Page 1

Technical Service s: Tel: (800) 381-9312 / Fax: (800) 791-5500

Model TFP PH2 — 5.6 K-factor

Institutional Pendent Sprinklers

Standard Response, Standard Coverage

General

Description

The Tyco® Model TFP PH2, 5.6

K-factor, Institutional Pendent Sprinklers are standard response standard

coverage, fusible solder type spray

sprinklers designed for use in areas

such as correctional, detention, and

mental health care facilities.

The unique features of the Model TFP

PH2 provide a tamper resistant sprinkler design that helps eliminate the

opportunity for individuals to injure

themselves or others with the components of a fire sprinkler. At the same

time, the Model TFP PH2 optimizes an

aesthetically appealing flush design

that conceals most of the operating

parts.

NOTICE

The Model TFP PH2 Institutional Pendent Sprinklers described herein must

be installed and maintained in compliance with this document, as well as

with the applicable standards of the

National Fire Protection Association, in

addition to the standards of any other

authorities having jurisdiction. Failure

to do so may impair the per formance

of these devices.

The owner is responsible for maintaining their fire protection system and

devices in proper operating condition.

The installing contractor or manufacturer should be contacted with any

questions.

IMPORTANT

Always refer to Technical Data

Sheet TFP700 for the “INSTALLER

WARNING” that provides cautions

with respect to handling and installation of sprinkler systems and components. Improper handling and

installation can permanently damage a sprinkler system or its components and cause the sprinkler to fail

to operate in a fire situation or cause

it to operate prematurely.

Sprinkler

Identification

Number (SIN)

TY3290

Technical

Data

Approvals

UL and C-UL Listed

NYC under MEA 351-01-E

(Refer to the Design Criteria section.)

Maximum Working Pressure

175 psi (12,1 bar)

Inlet Thread Connection

1/2 inch NPT

Discharge Coefficient

K=5.6 GPM/psi

Temperature Ratings

165°F/74°C or

212°F/100°C

Finishes

Sprinkler: Chrome Plated

Escutcheon: Chrome Plated

Physical Characteristics

Body ..................... Brass

Deflector................. Bronze

Deflector Reinforcement .... B r o n z e

Deflector Post............. Bronze

Deflector Post Pin ......... Bronze

Deflector Core ............ Bronze

Compression Screw........ Bronze

Lever.................... Bronze

Release Spring ............ Bronze

Core Sleeve ..............Copper

Sealing Assembly................

. . . . . . . . .Beryllium Nickel w/ Teflon†

Fusible Element .................

. . . . . Solder, Copper, Stainless Steel

Dust Cover .... Chrome Plated Steel

1/2

(80,6 LPM/bar

†

DuPont Registered Trademark

1/2

)

Operation

In the standby condition, the design

of the Model TFP PH2 is such that a

dynamic load of 80 lbs. (36 kg) or more

applied to the linkage mechanism will

release the sprinkler. Also, when properly installed, the escutcheon is held

fast to the ceiling to deter its removal.

The shape of the escutcheon cannot

be easily grasped, which further deters tampering.

A fusible solder operating element secures the linkage mechanism of the

Model TFP PH2. When the rated temperature is reached, the solder melts,

releasing the linkage mechanism that

holds the sprinkler closed. This allows

the deflector to extend downward and

water to flow.

Design

Criteria

The Tyc o® Model TFP PH2, 5.6

K-factor, Institutional Pendent Sprinklers (TY3290) are intended for use

with fire protection systems designed

in accordance with the standard installation rules recognized by the applicable Listing or Approval agency

(for example, Listing is based on NFPA

13 requirements).

Page 1 of 4 JULY 2009 TFP650

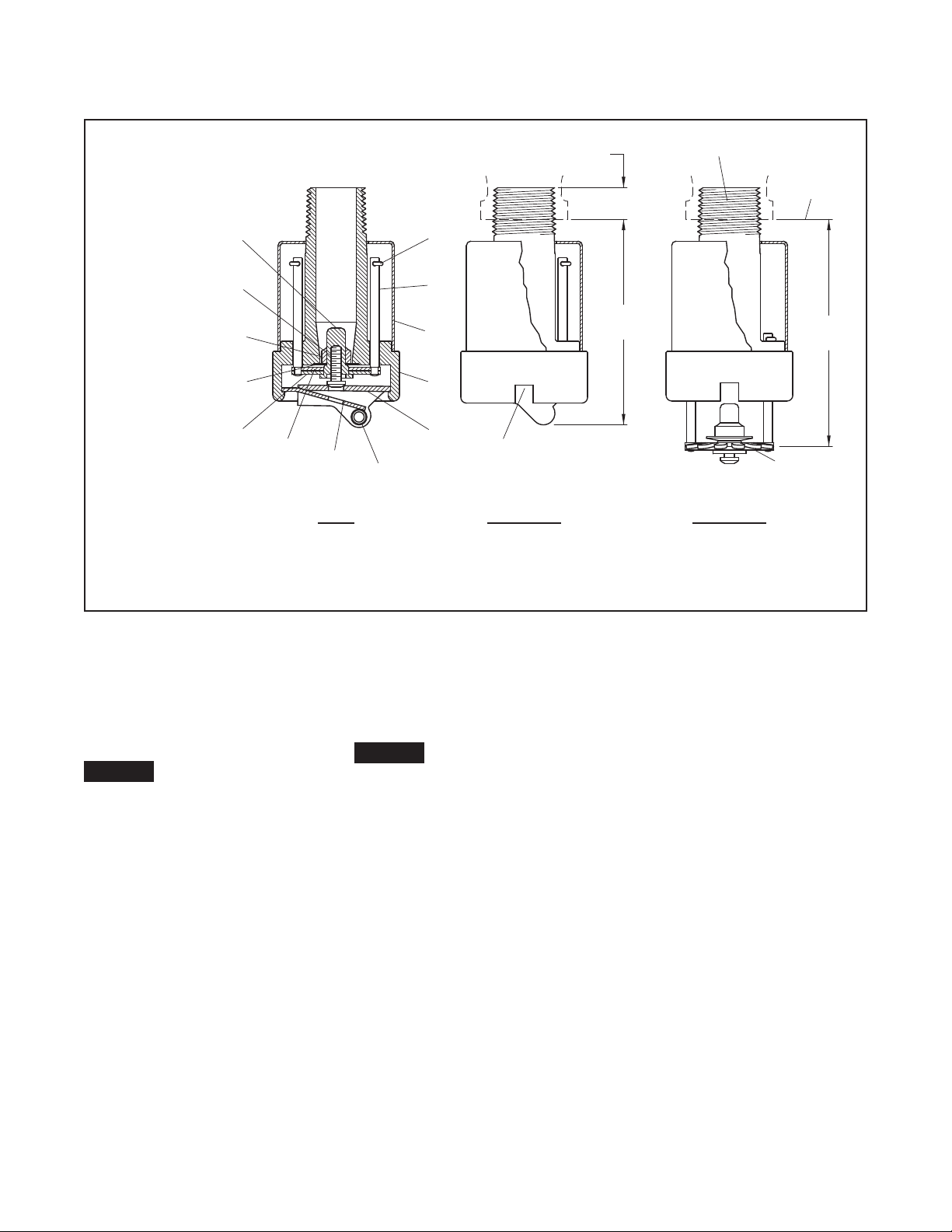

Page 2

TFP650

CROSS-SECTION

VIEW

INSTALLED

SIDE VIEW SIDE VIEW

OPERATED

Components:

1/2" NPT

SPRINKLER

WRENCHING

NOTCH (2)

DEFLECTOR

IN OPERATED

POSITION

SPRINKLER

FITTING

FACE OF

NOMINAL MAKE-IN

7/16" (11.1 mm)

(80.8 mm)

3.18"

2.81"

(71.4 mm)

13

12

9

1

4

5

10

8

2

3

11

7

6

-

2 Deflector

Screw

Deflector Core

Compression

Deflector Post

Deflector

-

8

-

4

7

-

3

-

Body1

-

Pin (2 Req'd)

Deflector Post

-

6

5

-

Reinforcement

(2 Req'd)

Dust Cover

Sealing Assembly

Fusible Element

Core Sleeve

Release Spring

Lever

9

-

10

-

11

-

12

-

13

-

Page 2 of 4

Only the Institutional Escutcheons

shown in Figure 2 can be utilized with

the Model TFP PH2. A maximum of

three Model 1752 Spacers only can be

utilized with Style B1 or C Institutional

Escutcheons when vertical adjustment

is desired.

NOTICE

The integrity of the tamper resistant

design of the Institutional Escutcheons

is dependent on the piping installation

d e si g n. W h en i n st a ll e d p ro p e r ly , th e I nstitutional Escutcheon is held fast to the

mounting surface by the tightening of

the sprinkler assembly into the sprinkler

fitting. In order to accomplish a proper

installation, the sprinkler fitting must be

p r o p e r l y l o c a t e d w i t h r e s p e c t t o t h e d i s tance from the face of the sprinkler fitting to the face of the mounting surface

(Ref. Fig. 2); the sprinkler fitting being

r i g i d l y s e c u r e d a n d h e l d i m m o b i l e ; a n d ,

the center-line of the sprinkler fitting

being perpendicular to the mounting

surface to assure that the escutcheon

sits squarely against the mounting

surface around the entire perimeter of

the Institutional Escutcheon.

fIguRe 1

MOdel TfP Ph2

INsTITuTIONAl PeNdeNT sPRINkleR

Installation

The Ty c o® Model TFP PH2, 5.6

K-f a ctor, Sprinklers must be installed

in accordance with the following

instructions.

NOTICE

Refer to the Design Criteria section for

important information regarding the

piping installation design and its effect

o n m ai nt ain in g t he int eg ri ty o f t he ta mper resistant design of the Institutional

Escutcheons.

Obtain a 1/2 inch NPT sprinkler joint

by applying a minimum to maximum

torque of 7 to 14 ft.lbs. (9,5 to 19,0

Nm). Higher levels of torque can distort the sprinkler Inlet with consequent

leakage or impairment of the sprinkler.

Do not attempt to compensate for improper location of the sprinkler fitting by

under- or over-tightening the sprinkler.

Re-adjust the position of the sprinkler

fitting to suit, or increase or decrease

the number of Model 1752 Spacers,

as applicable.

A f te r th e i n st a l la t i on i s c om p le t e, ma k e

certain that the Institutional Escutcheon

i s h e l d f a s t t o t h e m o u n t i n g s u r f a c e a n d

that it sits squarely against the ceiling

around its entire perimeter.

Step 1. Install the TFP PH2 Sprinklers

only in the pendent position and with

the center-line of the waterway perpendicular to the ceiling.

Step 2. With the Institutional Escutcheon in place and with pipe thread sealant applied to the pipe threads, hand

tighten the sprinkler into the sprinkler

fitting.

Step 3. Wrench-tighten the Sprinkler using only the Model 1509-3

Sprinkler Wrench (Ref. Fig. 4). Apply

the wrenching teeth of the Sprinkler

Wrench to the sprinkler wrenching

notch areas (Ref. Fig. 1).

Step 4. After the installation is complete, make certain that the Institutional Escutcheon is held fast to

the mounting surface and that it sits

squarely against the ceiling around its

entire perimeter.

Page 3

UP TO

#1752

THREE

SPACERS

1-3/16"

(30.2 mm)

1.11" (28.2 mm) MIN.

1.33" (33.8 mm) MAX.

1.70" (43.2 mm) MAX.

1.48" (37.6 mm) MIN.

WITH 3 SPACERS

WITH NO SPACERS

(127.0 mm)

5" DIA.

DIAMETER DETERMINED

BY CLEARANCE FOR

REDUCING COUPLING

(82.6 mm)

3-1/4" DIA.

(4.8 mm)

3/16"

(41.1 mm)

1.62"

(30.2 mm)

1.19"

DIAMETER DETERMINED

REDUCING COUPLING

BY CLEARANCE FOR

WITH 3 SPACERS

WITH NO SPACERS

DIAMETER DETERMINED

BY CLEARANCE FOR

REDUCING COUPLING

4-1/4" DIA.

(108.0 mm)

SPACERS

2-9/16"

UP TO

THREE

#1752

(65.1 mm)

2.81" (71.4 mm) MAX.

2.59" (65.8 mm) MIN.

FLUSH MIN.

0.22" (5.6 mm) MAX.

STYLE C

STYLE A

SPACERS

STYLE B1

WITH 3

(1)

(2)

(1)

(2)

(1)

(2)

(1)

(2)

(1)

(2)

(1)

(2)

TFP650

Page 3 of 4

Care and

Maintenance

The Tyc o® Model TFP PH2, 5.6

K-fa ctor Sprinklers must be maintained and serviced in accordance

with the following instructions.

NOTICE

Service inspections should be made

on a regular basis to detect possible

damage or alterations to the sprinkler

and escutcheon. Inspections should

include making certain that the Institutional Escutcheon is held fast to the

mounting surface. Damaged or altered

sprinklers are to be replaced immediately

to avoid personal injury and to prevent

use for causing personal injury, as well

as to maintain the sprinkler system in an

operative condition.

Before closing a fire protection system

main control valve for maintenance work

on the fire protection system that it controls, obtain permission to shut down

the affected fire protection systems

from the proper authorities and notify

all personnel who may be affected by

this action.

Replace sprinklers that are leaking or

exhibiting visible signs of corrosion.

Never paint, plate, coat, or otherwise

alter automatic sprinklers after they

leave the factory. Replace modified or

over-heated sprinklers.

Exercise care to avoid damage to the

sprinklers before, during, and after

installation. Replace sprinklers damaged by dropping, striking, wrench

twisting, wrench slipping, or the like.

Responsibility lies with the owner for

the inspection, testing, and maintenance of their fire protection system

and devices in compliance with this

document, as well as with the applicable standards of the National Fire

Protection Association (for example,

NFPA 25), in addition to the standards

of any other authorities having jurisdiction. Contact the installing contractor or sprinkler manufacturer regarding

any questions.

Automatic sprinkler systems should

be inspected, tested, and maintained

by a qualified Inspection Service in

accordance with local requirements

and/or national codes.

fIguRe 2

INsTITuTIONAl escuTcheON OPTIONs

fOR use wITh The MOdel TfP Ph2

Page 4

SHOULDER

PIPE PLUG

SPRINKLER

REDUCING

FITTING

CUP

RECESSED

CONCRETE

WOODEN

FORM

SYSTEM

PIPE

1"

SUPPORT

PIPE

MODEL 1754

MODEL 1290-8

MODEL 1753

1/2" DRIVE

ACCEPTS

TEETH

WRENCHING

TFP650

Page 4 of 4

INsTAllATION IN cONcReTe wITh sTyle A escuTcheON

fIguRe 3

Ordering

Procedure

Contact your local distributor for availability. When placing an order, indicate the full product name.

Sprinkler Assemblies

Specify: 5.6 K-factor, Chrome Plated, (temperature rating), Model TFP

PH2 (TY3290) Institutional Pendent

Sprinkler.

16 5F/ 74C ................ P/N 51-10 4-9 -165

212F/100C ............... P/ N 51-104-9-212

Separately Ordered Escutcheons

Specify: Style (A, B1, or C), Chrome

Plated, Institutional Escutcheons.

Style A ...................P /N 56- 012-7- 622

Style B1 .................P /N 5 6-0 01-7- 511

Style C ..................P /N 56 -001-7-513

Separately Ordered Wrenches

Specify: Model 1509-3 Sprinkler

Wrench, P/N 56-001-5-093.

Limited

Warranty

Products manufactured by Tyco Fire

Suppression & Building Products

(TFSBP) are war ranted solely to the

original Buyer for ten (10) years against

defects in mate rial and workmanship

when paid for and properly installed

and maintained under normal use and

service. This warranty will expire ten

(10) years from date of shipment by

TFSBP. No warranty is given for products or com ponents manufactured by

companies not affiliated by ownership

with TFSBP or for products and components which have been subject to

misuse, improper installation, corrosion, or which have not been installed,

maintained, modi fied or repaired in accordance with ap plicable Standards of

the National Fire Protection Association, and/or the standards of any other

Authorities Having Jurisdiction. Materials found by TFSBP to be defective

shall be either repaired or replaced, at

TFSBP’s sole option. TFSBP neither

assumes, nor authorizes any person

to assume for it, any other obligation

in connection with the sale of products

or parts of prod ucts. TFSBP shall not

be responsible for sprinkler system

design errors or inac curate or incomplete information sup plied by Buyer or

Buyer’s repre sentatives.

In no event shall TFSBP be liable, in

contract, tort, strict liability or under

any other legal theory, for incidental, indirect, special or consequential

dam ages, including but not limited to

labor charges, regardless of whether TFSBP was informed about the

fIguRe 4

MOdel 1509-3

sPRINkleR wReNch

possibility of such damages, and in no

event shall TFSBP’s liability exceed an

amount equal to the sales price.

The foregoing warranty is made in

lieu of any and all other warranties,

express or implied, including warranties of merchantability and fitness for

a particular purpose.

This limited warranty sets forth the exclusive remedy for claims based on

failure of or defect in products, materials or components, whether the claim

is made in contract, tort, strict liability

or any other legal theory.

This warranty will apply to the full extent permitted by law. The invalidity,

in whole or part, of any portion of this

warranty will not affect the remainder.

Separately Ordered Spacers for

Vertical Adjustment

Specify: Model 1752 Spacers for use

with Style B-1 and C Institutional Escutcheons, P/N 56-000-1-752.

Separately Ordered Parts for

Installation in Concrete With

Type A Escutcheon

(Refer to Figure 3.)

Specify: Model 1753 Recessed

Cup for use with Style A Escutcheon for installation in concrete,

P/N 56-000-1-753.

Specify: Model 1290-8 Pipe Plug With

Shoulder for use with Style A Escutcheon for installation in concrete,

P/N 56-001-2-908.

Specify: Model 1754 Pipe Support for

use with Style A Escutcheon for installation in concrete, P/N 56-000-1-754.

© 200 9 TYCO FIRE SUPPRESSION & BUILDING PRODUCTS

, 451 North Cannon Avenue, Lansdale, Pennsylvania 19446

Loading...

Loading...