Page 1

Instruction Sheet

WireSizeRange

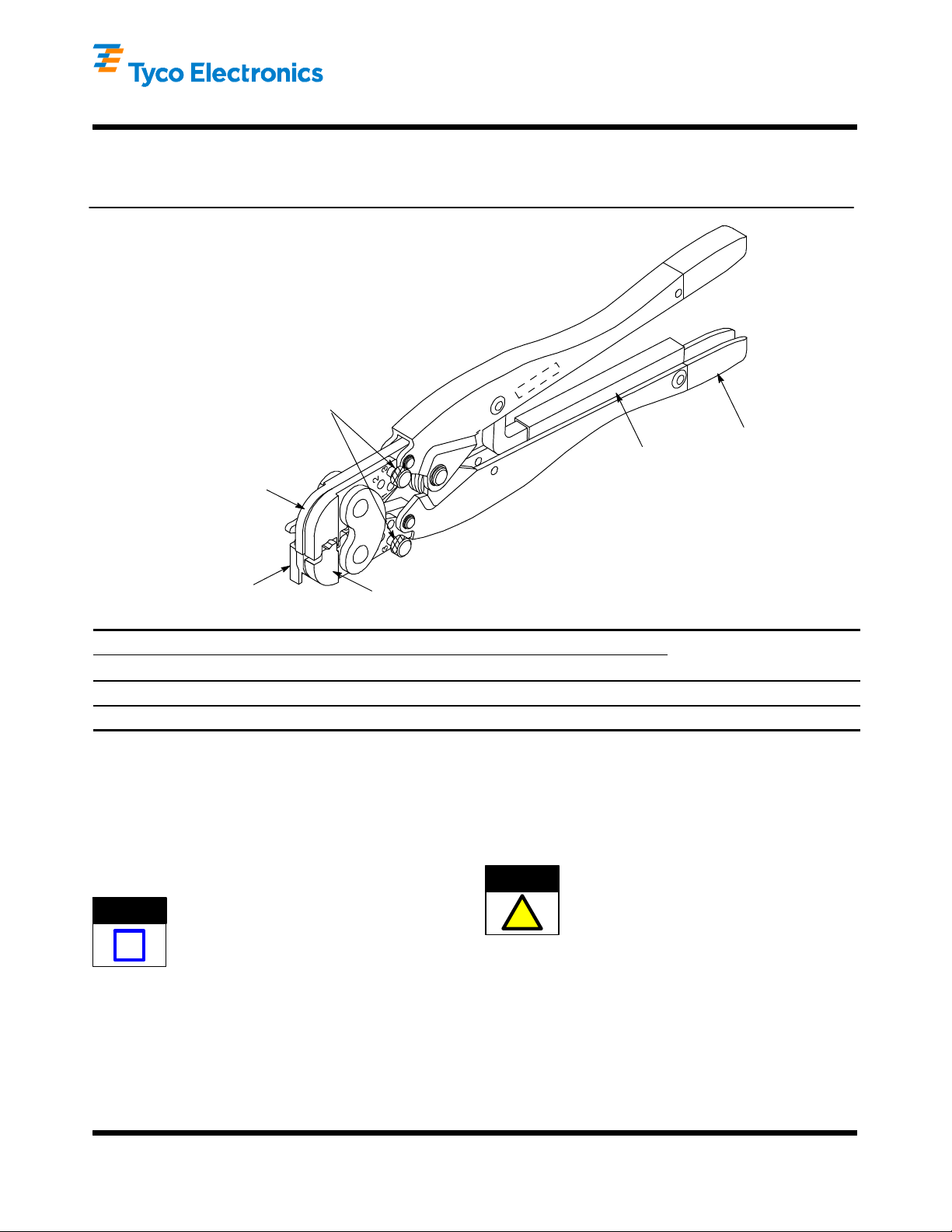

Double Action Hand Crimping Tools

PROPER USE GUIDELINES

Cumulative Trauma Disorders can resultfromthe prolonged useof manually powered hand tools. Hand tools areintended for occasional useand low volume

applications. A wide selection of powered application equipment for extended--use, production operations is available.

Insulation Crimp Adjustment Pins

(ShowninPosition3)

Ratchet

Fixed Jaw

(Crimper)

411--1097

27 MAY 10 Rev D525690 and 525691

Color--Coded

Handle

Locator/Insulation

Stop

Part Number Color Code Dot Code

525690 Red 1 20--18

525691 Blue 2 16--14

Movable Jaw

(Anvil)

TE Tool

1. INTRODUCTION

Double Action Hand Crimping Tools 525690 and

525691 crimp a wide variety of PIDG* terminals and

splices and PLASTI-- GRIP* terminals and splices

onto stranded copper wire sizes 20 through 14 AWG.

See Figure 1. Read these instructions thoroughly

before using the tools.

NOTE

Dimensions in this instruction sheet are in

millimeters [with inches in brackets]. Figures are

i

not drawn to scale.

Reasons for reissue of this instruction sheet are

provided in Section 7, REVISION SUMMARY.

2. DESCRIPTION

Each tool features a fixed jaw (crimper), a movable

jaw (anvil), a locator/insulation stop, and a ratchet

attached to a handle.

Wire Size Range

(AWG)

Figure 1

These tools are members of the CERTI--CRIMP*

hand crimping tool family. The ratchet on these tools

ensures full crimping of the product. Once engaged,

the ratchet will not release until the handles have

been FULLY closed.

CAUTION

The jaws bottom before the ratchet releases. This

design ensures maximum electrical and tensile

!

performance of the crimp. DO NOT re--adjust the

ratchet.

The locator/insulation stop positions the product

between the jaws and aids in locating the wire in the

product. When closed, the jaws form a crimping

chamber with two sections: an insulation barrel

section and a wire barrel section. The insulation barrel

section crimps the insulation barrel of the product

onto the wire insulation and, simultaneously , the wire

barrel section crimps the wire barrel of the product

onto the wire conductors.

E2010 Tyco Electronics Corporation, Berwyn, PA

All Rights Reserved

TE logo and Tyco Electronics ar e trademarks.

*Trademark. Other product names, logos, or company names might be trademarks of their respective owners.

TOOLING ASSISTANCE CENTER 1--800--722--1111

PRODUCT INFORMATION 1--800--522- -6752

This controlled document is subject to change.

For latest revision and Regional Customer Service,

visit our website at www.tycoelectronics.com

1 of 7

LOC B

Page 2

Double Action Hand Crimping Tools 525690 and 525691

P

r

oduct ColorCode

411- 1097

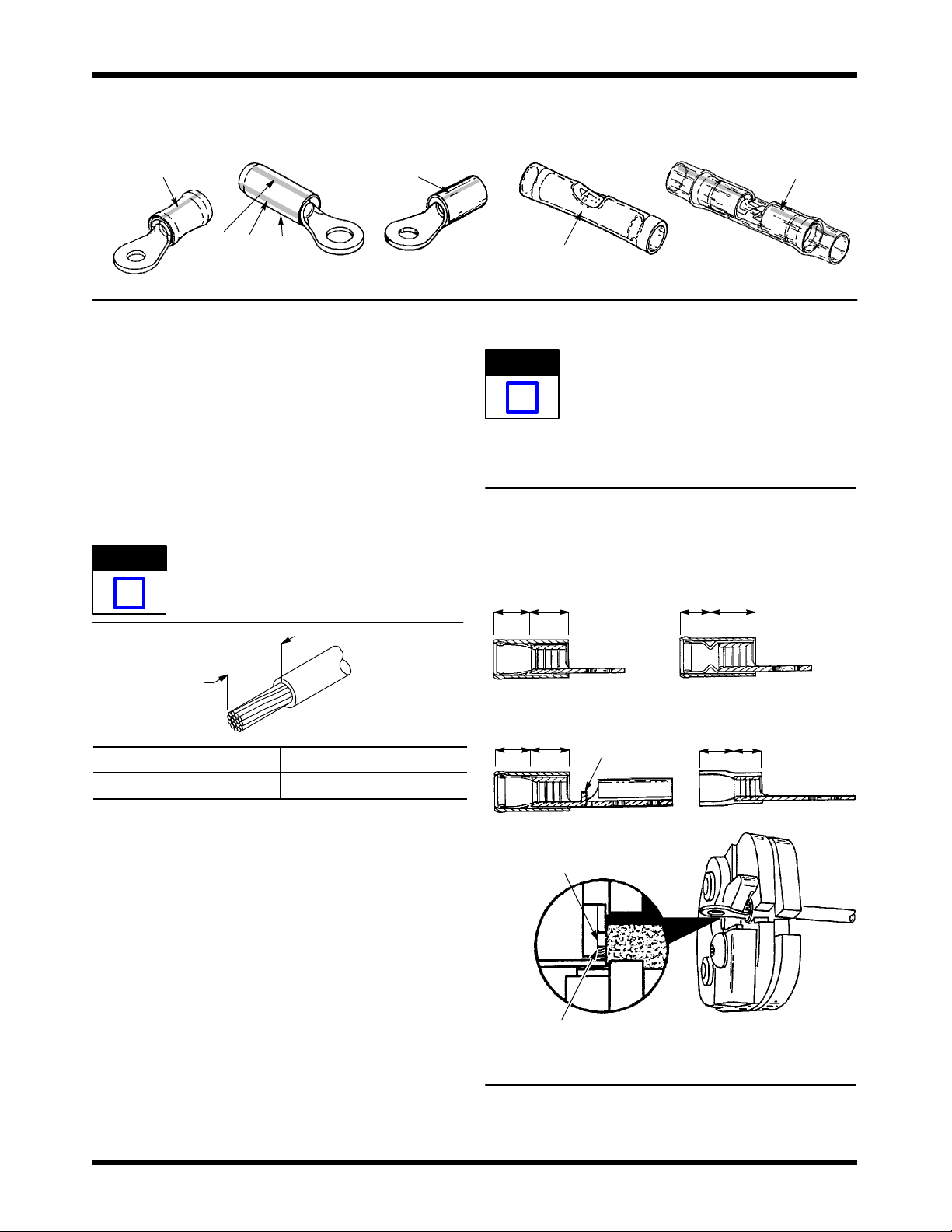

PLASTI--GRIP TerminalPIDG Terminals PIDG Butt Splice

Color Stripe on

Radiation Resistant

3 Equally Spaced

Color Stripes on

Insulation Restricting

Each tool handle is color coded to correspond to the

color code of the product (refer to Figure 2). Each tool

produces a dot code on the crimp to correspond to

the given wire size range (refer to Figure 1).

Color Stripe on

Heavy Duty

3. CRIMPING PROCEDURE

1. Strip the wire to the dimension given in Figure 3,

being careful to avoid nicking or damaging the

conductors.

NOTE

DO NOT use wire with nicked or missing

conductors.

i

PLASTI--GRIP

Color of Insulation

Figure 2

NOTE

Butt Splice

DO NOT allow the wire insulation to enter the

wire barrel.

Color Stripe on

Radiation Resistant

i

7. Close the tool handles until the ratchet releases.

Crimping a Terminal

“B” Equals Wire Barrel

“C” Equals Insulation Barrel

PIDG Terminal

“C” “B”

PIDG Insulation

Restricting Terminal

“C” “B”

Strip Length

Terminal Splice

5.08--5.84 [.20--.23] 6.35--7.11 [.25--.28]

Figure 3

2. Insert the insulation crimp adjustment pins in the

proper position according to Section 4.

3. Open the tool jaws by closing the handles until

the ratchet releases, then allow the handles to

open FULLY.

4. Place the terminal or splice in the crimping

chamber as shown in Figure 4 (for terminals) or

Figure 5 (for splices).

5. Close the tool handles until the terminal or splice

is held firmly in place. DO NOT deform the wire

barrel.

6. Insert a properly stripped wire into the wire

barrel as shown in Figure 4 (for terminals) or

Figure 5, Detail A (for splices).

PIDG FASTON Terminal PLASTI--GRIP Terminal

“C” “B”

Wire Barrel

Against Locator

End of Wire Conductor

Against Locator or,

If Present, Wire Stop

Wire Stop

Figure 4

“C” “B”

Rev D2 of 7 Tyco Electronics Corporation

Page 3

Double Action Hand Crimping Tools 525690 and 525691

411- 1097

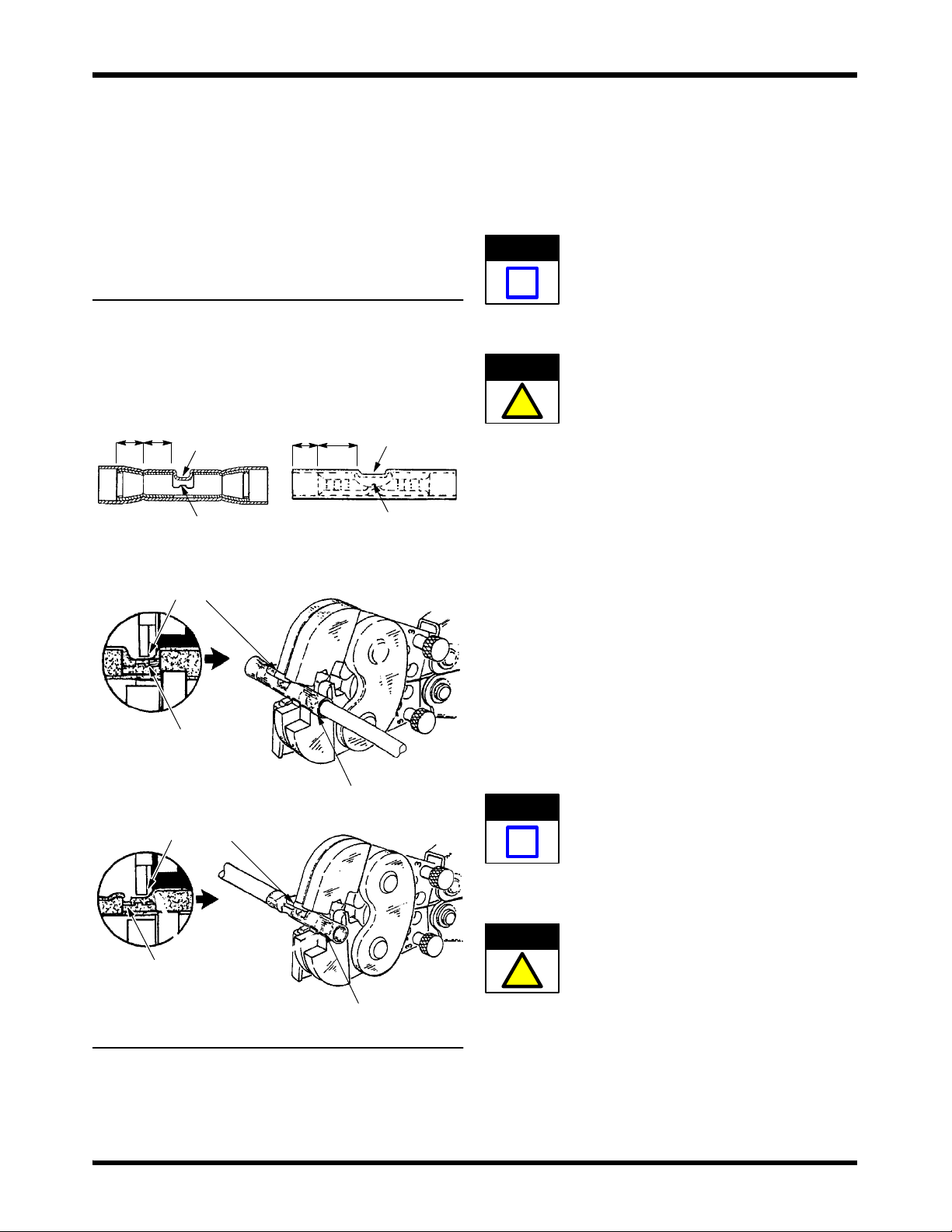

8. Release the tool handles, and allow them to

open FULLY. Remove the crimped terminal or

splice.

9. For splices, position the remaining wire barrel in

the crimping chamber as shown in Figure 5, Detail

B. Repeat Steps 5 through 8.

10. Inspect crimped terminal or splice by checking

the features described in Figure 6. Terminals and

splices not meeting the described conditions

should NOT be used.

Crimping a Butt Splice

“B” Equals Wire Barrel

“C” Equals Insulation Barrel

“C” “B”

Detail A

PIDG Splice

Window

Indent

Wire Stop

Locator Seats in

Window Indent

PLASTI--GRIP Splice

“C” “B”

Window

Indent

Wire Stop

4. INSULATION CRIMP ADJUSTMENT

The insulation barrel section of the crimping chamber

has three positions: 1 — tight, 2 — medium, and 3 —

loose. To adjust the grip resulting from the crimp of

the insulation barrel, proceed as follows:

4.1. PIDG Terminals and Splices

NOTE

PIDG terminals and splices feature a wire

“insulation grip.”

i

1. Insert each insulation crimp adjustment pin into

Position 3. Refer to Figure 1.

CAUTION

!

2. Position the terminal or splice in the crimping

chamber as described in Section 3.

3. Insert an UNSTRIPPED wire into ONLY the

insulation barrel of the terminal or splice.

4. Close the tool handles until the ratchet releases.

5. Release the tool handles, and allow the handles

to open FULLY. Remove the crimped terminal or

splice.

Make sure that both insulation crimp adjustment

pins are in the same position.

End of Wire Conductor

Against Splice Wire Stop

Detail B

Locator Seats in

Window Indent

End of Wire Conductor

Against Splice Wire Stop

Figure 5

Wire Barrel

Remaining

Wire Barrel

6. Check the insulation barrel crimp by bending the

wire back and forth once. The terminal or splice

should retain its grip on the wire insulation. If it

does not, insert each insulation crimp adjustment

pin into the next position (Position 2).

7. Repeat Steps 2 through 6 until the correct

insulation barrel grip is attained. DO NOT use a

tighter position than is necessary.

4.2. PLASTI- GRIP Terminals and Splices

NOTE

i

Insert each insulation crimp adjustment pin into

position according to the following:

CAUTION

PLASTI--GRIP terminals and splices feature a

wire “insulation support” only. Ideally, the terminal

or splice insulation should be in contact with the

wire insulation.

Make sure that both insulation crimp adjustment

pins are in the same position.

!

— Position 3 for wire having a large insulation

diameter.

— Position 2 for wire having a medium insulation

diameter.

— Position 1 for wire having a small insulation

diameter.

3 of 7Rev D Tyco Electronics Corporation

Page 4

Double Action Hand Crimping Tools 525690 and 525691

Crimp Inspection

Dot Code (1 or 2 Dots) Must Appear on All Crimps

411- 1097

PIDG Terminals and PLASTI--GRIP Terminals

1

3

4

2

5

7 8

6

PLASTI--GRIP Butt Splices

3

5

6

2

4

7

PIDG Butt Splices

3

8

6

Wire Stop

4

6

2

1a

1

Insulation barrel is in firm contact with wire insulation

2

Correct color code, dot code, and tool combination

Wire size is within wire size range stamped on terminal

3

tongue

4

Crimp is centered on wire barrel

Conductor end is flush with, or extends beyond, end of

5

wire barrel

Conductor end is against the wire stop, or is at least

6

flush with or extends slightly beyond wire barrel

7

Wire insulation does not enter wire barrel

8

No nicked or missing wire conductor strands

1b

Wire Stop

1

Splice insulation (a) or insulation barrel (b) is in contact

with wire insulation

2

Correct color code, dot code, and tool combination (dot

coding disappears from sealed splices when heat sealed)

Wire size is within wire size range stamped on center

3

of splice

4

Crimp is centered on wire barrel

No flash or extruded insulation

5

Conductor end is against wire stop, or is at least flush

6

with or extends slightly beyond wire barrel

7

Wire insulation does not enter wire barrels

8

No nicked or missing conductor strands

Figure 6

Rev D4 of 7 Tyco Electronics Corporation

Page 5

Double Action Hand Crimping Tools 525690 and 525691

nfi

gurat

ion

411- 1097

5. MAINTENANCE AND INSPECTION

It is recommended that a maintenance and inspection

program be performed periodically to ensure

dependable and uniform terminations. Though

recommendations call for at least one inspection a

month, frequency of inspection depends on:

1. The care, amount of use, and handling of the

tool.

2. The presence of abnormal amounts of dust and

dirt.

3. The degree of operator skill.

4. Your own established standards.

The tool is inspected before being shipped; however,

it is recommended that the tool be inspected

immediately upon arrival to ensure that the tool has

not been damaged during shipment.

5.1. Daily Maintenance

1. Immersed the tool (handles partially closed) in a

reliable commercial degreasing compound to

remove accumulated dirt, grease, and foreign

matter. When degreasing compound is not

available, the tool may be wiped clean with a soft,

lint--free cloth. DO NOT use hard or abrasive

objects that could damage the tool.

2. Make certain that the retaining pins are in place

and that they are secured with retaining rings.

3. All pins, pivot points, and bearing surfaces

should be protected with a THIN coat of any good

SAE 20 motor oil. DO NOT oil excessively.

4. When the tool is not in use, keep the handles

closed to prevent objects from becoming lodged in

the jaws. Store the tool in a clean, dry area.

5.2. Periodic Inspection

open quickly and fully, the spring is defective and

must be replaced. See Section 6, REPLACEMENT

AND REPAIR.

2. Inspect the head for worn, cracked, or broken

jaws. If damage is evident, return the tool for

evaluation and repair. See Section 6,

REPLACEMENT AND REPAIR

C. Gaging the Crimping Chamber

This inspection requires the use of plug gages

conforming to the dimensions provided in Figure 7.

To gage the crimping chamber, proceed as follows:

1. Remove traces of oil or dirt from the crimping

chamber and plug gage.

2. Insert each insulation crimp adjustment pin into

Position 1. See Figure 8.

NO--GO DiaGO Dia

Jaw Closure

Co

SUGGESTED PLUG GAGE DESIGN

FOR WIRE BARREL SECTION

TOOL

525690 2.768--2.776 [.1090--.1093] 2.918--2.921 [.1149--.1150]

525691 3.022--3.030 [.1190--.1193] 3.172--3.175 [.1249--.1250]

GO Dia NO--GO Dia

W

Jaw Closure

Configuration

GAGE ELEMENT DIAMETER

GO NO--GO

GO

NO

GO

W

A. Lubrication

SUGGESTED PLUG GAGE DESIGN

Lubricate all pins, pivot points, and bearing surfaces

with any good SAE 20 motor oil as follows:

Tool used in daily production — daily

TOOL

Tool used daily (occasional) — weekly

Tool used weekly — monthly

Wipe excess oil from the tool, particularly from the

crimping area. Oil transferred from the crimping area

525690

525691

onto certain terminations may affect the electrical

characteristics of an application.

B. Visual Inspection

1. Close the tool handles until the ratchet releases

and then allow them to open freely. If they do not

3. Close the tool handles until the jaws bottom,

and hold in this position. DO NOT force beyond

initial contact.

FOR INSULATION BARREL SECTION

GAGE ELEMENT THICKNESS

GO

0.889--0.897

[.0350--.0353]

1.143--1.151

[.0450--.0453]

NO--GO W

1.394--1.397

[.0549--.0550]

1.648--1.651

[.0649--.0650]

Figure 7

2.80--3.05

[.110--.120]

4.50--4.75

[.177--.187]

5 of 7Rev D Tyco Electronics Corporation

Page 6

Double Action Hand Crimping Tools 525690 and 525691

Ins

Ins

411- 1097

pectionof

Wire Barrel Section

of Crimping Chamber

Insulation Crimp Adjustment Pins in Position 1

Jaws Bottomed But

Not Under Pressure

GO Element Must Pass

Completely Through

Crimping Chamber

pectionof

Insulation Barrel Section

of Crimping Chamber

GO Element Must Pass

Completely Through Length of

Insulation Barrel Section But

Stop on Wire Barrel Section

correct, and should be lubricated with a THIN coat of

any good SAE 20 motor oil. If not, return the tool for

evaluation and repair. See Section 6,

REPLACEMENT AND REPAIR.

5.3. Ratchet Inspection

Check the ratchet to ensure that the ratchet does not

release prematurely, allowing the jaws to open before

they have fully bottomed. Proceed as follows:

1. Remove traces of oil or dirt from the bottoming

surfaces of the jaws.

2. Obtain a 0.025 mm [.001 in.] shim that is

suitable for checking the clearance between the

bottoming surfaces of the jaws.

3. Select a terminal or splice and maximum size

wire for the terminal or splice.

4. Position the terminal or splice in the crimping

chamber according to Section 3, CRIMPING

PROCEDURE. Holding the wire in place, squeeze

the tool handles together until the ratchet releases.

Hold the tool handles in this position, maintaining

just enough pressure to keep the jaws closed.

5. Check the clearance between the bottoming

surfaces of the jaws. If the clearance is 0.025 mm

[.001 in.] or less, the ratchet is satisfactory. If

clearance exceeds 0.025 mm [.001 in.], the ratchet

is out of adjustment and must be repaired. See

Section 6, REPLACEMENT AND REPAIR.

NO--GO Element May Start Entry, But Must Not

Pass Completely Through Crimping Chamber

Figure 8

4. Carefully insert the GO element into the

crimping chamber as shown in Figure 8; DO NOT

force it. For the wire barrel section of the crimping

chamber, the GO element must pass completely

through the crimping chamber. For the insulation

barrel section, the GO element must pass through

the length of the section but will stop against the

wire barrel section.

5. In the same manner, try to insert the NO--GO

element into the crimping chamber as shown in

Figure 8. The NO--GO element may begin entry,

but may not pass through the crimping chamber.

If the crimping chamber conforms to the gage

inspection, the tool is considered dimensionally

6. REPLACEMENT AND REPAIR

Customer--replaceable parts are listed in Figure 9.

A complete inventory should be stocked and

controlled to prevent lost time when replacement of

parts is necessary. Parts other than those listed

should be replaced by Tyco Electronics to ensure

quality and reliability. Order replacement parts

through your representative, or call 1--800--526--5142,

or send a facsimile of your purchase order to

717--986--7605, or write to:

CUSTOMER SERVICE (038--035)

TYCO ELECTRONICS CORPORATION

PO BOX 3608

HARRISBURG PA 17105--3608

For customer repair service, call 1--800--526--5136.

7. REVISION SUMMARY

Revisions to this instruction sheet include:

S Updated document to corporate requirements

S Added new data to tables in Figure 7

Rev D6 of 7 Tyco Electronics Corporation

Page 7

Double Action Hand Crimping Tools 525690 and 525691

7 8

6

45

9

1 23

411- 1097

3

REPLACEMENT PARTS

ITEM PART NUMBER DESCRIPTION QTY PER TOOL

1 01--23619--6 PIN, Retaining 2

2 525108 RING, Retaining 4

3 039207 PIN, Adjustment 2

4 00--21028--1 PIN 2

5 0--525355--8 LOCATOR 1

6 9--305927--1 SCREW 1

7 302994 HOUSING STOP 1

8 301201 SPRING 1

9 039208 RING 6

Figure 9

7 of 7Rev D Tyco Electronics Corporation

Page 8

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

TE Connectivity:

525691

Loading...

Loading...