Page 1

Instructions for Use

ENGLISH 1

Gebrauchsanleitung

DEUTSCH 6

Instructions d’utilisation

FRANÇAIS 11

Flowhood 5

Scott Health & Safety Oy

P.O.BOX 501

FI-65101 Vaasa, Finland

TECHNICAL SUPPORT & SALES

Tel. +358 (0)6 3244 543 or 544 or 535

TEKNINEN TUKI JA MYYNTI

Puh. (06) 3244 536 tai 537

Fax +358 (0)6 3244 591

fin-sales@tycoint.com

www.scottsafety.com

Ref. No. 009919

Edition A 05/2004

Page 2

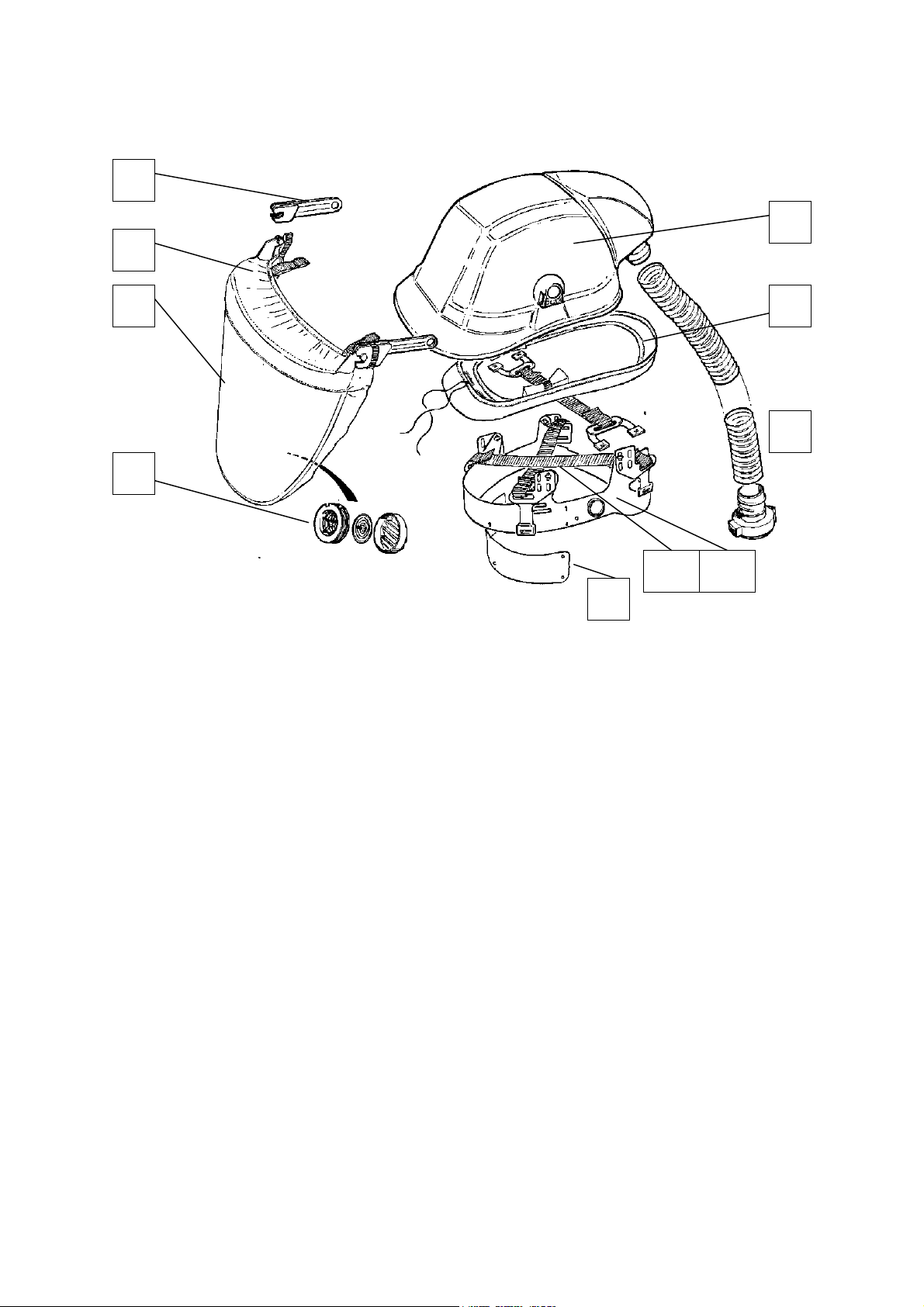

1

ENGLISH

1

5

2

6 3

7

4

1 Pivot arm

2 Face seal

3 Visor (polycarbonate)

4 Exhalation valve disc + seat

5 Helmet shell

6 Brim trim

7 Hose

8 Head harness

a) Headband

b) Crown strap

9 Sweatband

Spare parts Accessories

064297

064513

064295

064505

064296

064515

Hose PU FL3/5/25 (3 pcs)

Visor PC FL5 anti-mist

+ face seal FL5

Visor cover FL5/25 (10 pcs)

Head harness

Exhalation valve disc FL (2 pcs)

Brim trim

063780

064024

063581

063781

062976

063180

Blower device Proflow2, complete

Blower device Proflow2 SC, complete

Blower device Proflow3, complete

Blower device Proflow2 Ex, complete

Blower device Autoflow 120, complete

Blower device Autoflow 120 Ex, complete

9

8b

8a

Page 3

2

MARKINGS

Helmet shell

Protector or PSP manufacturer

Tuffmaster II helmet type

Tornado 6 device type

CE CE mark

0121 notified body

TH2 protective performance class

prEN 12941 conforms to European standard

EN 166 conforms to European standard

EN 175 conforms to European standard

EN 397 1996-1 helmet Certification, date and level of protection

50 – 60 cm size

-10 – 50 ºC operating temperature

MM molten metal splashes

L (S) head harness size adjustment

The helmet can be used safely down to -30 ºC and provides electrical protection against up to

1000 V (DC or AC) peak.

Visor frame PSP prEN166 48B CE

PSP manufacturer

prEN166 conforms to European standard

x shade

1 optical class

4 liquid splashes

B medium energy impact

F low energy impact

CE CE mark

0121 certifying body

Visor

PSP manufacturer

S high energy impact

8 non-adherence of molten metals

+30

C

-10

C

Symbols

See Instructions for Use! Recommended storage conditions

(temperature and humidity).

< 75 %

Page 4

3

Helmet Flowhood 5

064286

EC Type-examined by Berufsgenossenschaftliches Institut für Arbeitssicherheit, D- 53754 Sankt

Augustin, Germany, ID: 0121.

1. General

o The helmet Flowhood 5 is designed to be used together with a powered blower device and

filters to protect the respiratory system and face against hazardous gases and particles.

o The Flowhood 5 consists of a helmet, a visor and a breathing hose.

o The Flowhood 5 is connected to the blower unit Proflow2, Proflow2 SC, Proflow3, Proflow2 Ex,

Autoflow 120A or Autoflow 120 Ex.

o Air is drawn through particle filters connected to the blower, by an electronically-controlled fan

and led through the breathing hose into the facepiece (airduct). Exhaled air exits through an

exhalation valve found in the lower part of the hood.

2. Limitations of use

2.1 The filtering device must not be used if the environment and contamination are unknown. In

case of doubt, insulating respirators which function independently of the atmosphere must be

used.

2.2 The filtering device must not be used in restricted spaces (e.g. cisterns, tunnels) because of

oxygen deficiency or presence of heavy oxygen-displacing gases (e.g. carbon dioxide).

2.3 The filtering device may be used only if the oxygen content of the air is 18 - 23 vol.%.

2.4 Gas filters do not protect against particles. Similarly, particle filters do not provide protection

against gases or vapours. In case of doubt, use combined filters.

2.5 Normal filtering devices do not protect against certain gases such as CO (carbon monoxide),

CO

(carbon dioxide) and N2 (nitrogen).

2

2.6 Particle filters are allowed only for single use if they are applied against radioactive agents, microorganisms (virus, bacteria, fungi and spores) or enzymes.

2.7 It is likely that adequate protection cannot be guaranteed if the user’s beard, hair, spectacle

frames or clothing intrude into the faceseal.

2.8 When a breathing protector is used in explosive atmospheres, please follow the instructions

given for such areas. The use of Flowhood 5 is permitted when connected to an intrinsically

safe (ex) blower device.

2.9 The blower must be running while using the respirator. If the blower turns off by accident, the

device ceases to function as a respirator, and carbon dioxide levels may instantly rise. This is

considered an abnormal situation.

2.10 At a very intense working pace, the pressure in the facepiece can change into negative pressure

at peak inhalation.

2.11 Conditions -10 °C...+50 °C, relative humidity (RH) under 75 %.

Page 5

4

3. Start-up

See Instructions for Use of the blower device to be used and of the filters. Only use Pro2000 filters.

o Check intactness of helmet and breathing hose.

o Check intactness of visor+face seal.

• Fix the breathing hose of the helmet tightly to the blower device.

• Screw the filters tightly to the blower device.

• Don the blower unit according to its instructions.

• Switch on the blower device, then check adequate air flow (see Instructions for Use of the blower

unit).

• Loosen the headband using the ratchet knob (handwheel), and don the helmet.

• Slip the face seal under the chin.

• Tighten the ratchet knob so that the head harness fits comfortably over the forehead. It may be

necessary to adjust the crown strap to position the visor to the correct height.

• Pull te facepiece back so that it fits

comfortably and securely under the chin and around the

cheeks. The face seal shall fit above the ears and under the head harness.

•

The breathing hose trails freely down the back and is not kinked or looped.

4. Maintenance and storage

• Store in a cool and dry place (-10 °C...+30 °C, max. 75 % RH), protected from sunlight and any

impurities.

• Clean with a damp cloth or sponge (be careful not to scratch the visor). Use lukewarm water and

mild detergent (neutral, pH 6-8) (e.g. washing-up liquid). Allow to dry. Do not use solvents (e.g.

acetone, turpentine) or bleaching agents (perborate, percarbonate). Never clean with compressed

air or compressed water.

• Check intactness of visor, helmet and hose, and replace damaged items.

• Recommend replacement after 2 years if in every day use, particularly when used outdoors.

Service life of 5 years when properly stored.

• Only use original spare parts.

Replacing the breathing hose

• Unscrew the old hose from the airduct and screw in the new one.

Replacing the visor

• Release the elastic loops from the head harness. Tilt the visor fully up until the visor is released

from pivot arm. Pull the exhalation valve from the face seal and fit it to the new visor’s face seal.

• Check that the face seal is fully located arount the valve body. Locate the visor in the pivot arms

in a tilted-up attitude, then tilt down to clip into place.

Page 6

5

T

Replacing the exhalation valve

• Pull the valve cover from the valve and remove the disc.

• Insert a new disc ensuring that it lies flat on the seat.

• Align the valve cover with the slots and snap it in its place.

Replacing the pivot arms

• Use side clip to release pivot arm and withdraw arm from pivot post. Slide new pivot arm into

pivot post and secure with side clip.

Replacing the brim trim

• Release the elastic loops from the head harness. Untie the retaining cord of the old brim trim and

remove it from the helmet.

• Locate the rectangular slots in the new brim trim over the airducts at the front of the helmet,

arrange the brim trim around the brim of the helmet with the sponge pads tucked under the

helmet brim. Tie the retaining cord.

Replacing the head harness

• Tilt the visor to the fully-up position. By using both thumbs, press down on the white retaining tabs

to release the head harness from the helmet.

• When mounting, insert the white retaining tabs into the slots in the rim of the helmet, and press

down until they clik into place.

• Tilt the visor to the required position.

Replacing the sweatband

• Pull the old sweatband from the head harness hooks.

• Fit the new sweatband onto the four hooks in the lower front of the headband, fold across the

headband, then clip on to the two hooks at the top of the headband.

5. Selection of blower-assisted breathing protector equipped with filter

See Instructions for Use of the blower device to be used.

ype of protective device

(Assigned protection factor)

Values as given

in BS 4275

Power-assisted face shield with

particle filter

TH1P

TH2P (Flowhood 5)

TH3P

Device with combined filter The specified multiples of threshold value for the gas or particle filters are

Power-assisted face shield with

gas filter *)

TH1 gas filter class 1 or 2

TH2 gas filter class 1 or 2

TH3 gas filter class 1 or 2

*) Provided that the maximum permissible detrimental gas concentration for the gas filter is not exceeded. For

power-assisted filtering devices with gas filter, concentration must not exceed 0.05 vol.% in gas filter class 1

and 0.1 vol.% in gas filter class 2 and 0.5 vol.% in gas filter class 3.

10

20

40

given separately, but in all cases the lowest value applies.

10

20

40

APF

Values as given

in German BGR

190 - ZH1/701

5

20

100

5

20

100

Remarks, limitations

“Open” facepieces, such as helmets

or hoods, do not provide sufficient

protection in case of breakdown or

inferior output of the blower.

Therefore, devices of class TH1 must

never be used against carcinogenic,

very poisonous or radioactive gases

and vapours.

For devices with combined filter apply

the relevant limitations of gas and

particle filters.

Page 7

6

DEUTSCH

1

5

2

6 3

7

4

8a

1 Hebelarm

8b

9

2 Randdichtung

3 Sichtscheibe (Polykarbonat)

4 Ausatemventilscheibe und Sitz

5 Helmschale

6 Helmrahmen

7 Atemschlauch

8 Kopfbänderung

a) Kreuzverband

b) Kopfband

9 Stirnpolster

Ersatzteile Zusatzausstattung

064297

064513

064295

064505

064296

064515

Atemschlauch PU FL3/5/25 (3 St)

Sichtscheibe PC FL5, unbereift

+ Randddichtung FL5

Visierschutz FL5/25 (10 St)

Kopfbänderung

Ausatemventilscheibe FL (2 St)

Helmrahmen

063780

064024

063581

063781

062976

063180

Gebläseeinheit Proflow2, komplett

Gebläseeinheit Proflow2 SC, komplett

Gebläseeinheit Proflow3, komplett

Gebläseeinheit Proflow2 Ex, komplett

Gebläseeinheit Autoflow 120, komplett

Gebläseeinheit Autoflow 120 Ex, komplett

Page 8

7

MARKIERUNGEN

Helmschale

Protector oder PSP Hersteller

Tuffmaster II Helmtyp

Tornado 6 Gerätetyp

CE CE-Genehmigungszeichen

0121 Prüforgan

TH2 Schutzklasse

prEN 12941 entspricht EN Standard

EN 166 entspricht EN Standard

EN 175 entspricht EN Standard

EN 397 1996-1 Helmprüfbescheinigung mit Datum und Schutzstufe

50 – 60 cm Größe

-10 – 50 ºC Betriebstemperatur

MM Heisse Metallspritzer

L (S) Einstellung der Größe der Kopfbänderung

Der Helm kann ungefährdet bei Temperaturen bis zu -30 ºC eingesetzt werden und bietet

elektrischen Schutz bis zu 1000 Volt Gleich-und Wechselstrom (Spitzenspannung).

Sichtscheibenrahmen PSP prEN166 48B CE

PSP Hersteller

prEN166 entspricht EN Standard

x Dunkelheitsgrad

1 optische Klasse

4 Flüssigkeitsspritzer

B mittlere Schlagfestigkeit

F niedrige Schlagfestigkeit

CE CE-Genehmigungszeichen

0121 bescheinigende Behörde

Sichtscheibe

PSP Hersteller

S hohe Schlagfestigkeit

8 Metallschmeltzspritzer haften nicht

+30

C

-10

C

Symbole

Siehe Gebrauchsanleitung! Vom Hersteller empfohlene Lagerbedingungen

(Temperatur und Luftfeuchtigkeit).

< 75 %

Page 9

8

Helm Flowhood 5

064286

EG-Baumustergeprüft durch Berufsgenossenschaftliches Institut für Arbeitssicherheit, D- 53754

Sankt Augustin, Deutschland, Kenn-Nr.: 0121.

1. Allgemeines

o Der Helm Flowhood 5 wird zusammen mit einem batteriebetriebenen Gebläse und Filter

verwendet, um Atmungsorgane und Gesicht vor gas- und partikelförmigen Schadstoffen zu

schützen.

o Die Flowhood 5 besteht aus Helm, Sichtscheibe und Atemschlauch.

o Die Flowhood 5 wird mit dem Gebläsegerät Proflow2, Proflow2 SC, Proflow3, Proflow2 Ex,

Autoflow 120A oder Autoflow 120 Ex verwendet.

o Die Atemluft wird von dem Gebläse durch die Filter angesaugt und mit elektronisch gesteuertem

Druck durch den Atemschlauch in den Atemanschluß (Luftkanal) geführt. Die Luft entweicht durch

Ausatemventil im unteren Teil des Helms.

2. Einschränkungen

2.1 Filtergeräte dürfen nicht benutzt werden, wenn die Umgebungsverhältnisse unbekannt sind. In

Zweifelsfällen sind Isoliergeräte zu benutzen, die von der Umgebungsatmosphäre unabhängig

wirken.

2.2 Filtergeräte dürfen nicht in engen Räumen (z.B. Behälter, Tunnel) eingesetzt werden, da es

Sauerstoffmangel gibt oder schwere sauerstoffverdrängende Gase (z.B. Kohlendioxyd)

vorkommen.

2.3 Bei der Verwendung der Filtergeräte muß der Sauerstoffgehalt der Raumluft 18 – 23 Vol.%

betragen.

2.4 Ein Gasfilter schützt nicht gegen Partikel und ein Partikelfilter schützt nicht gegen Gase und

Dämpfe. Im Zweifelsfall Kombinationsfilter einsetzen.

2.5 Normale Filtergeräte schützen nicht gegen bestimmte Gase wie z.B. CO (Kohlenmonoxyd),

CO

(Kohlendioxyd) oder N2 (Stickstoff).

2

2.6 Partikelfilter gegen radioaktive Stoffe, Mikroorganismen (Viren, Bakterien, Pilze und deren

Sporen) und Enzyme sollen nur einmal verwendet werden.

2.7 Es ist unwahrscheinlich, daß die Anforderungen an Leckage erreicht werden, wenn sich Bart,

Haare, Brillenbügel oder Teile der Kleidung zwischen Dichtungsrand und Gesicht befinden.

2.8 Bei Gebrauch des Atemschutzgerätes in Räumen mit Explosionsgefahr sind die dafür

zutreffenden Vorschriften zu beachten. Anwendung der Flowhood 5 zugelassen, wenn in

Verbindung mit einem explosionsgeschützte (ex) Gebläsegerät verwendet.

2.9 Das Gerät muß bei laufendem Gebläse verwendet werden. Bei Ausfall des Gebläses kann

keine oder nur eine geringe Atemschutzfunktion des Gerätes erwartet werden; es besteht die

Gefahr einer sofortigen starken Anreicherung von Kohlendioxid. Gebläseausfall wird als ein

aussergewöhnlicher Zustand angesehen.

2.10 Bei starkem Atmen/grosser körperlicher Anstrengung kann im Atemanschluß ein Unterdruck

entstehen.

2.11 Anwendungsverhältnisse -10 °C...+50 °C, relative Feuchtigkeit (RH) unter 75 %.

Page 10

9

3. Inbetriebnahme

Siehe Gebrauchsanleitungen für das Gebläsegerät und die Filter. Es dürfen nur Pro2000 Filter

verwendet werden.

o Überprüfen den Zustand und die Unversehrtheit des Helms und des Atemschlauchs.

o Überprüfen daß die Sichtscheibe+Randdichtung unversehrt ist.

• Den Atemschlauch vom Helm sicher an das Gebläsegerät drehen.

• Filter am Gebläsegerät sicher festmachen.

• Gebläsegerät nach der jeweiligen Gebrauchsanleitung anlegen.

• Gebläsegerät anschalten, dann die erforderliche Luftströmung überprüfen (siehe

Gebrauchsanleitung des Gebläsegeräts).

• Den Kreuzverband mit Hilfe des Ratschenknopfes lockern, und den Helm aufsetzen.

• Die Randdichtung unter das Kinn ziehen.

• Den Ratschenknopf drehen bis die Kopfbänderung bequem auf der Stirn sitzt.

Bei Bedarf, das Kopfband so spannen daß die Sichtscheibe auf passende Höhe liegt.

•

Den Gesichtsschutz rückwärts ziehen, um einen festen Sitz unter dem Kinn und an den Wangen

erzielen. Die Randdichtung soll über den Ohren und unter dem Kreuzverband liegen.

•

Der Atemschlauch bleibt ohne Drehung über den Rücken hängen.

4. Wartung und Lagerung

• Einlagern an einem kühlen und trockenen Ort (-10 °C...+30 °C, max. 75 % RH), geschützt gegen

Sonnenlicht und Kontamination.

• Reinigen mit einem feuchten Tuch oder Schwamm (die Sichtscheibe nicht kratzen). Benutzen

Sie lauwarmem Wasser und mildem Reinigungsmittel (neutral, pH 6-8) (z.B. Geschirrspülmittel).

Trocknen lassen. Keine Lösungsmittel (z.B. Azeton, Terpentin) oder Bleichmittel (Perborat,

Perkarbonat) verwenden. Benutzung der Druckluft oder Druckwasser ist verboten.

• Überprüfen den Zustand der Sichtscheibe, des Helms und des Atemschlauchs, und diese bei

Bedarf austauschen.

• Empfohlene Austauschperiod 2 Jahre bei täglicher Benutzung, besonders in Freien. Lebensdauer

5 Jahre wenn ordentlich gelagert.

• Es dürfen nur Originalersatzteile verwendet werden.

Austausch des Atemschlauchs

• Alten Schlauch von Luftkanal losschrauben und einen neuen einschrauben.

Austausch der Sichtscheibe

• Elastische Schlaufen von Kreuzverband lösen. Sichtscheibe ganz hochklappen, bis sich dieser

von Hebelarm löst. Ausatemventil aus der Randdichtung ziehen und in die neue Randdichtung

einsetzen.

• Überprüfen daß die Randdichtung gut um das Ventilgehäuse sitzt. Sichtscheibe in hochgeklappter

Stellung in die Hebelarme einsetzen und dann nach unten klappen, damit die Sichtscheibe

einrasten kann.

Page 11

10

Austausch des Ausatemventils

• Ventildeckel ziehen und die Ventilscheibe entfernen.

• Neue Ventilscheibe einlegen, so daß sie flach auf dem Sitz aufliegt.

• Ventildeckel in die Positionierschlitzen richten, dann den Deckel in das Ventil einrasten.

Austausch des Hebelarms

• Den Hebelarm mit der seitliche Klemme lösen, und dieser dann vom Drehzapfen abziehen.

Neuen Hebelarm auf den Drehzapfen führen und mit der Klemme sichern.

Austausch des Helmrahmens

• Elastische Schlaufen von Kreuzverband lösen. Halteschnur des alter Helmrahmens losbinden

und diesen dann vom Helm abnehmen.

• Die rechteckigen Schlitze im neuen Helmrahmen so ausrichten, daß diese auf den

Ventilationsöffnungen vorn im Helm sitzen, und so daß die Schwammstücke unter dem Helmrand

eingestopft werden. Die Halteschnur festbinden.

Austausch der Kopfbänderung

• Sichtscheibe ganz hoch klappen. Weiße Haltezungen mit beiden Daumen von ihren Schlitze

herausdrücken, um die Kopfbänderung von Helm zu lösen.

• Beim Montieren, weiße Haltezungen in die Schlitze des Helmrands einpassen, und so lange

drücken bis sie in Position einrasten.

• Sichtscheibe in die gewünschte Stellung bringen.

Austausch des Stirnpolsters

• Alten Stirnpolster von den Haken des Kreuzverbands abziehen.

• Neuen Stirnpolster an den vier Haken vorn unten am Kreuzverband befestigen, dann über den

Kreuzverband falten, und dann an die beiden Haken oben am Kreuzverband befestigen.

5. Auswahl von Filtergeräten mit Gebläse

Siehe auch BGR 190 (ZH 1/701) (Regeln für den Einsatz von Atemschutzgeräten).

Siehe Gebrauchsanleitung für das jeweiligen Gebläsegerät.

Geräteart Vielfaches des

Grenzwertes (GW)

Gesichtsschutz mit Gebläse

und Partikelfilter

TH1P

TH2P (Flowhood 5)

TH3P

Geräte mit Kombinationsfilter Es gelten die jeweiligen Vielfachen des Grenzwertes für den Gas- oder

Gesichtsschutz mit Gebläse

und Gasfilter *)

TH1 Gasfilterklasse 1 oder 2

TH2 Gasfilterklasse 1 oder 2

TH3 Gasfilterklasse 1 oder 2

*) Sofern damit nicht bereits die auf das Gasaufnahmevermögen von Gasfiltergeräten mit Gebläse bezogenen

höchstzulässigen Einsatzkonzentrationen von 0,05 Vol.% in Gasfilterklasse 1 und 0,1 Vol.% in Gasfilterklasse 2

und 0,5 Vol.% in Gasfilterklasse 3 überschritten werden.

5

20

100

Partikelfilterteil, und zwar jeweils der schärfere Wert.

5

20

100

Bemerkungen, Einschränkungen

Die “offenen” Atemanschlüsse (Helm oder Haube)

bieten bei Ausfall oder Schwächerwerden des

Gebläses keinen ausreichenden Schutz. Deshalb

dürfen Geräte der Klasse TH1 nicht gegen

krebserregende, sehr giftige und radioaktive Gase

und Dämpfe eingesetzt werden.

Bei Geräten mit Kombinationsfilter gelten die

jeweiligen Einschränkungen für die Gas- und

Partikelfiter.

Page 12

11

FRANÇAIS

1

5

2

6 3

7

4

1 Pivot-bras

2 Joint du bord

3 Visière (polycarbonate)

4 Disque et siège de soupape expiratoire

5 Casquel

6 Bordure

7 Tuyau respiratoire

8 Harnais

a) Serre-tête

b) Sangle de tête

9 Coussinet frontal

Pièces de rechange Accessoires

064297

064513

064295

064505

064296

064515

Tuyau PU FL3/5/25 (3 pc)

Visière PC FL5, anti-buée

+ joint du bord L5

Protège-visière FL5/25 (10 pc)

Harnais

Disque de soupape expir. FL (2 pc)

Bordure

063780

064024

063581

063781

062976

063180

Appareil ventilateur Proflow2, complet

Appareil ventilateur Proflow2 SC, complet

Appareil ventilateur Proflow3, complet

Appareil ventilateur Proflow2 Ex, complet

Appareil ventilateur Autoflow 120, complet

Appareil ventilateur Autoflow 120 Ex, complet

9

8b

8a

Page 13

12

MARQUAGE

Casque

Protector ou PSP fabricant

Tuffmaster II type de casque

Tornado 6 type d’appareil

CE marque CE

0121 institut de test

TH2 classe de protection

prEN 12941 conforme à la norme europpéenne

EN 166 conforme à la norme europpéenne

EN 175 conforme à la norme europpéenne

EN 397 1996-1 certification du casque avec date et niveau de protection

50 – 60 cm taille

-10 – 50 ºC temperature d’utilisation

MM projections de métal en fusion

L (S) réglage de la taille du serre-tête

Le casque peut être utilisé avec sécurité en temperatures basses jusqu’à -30 ºC et offre

protection électrique contre jusque 1000 V (DC or AC) (de pointe).

Cadre de visière PSP prEN166 48B CE

PSP fabricant

prEN166 conforme à la norme europpéenne

x teinte

1 classe optique

4 projections liquides

B choc de moyenne énergie

F choc de bas énergie

CE marque CE

0121 institut de test

Visière

PSP fabricant

S choc de grande intensité

8 non-adhérence de métal en fusion

+30

C

-10

C

Symboles

Voir instructions d’utilisation! Recommandations de stockage du fabricant

(température et humidité).

< 75 %

Page 14

13

Casque Flowhood 5

064286

Examen CE de type par l'organisme Berufsgenossenschaftliches Institut für Arbeits-sicherheit, D53754 Sankt Augustin, Allemagne, ID: 0121.

1. Généralités

o Le casque Flowhood 5 est destiné à l’utilisation avec l’appareil ventilateur motorisé et les filtres

pour protéger les voies respiratoires et le visage contre les gaz et les particules nocives.

o The Flowhood 5 comprend un casque, une visière et un tuyau respiratoire.

o The Flowhood 5 est employé avec un appareil ventilateur Proflow2, Proflow2 SC, Proflow3,

Proflow2 Ex, Autoflow 120A or Autoflow 120 Ex.

o L’air à respirer est aspiré à travers les filtres dans le ventilateur et envoyé à la pièce faciale par

l'intermédiaire d'un tuyau respiratoire. L'air est évacué par le soupape expiratoire dans la partie

inférieure de la cagaoule.

2. Limites d’utilisation

2.1 Les appareils filtrants ne doivent pas être utilisés si l’on ne connaît pas les conditions

d'environnement. En cas d'incertitude, il est nécessaire d'utiliser des appareils de protection

isolants qui fonctionnent indépendamment de l’atmosphère ambiante.

2.2 Les appareils filtrants ne doivent pas être utilisés dans des espaces etroits (ex. citernes,

tunnels) si il y a un manque d'oxygène ou présence de matières lourdes déplaçant l'oxygène

(ex. dioxyde de carbone).

2.3 Les appareils filtrants peuvent uniquement être utilisés si l'air contaminé contient un volume

d'oxygène de 18 - 23 % en volume.

2.4 Les filtres à gaz ne protègent pas contre les particules. De même, les filtres à particule ne

protègent ni des gaz ni des vapeurs. En cas d'incertitude, il faut utiliser un filtre combiné.

2.5 Les appareils filtrants normaux ne protègent pas contre certains types de gaz, par exemple CO

(oxyde de carbone), CO

2.6 Les filtres à particules ne doivent être utilisés qu'une seule fois contre les substances

radioactives, les micro-organismes (virus, bactéries, moisissures) et les enzymes.

2.7 Il est probable qu’une protection sufficante ne peut être fournie si par example la barbe, les

cheveux, la monture de lunettes ou les vêtements sont entre le visage et le joint du bord.

2.8 Si l’appareil respiratoire est utilisé en atmosphère à risque d’explosion, il faut absolument

respecter le règlement afférent. L’utilisation de la Flowhood 25 est permise lorsqu’elle est

employée avec l’appareil ventilateur intrinsèquement sûr (ex).

2.9 Le bloc d’alimentation doit être utilisé avec le ventilateur en marche. Si le ventilateur s’arrête,

l’appareil ne sert pas de protection respiratoire et il peut se former une forte concentration de

dioxyde de carbone. Ceci est une condition exceptionelle.

2.10 Dans un travail au rythme intense il est possible que la pression dans la pièce faciale devienne

négative (dépression) lors du summum de l’inspiration.

2.11 Conditions d’utilisation: -10 °C...+50 °C, humidité relative (HR) moins de 75 %.

(dioxyde de carbone) et N2 (azote).

2

Page 15

14

3. Mise en service

Voir les instructions d’utilisation de l’appareil ventilateur et du filtre. Utiliser uniquement des filtres

Pro2000.

o Vérifier l’état et l’intégrité du casque et le tuyau respiratoire.

o Vérifier l’état et l’intégrité de la visière+joint du bord.

• Fixer le tuyau respiratoire du casque à l’appareil ventilateur.

• Visser bien les filtres à l’appareil ventilateur.

• Enfiler l’appareil ventilateur suivant ses instuctions d’utilisation.

• Démarrer l’appareil ventilateur, et vérifier la suffisance du flux d’air (voir les instructions d’appareil

ventilateur).

• Deserrer le serre-tête à l’aide du bouton de réglage (ratchet), et enfiler le casque.

• Glisser le joint du bord sous le menton.

• Serrer le bouton de réglage de manière a ce que le harnais reste bien sur la tête. Il est peut être

nécessaire ajuster régler la sangle de tête afin que la visière se trouve bien devant le visage.

• Tirer le joint du bord en arrière pour une confortable position sous le menton et autour des joues.

Le joint du bord doit s’étendre au-dessus des oreilles et sous le serre-tête.

•

Le tuyau descende le long du dos sans spirales ni coudes.

4. Entretien et entreposage

• Entreposer dans un endroit sec et frais (-10 °C...+30 °C, max. 75 % HR) à l’abri de la lumière du

soleil et des impuretés.

• Vérifier que la cagoule n’est pas froissée, éraillée ou déchirée.

• Nettoyer avec un chiffon ou éponge moite (prendre soin de ne pas rayer la visière). Utiliser l’eau

tiède contenant un détergent doux (neutre, pH 6-8) (ex. produit-vaisselle). Permettre sécher. Ne

pas se servir de solvants (ex. acétone, térébenthine), de l'eau brûlante ou d’agents de

blanchiment (perborate, percarbonate). L’utilisation de l’air comprimé ou de l’eau sous pression

est interdite.

• Vérifier l’état de la visière, le casque et du tuyau, et les remplacer en cas de défaillance.

• La fréquence de changement recommandée pour une utilisation quotidienne est de 2 ans, en

particulier dans utilisation en plein air. Durée de service est de 5 ans si correctement conservé.

• Utiliser uniquement des pièces de rechange originales.

Remplacement du tuyau respiratoire

• Deserrer le tuyau du conduite d’air et visser le nouveau tuyau.

Remplacement de la visière

• Libérer les élastiques du harnais. Plier la visière complètement vers le haut jusqu’à ce que la

visière se détache des pivot-bras. Tirer la soupape expiratoire du joint du bord, et fixer-la dans le

joint du bord de la nouvelle visière.

• Vérifier que le joint du bord se trouve complètement autour du corps de soupape. Avec les pivot-

bras vers le haut, positioner la visière en les bras, ensuite plier en bas pour laisser la visière

enclencher en place.

Page 16

15

Remplacement de la soupape expiratoire

• Détacher le couvercle de la soupape expiratoire et enlever le disque.

• Inserer un nouveau disque, et vérifier que le disque reste aplati dans le siège.

• Aligner le couvercle dans les encoches et enclenchez-le en place.

Remplacement des pivot-bras

• Libérer le pivot-bras à l’aide de la clip latérale et retirer le bras. Faire glisser le nouveau pivot-bra

dans l’attache et bloquer avec la pince latérale.

Remplacement de la bordure

• Libérer les élastiques du harnais. Dénouer le ruban d’attache de la bordure et retirer la bordure.

• Positionner les trous rectangulaires dans la nouvelle bordure sur le conduite d’air devant le

casque, et arranger la bordure autour du ourlet du casque entassant les bourres sous l’ourlet.

Nouer le ruban d’attache.

Remplacement du harnais

• Plier la visière complètement vers le haut. Appuyer les blanches brides d’attache avec les pouces

pour détacher le harnais.

• Pour montage, inserer les blanches brides d’attache dans les encoches au bord

du casque, et

appuyer pour enclencher-les en place.

• Plier la visière en position désirée.

Remplacement du coussinet frontal

• Tirer le coussinet des crochets du harnais.

• Placer le nouveau coussinet sur les quatre crochets ses trouvants dans le bord inférieur devant le

serre-tête, ensuite plier le coussinet de l’autre côté du serre-tête, et finalement fixer sur les deux

crochets en haut du serre-tête.

5. Choix de l’appareil de protection respiratoire filtrant équipé de ventilateur

Voir les instructions d’utilisation de l’appareil ventilateur en question.

Type d’appareil Multiple de valeur moyenne

d’exposition (V.M.E.)

Écran facial équipé de ventilateur et

filtre à particules

TH1P

TH2P (Flowhood 5)

TH3P

Appareil de protection respiratoire et

filtre combiné

Écran facial équipé de ventilateur et

filtre à gaz *)

TH1 catégorie de filtre à gaz 1 ou 2

TH2 catégorie de filtre à gaz 1 ou 2

TH3 catégorie de filtre à gaz 1 ou 2

*) À condition de ne pas dépasser les concentrations maximums autorisées de gaz nocifs qui sont pour les filtre

à gaz utilisés avec ventilateur 0,05 vol.% dans la catégorie de filtre à gaz 1 et 0,1 vol.% dans la catégorie de

filtre à gaz 2 et 0,5 vol.% dans la catégorie de filtre à gaz 3.

5

20

100

Les multiples des valeurs moyennes d’exposition sont communiqués

séparément pour les filtres à gaz et les filtres à particules, et dans

chaque cas il faut respecter la plus petite valeur.

5

20

100

Les appareils de protection respiratoire “ouverts”,

comme un casque ou une cagoule, n’offrent pas une

protection suffisante si le ventilateur défaille ou faiblit.

C’est pourquoi les protections de classe TH1 ne

doivent pas être utilisées pour se protéger contre les

gaz ou vapeurs cancérigénes, très toxiques ou

radioactifs.

Lors de l’utilisation de l’appareil de protection

respiratoire avec un filtre combiné, respecter les

restrictions des filtres à gaz et à parti cules.

Remarques, limitations

Loading...

Loading...