Page 1

Model WMA-1 Water Motor Alarm

Hydraulically Operated

Mechanical Sprinkler Alarm

Worldwide

Contacts

www.tyco-fire.com

General

Description

The TYCO Model WMA-1 Water Motor

Alarm is a hydraulically operated

outdoor alarm designed for use with

fire protection system waterflow detection valves. It is lightweight yet rugged,

and it can be used in conjunction with

alarm check, dry pipe, deluge, and preaction valves to sound a local alarm.

The Water Motor Alarm is suitable

for mounting to any type of rigid wall

and can accommodate a wall thickness range of 2 in. to 18 in. (50 mm

to 450 mm). It is provided with a listed

and approved TYCO Model WMA-1

Y-Strainer for use in the alarm line.

The Model WMA-1 utilizes a lightweight,

impeller design that can produce a very

high sound pressure level. The Gong,

Gong Mount, and Water Motor Housing

are fabricated from corrosion-resistant

aluminum alloys. The polymer drive

bearings do not require lubrication, and

the Gong is closely fitted to the Gong

Mount to eliminate the need for a separa te cover.

The Model WMA-1 Water Motor Alarm

is a re-designation for the Central

Model F-2, Gem Model F630, and Star

Model S450.

NOTICE

The TYCO Model WMA-1 Water Motor

Alarm described herein must be

installed and maintained in compliance

with this document, as well as with the

applicable standards of the NATIONAL

FIRE PROTECTION ASSOCIATION

(NFPA), in addition to the standards

of any authorities having jurisdiction.

Failure to do so may impair the performance of this device.

IMPORTANT

Refer to Technical Data Sheet

TFP2300 for warnings pertaining to

regulatory and health information.

The owner is responsible for maintaining their fire protection system

and devices in proper operating condition. Contact the installing contractor or product manufacturer with any

questions.

Technical

Data

Approvals

UL and ULC Listed

FM, LPCB and VdS Approved

Gong Finish

Red or Aluminum

Working Water Pressure Range

7 to 300 psi (0,5 to 20,7 bar)

Nozzle K-factor

0.7 gpm/psi½ (10,1 Lp m / b ar½)

Y-Strainer

3/4 in., cast iron, 20 mesh screen

Trim Components

Galvanized steel nipples and cast iron

ttings

Design

Data

The TYCO Model WMA-1 Water Motor

Alarm must be used in accordance with

the following design criteria:

Item 1. The Y-Strainer is to be located

at the alarm outlet of the waterflow

detection valve trim.

Item 2. The Water Motor Alarm

must only be mounted to a rigid

wall surface that will not permit the

Striker /Gong Mount to loosen and fall

out of alignment.

Item 3. In order to obtain the highest

possible sound level, the Water Motor

Alarm should be located as close as

possible to the waterflow detecting

valve. For guidance, refer to NFPA 13.

Item 4. The alarm line piping from the

alarm outlet of the waterflow detection

valve trim to the Water Motor Alarm

must be 3/4 in. (DN20) in size throughout and it must be galvanized steel,

brass, or other suitable corrosion-resistant material.

Item 5. The alarm line piping must be

positioned such that it can be drained

back to the waterflow detection valve

trim.

Item 6. The Clean-Out Sump Plug is to

be located vertically below the Inlet to

the Water Motor.

Item 7. Piping from the Water Motor

Drain must be a minimum of 1 in.

(DN25) in size throughout and directed

to an open drain in order to ensure

proper drainage for obtaining the

maximum sound pressure level.

Note: The Water Motor Alarm Drain

may be connected to the main drain

of a waterflow detection valve if a nonspring loaded swing-type check valve

is installed in a horizontal portion of the

water motor alarm drain piping (before

its connection to the main drain).

Item 8. In order to minimize any wall

staining that can be created by drain

water, it is recommended that the drain

piping from the Water Motor be galvanized steel, brass, or other suitable corrosion-resistant material.

Page 1 of 4 AUGUST 2018 TFP921

Page 2

TFP921

Page 2 of 4

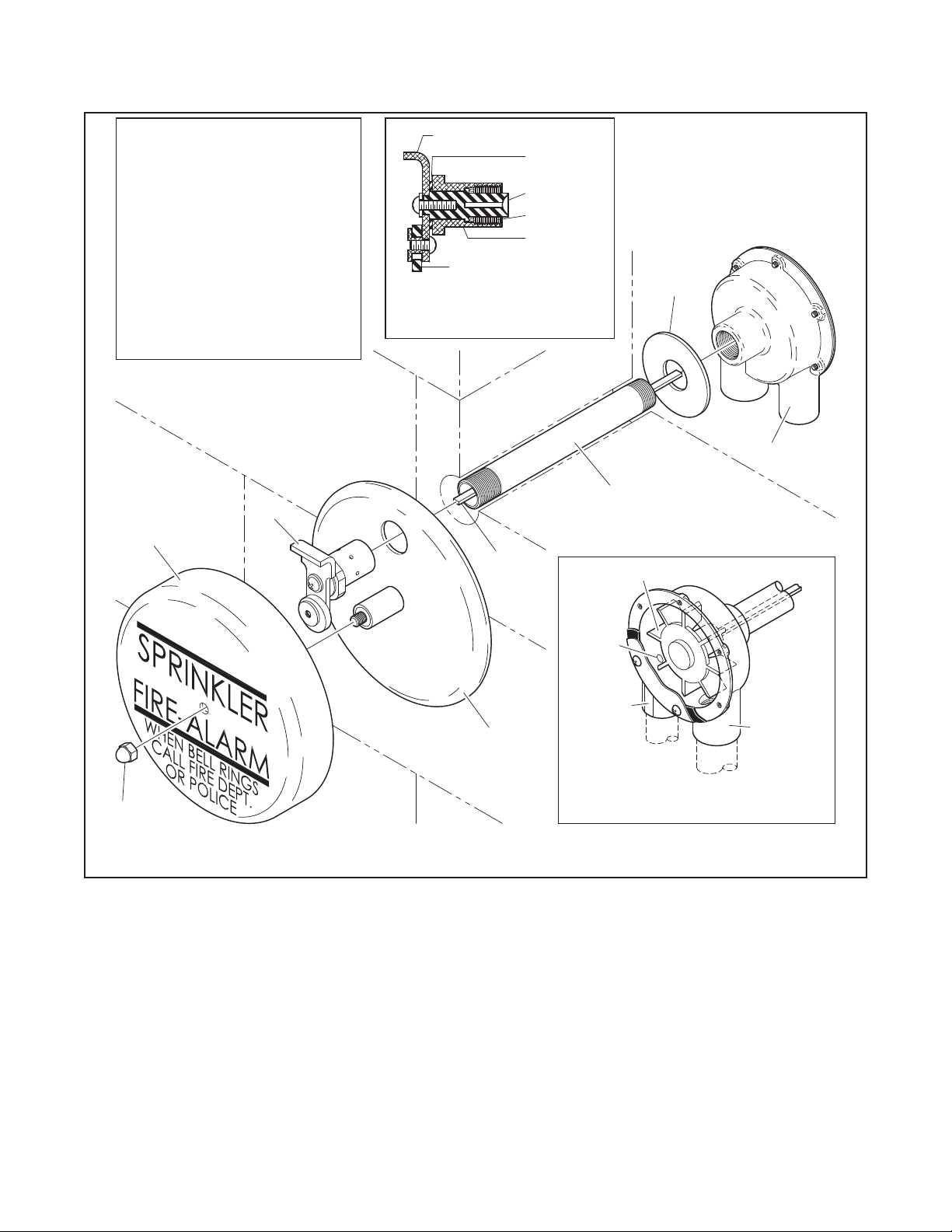

NO. DESCRIPTION REF.

1

Water Motor 92-630-1-012

2

Support Washer

3

Drive Shaft Sleeve

4

Drive Shaft

5

Gong Mount

6

7

8

(a)

(a)

NR: Not Replaceable

. . . . . . . . . . .

Gong

. . . . . . . . . . . .

Cap Nut

Red Gong Repair

Kit includes items:

Aluminum Gong Repair

Kit includes items:

6, 7 (alum.), and 8

7

. . . . . . . . .

. . . . . .

. . .

. . . . . . .

. . . . . .

. . .

QTY.

.

. .

1

1

1

1

1

1

1

1

1

1

6

NR

NR

NR

NR

See (a)Striker

See (a)

See (a)

92-630-1-0256, 7 (red), and 8

92-630-2-025

STRIKER ARM

COUPLING

SPACER

COUPLING

3/4" NPS

STRIKER

SHAFT

STRIKER

RING

CROSS-SECTION VIEW

OF STRIKER (ITEM 6)

BEARING

4

2

1

3

IMPELLER

8

Item 9. Drain water must be directed to

prevent accidental damage to property

or danger to persons when the alarm is

operating or thereafter.

Item 10. The alarm line drain, at the

waterflow detection valve, must be

maintained at a minimum temperature

of 40°F (4°C).

Item 11. A single Water Motor Alarm

may be connected to the alarm lines

from a maximum of three separate fire

protection systems. However, when

two or three alarm lines are interconnected, each alarm line must be provided with the following:

• 3/4 in. Model WM-1 Y-Strainer

(P/N 52-271-1001)

NOZZLE

INLET

5

FIGURE 1

MODEL WMA-1 WATER MOTOR ALARM

AS S E M B LY

•

3/4 in. Check Valve with 3/32 in.

orice (P/N 52-403-1-005)

Strainers must be located at the alarm

outlet in the trim of each of the waterflow detection valves. Check valves

must be located between each strainer

and the interconnection with the alarm

line from another system.

Operation

Upon operation of the alarm check,

dry pipe, deluge, or preaction valve to

which the TYCO Model WMA-1 Water

Motor Alarm is connected, water will

flow to the Water Motor and through

the Inlet Nozzle. As water flows through

DRAIN

INTERNAL VIEW OF

WATER MOTOR (ITEM 1)

the Inlet Nozzle, a high velocity jet is

formed that impinges on the Impeller,

causing the Impeller and the Striker

to rotate. With each rotation, the free

swinging Striker Ring hits the Gong and

sounds the alarm. The spent water is

then drained through the 1 in. outlet.

The alarm will sound as long as water

is flowing into the system and flowing

to the Water Motor Alarm. Water in the

alarm line will automatically drain back

through the orifice, which is also provided in the trim of the waterflow detection valve.

The Water Motor Alarm does not have

to be reset after an operation. However,

if the alarm was silenced during oper-

Page 3

(34,2 mm)

8-1/2" DIA.

2"

Y-STRAINER

2-9/16" T/O

(65,0 mm)

1-3/8"

7/8"

(22,2 mm)

WATER

MOTOR

2-1/2" T/O

(63,5 mm)

2-3/4"

(69,9 mm)

SLEEVE END

3/4" NPT

THREADED

BY INSTALLER

TFP921

Page 3 of 4

(50,8 mm)

3/4" NPS

2-7/16"

(61,9 mm)

(215,9 mm)

3/4" NPT

INLET

3/4" (DN20) NPS

GALVANIZED

STEEL OR

BRASS PIPE

1

3/4"

STRAINER

CLEAN-OUT

CAP

NOTES:

All installation dimensions are shown at nominal value.

1.

2. All dimensions are in inches and (mm).

Items shown in dotted lines are not included with the WMA-1.3.

Consult local Authority Having Jurisdiction for mechanical

4.

alarm isolating control valve requirements.

5. All included trim components are galvanized.

OPTIONAL ELECTRICALLY

SUPERVISED N.O.

ALARM CONTROL VALVE

1" NPT

DRAIN

1" (DN25) NPS

GALVANIZED

4

1

3

2

LOCATION FOR

(SEE NOTE 4)

STEEL OR

BRASS PIPE

MODEL WMA-1 WATER MOTOR ALARM

1-13/16"

(46,0 mm)

DRAIN CL

A

2-1/16"

(52,4 mm)

INLET CL

CLEAN-OUT

SUMP PLUG

STANDARD INLET TRIM

DESCRIPTION

NO.

3/4" x 3" Nipple

1

3/4" 90° Elbow

2

3/4" x 1/4" x 3/4" Tee

3

with 1/4" Plug

3/4" Union

4

FIGURE 2

TYPICAL INSTALLATION

. . . . .

. . . . . .

. . . . . . .

. . . . . . . . .

B

C

D

RIGID WALL

STRUCTURE

16" (457,2 mm)

MAXIMUM

2" (50,8 mm)

MINIMUM

OPTIONAL DRAIN TRIM

QTY.

NO.

DESCRIPTION

A

2

1 . . . . . . .

1

1

1" 90° Elbow

B

1" 45° Elbow

C

Wall Plate

D

1" x 1'-6" Pipe,

. . . . . . .

. . . . . . . . .

. . . . . . . . . . . .T.O.E.

10"

(254,0 mm)

MINIMUM

QTY.

1

1

1

1

ation by closing an alarm control

valve, the alarm control valve must

be reopened after the fire protection

system is restored to service.

Installation

The TYCO Model WMA-1 Water Motor

Alarm must be installed in accordance

with this section.

Step 1. Mark the through-wall locations

for the centerlines of the Sleeve and

Drain Outlet. The Drain Outlet must be

located at least 10 in. (250 mm) below

the Sleeve per Figure 2.

Step 2. Make 1-1/2 in. (38 mm) diameter holes straight through the wall at

both locations.

Step 3. Cut the non-threaded end of

the Sleeve to a length equal to that of

the wall thickness plus 0 in. to 1/8 in.

(0 mm to 3 mm). Thread the cut end to

3/4 in. NPT per ANSI B1.20.1.

Step 4. Install the alarm line piping up

to and including the Union half per Item

4, Figure 2.

Note: Use thread sealant sparingly on

male threads only.

Step 5. Prior to initiating installation

of the Water Motor Alarm, mount the

Drain Trim (less the Wall Plate and 45°

Elbow) as well as the balance of alarm

line piping, including the other Union

half, to the Water Motor.

Step 6. Tighten the NPT threaded end

of the Sleeve into the Body, hand-tight

plus 1/8 turn.

Step 7. Slip the Support Washer over

the Sleeve and place the assembly in

position against the wall.

Step 8. Tighten the 3/4 in. Union.

Install the Wall Plate and tighten the

45° Elbow.

Note: Apply pressure against the

outside edge of the Water Motor Body

and verify that the Body and Support

Washer sit squarely against the wall. If

not, adjust the alarm line and/or drain

piping to suit.

Step 9. From the outside wall, insert

the Drive Shaft through the Sleeve and

fully insert it into the Impeller.

Note: When fully inserted, the Shaft

should protrude beyond the face of

the wall by approximately 20 minus 2 in.

(508,0 minus 50,8 mm) wall thickness.

Mark the Drive Shaft at a point of

approximately 1/8 in. to 1/4 in. (3,2 mm

to 6,4 mm) inside the face of the wall.

Remove the Shaft and cut it where pre-

Page 4

TFP921

Page 4 of 4

viously marked. File off burrs from the

cut end of the Drive Shaft. Re-insert the

Drive Shaft through the Sleeve and fully

insert it into the Impeller.

Step 10. Hold the Gong Mount in

position against the wall, engage the

Coupling with the Drive Shaft, and

then carefully thread the Striker Shaft

Bearing onto the Sleeve. Securely

tighten the Striker Shaft Bearing using

a pair of tongue-and-groove pliers on

the 1-1/2 in. (38 mm) hex end.

Step 11. Spin the Striker by hand and

verify that it spins freely, without any

sign of binding. If it does not, make the

necessary adjustments.

Step 12. Install the Gong and securely

tighten the Cap Nut. The identification sign lettering must be orientated

horizontally.

Step 13. Test the Water Motor Alarm by

opening the alarm test valve in the trim

of the waterflow detection valve. The

alarm must be clear and steady. If it is

not, make the necessary adjustments.

NOTICE

Testing of the Water Motor Alarm may

result in operation of other associated

alarms. Consequently, notification

must be given to the owner and the fire

department, central control station, or

other signal station to which the alarms

are connected.

Care and

Maintenance

The TYCO Model WMA-1 Water Motor

Alarm must be maintained and serviced in accordance with this section.

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system

that it controls, obtain permission to

shut down the affected fire protection

system from the proper authorities

and notify all personnel who may be

affected by this decision.

Testing of the Water Motor Alarm may

result in operation of other associated

alarms. Consequently, notification

must be given to the owner and the fire

department, central control station, or

other signal station to which the alarms

are connected.

If the alarm was silenced during operation, the alarm control valve must be

reopened immediately after the fire protection system is restored to service.

The owner is responsible for the inspection, testing, and maintenance of their

fire protection system and devices in

compliance with this document, as well

as with the applicable standards of the

NATIONAL FIRE PROTECTION ASSOCIATION (e.g., NFPA 25), in addition to

the standards of any other authorities

having jurisdiction. Contact the installing contractor or product manufacturer

regarding any questions.

Automatic sprinkler systems are recommended to be inspected, tested,

and maintained by a qualified Inspection Service in accordance with local

requirements and/or national codes.

The following procedures and inspections should be performed as indicated,

in addition to any specific requirements

of the NFPA, and any impairment must

be immediately corrected:

Step 1. The Model WMA-1 Water Motor

Alarm does not require any regularly

scheduled maintenance. Rotating parts

do not require lubrication. It is recommended, however, that fire alarms be

periodically operated (inspected) to

verify that they generate a clear and

steady sound. Correct any impairment

immediately.

Step 2. The inspection should be made

quarterly or more frequently, as may

be necessary for locations subject to

vandalism.

The Y-Strainer and Sump are to be

cleaned out after each operation of the

Water Motor Alarm and after the alarm

line piping has been drained.

NOTICE

With reference to Figure 2, in the event

of a WMA-1 malfunction, inspect and

clean the Y-Strainer of obstruction prior

to removing the Water Motor.

Make no attempt to disassemble,

repair, or internally clean the Water

Motor. The Water Motor is not a field

serviceable part and must be replaced

if malfunction is determined.

Limited

Warranty

For warranty terms and conditions, visit

www.tyco-fire.com.

Ordering

Procedure

Orders for the WMA-1 Water Motor

Alarm Assembly, Optional Drain Trim,

and replacement parts must include

the description and Part Number (P/N).

The complete Model WMA-1 Alarm

Assembly includes the Model WMA-1

Water Motor Alarm, Model WM-1

Strainer, and Standard Inlet Trim.

WMA-1 Water Motor Alarm

Assembly

Specify: Model WMA-1 Water Motor

Alarm, (specify) Finish, P/N (specify):

Red Finish Gong .........P/N 5 2- 6 3 0 -1- 0 01P

Aluminum Finish Gong. . . . . P/ N 52-630 -2-001P

Optional Drain Trim

Specify: Optional Drain Trim for

Model WMA-1 Water Motor Alarm,

P/N 52-630-2-002

Separately Ordered Parts for

Multiple Systems

Specify: Model WM-1 Y-Strainer,

P/ N 52-271-1-001

Note: One Y-Strainer is required for

two systems; two Y-Strainers are

required for three systems.

Specify: 3/4 in. Check Valve with 3/32

in. Orifice, P/N 52-403-1-005

Note: Two Check Valves are required

for two systems; three Check Valves

are required for three systems.

Replacement Parts for

Water Motor Alarm

Specify: (description) for use with

Model WMA-1 Water Motor Alarm,

P/N (see Figure 1)

1400 Pennbr ook Parkway, Lansdale , PA 19446 | Telephone +1-215-3 62- 0700

© 2018 John son Control s. All right s reserved. A ll specifica tions and ot her informa tion shown wer e current as o f document rev ision date an d are subject t o change wit hout notice.

NATIONAL FIRE P ROTECTION ASSOCIATIO N and NFPA are register ed trademarks of N ational Fire Protec tion Associati on;

Loading...

Loading...