Page 1

FV300 SERIES

INFRA-RED

FLAME

DETECTION

FLAME

DETECTORS

USER MANUAL

IR ARRAY

FlameVision

Page 2

PAGE

INTRODUCION 1

PRINCIPLES OF OPERATION 3

APPLICATION 7

SYSTEM DESIGN INFORMATION 10

OPERATION 29

INSTALLATION 34

COMMISSIONING 43

MAINTENANCE 52

ORDERING INFORMATION 54

ANNEX A - MODBUS OVERVIEW 55

ANNEX B - CCTV DETAILS 59

FV300 USER MANUAL INDEX

Page 3

INTRODUCTION

1

1. INTRODUCTION

The FV300 FlameVision range is a new family of adv anced, high technology infra-red ar ray flame

detectors with reliable wide area flame detection and excellent false alarm immunity. The FV300

FlameVision detectors offer a major impro vement in both flame detection capability and immunity

to false alarm sources over triple IR detectors. The detector can be supplied with an optional builtin colour video camera for connection to CCTV systems to display the field of view with an

overlay showing alarm location and status information. All FV300 models provide fire and fault

relays, 4-20mA output and a field network interface as standard for connecting to external

equipment.

The FV300 FlameVision detectors use an array of 256 sensitive infra-red sensors to view the

protected area. The IR array is combined wi th 2 other optical sensors to pro vide 3 highly sensitive

optical channels. Powerful algorithms running on a Digital Signal Processor (DSP) are tuned to the

characteristics of a f ire and a nalyse the signals fro m these 3 channels to reliably identify fires. The

FV300 offers sensitive flame detection over a long range with a wide and consistent field of view.

It also has excellent immunity to false alarms.

One of the key advantages of using an array is that the detector can identify the location of the

flame within the field of view. The location information is used to overlay a marker on the live

camera image to highlight the fire. The user can quickly see the location of the fire and decide on

the appropriate action. The location information is also available on the field network interface.

The FV300 FlameVision range is highly configurable to provide flexible detectors for all

applications. The most common options are set using DIP switches with more advanced options

set using a PC tool. The detectors also include features designed to reduce maintenance, including

remote configuration, internal diagnostic logs and built-in alarm and window cleanliness tests. A

portable test tool, suitable for use in hazardous areas is available to operate the alarm and window

test facilities remotely.

The FV300 FlameVison detectors are housed in a rugged stainless steel enclosure suitable for harsh

environments. All detectors share the same detection circuitry, optics and mechanics and the

choice of two back box variants gives two basic flameproof (explosion proof) flame detector

models. The FV311S series features cable gland entries and integral cable termination

facility. The FV312S series features a sealed back box with cable for connection of field wiring

via an EExe junction box.

Each model is available in three variants depending whether the detector is fitted with an internal

CCTV camera and which type of camera is fitted. The range of variants includes:

FV311S Cable entries No CCTV camera

FV311SC Cable entries PAL CCTV camera

FV311SC-N Cable entries NTSC CCTV camera

FV312S Sealed back box No CCTV camera

FV312SC Sealed back box PAL CCTV camera

FV312SC-N Sealed back box NTSC CCTV camera

Page 4

INTRODUCTION

2

Summary of features:

Advanced array based detector

Powerful signal processing on DSP with algorithms to give reliable flame detection

Detection range: Over 50m for 0.1m

2

n-heptane pan fire

Field of view: 90° horizontal, 80° vertical with full range maintained

High immunity to false alarms

Solar blind

Built-in video camera (option): View protected area with alarm location and status

overlay

Masking of areas in field of view

Self-test: Automatic Self-test of detector features

: Window test (automatic/manual/remote operation)

: Alarm test (automatic/manual/remote operation)

Electrical Interfaces (Standard on all models):

Fire and Fault re lays (NO or NC contacts)

4 - 20 mA (Source or Sink)

Video twisted pair balanced line (NSTC/PAL)

Modbus (RS485) interface

Configuration port (RS485)

FV311SC-N

D

O

N

O

T

O

P

E

N

W

H

E

N

A

N

E

X

P

L

O

S

I

V

E

G

A

S

A

T

M

O

S

P

H

E

R

E

I

S

P

R

E

S

E

N

T

TYCO TW16 5DB UK

FlameVision

SEAL

CONDUITS

WITHIN 18"

APPROVED

F M

Ui = 30V

Pi = 10W

PATENTED

IP66/67

1180

tyco

CI I Div 1 Grp B,C,D

CI II Grp E,F,G CI III

T

O

R

Q

U

E

C

O

V

E

R

B

O

L

T

S

(

M

I

N

.

G

R

A

D

E

A

4

-

7

0

)

T

O

7

L

B

.

F

T

(

1

0

N

m

)

:

T

ATEX

Baseefa07

ATEX0178X

II 2 G D

IECEx

BAS07.0048X

Ex d IIC

Ex t D A21

T135

o

C

T -

40oC

to +

80oC

a

T100

o

C

:

- 40

o

C to + 70oC

a

C

A

B

L

E

E

N

T

R

I

E

S

:

M

2

0

C

A

B

L

E

R

A

T

I

N

G

:

T

a

+

2

5

K

T : - 4 0oC to + 80oC

a

S/No.12354

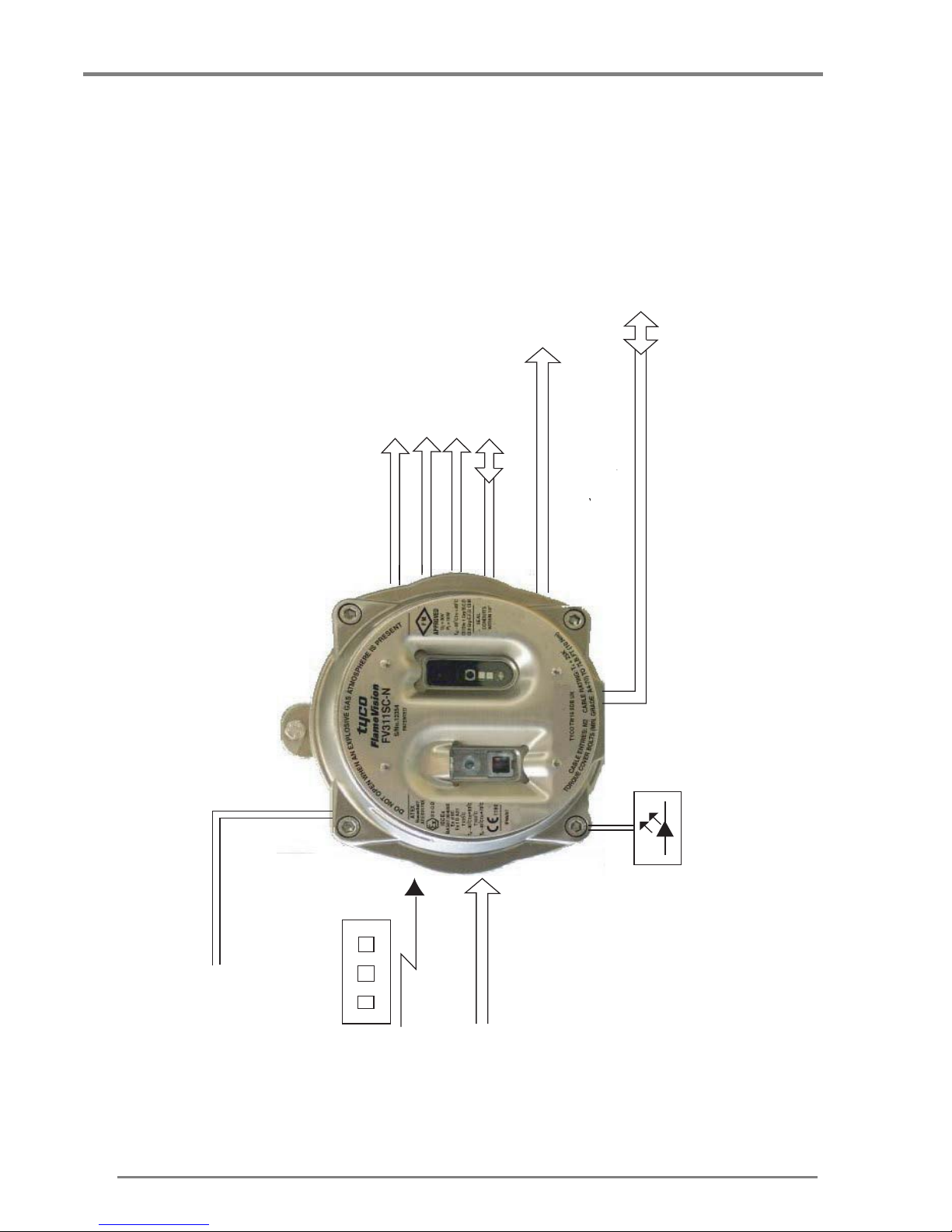

Fig. 1 FV300 Series Detector - General View

Page 5

PRINCIPLES OF OPERATION

3

2. PRINCIPLES OF OPERATION

2.1 GENERAL

In order to optimise the detection of flames from hydrocarbon, the FV300 detectors analyse radiant

infrared energy at the peak carbon dioxide emission wa velength around 4.5µm. In a separate guard

channel, the detectors also sense additional wavelengths between 4.8 and 5.8µm to determine

whether the spectral content received possesses the signature of a real flame. The signal received

is further analysed to determine whether its modulation frequency has the irregular and quasirandom characteristic of a flame within a pre-determined frequency band. A powerful Digital

Signal Processor (DSP) is continuously analysing the radiation signals to detect a fire.

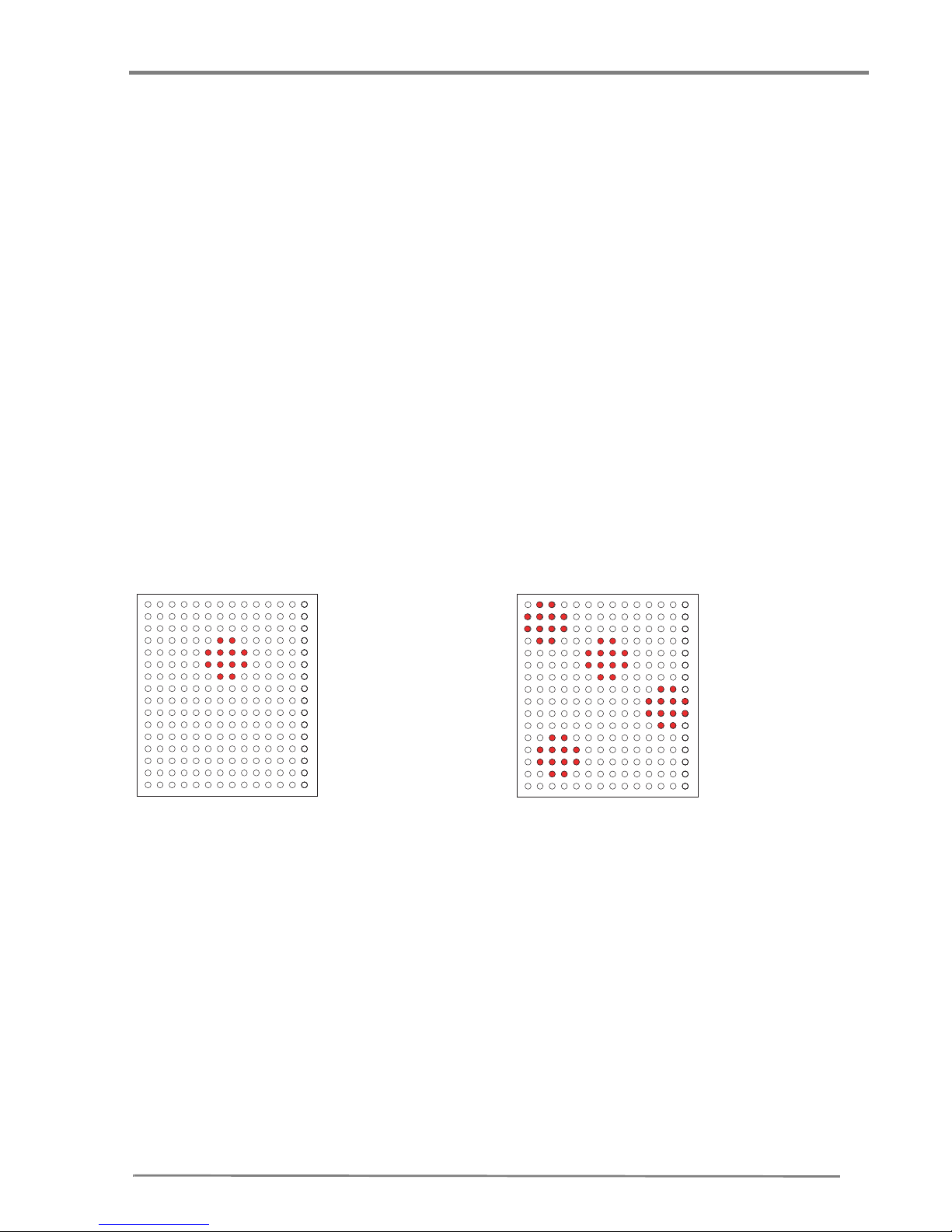

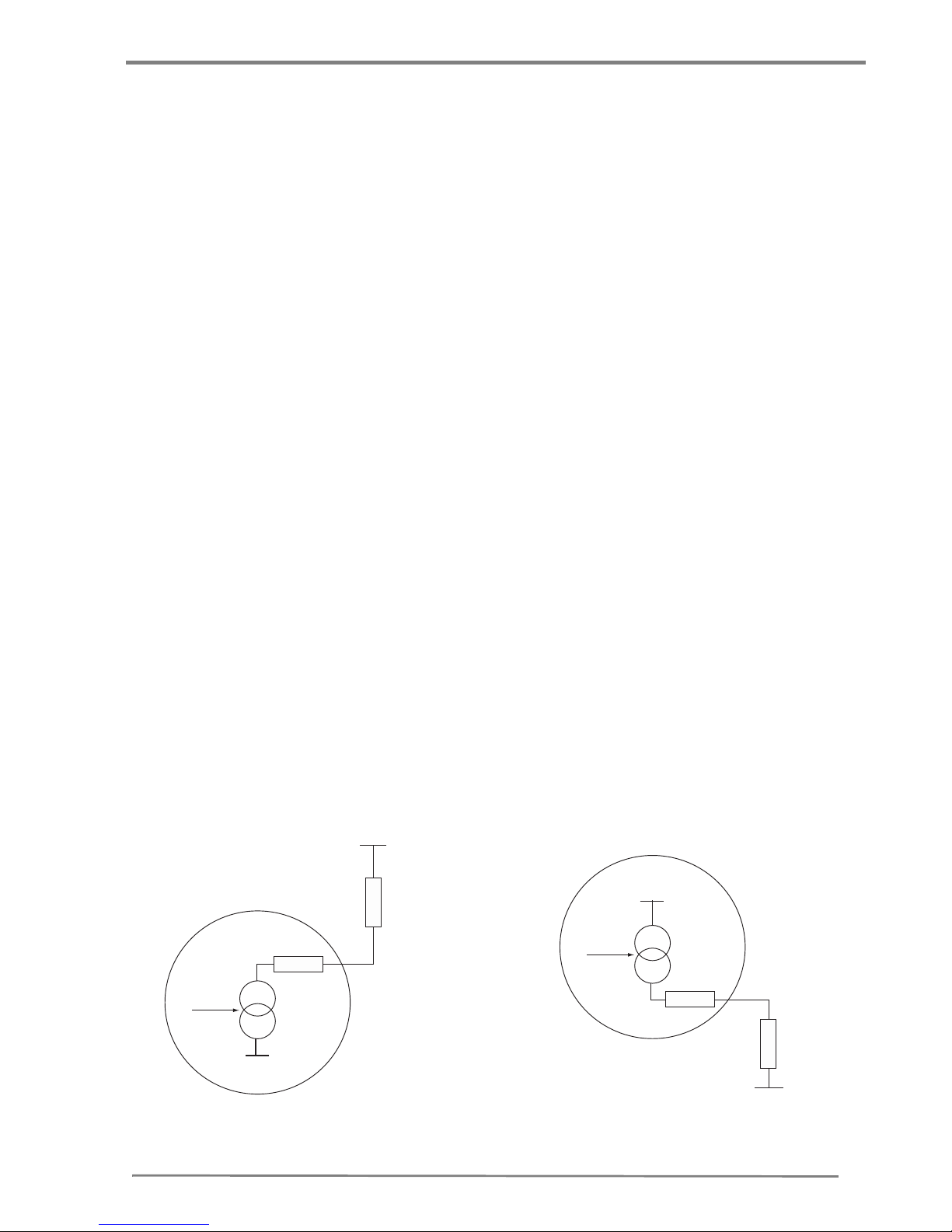

2.2 ARRAY-BASED FLAME DETECTION

The field of view of the detector is scanned by a 16 by 16 array of highly sensitive pyroelectric

sensors. A sapphire convergent lens collimates the infrared ener gy onto the sur face of the array . A

precise narrow band interference filter centred at 4.5µm then eliminates unwanted wavelengths.

If the signal received is of sufficient intensity to form a detectable image on several elements on

the array, called a cluster, the DSP analyses their frequency characteristic as well as their

correlation and spectral ratio with the signal present on the guard channel. A value representing

the instant probability that a real fire is present, results from this calculation. This probability

value is then analysed o ver a period of time to confirm whether a flame has been detected.

By using an array as the sensing component, the FV300 detectors are able to locate the angular

position of the fire within the field of view. The detectors use this information to provide

superimposed location information on a composite video output from an internal CCTV camera

and to signal the coordinates of this location on its field bus data output. The array, together with

its optical components and software intelligent interpolation gives the detector an angular

resolution of better than 0.5 degrees.

Array-based detection also enables the FV300 detectors to identify several separate radiation

sources within its field of view. For practical purposes, the number of separate detectable sources

that are reported has been limited to the four strongest, with information on these av ailable on both

video and field bus outputs.

Fig. 2 Array Cluster

SINGLE ACTIVE

ARRAY CLUSTER

MULTIPLE ACTIVE

ARRAY CLUSTERS

Page 6

PRINCIPLES OF OPERATION

4

Another advantage of array-based detection is that non-flame interferences, e g, black body or light

sources, can be uniquely identified to within an area of the f ield of vie w. This ability to separately

analyse signals from flame and non-flame sources enables array based flame detectors to not be

desensitised in the presence of non-flame in terferences, unless such sources are physically

coincidental. It also enables a known but unwanted source of radiation that is likely to be present

in the field of view of the detectors, to be ignored by applying of a ‘software’ mask to the signal

processing but still detect fires in the rest of the area.

2.3 REJECTION OF NON-FLAME SOURCES

2.3.1 GENERAL

In a new concept for eliminating nuisance alarms from modulated blackbody and other unwanted

non-flame radiation sources, the FV300 employs a combination of multiple spectral analysis and

time domain analysis techniques.

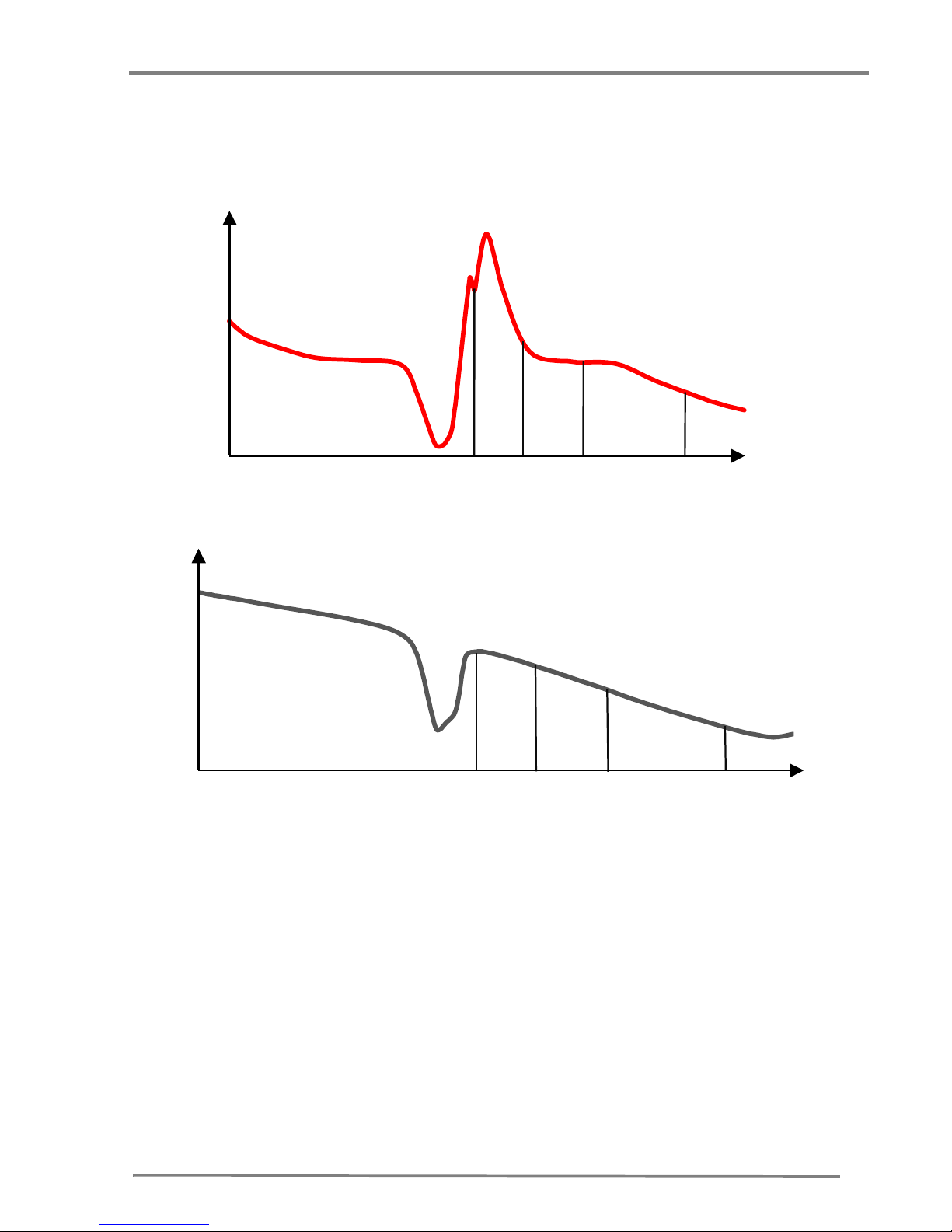

2.3.2 BLACKBODY REJECTION

A measure of the radiated energy in the CO2 emission waveband, between 4.4µm and 4.7µm, and

in a higher waveband, between 5µm and 5.7µm, provides a means to discriminate real flames from

blackbodies. Unfortunately, most fuels do not have a clean burn and, excep t for a d istinctive peak

at the carbon dioxide emission wavelength, possess a characteristic more akin to that of a

blackbody, exhibiting the distinctive CO

2

atmospheric emission band as well as a significant

emission beyond 4.7µm.

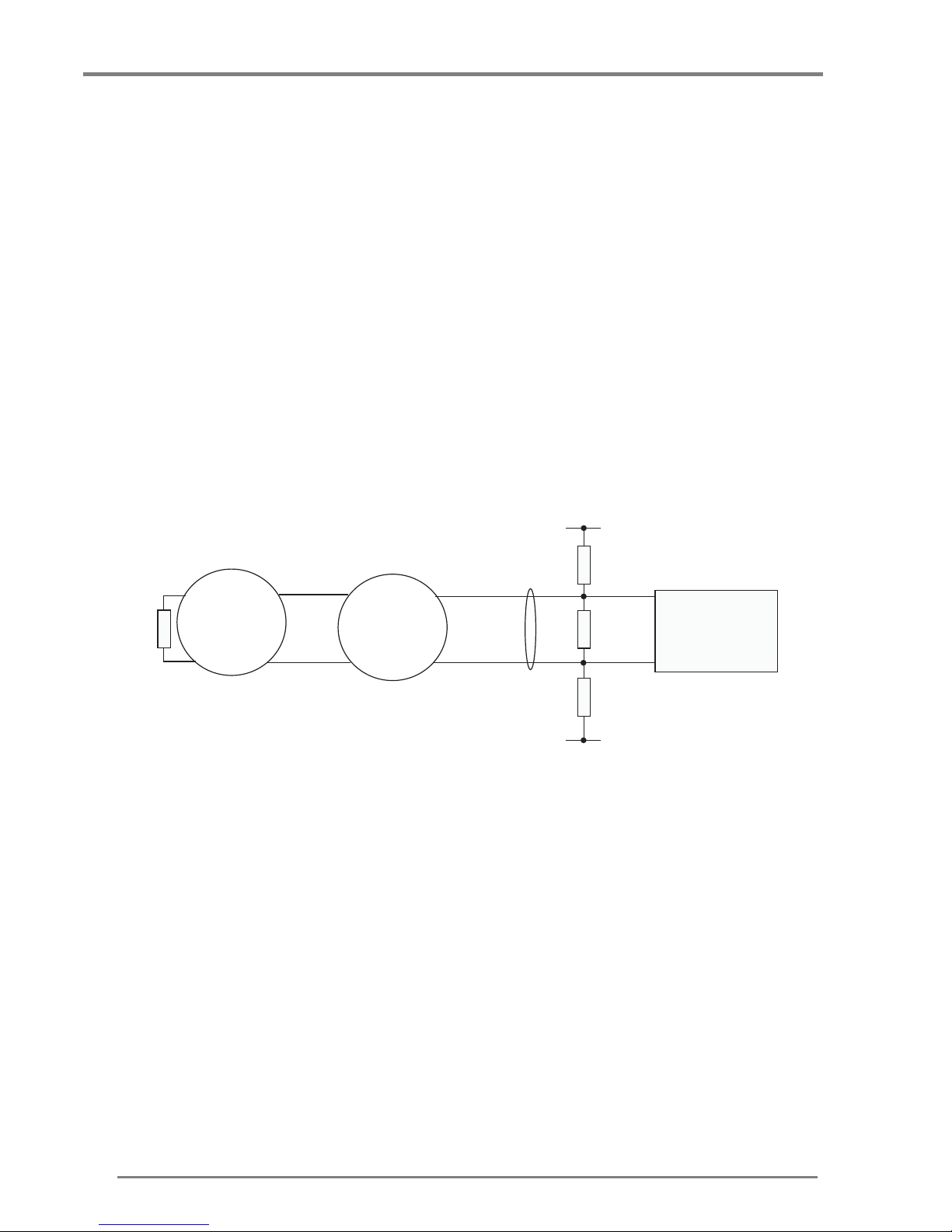

Fig. 3

Page 7

PRINCIPLES OF OPERATION

5

To ensure that flames from all potential fuels are detected whilst minimising the risk of nuisance

alarms, an optimum spectral signature of a flame, defined by its ratio at the two measuring

wavebands (A/B in Fig. 4) has been established experimentally by lighting characteristic fuels at

different distances. This was compared with a similarly obtained blackbody ratio (C/D in Fig. 5),

enabling an optimum flame decision threshold to be defined.

In addition to the above spectral analysis, the modulated infrared energy seen by each activated

cluster of the array is further analysed for frequenc y irre gularities o v er a period of time t hat w ou ld

be typical of that of a flame, but not a blackbody source. With this sophisticated level of signal

processing, the FV300 FlameVision range of detectors offers a high degree of immunity to all

blackbody sources likely to be present in the application.

Petrol fire

at 20m

3 3.5 4 4.5 5 5.5 6

A

B

Energy

Wavelength (m)

Fig. 4 Measured Flame Spectral Charac teristics

Black body

1200 K at 2m

33.544.555.56

C

D

Energy

Wavelength (m)

Fig. 5 Measured Blackbody Spectral Characteristics

Page 8

PRINCIPLES OF OPERATION

6

2.3.3 IMMUNITY TO SOLAR RADIATION

Modulated radiation from direct or reflected sunlight as well as modulated radiation from strong

sources of artificial lighting can produce an unwanted response from infrared flame detectors. To

counter this possibility, the FV300 detector looks for the flame in a very narrow waveband where

most of the sun radiation is absorbed by CO

2

gases in the atmosphere. Secondary re-radiation

effects from sun heated optical components is minimised by an additional long wave IR filter on

the guard channel and a special sun-block coating on the array lens.

To further eliminate the risk of unwanted alarms from modulated sun radiation or radiation from

sources of artificial lighting, the FV300 incorporates a third sensor looking specifically for

radiation in the visible and short wave infrared band. The output signal from this sensor is mixed

with that of the long wav elength infrared filter to operate as a sp ectral guard for modulated sunlight

or any other strong artificial lights.

2.4 DETECTION RANGE

The FV300 FlameVision detectors can detect a fully developed 0.1 m2 n-heptane or petrol

(gasoline) fire at 50m. The collimating optics and the ability of the detector to separately process

signals from individual sensing elements of the array enables the detector to correct signal losses

due to off-axis incident angles. This results in a ‘flatter’ response throughout the detector field of

view. Performance details are given in the System Design Information section.

2.5 MULTIPLE FIRES DETECTION

The FV300 sensor array, together with its associated digital signal processing, can identify more

than one fire event occurring at the same time within the detector field of view. At any one time,

up to four alarms from the strongest flames can be reported and signalled. Fires that are

sufficiently close or in the same line of sight will generate merged activity clusters on the sensor

array and can only be identified as a single fire ev ent.

2.6 DETECTION OF FLAME IN THE PRESENCE OF BLACKBODY

The ability of the detector to identify and process multiple activity clusters wit hin its f ield of view

allows radiation signals from fire sources and blackbody sources to be analysed separately for both

their spectral and time domain signature. Thus, in the presence of modulated blackbody sources,

the detector will not generally be desensitised when responding to a fire event. In some

applications, large blackbody sources may overshadow areas of the field of view where detection

is required. In these cases, care should be taken in the number and positioning of detectors that are

needed for achieving the degree of protection required.

Page 9

APPLICATION

7

3. APPLICATION

3.1 GENERAL

The FV300 FlameVision detecto rs are intended for the protection of high -risk areas in which

accidental fires are likely to result in flaming combustion with the production of carbon

dioxide. Typical materials in this type of risk are:

a) Flammable liquids, including petroleum products, alcohol and glycol, etc.

b) Flammable gases, including methane.

c) Paper, wood and packing materials.

d) Coal.

e) Plastics.

These substances ignite readily and burn rapidly, producing flame, often accompanied by large

volumes of dark smoke.

Note: The detectors are not designed to respond to flames emanating from fuels which

do not contain carbon, eg, hydrogen, ammonia or metals, and should not be used

for such risks without satisfactory testing.

The FV300 detectors, by virtue of their construction and rejection of spurious radiation, are

suitable for use indoors and outdoors in a wide range of applications. The System Design

Information section giv es system design recommendations and the I nstallation section, installation

recommendations.

3.2 USE IN HAZARDOUS ATMOSPHERES

The FV300 FlameV isio n detectors are certif ied 'Flamep roof' to the ATEX directive and IECEx by

Baseefa. They are classified as suitable for zone 1 a nd 2 areas over an ambient temperature range

-40°C to +80°C for temperature class T135°C (T4) gasses and dust, or -40°C to +70° C for

temperature classification T100°C (T5) gasses and dust. See System Design - Section 4.9 for

certification and marking details.

The FV311 detectors are also certified ‘Explosionproof’ by Factory Mutual (FM) approvals. The

FV311 detectors meet the requirements of FM 3600 and FM 3615 and are suitable for hazardous

locations Class 1 Division1 Groups B, C and D, Class 2 Groups E, F and G and Class 3.

3.3 FEATURES AND BENEFITS OF THE FV300 FlameVision

DETECTORS

The FV300 Flamevision detector s are a family of advanced, high technology array based infra-red

flame detectors. The y hav e been designed to gi v e reliable wide area flame detection with excellent

false alarm immunity . The FV300 detectors also hav e a wide range of features to provide a fle xible

detector that can operate in all environments and can be connected to many different types of

system.

Page 10

APPLICATION

8

Summary of FV300 FlameVision features and benefits:

Detection:

The FV300 provides high sensitivity flame detection with high false alarm immunity,

undiminished throughout a wide field of view.

An infra-red array combined with 2 other optical sensors provides 3 sensitive optical

channels. Signals are analysed by powerful algorithms running on a DSP to give reliable

flame detection. The algorithms have been extensively proven with real fir es.

Operational range 50m (0.1m

2

heptane pan fire) with no reduction in range across the

90° horizontal and 80° vertical field of view.

Consistent detection of different sizes of flames from a wide range of hydrocarbon fuels

from alcohol to aviation fuel (JP4 and JP5).

Excellent false alarm immunity. Proven to be immune to common radiation sources

(continuous or modulated) such as halogen lamps, welding, heaters, etc.

Solar blind.

By using an array, the FV300 can locate the flame within the field of vie w and displays th e

information on the video overlay to pinpoint the location of the fire enabling more ef fectiv e

counter measures to be taken. The location information is also available on the network

interface for use in external systems.

Software Field of View Masking: The array can locate and track active known permanent

sources, such as a flare stack, within the field of vie w. The detector can be configured to

ignore such sources, including flames, in a certain area of the field of view. External,

physical blinkers and shutters are not required.

Interfaces:

Fire and fault relays, 4-20mA output and a field network (RS485) interface are standard

on all models to connect to monitoring equipment.

Modbus protocol is supported on the field network interface to connect to PLCs.

Internal wide angle CCTV camera (optional) cov ering detection f ield of view. With a video

output (balanced line) to connect to on-site video monitoring (CCTV) system. Detector

overlays identification information on the video image to show alarm location and details.

Functions:

W i ndow heater standard on all models to reduce misting.

Flexible configuration: Primary options on DIP switches such as alarm delay timings, fire/

fault latching, etc. Advanced options set using PC configuration tool such as mask area,

network parameters etc.

Regular self-testing of critical electronic circuits and regular monitoring of the detector

window cleanliness and optical path (OPM) which reduces the frequency of regular

maintenance visits.

Integral flame simulation for verification of detection path enabling either easy walk-

testing of the installation or testing by remote control to ensure continued reliability of th e

detector operation.

Diagnostic logs: The detec tor keeps a log of all e v ents, alarms e tc. This information can be

read remotely using the configuration tool for maintenance purposes.

Hand-held walk test tool available to initiate alarm and window tests and reset detector on

demand. Tool can activate detectors from up to 6m away so can be used without poles or

other access methods. Walk-test tool is ATEX approved by Baseefa and can be used in

hazardous areas.

Page 11

APPLICATION

9

Mechanical:

Rugged two part stainless steel 316L housing sealed to IP66/IP67 for use in harsh

environments.

Choice of gland entry back box with terminal blocks for direct field wire termination or

sealed entry back box fitted with a flying lead to connect to an e xter nal EExe junction box.

Optional mounting bracket in 316L stainless steel allo ws 90° adjustment in both horizontal

and vertical plane and includes angular markings.

Detector ATEX and IECEx certified (‘Flameproof’) by Baseefa.

The FV300 FlameVision series are infrared flame detectors giving the FV300 major benefits over

detectors working in the visible or ultra-violet regions of the spectrum, such as UV detectors or

video flame detectors. These include:

Highly sensitive to flame, thus increasing probability of early detection of hydrocarbon

fires over a longer range.

Much less affe cte d by window contamination from dirt and oil deposit, thus decreasing

maintenance requirements leading to operating cost reduction.

Able to see flames through smoke and through high densities of solvent vapours thus

increasing the probability of early detection of hydrocarbon fires, particularly from heavy

black smoke generating fuels.

3.4 POINTS TO NO TE WHEN USING FV300 FlameVision DETEC TOR S

OR S200 FLAME DETECTORS

The FV300 FlameVision series are a whole new range of flame detectors developed from the

knowledge and experience built up from previous detectors such as the S100 and S200 series.

However, the FV300 series is not a complete replacement for the existing detectors and the

following should be considered:

The FV300 will only be available in Flameproof versions. An IS version will not be

available due to the power consumed, especially by the camera. The S200 range should

continue to be used in these applications.

The FV300 consumes more power than the S200 and needs an external PSU.

The FV300 is smaller than the S200 and does not fit the S100/200 bracket. To replace an

S200 with an FV300 the FV300 bracket will have to be f itted .

FV300 has a discrete 4-20mA level for pre-alarm. It is not variable like the S200.

The FV300 has a consistent range over the f ield of view and automatically adjusts to the

distance and size of a fire. It does not need adjustable sensitivity as used on the S200.

The FV300 has a clear field of view, there are no blind spots.

The FV300 provides all electrical interfaces (relays, 4-20mA, etc.) on ALL models.

Page 12

SYSTEM DESIGN INFORMATION

10

4. SYSTEM DESIGN INFORMATION

The electrical, mechanical, environmental characteristics and the performance of the FV300

FlameVision series detectors must be taken into account when designing a system which uses these

detectors. This information is giv en in this section, together with guidance on detector siting. Fig.

6 shows the interfaces available on the detectors.

FIRE RELAY

FAULT RELAY

4 - 20 mA OUTPUT

NETWORK INTERFACE

}

TO

MONITORING

SYSTEM

VIDEO (BALANCED PAIR)

TO CCTV SYSTEM

POWER (18 - 30V dc)

WALK TEST TOOL

ACTIVATE:

ALARM TEST

RESET

WINDOW TEST

WALK TEST INPUT

IR

}

REMOTE INDICATOR

(OPTION)

CONFIGURATION/DIAGNOSTICS PORT*

TO PC

* IT IS RECOMMENDED TO PROVIDE CABLES FOR

THIS PORT TO ENABLE REMOTE CONFIGURATION

AND DIAGNOSTICS

Fig. 6 FV300 Interfaces

Page 13

SYSTEM DESIGN INFORMATION

11

4.1 ELECTRICAL CHARACTERISTICS

4.1.1 GENERAL

Supply voltage: 20V to 30V dc

Power: up to 10W (depending on model)

Quiescent current:

- no camera fitted: 158mA at 24V

- with camera: 196mA at 24V

Alarm current:

- no camera fitted: 166mA at 24V

- with camera: 205mA at 24V

Additional current when using 4 to 20 mA output in source mode

- Quiescent: 4.0mA at 24V

- Alarm: 11.5mA at 24V

Window heater additional current: V

Supply

÷ 270Ω (90mΑ at 24V)

Stabilisation time after po wer up: 5 - 20 minutes

4.1.2 RELAY CONTACT OUTPUTS

Fault relay: Selectable normally closed or open contact.

Alarm relay: Selectable normally closed or open contact.

Alarm relay coil monitoring: Supplied as standard.

Contact rating: 2A at 30V dc

4.1.3 4 to 20 mA OUTPUT

Signalling currents: Nominal Range

General fault: 0mA (0.0 to 0.7mA)

Window dirty: 2mA (1 to 3mA)

Normal: 4.5mA (3.5 to 5.5mA)

Pre-alarm: 11.5mA (10 to 13mA)

Alarm: 17mA (15 to 19mA)

Maximum current monitor resistance

in source mode: 150Ω

Output mode: Selectable current sink or current source output (SW2).

4-20mA SINK MODE

24V

7.7V

DETECTOR

R

MONITOR

100R

R

MONITOR

100R-390R

7.7V

DETECTOR

R

MONITOR

100R

R

MONITOR

100R-120R

0V

4-20mA SOURCE MODE

4-20mA OUTPUT

4-20mA OUTPUT

Fig. 7 4-20mA Current Sink/Source Wiring Diagrams

Page 14

SYSTEM DESIGN INFORMATION

12

4.1.4 MODBUS NETWORK INTERFACE

The FV300 can be a slave RTU device on a MODBUS netwo rk using a standard RS485 electrical

interface.

4.1.4.1 MODBUS COMMUNICATIONS PARAMETERS

Baud rate: 9,600 or 19,200 selectable.

Maximum number of units: 32

Protocol: T o MODB US Application Protocol Specif ication V1.1 - See

‘Annex A for register definitions

Mode: R TU

4.1.4.2 MODBUS LINE TERMINATION

The MODBUS network should hav e 390Ω bias resistors, to gi ve def ined v oltage lev els on the line,

and a 220Ω matching resistor fitted near to the controller, as shown below. In addition, a 220Ω

termination should be fitted at the end of the pair cable to give reliable operation, especially with

long cable runs.

4.1.5 VIDEO OUTPUT

The FV300 provides a video output from the optional internal camera for connection to CCTV

systems. It is available in either PAL or NTSC format (option). The detector superimposes an

overlay with status information on top of the picture to notify alarms, including location, and faults.

The video output can be used on units without a camera to display the status information overlay

on a CCTV system. The status information is displayed on a coloured background. The output is

enabled by configuration.

The video output is a balanced signal suitable to drive twisted pair cable. The cable should be

terminated in a balun to provide the connection to the video system.

The video output operates over a reduced temperature range from -40 to +70°C. The detector

controls the video output to prevent damage if the temperature goes outside the ran ge. See Table 1.

Output impedance: 100Ω into 100Ω twisted pair.

Receiving end: Active balun NV - 652W (603.015.027).

+5V

MODBUS

CONTROLLER

0V

390Ω

220Ω

390Ω

TWISTED

PAIR

DETECTOR

DETECTOR

220Ω

Fig. 8 Line Termination

Page 15

SYSTEM DESIGN INFORMATION

13

A 24V supply is required - it must be isolated from detector supply if the RS485 interface option

is used. Leave the balun ground connection O/C.

Note: The detector monitors the internal temperature to decide when to switch the

video output mode. The temperatu res in Table 1 are external temp eratures an d

vary depending on the environmental conditions and if the window heater is

enabled.

4.1.6 WINDOW HEATER

The FV300 has a heater to warm the sensing window and prevent misting. The heater is enabled

on the DIP switches. When enabled, the heater will turn off when the detector temperature rises

above +40º C.

4.1.7 WALK TEST INPUT

The walk test input provides a means to connect remote switches to the FV300 detector to activ ate

the alarm test and window test (OPM) functions or to reset the detector. The required operation is

selected by connecting the appropriate resistor value, see Fig 9, between the walk test input and

0V using a momentary switch. The switch should be opened once the function has been

activated. See Figs. 24, 25 and 26.

Note: The FV300 detectors are approv ed f or use in both gas and dust atmospheres but

the WT300 Test tool is only approved for gas atmospheres. Where FV300

detectors are installed in dust risk environments the walk-test wired input should

be used.

From (º C)To(º C) Text

overlay

Video

camera

Video output

+70 +80 Off Off No video signal

+50 +70 On Off Overlay with blue background

-10 +50 On On Camera or blue background with

overlay

-30 -10 On Off Overlay with blue background

-40 -30 Off Off No video signal

Table. 1 Video Output

15k

WINDOW

TEST

4k7

RESET

1k8

ALARM

TEST

WALK TEST

INPUT

0V

Fig. 9 Walk Test Input

Page 16

SYSTEM DESIGN INFORMATION

14

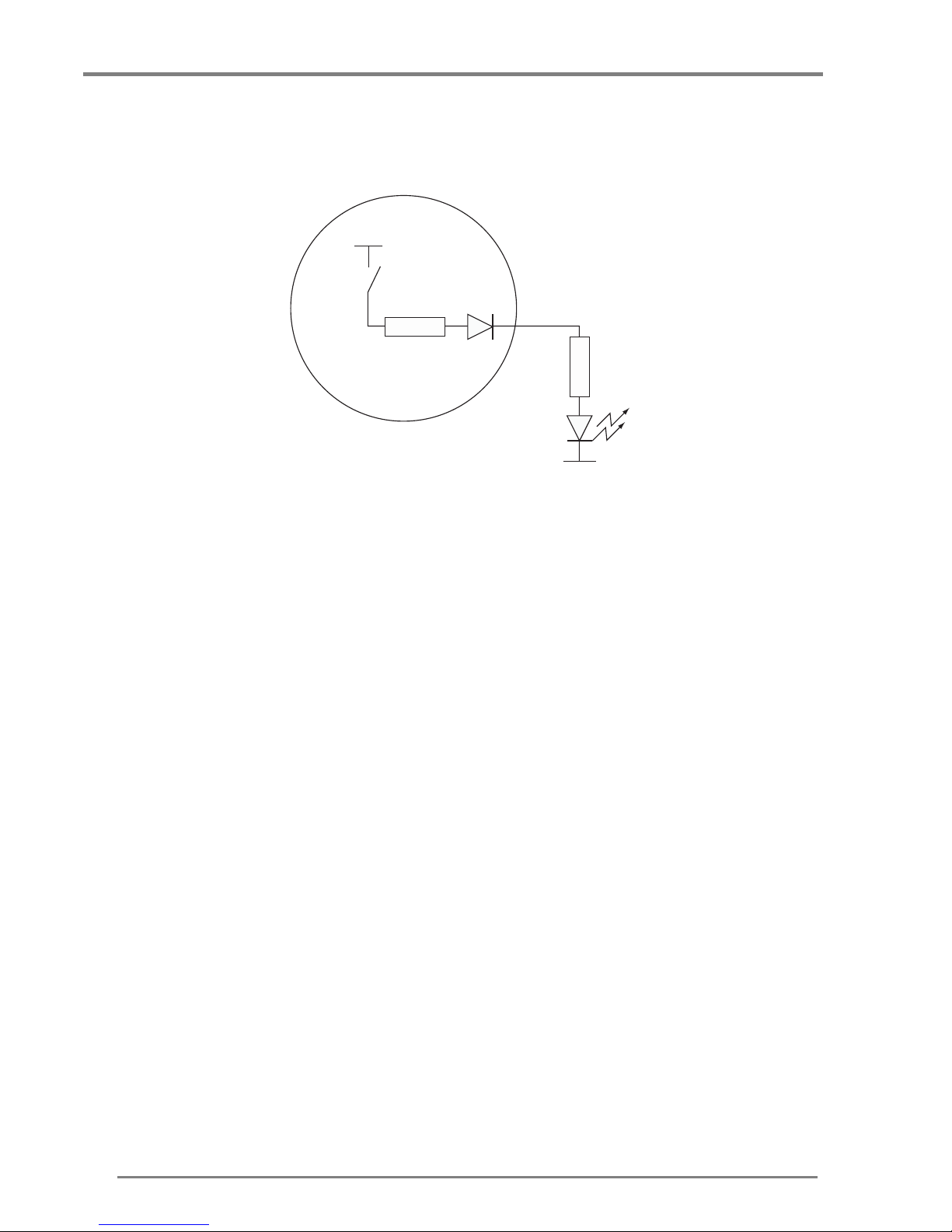

4.1.8 REMOTE LED

An external LED indicator can be connected to the detector . The output follows the indications of

the alarm LED. The connection is as follows:

Note: The external L ED output shoul d be used for visual indication o nly. It should not

be used for signalling alarms to other equipment

4.2 MECHANICAL CHARACTERISTICS

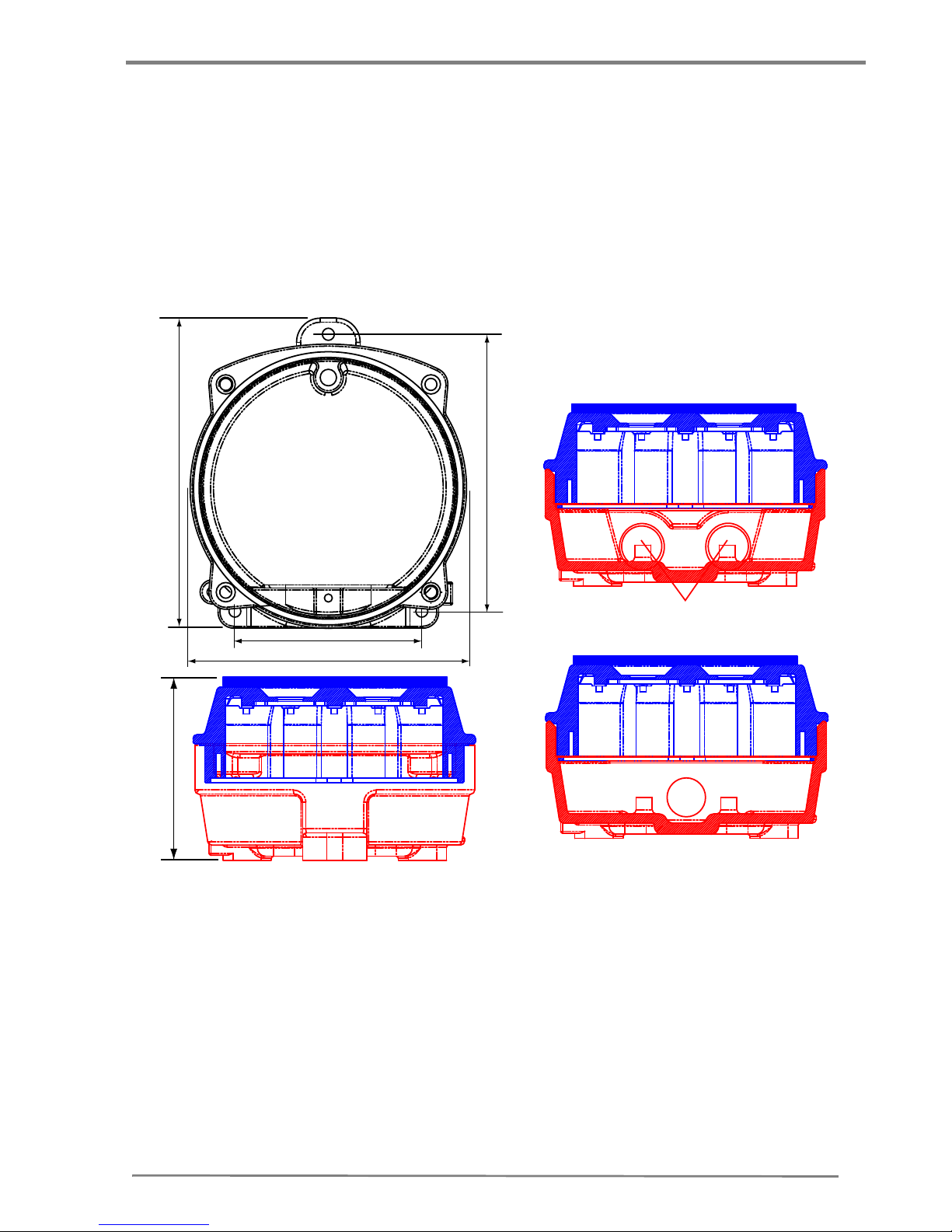

4.2.1 DIMENSIONS (SEE FIGURES 11 AND 12)

Height: 138.8 mm

Width: 152.8 mm

Depth: 91.7 mm

Weight: 3.96 kg

Mounting bracket

weight: 1.54 kg

4.2.2 MATERIALS

Enclosure: Stainless steel 316L, ANC4BFCLC to BS 3146: Part 2

Detection window: Sapphire

Camera window: Toughened glass

Guard/label plate: Stainless steel 316S16 to BS 1449: Part 2

Mounting bracket: Stainless steel 316S16 to BS 1449: Part 2

Screws etc. Exposed

to the elements: Stainless steel 316 A4

Electronic modules: Fibreglass substrate

DETECTOR

+12V

140R

R

*

0V

* OPTIONAL CURRENT LIMITING RESISTOR

REMOTE ALARM

LED OUTPUT

Fig. 10 Remote LED Wiring Diagram

Page 17

SYSTEM DESIGN INFORMATION

15

4.2.3 ELECTRICAL ACCESS

FV311 series detectors: Standard M20 gland holes (two)

FV312 series detectors: Multi twisted pair screened cable

4.2.4 IP RATING:

Enclosure protection: Tested to IP66 and IP67*

* Cable gland entries must be suitably sealed to achieve the required IP rating (see Section 6.3.3).

94

139

155.5

FV311 RANGE : 2 x 20mm GLAND HOLES

FV312 RANGE : PRECABLED WITH

CONDUIT COUPLING

98.5

Fig. 11 FV300 Series - Overall Dimensions

Page 18

SYSTEM DESIGN INFORMATION

16

4.3 GENERAL CONSTRUCTION

Fig. 13 shows a general view of a complete detector with its mounting bracket.

The detector is of robust construction to allow its use in harsh environments.

The detector comprises a two-part stainless steel ‘spigot-type’ enclosure. Both halves of the

enclosure are guided into the correct position by an alignment pin. T he front section of the

enclosure contains the detector optical and electronic sub-assemblies. Mating connectors at the

rear of the front section and on the terminal board mounted in the rear section of the enclosure

provide a means of electrical connection to the installation cables.

The rear enclosure of the FV311 series of detectors is provided with two M20 gland entry holes at

the bottom of the detector . Two 10-way terminal block arrangements are provided for termination

of installation cables.

The rear enclosure of the FV312 series of detectors is pro vid ed with a permanently attached cable

sealed in the enclosure. With these detectors, termination of installation cables is made in an

external EExe junction box.

Both types of rear enclosure have a dedicated earthing point on the side of the casting ( Fig. 14) to

connect an earth bonding wire from the nearest safety earthing point to the enclosur e. Also, a

tagging loop is provided on the side of the rear enclosure to attach a suitable label to identify the

detector on site.

124.2

92

181

122.4

94.4

THE BRACKET

MUST

BE MOUNTED

IN THIS ORIENTATION

Fig. 12 Adjustable Mounting Bracket and Surface Mounting Dimensions

Page 19

SYSTEM DESIGN INFORMATION

17

A hanging cord enables the two halves of the enclosure to remain attached when opening the

detector during maintenance work.

The front section of the enclosure is attached to the rear section by four captive screws. A seal

provided between the front and rear sections ensures protection to IP66 and IP67.

D

O

N

O

T

O

P

E

N

W

H

E

N

A

N

E

X

P

L

O

S

I

V

E

G

A

S

A

T

M

O

S

P

H

E

R

E

I

S

P

R

E

S

E

N

T

TYCO TW16 5DB UK

FV311SC-N

S/No.12365

FlameVision

PATENTED

tyco

T

O

R

Q

U

E

C

O

V

E

R

B

O

L

T

S

(

M

I

N

.

G

R

A

D

E

A

4

-

7

0

)

T

O

7

L

B

.

F

T

(

1

0

N

m

)

C

A

B

L

E

E

N

T

R

I

E

S

:

M

2

0

C

A

B

L

E

R

A

T

I

N

G

:

T

a

+

2

5

K

SEAL

CONDUITS

WITHIN 18"

APPROVED

F M

Ui = 30V

Pi = 10W

CI I Div 1 Grp B,C,D

CI II Grp E,F,G CI III

T : - 40oC to + 80oC

a

IP66/67

1180

:

T

ATEX

Baseefa07

ATEX0178X

II 2 G D

IECEx

BAS07.0048X

Ex d IIC

Ex t D A21

T135

o

C

T -

40oC

to +

80oC

a

T100

o

C

:

- 40

o

C to + 70oC

a

Fig. 13 FV300 Detector - General View

Fig. 14 Earthing and Label Fixing Points

EARTH BONDING CONNECTION

TAGGING LOOP CONNECTION POINT

Page 20

SYSTEM DESIGN INFORMATION

18

Fig. 15 FV311/FV312 Top Section

Fig. 16 FV312 Bottom Section

Page 21

SYSTEM DESIGN INFORMATION

19

The front section of the enclosure is fitted with a window guard plate to protect the two detector

viewing windows. A locally formed section of this plate acts as a mirror for the Optical Path

Monitoring test. This plate also contains the mandatory markings required by the Flameproof and

Explosion Proof Regulatory standards (ATEX, IECEx and FM).

The detector may be fitted directly to a suitable surf ace or an optional adjustable mounting bracket

may be used. An optional weather hood is available for use where protection against extreme

environmental conditions such as hot sun or downpour is needed.

A weather hood is available for use in tropical climates where intense sunlight may occur (Fig. 18).

It also provides protection from rain falling on the window.

Fig. 17 FV311 Bottom Section

Page 22

SYSTEM DESIGN INFORMATION

20

4.4 ENVIRONMENTAL CHARACTERISTICS

4.4.1 GENERAL

The design and construction of the FV300 series detectors are such that they may be used over a

wide range of environmental conditions. Relevant limits are given in Para 4.2.

4.4.2 TEMPERATURE AND HUMIDITY

FV311S/FV312S - models without camera

Operating temperature range: -40°C to +80°C

Storage temperature range: -40°C to +80°C

FV311SC(-N)/FV312SC(-N) - models with camera

Operating temperature range: -10°C to +50°C*

Storage temperature range: -20°C to +70°C

All models

Relative humidity: Up to 99% (non-condensing)

Note: * The detector will turn the camera off if the temperature goes outside this range

but fire detection capability is still present when the video is switched off.

Fig. 18 FV300 Detector With Weather Hood Fitted

Page 23

SYSTEM DESIGN INFORMATION

21

4.4.3 VIBRATION AND SHOCK

The FV300 detectors have been designed and tested for vibration and shock and comply with the

requirements of:

EN 54-10, European standard for point flame detectors,

Lloyd’s Register of Shipping (LRS) Test Specification Number 1 (2002),

Det Norske Veritas (DNV) Certification Notes No 2.4 (April 2001) Class A,

Germanischer Lloyd (GL) Rules for Classification and Construction, Test Requirements for

Electrical, Electronic Equipment, Computers and Peripherals (April 2001),

Factory Mutual FMRA 3260, Approv al Standard for Radiant Energy-Sensing Fire Detecto rs for

Automatic Fire Alarm Signalling.

The following maximu m levels are applicable:

Operational vibration: 1.24 mm displacement (from 5 Hz to 14.2 Hz)

1.0 g (from 14.2 Hz to 150 Hz)

Operational shock/impact: 20.0ms

2

4.4.4 ELECTROMAGNETIC COMPATIBILITY

The FV300 detector is insensitive to normal levels of radio frequency interference. It has been

designed and tested, and complies with the following requirements:

EN 50130-4, the European product family standard for components of fire and

security systems,

VdS 2504 1996-12 (01),

LRS Test Specification Number 1 (2002),

DNV Certification Notes No 2.4 (April 2001), Class A,

GL Rules for Classification and Construction, Test Requirements for Electrical, Electronic

Equipment, Computers and Peripherals (April 2001),

Factory Mutual FMRA 3260, Approval Standard for Radiant Energy-Sensing Fire

Detectors for Automatic Fire Alarm Signalling.

The following maximu m levels of interference are applicable:

Radiated radio frequency: 10V/m (from 80MHz to 2GHz)

30V/m (from 415MHz to 466MHz)

30V/m (from 890MHz to 960MHz)

Conducted radio frequency*: 10V/m (from 150kHz to 100MHz)

Fast electrical transient burst: ± 2kV (applied for 5 minutes)

Slow high-energy surge: ± 2.4kV

Electrostatic discharge: ± 8kV (air discharge)

± 6 kV (contact discharge)

*Radio frequency coupled into signalling, d.c. power supply and screen/earthing wires.

The FV300 detector has also been tested for compliance with the radio frequency emission

requirements of EN 61000-6-3 and, hence, meets the European Union EMC Directive 89/336/

EEC. It also complies with the radio frequency emissions requirements of LRS, DNV and GL

Maritime Societies.

Page 24

SYSTEM DESIGN INFORMATION

22

4.4.5 IONISATION RADIATION

The FV300 detector, like other infrared detectors, is insensitive to X-rays and gamma radiation as

used in non-destructive testing.

The detector will operate normally and will not false alarm when exposed to this type of radiation.

However, long-term exposure to high radiation levels may lead to permanent damage.

4.4.6 CORROSION

The use of a sealed stainless steel 316L enclosure allows the FV300 detector to withstand the

effects of most corrosive substances and gas. In particular, it meets the requirements for sulphur

dioxide (SO2) conditioning in EN 54-10 and exposure to salt mist concentration as specified in

LRS, DNV and GL test specifications for approval of equipment for marine use.

Note: Over time, the outer surfaces of the detector may discolour and give an

appearance of being ‘rusty’. This discolouration is caused by the oxidation of

contaminants collected on the surface of the enclosure, especially areas with a

textured finish. It only affects the surface of the material and does not reduce the

thickness or affect the mechanical properties of the enclosure in any way.

Page 25

SYSTEM DESIGN INFORMATION

23

4.5 FIRE DETECTION CHARACTERISTICS

4.5.1 GENERAL

A large number of fire tests have been carried during the development phase of the FV300

FlameVision detector to determine the response limits. The results of these tests are summarised

below.

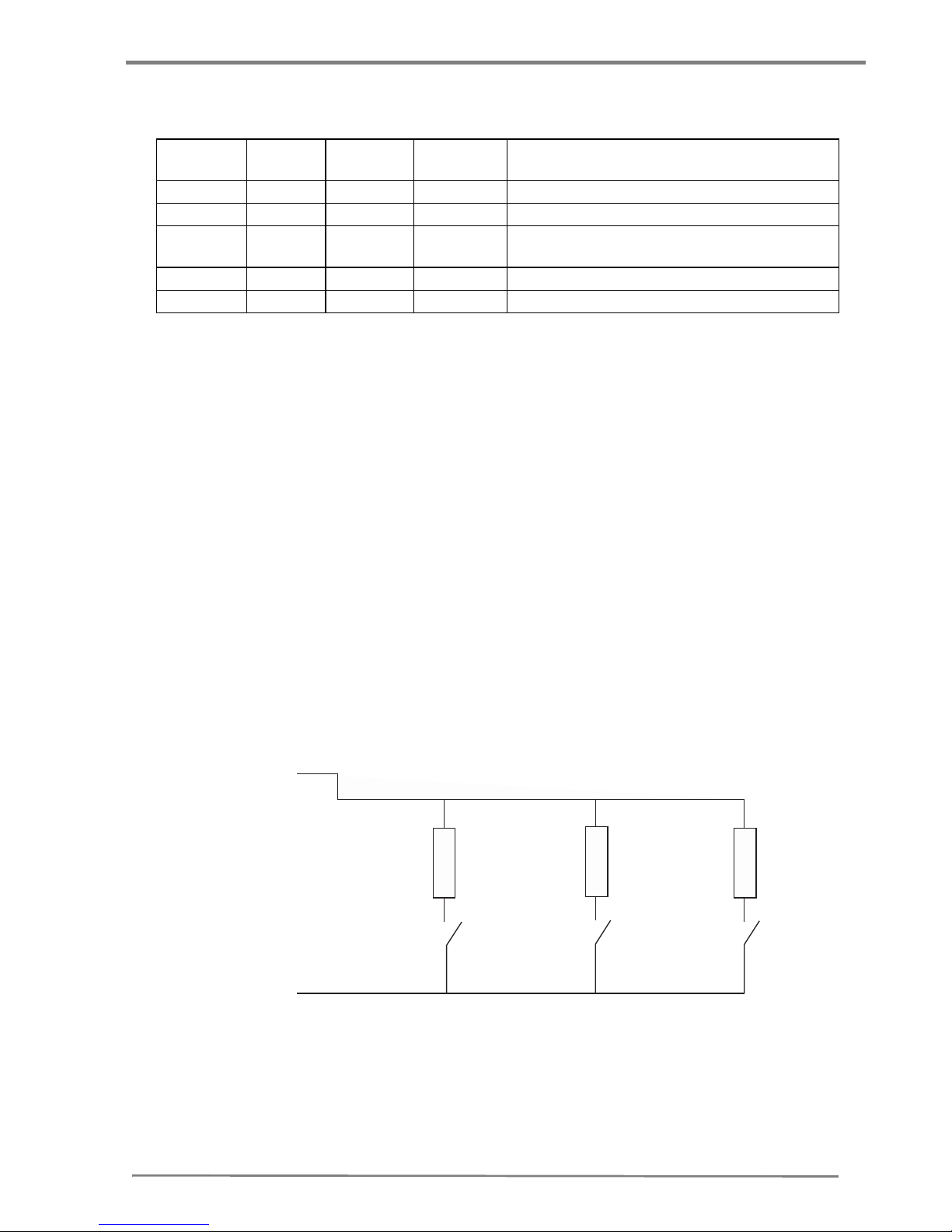

4.5.2 FIRE DETECTION RANGE AND RESPONSE TIME

The following table shows the detection range and field of view for the FV300 detectors for a

selection of typical fuels. The FV300 dynamically adjusts to the fire size and does not need

selectable sensitivity levels. These performance figures have been tested and confirmed by FM

Approvals apart from the f igure mark ed †.

The detector range is unaffected by the presence of hot objects (black bodies) within the field of

view.

The typical response time for the detector is less than 12 seconds. The following table shows the

response time for a selection of fuels measured on axis for fully developed fires. These

performance figures have been tested and confirmed by FM Approvals.

Fuel

Size

m

2

(ft x ft)

Field of View

H: Horizontal

V: Vertical

Distance

m (ft)

N-Heptane 0.1 (1 x 1) H: ±45°

V: ±40°

50 (165)

Petrol 0.1 (1 x 1) H: ±45°

V: ±35°

50 (165)

Aviation fuel (JP5) 0.4 (2 x 2) H: ±45°

V: ±40°

50 (165)

Alcohol (Methylated spirits) 0.1 (1 x 1) H: ±45°

V: ±40°

35 (115)

Diesel 0.1 (1 x 1) H: ±45°

V: ±30°

25 (82) †

Diesel 0.1 (1 x 1) H: ±45° 24 (80)

Diesel 0.1 (1 x 1) V: ±30° 15 (50)

Methane plume 30 inches H: ±45°

V: ±40°

20 (64)

Fuel

Size

m

2

(ft x ft)

Distance

m (ft)

Response Time

Seconds

N-Heptane 0.1 (1 x 1) 50 (165) 9

N-Heptane 0.1 (1 x 1) 61 (200) 11

N-Heptane 0.2 (1.5 x 1.5) 61 (200) 7

Petrol 0.1 (1 x 1) 55 (180) 9

Aviation fuel (JP5) 0.4 (2 x 2) 61 (200) 9

Alcohol (Methylated spirits) 0.1 (1 x 1) 35 (115) 11

Diesel 0.1 (1 x 1) 30 (100) 11

Diesel 0.4 (2 x 2) 50 (165) 7

Methane plume 30 inches 24 (80) 18

Page 26

SYSTEM DESIGN INFORMATION

24

4.6 DIRECTIONAL SENSITIVITY

The FV300 FlameVision detector has been designed to achie v e constant sensiti vity across the f ield

of view. The relative var iation of range with angle of incidence (polar diagrams) is sho w n in Figs.

19 and 20 for open-air tests using 0.1m

2

pan petrol fires.

The continuous line indicates response of the detector within 30 seconds (as required by both

FMRC 3260 and EN 54-10), with the detector at the minimum alarm delay. The dotted line

indicates response of the detector within 12 seconds, for the minimum alarm delay.

Note: When test fires are carried out outdoors, the response of the detector can be

significantly affected by wind as the flame may be blown horizontally outside its

field of view, at least dur i ng part of the test. In e ffect, the detector is seeing only

a portion of the total radiant energy from the fire during a given period. This effect

is accentuated, as the fire gets closer to the 45° position.

DETECTOR

90

80

70

60

50

40

30

20

10

90

80

70

60

50

40

30

20

10

0

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

0.20

0.40

0.60

0.80

1

45

o

45

o

Fig. 19 Relative Range vs Angle of Incidence - Horizontal Plane

DETECTOR

45

40

30

15

15

o

o

o

o

o

30

o

0.20

0.40

0.60

0.80

1

45

o

40

o

0

o

Fig. 20 Relative Range vs Angle of Incidence - Vertical Plane

Page 27

SYSTEM DESIGN INFORMATION

25

4.7 FALSE ALARM IMMUNITY

The FV300 has been subjected to the following stimuli that might b e considered po tential sources

of false alarms. Unless otherwise specified, test s were performed at a minimum distance between

source and detector. Steady state sources were chopped at both regular and random frequencies in

the range 0 - 10Hz.

4.8 DESIGN OF SYSTEM

4.8.1 GENERAL

Using the information given in Sections 4.5 and 4.6, it is possible to design a flame detection

system having a predictable performance. Guidelines on the application of the abov e data, and on

siting of detectors, are given in the following paragraphs.

CAUTION:

THE GUIDELINES GIVEN HERE CANNOT CATER FOR ALL

EVENTUALITIES THAT MAY BE ENCOUNTERED ON A SITE.

FALSE ALARM SOURCE IMMUNITY DISTANCE RESPONSE (m)

1 Sunlight No response

2 Sunlight with rain No response

3 150W tungsten filament lamp 1m

4

Fluorescent lamp (bank of 4 x

32 W circular lamps)

1m

5 70W sodium lamp 1m

6 125W mercury vapour lamp 1m

7 4.8kW IR radiant heater 1m

8

2 x 500W quartz halogen lamps

(unshielded)

2m

9 2 kW fan heater 1m

10 Car headlights (60W halogen) No response

11 Car headlights (60W xenon) 4m

12 Lighted cigarette No response

13

Grinding of ducting metal

(angle grinder)

No response

14

Electric arc welding (2.5mm

rod)

4m

15 MIG welding 1m

16 Vibration N/A

Page 28

SYSTEM DESIGN INFORMATION

26

4.8.2 USE OF FIRE TEST DATA

It has been explained in Sections 4.5 and 4.6 that the sensitivity of the detector is most easily

specified in terms of its response to well-defined test fires. Tests are conveniently carried out using

a 0.1m

2

pan. Sensitivity to other pan areas is estimated from field trial results.

4.8.3 DETERMINING THE NUMBER OF DETECTORS

It will be clear that the number of detectors required for a particular risk will depend on the area

involved and the fire size at which detection is required. Large areas or small fires require large

numbers of detectors.

There are as yet no agreed ‘rules’ for the application of flame detectors and the overall system

sensitivity must, therefore, be agreed between the installer and the end user. Once this agreement

has been reached the system designer can determine the area covered by each detector using a

scaled plot based on Figs. 20 and 21 and the fire test data. This plot is best drawn to the same scale

as the site plan so that direct superposition can be used to determine detector coverage.

In carrying out the design, certain factors should be kept in mind:

a) Mounting the detectors on the perimeter of the area and pointing into the area will

give the best coverage for area rather than spot protection.

b) As the FV300 detectors are line of sight detectors any object within the detector’s

field of view will cause a ‘shadow’ in the protected area. Even small objects close

to the detector can cause large shadows.

c) The detector should not be mounted in such a position that water will collect on

the window.

d) The detectors are passive devices and will not react with one another. They may

therefore be positioned with their fields of view overlapping.

4.9 APPROVALS, COMPLIANCE WITH STANDARDS AND PATENTS

4.9.1 FLAMEPROOF CERTIFICATION

All models of the FV300 FlameVision detectors are flameproof and are certified to the ATEX

directive and IECEx by Baseefa.

The detectors are designed to comply with EN60079-0: 2006 , EN60079-1: 2004, EN600797:2006, IEC61241-0: 2006 and IEC61241-1: 2004.

They are certified:

ATEX code: II 2 G D

Certificate: Baseefa07ATEX0178X

IECEx/Cenelec code: Ex d IIC Ex t D A21 IP66 (-40°C ≤ Ta ≤+80°C)

or T5 (-40°C ≤ Ta ≤+70°C)

Certificate: BAS07.0048X

Page 29

SYSTEM DESIGN INFORMATION

27

These detectors are designed and manufactured to protect against other hazards as defined in

paragraph 1.2.7 of Annex I1 of the ATEX directive 94/9/EC.

The one special condition of the certification is that, when using the fitted cable from the FV312

series detectors, this cable must be suitably terminated and protected from impact. See the

installation section for installation recommendations.

The detectors are also designed to comply with the requirements of Factory Mutual FMRC 3600

and FMRC 3615 for use in hazardous area locations Class I, Div 1, Group B, C, D and Class II

Group E, F G and Class III. The certified label for the FV300 detectors are shown in Fig. 21.

4.9.2 OTHER APPROVALS

The FV300 FlameV ision detectors ha ve been designed to and comply with requirements of Factory

Mutual FMRC 3260, the approval standard for Radiant Energy-Sensing Fire Detectors for

Automatic Fire Alarm Signalling.

4.10 MARKING

All the marking required by the various approv al bodies is on the front plate (see Fig. 21) with the

exception of the Year of Manufacture/Construction which is stated on a label affixed to the rear of

the front case assembly. This is only visible when the front case assembly is unbolted from the

base assembly.

Page 30

SYSTEM DESIGN INFORMATION

28

4.10.1 PATENTS

The FV300 design and manufacture is covered by the following patents licensed from InfraRed

Integrated System s Limited:

UK patents: GB 2 353 856, GB 2 353 424 and GB 2 372 317

European patents: EU 1 079 349 and EP 1 233 386

US patents: US 6 528 788, US 6 476 859 and US 6 818 893

Hong Kong patent: HK 1 050 951

FV311SC-N

S/No.XXXXX

D

O

N

O

T

O

P

E

N

W

H

E

N

A

N

E

X

P

L

O

S

I

V

E

G

A

S

A

T

M

O

S

P

H

E

R

E

I

S

P

R

E

S

E

N

T

TYCO TW16 5DB UK

FlameVision

SEAL

CONDUITS

WITHIN 18"

APPROVED

F M

Ui = 30V

Pi = 10W

PATENTED

IP66/67

1180

tyco

CI I Div 1 Grp B,C,D

CI II Grp E,F,G CI III

T

O

R

Q

U

E

C

O

V

E

R

B

O

L

T

S

(

M

I

N

.

G

R

A

D

E

A

4

-

7

0

)

T

O

7

L

B

.

F

T

(

1

0

N

m

)

:

T

ATEX

Baseefa07

ATEX0178X

II 2 G D

IECEx

BAS07.0048X

Ex d IIC

Ex t D A21

T135

o

C

T -

40

o

C t o + 80oC

a

T100

o

C

:

- 40

o

C to + 70oC

a

C

A

B

L

E

E

N

T

R

I

E

S

:

M

2

0

C

A

B

L

E

R

A

T

I

N

G

:

T

a

+

2

5

K

T : - 40oC to + 80

o

C

a

Fig. 21 View of Detector Label with Regulatory Markings

Page 31

OPERATION

29

5. OPERATION

5.1 INDICATORS

The FV300 FlameVision detector has a red LED for repo rting alarms and a yellow LED for

reporting faults. Both LEDs are located in the camera window, see Fig. 22. The alarm LED turns

on to report an alarm. The fault LED turns on to report hardware faults or is flashed to show an

OPM ‘dirty window’ fault.

The red LED will turn on briefly when an alarm test is performed.

5.2 POWER UP AND INITIALISATION

On power up, the detector performs a complete self-test to check all functions. The alarm (red) and

fault (yellow) LEDs flash briefly as power is applied. The alarm LED then turns off and the fault

LED remains on for the duration of the self-tests. If a fault is detected the LED remains on and the

fault signalled as below.

With the self-tests complete, the array is now allowed to warm-up and settle. During this time the

fault LED will flash rapidly (about 3 times per second). When the array is ready , the fault LED will

turn off. This will take about 5-20 minutes. If the array does not settle within 30 minutes then a

fault will be indicated and signalled.

Note: The detector cannot detect alarms, do OPM tests or alarm tests whilst the array

is settling.

5.3 ALARM AND PRE-ALARM INDICATION

The alarm (red) LED will i lluminate whe n the detector i s in al arm. It will re main ill uminated until

the reason for the alarm has cleared (non-latching mode) when it will turn off. In latching mode

the detector will also need to be reset, see below.

The alarm (red) LED remains off when the detector enters the pre-alarm state.

The alarm LED is located in the camera window, se e F ig. 22.

The remote LED output will be activated when the alarm LED is on to give an external alarm

indication.

REINFORCED

GLASS

WINDOW

IR RECEIVER

RED LED (ALARM)

YELLOW LED (FAULT)

WINDOW TEST

LAMPS UNDER

RELECTOR

SAPPHIRE

WINDOW

Fig. 22 LED Location

Page 32

OPERATION

30

5.4 ALARM SIGNALLING

The FV300 detector has a number of external interfaces. An alarm condition is signalled on all of

these interfaces as follo ws:

Alarm relay: The alarm relay will close.

4-20mA: The current (source or sink) becomes 17mA

Modbus: The alarm bit is set in the status register and is av ailable at the ne xt read of th e

unit.

V ideo: An alarm banner will be superimposed on the CCTV image along with a target

showing the location of the alarm.

Each interface will remain activ ated until the reason for the alarm has cleared (non-latching mode)

when it will turn off. In latching mode the detector will also need to be reset, see below.

5.5 PRE-ALARM SIGNALLING

The detector enters a pre-alarm state when it detect s a source within the field of view that has not

yet reached the alarm threshold. The so urce may be worthy of investigation.

The FV300 detector has a number of external interfaces. A pre-alarm condition is signalled on

some of these interfaces as follows:

Alarm relay: No change, the alar m rela y will remain open.

4-20mA: The current (source or sink) becomes 11.5mA

Modbus: The pre-al arm bit is se t in the status register and is av ailable at the next read

of the unit.

Video: No change.

The pre-alarm condition will escalate into a full alarm if the source is determined to be a fire. Or

it will clear if the source is removed.

5.6 FAULT AND OPM INDICATION

The fault (yellow) LED will illuminate when the detector has detected a hardware fault. It will

remain illuminated until the reason for the fault has cleared (non-latching mode) when it will turn

off. In latching mode the detector will also need to be reset, see 5.9.

If the regular OPM test determines that the window is dirty then the fault (yellow) LED will flash

approx.(1 second, 1 second off). If the window is found to be completely obscured it is treated as

a hardware fault and the fault LED is illuminated.

The fault LED is located in the camera window, see Fig. 22.

5.7 SERVICE MODE INDICATION

The detector is put into the Service Mode when it is connected to a PC for configuration or

diagnostics. When in this mode, the fault (yellow) LED wil flash slowly (2 seconds on, 2 seconds

off).

Note: In Service Mode the detector is disabled and will not detect a fire.

Page 33

OPERATION

31

5.8 FA U LT AND OPM SIGNALLING

The FV300 detector has a number of external interfaces. A fault condition is signalled on these

interfaces as follows:

Fault relay: The fault relay will open. (Hardware, window and OPM faults)

4-20mA: The current (source or sink) become 0mA for hardware and window

faults or 2mA for OPM faults.

Modbus: The appropriate fault bit will be set in the status register and is available

at the next read of the unit. Hardware faults, window obscured and

window dirty are separately identified.

Video: A fault banner will be superimposed on the CCTV image with an

information field to specify the fault type.

Each output will remain activated until the reason for the fault has cleared (non-latching mode)

when it will return to normal status. In latching mode the detector will also need to be reset, see

section 5.9.

5.9 DELAY TO ALARM

The FV300 processes the array and sensor signals to identify a potential alarm event twice a

second. The detector takes 9 cycles, 4.5 seconds, to confirm that there is an event to report. The

detector considers each report and will indicate and signal an alarm if several alarm event reports

are produced within a time window . The number of reports to consider is selectable and def ines the

response time. The detector response time consists of the initial 4.5 seconds followed by the

selectable delay.

The FV300 detector provi des 4 selectable alarm response times. These a re set on the DIP switches,

see Section 7.2.2.

The default setting requires that in an 8 second wind ow the e vent should be reported for at least 4.5

seconds to put the detector into alarm. This gives an overall response time of 9 se conds. The

minimum time from the presentation of a detectable fire to activation of the outputs is 6 seconds

(short delay). The alarm delay response times are also used for the pre-alarm response.

The selected response time also defines the alarm clearing time in non-latching mode. An alarm is

cleared when a number of reports of no alarm are produced. The default setting requires that 20

reports (10 seconds) are detected. Thus a detector will remain in alarm for at least 10 seconds.

SW

1-2

SW

1-3

Delay

Description

Alarm / Prealarm

ON condition

Alarm / Prealarm

OFF condition

0 1 SHORT

1.5 seconds over threshold

in any 4 second period

10 seconds under

threshold

0 0

MEDIUM

(Default)

4.5 seconds over threshold

in any 8 second period

10 seconds under

threshold

1 0 LONG

9 seconds over threshold in

any 12 second period

12 seconds under

threshold

1 1 EXTRA LONG

12 seconds over threshold in

any 15 second period

15 seconds under

threshold

Page 34

OPERATION

32

5.10 RESETTING ALARM AND FAULT CONDITIONS

In latching mode, alarms and faults will continue to be indicated and signalled, e ven if the original

cause has been removed. The detector needs to be reset to clear the condition. The detector can b e

reset by activating the wired input or remotely usin g the walk-test trigger tool. During the reset the

indicators and outputs will be turned off but if the alarm or fault is still present the condition will

be re-established. The detector will perform re-tests if necessary , such as an OPM test, to determine

if faults have cleared.

5.11 SELF-TEST

The FV300 detector performs a regular self-test of the electronics and monitors the interfaces in

the detector. This occurs automatically at pre-set timed intervals and does not disturb the normal

operation of the detector. If a fault is detected it will be indicated and signalled as described in

section 5.7.

5.12 OPTICAL PATH MONITORING (OPM) TEST

The FV300 detector can check the cleanliness of the window used by the array and other optical

sensors. The detector flashes a lamp that radiates IR at the same w av elength used for fi re detection

for about 5 seconds. The lamp shines onto a mirror that reflects the energy back through the

window onto a specific section of the array. The detector analyses the reflected signal to assess if

the window is dirty.

The OPM test can be initiated manually, on demand, using the walk-test trigger tool, the walk-test

wired input or from the field bus interface. When the OPM test is activated manually, a single test

is performed and the result reported on the indicators and outputs. If the window is considered to

be dirty or obscured then an OPM fault is reported. The fault will be cleared when the window is

cleaned and the test re-run to give a clean result. Requests for a manual OPM test will be ignored

if the detector is in alarm, pre-alarm or performing an alarm test.

Alternatively, the detector can be configured to perform the OPM test automatically at regular

intervals by setting a DIP switch (OPM Man/Auto). The default is automatic OPM testing. The

time interval can be adjusted using the PC configuration tool. The default OPM test interval is

every 20 minutes. The first OPM test will be made 20 minutes (or the conf igured time) after po werup. The regular OPM test will be delayed if the detector is in alarm, pre-al arm or performing an

alarm test. A manual OPM test can be initiated at any tim e when the detec tor is in automatic OPM

mode and will produce an immediate test result reported on the indicators and outputs as described

above.

If the automatic OPM test detects the dirty condition (5-50%) for 20 successive tests then an OPM

fault is reported. If the window is considered to be obscured (<5%) then the OPM test interval

reduces to 5 minutes and if the window remains obscured for 5 further tests then an OPM fault is

reported. The obscured condition is thus detected and reported much faster. Either fault will be

cleared when the window is cleaned and the test re-run to give a clean result. The test can be

activated manually after cleaning rather than waiting for the next timed automatic test.

The detector is fitted wit h 2 lamps. These a re used alternate ly to maximise their lifetime. If a lamp

should fail then the detector can continue using the one lamp without reporting a fault. The f ailur e

of both lamps will be reported as a hardware fault.

Page 35

OPERATION

33

5.13 WALK-TEST (ALARM TEST)

WARNING:

THE DETECTOR OUTPUTS WILL BE ACTIVATED DURING A

WALK-TEST. DISCONNECT ALL EXTINGUISHING SYSTEMS OR

EXTERNAL DEVICES THAT SHOULD NOT BE ACTIV ATED DURING A TEST .

The FV300 detector has a buil t in ala r m test facility . The lamps used for the OPM test are flashed

in a pattern to simulate a flame. The IR output from the lamps reflects off the mirror and onto the

array. The lamp signal is then processed using the same algorithms as used for external sources to

produce an alarm which is then indicated on the LED and signalled on all external interfaces. This

is a true test of the ability of the detector to detect a fire.

The alarm test can be triggered from the wired walk-test input or remotely using the walk-test

trigger tool.

When the test is started, a lamp will flash until an alarm is detected, typically after 10 seconds. The

lamp will then turn off. The detector will indicate the alarm on the LED and activate all outputs as

described above. The outputs will remain active for the duration of the alarm hold time set on the

DIP switches (10-15 seconds).

If the flashing lamps do not trigger an alarm then a hardware fault is reported and the lamps are

turned off.

Note: The alarm test cannot be performed whilst the array is settling or whilst the

detector is in alarm, pre-alarm or performing an OPM test.

The alarm test may not generate an alarm if a strong black body source is in the field of view or

modulated sunlight falls onto the detector.

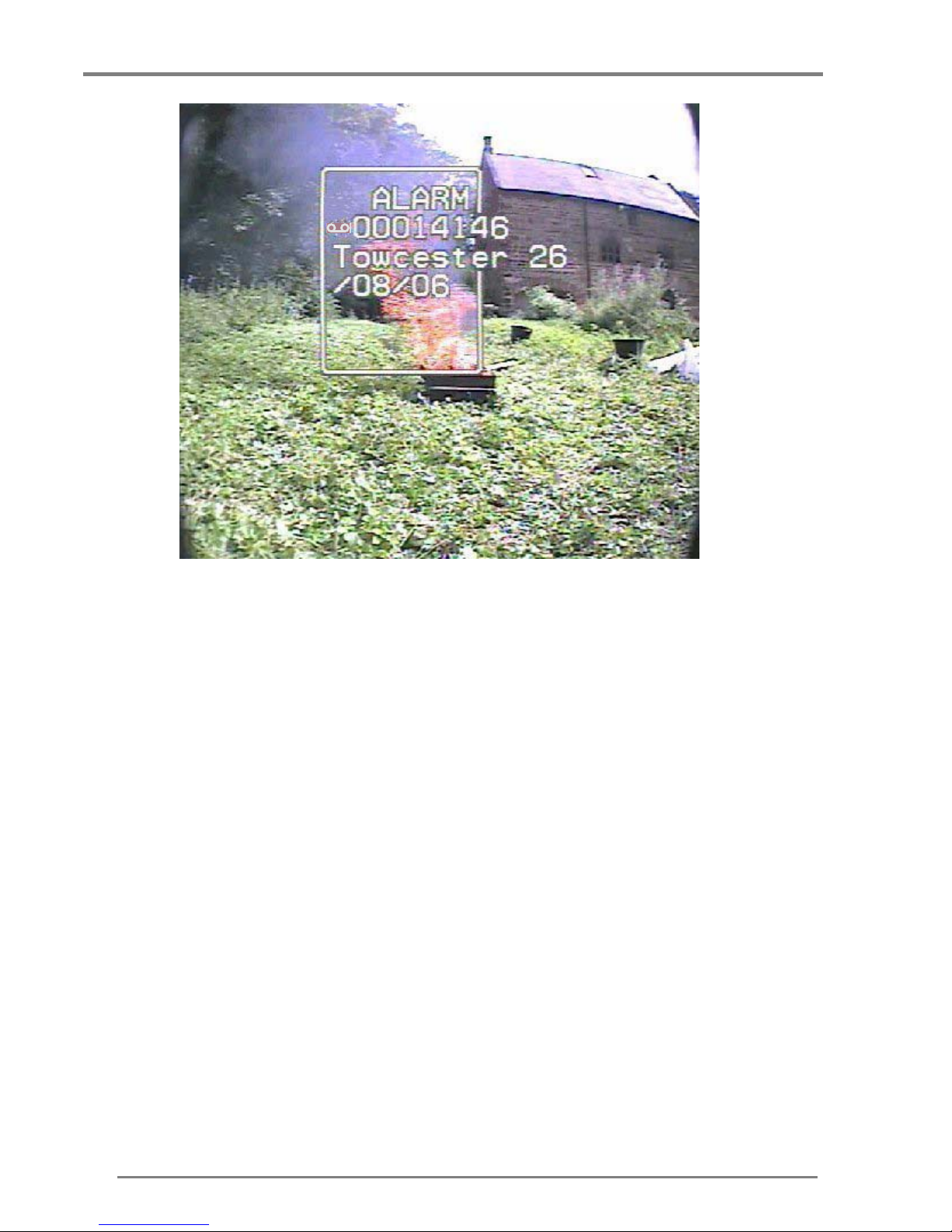

5.14 VIDEO DISPLAY

The FV300 can overlay alarm and fault information on top of the camera picture (CCTV output).

The overlay is normally enabled but can be disabled by configuration. If no camera is fitted then

the overlay can be viewed on a plain colour background. This is enabled by configuration.

If an alarm is detected, the overlay will flash an alarm message and display a box drawn around

the alarm source to show the location within the field of view.

Faults are individually identif ied on the display as shown in Annex B.

Page 36

INSTALLATION

34

6. INSTALLATION

6.1 GENERAL

The FV300 Series detectors may be surface mounted or may use the FV300 adjustable mounting

bracket.

On the FV311 series, all electrical connections are made via terminal blocks inside the detector

rear housing. Two 20mm cable entries are provided. On the FV312 series, electrical connections

are made through the FlameVision Exe junction box, selecting the appropriate circuits required.

Guidance on mounting and wiring the detectors is given below.

6.2 MOUNTING A DETECTOR

6.2.1 GENERAL

The location of each detector should have been determined at the system design stage according to

the principles detailed in the System Design Information section and marked on the site plan.

The actual mounting position must, howev er, be decided during the installation and in choosing the

position, the following principles together with the original system requirements should be

followed.

6.2.2 CHOICE OF MOUNTING POSITION

The following points must be observed when choosing the mounting position:

a) The detector should not be installed where it may be subject to mechanical or

thermal stresses or where it may be attacked by existing or foreseeable aggressive

substances.

b) The detector must be positioned such that a clear line of sight is provided to all

parts of the risk area. Roof trusses, pipework, supporting columns etc. in front of

the detector can cause significant shadowing and should be avoided.

c) If supervision of an area immediately below the detector is required, it is essential

that the angle between the detector and the horizontal is not less than 50°.

d) The detector should not be sited in a position where it will be continuously

subject to water drenching. The FlameVision Weather hood should be use to

protect the detector from heavy downpours that may be frequent in certain

climates.

e) In outdoor installations, in areas of high solar radiation, some form of sunshade

is recommended to prevent excess heating of the detector. The FlameVision

Weather hood can provide protection against direct sun.

f) The detector should not be sited in a position in which it will be subject to se v ere

icing.

g) Where a certain amount of icing or water condensation can occur, it is

recommended that the window de-mister be selected. See the System Deign

Information section for additional power requirement.

h) The detector must be mounted on a stable structure that is readily and safely

accessible for maintenance staff.

Page 37

INSTALLATION

35

i) Preferably, the detector should be mounted such that the face is tilted do wnw ards

to prevent water collection and lessen the settlement of particle deposits on the

window.

The detector mounting bracket must be secured to the mounting surface with four M8 Bolts, studs

or screws at the fixing centres shown in the orientation shown in Fig. 12. A drilling template is

provided to allow optimum selection of the fixing centres. The detector is to be secured to the

bracket using the three M6 studs with nuts and locking washers provided.

The FV300 Series may be operated in any position but the mounting point must obviously be

chosen to allow sufficient clearance for adjustment of the angle and must al so allow space for the

cable assembly. A clearance of 200mm, in all directions, from the fixing point will normally be

sufficie nt to allow the full range of adjustment. (Fig. 23 refers).

Alternativ ely, the detector may be secured directly to the fixing surface with three M6 bolts, studs

or screws at the fixing centres shown in Fig. 11. The surface chosen for the mounting should be

flat over the area of the bracket to ensure a stable fixing.

CENTRE OF DETECTOR

FIELD OF VIEW

INCORRECT METHOD

CENTRE OF DETECTOR

FIELD OF VIEW

PREFERRED METHOD

Fig. 23 Detector Orientation Relative to Horizon

Page 38

INSTALLATION

36

6.2.3 MOUNTING THE FV312 SERIES DETECTOR WIRING

In addition to the installatio n recommendat ions given in 6.2, the following appl ies when installing

FV312 series detector:

a) The detector in-built cable should interface with the field cable via an EExe

junction box with EExe cable entry glands suitable for the size of cable used. The

FlameVision EExe has been designed to provide a ready-made solution to

interfacing with any of the inputs/outputs of the FV300 detector.

b) It is a requirement of the ATEX/IECEx approval that the cable between the

detector and the EExe junction is protected against mechanical damage. For this

purpose the FV312 has been designed to mate with a flexible metal conduit. It is

recommended that the Kopex Liquid Tight LT-H 316 stainless steel 20mm

conduit system is used (Kopex FSH04). This conduit uses a Type H flame

retardant covering to gi ve a high resistance to oils and chemicals. A connector kit

(Kopex KSO/1005) is a v ailable to terminate the co nduit and couple directly onto

the FV312 enclosure.

c) The selected mounting position for the detector must take into account the siting

of the EExe junction box. The detector is supplied with a maximum of 1m cable

and allows sufficient slack in the flexible conduit for adjusting the orientation of

the detector when using the adjustable mounting bracket.

6.3 DETECTOR WIRING

6.3.1 GENERAL

The wiring between the detectors and control equipment must provide the required degree of

mechanical protection b ut be sufficiently flexibl e to all ow the detector alignment to be adjusted to

suit the area protected.

To meet the mandatory EMC requirements of EN 61000-6-3 for emissions and EN 50130-4 for

susceptibility, it is necessary to terminate the armouring / screening of the cable through 360° at

the detector cable gland and ensure that the detector is solidly bonded to a good local earth.

Fig. 24 through to Fig. 26 show wiring diagrams for the FV311 series of detectors. The FV312

series detectors are wired in the same way. The cores are listed in Table 5.

Notes:

1) If FV300 detectors are installed in dust risk environments then the walk-test wired

input should be used. The WT300 is not approved for dust risk environments.

2) It is recommended that the RS485 Confi guration port from the FV300 is wired

back to a central point to suppor t remote configuration and diagnostics. The

configuration port can be wi red as a bus connecting up to 16 detectors. An

RS485 to PC interface (RS232 or USB) is req uired that can communica te at up

to 38,400 baud with direction controlled by the RTS line.

Page 39

INSTALLATION

37

6.3.2 RECOMMENDED CABLE TYPE

6.3.2.1 CONVENTIONAL CIRCUITS

The cable selected for interconnection to the control equipment should meet the requirements of

any national codes (eg, BS5839) or relevant approval bodies. Cables should not normally have a

cross sectional area of less than 1mm2 for solid conductors or 0.5mm2 for stranded conductors.

Cable temperature rating must allow for an increase in the enclosure temperature of 25° above

ambient.

The following cables are generally recommended for use:

a) Shipwiring Cable to BS6883.

b) PVC insulated cable to BS6004, run in screwed steel conduit to BS4568 Part 1.

c) 16/0.2mm twin or multi-core cable to DEF Standard 61-12 (Part 5), run in

screwed steel conduit to BS4568 Part 1.

d) PVC insulated cable to BS6231, Type BK, run in screwed steel conduit to

BS4568 Part 1, or plastic conduit to BS4607, or trunking. (Conductors having a

cross-section of less than 1mm2 should not be drawn into conduit bu t can be run

in trunking).

e) Mineral insulated cable, twin or multi-core, to BS6207 Part 1, with all cable

terminations and fittings supplied by the manufacturer of the cable.

f) PVC insulated, PVC inner sheathed, steel wire armoured and PVC oversheathed

cable to BS6346.

g) Cabling and conduit for flameproof circuits must comply with BS EN60079-

14:2003.

h) For the FV312 series, the EExe ju nction box must be mounted within 0.6m of the

detector.

6.3.2.2 CABLE ROUTING

All interconnecting cables should be run in conduit or trunking which is reserved exclusively for

fire alarm circuits. Where such separation is not possible MICC cable should be used.

Particular care must be taken to ensure that detector wiring is not run close to a.c. power cir cuits.

6.3.3 CABLE ENTRY SEALING

CAUTION:

CABLE GLANDS AND STOPPING PLUGS MUST BE SUITABLY SEALED TO

PREVENT THE INGRESS OF MOISTURE.

Only cable glands incorporating an inner cable seal should be used. In exposed outdoor areas, it

is recommended that a shroud be fitted over the cable glands. Cable glands should also be sealed

to the detector housing by fitting a nylon washer between their flange and the housing.

In applications where the ambient temperature is expected to be 40

o

C or higher, cable glands with

a silicon inner seal must be used and, when fitted, the shroud must be made of CR rubber.

Page 40

INSTALLATION

38

The use of stopping plugs with a mushroom head and integral ‘O’ ring is recommended.

The glands/stopping plugs should be hand-tightened with the addition of, at least, a further

1

/4 turn

applied by spanner or other suitable tool.

Where it is not practicable to use a n ylon gland w asher or wher e an anti-seizing union is required,

the following alternative methods may be used:

a) The thread of cable glands/stopping plugs may be sealed using PTFE tape or

other jointing putty or mastic.

b) For Flameproof applications the threads of the flameproof glands/stopping plugs

may be sealed using any non-setting grease or putty as described in BS EN

60079-14 : 1997.

PBC BA 200 loaded mineral oil based grease is a suitable compound and is

available in 100g tubes (Stock Code No. 517.001.250).

Page 41

INSTALLATION

39

6.3.4 FLAMEPROOF WIRING

Cabling and conduit systems must comply with BS EN 60079-14 : 1997.

CONTROL

EQUIPMENT

+VE

-VE

TB1

S300 RELAY / 4 - 20mA

FIELDBUS TERMINAL PCB

24V

4 - 200v0v

FB+

FB-

EXC+

EXC-

VID+

VID-

10

TB2

24VWT0V

FLT

FLTC

ALED

ALM

ALMC

SCRI

SCRO

20

R

E

O

L

TO

MONITOR

CIRCUIT

NOTE: POWER DISIPATION OF MONITORING CIRCUIT NOT TO EXCEED X.XW

CONFIGURATION/

DIAGNOSTICS

ACCESS*

* IT IS RECOMMENDED THAT AN

RS485 CONNECTION IS PROVIDED

TO CONNECT TO A PC FOR REMOTE

CONFIGURATION AND DIAGNOSTICS

RS485

INTERFACE

BALUN

OPTIONAL VIDEO OUTPUT

1k8 4k7 15k

ALARM

TEST

RESET

WINDOW

TEST

Fig. 24 Relay Wiring Diagram

Page 42

INSTALLATION

40

PLC

+VE

-VE

TB1

S300 RELAY / 4 - 20mA

FIELDBUS TERMINAL PCB

24V

4 - 200v0v

FB+

FB-

EXC+

EXC-

VID+

VID-

10