

┌─┐ ┌──────┐ ┌──────┐ ┌──────┐

│E├───┼o+ +o┼──┼o+ +o┼── ─ ─ ─ ─ ─┼o+ +o┼

│O│ │OUT IN│ │OUT IN│ │OUT IN│

│L├───┼o- -o┼──┼o- -o┼── ─ ─ ─ ─ ─┼o- -o┼

└─┘ └──────┘ └──────┘ └──────┘

┌─┐ ┌──────┐ ┌──────┐ ┌──────┐ │ ├─┤

│E├───┼o+ +o┼──┼o+ +o┼────────────┼o+ +o┼───────────────┤O│ +

│O│ │OUT IN│ │OUT IN│ │OUT IN│ │ ├─┤AZC

│L├───┼o- -o┼──┼o- -o┼────────────┼o- -o┼───────────────┤O│ └─┘ └──────┘ └──────┘ └──────┘ │ ├─┤

┌──────┐

│o+ +o┼

│OUT IN│

│o- -o┼

└──────┘

┌─┐ ┌──────┐ ┌──────┐ ┌──────┐ │ ├─┤

│E├───┼o+ +o┼──────────┼o+ +o┼────┼o+ +o┼───────────────┤O│ +

│O│ │OUT IN│ │OUT IN│ │OUT IN│ │ ├─┤AZC

│L├───┼o- -o┼──────────┼o- -o┼────┼o- -o┼───────────────┤O│ └─┘ └──────┘ └──────┘ └──────┘ │ ├─┤

┌─┐ ┌──────┐

│E├───┼o+ +o┼

│O│ │OUT IN│

│L├───┼o- -o┼

└─┘ └──────┘

Figure 2.10

Incorrect AZC Wiring Examples

Issue 3.04 24 March 2006 Page 2-15

Page 28

F08 Installation & Programming Manual Document No: LT0082

FIP Installation

2.7.2 INPUT TYPES

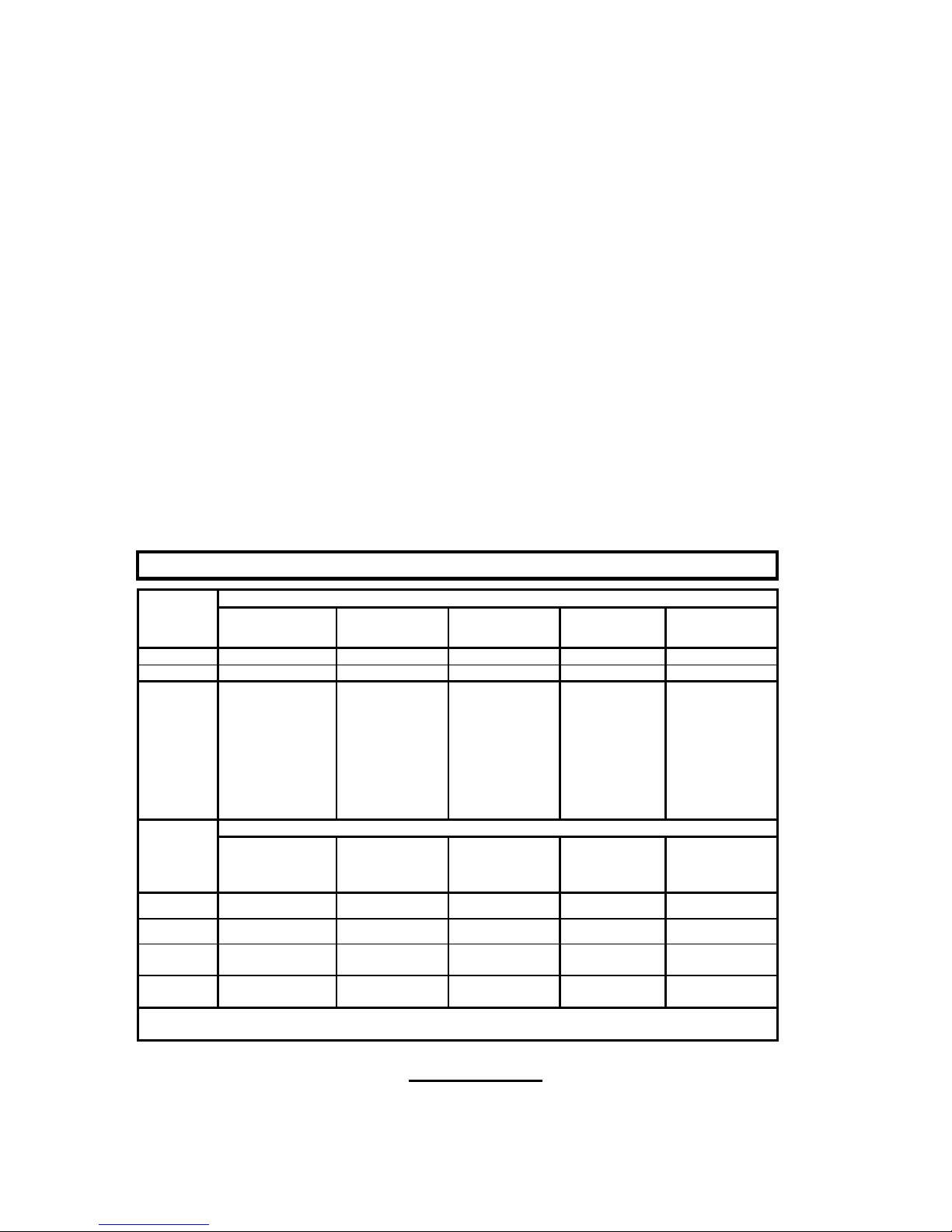

Each AZC can be programmed with one of ten different input types (refer Section 4.7).

These types are defined as follows and in Table 2.1.

Input Type 1 : Standard

Standard detector circuit without AVF. Both MCPs and detectors are allowed. Delay

into alarm is 2 seconds.

Input Type 2 : AVF/RAD

Standard detector circuit with AVF. MCPs are allowed and override AVF. AVF

sequence is: 2 seconds before first recognition, 5 second delay, 5 second reset, 2

second ignore, 2 second alarm recognition, 150 second acceptance period.

Input Type 3 : SAD

AS1668 SAD circuit (Supply Air Detector). 0-17V band is alarm with 2 seconds delay

into alarm and 60 seconds delay out of alarm. The detector must be non-latching and

the zone should be programmed as non-latching.

Input Type 4 : AVF/SAD

AS1668 AVF/SAD. 0-17V band is alarm with AVF (as for circuit type 2 AVF/RAD).

Delay out of alarm is 60 seconds. The detector must be non-latching and the zone

should be programmed as non-latching. 60 seconds of continuous non-alarm must be

present on the AZC input before the zone indicates non-alarm.

This input type can also be used with latching detectors that have a high alarm voltage

(up to 17V), when AVF is required (e.g. with IS isolating repeaters). Configure the

zone as latching. When the zone is reset the detector will be reset and the zone taken

out of alarm immediately, overriding the 60 second delay out of alarm.

Input Type 5 : Flowswitch

0-13V band is alarm with 20 second delay into alarm. 13-17V band is normal. The

detector is non-latching and the zone should be programmed as non-latching. 20

seconds of continuous alarm must be present on the AZC input before the zone

indicates alarm.

Input Type 6 : Standard/No MCP

Standard detector circuit without AVF. MCPs are not allowed and 13-17V band is

interpreted as fault to provide line leakage fault indication. The delay into alarm is 2

seconds. The delay into fault for 13-17V band is half a second.

Input Type 7 : AVF/RAD/No MCP

Standard detector circuit with AVF as for Type 2 AVF/RAD except that MCPs are not

allowed and 13-17V band is interpreted as fault to provide line leakage fault indication.

The delay into fault for 13-17V band is half a second.

Input Type 8 : Fast Supervision

13-17V band is alarm with half a second delay into alarm. 0-13V band is fault

providing both short circuit and open circuit fault detection. This is typically used for

sub-panel monitoring with sub-panel alarm relay in series with 15V zener diode. The

delay into fault for 0-13V band is half a second.

Page 2-16 24 March 2006 Issue 3.04

Page 29

Document No: LT0082 F08 Installation & Programming Manual

FIP Installation

INPUT TYPES (CONTINUED)

Input Type 9 : Loop Powered Circuit / Fast Alarm

0-13V band is alarm with half a second delay into alarm. 13-17V band is normal for

15V loop powered circuit.

Input Type 10 : Normally Closed Contact

13-17V band is alarm with 2 seconds delay into alarm. 0-13V band is interpreted as

normal.

Delay Out of Alarm

For a non-latching zone, the delay out of alarm for all circuit types other than type 3 (SAD)

and type 4 (AVF/SAD) is 120 millisconds.

Detector LED Current Boost

Input Type 1-7:

When the AZC input is currently in any alarm band, a 50 millisecond current boost will

be applied to the circuit once a second.

Input Type 8 (Fast Supervision), 9 (Loop Powered) and 10 (Normally Closed):

When the AZC input is currently in any alarm band and the zone is in alarm or latched

in alarm then a 50 millisecond current boost will be applied to the circuit once a

second.

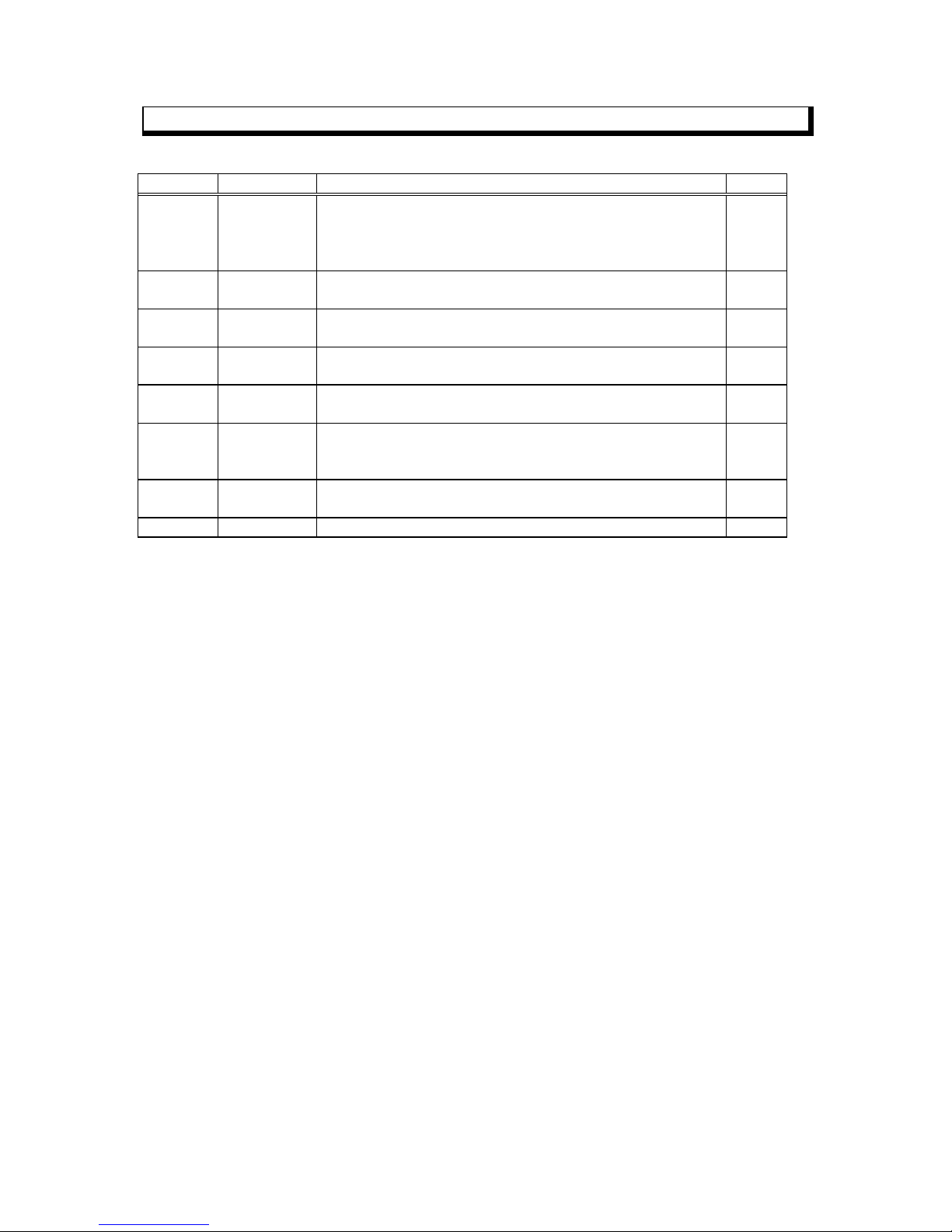

INPUT TYPES

INPUT TYPE

VOLTAGE

1

INSTANT

2

AVF/RAD

3

SAD

4

AVF/SAD 5 FLOW SWITCH

24V Fault Fault Fault Fault Fault

17-23V Normal Normal Normal Normal Normal

13-17V 0-17 Volt treated

as the same

state.

Alarm after 2

seconds.

0-17 Volt

treated as the

same state.

0-17 Volt

treated as the

same state.

Normal

0-13V Alarm after 2

seconds.

AVF into alarm. Alarm after 2

seconds.

Delay out of

alarm is 60

seconds.

Alarm after

AVF.

Delay out of

alarm is 60

seconds.

20 Second

delay into

alarm.

No delay out of

alarm.

INPUT TYPE

VOLTAGE 6

LEAKY CCT

7

LEAKY CCT

& AVF

8

SUB-PANEL

S/C FAULT

9

FAST ALARM

10

NORMALLY

CLOSED

24V Fault Fault Fault Fault Fault

17-23V Normal Normal Normal Normal Normal

13-17V Fault

0.5 seconds

Fault

0.5 seconds

Alarm after

0.5 seconds.

Normal Alarm after 2

seconds.

0-13V Alarm after 2

seconds.

AVF into alarm. Fault after 0.5

seconds.

Alarm after 0.5

seconds.

Normal

AVF = 2 second alarm, 5 second delay (circuit still energised), 5 secon d reset, energise 2 second ignore,

start processing.

Table 2.1

F08 Input Types

Issue 3.04 24 March 2006 Page 2-17

Page 30

F08 Installation & Programming Manual Document No: LT0082

FIP Installation

2.8 BELL OUTPUT WIRING

2.8.1 GENERAL

At the bottom of J8 terminals "BELLS +" and "0V" are provided for connection to external bell

circuits. The Bell Output is a switched 24V DC output, derived from +VB through the Bell

fuse F1.

NOTES:

1) Connect ONLY 24 VDC devices.

2) Observe correct polarity for polarised devices, eg electronic sirens.

3) Maximum load current is 1.0 Amps as the bells are an inductive load. (Please note

total load constraints). For heavier loads use an interposing relay.

4) The "BELLS+" output is fused by fuse F1, labelled "BELLS", and is rated at 1.6 A.

5) The "BELLS" circuit is not supervised.

6) Figure 2.11 shows an example of bell wiring.

7) For optimum suppression install diodes across each BELL.

- Use diode type 1N4004 (400V 1A) or similar.

- Note polarity of diode. (Cathode to Bell Positive).

2.8.2 SUPERVISED BELL OUTPUT

A supervised bell output can be arranged with an optional 24V Bell Monitor Board (part

number PA0494) and a 24V GP Relay Board (part number PA0730). The Bell Monitor

Board supervises the bell wiring for open or short circuits.

On a fault, the Ext Def- output of the Bell Monitor goes “low” and turns off the relay on the

GP Relay Board, causing the EOLR to be disconnected from the F08’s detector circuit.

The AZC should be programmed as Input Type 1 (default option).

The Bell Monitor Board can support wiring of up to 3 separate branches (each with an EOL

resistor), and a load current of 1.0A (as limited by the F08 Bell Output). The end of line

resistor depends on the number of branches.

Number of Branches EOL

1

2

3

10k 5%

18k 5%

27k 5%

Note that a diode is required with any device that does not already contain a series diode.

Figure 2.12 shows the wiring arrangement for the Bell Monitor board.

The 10k pull-up resistor should be soldered between the Ext Def- tab and the left end of link

A3. After soldering, check that the solder joints on the bottom of link A3 are still good.

Page 2-18 24 March 2006 Issue 3.04

Page 31

Document No: LT0082 F08 Installation & Programming Manual

FIP Installation

/\/\/\/\/\/\/\/\/│

J8 │

──────── ┌┬─┐ │

A COM ││O│ │

L │├─┤ │

A NC ││O│ │

R │├─┤ │

M NO ││O│ │

──────── │├─┤ │

COM ││O│ │

│├─┤ │

A NC ││O│ │

N │├─┤ │

C NO ││O│ │

I │├─┤ │

L SUP ││O│ │

L │├─┤ │

A +VB ││O│ │

R │├─┤ │

Y +VNB ││O│ │

│├─┤ │

0V ││O│ │

──────── │├─┤ │ RED WIRE

BELLS+ ││O╞═══════════════════════════╦═══════╗

│├─┤ │ BLACK WIRE ║ ║

0V ││O╞════════╦═══════╗ DIODE ║ ║

──────── └┴─┘ │ ║ ║ _┌───╥┐_ ║ ║

▄▄ │ ║ ║│ └───╨┘ │║ ║╔══════════════╗

││ │ ║ ┌──╨┴────────┴╨──┐ ║║ REMEMBER ║

▀▀ │ ║ │ - + │ ║║ MAX LOAD ║

─────────────────┘ ║ │ BELL │ ║║ 1.0 A ║

║ │ │ ║╚══════════════╝

║ └────────────────┘ ║

║ ║

║ ║

╚═══════╗ ╔═══════╝

║ ║

║ DIODE ║

║ _┌───╥┐_ ║

║│ └───╨┘ │║

┌──╨┴────────┴╨──┐

│ - + │

│ BELL │

│ │

└────────────────┘

Figure 2.11

Bell Output Wiring

Issue 3.04 24 March 2006 Page 2-19

Page 32

F08 Installation & Programming Manual Document No: LT0082

FIP Installation

6+

6-

7+

7-

8+

8-

0V

BATT+

BATT-

EARTH

:

:

:

:

:

+VB

+VNB

0V

BELLS+

0V

PROGRAM

INPUT

TYPE 1

(

DEFAULT

)

+V

+V

7+

EVAC

0V

+VExt

0V

7+

EVAC-

EVAC+

PA0494 24V BELL

MONITOR BOARD

+

SIG

-

C

NC

NO

C

NC

PA0730 24V

RELAY BOARD

NO

+ +

* EOL

+ +

* EOL Value –

Refer to Bell

Monitor

Installation

Instructions

LT0190

F08 EOL

0V

BELLS+

+

A

3

*10k

Ext Def-

*Solder the 10k resistor from

the Ext Def- tab to the l.h.s.

of link A3

J3 J8

Cut Lk1

Figure 2.12

F08 Bell Output with PA0494 Bell Monitor Board

Page 2-20 24 March 2006 Issue 3.04

Page 33

Document No: LT0082 F08 Installation & Programming Manual

FIP Installation

2.8.3 CONNECTING T-GEN 50 TO F08

T-GEN 50 is a self contained AS2220 Alert and Evacuate tone generator and may be used

on the F08 as well as, or instead of, the standard bells output.

There are four ways to connect the T-GEN to the F08. For each the T-GEN must be

powered from the battery terminals through a 3A slow blow fuse and T-GEN’s DEF- output

wired into an AZC input to signal a fault with the wiring. This AZC must be programmed for

circuit type 8 (short circuit fault).

1) Connect T-GEN using the Bells Relay.

T-GEN requires a closed contact output to 0V to allow operation. The standard F08

Bells output is switched 24V so it needs to be modified.

1) Remove the “Bell Fuse” F1.

2) Solder a wire to the top Bell Fuse holder and connect it to 0V as per

Figure 2.13A.

3) Connect the T-GEN as per Figure 2.13A.

Issue 3.04 24 March 2006 Page 2-21

Page 34

F08 Installation & Programming Manual Document No: LT0082

FIP Installation

The T-GEN can then be connected as follows:

EARTH

BATT-

BATT+

0V

A

ZC-

A

ZC+

0V

BELLS+

0V

+VNB

+VB

:

:

:

:

:

F08

MAIN

BOARD

A

/I/F-

A

LM-

DEF-

SIG

PROGRAM

INPUT

TYPE 8

10k

5%

SOLDER WIRE

FROM TOP

HOLDER TO 0V

REMOVE BELLS

FUSE F1

+24V

+24V

0V

0V

Figure 2.13A

F08 using T-GEN on Bells Relay

T-GEN 50

F08

EOL

3A

SLOW

BLOW

FUSE

Page 2-22 24 March 2006 Issue 3.04

Page 35

Document No: LT0082 F08 Installation & Programming Manual

FIP Installation

2) Connect T-GEN using the Ancillary Relay.

If the Ancillary Relay is not being used, it may be used to control the T-GEN.

The Ancillary Relay must be programmed to operate on all the zones that require

tone signalling.

With the T-GEN connected in this fashion, pressing the silence key will not silence

the T-GEN, the only way T-GEN can be silenced is by isolating the Ancillary Relay.

Also, performing a Bells test will not activate T-GEN, the Ancillary Relay test will

need to be used instead.

Figure 2.13B

EARTH

BATT-

BATT+

0V

A

ZC-

A

ZC+

0V

BELLS+

0V

+VNB

+VB

SUP

NO

NC

COM

:

F08

MAIN

BOARD

A

/I/E-

A

LM-

DEF-

SIG

PROGRAM

INPUT

TYPE 8

10k

5%

+24V

+24V

0V

0V

T-GEN 50

F08

EOL

3A

SLOW

BLOW

FUSE

ANCILLARY

F08 using T-GEN on Ancillary Relay

Issue 3.04 24 March 2006 Page 2-23

Page 36

F08 Installation & Programming Manual Document No: LT0082

FIP Installation

3) Connect T-GEN using the Alarm Relay.

As the F08’s Brigade Interface has two Alarm contacts, the second set of contacts

may be used to activate T-GEN as shown in Figure 2.13C.

This method has some limitations. All zones that are required to operate the T-GEN

must be mapped to Master Alarm as well.

Pressing Silence will not silence T-GEN and this must be done through isolating all

zones in alarm.

There is no way of performing a Test on the T-GEN, except by putting a zone into

alarm.

Figure 2.13C

EARTH

BATT-

BATT+

0V

A

ZC-

A

ZC+

0V

BELLS+

0V

+VNB

+VB

SUP

NO

NC

COM

NO

F08

MAIN

BOARD

A

/I/E-

A

LM-

DEF-

SIG

PROGRAM

INPUT

TYPE 8

10k

5%

+24V

+24V

0V

0V

T-GEN 50

F08

EOL

3A

SLOW

BLOW

FUSE

NC

COM

ANCILLARY

ALARM

F08 using T-GEN on Alarm Relay

Page 2-24 24 March 2006 Issue 3.04

Page 37

Document No: LT0082 F08 Installation & Programming Manual

FIP Installation

4) Connect T-GEN using the Auxiliary Outputs.

The Ancillary outputs (Aux1 → Aux 8) may be used to operate T-GEN. The outputs

must be programmed as isolatable otherwise there will be no way of silencing T-GEN

apart from resetting the alarm condition. Also, Bells test will not operate T-GEN - a

zone alarm test can be used instead.

Wire the Auxiliary output of each zone that is to operate T-GEN together and connect

to T-GEN as per Figure 2.13D. These outputs are open collector, so they may be

wired in parallel. Figure 2.13D shows the wiring for zones 1, 2 and 4 operating TGEN

Figure 2.13D

F08 using T-GEN via Auxiliary Outputs

EARTH

BATT-

BATT+

0V

A

ZC-

A

ZC+

0V

+VNB

+VB

+VB

A

UX8

A

UX7

A

UX6

A

UX5

A

UX4

A

UX3

F08

MAIN

BOARD

A

/I/E-

A

LM-

DEF-

SIG

PROGRAM

INPUT

TYPE 8

10k

5%

+24V

+24V

0V

0V

T-GEN 50

F08

EOL

3A

SLOW

BLOW

FUSE

A

UX1

A

UX2

Issue 3.04 24 March 2006 Page 2-25

Page 38

F08 Installation & Programming Manual Document No: LT0082

FIP Installation

2.9 ANCILLARY RELAY OUTPUT WIRING

The "ANCILLARY" relay on connector block J8 provides voltage free changeover contacts.

Terminals available are:

(a) COM - Common

(b) NC - Normally Closed

(c) NO - Normally Open

(d) SUP - Input for supervision (Not voltage free).

NOTES:

1) Maximum allowable load is 18 ohms (1.5 A). Note that the total load current available

from the F08 is 1.5A.

2) Relay rating is 2 A @ 30 VDC resistive, 1 A inductive. Use interposing relay for

higher loads.

3) Only ELV is allowed into the cabinet.

4) The supervision input can be programmed to supervise the integrity of the circuit to

the controlled device. Allowable output load is 400 ohms to 4kohms. (A diode must

be added to loads < 400 ohms).

5) For supervised loads less than 400 ohms use a series diode, fitted at the load

(observe polarity and ensure diode rating is compatible with the load current).

6) For inductive loads use a suppression diode rated at 50 Volts or greater and a

current rating of:

- 0.5 A for loads greater than 100 ohms

- 1.0 A for loads greater than 30 ohms

- 1.5 A for loads greater than 20 ohms

7) For voltage free or non supervised loads, ensure that no connection is made to the

"SUP" input.

8) Figure 2.14 shows examples of wiring a device powered from the battery-backed

+VB.

9) The Ancillary relay can be isolated via the keypad, but Master Alarm, Fault, and

Isolate Relays cannot. They are however automatically isolated during System Test.

Page 2-26 24 March 2006 Issue 3.04

Page 39

Document No: LT0082 F08 Installation & Programming Manual

FIP Installation

/\/\/\/\/\/\/\/\/│

J8 │

──────── ┌┬─┐ │

A COM ││Q│ │

L │├─┤ │

A NC ││Q│ │

R │├─┤ │

M NO ││Q│ │

──────── │├─┤ │

A COM ││Q├───────────────────────────────────┐

N │├─┤ │ │

C NC ││Q├───────────┐ ├─────┐

I │├─┤ │ │ + │ │

L NO ││Q├───────┐ │ ┌──┴──┐ │

L │├─┤ │ │ │ INTERPOSING │ │ SUPPRESSION

A SUP ││Q├───────┼───┘ RELAY │ │ DIODE

R │├─┤ │ │ │ │

Y +VB ││Q├───────┘ └──┬──┘ │

│├─┤ │ - │ │

+VNB ││Q│ │ ├─────┘

│├─┤ │ │

0V ││Q├───────────────────────────────────┘

──────── │├─┤ │

\/\/\/\/\/\/\/\/\│

(A) Field Wiring for Interposing Device with a load Resistance greater than 400 OHMS

/\/\/\/\/\/\/\/\/│ SERIES DIODE

A COM ││Q├─────────────────── ─────────┐

N │├─┤ │ │

C NC ││Q├───────────┐ ├──────┐

I │├─┤ │ │ + │ │

L NO ││Q├───────┐ │ ┌──┴──┐ │

L │├─┤ │ │ │ INTERPOSING │ │ SUPPRESSION

A SUP ││Q├───────┼───┘ RELAY │ │ DIODE

R │├─┤ │ │ │ │

Y +VB ││Q├───────┘ └──┬──┘ │

│├─┤ │ - │ │

+VNB ││Q│ │ ├──────┘

│├─┤ │ │

0V ││Q├───────────────────────────────────┘

│├─┤ │

\/\/\/\/\/\/\/\/\│

(B) Field Wiring for Interposing Device with a load Resistance less than 400 OHMS

Figure 2.14

Examples of Supervised Ancillary Output

Issue 3.04 24 March 2006 Page 2-27

Page 40

F08 Installation & Programming Manual Document No: LT0082

FIP Installation

2.10 AUXILIARY OUTPUT WIRING

The "OPEN COLLECTOR" Auxiliary Outputs (AUX1 to AUX8) must only be connected to

external equipment via approved isolating devices such as relays or optoisolators mounted

within the panel.

An example of how to wire an auxiliary relay from the battery-backed supply +VB is shown in

Figure 2.15. In this example the relay turns on if zones 1 or 3 go into alarm.

NOTES:

(a) Use 24V devices, and allow for relay current in power requirement calculations.

(b) Use reverse E.M.F. suppression diode on relays.

(c) If a zone auxiliary output connects to more than one auxiliary relay, steering diodes

must be fitted.

(d) An auxiliary open collector output may or may not be isolated when the

corresponding zone is isolated depending on programming. Refer to Section 4.10.

(e) MAXIMUM current on each Auxiliary Output is 50 mA.

─────────────────┐

J6 │

┌┬─┐ │

AUX1 ││O╞════════════════════════╗

│├─┤ │ ║

AUX2 ││O│ │ ║

│├─┤ │ ║

AUX3 ││O╞════════════════════════╣

│├─┤ │ ║

AUX4 ││O│ │ ╔══════════╣ - ┌─┐

│├─┤ │ ║ ┌──╨──┐ ────────┤Q│ NC ┐ FIELD

AUX5 ││O│ │ ┌╨┐ │ │ ├─┤ │ WIRING

│├─┤ │ DIODE │ │ │RELAY│ ────┤Q│ COM │ TO

AUX6 ││O│ │ ╞═╡ │ │ ├─┤ │ RELAY

│├─┤ │ └╥┘ └──╥──┘ ────────┤Q│ NO ┘ CONTACTS

AUX7 ││O│ │ ║ ║ + └─┘

│├─┤ │ ╚══════════╣

AUX8 ││O│ │ ║

│├─┤ │ ║

+VB ││O╞════════════════════════╝

│├─┤ │

+VB ││O│ │

│├─┤ │

+VNB ││O│ │

│├─┤ │

+0V ││O│ │

└┴─┘ │

/\/\/\/\/\/\/\/\│

Figure 2.15

Example of Auxiliary Output Wiring

Page 2-28 24 March 2006 Issue 3.04

Page 41

Document No: LT0082 F08 Installation & Programming Manual

FIP Installation

2.11 DOOR HOLDER WIRING

The second "ALARM" (FIRE) relay on connector block J8 provides clean changeover

contacts suitable for Door Holder Power Supply connections. This operates on MASTER

ALARM and cannot be isolated manually via the F08 keypad.

NOTES:

1) The Master Alarm Relay will only operate if the zone in alarm is programmed to be

"mapped" to the Master Alarm Relay.

2) Use NON-BATTERY backed supply "+VNB" to power door holders.

3) "+VNB" rating is 1.5 A. ( Note total F08 load must be < 1.5A ).

4) Relay rating is 2 A @ 30 VDC resistive, 1A inductive.

5) Only ELV is allowed into the cabinet. Use an interposing relay located outside the

F08 cabinet if switching anything other than ELV.

6) For inductive loads, use a suppression diode rated at 50 Volts or greater and with a

current rating of:

- 0.5 A, for loads greater than 100 ohms

- 1.0 A, for loads greater than 30 ohms

- 1.5 A, for loads greater than 20 ohms

7) Figure 2.16 shows an example of Door Holder wiring. Note the normally closed

contact of the relay is used so that the door holders are de-energised on alarm.

/\/\/\/\/\/\/\/\/│

J8 │

──────── ┌┬─┐ │

A COM ││Q╞═══════════════════════╗

L │├─┤ │ ║

A NC ││Q╞═════════╗ ║

R │├─┤ │ ║ ║

M NO ││Q│ │ ║ ║

──────── │├─┤ │ ║ ║

A COM ││Q│ │ ║ ║

N │├─┤ │ ║ ╚═════════> +

C NC ││Q│ │ ║ TO DOOR HOLDERS

I │├─┤ │ ║ ╔═════════> L NO ││Q│ │ ║ ║

L │├─┤ │ ║ ║

A SUP ││Q│ │ ║ ║

R │├─┤ │ ║ ║

Y +VB ││Q│ │ ║ ║

│├─┤ │ ║ ║

+VNB ││Q╞═════════╝ ║

│├─┤ │ ║

0V ││Q╞═══════════════════════╝

──────── │├─┤ │

BELLS+ ││Q│ │

│├─┤ │

0V ││Q│ │

└┴─┘ │

▄▄ │

││ │

▀▀ │

─────────────────┘

Figure 2.16

Example of Door Holder Wiring

Issue 3.04 24 March 2006 Page 2-29

Page 42

F08 Installation & Programming Manual Document No: LT0082

FIP Installation

2.12 BRIGADE INTERFACE RELAYS

The F08 FIP provides space below the Mains Transformer and Mains Switch for the

installation of the Brigade Interfacing Devices.

A brigade interface bracket is available for fitting the following brigade interfacing units:

(a) Randata Deltec

(b) Mimimux Deltec

(c) Tyco Centaur ASE

(d) Line Isolating Unit; LIU001

(e) Torrens Transponder Unit

(f) Transponder Interface Adaptor; TIA001

The F08 provides four (4) sets of voltage free, changeover relay contacts at connector J7, as

shown in Figure 2.17.

The four relays are detailed below.

2.12.1 “STANDBY” RELAY

(a) Normally energised coil, (COM closed to NO).

(b) The Standby Relay de-energises on battery flat voltage, complete battery

power failure, watchdog timeout, or disconnection of the Display/Keyboard flat

ribbon cable. (ie. COM switches from NO to NC).

(c) THIS RELAY MUST BE USED T O SIGNAL TO THE BRIGADE ON ANY OF

THE ABOVE CONDITIONS, unless otherwise notified by the local Fire

Authority.

(c) If no "STANDBY" signal is required by the local Fire Authority, it is

recommended that a "LOCAL FAULT" alarm be activated by the "STANDBY"

relay.

** REMEMBER: WHEN THE "STANDBY" RELAY DE-ENERGISES, THE SYSTEM IS

INDICATING THAT IT IS NO LONGER AN OPERATIONAL FIRE

ALARM PANEL.

2.12.2 “FAULT” RELAY

(a) Normally de-energised.

(b) The Fault Relay will energise on any non-isolated fault condition on a zone

mapped to the "MASTER ALARM" or the supervised Ancillary Output. ( COM

switches from NC to NO). It will also energise on all enabled zones being

isolated.

Page 2-30 24 March 2006 Issue 3.04

Page 43

Document No: LT0082 F08 Installation & Programming Manual

FIP Installation

2.12.3 “ISOLATE” RELAY

(a) Normally de-energised.

(b) The Isolate Relay will energise on Isolation of any zone mapped to "MASTER

ALARM" or the supervised Ancillary Output. (ie. COM switches from NC to

NO).

2.12.4 “ALARM” RELAY

(a) Normally de-energised.

(b) The Alarm Relay will energise on an Alarm condition on any non-isolated

zone that is mapped to "MASTER ALARM". (i.e. COM switches from NC to

NO).

- Two sets of alarm contacts are provided, labelled "ALARM A" and

"ALARM B".

Normally "ALARM A" is used for brigade signalling and "ALARM B" is

used for Door Holders or other alarm functions.

NOTES:

(a) Some brigade interfaces require +24 VDC and 0 VDC, use "+VBF" and "0V"

terminals.

(b) Refer to instructions supplied with the Brigade interfacing units for connection

details.

Issue 3.04 24 March 2006 Page 2-31

Page 44

F08 Installation & Programming Manual Document No: LT0082

FIP Installation

/\/\/\/\/\/\/\/\/\/\/│

│├─┤ │

││Q│ +VB │ <─┐

│├─┤ │ │

││Q│ +VB │ <─┴── Use these terminals, if +24 VDC

│├─┤ │ Battery Backed voltage required

││Q│ +VNB │

│├─┤ │

││Q│ 0V │ <──── Use this terminal if 0 VDC is

└┴─┘ │ required

J7 │

┌┬─┐ ───── │

││Q│ COM │

│├─┤ │

STANDBY ││Q│ NC │ <──── "STANDBY" relay NORMALLY ENERGISED

│├─┤ │ (COM closed to NO)

││Q│ NO │

├┼─┤ ───── │

││Q│ COM │

│├─┤ │

FAULT ││Q│ NC │

│├─┤ │

││Q│ NO │

├┼─┤ ───── │

││Q│ COM │

│├─┤ │

ISOLATED ││Q│ NC │

│├─┤ │

││Q│ NO │

├┼─┤ ───── │

││Q│ COM │

ALARM │├─┤ │

(FIRE) ││Q│ NC │

│├─┤ │

││Q│ NO │

└┴─┘ │

/\/\/\/\/\/\/\/\/\/\/

\/\/\/\/\/\/\/\/\/\/\

││Q│ +VNB │

│├─┤ │

││Q│ 0V │

│├─┤ ───── │

││Q│ BELLS+│

│├─┤ │

││Q│ 0V │

└┴─┘ ───── │

▄▄ │

││ │

▀▀ │

─────────────────────┘

Page 2-32 24 March 2006 Issue 3.04

Page 45

Document No: LT0082 F08 Installation & Programming Manual

FIP Installation

Figure 2.17

Brigade Relay Termination

Issue 3.04 24 March 2006 Page 2-33

Page 46

F08 Installation & Programming Manual Document No: LT0082

FIP Installation

2.13 DISPLAY & ZONE LABELLING

2.13.1 ZONE NAMING LABEL

The F08 Zone Labelling can be simply done on a typewriter or word-processor.

Note: For a typewriter use a photocopy of the label supplied with the panel or

provided in Appendix A.3.

The type format is:

6 lines per inch.

30 characters at 10 CPI or 36 characters at 12 CPI

Two and a half (2.5) lines between each zone window.

To install the Zone Naming label, loosen the four left hand-side screws that hold the Display

Assembly onto the inner door. Insert the zone label behind the Keyboard mylar and adjust

such that the zone labelling is aligned correctly. Fasten the four screws.

2.13.2 DISPLAY BOARD REMOVAL OR INSTALLATION

The F08 Display Board is attached to the rear of the internal door by five M4 x 12mm screws

and flat washers.

To remove the display board simply unplug the display FRC from J1 on the Main Board, then

remove all 5 screws.

Reverse the process to install the display board.

2.13.3 MYLAR REPLACEMENT

To replace the Keyboard Mylar requires the front six Phillips-Head screws on the inside door

to be removed, leaving the center two to last.

The Display Board assembly has to be held whilst replacing the Mylar.

Replace the center two screws first and adjust the Mylar such that LEDs are aligned

correctly. Fasten the two center screws first, then all other screws.

Page 2-34 24 March 2006 Issue 3.04

Page 47

Document No: LT0082 F08 Installation & Programming Manual

FIP Installation

2.14 DOCUMENTATION

The following documentation MUST be included inside the F08 panel:

(a) F08 Operator's Manual

(b) A Maintenance Log-Book

(c) An "AS INSTALLED" fire detection system diagram and/or summary describing the

installed layout of the F08 fire detection system.

Issue 3.04 24 March 2006 Page 2-35

Page 48

Page 49

Document No: LT0082 F08 Installation & Programming Manual

Placing into Operation

3. PLACING INTO OPERATION

Issue 3.04 24 March 2006 Page 3-1

Page 50

F08 Installation & Programming Manual Document No: LT0082

Placing into Operation

3.1 GENERAL

Before undertaking any placing into operation activities, inspect the unit interior visually.

Check that all panel equipment is securely mounted and that all cables are connected at the

appropriate points (see Figure 3.1).

3.2 MAINS ISOLATE SWITCH

To switch the F08 FIP ON or OFF, open the front protective door. The "MAINS ISOLATE

SWITCH" is located at the bottom of the cabinet, to the right of the mains transformer. This

switch controls the mains power supply to the panel, including the battery charger.

The normal position of this switch is ON and should only be turned OFF (ie MAINS

ISOLATED), when testing that the FIP will run on batteries, or when servicing the unit.

NOTE: The Battery is not disconnected by the "MAINS ISOLATE SWITCH".

Page 3-2 24 March 2006 Issue 3.04

Page 51

Document No: LT0082 F08 Installation & Programming Manual

Placing into Operation

Figure 3.1

F08 Internal View

Issue 3.04 24 March 2006 Page 3-3

Page 52

F08 Installation & Programming Manual Document No: LT0082

Placing into Operation

3.3 POWER UP

To place a correctly installed and programmed F08 FIP into operation perform the following

steps:

STEP 1 : Ensure that the Mains Isolate Switch is OFF and that 240VAC is

available to the panel from the mains distribution switchboard.

STEP 2 : Disconnect or physically isolate any outputs that must not be activated

as a result of an alarm or fault during commissioning. Eg Fire Brigade,

Alarm Bells or Suppression System.

STEP 3 : Turn the Mains Isolate Switch ON.

STEP 4 : Check that the green "MAINS ON" LED indicator is illuminated and all

other LED indicators are OFF.

STEP 5 : Perform a System Test.

(a) With the FIP in GLOBAL mode (all "SEL" LED indicators OFF)

Press the key once.

(b) The amber "ISO" LED indicators for Ancillary Relay, Master Alarm and Alarm

Bells will illuminate.

TEST

(c) After 5 seconds all LED indicators will illuminate and the internal sounder will

produce a steady tone for a period of 2 seconds.

(d) A fault test will be carried out on each enabled and non-isolated zone,

stepping through zones by illuminating the "SEL" and "FLT" LED indicators.

(e) An alarm test will be carried out on each enabled and non-isolated zone,

stepping through zones by illuminating "SEL" and "ALM" LED indicators.

(f) All indicators turn off. (Except MAINS ON)

(g) If a zone fault or alarm occurs during the test or the test fails, then check the

AZC connections.

STEP 6 : Install and connect the batteries.

Page 3-4 24 March 2006 Issue 3.04

Page 53

Document No: LT0082 F08 Installation & Programming Manual

Placing into Operation

POWER UP (CONTINUED)

STEP 7 : Perform a Battery Test.

(a) Select Battery/Charger ( By pressing SELECT until the Battery/Charger "SEL"

indicator is illuminated).

(b) Press the key once.

- The Battery/Charger "SEL" indicator will flash to indicate a battery test

is in progress.

TEST

- The test will take 1 minute to complete.

(c) If the Battery test fails the amber "FLT" LED indicator will flash;

i. Check battery connections;

ii. If the battery is flat, leave on charge for 24 hours and retest.

iii. Check Battery Low Monitoring circuit for correct operation.

STEP 8 : Perform an MCP test.

(a) Insert the plastic MCP test key into the MCP for a period of 2 to 3 seconds.

(b) The zone that the MCP is wired to should indicate an alarm by flashing its

"ALARM" LED and any programmed outputs should operate.

(c) Press the key once to clear the ALARM.

(d) Disconnect a wire at the MCP.

RESET

(e) The zone that the MCP is wired to should indicate a fault by a steady "FLT"

LED.

(f) Re-connect the wire to the MCP.

(g) Press the SELECT key until the MCP zone is selected.

Press the key once to clear the FAULT.

RESET

Issue 3.04 24 March 2006 Page 3-5

Page 54

F08 Installation & Programming Manual Document No: LT0082

Placing into Operation

3.4 COMMISSIONING CHECKLIST

The commissioning of an F08 FIP is the most important phase of any contract.

If any problems are not corrected in this stage, experience shows that even the simplest of

mistakes can cause major problems over a long period of time.

The following procedure should be regarded as the minimum requirements for a

commissioning check.

Please complete this checklist carefully. Some major points to be noted are:

1. Ensure that the F08 FIP is correctly programmed to meet statutory requirements and

the Customer's specifications.

2. Ensure the INSTALLATION meets the standards defined by AS1670.1 and any other

local standards.

3. Ensure that the "AS INSTALLED" drawing represents the TRUE site installation,

complete with;

(a) Detector location and types.

(b) F08 FIP Programmed Configuration.

4. Ensure that a copy of the "AS INSTALLED" drawing is included inside the panel for

maintenance purposes.

5. Ensure that a copy of the "F08 OPERATOR'S MANUAL" is included inside the panel

and the system detail pages are completed.

6. Ensure that interface devices are connected to the "AUXILIARY OUTPUTS" if these

outputs are used externally.

7. Ensure that only APPROVED brigade interfacing devices are connected to the

brigade relays; "STANDBY", "FAULT", "ISOLATE", and "ALARM" (FIRE).

- Approved interfaces include:

(a) Randata Deltec

(b) Minimux Deltec

(c) Torrens Transponder

via Transponder Interface Adapter - TIA001

(d) Line Isolating Unit - LIU001

(e) MFB - Alarm Interface Unit.

(f) Tyco Fire Monitoring - Centaur.

8. Ensure that all ENABLED ZONES, ANCILLARY RELAY and ALARM BELLS can be

isolated.

9. Ensure batteries are charged and that a battery test passes. Turn off the mains

switch and check the system operates off the batteries.

Page 3-6 24 March 2006 Issue 3.04

Page 55

Document No: LT0082 F08 Installation & Programming Manual

Placing into Operation

COMMISSIONING CHECKLIST (CONTINUED)

10. Ensure System and Zone Tests perform satisfactorily.

11. Verify the programming, wiring and operation of the system.

Ie Check for each zone:

a) Alarm and fault conditions can be generated.

b) The alarm delay is as the input type. Ie Normal, AVF, 1668 or Flow Switch.

c) The zone is enabled and latching or non-latching as required.

d) The appropriate outputs (Ancillary Relay, Auxiliary, Brigade and bells) operate

as programmed or wired.

e) The Ancillary Relay supervision detects open and short circuit faults, if it is

enabled.

Issue 3.04 24 March 2006 Page 3-7

Page 56

F08 Installation & Programming Manual Document No: LT0082

Placing into Operation

THIS PAGE INTENTIONALLY LEFT BLANK

Page 3-8 24 March 2006 Issue 3.04

Page 57

Document: LT0082 VIGILANT F08 Installation & Programming Manual

Programming

4. PROGRAMMING

Issue 3.04 24 March 2006 Page 4-1

Page 58

VIGILANT F08 Installation & Programming Manual Document: LT0082

Programming

4.1 PROGRAMMING FEATURES

The F08 FIP provides a "PROGRAMMING MODE" so that the installer can configure the

panel to meet specified input and output requirements.

Programming should only be carried out by a suitably qualified FIRE-PROTECTION

technician or engineer.

If the F08 FIP was pre-programmed prior to delivery, it may NOT NEED TO BE RE-

PROGRAMMED in the field.

The F08 "PROGRAMMING MODE" provides four (4) programming functions with

the programming keys and indications summarised in Tables 4.1 and 4.2.

FUNCTION 1; ZONE OUTPUT MAPPING

This programming function allows the programmer to select which of the zone inputs will

operate each of the following outputs:

i. Ancillary Relay

ii. Master Alarm

iii. Alarm Bells.

FUNCTION 2; ZONE LATCHING / NON-LATCHING

This programming function enables the programmer to select zone inputs as alarm state

latching or non latching and fault state latching or non-latching.

FUNCTION 3; ZONE INPUT TYPE

This programming function enables the programmer to select for each zone, one of the

following input types. (Refer Section 2.7.2 for a full description):

i. 2 second transient suppression delay to alarm (default). Both detectors and 15V

MCP allowed on circuit.

ii. AVF/RAD 16 second delay to alarm for detectors, 2 second delay to alarm for 15V

MCP.

iii. AS1668 SAD. Delay into alarm 2 seconds. Delay out of alarm 60 seconds.

Detector is non-latching and zone should be programmed as non-latching.

iv. AS1668 AVF/SAD. 16 second AVF delay into alarm. Delay out of alarm 60

seconds. Detector is non-latching and zone should be programmed as non-latching.

v. Flowswitch. 20 second delay into alarm. No delay out.

vi. 2 second delay to alarm. Detectors only. MCP not allowed. 13-17V band indicates

fault. This circuit type is used to provide line leakage fault indication.

vii. AVF/RAD 16 second delay into alarm. Detectors only - MCP not allowed. 13-17V

band indicates fault. This circuit type is used to provide line leakage fault indication.

viii. Fast alarm - 0.5 seconds delay into alarm for supervisory contact with 15V zener

diode. This is typically used for sub-panel monitoring. 0-13V band indicates fault.

ix. Fast alarm - 500 milliseconds delay into alarm for 0-13V band. 13-17V band is

normal for 15V loop powered circuit.

x. Delay into alarm is 2 seconds for 13-17V band. 0-13V band is normal for normally

closed (S/C) circuit.

Page 4-2 24 March 2006 Issue 3.04

Page 59

Document: LT0082 VIGILANT F08 Installation & Programming Manual

Programming

PROGRAMMING FEATURES (CONTINUED)

FUNCTION 4; ZONE & ANCILLARY RELAY SUPERVISION - ENABLED / DISABLED;

AUXILIARY ZONE OUTPUT OPERATION MODE

This programming function enables the programmer to select which zone inputs are enabled

and also select whether or not the Ancillary Relay Output is Supervised. Disabled zones do

not require EOL units and are inhibited from any zone or system tests.

This function is also used to select whether or not isolating a zone forces the auxiliary zone

output to be off - this is a single global parameter which applies to all eight zones.

┌─────────────────────────┬──────────┬─────────────────────────────┐

│ FUNCTION │PRESS KEY │ COMMENTS │

╞═════════════════════════╧══════════╧═════════════════════════════╡

│┌────────────────────────┬──────────┬────────────────────────────┐│

││ ENTER PROGRAMMING │ PROGRAM │Located on Main Board ││

││ MODE │ │PRESS & HOLD FOR 4 BEEPS ││

││ │ │-Zone Output Mapping ││

││ │ │entered for "ANCIL RELAY" ││

│└────────────────────────┴──────────┴────────────────────────────┘│

│ │

│┌────────────────────────┬──────────┬────────────────────────────┐│

││ EXIT PROGRAMMING MODE │ PROGRAM │Sounder on Continuously ││

││ │ │-Select one EXIT FUNCTION: ││

│├────────────────────────┼──────────┼────────────────────────────┤│

││ 1. EXIT WITHOUT │ TEST │Parameters NOT changed ││

││ SAVING CHANGES │ │-EXITS TO NORMAL OPERATION ││

│├────────────────────────┼──────────┼────────────────────────────┤│

││ 2. EXIT AND SAVE │ SELECT │Parameters SAVED in EEPROM ││

││ CHANGES │ │with any changes made. ││

││ │ │-EXITS TO NORMAL OPERATION ││

│├────────────────────────┼──────────┼────────────────────────────┤│

││ 3. RESET TO DEFAULT │ RESET │Parameters forced to default││

││ PARAMETERS │ │state. ││

││ │ │-REMAINS IN PROGRAMMING MODE││

│└────────────────────────┴──────────┴────────────────────────────┘│

└──────────────────────────────────────────────────────────────────┘

Table 4.1

Programming Key Summary - Entering/Exiting Programming Mode

Issue 3.04 24 March 2006 Page 4-3

Page 60

VIGILANT F08 Installation & Programming Manual Document: LT0082

Programming

FUNCTION PRESS KEY INDICATED BY

1. Enter into Zone Output

Mapping

TEST Ancil Relay “SEL” LED Flashing

Output “ISO” LEDs Flashing

Select Output for Mapping TEST Selected Output “SEL” LED Flashing

Select Zones SELECT Selected Zone “SEL” LED ON

Output “SEL” LED Flashing

Zone Mapped to Selected

Output

TEST “ALM” LED Steady = MAPPED

(TOGGLE) “ALM” LED Off = NOT MAPPED

2. Enter into Zone Latching/

Non-Latching Programming

RESET Selected Zone “SEL” LED ON

Zone fault state non-latching indicated

by zone fault LED ON. Zone alarm

state non-latching indicated by zone

alarm LED ON.

Select Zone SELECT Selected Zone “SEL” LED ON

Toggle as Latching or Non-

Latching

RESET Fault/Alarm LED ON = Non-latching,

LED OFF = Latching.

(CYCLES)