Page 1

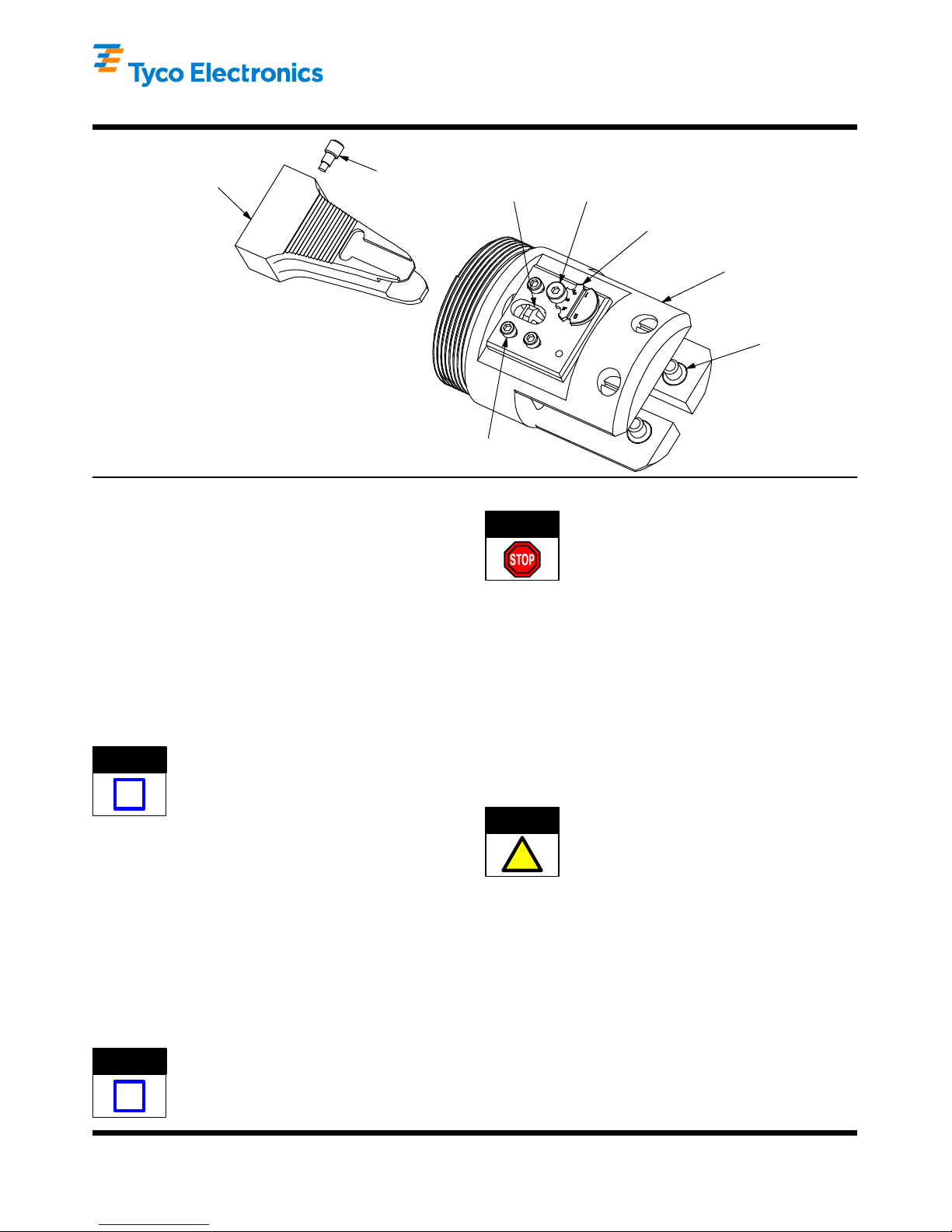

Cam

Pneumatic CERTI- CRIMP* Tool

Holder 356304 - 1 (For Use with 626

Eccentric

Cam

Setscrew

Ratchet

Pawl

Adjustment

Screw

Instruction Sheet

408--4321

11 MAR 10 Rev CPneumatic Tooling Assemblies)

Adjustable

Eccentric

Tool Holder

Body

Applicable Crimp Head Adapters:

Straight Action Crimper 217200--1

Heavy--Head Pneumatic Adapter 318453--1

Modular Plug Adapter 318510--1

Straight Action Crimp Head Adapter 217201--1

“T”--HEAD* Pneumatic Adapter 217202--1

C--Head Pneumatic Adapter 318161--1

Securing Screw (3 Places)

Figure 1

1. INTRODUCTION

Pneumatic CERTI--CRIMP Tool Holder 356304--1 is

used in conjunction with 626 Pneumatic T ooling

Assemblies 189721--1 or 189722--1 to crimp various

types of connectors. The tool holder is designed to

accept interchangeable crimp head adapters (listed in

Figure 1) which hold various crimping die assemblies.

For questions concerning the setup and operation of

the pneumatic tools, refer to Customer Manual

409--5862.

Read these instructions thoroughly before installing

the crimp head adapters and using the tool holder.

NOTE

i

Reasons for reissue of this sheet are provided in

Section 7, REVISION SUMMARY.

Dimensions are in millimeters [with inch

equivalents in brackets]. Figures and illustrations

are for identification only and are not drawn to

scale.

2. DESCRIPTION (Figure 1)

The tool holder consists of a tool holder body, cam,

cam setscrew, adjustable eccentric, pivot pins, and

ratchet pawl with emergency release. The ratchet

ensures that the tool completes the crimp cycle.

Pivot Pin

(4 Places)

DANGER

If the piston is not extended, it must first be extended

to allow installation of the cam. To extend the piston,

firmly grasp the piston with piston pliers and pull away

from the body of the tool. Piston pliers are provided

with the power unit.

A strip of adhesive--backed safety labels, printed in

various languages, is packaged with the tool holder.

Remove the appropriate language label from the strip

and attach it to the tool holder body.

CAUTION

!

Proceed as follows:

1. If cam setscrew is not installed in cam, thread

setscrew into cam two to three turns. See Figure 2.

Air pressure must be removed from the tool while

head or tool holder is detached.

Be sure to use the correct combination of cam

and tool holder. If incorrect combination is used,

system will not operate properly.

ORIGINAL INSTRUCTIONS

3. INSTALLATION PROCEDURE

3.1. Tool Holder Installation

NOTE

i

E2010 Tyco Electronics Cor poration, Berwyn, PA

All Rights Reserved

TE logo and Tyco Electronics are trademarks.

*Trademark. Other product names, logos, or company names might be trademarks of their respective owner s.

Previously installed cams and tool holders must

be removed before installing different ones.

Removal is the reverse of installation.

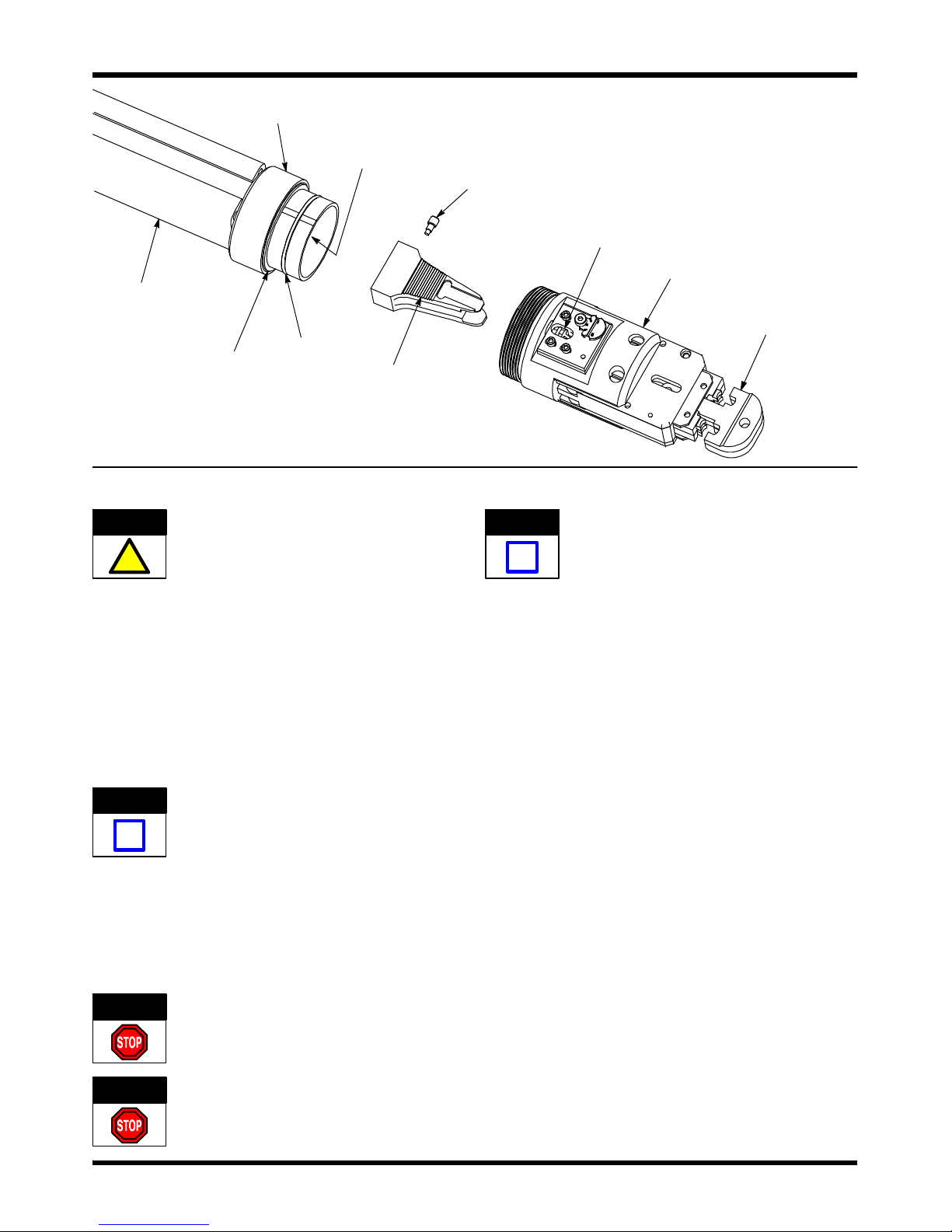

2. Place cam (with setscrew) onto piston rod. The

cam should butt against the piston rod face. If not,

turn cam setscrew counterclockwise until cam fits

on piston rod properly.

3. Tighten cam setscrew, then pull on cam to

ensure that it is firmly attached.

TOOLING ASSISTANCE CENTER 1--800--722-- 1111

PRODUCT INFORMATION 1--800--522--6752

This controlled document is subject to change.

For latest revision and Regional Customer Service,

visit our website at www.tycoelectronics.com

1 of 4

LOC B

Page 2

Pneumatic CERTI- CRIMP Tool Holder 356304- 1

Locking

Ring

Piston

Rod

Cam

Setscrew

Ratchet

Pawl

408- 4321

Tool

Holder

Pneumatic Tooling

Assembly (Power

Unit) (Ref)

Friction

Ring

Cam

Teeth

CAUTION

Stop

Ring

Over--tightening the cam setscrew may damage

the setscrew or cam.

!

4. Properly align tool holder ratchet pawl with the

cam teeth and push tool holder onto power unit so

that it passes over the friction ring on the power

unit piston. See Figure 2.

5. Slide power unit locking ring toward tool holder

until it butts against the stop ring on the power unit.

Then turn ring clockwise to engage threads on the

bottom of the tool holder. Tighten locking ring to

fully secure the tool holder.

NOTE

i

6. Rotate the tool holder one full turn in each

direction and note that the power unit locking ring

rotates with the tool holder.

DANGER

When tool holder is properly installed, the locking

ring should be butted against the stop ring, and

threads of the tool holder should not be visible. If

not properly installed, check that correct

combination of cam and tool holder is used and

that they are aligned properly.

T o avoid personal injury, periodically check that

locking ring is tightly securing the tool holder.

Crimp Head

Adapter (Ref)

Figure 2

NOTE

Removal is the reverse of installation.

i

3.2. Crimp Head Adapter and Crimping Die Installation

Refer to the instruction sheet packaged with the crimp

head adapter for the particular product to be crimped.

4. CRIMP HEIGHT ADJUSTMENT

The tool holder features an adjustable eccentric and a

ratchet mechanism with a range of settings. The

position of the pawl ensures that the tool completes

the cycle. The eccentric controls the amount of cam

pressure exerted on the crimping dies during the

crimping procedure. Although the ratchet is preset

prior to shipment, it is important that you verify the

crimp height. Also, general use and subsequent wear

may cause the tool to go out of adjustment. It is

recommended that the crimp height be inspected, and

adjusted, if necessary, on a regular basis by quality

control personnel.

1. Connect pneumatic tooling to an adequate air

supply between 620--690 kPa [90--100 psi]. For

specific information on air line requirements and air

hose installation, refer to the instructions packaged

with the pneumatic tooling assembly.

2. Place a contact in the crimp nest and place a

properly prepared wire of the correct size into the

wire barrel.

DANGER

After installation, ALWAYS ensure that the tool

holder pivot pins are fully tightened to avoid

personal injury or damage to the tool.

3. Place a .025--mm [.001--in.] shim between the

crimping dies where the dies bottom against each

other.

Rev C2 of 4 Tyco Electronics Corporation

Page 3

Pneumatic CERTI- CRIMP Tool Holder 356304- 1

408- 4321

4. Slowly crimp the contact onto the wire until the

crimping dies bottom on the shim. Check that the

ratchet releases after the dies bottom.

DANGER

5. If the ratchet releases before the dies bottom,

loosen the three securing screws, remove the

eccentric adjustment screw (refer to Figure 1) and

rotate the eccentric clockwise to a higher setting.

Tighten the securing screws. Repeat as required.

NOTE

i

Ratchet Pawl with

Emergency Release

6. If the ratchet does not release after the crimping

dies bottom, loosen the three securing screws,

remove the eccentric adjustment screw and rotate

the eccentric counterclockwise to a lower setting.

Tighten the securing screws. Repeat as required.

7. If the crimp cannot be made to conform to the

dimensions provided in the appropriate application

specification, the crimp head adapter and/or

crimping dies are defective and must be replaced.

Before adjusting the ratchet pawl position,

DISCONNECT THE TOOL FROM THE AIR

SUPPL Y. After the adjustment, ALWAYS ensure

that the tool holder pivot pins are fully tightened

to avoid personal injury or damage to the tool.

If the ratchet does not release and the tool will

not return, slowly actuate the tool until the force

of the cam teeth is off the pawl, then push on the

pawl with a small screwdriver until the pawl is

released from the teeth, release the tool switch

and allow the tool to return. See Figure 3.

Press Pawl with

Screwdriver

Figure 3

5. MAINTENANCE AND INSPECTION

DANGER

Tyco Electronics recommends that a maintenance

and inspection program be performed periodically to

H Trademark of Dow Corning Corporation

To avoid injury, DISCONNECT TOOL FROM AIR

SUPPL Y before performing any maintenance or

inspection procedures.

ensure dependable and uniform terminations. The

tool holder should be inspected once a week.

Frequency of inspection should be adjusted to suit

your requirements through experience, and depends

on:

S Care, amount of use, and handling of tool

holder

S Type and size of the products crimped

S Degree of operator skill

S Presence of abnormal amounts of dust and dirt

S Your own established standards.

The tool holder is thoroughly inspected before

packaging. Since there is the possibility of damage

during shipment, the tool holder should be inspected

immediately upon arrival at your facility.

5.1. Maintenance

A. Cleaning

Remove dust, moisture, and other contaminants with

a clean, soft brush, or a soft, lint--free cloth. Do NOT

use objects that could damage the tool. Lubricate tool

holder as instructed in Paragraph 5.1,B, Lubrication,

before placing the it back into service.

B. Lubrication

Lubricate all pins, pivot points, and bearing surfaces

with a high quality grease. Tyco Electronics

recommends the use of MolykoteH grease, which is a

commercially available lubricant. Lubricate according

to the following schedule:

Holder used in daily production—lubricate daily

Holder used daily (occasional)—lubricate weekly

Holder used weekly—lubricate monthly

Wipe excess grease from tool holder, particularly from

die closure areas. Grease transferred from the die

closure area onto certain terminations may affect the

electrical characteristics of an application.

5.2. Periodic Inspection

Regular inspections of the tool holder should be

performed by quality control personnel. A record of

scheduled inspections should remain with the tool

holder or be supplied to supervisory personnel

responsible for the tool holder. Inspection frequency

should be based upon amount of use, working

conditions, operator training and skill, and established

company standards.

1. Inspect the tool holder for missing pins or parts.

If parts are missing or defective, replace them by

referring to Figure 4.

2. Check all bearing surfaces for wear. Replace

any worn parts.

3. Inspect crimping dies for flattened, chipped, or

broken areas. Worn or damaged surfaces are

objectionable and will affect the quality of the

crimp.

3 of 4Rev C Tyco Electronics Corporation

Page 4

Pneumatic CERTI- CRIMP Tool Holder 356304- 1

408- 4321

4. When the tool holder is not in use, store in a

clean, dry area.

6. REPLACEMENT AND REPAIR

Replacement parts and recommended spares are

listed in Figure 4. The recommended spares should

be stocked for immediate replacement. Order

replacement parts through your Tyco Electronics

Representative or call 1--800--526--5142, or send a

facsimile of your purchase order to 1--717--986--7605,

or write to:

10

CUSTOMER SERVICE (38--35)

TYCO ELECTRONICS CORPORATION

PO BOX 3608

HARRISBURG PA 17105--3608

Tools may also be returned to Tyco Electronics for

evaluation and repair. For tool repair service, contact

a Tyco Electronics Representative at:

1--800--526--5136.

7. REVISION SUMMARY

The following changes were made since the previous

release of this sheet:

S Updated document to corporate requirements

S Added ORIGINAL INSTRUCTIONS

9

2

6

1

4

REPLACEMENT PARTS AND RECOMMENDED SPARE PARTSG

ITEM PART NUMBER DESCRIPTION

1 356623--1 CAM 1

2 356439--1 ECCENTRIC 1

3 356624--1 TOOL HOLDER BODY 1

4 356441--1 PAWL, Ratchet 1

5 4--21028--9 PIN, Slotted Spring, .125 x .375 1

6

7 356437--1 PLATE, Eccentric Adjustment 1

8 9--21000--0 SCREW, Socket Head Cap, 4--40 x .31 3

9 21989--3 SCREW, Socket Head Shoulder, .125 x .25 1

10

11 37887 SPRING 1

354425--1G

189765--1G

PIN, Pivot 4

SETSCREW, Special 1

Figure 4

8

5

7

11

3

QTY PER

TOOL HOLDER

Rev C4 of 4 Tyco Electronics Corporation

Loading...

Loading...