Page 1

Instruction Sheet

NOTE

i

NOTE

i

NOTE

i

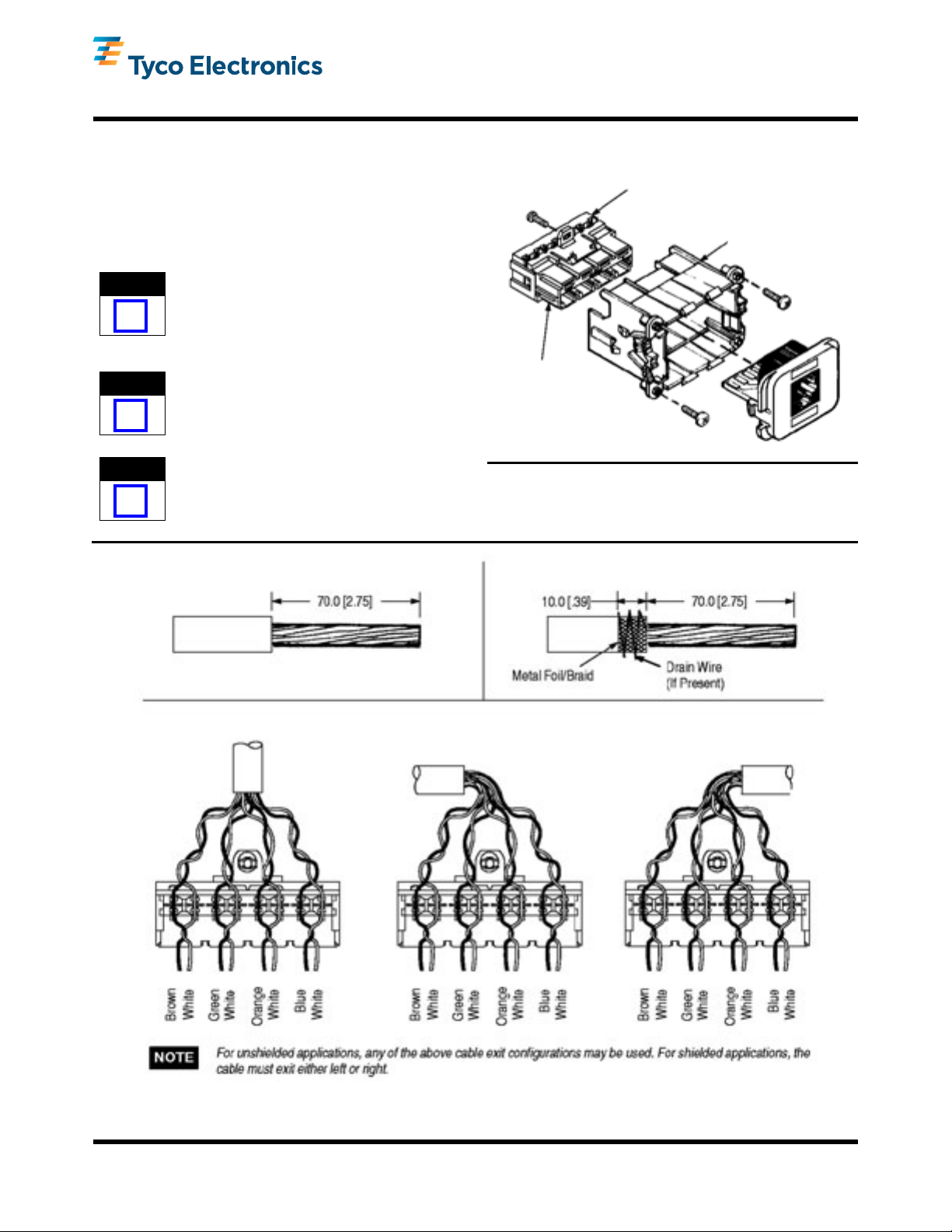

Cover

Single Port

Housing

110Connect

Card Edge

Connector

Unshielded Applications Shielded Applications

Exit Left Exit Right

AMP Communications Outlet (ACO)

Single Port Kits (Cat 6)

1. INTRODUCTION

This instruction sheet provides termination and

installation procedures for ACO Single Port Kits. The

kits can be used in panel mount or furniture raceway

applications. Optional faceplate kits and various

adapter insert assemblies are available to meet either

application.

Dimensions on this sheet are in millimeters [with

inches in brackets]. Figures are not drawn to scale.

2. TERMINATION PROCEDURES

The 110Connect card edge connector comes preinstalled in a single port housing. The single port

housing functions as a secure holding fixture while

terminating.

The edge connector is approved for use with 22

through 24 AWG solid wire with a maximum outside

insulation diameter of 1.6 mm [.06 in.] (100 ohm

UTP or STP).

408-8700

05 JAN 11 Rev A

Figure 1

Figure 2

©2011 Tyco Electronics Corporation, Berwyn, PA

All Rights Reserved

TE logo and Tyco Electronics are trademarks.

*Trademark. Other products, logos, and company names might be trademarks of their respective owners.

TOOLING ASSISTANCE CENTER 1-800-722-1111

PRODUCT INFORMATION 1-800-522-6752

This controlled document is subject to change.

For latest revision and Regional Customer Service,

visit our website at www.tycoelectronics.com

1 of 4

LOC B

Page 2

408-8700

NOTE

i

NOTE

i

Housing

Latch

Pins

Cover

47.75 [1.88]

(Approx)

33.27 [1.31]

(Approx)

Panel

Cutout

2.1. Unshielded Applications

1. Remove approximately 70.0 mm [2.75 in.] of the cable jacket.

2. Determine the direction of the cable exit. Using any of the configurations in Figure 2, arrange pairs accordingly.

It is recommended to maintain the pair twists to

within 6.4 mm [.25 in.] of the termination with

Category 6 cables

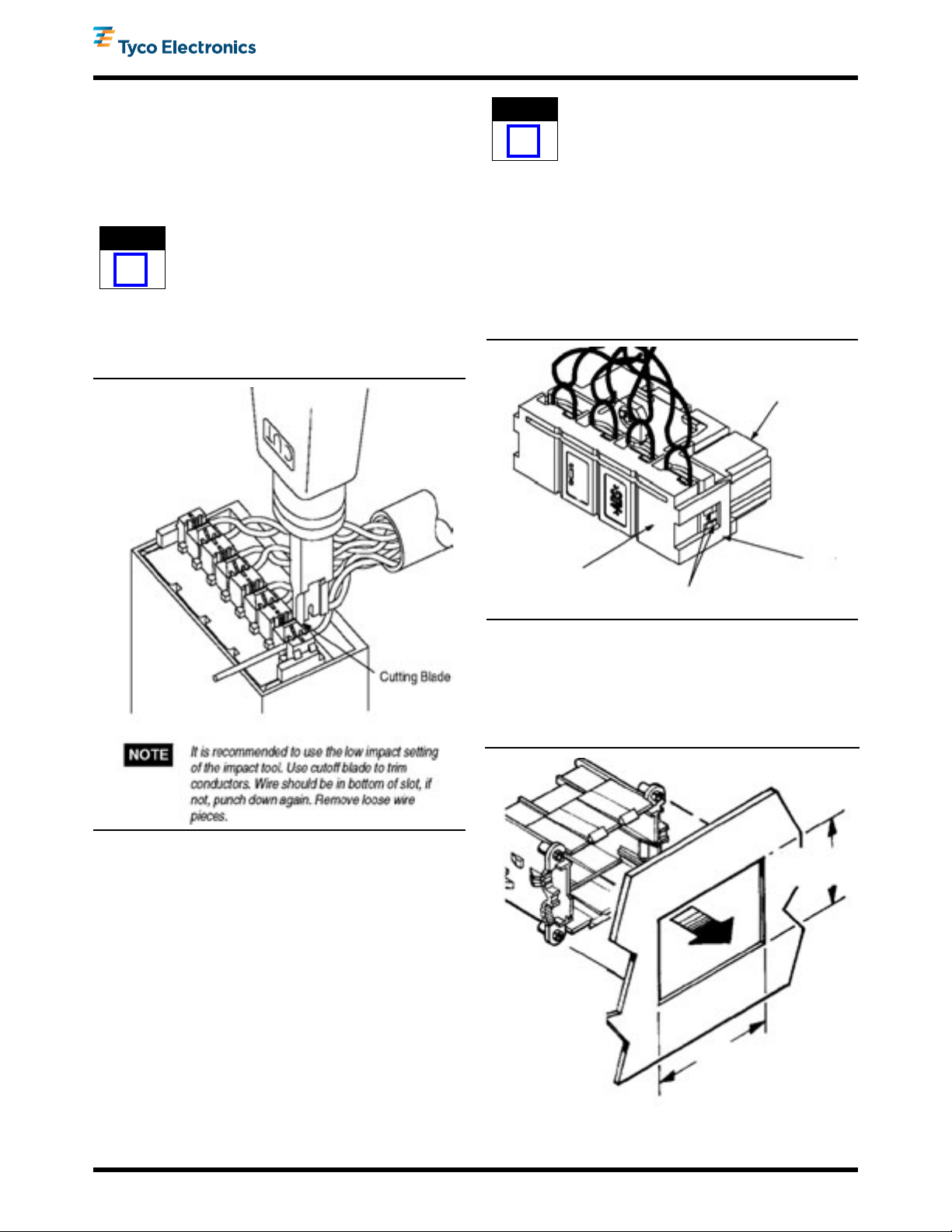

3. Terminate conductors using Impact Tool 558418-1, 569994-1, 346859-1, or 1375308-1. See Figure 3.

It is recommended to maintain the pair twists to

within 6.4 mm [.25 in.] of the termination with

Category 6 cables

5. Terminate conductors using Impact Tool 558418-1, 569994-1, 346859-1, or 1375308-1. See Figure 3.

3. INSTALLING COVER

Mate cover as shown in Figure 4. Make sure latches on cover enter to all pins in the housing. Listen for the double click, which indicates correct connection.

Figure 3

2.2. Shielded Applications

1. Remove approximately 70.0 mm [2.75 in.] of the cable jacket.

2. Remove 60.0 mm [2.36 in.] of the metal foil/braid. Fold the 10.0 mm [.39 in.] metal foil/braid back over the cable jacket as shown in Figure 2.

3. If a drain wire exists, do not remove it. Wrap all of the drain wire around the metal foil/braid.

4. Determine the direction of the cable exit (either left or right). Using the template in Figure 2, arrange pairs accordingly.

Figure 4

4. PANEL MOUNT

4.1. Unshielded Option

1. Snap housing into back of panel.

(Figure 5)

Figure 5

Rev A

2 of 4

Page 3

2. Install two No. 2 screws into two posts located

Screw

Serrated Washer

Housing Post

Existing Panel

Cutout

68.6 [2.70]

(Approx)

35.05 [1.38] (Approx)

228.5 to 457.2

[9 to 18]

Bezel

Adapter

Housing

NOTE

i

NOTE

i

Shield Clip

Guide

Latches

Remove to

Fit Cable

diagonally apart. Tighten screws to clamp housing

to panel. See Figure 6.

Figure 6

4.2. Shielded Option (Grounding Option)

Inserting the housing into a metal panel will ground the housing; however, if an absolute electrical ground is required, proceed as follows:

1. Press the two No. 4 serrated washers onto two diagonal posts of the housing. See Figure 7.

408-8700

Figure 7

2. Snap housing into BACK of panel.

3. Install the two No. 2 screws onto the two posts which hold the serrated washers. Tighten screws to clamp housing to panel. See Figure 6.

5. FURNITURE RACEWAY (Figure 8)

1. Pull cable through panel cutout.

2. Snap housing into BACK of bezel adapter.

3. If using furniture raceway faceplate kits, snap the bezel adapter and housing assembly into the raceway opening.

6. SHIELDED APPLICATIONS

1. Break away a portion of the tab on the side of the metal shield (side oriented with cable exit). See Figure 9.

Figure 8

To minimize electromagnetic interference (EMI),

remove a small portion of the tab at a time to

provide a tight fit around the cable shield.

To ensure optimum performance, be sure to follow

national and local grounding ("earthing"), bonding,

and EMC regulations and procedures.

2. Install shield clip as shown in Figure 9. Shield clip should make contact with metal braid.

Figure 9

Rev A

3 of 4

Page 4

3. Slide the metal shield onto the guides on the

Blank Insert

CAUTION

!

BACK of the housing. Push shield over housing until

all four latches snap into place.

7. INSTALLATION OF INSERTS

1. Install connector inserts by pushing the insert into the appropriate port. Align insert latches with tabs on the edge of the housing. If a port is not used, install a blank insert into the port. See Figure 10.

Figure 10

408-8700

Figure 12

9. BEZEL ADAPTER REMOVAL

Release each corner latch with the blade of a small screwdriver while pulling outward lightly on the bezel adapter. See Figure 13.

2. If installing the faceplate kit, align and press the faceplate onto the FRONT of the housing. See Figure 11.

Figure 11

8. CONNECTOR INSERT REMOVAL

1. Pull the faceplate straight out or pry the faceplate at the slot on each side.

2. Insert a small screwdriver blade into the gap on the side of the insert (between the insert and the tab on the edge of the housing). As each latch disengages, rock the insert to release the side. See Figure 12.

3. Repeat procedure on the other side; then remove insert.

Do NOT try to pry insert out.

Figure 13

10. REVISION SUMMARY

Since the previous release of this instruction sheet, the TE logo has been applied.

Rev A

4 of 4

Loading...

Loading...