Page 1

Worldwide

Contacts

www.tyco-fire.com

Series TY-FRB – 5.6 and 8.0 K-factor

Upright and Pendent Intermediate Level Sprinklers

Quick Response

General

Description

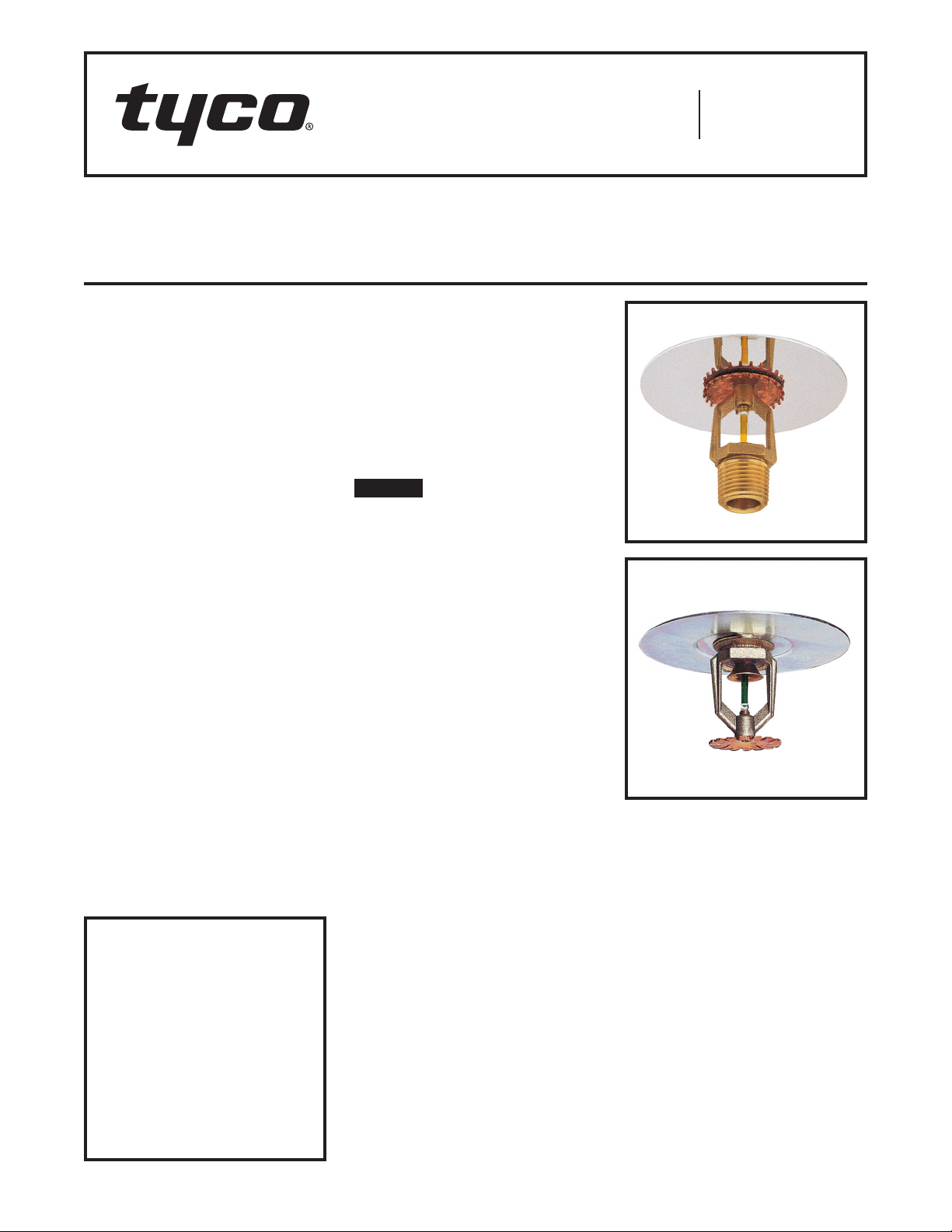

TYCO Series TY-FRB 5.6K and 8.0K

Quick Response Upright and Pendent

Intermediate Level Sprinklers are automatic sprinklers of the quick response

3 mm frangible bulb type. They are

standard spray sprinklers intended for

use in fire sprinkler systems designed

in accordance with the standard installation rules recognized by the applicable listing or approval agency (e.g.,

UL Listing is based on NFPA requirements). Both the pendent and upright

sprinklers produce a hemispherical

water distribution pattern below the

deflector.

Intermediate level sprinklers are primarily designed for use in rack storage

sprinkler systems where their thermally

sensitive elements must be shielded

from the water spray of higher elevation sprinklers that could operate

earlier during a fire. Intermediate level

sprinklers are also used in other applications such as beneath open gridded

catwalks.

Corrosion-resistant coatings, where

applicable, are utilized to extend the life

of copper alloy sprinklers beyond that

which would otherwise be obtained

when exposed to corrosive atmospheres. Although corrosion-resistant

coated sprinklers have passed the

standard corrosion tests of the applicable approval agencies, the testing is

not representative of all possible cor-

rosive atmospheres. Consequently,

it is recommended that the end user

be consulted with respect to the suitability of these coatings for any given

corrosive environment. The effects of

ambient temperature, concentration of

chemicals, and gas/chemical velocity,

should be considered, as a minimum,

along with the corrosive nature of the

chemical to which the sprinklers will be

exposed.

NOTICE

The Series TY-FRB Sprinklers

described herein must be installed

and maintained in compliance with this

document, as well as with the applicable standards of the National Fire Protection Association (NFPA), in addition

to the standards of any other authorities having jurisdiction. Failure to do so

may impair the performance of these

devices.

The owner is responsible for maintaining their fire protection system

and devices in proper operating condition. Contact the installing contractor or product manufacturer with any

questions.

Sprinkler

Identification

Numbers (SINs)

TY3133 – Upright, 5.6K, 1/2 in. NPT

TY3231 – Pendent, 5.6K, 1/2 in. NPT

TY4133 – Upright, 8.0K, 3/4 in. NPT

TY4231 – Pendent, 8.0K, 3/4 in. NPT

Refer to Technical Data Sheet

TFP2300 for warnings per taining to

regulatory and health information.

Always refer to Technical Data

Sheet TFP700 for the “INSTALLER

WARNING” that provides cautions

with respect to handling and installation of sprinkler systems and components. Improper handling and

installation can permanently damage

a sprinkler system or its components and cause the sprinkler to fail

to operate in a fire situation or cause

it to operate prematurely.

IMPORTANT

Page 1 of 6 AUGUST 2018 TFP356

Page 2

TFP356

* ** †

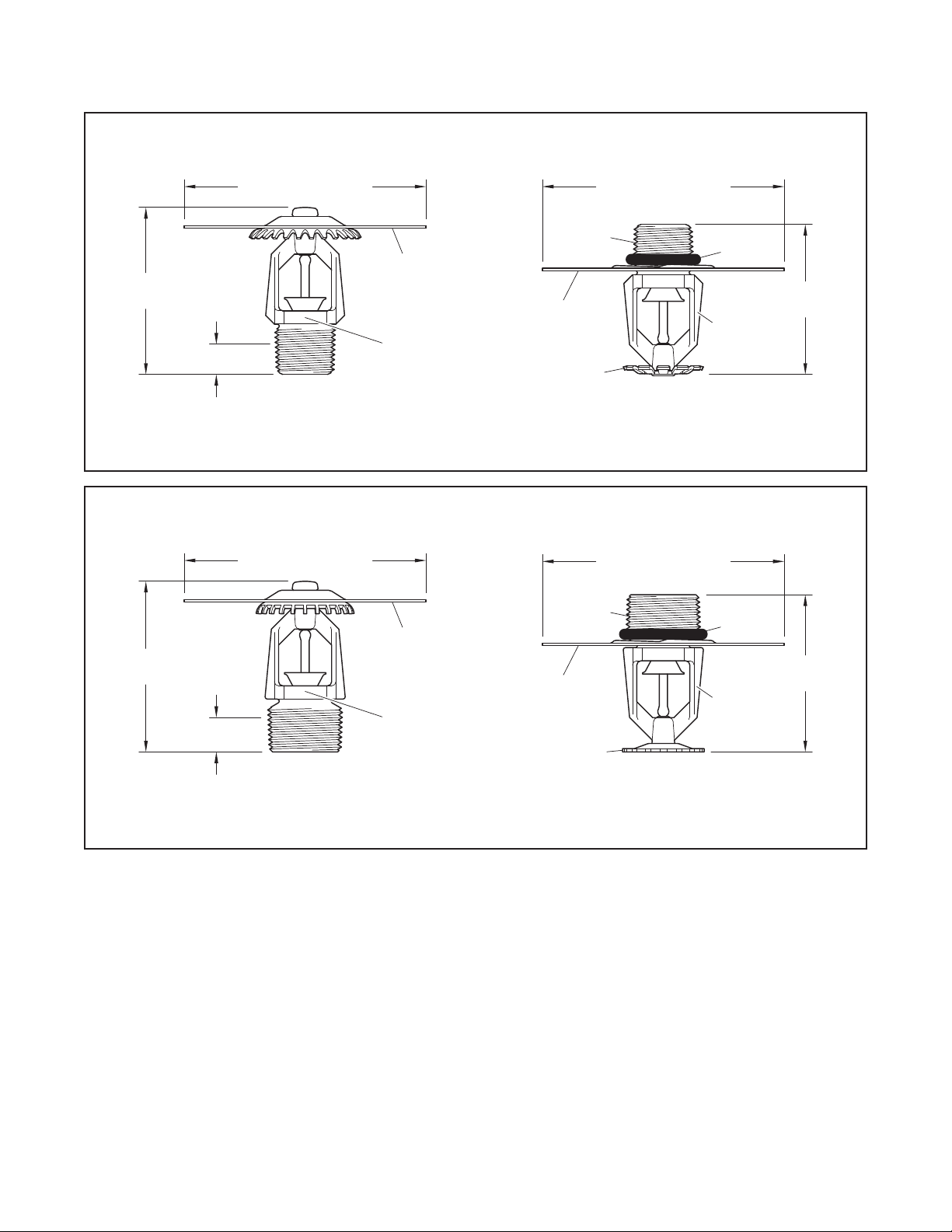

FIELD ASSEMBLED PENDENTFACTORY ASSEMBLED UPRIGHT

(55,6 mm)

(60,3 mm)

* ** †

FACTORY ASSEMBLED UPRIGHT FIELD ASSEMBLED PENDENT

(61,9 mm)

(58,7 mm)

Page 2 of 6

Temperature rating is indicated

on Deector, Shield or adjacent

to orice seat on frame

3-1/2" (88,9 mm) DIA.

7/16"

2-3/8"

(11,1 mm)

NOMINAL

MAKE-IN

Pipe thread connections per

ISO 7-1 can be provided on

special request

FACTORY

ASSEMBLED

UPRIGHT SHIELD

WITH SCREW

WRENCH

FLATS

*

FIELD ASSEMBLED

MODEL S2 SHIELD

(SEE INSTALLATION

Order Pendent Series TY-FRB Sprinkler and

Model S2 Shield Package separately for

pendent assembly (Ref. Ordering Procedure)

3-1/2" (88,9 mm) DIA.

1/2" NPT

SECTION)

DEFLECTOR

**

*

O-RING

PENDENT

SERIES

TY-FRB

†

FIGURE 1

SERIES TY-FRB UPRIGHT (TY3133) & PENDENT (TY3231) INTERMEDIATE LEVEL SPRINKLERS

5.6K, QUICK RESPONSE, 1/2 INCH NPT

Temperature rating is indicated

on Deector, Shield or adjacent

to orice seat on frame

3-1/2" (88,9 mm) DIA.

Pipe thread connections per

ISO 7-1 can be provided on

special request

Order Pendent Series TY-FRB Sprinkler and

Model S2 Shield Package separately for

pendent assembly (Ref. Ordering Procedure)

3-1/2" (88,9 mm) DIA.

2-3/16"

FACTORY

ASSEMBLED

UPRIGHT SHIELD

WITH SCREW

WRENCH

FLATS

2-7/16"

1/2"

(12,7 mm)

NOMINAL

MAKE-IN

SERIES TY-FRB UPRIGHT (TY4133) & PENDENT (TY4231) INTERMEDIATE LEVEL SPRINKLERS

8.0K, QUICK RESPONSE, 3/4 INCH NPT

Maximum Working Pressure

Technical

Data

Approvals

UL and C-UL Listed

FM and NYC Approved

(Refer to Table A for complete approval

information, including corrosion-resistant

status.)

175 psi (12,1 bar)

Discharge Coefficients

K=5.6 GPM/psi½ (80,6 LPM/bar½)

K=8.0 GPM/psi½ (115,2 LPM/bar½)

Temperature Ratings

Refer to Table A

Finishes

Sprinklers: Refer to Table A

*

FIELD ASSEMBLED

MODEL S2 SHIELD

(SEE INSTALLATION

FIGURE 2

3/4" NPT

SECTION)

DEFLECTOR

**

O-RING

2-5/16"

PENDENT

SERIES

TY-FRB

*

†

Physical Characteristics

Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bronze

Button . . . . . . . . . . . . . . . . . . . . . . Brass/Copper

Sealing Assembly ..Ber yllium Nickel w/TEFLON

Bulb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Glass

Compression Screw . . . . . . . . . . . . . . . . .Bronze

Deflector . . . . . . . . . . . . . . . . . . . . . . . . . Copper

Shield . . . . . . . . . . . . . . . . . . . . . . . .Plated Steel

Page 3

TFP356

Page 3 of 6

K-FACTOR

5.6

1/2 in. NPT

SPRINKLER

TYPE

UPRIGHT

(TY3133)

UPRIGHT

(TY3231)

PENDENT

( T Y413 3 )

TEMPERATURE

RATING

135 °F (57 °C) Orange

155 °F (68 °C) Red

175 °F (79 °C) Yel l ow

200 °F (93 °C) Green

286 °F (141 °C) Blue

135 °F (57 °C) Orange

155 °F (68 °C) Red

175 °F (79 °C) Yel l ow

200 °F (93 °C) Green

286 °F (141 °C) Blue

135 °F (57 °C) Orange

155 °F (68 °C) Red

175 °F (79 °C) Yel l ow

200 °F (93 °C) Green

BULB

LIQUID COLOR

SPRINKLER FINISH

NATURAL

BRASS*

1, 2, 3, 4

LEAD

COATE D**

1, 2, 3, 4

N/A

1, 2, 3, 4

8.0

3/4 in. NPT

PENDENT

(TY4231)

Notes:

1. UL Liste d as quick re sponse s prinklers

2. C-UL Liste d as quick re sponse s prinklers

3. F M Approved as quick re sponse sprinkle rs

4. A pproved by t he City of N ew York (NYC) under MEA 354- 01-E

* With zin c plated shield

** Whe re Lead Coated sprinklers a re noted to be U L and C-UL Listed, th e sprinkl ers are Listed as co rrosio n-resistant spr inkler s;

where Lead Coated sprinkl ers are no ted to be FM App roved, the s prinkle rs are Ap proved as corrosio n-resi stant sprinkler s.

N/A – Not App licable

286 °F (141 °C) Blue

135 °F (57 °C) Orange

155 °F (68 °C) Red

175 °F (79 °C) Yel l ow

200 °F (93 °C) Green

286 °F (141 °C) Blue

N/A

TABL E A

5.6K & 8 .0K SERIES TY-FRB UPRIGHT & PENDENT INTERMEDIATE LEVEL SPRINKLERS, QUICK RESPONSE

LABORATORY LISTINGS AND APPROVALS

Design

Criteria

TYCO Series TY-FRB 5.6K and 8.0K

Quick Response Upright and Pendent

Intermediate Level Sprinklers are

intended for fire protection systems

designed in accordance with the standard installation rules recognized

by the applicable listing or approval

agency (e.g., UL Listing is based on

the requirements of NFPA 13, and FM

Approval is based on the requirements

of FM Approvals’ Loss Prevention Data

Sheets).

Operation

The glass bulb contains a fluid which

expands when exposed to heat. When

the rated temperature is reached, the

fluid expands sufficiently to shatter the

glass bulb, allowing the sprinkler to

activate and water to flow.

Page 4

TFP356

(END "A" USED FOR

3/4" NPT MODELS)

Page 4 of 6

WRENCH RECESS

1/2" NPT MODELS)

WRENCH RECESS

(END "B" USED FOR

FIGURE 3

W-T Y PE 6

SPRINKLER WRENCH

Installation

TYCO Series TY-FRB 5.6K and 8.0K

Quick Response Upright and Pendent

Intermediate Level Sprinklers must

be installed in accordance with this

section.

NOTICE

Do not install any bulb-type sprinkler

if the bulb is cracked or there is a loss

of liquid from the bulb. With the sprinkler held horizontally, a small air bubble

should be present. The diameter of the

air bubble is approximately 1/16 in.

(1,6 mm) for the 135°F (57°C) to 3/32 in.

(2,4 mm) for the 286°F (141°C) temperature ratings.

General Instructions

A leak-tight 1/2 in. NPT sprinkler joint

should be obtained by applying a

minimum-to-maximum torque of 7 to

14 lb-ft (9,5 to 19,0 N∙m). A leak-tight

3/4 in. NPT sprinkler joint should be

obtained by applying a minimum-tomaximum torque of 10 to 20 lb-ft (13,4

to 26,8 N∙m). Higher levels of torque

may distort the sprinkler inlet and

cause leakage or impairment of the

sprinkler.

Upright Sprinklers

The Series TY-FRB Intermediate Level

Upright Sprinklers must be installed

in accordance with the following

instructions:

Step 1. With pipe thread sealant

applied to the pipe threads, handtighten the sprinkler into the sprinkler

fitting.

Step 2. Tighten the sprinkler into the

sprinkler fitting using only the W-Type

6 Sprinkler Wrench (Ref. Figure 3). With

reference to Figure 1 or 2, the W-Type

6 Sprinkler Wrench is to be applied to

the wrench flats.

Pendent Sprinklers

The Series TY-FRB Intermediate Level

Pendent Sprinklers must be installed

in accordance with the following

instructions:

Step 1. Thread the Model S2 Shield

onto the sprinkler threads with the

stamped markings toward the deflector

and just to the end of the threads. The

final assembly step is easier to accomplish if the shield is not disengaged by

continuing to turn the shield past the

threads.

Step 2. Roll the O-ring over the sprinkler threads until it seats against the

shield.

Step 3. With pipe thread sealant

applied to the pipe threads, handtighten the sprinkler into the sprinkler

fitting.

Step 4. Tighten the sprinkler into the

sprinkler fitting using only the W-Type

6 Sprinkler Wrench (Ref. Figure 3). With

reference to Figure 1 or 2, the W-Type

6 Sprinkler Wrench is to be applied to

the wrench flats.

Step 5. Rotate the Model S2 Shield

clockwise (looking up) so that it slightly

compresses the O-ring between the

shield and sprinkler fitting.

Care and

Maintenance

TYCO Series TY-FRB 5.6K and 8.0K

Quick Response Upright and Pendent

Intermediate Level Sprinklers must be

maintained and serviced in accordance

with this section.

Before closing a fire protection system

control valve for maintenance work on

the fire protection system that it controls, permission to shut down the

affected fire protection system must

be obtained from the proper authorities

and all personnel who may be affected

by this action must be notified.

Sprinklers that are found to be leaking

or exhibiting visible signs of corrosion

must be replaced.

Automatic sprinklers must never be

painted, plated, coated or otherwise altered after leaving the factory.

Modified sprinklers must be replaced.

Sprinklers that have been exposed to

corrosive products of combustion, but

have not operated, should be replaced

if they cannot be completely cleaned

by wiping the sprinkler with a cloth or

by brushing it with a soft bristle brush.

Care must be exercised to avoid

damage to the sprinklers before,

during, and after installation. Sprinklers damaged by dropping, striking,

wrench twist/slippage, or the like, must

be replaced. Also, replace any sprinkler

that has a cracked bulb or that has lost

liquid from its bulb. Refer to the Installation section for additional information.

Frequent visual inspections are recommended to be initially performed

for corrosion resistant coated sprinklers, after the installation has been

completed, to verify the integrity of the

corrosion-resistant coating. Thereafter,

annual inspections per NFPA 25 should

suffice; however, instead of inspecting

from the floor level, a random sampling

of close-up visual inspections should

be made, so as to better determine the

exact sprinkler condition and the long

term integrity of the corrosion resistant

coating, as it may be affected by the

corrosive conditions present.

The owner is responsible for the

inspection, testing, and maintenance of

their fire protection system and devices

in compliance with this document, as

well as with the applicable standards of

the National Fire Protection Association

(e.g., NFPA 25), in addition to the standards of any other authorities having

jurisdiction. Contact the installing contractor or sprinkler manufacturer with

any questions.

It is recommended that automatic

sprinkler systems be inspected, tested,

and maintained by a qualified Inspection Service in accordance with local

requirements and/or national codes.

Page 5

P/N 57 — XXX — X — XXX

TFP356

Page 5 of 6

1

7

SPRINKLER

FINISH

NAT URAL

BRASS

LEAD

CO ATE D

SIN

333 5.6K UPRIGHT (1/2 in. NPT) TY3133

343 8.0K UPRIGHT (3/4 in. NPT) T Y4133

TABL E B

SERIES TY-FRB UPRIGHT INTERMEDIATE LEVEL SPRINKLERS, QUICK RESPONSE

PART NUMBER SELECTION

P/N 57 — XXX — X — XXX

1

7

SPRINKLER

FINISH

NAT URAL

BRASS

LEAD

CO ATE D

SIN

371 5.6K PENDENT (1/2 in. NPT ) TY3231

391 8.0K PENDENT (3/4 in. NPT) TY4231

TEMPERATURE

RATING

135 13 °F (57°C)

155 155° F (68°C)

175 17 5° F (7 9°C )

200 200°F (93°C)

286 28 6° F (141°C)

TEMPERATURE

RATING

135 135°F (57°C)

155 155° F (68°C)

SERIES TY-FRB PENDENT INTERMEDIATE LEVEL SPRINKLERS, QUICK RESPONSE

(MODEL S2 PENDENT SHIELD MUST BE SEPARATELY ORDERED)

Limited

Warranty

For warranty terms and conditions, visit

www.tyco-fire.com.

Ordering

Procedure

Contact your local distributor for availability. When placing an order, indicate the full product name, including

description and part number (P/N).

TABL E C

PART NUMBER SELECTION

Upright Sprinkler Assemblies with

NPT Thread Connections

(with Shield)

Specify: Series TY-FRB Upright Intermediate Level Sprinkler, (specify

K-factor), Quick Response, (specify)

temperature rating, (specify) finish, P/N

(specify from Table B)

Pendent Sprinkler Assemblies with

NPT Thread Connections

(Shield ordered separately)

Specify: Series TY-FRB Pendent

Sprinkler, (specify K-factor), Quick

Response, (specify) temperature

rating, (specify) finish, P/N (specify from

Tabl e C)

175 17 5° F (7 9°C )

200 200°F (93°C)

286 28 6° F (141°C)

Model S2 Sprinkler Shield

Includes S2 Shield and one O-Ring.

Specify: Model S2 Sprinkler Shield,

(specify) Thread Size, P/N (specify):

1/2 in. NPT . . . . . . . . . . . . . . . . . . 56- 070-9 -332

3/4 in. NPT . . . . . . . . . . . . . . . . . . 56- 070-9 -342

Sprinkler Wrench

Specify: W-Type 6 Sprinkler Wrench,

P/N 56-000-6-387

Page 6

TFP356

Page 6 of 6

1400 Pennbro ok Park way, Lans dale, PA 19446 | Telephone +1-215- 362- 0700

© 2018 John son Control s. All right s reserved. A ll specifica tions and ot her informa tion shown wer e current as o f document rev ision date an d are subject t o change wit hout notice.

NATIONAL FIRE P ROTECTION ASSOCIATIO N and NFPA are register ed trademarks of N ational Fire Protec tion Associati on;

TEFLON is a regi stered tradema rk of DuPont

Loading...

Loading...