Page 1

Installation Instructions and User Guide

®

F

M

APPROVED

R

LISTED

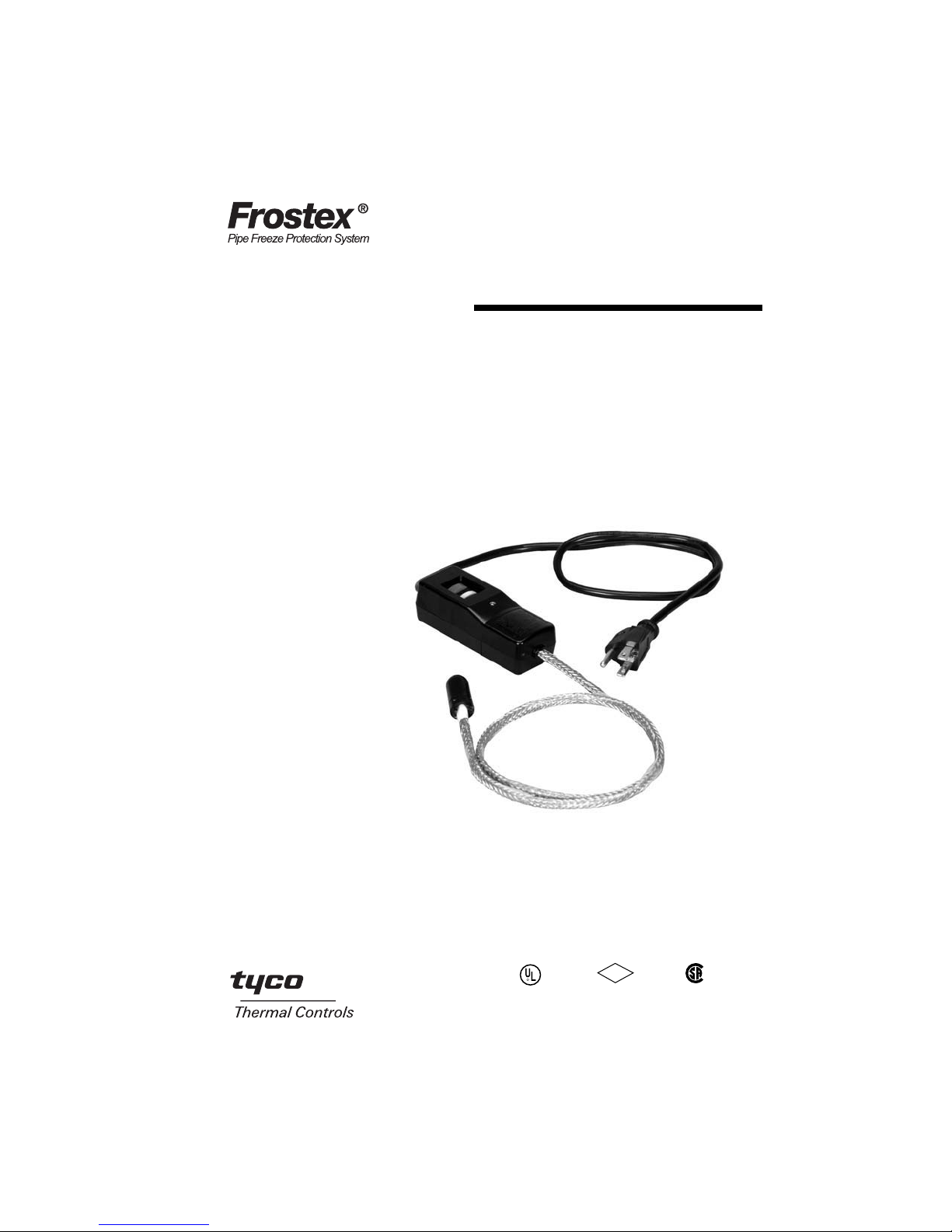

for the Frostex Pipe Freeze Protection System

Using the 9800 FlexFit Plug Kit

Directives d’installation et Guide de l’Utilisateur

du Système Frostex de Protection Anti-gel des

Tuyaux Utilisé avec le Kit Frostex 9800 FlexFit

Keep pipes from freezing

Protection anti-gel des tuyaux

60J9 Residential

and Mobile Home

Pipe Heating Cable

Page 2

Contents

Five Important Safety Warnings 1

General Instructions 2

Installation Instructions 2

Periodic Inspections 8

Troubleshooting 8

ENGLISHFRANÇAIS

Limited Warranty 9

Table des matières

Cinq avertissements de sécurité importants 1

Directives générales 10

Directives d’installation 10

Inspections périodiques 16

Dépannage 16

Garantie limitée 17

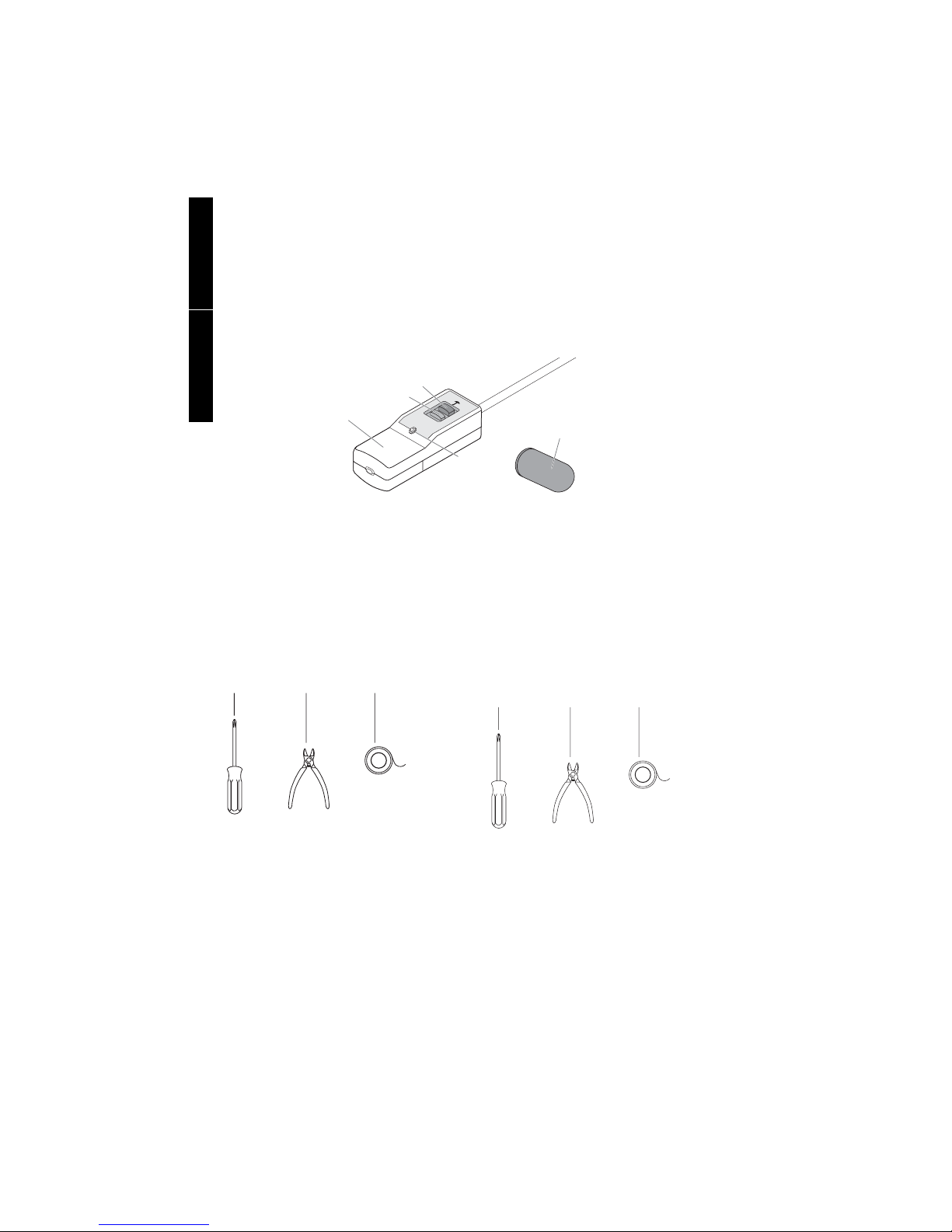

9800 FlexFit plug

Ground-fault unit

Reset button

Test button

K

G

a

rd

T

ES

er

T

au s

ec

Before You Begin

Make sure your 9800 FlexFit Plug Kit is complete. It should contain:

1 9800 FlexFit plug

1 Push-on end seal

2 Orange warning labels in English

2 Orange warning labels in French

1 White tape strip

1 Installation instruction

Make sure you have sufficient braided Frostex heating

cable for the job. Do not use earlier versions of Frostex

heating cable that have no braid. Also make sure you

have the following items:

#2 Phillips

screwdriver

Wire cutters

1/2"–1"

(13 mm–25 mm)

tape*

ee

p

dry

Gel-filled end seal

Indicator

light

Avant de débuter

Assurez-vous que votre kit 9800 FlexFit contient tout ce qui

suit:

1 Fiche 9800 FlexFit

1 Obturateur à pousser

2 Étiquettes oranges d’avertissement en anglais

2 Étiquettes oranges d’avertissement en français

1 Bande de ruban blanc

1 Manuel des directives d’installation

Assurez-vous d’avoir suffisamment de câble chauffant tressé

Frostex pour effectuer le travail. N’employez pas les versions

antérieures des câbles chauffants Frostex sans tresses.

Ayez également les articles suivants en main:

Tournevis

Phillips°2

Un

coupe-câble

Du ruban *

de 13 mm-25 mm

(1/2-1po)

*Frostex 9610 application tape is recommended.

Two 10" (25 cm) plastic cable ties (not included) may be used

to secure ground-fault unit to pipe insulation.

If you have any questions after reading this guide, call this

toll-free Tyco Thermal Controls number: (800) 545-6258.

Save this installation instruction and user guide. It contains important safety warnings and maintenance information.

*Le ruban de fixation Frostex 9610 est recommandé.

Deux colliers de serrage en plastique de 25 cm (10 po) (non

inclus) peuvent être utilisés pour fixer le disjoncteur différentiel

à l’isolant de tuyaux.

Si vous avez des questions après la lecture du présent guide,

contactez le numéro sans frais de Tyco Thermal Controls au :

(800) 545-6258.

Conservez ces directives d’installation ainsi que le

guide de l’utilisateur. Ils contiennent d’importants

avertissements de sécurité et une notice d’entretien.

Page 3

Five Important Safety Warnings

Follow all five of these instructions to prevent fire

or shock:

1. Use the correct heating cable.

• Use only braided versions of Frostex heating cable.

• Earlier versions of Frostex heating cable with no braid

are not compatible.

2. Use the right end seal and plug.

• Seal the heating cable only with the end seal provided;

do not use electrical tape.

• Use the 9800 FlexFit plug contained in this kit. It has

special safety features.

• Use the 9800 FlexFit Plug Kit only with Frostex heating

cable.

3. Do not twist wires together or allow them to

touch each other.

• Do not strip the heating cable. If wires touch, the nonreplaceable fuse will blow and the system will not work.

4. Keep the entire Frostex system dry. This includes

the insulation.

If the system gets wet, pipes may freeze.

• Use the system only on insulated residential pipes

carrying water.

• Do not use the system on buried pipes.

• Do not use the system to de-ice roofs or gutters.

• Do not install any part of the heating system where it

would be under water.

• Do not use where water is likely to enter the plug.

5. The blue plastic heating cable and the metal

braid must not be cut or damaged.

• Before you begin, inspect the pipe. File and remove any

sharp edges. Make sure the heating cable crosses only

smooth, nonabrasive surfaces.

• Where the system might be damaged by animals or

objects, protect the complete system with a solid cover,

such as sheet metal or additional pipe insulation.

• Do not use any wire or clamps to attach the heating

cable to the pipe. Instead, use the Frostex 9610 application tape, or equivalent 1/2"–1" (13 mm–25 mm) tape,

or plastic cable ties.

• Inspect the heating cable periodically for damage. If you

discover broken braid or other damage, immediately disconnect the system and replace the heating cable. Do not

splice or repair a damaged heating cable. You must replace

any damaged insulation or waterproof covering.

6. Do not install Frostex heating cable close to

flammable materials, liquids, or fumes.

Use only 1/2" (13 mm) or thicker fire-retardant and waterproof

pipe insulation, in accordance with Table 1 or 2.

Cinq avertissements de sécurité

importants

Veuillez suivre les cinq directives suivantes afin de

prévenir les risques d’incendie ou de choc électrique:

1. Utilisez le câble chauffant adéquat.

• Employez uniquement les versions tressées des câbles

chauffants Frostex.

• Les versions antérieures des câbles chauffants Frostex

sans tresses ne sont pas compatibles.

2. Utilisez la fiche et l’obturateur appropriés.

• Étanchéifiez le câble chauffant à l’aide de l’obturateur

fourni seulement; n’utilisez pas de ruban isolant.

• Utilisez la fiche 9800 FlexFit incluse dans ce kit; elle est

dotée de caractéristiques de sécurité spéciales.

• Utilisez le kit 9800 FlexFit uniquement avec le câble

chauffant Frostex.

3. Ne torsadez pas les fils ensemble ni ne leur permettez de se toucher.

• Ne dénudez pas le cable chauffant. Si des fils se

touchent, le fusible non remplaçable sautera et le système ne fonctionnera plus.

4. Gardez le système Frostex au sec en entier, y

compris l’isolant.

Les tuyaux risquent de geler si de l’humidité pénètre dans

le système.

• Utilisez le système uniquement sur des tuyaux résidentiels et isolés, transportant de l’eau.

• N’utilisez pas le système sur des tuyaux souterrains.

• N’utilisez pas le système pour dégivrer des toits ou des

gouttières.

• N’installez aucun élément du système de chauffage en

zones immergées.

• N’utilisez le système pas dans des zones où de l’eau risquerait de pénétrer dans la fiche.

5. Le câble chauffant en plastique bleu et la tresse

métallique ne doivent pas être coupés ou endommagés.

• Avant de débuter l’installation, inspectez le tuyau, limez et

enlevez les rebords acérés. Le câble ne doit croiser que des

surfaces lisses et non-abrasives.

• Si le système risque d’être endommagé par des animaux ou

des objets, protégez le en le recouvrant en entier d’un

revêtement solide comme une tôle, ou de l’isolant à tuyau

supplémentaire.

• N’utilisez pas de fils ou de griffes pour fixer le câble chauffant sur le tuyau. Utilisez plutôt le ruban de fixation Frostex

9610, ou un autre ruban équivalent de 1/2 po-1 po (13

mm-25 mm), ou des colliers de serrage en plastique.

• Inspectez le câble chauffant périodiquement. Si vous

décelez la présence de tresses brisées ou autres éléments

endommagés, débranchez le système immédiatement et

remplacez le câble chauffant. Vous ne devez pas tenter de

coller ou de réparer un câble chauffant endommagé. Vous

devez remplacer les isolants et recouvrements imperméables endommagés.

6. N’installez pas le câble chauffant Frostex à proximité de matières, liquides ou vapeurs inflammables.

N’utilisez que de l’isolant à tuyau ayant 1/2 po (13 mm) d’épaisseur ou plus, ignifuge et résistant à l’eau, conformément au Tableau 1 ou 2.

1

ENGLISH FRANÇAIS

Page 4

General Instructions

• Observe the safety warnings on page 1. Follow the

installation steps (pages 2–7) in the exact order given.

• To ensure the plug is properly connected, do not assemble

at temperatures below 0°F (–18°C).

• The Frostex system can be left plugged in all year, but you

ENGLISH

will save energy by unplugging the system when there is

no risk of freezing.

• Use a properly grounded, 3-prong, 120-volt outlet. If you

are not sure if your outlet is properly grounded, call a

professional service person.

• In manufactured housing installations, use the electrical

receptacle on the underside of the home. Do not use an

extension cord or there may be danger of fire or shock.

Using an extension cord is not in compliance with national

electrical codes.

• Frostex heating cable may be used on metal or plastic pipes

and tubing. Do not install on garden hoses or in applications

with tubing that is flexed frequently.

• Exposure to temperatures above 150°F (65°C) will shorten

the life of your Frostex heating cable. Before installing the

heating cable on hot water pipes, set the water heater thermostat below 150°F (65°C), low to medium on most thermostats.

• Remove any old heating tapes and insulation before you

install the Frostex heating cable.

• Do not use more than 50 feet (15 meters) of Frostex heating cable with each 9800 FlexFit plug. Longer lengths will

blow the nonreplaceable fuse in the plug.

• The homeowner will need to keep these instructions for

future reference. It contains important safety warnings and

maintenance information.

• If you have any difficulty installing the system, please contact

Tyco Thermal Controls for information at (800) 545-6258, or

call a professional service person for help.

• Remove the clear label that covers the test and reset buttons

after installation.

Installation Instructions

Step 1.

Determine the length of heating cable you need.

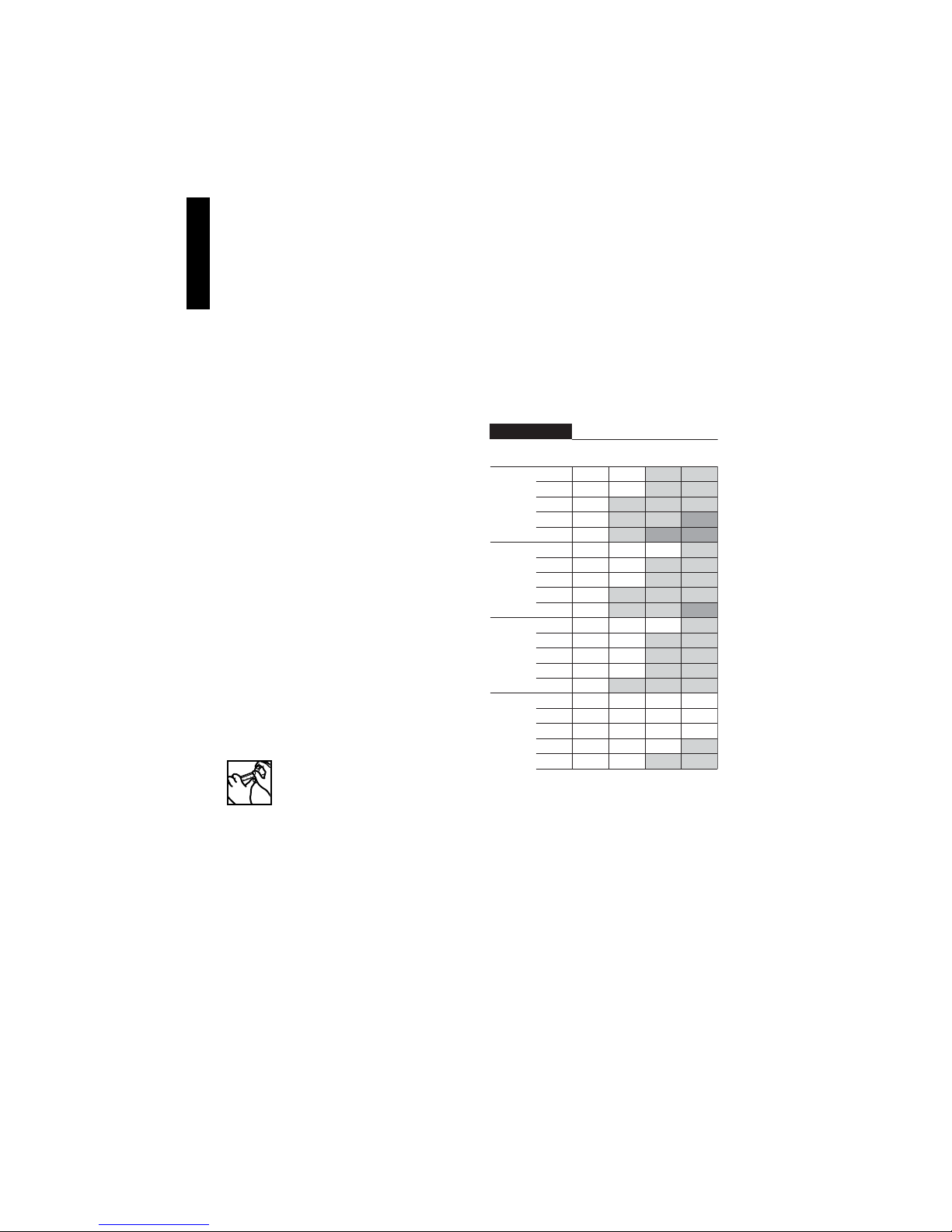

1B. Determine the amount of Frostex heating

cable you will need.

How to use the tables:

• Decide on the lowest temperature you can expect in your

area, down to –40°F (–40°C).

• Measure the diameter of your pipe in inches.

• Using Table 1 or 2 depending on pipe material, determine

how many straight runs of Frostex heating cable required to

protect the pipe. One run is equal to the length of the pipe.

• To minimize the amount of heating cable required, select the

optimal insulation thickness from Table 1 or Table 2.

Cable Length Selection Tables

Table 1. Metal Pipe

Number of heating cable runs required

Metal Pipe

Thickness

1" 1 1 1 2

1 1/2" 1 1 1 1

Lowest Expected Temperature

Pipe SizeInsulation

20°F

0°F

(–20°C)

–20°F

(–30°C)

(–10°C)

1/2"1/2" 1 1 2 2

3/4" 1 1 2 2

1" 1 2 2 2

1 1/4" 1 2 2 3

1 1/2" 1 2 3 3

1/2"3/4" 1 1 1 2

3/4" 1 1 2 2

1" 1 1 2 2

1 1/4" 1 2 2 2

1 1/2"

3/4"

1"

1 1/4"

1 1/2"

2"

3/4"

1"

1 1/4"

1 1/2"

2"

1223

1122

1122

1122

1222

1111

1111

1112

1122

–40°F

(–40°C)

1A. Collect the necessary information.

You will need to know the following:

• Type of pipe (plastic or metal).

• Length and diameter of pipe.

• Lowest expected air temperature (disregard windchill).

• Number of valves and spigots (requires additional heating

cable).

• If there is a crock (typically used for manufactured housing

applications).

2

Page 5

Table 2. Plastic Pipe

Number of heating cable runs required

Plastic Pipe

Thickness

1" 1 1 2 2

1 1/2" 1 1 1 2

Lowest Expected Temperature

Pipe SizeInsulation

20°F

0°F

(–20°C)

–20°F

(–30°C)

(–10°C)

1/2"1/2" 1 2 2

3/4" 1 2 2 3

1" 1 2 3 3

1 1/4" 2 2 3

1 1/2" 2 3 3

1/2"3/4" 1 2 2 2

3/4" 1 2 2 3

1" 1 2 2 3

1 1/4" 1 2 3 3

1 1/2"

3/4"

1"

1 1/4"

1 1/2"

2"

3/4"

1"

1 1/4"

1 1/2"

2"

233

1122

1223

1233

1233

1122

1122

1122

1223

–40°F

(–40°C)

= Increase insulation thickness

1C. Calculate the total length of heating cable

required.

Multiply the number of heating cable runs by your pipe length.

Add one extra foot (30 cm) for each valve in your line. Add one

extra foot (30 cm) for the distance to the power connection. For

installations in a crock, add an additional 2 feet (60 cm) of

heating cable. After cutting the Frostex heating cable to the

length you need, proceed to Step 2.

The total length of heating cable equals:

32 ft (10 m) 2 runs x 16 ft (5 m) of pipe

+ 1 ft (0.3 m) for one ball valve

+ 1 ft (0.3 m) for one power connection

+ 2 ft (0.6 m) for installing in a crock

Total length = 36 ft (11 m)

Note: Do not use more than 50 feet (15 meters) of heating

cable per plug. If the total calculated length exceeds 50 feet

(15 meters), you will need additional 9800 FlexFit plugs and

outlets. Longer circuit lengths will blow the nonreplaceable

fuse in the 9800 FlexFit plug. If you require more than 50 feet

per length (15 meters), call Tyco Thermal Controls for information on other products.

ENGLISH

Example:

Pipe size and material: 1 inch diameter, plastic

Lowest ambient temperature: -20°F (-30°C)

Pipe length: 16 feet (5m)

Valves: 1 ball valve is used

The water connection is in a crock.

From Table 2, Plastic Pipe, for -20°F (-30°C), either two or

three runs of Frostex heating cable is required depending on

pipe insulation thickness.

Optimal Pipe insulation thickness: 3/4"

Selecting 3/4" thick insulation requires two runs of Frostex

heating cable installed along the entire length of the pipe (Table

2).

3

Page 6

Step 2.

Install the end seal.

Note: The end seal can only be used once, so do not install it until step 2D.

ENGLISH

Heating Cable Construction

2A. Prepare the heating cable.

Cleanly cut off one end of the heating cable.

2C. Remove the plastic wrap.

1"

(25 mm)

Clear plastic

wrap

Braid Blue jacket

2B. Push the braid back.

Push the braid back 1" (25 mm) from heating cable end.

2D. Install the end seal.

Black core

(bus wires inside)

1"

(25 mm)

Cut and remove the clear plastic wrap. Do not cut into the

blue jacket.

2E. Secure the braid.

Slide the braid up against the end seal and wrap it securely with

a 4" (10 cm) strip of glass fiber or vinyl tape.

Firmly push the end seal at least 3/4" (2 cm) onto the heating

cable. Some gel may ooze out.

10

in

10 2010 20

0

mm

4

Page 7

Step 3.

Back wall

Indicator

post

Install the 9800 FlexFit plug.

ENGLISH

Reset button

Test button

Ground-fault

unit

Ga

rder a

K

eep

d

ry

T

E

ST

u s

ec

Indicator

light

Cable guide

Ground contact

3A. Prepare the cable.

3/4"

(2 cm)

Cleanly cut off the end of the cable. Push back the braid 3/4" (2

cm) and then twist the end of the braid around the cable to

ensure the braid strands are not sticking up.

Note: The clear plastic wrap does not need to be removed.

3C. Complete the connection.

Cover

Back wall

Indicator post

3B. Insert the cable.

Insert the heating cable all the way into the cable guide until the

cable hits the back wall.

Be sure no braid wire strands enter cable

guide.

3D. Install the cover.

Screw down the cable guide, alternating between the two

screws, until the cable guide is flush with the indicator posts

and the screws bottom out.

0

in

01

cm

Install the cover by tightening the screws completely.

Note: The screws will require many turns before the cover

starts to close.

3/4

2

5

Page 8

Step 4.

Attach the heating cable to the

pipe.

ENGLISH

4A. Prepare to install the heating cable.

Begin the installation at the electrical outlet. Leave at least

1 foot (30 cm) of extra heating cable so the ground-fault unit

can be secured to the outside of the thermal insulation, as

shown in Figures 1 and 2. This will relieve any strain on the

heating cable or plug. However, be careful not to leave heating

cable hanging in a loose loop where it could be accidentally

snagged and pulled out.

Make certain you have removed any old heating tapes and

insulation.

Important: The ground-fault unit and plug must be kept dry.

It is important to include the drip loop to prevent water from

getting into the ground-fault unit.

Outlet

cover

9800

Flexfit

plug

Drip loop

Thermal

insulation

Cable ties

or tape

Multiple run method

When two or more runs are required, install the heating cable in

the 4 o’clock and 8 o’clock positions as shown in Figure 4.

When three runs are required, install the heating cable as

shown in Figure 5.

12

84

84

Figure 4. Double runs. Figure 5. Triple runs.

4C. Tape the heating cable and end seal to the pipe.

• Fasten the heating cable to the pipe at 1-foot (30-cm)

intervals, using two or three thicknesses of 9610 application tape or equivalent.

• Provide extra heat at valves and spigots by wrapping each

with 1 foot (30 cm) of additional heating cable, overlapping as required.

• If you have excess heating cable at the end of your pipe,

double it back along the pipe where the insulation will

completely cover it as shown in Figure 6. Using 9610

application tape or equivalent, tape the end seal to the pipe

as shown in Figures 1, 2, and 6.

Outlet

cover

End seal

End seal

Figure 1. Typical manufactured housing installation.

Figure 2. Typical installation.

4B. Install the heating cable.

Single run method

Run the heating cable in a straight line approximately a third of

the way up from the bottom of the pipe, as shown in Figure 3.

Frostex 9610

application tape;

1-foot spacing

Figure 3. Single run method.

9800

FlexFit

plug

Drip loop

Ground

level

Pipe

Crock

Cable ties

or tape

Thermal

insulation

Figure 6. Multiple run installation.

Important: In a crock or standpipe, run the Frostex heating

cable down and back up the pipe (as shown in Figure 6), so

that the end seal is well above the ground level and

will not be sitting in water.

6

Page 9

Step 5.

Install the insulation.

• The signal light will go on indicating that the ground-fault

protection device and the fuse are working properly.

However, the light does not confirm that the heating cable

is properly connected. See Step 7, “Test the System.”

ENGLISH

Thermal insulation must be used. It protects the Frostex heating cable from damage and helps keep the pipes from freezing.

Before you insulate, be sure the Frostex heating cable is

undamaged—no nicks or cuts—and the braid is intact.

Replace the heating cable if necessary.

5A. Cover the system with the insulation.

Cover the pipe, heating cable, connections, valves, and spigots

with clean, dry, waterproof, fire-retardant thermal insulation,

such as closed-cell foam insulation, as shown in Figure 7. The

insulation must be at least as thick as selected in Table 1 or 2.

Secure the 9800 FlexFit plug to the insulation with tape or

plastic cable ties, being careful not to cover the light or test

buttons.

Warning

labels

Figure 7. Thermal insulation.

• Do not leave the heating cable exposed, except for the

short distance from the pipe to the power connection.

• Fully insulate and weatherproof all exposed piping. Put

additional insulation on areas that cannot be heat traced.

5B. Waterproof the insulation.

Make sure the thermal insulation is waterproof and stays dry.

Install a watertight sleeve and a solid cover or a barrier such as

polyethylene sheeting around the insulation wherever there is

any chance that the insulation might get wet.

5C. Install the warning label.

Install the orange warning labels on the insulation with one

near the electrical outlet, as shown in Figure 7.

Additional labels and installation tape are available from Tyco

Thermal Controls in the Frostex 9610 kit.

Step 6.

Start up the system.

6B. Test the plug.

• Press the white test button. The red reset button should

pop out from the surface of the plug and the signal light

should go out.

• When the red reset button pops out, push it in to restore

power and proceed to Step 7.

If the red reset button fails to pop out,

“Troubleshooting.”

If the red reset button pops out immediately but cannot

be reset,

skip to “Troubleshooting.”

If the signal light does not light,

skip to

skip to “Troubleshooting.”

Step 7.

Test the system.

Test the system using one of the two following procedures.

7A. Test the water temperature.

After plugging in the system, wait about an hour. Turn on a

water tap on the Frostex-protected pipe and test the temperature of the water. It should feel warm almost immediately

because the water heated by the Frostex heating cable will be

briefly running through the pipe.

If the water is warm,

If the water is not warm,

7B. Test the heating cable’s resistance.

It is possible to test the resistance of Frostex heating cable

using a multimeter. Follow these steps:

• Be sure the 9800 FlexFit plug is unplugged.

• Push in the red reset button on the plug.

• Connect the two lead wires on the meter to the two flat

prongs on the plug. The meter reading should be between

2 and 20,000 ohms.

If your reading is within this range,

the installation.

If your reading is not within this range,

“Install the 9800 FlexFit plug” and retest.

If your reading is still not within this range or you

have questions,

cal support at (800) 545-6258.

you have completed the installation.

skip to “Troubleshooting.”

you have completed

repeat Step 3,

call Tyco thermal controls for techni-

6A. Plug in the heating cable.

After installing the heating cable and insulation, remove the

clear label that covers the test and reset buttons. Then, plug the

9800 FlexFit plug into a grounded and properly installed outlet.

• If the Frostex heating cable length is longer than 40 feet

and the air temperature is lower than 30°F, run water

through the pipe before plugging in the unit. This will

warm up the pipe and help avoid blowing the nonreplaceable fuse in the 9800 FlexFit plug.

7

Page 10

Periodic Inspections

Troubleshooting

Each month

• Test the 9800 FlexFit plug as described in Step 6B.

Periodically

ENGLISH

Each time you plug in the system, and at least once a year,

do the following:

• Check the entire Frostex system for signs of damage.

Inspect any exposed portion of the heating cable for

evidence of cuts, nicks, abrasions, gnawing by animals,

and any other physical damage.

If there is damage, immediately replace the damaged

heating cable system and thermal insulation. Do not

attempt to repair any part of the heating cable system.

• After a thorough inspection, start up the system and test the

9800 FlexFit plug and system as described in Steps 6 and 7.

Problem: The red button pops out immediately when

the plug is plugged in, or the button will not reset.

What to do: A strand of braid may have entered the heating cable

guide during Step 3B.

• Unplug the 9800 FlexFit Plug.

• Remove the cover (the reverse of Step 3D).

• Unscrew the two screws of the heating cable guide (the

reverse of Step 3C).

• Using a flat blade screwdriver, gently pry the heating cable

guide up until the heating cable can be removed.

• Reinstall the screws completely into the heating cable guide

before re-attaching.

• Repeat installation steps 3A–3D, ensuring no braid strands

enter the heating cable guide during Step 3B.

• Repeat Step 6, “Start up the system.”

Note: If the 9800 FlexFit Plug red test button continues to pop

out, your system is damaged and must be replaced.

Problem: The signal light does not light up.

What to do: Check to be sure the outlet has power. If you are

not certain how to do this, call a professional service person.

If the outlet has no power,

“Start up the system.”

correct the problem, then follow Step 6,

If the outlet has power but the signal light still does not light up after

you conduct the test described in Step 6B, “Test the plug,” the

internal nonreplaceable fuse is blown. This means the Frostex

system is damaged and must be replaced.

Problem: The 9800 FlexFit plug does not trip

(red button does not pop out).

What to do: Check to be sure the outlet has power. If you are

not certain how to do this, call a professional service person.

If the outlet has no power,

instructions in Steps 6 and 7.

correct the problem, then follow the

If the outlet has power but the 9800 FlexFit plug still fails to trip,

the Frostex system is damaged and must be replaced.

Problem: The heating cable fails to warm up or water

is not warm after testing the system.

What to do: The heating cable may not be fully inserted into the

heating cable guide, or the guide may not be screwed down completely.

• Unplug the 9800 FlexFit Plug.

• Remove the cover (the reverse of Step 3D).

• Unscrew the two screws of the heating cable guide (the

reverse

of Step 3C).

• Using a flat blade screwdriver, gently pry the heating cable

guide up until the heating cable can be removed.

• Reinstall the screws completely into the heating cable guide

before re-attaching.

• Repeat installation steps 3A–3D, ensuring no braid strands

enter the heating cable guide during Step 3B.

• Repeat Step 6, “Start up the system.”

8

Page 11

Limited Warranty

Tyco Thermal Controls warrants all Frostex

self-regulating heating cables and components against faulty workmanship and use

of defective materials for two (2) years

from the date of purchase. This warranty

can be amended only by a written instrument signed by a duly authorized officer of

Tyco Thermal Controls. Buyer's exclusive

remedy under this warranty shall be to

have Tyco Thermal Controls, within a reasonable time, repair such goods or supply

replacement goods or credit Buyer's

account for such goods and accept their

return whichever Tyco Thermal Controls

may elect at its sole discretion. Tyco

Thermal Controls shall in no event be liable

for the cost of removal or installation, for

loss or damage to or loss of use of facilities or other property, loss of revenue, loss

of use of revenue, loss of anticipated profits, or other damages or costs of any kind

whatsoever, whether direct, indirect, incidental, or consequential.

Notwithstanding the foregoing, Tyco

Thermal Controls shall have no liability

whatsoever unless: (a) Buyer promptly

notifies Tyco Thermal Controls in writing

after discovery of an alleged nonconformity

and includes a detailed explanation of the

alleged nonconformity; (b) Buyer promptly

returns the goods to Tyco Thermal

Controls postage prepaid, at 300

Constitution Drive, Menlo Park, California

94025-1164, USA; and (c) Tyco Thermal

Controls examination of such goods establishes to Tyco Thermal Controls satisfaction that such alleged nonconformities

actually exist and occurred in the cause of

proper and normal use and were not

caused by accident, misuse, neglect, alteration or improper installation, repair or

testing or such other cause outside of the

responsibility of Tyco Thermal Controls

under this Limited Warranty.

THE FOREGOING WARRANTY IS IN LIEU

OF ALL OTHER REPRESENTATIONS, WARRANTIES, OR CONDITIONS, EXPRESS OR

IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NONINFRINGEMENT,

AND OF ANY OTHER OBLIGATION OR LIABILITY ON THE PART OF TYCO THERMAL

CONTROLS, WHETHER BY STATUTE,

CONTRACT, STRICT LIABILITY, TORT OR

OTHERWISE.

If the goods are a consumer product in

buyer's jurisdiction, the above exclusion or

limitation of incidental or consequential

damages and the above disclaimer of

implied warranties may not apply. The term

of any such implied warranty is limited to

the term of this two-year Limited Warranty.

Some jurisdictions do not allow limitations

on how long an implied warranty lasts, so

the above limitation may not apply. This

warranty gives consumers specific legal

rights, and consumers may also have other

rights, which vary by jurisdiction.

ENGLISH

9

Loading...

Loading...