Page 1

CXP Receptacle Assembly

NOTE

i

CAUTION

!

CAUTION

!

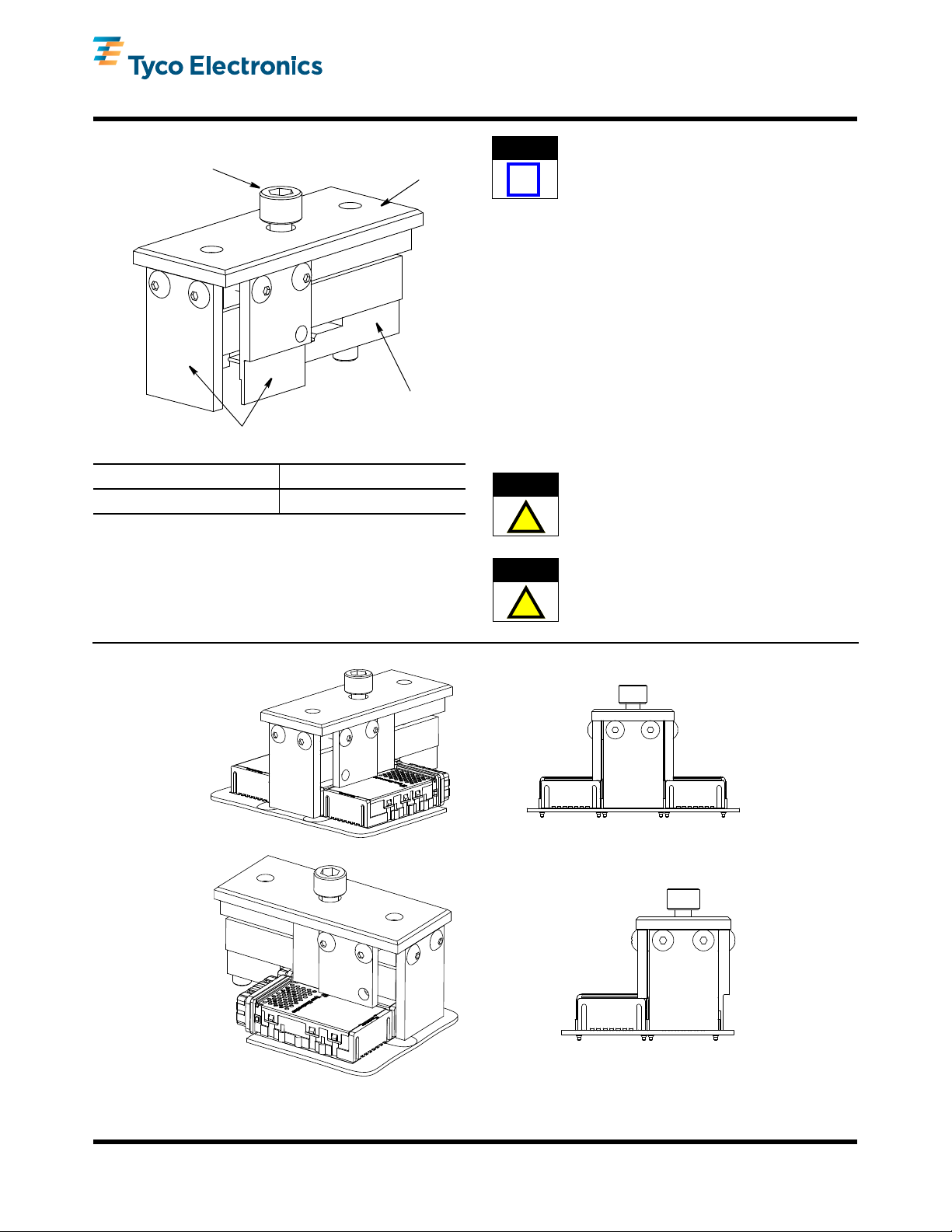

Extraction Screw

Upper Tooling

Assembly

Removal Blade

Assembly

Side Plates

Removal Tool

2161060-1

REMOVAL TOOL CONNECTOR DESCRIPTION

2161060-1 CXP Receptacle Assembly

Figure 1

Instruction Sheet

408-10415

14 DEC 10 Rev A

Dimensions in this instruction sheet are in

millimeters [with inches in brackets]. Figures and

illustrations are for reference only and are not

drawn to scale.

Read these instructions and understand them before

using the removal tool.

2. DESCRIPTION

The tool consists of a removal blade assembly, and an

upper tooling assembly. See Figure 1.

The side plates of the upper tooling assembly push on

the pc board surface while removing the receptacle.

The removal blade assembly engages the receptacle

and pulls it from the pc board. The extraction screw

draws the removal blade assembly up and pulls the

CXP receptacle assembly up and off of the pc board.

3. REMOVAL PROCEDURE

There are (4) M2 screws holding the receptacle

assembly to the pc board. These M2 screws must

be removed prior to removing the receptacle

assembly.

ORIGINAL INSTRUCTIONS

1. INTRODUCTION

The CXP Receptacle Assembly Removal Tool

2161060-1 is designed to remove the conne cto r listed

in Figure 1 from the printed circuit (pc) board.

Be certain to remove tool assembly does not

contact any components on the pc board during

use. To prevent damage, the side plates can be

routed to clear adjacent components. See Figure 2.

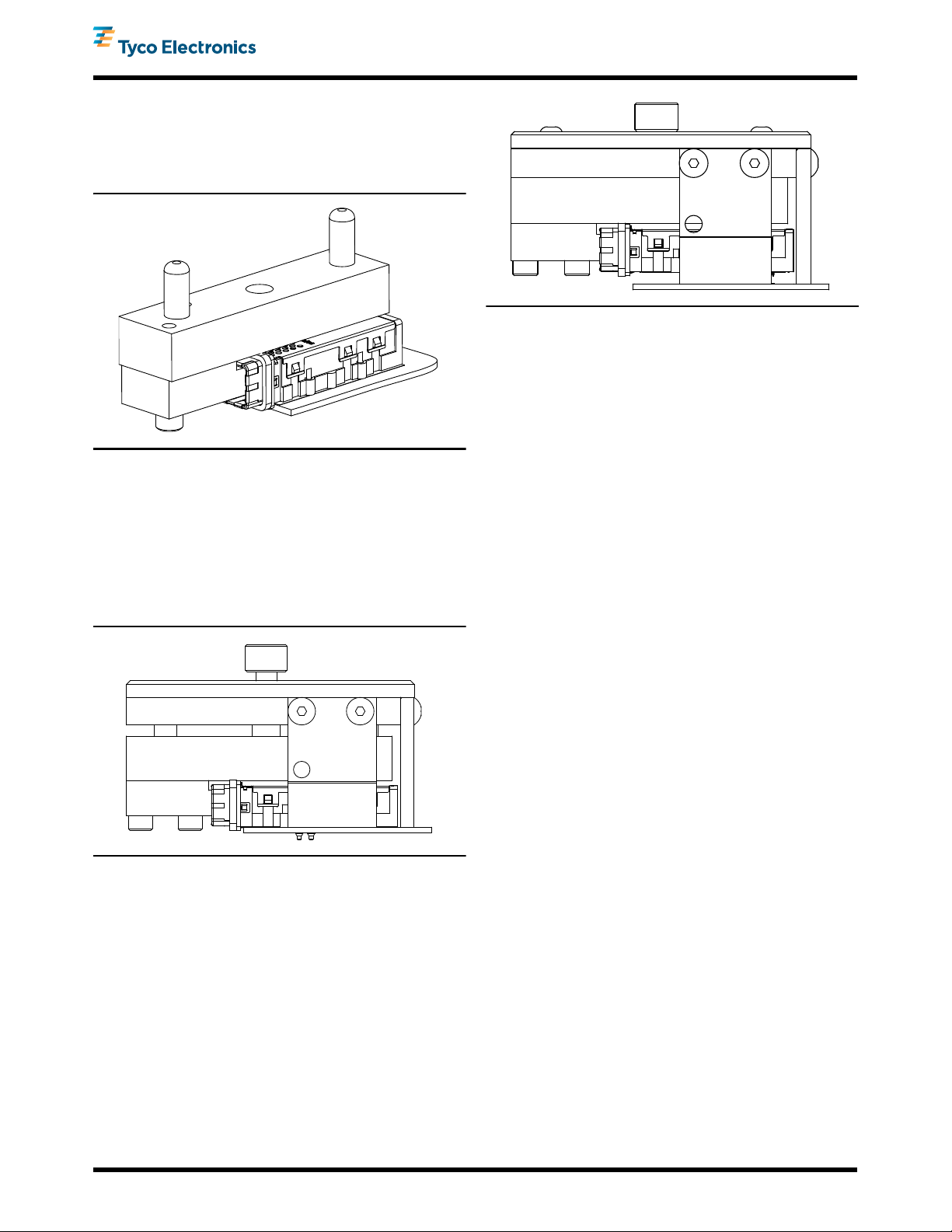

Figure 2

©2010 Tyco Electronics Corporation, Berwyn, PA

All Rights Reserved

TE logo and Tyco Electronics are trademarks.

*Trademark. Other products, logos, and company names might be trademarks of their respective owners.

TOOLING ASSISTANCE CENTER 1-800-722-1111

PRODUCT INFORMATION 1-800-522-6752

This controlled document is subject to change.

For latest revision and Regional Customer Service,

visit our website at www.tycoelectronics.com

1 of 2

LOC B

Page 2

1. Disassemble the upper tooling assembly and

removal blade assembly by unscrewing the

extraction screw.

2. Insert the removal blade assembly into the

receptacle. See Figure 3.

Figure 3

3. Properly orient the side plate(s) of the upper

tooling assembly based on any adjacent receptacle

assembly(s). See Figure 2.

4. Position the upper tooling assembly over the pins

in the blade removal assembly. Lower the upper

tooling assembly until the side plates contact the pc

board. See Figure 4.

408-10415

Figure 5

4.1. Daily Maintenance

It is recommended that each operator be made aware

of, and responsible for, the following steps of daily

maintenance:

1. Remove dust, moisture, and other contaminants

with a clean, soft brush, or lint-free cloth. DO NOT

use objects that could damage the tool or any of its

components.

2. When the tool is not in use, store it in a clean, dry

area.

4.2. Periodic Inspection

Regular inspections should be performed by quality

control personnel. A record of scheduled inspections

should remain with the tool or be supplied to personnel

responsible for the tool. The inspection frequency

should be based on the amount of use, working

conditions, operator training and skill, and established

company standards.

Figure 4

5. Tighten the extraction screw to remove the

receptacle assembly from the pc board. See

Figure 5.

4. MAINTENANCE AND INSPECTION

It is recommended that the tool be inspected

immediately upon its arrival to ensure that it has not

been damaged during shipment.

5. REPLACEMENT AND REPAIR

Order tools through your representative, or call

1-800-526-5142, or send a facsimile of your purchase

order to 717-986-7605, or write to:

CUSTOMER SERVICE (038-035)

TYCO ELECTRONICS CORPORATION

PO BOX 3608

HARRISBURG PA 17105- 3608

For customer repair service, call 1-800-526-5136.

6. REVISION SUMMARY

•Initial release of document

Rev A

2 of 2

Loading...

Loading...