Page 1

F3200

FIRE INDICATOR PANEL

INSTALLATION & PROGRAMMING MANUAL

F3200 PRODUCT MANUAL

Document Number: LT0122

Issue .......... 2.7; 5 July 2001

-- A P P R O V A L S --

AUSTRALIAN STANDARD AS1603.4 1987 (Incl. Amdt 1 & 2)

AUSTRALIAN STANDARD AS4050(INT) 1992

- SSL Listing Number afp789

AUSTRALIAN STANDARD AS3548 1995 Class A

The F3200 Fire Indicator Panel is manufactured for

Tyco Services Fire & Safety

25 Cleeland Road

Oakleigh South

VIC 3167

AUSTRALIA

Tel : +61-3-9543 2220

Fax : +61-3-9543 2155

COPYRIGHT (C) 2001

Information contained in this document is subject to copyright, and shall not be reproduced

in any form whatsoever, without the written consent of Tyco Services Fire & Safety.

Information contained in this document is believed to be accurate and reliable, however

Tyco Services Fire & Safety reserves the right to change the content without prior notice.

Page 2

F3200 Installation & Programming Manual Document No: LT0122

TYCO SERVICES FIRE & SAFETY

END USER LIABILITY DISCLAIMER

The F3200 Fire Indicator Panel has a configuration programming facility which may be

accessed from the keypad by using a password.

This programming facility allows the user to define detail of the operation of the F3200

System which is being customised. It is possible for the user to program operational

features that prevent the installed FIP from meeting statutory requirements.

Tyco Services Fire & Safety does not accept responsibility for the suitability of the functions

programmed by the user.

Page ii 5 July 2001 Issue 2.7

Page 3

Document No: LT0122 F3200 Installation & Programming Manual

TABLE OF CONTENTS

End User Liability Disclaimer ...................................................................................................ii

Amendments .......................................................................................................................... vi

CHAPTER 1 INTRODUCTION...............................................................................1-1

1.1 SCOPE....................................................................................................................................1-2

1.2 ASSOCIATED DOCUMENTATION........................................................................................1-3

1.3 PRODUCT HISTORY LOG.....................................................................................................1-4

1.4 GLOSSARY OF ABBREVIATIONS .......................................................................................1-6

1.5 GLOSSARY OF TERMINOLOGY ..........................................................................................1-7

CHAPTER 2 SYSTEM DESCRIPTION.................................................................. 2-1

2.1 OVERVIEW .............................................................................................................................2-2

2.2 PHYSICAL STRUCTURE .......................................................................................................2-7

2.3 SYSTEM STRUCTURE.........................................................................................................2-10

CHAPTER 3 SYSTEM SPECIFICATIONS.............................................................3-1

3.1 GENERAL...............................................................................................................................3-2

3.2 MECHANICAL SPECIFICATIONS .........................................................................................3-3

3.3 ELECTRICAL SPECIFICATIONS...........................................................................................3-4

3.4 INPUT SPECIFICATIONS.......................................................................................................3-8

3.5 OUTPUT SPECIFICATIONS.................................................................................................3-14

3.6 CONTROLS ..........................................................................................................................3-19

3.7 DISPLAYS.............................................................................................................................3-20

CHAPTER 4 ORDERING INFORMATION............................................................. 4-1

4.1 ORDERING INFORMATION...................................................................................................4-2

CHAPTER 5 CONFIGURING A FIP....................................................................... 5-1

5.1 GENERAL...............................................................................................................................5-2

5.2 MODULE CONFIGURATION..................................................................................................5-2

5.3 BATTERY & POWER SUPPLY..............................................................................................5-3

5.4 LINKS ON PCB MODULES..................................................................................................5-11

5.5 ERROR MESSAGES DURING FIP CONFIGURATION.......................................................5-12

CHAPTER 6 PROGRAMMING.............................................................................. 6-1

6.1 INTRODUCTION.....................................................................................................................6-2

6.2 SET MENU & OPERATOR PROGRAMMING FUNCTIONS ...............................................6-12

6.3 INITIALISING, ACCESSING, DE-ACCESSING, PRINTING, SAVING, LOADING &

VERIFYING THE DATABASE.............................................................................................6-13

6.4 PROGRAM DATA MENU, TEXT & GLOBAL PARAMETERS............................................6-17

CHAPTER 7 PROGRAMMING SYSTEM CONFIGURATION............................... 7-1

7.1 SYSTEM CONFIGURATION MENU.......................................................................................7-2

7.2 CONFIGURING CIRCUITS (AZCS)........................................................................................7-6

7.3 CONFIGURING ZONES........................................................................................................7-11

7.4 PROGRAMMING OUTPUTS................................................................................................7-13

7.5 RELAY SUPERVISION.........................................................................................................7-33

7.6 RDU.......................................................................................................................................7-35

CHAPTER 8 INSTALLATION & WIRING..............................................................8-1

8.1 INSTALLATION ......................................................................................................................8-2

8.2 FIELD WIRING........................................................................................................................8-8

Issue 2.7 5 July 2001 Page iii

Page 4

F3200 Installation & Programming Manual Document No: LT0122

8.3 AZC WIRING.........................................................................................................................8-10

8.4 MAF ANCILLARY RELAY WIRING .....................................................................................8-12

8.5 WARNING SYSTEM WIRING...............................................................................................8-15

8.6 MODULE RELAY WIRING ...................................................................................................8-20

8.7 OPEN COLLECTOR WIRING...............................................................................................8-22

8.8 ASE INSTALLATION AND WIRING ....................................................................................8-23

8.9 RDU WIRING.........................................................................................................................8-24

8.10 SLIMLINE NDU (FP0714) WIRING......................................................................................8-26

8.11 INSTALLATION OF 19" NDU (FP0733)..............................................................................8-26

CHAPTER 9 APPLICATIONS................................................................................9-1

9.1 AS1668 AIR CONDITIONING CONTROL..............................................................................9-2

9.2 GAS FLOOD ...........................................................................................................................9-9

9.3 SUB FIP MONITORING........................................................................................................9-19

9.4 FIRE DETECTION IN HAZARDOUS AREAS (EXPLOSIVE ATMOSPHERES) .................9-22

9.5 USE OF NORMALLY CLOSED CONTACTS.......................................................................9-32

9.6 SPECIAL CONNECTIONS TO DETECTORS......................................................................9-33

CHAPTER 10 ALIGNMENT, ADJUSTMENT & PLACING INTO OPERATION.. 10-1

10.1 ALIGNMENT & ADJUSTMENT...........................................................................................10-2

10.2 PLACING INTO OPERATION .............................................................................................10-3

CHAPTER 11 NETWORK PROGRAMMING....................................................... 11-1

11.1 INTRODUCTION ..................................................................................................................11-2

11.2 PROGRAMMING METHODS ..............................................................................................11-4

11.3 NETWORK CONFIGURATION MENU................................................................................11-9

11.4 SID CONFIGURATION ......................................................................................................11-12

11.5 NETWORK MAF CONFIGURATION.................................................................................11-14

11.6 NET COMMANDS..............................................................................................................11-15

11.7 NET FFCIF CONFIGURATION..........................................................................................11-16

11.8 NETWORK EVENT CONFIGURATION.............................................................................11-18

11.9 NETWORK LOGIC VARIABLES.......................................................................................11-20

11.10 NET STATUS REFRESH...................................................................................................11-21

11.11 NDU OPERATION..............................................................................................................11-22

11.12 DEFAULT VALUES FOR PANEL-LINK VARIABLES......................................................11-24

CHAPTER 12 NEW ZEALAND OPERATION......................................................12-1

12.1 GENERAL ............................................................................................................................12-2

12.2 NZ DISPLAY EXTENDER BOARD .....................................................................................12-2

12.3 MANUAL CALLPOINT (MCP) .............................................................................................12-4

12.4 PROGRAMMABLE OPTIONS.............................................................................................12-5

12.5 LOGIC TOKENS ..................................................................................................................12-6

12.6 SYSTEM STATES & INDICATIONS....................................................................................12-7

12.7 NETWORK PARAMETER PROGRAMMING......................................................................12-8

12.8 INSTALLATION : NZ DISPLAY EXTENDER BOARD & BRIGADE DISPLAYS .............12-10

CHAPTER 13 TANDEM LCD MODE................................................................... 13-1

13.1 TANDEM LCD MODE ..........................................................................................................13-2

APPENDIX A COMPATIBL E ACTUATING DEVICE S (DETE CTO R S).......................A-1

APPENDIX B F3200 CONFIGURATION SHEETS....................................................... B-1

Page iv 5 July 2001 Issue 2.7

Page 5

Document No: LT0122 F3200 Installation & Programming Manual

AMENDMENTS

ISSUE DATE COMMENTS ECN

1 20/04/94 Original. Corresponds to V1.10 software, which

includes RZDUs, multiple access codes, revised print

menu, NSW Coder, Programmable Alarm Text, Inst

Alarm Text (not in V1.01)

2 30/01/95 Was WP5.1. Upgraded for small FIP,6A PSU.

Upgraded ordering info, AS1668 Application, Detector

List and added I.S.(9.4). Also some

corrections.

2.1 01/02/96 Auto-Test Disable note added to 6.4.4.

Note 10 (Pg A-5) modified.

Table III updated.

Applications note 9.5 added.

PA0443 added to Ordering Info P4-5.

2.2 16/04/96 Deleted paragraph headed "C29BEx" in Section

9.4.3.4.

2.3 01/12/97 F3200 V2.00 software release.

Chapters 6, 7 modified.

Network programming Chapter 11 added.

Daylight saving, output logic control of zone LEDs,

selectable event types for history and printing,

database verify, database CRC recall.

Controller Board was 1931-2-1.

2.4 09/04/98

2.5 22/03/99 V2.06 software. Section 1.3 add V2.06. Section 6.4.4

2.6 14/06/00 Corresponds to V2.07/V2.08 software. Changes

2.7 05/07/01 Corresponds to V2.09 software. New buzzer mode &

Section 1.3.2 add V2.01-V2.04 details.

"Minute" timers 65-72, Section 3.8.

Section 4.1 new part numbers, Figs 6.1.2 and 7.1.1.

Fault Action Text & PC Programming Section 6.4.3.

RDU zone name transmission Section 7.6. Output

logic commands for zone isolate, zone de-isolate, and

zone reset, Section 7.4.9. RDU wiring Section 8.8.

Add AS/NZ 3548 Class A warning.

Bells/Ancil Isol key disabling; mains frequency

50/60Hz. Section 11.3.5, 11.11, 11.12 ACK

Broadcast Specific SID. System Configuration Sheets

Page 2 and Network Parameters.

throughout but mainly Sections 5.5, 5.6, 6.3.7, 6.4.4

and Chapters 12 and 13 added.

sounder silence options in Chapter 6. Sect 7.2.4

change to SAD type. Section 7.4.6 SNA option new.

Section 7.5 Relay supervision. Appendix A Simplex

detectors. Appendix B modified. Section 3.3.5.2 NDU

Quiescent current added. Section 12.8 NZ mode

installation added.

Chapter 8 Installation revised and Section 9.2 Gas

Flood revised. Complete re-print.

2162

2360

2417

2620

2709

2742

2937

3079

3165

3154

Issue 2.7 5 July 2001 Page v

Page 6

F3200 Installation & Programming Manual Document No: LT0122

THIS PAGE IS INTENTIONALLY LEFT BLANK

Page vi 5 July 2001 Issue 2.7

Page 7

Document No: LT0122 F3200 Installation & Programming Manual

Introduction

CHAPTER 1

INTRODUCTION

Issue 2.7 5 July 2001 Page 1-1

Page 8

F3200 Installation & Programming Manual Document No: LT0122

Introduction

1.1 SCOPE

This manual provides information for the personnel responsible for planning, ordering,

installing and programming an F3200 Fire Alarm System. It is assumed that such staff have

been trained to plan/install fire alarm equipment and are familiar with the relevant standards.

The manual is divided into the following chapters:

Chapter 1 Introduction: Information on this manual.

Chapter 2 System Description: A description of the structure of the F3200 FIP.

Chapter 3 Specifications: A detailed specification for the F3200 FIP.

Chapter 4 Ordering Information: Part numbers for the various system components.

Chapter 5 Configuring a FIP: General information and detail on fitting of various links

and resistors when configuring a system.

Chapter 6 Programming: An introduction to programming and a description of the

programming menus and global parameters.

Chapter 7 System Configuration: Detail on specific programmable options in the FIP

I/O.

Chapter 8 Installation & Wiring: Detail of installation and field wiring.

Chapter 9 Applications: Detail of configuration and wiring for specific applications.

Chapter 10 Alignment, Adjustment & Placing Into Operation: Detail on how to adjust an

F3200 in the field and place it into operation.

Chapter 11 Networking: Detail on programmable options for networked F3200s and

NDUs.

Chapter 12 NZ Operation: Describes operation of the NDU in NZ mode.

Chapter 13 Tandem LCD Mode: Describes operation of Tandem LCD mode.

Appendix A 1. Compatible Detectors: A list of detectors which are approved for use

with F3200.

2. Detector Configuration: Detail on AZC and zone configuration for

specific detector types.

Appendix B Configuration Forms: A set of master forms for recording programming detail.

Page 1-2 5 July 2001 Issue 2.7

Page 9

Document No: LT0122 F3200 Installation & Programming Manual

Introduction

1.2 ASSOCIATED DOCUMENTATION

1.2.1 PRODUCT

Additional information on the AS1603.4 approved F3200 FIP is found in the following product

manuals.

F3200 Operator's Manual A guide to the operation and maintenance of the F3200 FIP.

Part Number LT0119 is a loose A4 version.

Part Number LT0120 is a bound A5 version.

F3200 Technical Manual A technical description of the F3200 system and modules.

Part Number LT0121.

F3200 Installation & This manual.

Programming Manual Part Number LT0122.

F3200 Panel-Link Upgrade Upgrade instructions on how to make the F3200 panel

and Installation Manual network capable. Part Number LT0198.

Information on the AS4428.1 approved F3200 is found in the following manuals:

F3200 AS4428.1 Operator’s Manual For panels that comply with AS4428.1

LT0251 is in A4, loose leaf form.

LT0250 is in A5, bound form.

F3200 AS4428.1 Installation & Provides information for designing, installing

Configuration Manual and commissioning an F3200 and NDU. Part

Number LT0255.

F3200 AS4428.1 Programming Manual Provides information for programming

an F3200 and NDU. Part Number LT0256.

1.2.2 STANDARDS

This manual makes reference to the following Australian and New Zealand Standards:

AS1603.4 Automatic Fire Detection and Alarm Systems

Part 4 - Control and Indicating Equipment.

AS4050 (int) Fire Detection and Fire Alarm Systems - Fire Fighter's Control

and Indicating Facilities.

AS1668 SAA Mechanical Ventilation and Airconditioning Code.

AS1670.1 Automatic Fire Detection and Alarm Systems - System Design,

Installation and Commissioning.

AS4428.1 Fire Detection, Warning, Control and Intercom Systems -

Control and Indicating Equipment

Part 1 : Fire

NZS4512 Automatic Fire Alarm Systems in Buildings

Issue 2.7 5 July 2001 Page 1-3

Page 10

F3200 Installation & Programming Manual Document No: LT0122

Introduction

1.3 PRODUCT HISTORY LOG

1.3.1 HARDWARE

Part No. Description

PA0490 Controller/ A 1 11/11/93 1931-2

Display A 2 24/02/94

PA0491 MAF/PSU A 1 13/10/93 1931-3

B 2 28/02/94

PA0492 8 ZONE MODULE A 1 27/09/93 1931-4

PA0493 8 RELAY MODULE A 1 10/09/93 1931-5

PA0773 RS485 Comms Bd C 4 10/04/01 1901-139

PA0797 F3200 B 3 04/02/99 1931-84-1

Controller/ C 4 02/05/00

Display

PA0804 F3200 B 2 29/09/97 Used as replace-

Networkable C 4 02/05/00 ment board for all

Controller/ F3200/NDU panels

Display 1931-84-1

Iss Rev Date Drawing

A 3 16/06/94

B 3 10/06/94

B 4 21/02/95

B 5 14/05/97

C 6 11/11/97

D 9 14/05/01

A 2 29/04/99

A 2 22/09/99

1.3.2 SOFTWARE

Part No. Description

SF0089 F3200 EPROM V1.00 12/12/93 Pre-production

SF0089 F3200 EPROM V1.01 24/02/94 1st production

SF0089 F3200 EPROM V1.10 13/05/94 Includes RZDU, multiple

SF0164 F3200 EPROM V2.00 Nov. 1997 Networking

SF0175 NDU EPROM V2.00 Nov. 1997 First Release

SF0178 F3200 EPROM V2.00 Nov. 1997 Non-networking

SF0164 F3200 EPROM V2.01 Feb. 1998 F3200 Networked

SF0175 NDU EPROM V2.01 Feb. 1998

SF0178 F3200 EPROM V2.01 Feb. 1998 Non-Networked

SF0178 F3200 EPROM V2.02 Mar. 1998 Non-Networked

SF0164 F3200 EPROM V2.03 April 1998 F3200 Networked

SF0175 NDU EPROM V2.03 April 1998

SF0178 F3200 EPROM V2.03 April 1998 Non-Networked

SF0164 F3200 EPROM V2.04 August 1998 Networked

SF0175 NDU EPROM V2.04 August 1998

SF0178 F3200 EPROM V2.04 August 1998 Non-Networked

Revision Date Comments

access, etc.

SF0164 F3200 Net EPROM V2.05 Feb 1999

SF0175 NDU EPROM V2.05 Feb 1999

SF0178 F3200 Std EPROM V2.05 Feb 1999

Page 1-4 5 July 2001 Issue 2.7

Page 11

Document No: LT0122 F3200 Installation & Programming Manual

Introduction

SOFTWARE HISTORY LOG (CONTINUED)

SF0164 F3200 Net EPROM V2.06 Mar 1999

SF0175 NDU EPROM V2.06 Mar 1999

SF0178 F3200 Std EPROM V2.06 Mar 1999

SF0229 F3200, Std Panel, c/w Tandem V2.07 May 2000

SF0230 F3200, Networked, c/w Tandem V2.07 May 2000

SF0231 NDU, c/w Tandem V2.07 May 2000

SF0229 F3200, Std Panel, c/w Tandem V2.08 July 2000

SF0230 F3200, Networked, c/w Tandem V2.08 July 2000

SF0231 NDU, c/w Tandem V2.08 July 2000

SF0229 F3200, Std Panel, c/w Tandem V2.09 May 2001

SF0230 F3200, Networked, c/w Tandem V2.09 May 2001

SF0231 NDU, c/w Tandem V2.09 May 2001

Issue 2.7 5 July 2001 Page 1-5

Page 12

F3200 Installation & Programming Manual Document No: LT0122

Introduction

1.4 GLOSSARY OF ABBREVIATIONS

The following abbreviations are used throughout this manual:

A/C : Air Conditioning

ac : Alternating Current

AEOL : Active End of Line

AHr : Ampere Hour

ANC 1 : Ancillary Relay 1

AZC : Alarm Zone Circuit, or Detection Zone

AZF : Alarm Zone Facility, or Group

AVF : Alarm Verification Facility, or Check Alarm

Bd : Board

CIE : Control & Indicating Equipment

Char : Character

CCT : Circuit

COM : COMMON relay contact

dc : Direct current

EEPROM : Electrically Erasable Programmable Read Only Memory

ELV : Extra Low Voltage

EOL : End Of Line (device)

EOLR : End of Line Resistor

Expn : Expansion

E2 : Electrically Erasable Programmable Read Only Memory ....

FFCIF : Fire Fighter's Control & Indicating Facility

FIP : Fire Indicator Panel

FRC : Flat Ribbon Cable

I/O : Input/Output

LCD : Liquid Crystal Display

LED : Light Emitting Diode

MAF : Master Alarm Facility

Max : Maximum

Min : Minimum

MCP : Manual Call Point (Break Glass Switch)

MOV : Metal Oxide Varistor (Used for Surge Protection)

msec : Millisecond

NC : Normally Closed

NO : Normally Open

No : Number

Nom : Nominal

PC : Personal Computer (small computer)

PCB : Printed Circuit Board

PSU : Power Supply Unit

PTC : Positive Temperature Co-efficient (Thermistor)

R1 : Module Relay Number 1 (program abbreviation)

RL1 : Module Relay Number 1 (text abbreviation)

RAD : Return Air Duct (Air Conditioning Plant)

RMS : Root Mean Square

Reqd : Required

RTC : Real Time Clock

RZDU : Remote Zone Display Unit

SAD : Supply Air Duct (Air Conditioning Plant)

SID : System Identification Number (Network device)

sq mm : square millimetre

T1 : Programmable Timer Number 1 (program abbreviation)

Tmnl : Terminal

V1 : Programmable Variable Number 1

Page 1-6 5 July 2001 Issue 2.7

Page 13

Document No: LT0122 F3200 Installation & Programming Manual

Introduction

GLOSSARY OF ABBREVIATIONS (CONTINUED)

VA : Volts Amperes

VB : Battery Backed Voltage

VNB : Non Battery Backed Voltage

+VBF : Fused Battery-Backed Voltage

+VNBF : Fused Non-Battery-Backed Voltage

Z1 : Zone Number 1 (program abbreviation)

Zn1 : Zone Number 1 (text abbreviation)

8RM : 8 Relay Module

8ZM : 8 Zone Module

1.5 GLOSSARY OF TERMINOLOGY

The following terminology is used throughout this manual:

Ancillary Equipment : Equipment external to Fire Alarm system

Ancillary Relay : Relay in FIP which operates Ancillary equipment

Auto-Reset : Mode for one person testing of detectors

Auxiliary Output : Output for driving additional LEDs/relays

Baud : Bits per second

Control Output : Output from FIP to other equipment

Default : Pre-programming option or logic equation i.e. one that exists

without the user programming it.

Detector : Alarm Detection Device (electrical transducer)

Fire Control Station : Fire Brigade Authority, or any other authority which receives

the FIP alarm signals.

Mapping : Programmable causal relationship between inputs and outputs

Zone : Fire searchable area of building represented by a unique

number and name in the FIP, and associated with the AZC of

the same number.

Issue 2.7 5 July 2001 Page 1-7

Page 14

F3200 Installation & Programming Manual Document No: LT0122

Introduction

THIS PAGE INTENTIONALLY LEFT BLANK

Page 1-8 5 July 2001 Issue 2.7

Page 15

Document No: LT0122 F3200 Installation & Programming Manual

System Description

CHAPTER 2

SYSTEM DESCRIPTION

Issue 2.7 5 July 2001 Page 2-1

Page 16

F3200 Installation & Programming Manual Document No: LT0122

System Description

2.1 OVERVIEW

2.1.1 GENERAL

The F3200 is a self-contained, modular, intelligent Fire Indicator Panel (FIP) which performs

the functions of the Control and Indicating Equipment (CIE) as specified by the Australian

Standard AS1603.4 Automatic Fire Detection and Alarm Systems.

It is also available in formats that comply with AS4428.1. Refer to the relevant manuals that

apply to the AS4428.1 approved products.

The F3200 has a high degree of flexibility and expandability, catering for medium to very

large buildings from 8 zones or less, to 64 zones maximum. Refer to the constraints

specified in Section 3.1.3. More panels and zones can be added through the use of the

Vigilant Panel-link Network and the appropriate networkable F3200s.

This manual is also used for the installation of an NDU (Network Display Unit). NDU

operation is described in Section 11.11. An NDU may be programmed to operate in either

Australian mode (default) or New Zealand mode, and the operation of an NDU in New

Zealand mode is described in Chapter 12.

2.1.2 DETECTOR CIRCUITS

The F3200 detector interface electronics caters for a wide range of detectors, including

various types which have high alarm current requirements. It also caters for interfacing to:

Intrinsically safe circuit barriers/isolators (hazardous areas).

Long line circuits e.g. from a sub-indicator FIP.

Tamper-proof circuits e.g. for water valve supervision.

A full range of compatible detectors is listed in the Appendix A.

2.1.3 DISPLAYS

The primary display of the F3200 is a 2 line by 40 character LCD on which status messages

and prompts are shown. The LCD has backlight illumination which is turned on when there

is an alarm or operator interaction.

Common conditions such as zone ALARM, ISOLATED and FAULT, and various system

states such as BELLS ISOLATED are displayed on LEDs adjacent to the LCD.

The display panel composed of the LCD, LEDs and operator keypad meets the requirements

of AS4050 (int) for a Fire Fighter's Control and Indicating Facility (FFCIF).

As an optional extra, individual zone status (ALARM, ISOLATE and FAULT) can be

displayed on LEDs by fitting the appropriate number of 16 Zone LED Display Bds.

The F3200 electronics includes, as standard, an open collector transistor output for each

zone which can be used to drive an internal or remote mimic display.

Page 2-2 5 July 2001 Issue 2.7

Page 17

Document No: LT0122 F3200 Installation & Programming Manual

System Description

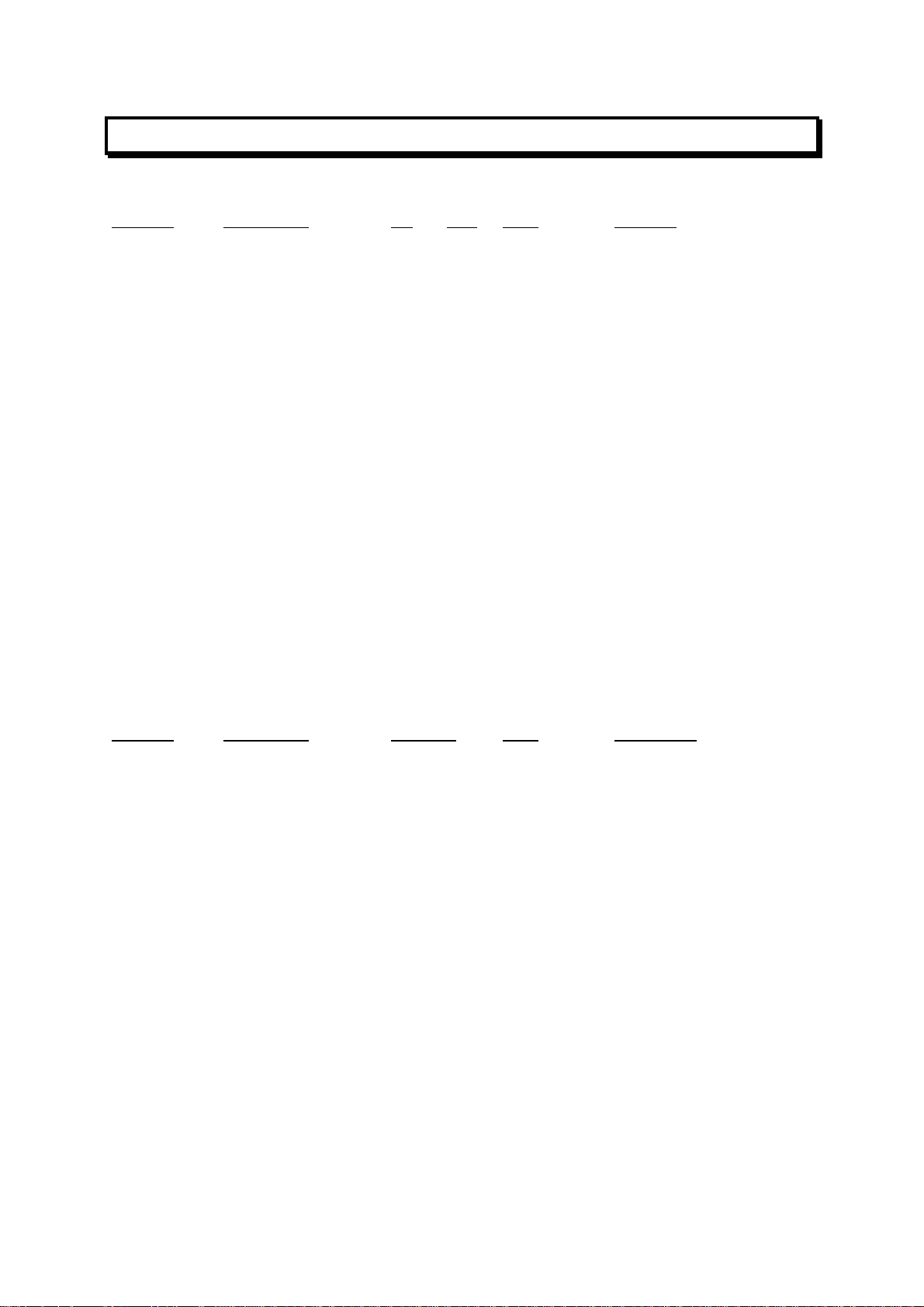

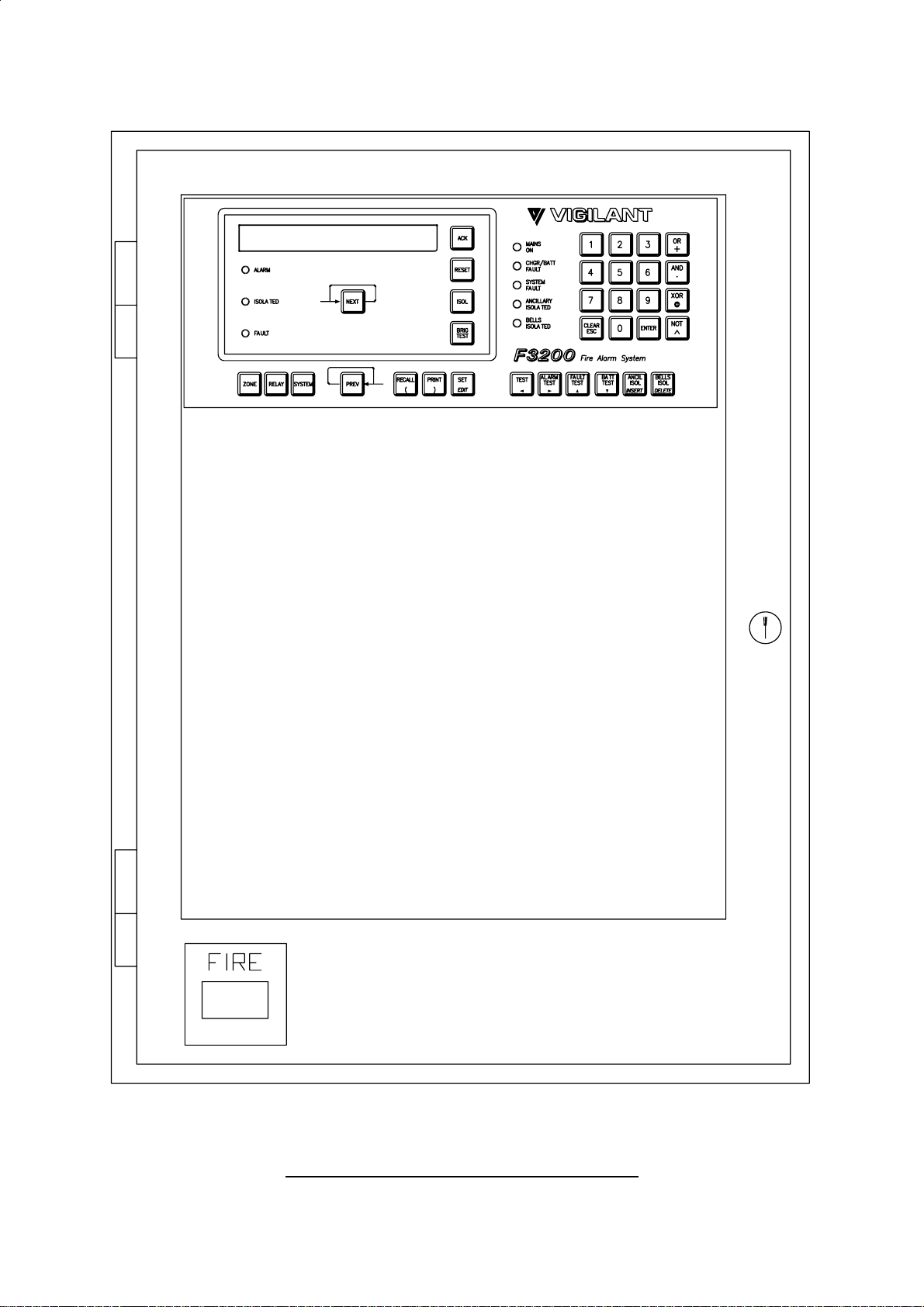

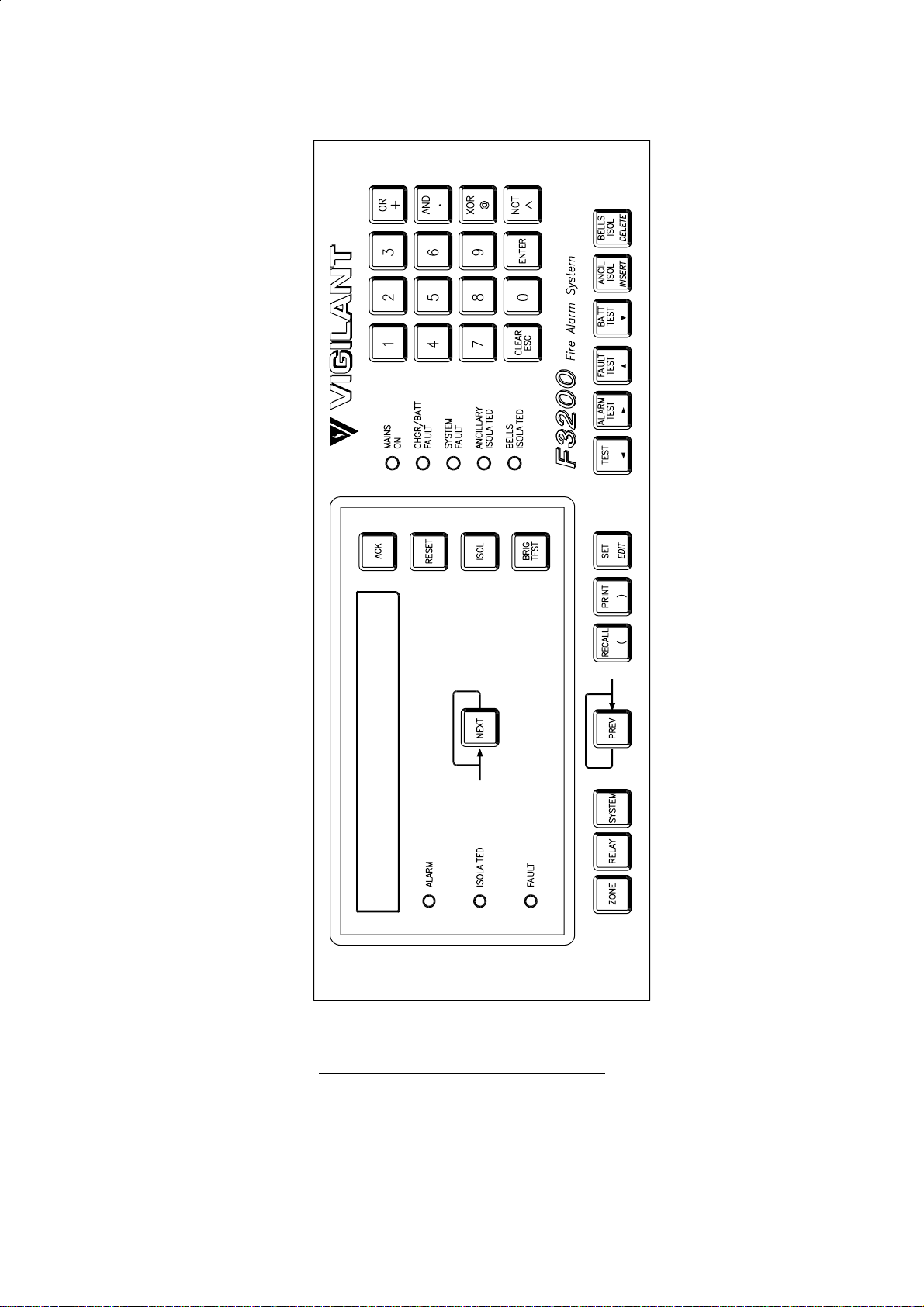

FIG 2.1.1

F3200, STANDARD CABINET - FRONT VIEW

Issue 2.7 5 July 2001 Page 2-3

Page 18

F3200 Installation & Programming Manual Document No: LT0122

System Description

FIG 2.1.2

F3200 OPERATOR DISPLAY PANEL

Page 2-4 5 July 2001 Issue 2.7

Page 19

Document No: LT0122 F3200 Installation & Programming Manual

System Description

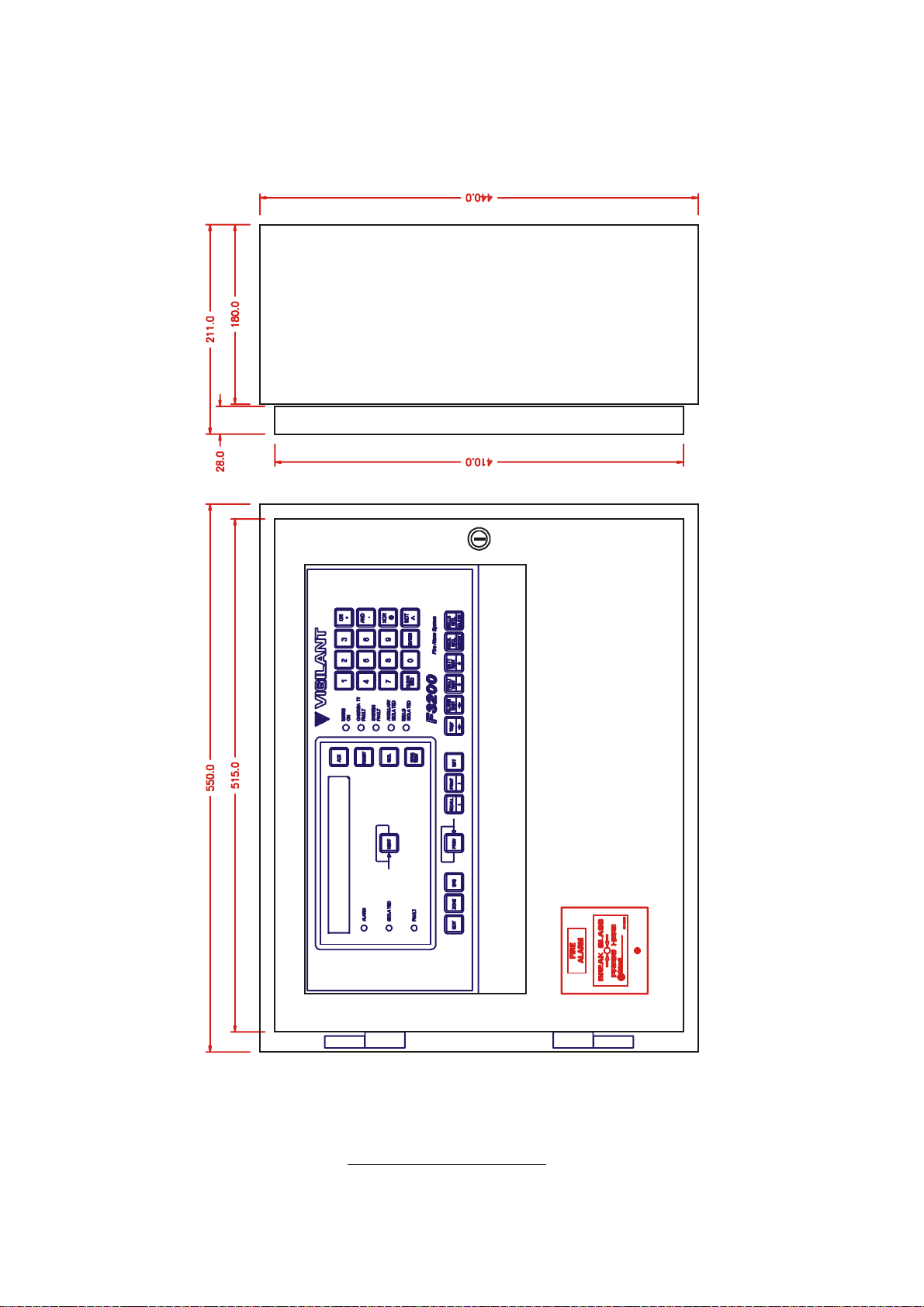

FIG 2.1.3

F3200 - SMALL CABINET

Issue 2.7 5 July 2001 Page 2-5

Page 20

F3200 Installation & Programming Manual Document No: LT0122

System Description

2.1.4 OUTPUTS

The F3200 MAF/PSU Module provides 7 relays as standard. These are used for signalling

to the Brigade (Fire Control Station) and for switching alarm bells and ancillary equipment

such as door holders, airconditioning shutdown, etc.

When more than 7 relays are required, additional sets of 8 can be added by fitting 8 Relay

Modules.

All outputs, including the open collectors on the 8 Zone Modules, are individually

programmable by a logic equation of zone and FIP status.

2.1.5 POWER SUPPLY

The F3200 has a 3 Amp battery charger/power supply as standard. There is adequate room

for large batteries.

An optional 6 Amp battery charger/power supply is available. This is factory fitted, but is not

available in the small cabinet FIPs.

Fuse protected battery backed and non-battery backed supplies are available to power

external loads such as bells, illuminated signs, interposing relays, gas release solenoids,

door holders, etc.

2.1.6 REMOTE DISPLAY & PRINTER

A serial port is included in the F3200 to provide a 3 or 4 wire link to a Remote Zone Display

Unit (RZDU). Several versions of F3200 remote displays are available, including the small,

Remote LCD unit.

The F3200 also has a serial port to drive a logging printer, which records all events as they

occur, with time and date. Logging of relay events is programmable. For network systems,

events from other selected devices on the network may be logged into the history and

printed on the local printer, and events generated locally by this system may be printed by

some other device on the network.

2.1.7 NETWORKING

Networking of F3200s allows the sharing of zone, event and alarm information, the ability to

remotely control other F3200s, and, overall, the expansion of an F3200 system beyond 64

zones.

Networking is achieved through a different software version and the fitting of an RS485

Communications board.

Page 2-6 5 July 2001 Issue 2.7

Page 21

Document No: LT0122 F3200 Installation & Programming Manual

System Description

2.2 PHYSICAL STRUCTURE

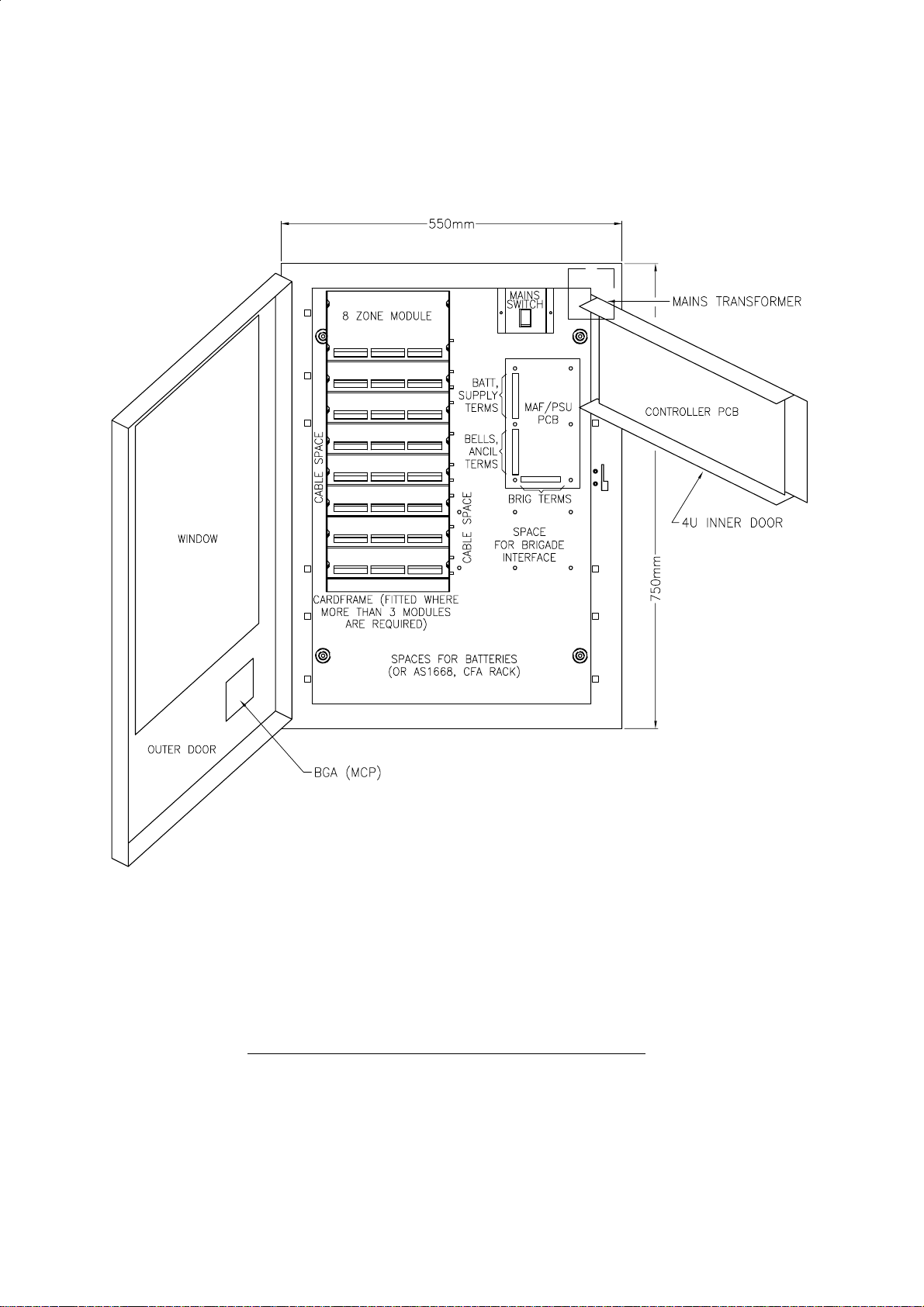

The F3200 has a rugged, lockable painted steel cabinet, which houses 19 inch rack-mount

equipment and comes in two height options (both have the same width and depth). The

standard cabinet accommodates 15U total and the small cabinet accommodates 8U (where

1U = 1 3/4" = 44.5mm).

The Operator Display has a screened, polyester overlay mounted on a hinged inner door

fitted to the top 4U position. The Controller/Display pcb mounts directly to the rear of this

door.

Standard Cabinet

In the standard cabinet the space below the 4U Operator Display panel is covered by a

blanking plate, but there is provision for mounting other equipment (e.g. a 7U hinged inner

door for a mimic, or 16 Zone LED Display Bds), in place of this blanking plate.

There is provision for mounting additional equipment in the bottom 4U (e.g. an AS1668

control rack), but this would encroach on battery space.

The outer door has a large acrylic window to allow viewing of the equipment inside.

Four versions of FIP are available in this cabinet. The FP0551, which caters for up to 64

zones, has a cardframe fitted to the rear wall as shown in Fig 2.2.1. The FP0550 has

provision (pcb stand-offs) for mounting up to three 8 way modules (i.e. 3 x 8 Zone or 8 Relay

Modules) on the rear wall. Both are supplied with 1 8 Zone Module fitted.

Versions of these two FIPs are also available with a 6 Amp power supply:

FP0713 (8 module capacity), and FP0712 (3 module capacity).

Small Cabinet

In the small cabinet, only 1U (of the 4U) below the 4U Operator Display is visible through the

outer window. The gap is covered by a blanking plate (2U), which can be replaced by a

bracket for mounting a limited range of equipment, eg. a 1U AIU bracket, or a 1U 1 Zone

Gas Control Panel.

A 6A PSU or a 7U LED Display door cannot be fitted.

Up to four 8 way modules can be mounted on the rear wall, but the bottom two of these

share space with the batteries. Mounting arrangement and maximum capacity are shown in

Fig 2.2.2.

Only one FIP is available (FP0583), and this comes with one 8 Zone Module fitted (in the top

left position).

Issue 2.7 5 July 2001 Page 2-7

Page 22

F3200 Installation & Programming Manual Document No: LT0122

System Description

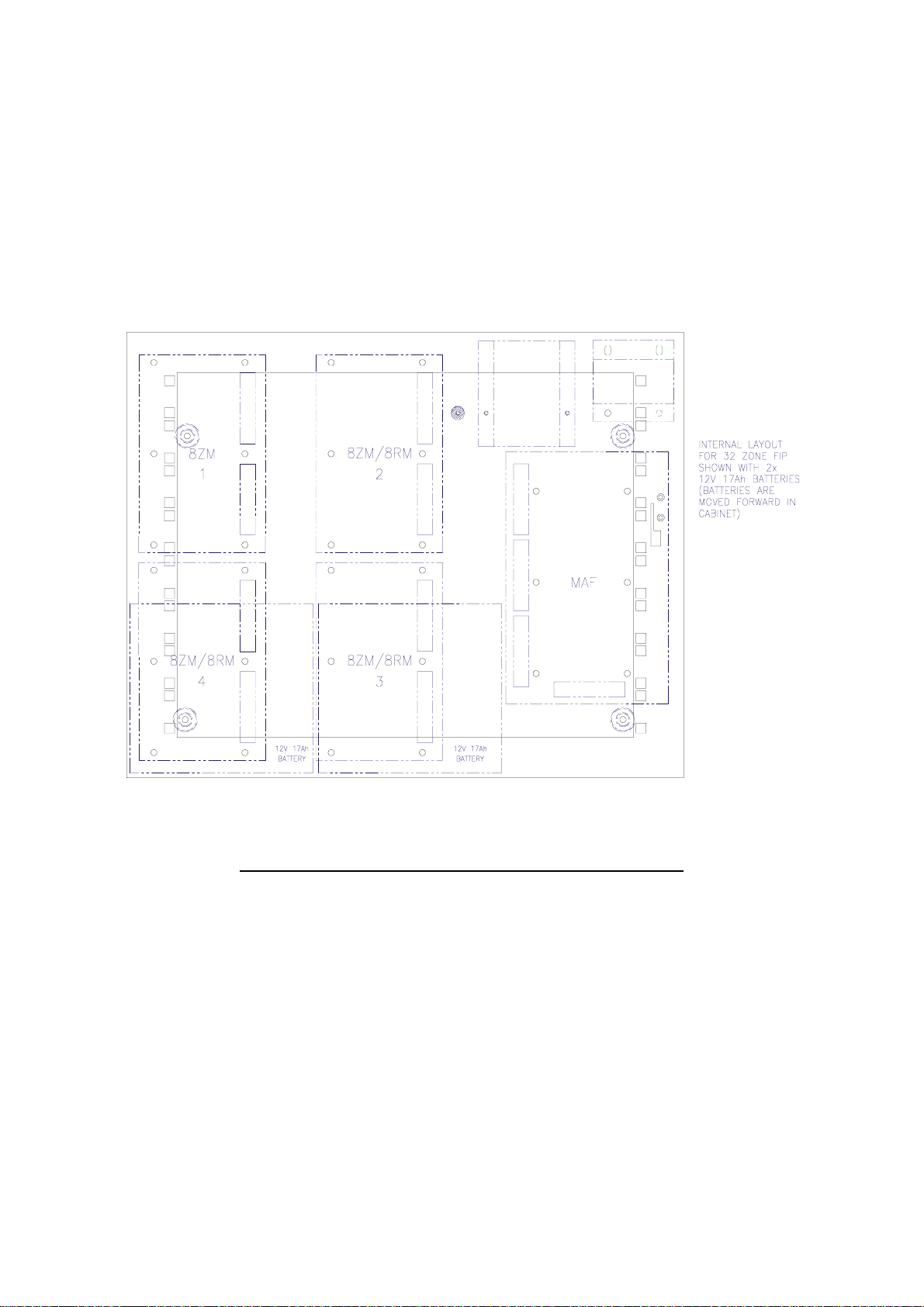

Note: FP0551 and FP0713 have the cardframe as shown.

FP0550 and FP0712 have the modules (3 max.) mounted on the rear wall.

FIG 2.2.1

F3200 STANDARD CABINET - INTERNAL LAYOUT

Page 2-8 5 July 2001 Issue 2.7

Page 23

Document No: LT0122 F3200 Installation & Programming Manual

System Description

FIG 2.2.2

F3200, SMALL CABINET, MAXIMUM CONFIGURATIONS

Issue 2.7 5 July 2001 Page 2-9

Page 24

F3200 Installation & Programming Manual Document No: LT0122

System Description

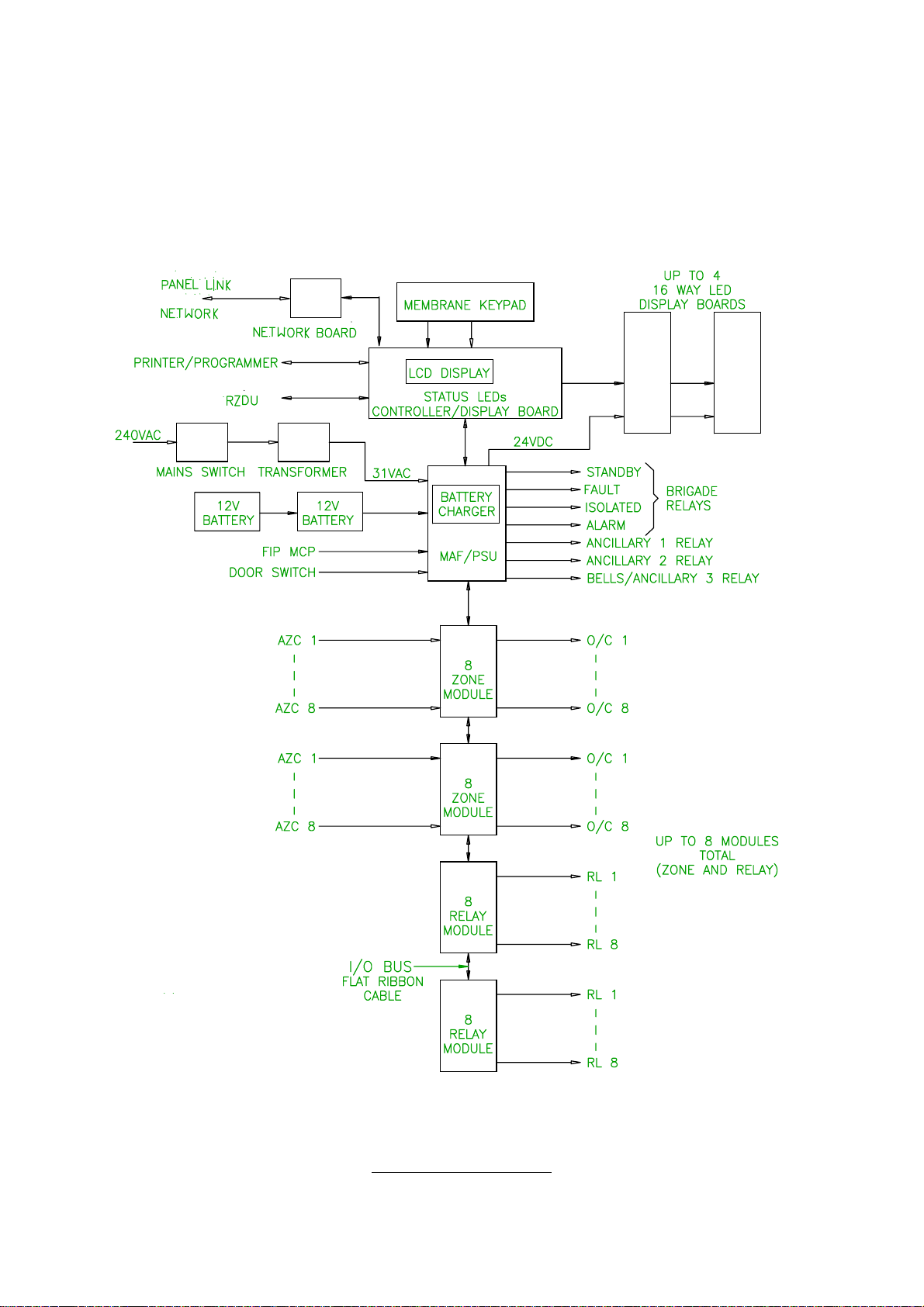

2.3 SYSTEM STRUCTURE

2.3.1 PCB MODULES

The 6 printed circuit boards which are used in an F3200 are as follows:

Controller/Display

Mounts on 4U inner door.

Includes: LCD, status LEDs and buzzer

keypad connection

5Vdc supply

voltage monitors for battery charger

microprocessor & memory

serial I/O bus control for all other modules

reference voltage generation for I/O modules

UARTs and serial port electronics

real time clock calendar integrated circuit

FRC connection to other modules.

MAF/PSU

Mounts on cabinet rear wall.

Includes: battery charger/PSU

22V regulator for detector circuits

Brigade & Ancillary relays and supervision circuitry

MCP & door switch inputs

screw terminals (most demountable) for field wiring

FRC connection to other modules.

8 Zone Module

Mounts on cabinet rear or in cardframe.

Includes: electronics to I/F to 8 Alarm Zone Circuits (AZCs)

8 open collector auxiliary outputs

demountable screw terminals for field wiring

FRC connection to other modules.

8 Relay Module

Mounts on cabinet rear or in cardframe.

Includes: 8 relays and supervision circuitry

demountable screw terminals for field wiring

FRC connection to other modules.

16 Zone LED Display

Mounts on 7U inner door.

Includes: 16 sets of 3 LEDs

electronics to control the LEDs (serial bus)

Page 2-10 5 July 2001 Issue 2.7

Page 25

Document No: LT0122 F3200 Installation & Programming Manual

System Description

RS485 "Panel-Link" Network Board

Connects to the Controller/Display Board

Includes: RS485 Board used for connection to the Vigilant Network.

FIG 2.3.1

SYSTEM STRUCTURE

Issue 2.7 5 July 2001 Page 2-11

Page 26

F3200 Installation & Programming Manual Document No: LT0122

System Description

2.3.2 INTER-CONNECTION & STRUCTURE

A basic F3200 system

all connected by Flat Ribbon Cable (FRC) on a common Input/Output (I/O) Bus.

Additional 8 Zone Modules and/or 8 Relay Modules

maximum of eight 8 way modules. This is shown in the block diagram of Fig 2.3.1.

The physical maximums are:

three 8 way modules in an FP0550 or FP0712.

four 8 way modules in an FP0583 (with restrictions)

eight 8 way modules in an FP0551 or FP0713.

Expansion is from top to bottom.

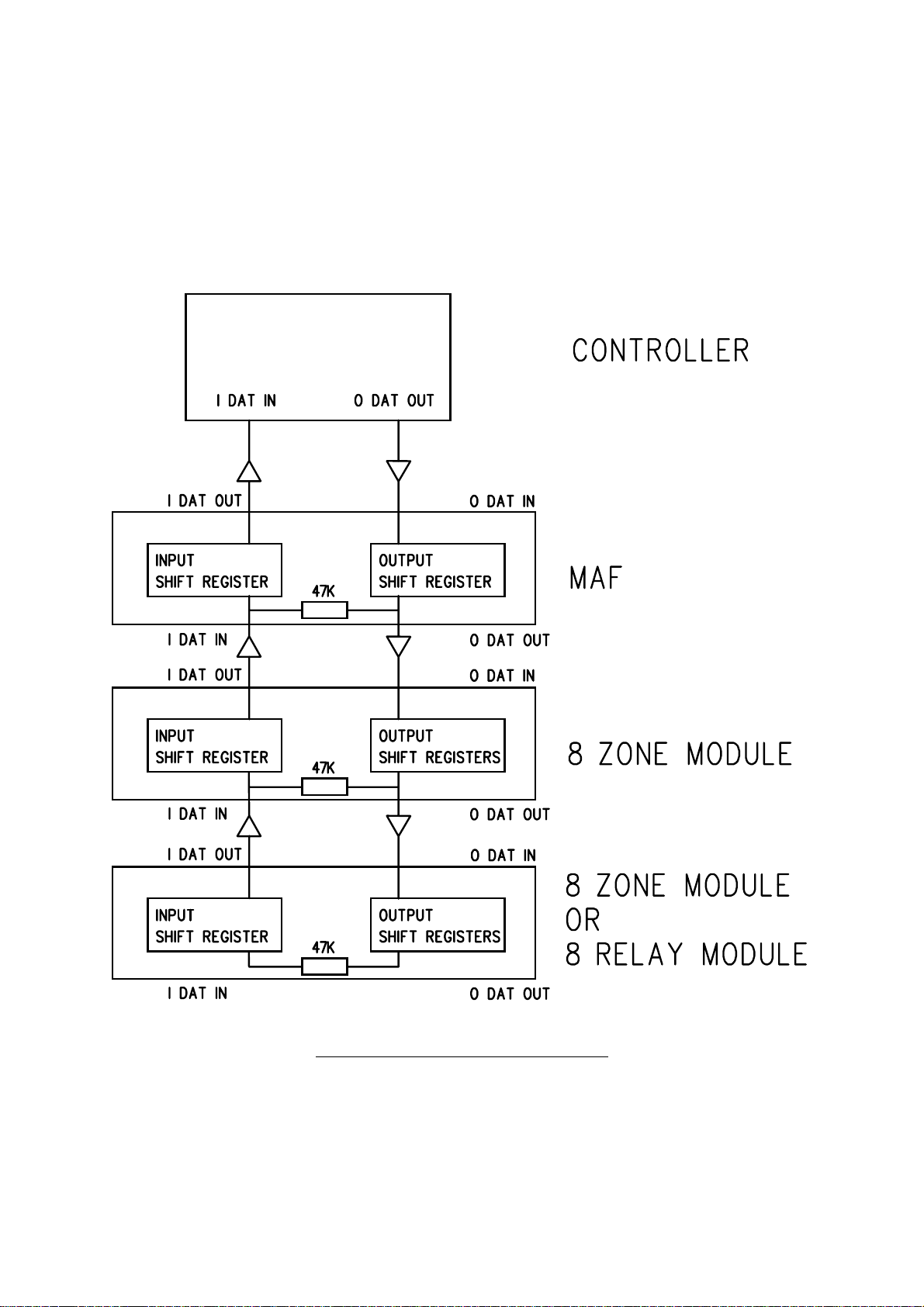

The I/O Bus Out of one module connects to the I/O Bus In of the next module via the 20 way

FRC provided (LM0053).

No link or "End of Bus" is required on the last module because the data from the furthest

output shift register is fed into the furthest input shift register via the wrap-around resistor as

shown in Fig 2.3.2.

Refer to Section 3.1.3 Specifications for detail on the structural arrangement of AZCs and

relays.

To further extend these capabilities, up to 64 F3200s may be networked together, with full

sharing of information and remote control of each panel by a master panel.

has one Controller/Display, one MAF/PSU, and one 8 Zone Module,

can be fitted to the I/O bus, with a

16 Zone LED Display bds

They receive power from the MAF/PSU via two power leads. Where more than one is

required they are connected in series (up to 4 maximum) from right to left (as viewed from

the front) on the FIP. The 26 way FRC from J13 of the Controller goes to J1 ("From

Previous") of the right hand Display Bd. Zone 1 (default) corresponds to the top LEDs on

the left hand Display Bd. The last board requires the "end of bus" minijump connector to be

fitted. Note that a special FRC cable is required to connect the Controller Board to the first

Display Board (LM0092).

Where LED Display bds are fitted, the default programming requires one Display bd (16

zones) for every two 8 Zone Modules, i.e. one for 1-16 zones, two for 17-32 zones, etc.

Zone 1 corresponds to the top row of 3 LEDs on the left most Display. Zone 2 to the row

below it, etc, (top to bottom, left to right).

LED Display bds may also annunciate relay status, i.e. Alarm <-> relay energised, Isolated

<-> relay isolated, Fault <-> relay wiring fault (i.e. supervision fault).

The default programming for displaying both zone and relay status requires one Display bd

for every two 8 way modules (zone and relay).

are driven from a separate serial bus on the Controller/Display.

Page 2-12 5 July 2001 Issue 2.7

Page 27

Document No: LT0122 F3200 Installation & Programming Manual

System Description

INTER-CONNECTION & STRUCTURE (CONTINUED)

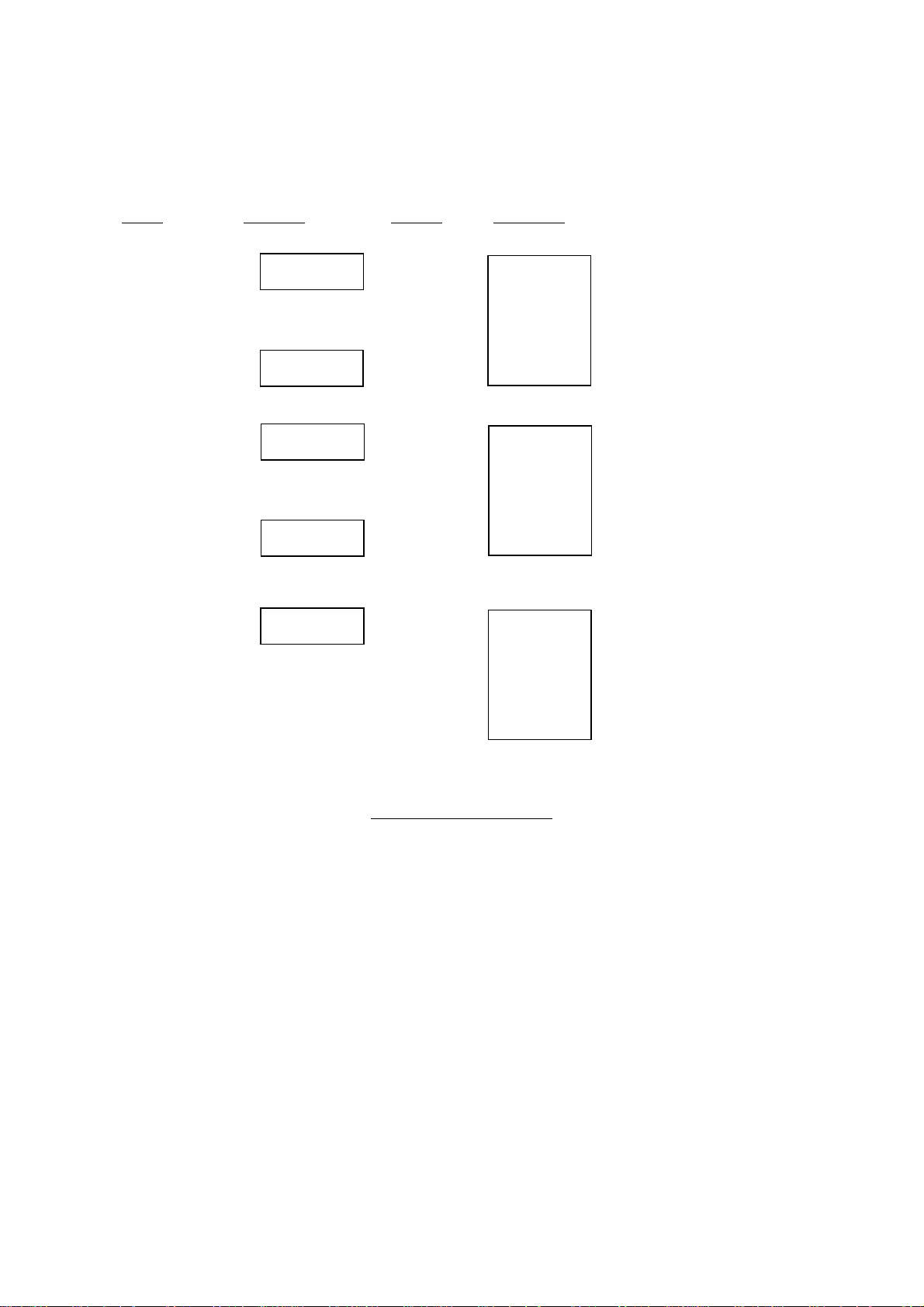

The relay LEDs simply follow the zone LEDs in the same order that they occur in the

modules. E.g. a system with three 8 Zone Modules and two 8 Relay Modules would require

3 Display bds. Relay 1 would be annunciated on the 25th row of LEDs and the last 8 rows

would be unused as shown in Fig 2.3.3.

Mapping zones and relays to LEDs in other patterns is programmable.

FIG 2.3.2

SERIAL DATA FLOW IN THE I/O BUS

Issue 2.7 5 July 2001 Page 2-13

Page 28

F3200 Installation & Programming Manual Document No: LT0122

System Description

Zone Module

1 1 ........1 1

8 8 8

9 1 9

16 8 ........16 16

17 1 ........1 17

24 8 24

1 1 25

8 8....16 32

1 9....1 33

8 16.... 40

8ZM 1

8ZM 2

8ZM 3

8RM 1

8RM 2

Relay Display

1

2

3

LAST 8 UNUSED 16

FIG 2.3.3

DISPLAY STRUCTURE

(DEFAULT MAPPING)

EXAMPLE FOR SYSTEM WITH 3 8ZM & 2 8RM

The F3200 can be configured to have a lesser number of Display Bds than required by the

default structure, with selective mapping of zones/relays to Display LEDs.

Page 2-14 5 July 2001 Issue 2.7

Page 29

Document No: LT0122 F3200 Installation & Programming Manual

System Specifications

CHAPTER 3

SYSTEM SPECIFICATIONS

Issue 2.7 5 July 2001 Page 3-1

Page 30

F3200 Installation & Programming Manual Document No: LT0122

System Specifications

3.1 GENERAL

3.1.1 FIP PART NUMBER & DESCRIPTION

Refer to Section 4 also.

FP0550, F3200 FIP, NO CARDFRAME, 24 ZONE MAX, 1931-15

Includes: Full size cabinet (ie. standard cabinet)

Controller/Display with FFCIF LCD & Keypad

MAF/PSU (includes 7 relays, 3A PSU)

1 x 8 Zone Module with standard EOLRs

Modules fit to cabinet rear wall (up to 3 modules max)

FP0551, F3200 FIP, C/W CARDFRAME, 64 ZONE MAX, 1931-16

Includes: Full size cabinet (ie. standard cabinet)

Controller/Display with FFCIF LCD & Keypad

MAF/PSU (includes 7 relays, 3A PSU)

Cardframe (can house up to 8 modules)

1 x 8 Zone Module fitted in cardframe

includes standard EOLRs

FP0583, F3200 FIP, SMALL CABINET

Includes: Small cabinet

Controller/Display with FFCIF LCD & Keypad

MAF/PSU (includes 7 relays, 3A PSU)

1 x 8 Zone Module with standard EOLRs

Modules fit to cabinet rear wall (up to 4 modules max)

FP0712, F3200 FIP, NO CARDFRAME, 24 ZONE MAX, C/W 6 AMP PSU

Includes: Full size cabinet (ie. standard cabinet)

Controller/Display with FFCIF LCD & Keypad

MAF/PSU (includes 7 relays, 6A PSU)

1 x 8 Zone Module with standard EOLRs

Modules fit to cabinet rear wall (up to 3 modules max)

FP0713, F3200 FIP, 64 ZONE MAX, C/W 6 AMP PSU

Includes: Full size cabinet (ie. standard cabinet)

Controller/Display with FFCIF LCD & Keypad

MAF/PSU (includes 7 relays, 6A PSU)

Cardframe (can house up to 8 modules)

1 x 8 Zone Module fitted in cardframe

includes standard EOLRs

3.1.2 SYSTEM EXPANSION

Expansion to the base panels is by adding 8 way zone input or relay output modules, or by

networking multiple panels together.

FP0553, F3200 8 ZONE INPUT EXPANSION KIT

Includes: 8 Zone Module, FRC, 8 x EOLR (std)

FP0554, F3200 8 RELAY EXPANSION KIT

Includes: 8 Relay Module, FRC, 8 x Minijump links (for supervision selection)

Page 3-2 5 July 2001 Issue 2.7

Page 31

Document No: LT0122 F3200 Installation & Programming Manual

System Specifications

3.1.3 ENVIRONMENTAL

Operating Temperature : -5°C to 45°C (Ambient)

Relative Humidity : 95% maximum @ 40°C (non-condensing)

3.2 MECHANICAL SPECIFICATIONS

CABINETS

Style : Wall mounting

Hinged outer door with large window (hinges to left)

Accepts 19" rack mounting equipment

4U Display on hinged inner door (hinges to right)

Construction : Welded steel

Material : 1.2mm and 1.6mm mild steel

Size :

- Standard : 750mm (H) x 550mm (W) x 210mm (D) * (Iss B cabinet)

- Small : 410mm (H) x 550mm (W) x 210mm (D) *

* MCP is an additional 20mm.

Finish : Powdercoat BFF-998-CW

Cream Wrinkle

(Iron Phosphate pre-treat)

Weight : Unpackaged Packaged

FP0550 20kg 22kg

FP0551 22kg 24kg

FP0583 17kg 19kg

FP0712 22kg 24kg

FP0713 24kg 26kg

Issue 2.7 5 July 2001 Page 3-3

Page 32

F3200 Installation & Programming Manual Document No: LT0122

System Specifications

3.3 ELECTRICAL SPECIFICATIONS

3.3.1 MAINS SUPPLY

Voltage : 240Vac +6% -10%

Current : 0.5A

Frequency : 50Hz

Termination : For up to 2.5sq mm TPS

3 Way block with wire protectors

3.3.2 BATTERY CHARGER & PSU

Input Voltage : 31Vac rms

(Transformer sec)

Charger Voltage : 27.3Vdc (nominal at 20°C)

Temperature : -36mV per °C nominal

Compensation

Non-Battery Backed : 28.0 nominal

Voltage

Max Total Current : 3Adc for std PSU (Charger, Quiescent & Alarm)

6Adc (for 6A PSU only)

Max Bell Current : 2Adc

Max. Ancillary : 2Adc

Current on VBF1

Max. Ancillary : 2Adc (allows 3A max LED Display)

Current on VBF2

Max. Ancillary : 2Adc (e.g. for door holders)

Current on VNBF

(VBF <-> battery backed, fused. VNBF <-> non-battery backed, fused)

Current Limit

Standard PSU 6A PSU

Battery to

MAF/PSU : PTC, 6A nom, 3.6A min (see notes below)

PSU/Charger : 3.3A nom, 3.0A min 6.7A nom, 6.0A min

Notes 1) : The 6A PSU is factory fitted in the FP0712 and FP0713. It is

not available in the FP0583.

2) : For the 6A PSU, the PTCs on the MAF are shorted out and a

Derwent 10A thermal cutout is wired between the battery +

terminal and the MAF/PSU.

Page 3-4 5 July 2001 Issue 2.7

Page 33

Document No: LT0122 F3200 Installation & Programming Manual

System Specifications

STATE MIN NOM MAX COMMENTS

Charger High 28.05 28.125 28.20 Adjust with pot

Charger Low 26.40 26.57 26.75

Battery Low 24.15 24.33 24.55

Standby Off 21.5 22.0 22.5 For voltage falling

Notes:

1. All voltages stated in VDC at temperature of 20°C.

2. Apply temperature compensation of -36 mV/°C for temperature deviation from 20°C.

3. This applies also to charger voltage 27.3 VDC.

4. There are thermal delays, therefore if checking or adjusting in field ensure unit has been

running for some hours.

5. Standby Relay is normally energised (on), and turns off for Battery fail.

TABLE 3.3.2

BATTERY AND CHARGER MONITORING VOLTAGE SPECIFICATIONS

3.3.3 BATTERY

Battery Voltage : 24Vdc nominal (2 x 12Vdc)

Compatible Makes Sonnenschein A200 & Sonnenschein A300 series

Powersonic PS12 series

Yuasa NP series

Capacity : 6 to 50 Ahr (dependent on configuration)

Space (mm) : - Standard Cabinet

Up to 220H, 440W, 175D (Iss B cabinet)

- Small Cabinet

Up to 200H, 185W, 175D (3 modules fitted)

Up to 200H, 370W, 125D (4 modules fitted)

(Refer to Fig 2.2.2)

Battery Test Load : 46 Ohm nominal. Suitable for 6 Ahr battery (with quiescent

current)

Provision for fitting extra resistors

NOTE: BATTERY TEST RESISTORS (R52, R53) MUST BE REMOVED FOR NEW

ZEALAN D OPERAT ION.

3.3.4 FUSES

Location : MAF/PSU PCB

Number Name

F1 +VBF1 5 x 20mm 2A Glass Cartridge, Std

F2 +VBF2 5 x 20mm 6A Glass Cartridge, Std

F3 +VNBF 5 x 20mm 2A Glass Cartridge, Std

F4 +VE 5 x 20mm 2A Glass Cartridge, Std

F5 Mains In 5 x 20mm 6A Glass Cartridge, Std

F7 +VBELLS 5 x 20mm 2A Glass Cartridge, Std

Size Rating Type

Issue 2.7 5 July 2001 Page 3-5

Page 34

F3200 Installation & Programming Manual Document No: LT0122

System Specifications

3.3.5 CURRENT CONSUMPTION

3.3.5.1 F3200 Quiescent & Alarm Currents

At 24Vdc battery supply, nominal currents:

Quiescent Alarm

FP0550, FP0551, FP0583, FP0712, FP0713 130mA 275mA

(notes 1-4)

8 Zone Module

- all AZCs disabled 4mA

- all AZCs enabled (notes 2-6) 82mA 97mA

Current per enabled AZC (note 3) 10mA

8 Relay Module

- all supervision disabled 4mA

- all supervision enabled 6mA

Current per relay on 11mA

MAF/PSU

- all relays off 9mA

Current per Ancillary Relay

(includes bells) 11mA 11mA

Current per Brigade Relay 16mA 16mA

(2 Zone)

22V Supply (supplies 8 Zones) max rating 800mA

Controller/Display

- LCD backlight off, status LEDs off 19mA

- LCD backlight on, status LEDs off 75mA

Current per status LED on 3mA

16 Zone LED Display 0mA 16mA/LED (steady)

RS485 network interface board PA0773 7.5mA

Total electronics and detector max rating 2000mA

Notes

1. FP0550/551/583/712/713 currents include Controller/Display, MAF/PSU and 1 x 8ZM

with all ACZs enabled and with EOLRs (2K7 for mode 1 or 2).

2. Quiescent current for an enabled AZC is for modes 1 or 2 (standard or high current)

and includes the 2k7 EOL, but not the detector current (up to 4mA detector current

per AZC).

3. Quiescent current is only 2.5mA per AZC for mode 3 and 1mA for mode 4.

4. Alarm current is for AZC mode 1, refer AZC specifications for other modes.

5. The 8 Zone Modules (8ZMs) are supplied from the fused battery supply via the 22V

regulator which has a maximum rating. The 8 Relay Modules (8RMs) are supplied

directly from the fused battery supply.

6. Quiescent and alarm currents do not include external loads e.g. door holders, bells,

etc.

Page 3-6 5 July 2001 Issue 2.7

Page 35

Document No: LT0122 F3200 Installation & Programming Manual

System Specifications

3.3.5.2 NDU Quiescent and Alarm Currents

4

Slimline NDU (FP0714/FP0773/FP0774

)

Operating Voltage : 24Vdc (18-28V)

Termination : For up to 2.5sqmm TPS

Quiescent Alarm

Current Consumption : 25mA 80mA

Full cabinet NDU (FP0715)

Quiescent Alarm

70mA 165mA

85mA 150mA

Current Consumption (Aust mode)

Current Consumption (NZ mode)

1

2

1. Includes controller, MAF/PSU, energised standby relay, PA0773 RS485 Bd, LCD

backlight off in quiescent state.

2. Includes controller, MAF/PSU, NZ Display Extender, energised standby and alarm

relays, PA0773 RS485 Bd. LCD backlight off in quiescent state.

3. Refer to Section 3.3.5.1 for additional module currents.

4. For FP0774 the I-Hub currents must be added.

Issue 2.7 5 July 2001 Page 3-7

Page 36

F3200 Installation & Programming Manual Document No: LT0122

System Specifications

3.4 INPUT SPECIFICATIONS

3.4.1 AZC SPECIFICATIONS

General

Terminations On 8 Zone Module, 2 per AZC.

Demountable screw terminal 1.5sq mm cable max.

Number 8 AZCs per 8 Zone Module.

64 max per system.

End of Lines (EOLs)

Mode EOL

1 Standard 2k7, 5%, 400mW resistor

2 High Current 2k7, 5%, 400mW resistor

3 Low Current 10k, 5%, 400mW resistor

4 Tamper EOL002B active EOL

5 Disabled None

Circuit Resistance & Capacitance

Mode Capacitance Resistance

1, 2 & 4 500nF 50 Ohm max

3 1000nF 800 Ohm max for B2 Alarm

2k Ohm max for B3 Alarm

Voltages

Min Typ Max

Detector Supply on MAF/PSU (note 1) 21.2V 22.0V 22.2V

(21.8V)

at AZC terminals 18.75V 20.3V 22.1V

at end of circuit 18.0V 20.3V 22.1V

Alarm Voltage Thresholds

Band B3 upper threshold 17.2V 17.5V 17.8V

Band B3 lower threshold 12.75V 13.1V 13.45V

Band B2 upper threshold

Band B2 lower threshold 2.7V 2.9V 3.1V

Band B1 upper threshold

Band B1 lower threshold 0V 0V 0V

Page 3-8 5 July 2001 Issue 2.7

Page 37

Document No: LT0122 F3200 Installation & Programming Manual

System Specifications

AZC SPECIFICATIONS (CONTINUED)

Min Typ Max

AZC current limit (note 1) 13.5mA 15.5mA 16.5mA

(14.5mA)

EOL & detector quiescent 11.95mA

EOL, no detectors 7.0mA 7.8mA 8.2mA

(7.2mA)

Fault threshold 4.4mA 5.75mA 6.8mA

Detector quiescent 0mA 4.0mA

Notes

1. The minimum figures shown are for battery voltage greater than the minimum

Standby (Battery Fail) level i.e. 21.5V. The figures shown in brackets are for a

battery voltage greater than 22.5V.

2. Modes 1 & 2 have the same thresholds before the Alarm state is latched. For Mode

2 additional current is turned on once the Alarm state is latched (refer to Graph

3.4.2).

Min Typ Max

Mode 3 Only

Current into short circuit 34.3mA

Current into 800 Ohm (note 3) 14.2mA 14.8mA 15.3mA

Current into 2000 Ohm (note 4) 8.0mA 8.2mA 8.4mA

EOLR Current 2mA

Minimum current for EOLR & 2k circuit 1.64mA

Modes 3 & 4

Fault thresholds 0.85mA 1.28mA 1.59mA

Maximum allowable load or circuit leakage 0.5mA

Notes

3. I.e. short at end of an 800 Ohm circuit (gives voltage band B2 alarm, ref graph 3.4.1).

4. I.e. short at end of a 2000 ohm circuit (gives voltage band B3 alarm, ref graph 3.4.1).

MCP Zener Diode

For voltage band B3 operation BZT03C15 3W, 15V.

Issue 2.7 5 July 2001 Page 3-9

Page 38

F3200 Installation & Programming Manual Document No: LT0122

System Specifications

AZC SPECIFICATIONS (CONTINUED)

Detector Alarm Currents

The current available to a latched detector is the AZC supply current at the detector "Alarm"

voltage minus the EOLR current and the remaining quiescent current at that voltage.

The following graphs show current/voltage characteristics for the various modes of

operation.

GRAPH 3.4.1

AZC CURRENT LIMIT CHARACTERISTICS (MODES 1 & 2)

ICL = Current Limit

IAV = Current Available to Detectors with EOLR fitted

IAV = ICL - IEOLR

GRAPH 3.4.2

AZC CURRENT VS VOLTAGE : MODE 1 (STANDARD)

Page 3-10 5 July 2001 Issue 2.7

Page 39

Document No: LT0122 F3200 Installation & Programming Manual

System Specifications

ICL+R = Current sourced through current limit and pull up resistor

IAV = Current available to detectors with EOLR fitted

IAV = ICL+R - IEOLR

GRAPH 3.4.3

AZC CURRENT VS VOLTAGE MODE 2 (HIGH CURRENT)

A short circuit at the end of an 800 Ohm line will give a B2 (Detector Operated) alarm.

A short circuit at the end of a 2k Ohm line will give a B3 (programmable) condition.

GRAPH 3.4.4

ACZ CURRENT VS VOLTAGE MODES 3 & 4 (LOW CURRENT & TAMPER)

Issue 2.7 5 July 2001 Page 3-11

Page 40

F3200 Installation & Programming Manual Document No: LT0122

System Specifications

AZC SPECIFICATIONS (CONTINUED)

Timing

Standard Delay 2.3 sec (2.0 - 2.6 sec)

(into Alarm, Fault, Normal)

AZC Reset 5.3 sec (5.0 - 5.6 sec)

AZC Ignore Period 1 2 sec nom (plus std 2.3 sec delay)

(after Reset)

AZC Ignore Period 2 1 sec nom (plus std 2.3 sec delay)

(after Start Up or Programming)

AZC Time Into Alarm Programmable 0-250 sec

AZC Time Out of Alarm Programmable 0-250 sec

Refer to Section 7.2.4 for detail on other sequences and programmable delays.

3.4.2 MAF/PSU INPUTS

Battery Termination One pair screw terminals; 4sq mm max cable

AC Input 31V rms; 3.6A rms; 2.8mm tab terminals

Door Switch 5V, 0.5mA, Unsupervised, 4 Way .1" pcb header, J6

MCP 5V, 1mA, 2k7 EOLR, 4 Way .1" pcb header, J6

Spare Inputs (not fitted) 5V, 0.5mA, Unsupervised, Cabinet internal use only, 4 Way

.1" pcb header, J5

Relay Supervision

Anc 1 Sup/Anc 2 Sup One screw terminal each

Modes of Operation 1 Door holder (Default for Anc 1)

2 Load (Default for Anc 2)

Relay Off Relay On

Door Holder Mode expects Voltage Present No Voltage Present

Load mode expects Resistive to 0V Open Circuit or Voltage Present

Voltage Threshold 3.65V Nom

(Door Holder Mode)

Supervision Current 0mA @ +5V, 1mA @ 0V

Load Resistance 400 Ohm - 10k Ohm

(Load Mode) less than 400 Ohm with series diode at load.

14 Ohm absolute minimum.

Bells Relay

Form Reverse polarity - requires series diode at each device

Page 3-12 5 July 2001 Issue 2.7

Page 41

Document No: LT0122 F3200 Installation & Programming Manual

System Specifications

MAF/PSU INPUTS (CONTINUED)

End of Line Resistor No. of Circuits Type

1 3k3, 5%, 250mW resistor

2 6k8, 5%, 250mW resistor

3 10k, 5%, 250mW resistor

Supervision Current 0mA @ +5V, 1.5mA @ 0V, +ve to BELLS- terminal

Circuit Resistance 100 Ohm max.

3.4.3 CONTROLLER/DISPLAY INPUTS

Spare DC Input/Output 24Vdc nom demountable screw terminal, 4 way, J5

Spare Input 22V, 10k Ohm pull up resistor

Provision for supervision (up to 5 band)

Spare Inputs IP0, 1, 2 Unsupervised, Cabinet internal use only

(not fitted) +5V, 100k pull up resistor, 10 Way FRC header, J10

Serial I/O RZDU Refer Section 3.5.3; Others 3.5.2

3.4.4 8 RELAY MODULE SUPERVISION

Form Load monitoring

Relay Off Relay On

Expects Resistance to 0V Voltage Present

Selected By Minijump link on pcb & programming of FIP

Default Programming Disabled (unsupervised)

Load Resistance 400 Ohm - 10k Ohm

Less than 400 Ohm with series diode at load

14 Ohm absolute minimum

Voltage Threshold 3.65V nom.

Supervision Current 0mA @ +5V, 1mA @ 0V

3.4.5 NZ MODE DISPLAY EXTENDER BOARD INPUTS

The Display Extender Board is used with New Zealand operation only. The inputs it

provides are : Silence Alarms, Trial Evac, Building Services Restore, Lamp Test and

External Defect. All inputs have closure to zero volts to assert the input. An input may be

left open or unconnected if not used. Refer to section 12.8 for wiring.

All Inputs Closure below 1.5V @ 0.35mA required to activate.

Open voltage = 5V

Issue 2.7 5 July 2001 Page 3-13

Page 42

F3200 Installation & Programming Manual Document No: LT0122

System Specifications

3.5 OUTPUT SPECIFICATIONS

3.5.1 8 ZONE MODULE OUTPUTS

Type Darlington open collector

Switch to 0V

Voltage Rating 28.5V max, "off" state

1V max @ 30mA, "on" state

1.1V max at 100mA

Current Rating 100mA max per O/P, 0.6A max per module

1A max per FIP.

Transient Protection Allows external wiring

Terminations 8 Way demountable screw terminal

1.5sq mm max. cable

Operation Programmable

Default O/C 1 = Zone 1 Alarm

O/C 2 = Zone 2 Alarm

etc.

3.5.2 8 RELAY MODULE OUTPUTS

Form 1 Pole changeover contacts

Voltage-free when unsupervised

Termination Demountable screw terminals

1.5sq mm max cable

Rating ELV only

30V, 2Adc resistive

30V, 1Adc inductive

Note The relays are 2 pole, with the second pole terminated on pcb pads.

Operation Programmable

Supervision Ref 3.4.4.

Looping Terminals 2 Sets of 4 joined

voltage-free terminals per module

Page 3-14 5 July 2001 Issue 2.7

Page 43

Document No: LT0122 F3200 Installation & Programming Manual

System Specifications

3.5.3 MAF/PSU OUTPUTS

Brigade Relays

Number 4

Standby Normally energised

De-energises on battery fail or panel fail

Fault, Isolated, Alarm Normally de-energised

Energise on active state

Form 1 Pole changeover contacts

Voltage-free

Termination Demountable screw terminals

1.5sq mm max cable

Rating ELV only

30V, 5Adc resistive

30V, 3Adc inductive

Isolation 1500V rms contact to coil

Ancillary & Bells

Number 3

Anc 1, Anc 2

Termination Demountable screw terminals

Rating ELV only

(Note: The relays are 2 pole, with second pole terminated on pcb pads).

Operation Programmable

Default Active on any unisolated Zone Alarm.

Supervision Separate terminal (ref 3.4.2)

Anc 3/Bells

1 Pole changeover contacts

Voltage-free

1.5sq mm max cable

30V, 2Adc resistive

30V, 1Adc inductive

2 pole relay

Link selectable function

Standard Format Bells

Switched 24Vdc output

2 terminals, Bells +, Demountable screw terminals

1.5sq mm max cable

Issue 2.7 5 July 2001 Page 3-15

Page 44

F3200 Installation & Programming Manual Document No: LT0122

System Specifications

MAF/PSU OUTPUTS (CONTINUED)

Option 1 Pole changeover contacts

Voltage-free

Snip Links Lk2, 3, 4.

Rating ELV only

30V, 2Adc resistive

30V, 1Adc inductive

24V, 1.5Adc inductive bells

Operation Programmable

Default Active on any unisolated zone alarm

Supervision On Bells +, - only

(ref 3.4.2)

Power Supply Outputs

0Vdc

Termination 1 non-demountable screw terminal

4sq mm max cable

2 demountable screw terminals

1.5sq mm max cable

1 2.8mm tab terminal (LED Display)

Battery Backed DC Supply

Rating 27.3Vdc nom.

(24V battery nom)

2Adc, fused.

+VBF1

Termination 1 non-demountable screw terminal

4sq mm max cable

1 demountable screw terminal

1.5sq mm max cable

+VBF2

Termination 1 non-demountable screw terminal

4sq mm max cable

1 demountable screw terminal

1.5sq mm max cable

1 2.8mm tab terminal (LED Display)

Page 3-16 5 July 2001 Issue 2.7

Page 45

Document No: LT0122 F3200 Installation & Programming Manual

System Specifications

MAF/PSU OUTPUTS (CONTINUED)

Non-Battery Backed DC Supply

Rating 28Vdc nom

2Adc, fused

+VNBF

Termination 1 non-demountable screw terminal

4sq mm max cable

1 demountable screw terminal

1.5sq mm max cable

RZDU Comms

Tx, Rx, 0V 3 Wire (+VBF2 also available)

Transmission Rate 1200 Baud

Protocol Vigilant F4000

Termination Demountable screw terminals

1.5sq mm max cable

3.5.4 CONTROLLER/DISPLAY OUTPUTS

Spare Parallel Outputs

Number 6

Type CMOS

Voltage Rating 0-5V

Termination 10 Way FRC pcb header, J10

Serial I/O

Printer/Programmer Port

Form Pseudo RS232

Transient Protection Allows external wiring

(not fitted)

Rx, Tx, 0V signals only

Transmission Rate 9600 Baud

Protocol ASCII Xon, Xoff

Termination 4 Way .156" male molex (J1)

9 Way Miniature D available via transition cable

Part number LM0041

Female Pins (socket)

Issue 2.7 5 July 2001 Page 3-17

Page 46

F3200 Installation & Programming Manual Document No: LT0122

System Specifications

CONTROLLER/DISPLAY (CONTINUED)

Pin 2 3 5 1 4 6 7 8

Tx Rx 0V └──┴──┘ └──┘

25 Way Miniature D available via transition cable Part Number

LM0042

Female Pins (socket)

Pin 2 3 7 6 8 20

Rx Tx 0V └──┴──┘

Alternative Function (on same serial port)

Serial Port 0

Network 1

Network 2

3.5.5 RS485 BOARD

CMOS Modem: 10 Way FRC header

+12V, RXD- TXD-, RTS-, CTS-, 0V, DCD-, +5V

Network: 6 Way demountable screw terminals

RS485 standard signals

A+, A-, B+, B-, 0V ISOL, Earth

3.5.6 NZ DISPLAY EXTENDER BOARD OUTPUTS

10 Way FRC header, J2

UART signals: RXD, TXD, RTS-, CTS-, DCD5V levels; 0V, +5V, +24V also available

10 Way FRC header, J7

(fitted only for network systems)

10 Way FRC header, J9

(fitted only for network systems)

UART signals for Network 1/2

RXD, TXD, RTS-, CTS-, DCD5V levels; 0V, +5V, +24V also available

This is used in New Zealand mode only. Refer to section 12.8 for wiring of the outputs on

the unprotected termination board. The Display Extender Board already has common

Normal, Defect and Fire status LEDs fitted to it, but these may be replicated externally if

necessary. There are also ancillary defect and fire outputs which are active low open

collector, and an output to drive an index lamp.

All Outputs (except LAMP) Open collector pulldown to 0V

Off voltage = 30Vmax

On voltage = 1.1V @ 100mA (max)

On Current = 100mA max

LAMP + Open collector pull up to VBATT

Off voltage = 0V

On voltage = VBATT-1V

On current = 400mA max

LAMP - Connected to Battery –

Page 3-18 5 July 2001 Issue 2.7

Page 47

Document No: LT0122 F3200 Installation & Programming Manual

System Specifications

3.6 CONTROLS

KEYPAD

Type : Polyester Membrane

Keypress : Buzzer gives short "beep" for valid keypress

Number of

Keys : 34 (plus 5 concealed with no function)

FFCIF Keys : ACK; RESET; ISOL; BRIG TEST

Other Keys : Ref F3200 Operator's Manual for description

INTERNAL CONTROLS

Mains On : Switch in cabinet

Database Write Protect

Function : Enables/disables writing to EEPROM

Form : 2 position minijump shunt, Lk7

On Controller/Display PCB

E2 INIT

Function : Initiates self-programming of system configuration on system power

up (i.e. number of modules, etc)

Requires DATABASE WRITE PROTECT to be in WRITE position.

Form : 2 Way .1" male pins on Controller/Display PCB

Short circuit pins to initiate.

BUZZER

Mounted on Controller/Display pcb

Type : Piezo Electric

Frequency : 2800Hz nominal

Sound Level : 70dB min at 1m (outer door closed)

Issue 2.7 5 July 2001 Page 3-19

Page 48

F3200 Installation & Programming Manual Document No: LT0122

System Specifications

3.7 DISPLAYS

Standard Display

Includes : LCD; FFCIF LEDs; System Status LEDs

Panel Size : 19", 4U

FFCIF Type : 3 (common indicators & common controls)

Standard : Complies with AS4050 (int) - 1992

LCD Size : 2 Lines of 40 characters

5.5mm (H) x 3.2mm (W) per character

Site Name : 40 Characters max.

Zone Name : 30 Characters max.

Relay Name : 30 Characters max.

FFCIF LEDs : ALARM (red); ISOLATED (yellow); FAULT (yellow)

System

Status LEDs : MAINS ON (green); CHGR/BATT FAULT (yellow); SYSTEM FAULT

(yellow); ANCILLARY ISOLATED (yellow); BELLS ISOLATED (yellow)

Internal : Mains On (green), Fuse Blown (yellow) on MAF/PSU pcb.

Status

LEDs

Optional Additional Display

Requires 1 x ME0060 plus: 1 x FZ3031 plus 1-3 FP0475 as required.

Note: FZ3031 contains the FRC cable (LM0092) that is

required to connect the Controller Board to the first

Display Board.

ME0060, MECH ASSY, 1901-79, F4000 RAC, EXT INNER DOOR

(19", 7U, mounts up to 4 of 16 Zone LED Display Bd)

FP0475, FP, 16 ZONE LED DISPLAY EXTENDER KIT, 1901-26

Includes : 1 x 16 Zone LED Display Bd; FRC; Power leads; zone name label

(FP0475 has 0.5m FRC, FZ3031 has 1.2m FRC).

Format : 7U Parallel LED display mounts directly below the standard 4U LCD.

The LCD and common LEDs operate as per standard. Zone status is

additionally shown on the zone LEDs.

FFCIF Type : 2 (individual zone indicators and common controls)

Zone LEDs : ALARM (red); FAULT (yellow); ISOLATED (yellow)

Name Space : 10mm x 60mm per zone on paper label.

E.g. 2 lines of 23 characters at 10 per inch.

Page 3-20 5 July 2001 Issue 2.7

Page 49

Document No: LT0122 F3200 Installation & Programming Manual

Ordering Information

CHAPTER 4

ORDERING INFORMATION

Issue 2.7 5 July 2001 Page 4-1

Page 50

F3200 Installation & Programming Manual Document No: LT0122

Ordering Information

4.1 ORDERING INFORMATION

The following lists the part numbers for the range of products and spares associated with the

AS1603.4 approved F3200. It includes a brief description where considered necessary.

FA1227,FAB,1931-24,F3200 BLANK PANEL,PLASTIC,9.5U

FA1235,FAB,1919-27-5,F3200,FLUSH SURROUND (P) (STD CABINET)

FA1298,FAB,1919-27-6,F3200,SMALL FLUSH SURROUND (P)

FA1299,FAB,1919-27-7,F3200,STD + BATT BOX,FLUSH SURROUND (P)

FA1300,FAB,1919-27-8,F3200,SMALL + BATT BOX,FLUSH SURROUND (P)

FP0475,16 ZONE LED DISPLAY EXTENDER KIT,1901-26

(includes Display Bd, 0.5m FRC, power leads and label master. Cannot be used for first

LED Display. See FZ3031)

FP0550,F3200 FIP,NO CARDFRAME,24 ZONE MAX,1931-15

(ref Section 3.1.1)

FP0551,F3200 FIP,C/W CARDFRAME,64 ZONE MAX,1931-16

(ref Section 3.1.1)

FP0553,F3200 8 ZONE INPUT EXPANSION KIT

(ref Section 3.1.2)

FP0554,F3200 8 RELAY EXPANSION KIT

(ref Section 3.1.2)

FP0556,F3200 CABINET,EMPTY,C/W DOOR,WINDOW,LOCK

FP0557,F3200 CABINET,EMPTY,C/W BLANK OUTER DOOR

FP0558,F3200 REMOTE LCD DISPLAY UNIT, FULL CABINET & MAF/PSU

Similar to FP0550, but with RDU Controller and Software, No 8ZM. Previously called RZDU.

Refer to manuals LT0133 and LT0148.

FP0559,F3200 REMOTE LCD,DISPLAY UNIT,SLIMLINE,WALL MOUNT

(small, low profile cabinet with F3200 RDU Controller fitted, no MAF or PSU)

FP0570,FP,1937-3-1,LOCAL GAS CONTROL STATION,AUTO

(wall mounting box with flip cover break glass "Gas Start" switch and double action toggle

"Gas Inhibit" switch, includes buzzer and LEDs)

FP0572,FP,1937-3-2,LOCAL GAS CONTROL STATION,MANUAL

(as per above, but without "Gas Inhibit" switch, LED and buzzer)

FP0576,FP,F3200,BATTERY BOX

FP0577,FP,REMOTE LCD DISPLAY UNIT,4U 19" RAC UNIT

(Includes ME0064 plus I/F PCB, FRC, earth wire, RDU, Operator's Manual, door switch (c/w

bracket and loom) and MCP loom).

FP0583,FP,F3200 FIP,SMALL CABINET

FP0584,FP,F3200,SMALL EMPTY CABINET,FULL WINDOW

FP0585,FP,REMOTE LCD DISPLAY,SMALL CABINET,C/W MAF/PSU

Page 4-2 5 July 2001 Issue 2.7

Page 51

Document No: LT0122 F3200 Installation & Programming Manual

Ordering Information

ORDERING INFORMATION (CONTINUED)

FP0712,FP,F3200 FIP,NO CARDFRAME,24 ZONE MAX,6A PSU

FP0713,FP,F3200,FIP,64 ZONE MAX,6A PSU

FP0714,FP,NETWORK DISPLAY UNIT (NDU),SLIMLINE,WALL MOUNT

FP0715,FP,NETWORK DISPLAY UNIT (NDU),FULL CAB & MAF/PSU

FP0731,FP,RDU TO NDU UPGRADE KIT

FP0733,FP,NETWORK DISPLAY UNIT,4U 19" RACK MTG,NO MAF/PSU

FP0749,FP,F3200 6A PSU UPGRADE KIT,1931-44

Kit to purchase to upgrade on existing panel to a 6A PSU.

FP0772,FP,REMOTE LCD DISPLAY (RDU),SLIMLINE,FLUSH MOUNT

Same as FP0559 except is a flush mounting cabinet.

FP0773,FP,NETWORK DISPLAY UNIT (NDU),SLIMLINE,FLUSH MOUNT

Same as FP0714 except is a flush mounting cabinet.

FP0774,FP,NDU,NETWORK DISPLAY,C/W I-HUB,SLIMLINE,SURFACE

Surface mount NDU, contains I-Hub for networking.

FZ3010,F3200,16 ZONE,STD CAB,NO CARDFRAME,NO LED,1U SHELF

(FP0550 with second 8ZM and 1U document shelf fitted)

FZ3024,F3200,8 ZONE,NO CARDFRAME,NO LEDS,7U BLANK,1U SHELF

(FP0550 with 7U blank hinged door and 1U document shelf fitted)

FZ3027,F3200,64 ZONE,C/W LEDS,1U SHELF

FZ3031,KIT,F3200,16 ZONE LED DISPLAY,LHS POSITION

(as per FP0475, but with 1.2m FRC, allows mtg of Display Bd in furthest left position.

Required for first display).

FZ3034,F3200,8 ZONE,NO CARDFRAME,NO LEDS,6A PSU

FZ3051,F3200,1 ZONE GAS CONTROL,SMALL CABINET

FZ9002,FP,19" RAC,7U BLANK INNER DOOR

FZ9009,KIT,19" RAC,3U AIU BRKT (mounts 2 Melbourne F.B. AIUs)

FZ9010,KIT 19" RAC,1U AIU BRKT (mounts 2 Melbourne F.B. AIUs)

(These include bracket and screws, etc, The 1U item is 1U at the front, but larger at the rear,

as required for F3200 small cabinet).

KT0072,KIT,F3200,CARDFRAME UPGRADE

KT0075,KIT,F3200,PSU UPGRADE,3A TO 6A,1931-44 (Factory fitted option only)

KT0111 KIT,1945-1-1,AS1668 CONTROL MODULE,TYPE 1 (refer PBG0015)

KT0112 KIT,1945-1-2,AS1668 CONTROL MODULE,TYPE 2 (refer PBG0015)

KT0113 KIT,1945-1-3,AS1668 CONTROL MODULE,TYPE 3 (refer PBG0015)

LM0041,LOOM,1888-58,PROG PORT TO 9 PIN SERIAL

(cable to connect printer/computer to Controller, has 9 pin min D)

Issue 2.7 5 July 2001 Page 4-3

Page 52

F3200 Installation & Programming Manual Document No: LT0122

Ordering Information

ORDERING INFORMATION (CONTINUED)

LM0042,LOOM,1888-62,PROG PORT TO 25 PIN SERIAL

(cable to connect printer/computer to Controller, has 25 pin min D)

LM0044,LOOM,1901-81-1,DISPLAY EXTENDER FRC,2M

LM0045,LOOM,1901-81-2,DISPLAY EXTENDER FRC,5M

LM0046,LOOM,1901-81-3,DISPLAY EXTENDER FRC,0.5M

LM0049,LOOM,1901-81-4,DISPLAY EXTENDER FRC,0.25M

LM0053,LOOM,1931-28-1,F3200 20 WAY FRC,300MM

(standard FRC for interconnecting 8 way modules, included in FP0553, 554)

LM0092,LOOM 1901-88 CONTROLLER TO 1ST DISPLAY, FRC, 1.2M

(connects Display Bd to Controller, allows mounting of Display Bd in furthest left position,

included with FZ3031).

LT0119 LITERATURE,1931-17,F3200 OPERATOR'S MANUAL,A4,LOOSE

LT0120 LITERATURE,1931-18,F3200 OPERATOR'S MANUAL,A5

LT0121 LITERATURE,1931-19,F3200 TECHNICAL MANUAL

LT0122 LITERATURE,1931-20,F3200 PROGRAMMING & INSTALLATION MANUAL

LT0130 LITERATURE,1931-32,F3200 PRESENTATION,ACAD12 DISK

LT0133 LITERATURE,1931-46,REMOTE LCD UNIT,OPERATOR MANUAL,A4

LT0135 LITERATURE,1931-52,F3200 ARCHITECTS SPEC,A4

LT0148 LITERATURE,1931-64,RDU INSTALLATION & PROGRAM MANUAL

LT0212 LITERATURE,RDU TO NDU UPGRADE INSTRUCTIONS

ME0060,MECH ASSY,1901-79,RAC CABINET,EXT INNER DOOR

(hinged 7U inner door for mounting Display Bds on, includes screws, perspex window, cage

nuts and pcb standoffs)

ME0063,MECH ASSY,1931-15-1,F3200 4U HINGED CONTROL PANEL

(4U hinged door with keypad and Controller/Display pcb mounted on it).

ME0064,MECH ASSY,1931-15-1,F3200 4U HINGED RDU CONTROL PANEL

(4U hinged door with no-name keypad and RDU Controller/Display mounted on it).

ME0065,MECH ASSY,1931-47,1 ZONE GAS CONTROL 7U DOOR

ME0066,MECH ASSY,1931-47,2 ZONE GAS CONTROL 7U DOOR

ME0067,MECH ASSY,1931-47,3 ZONE GAS CONTROL 7U DOOR

ME0068,MECH ASSY,1931-47,4 ZONE GAS CONTROL 7U DOOR

(ME0065-68 include screened 7U door, field connector and looms for connecting to 8RMS

and 8ZMs, screws and cage nuts - for 1,2,3 or 4 gas zones)

Page 4-4 5 July 2001 Issue 2.7

Page 53

Document No: LT0122 F3200 Installation & Programming Manual

Ordering Information

ORDERING INFORMATION (CONTINUED)

ME0069,MECH ASSY,1931-57,1 ZONE, 1U GAS CONTROL PANEL

(similar to ME0065 except on a non-hinged, 1U panel)

ME0072,MECH ASSY,1931-70,F3200 RACK MTG GEARPLATE

(allows F3200 internals to be fitted to a RAC cabinet. Factory fit option only. See Note 1)

ME0155,MECH ASSY,694-384,19" 4U CFA ASSEMBLY

ME0250,MECH ASSY,1919-35,RAC CABINET,IP65,20U X 200 (ie. waterproof)

ME0258,MECH ASSY,1919-21-2,RAC CABINET,1U SHELF,135 DEEP

(includes screws and cage nuts for mounting to FIP)

PA0443,PCB ASSY,1841-18,CONTACT CONVERSION MODULE

PA0491,PCB ASSY,1931-3,F3200 MAF/PSU

PA0492,PCB ASSY,1931-4,F3200 8 ZONE MODULE (See FP0553)

PA0493,PCB ASSY,1931-5,F3200 RZDU CONTROLLER/DISPLAY (See FP0554)

PA0703,PCB ASSY,1931-27,F3200 REMOTE I/F BD

PA0707,PCB ASSY,1931-39,F3200 3A RECTIFIER BD

PA0773,PCB ASSY,1901-139-3,RS485 COMMS BD,CMOS;FRC ONLY

PA0797,PCB ASSY,1931-84-1,F3200 CONTROLLER/DISPLAY

PA0798,PCB ASSY,1931-84-2,F3200 RDU CONTROLLER/DISPLAY

PA0804,PCB ASSY,1931-84-1,F3200 CTRL NETWORK/NDU,NO S/W

RR0509,RESISTOR,WIRE WOUND,10W,68 OHM

SF0089,SOFTWARE,F3200 FIRE CONTROLLER,V1.10 EPROM

SF0094,SOFTWARE,REMOTE LCD DISPLAY,RDU,V1.35 EPROM

SF0164,SOFTWARE,F3200 FIRE CONTROLLER NETWORKED,V2.04,EPROM

SF0175,SOFTWARE,NETWORK DISPLAY UNIT (NDU),V2.04,EPROM

SF0178,SOFTWARE,F3200 FIRE CONTROLLER,V2.04,EPROM

SF0179,SOFTWARE,REMOTE LCD DISPLAY,RDU,V2.02 EPROM

SF0229,SOFTWARE,F3200,STD PANEL,C/W TANDEM,V2.09 EPROM

SF0230,SOFTWARE,F3200,NETWORKED,C/W TANDEM,V2.09,EPROM

SF0231,SOFTWARE,NDU,C/W TANDEM,V2.09,EPROM

Issue 2.7 5 July 2001 Page 4-5

Page 54

F3200 Installation & Programming Manual Document No: LT0122

Ordering Information

ORDERING INFORMATION (CONTINUED)

NEW ZEALAND OPERATION ONLY

A variety of display options are available to satisfy varying NZ requirements. These are

covered in detail in Section 12.8. Ordering codes are included for the various components

for each option. Major items are as follows:

PA0499 PCB ASSY, NZ DISPLAY EXTENDER BOARD

NZ Display Extender Board in standard 16 Zone LED board format.

PA0742 PCB ASSY, PFD NZ DISPLAY EXTENDER BOARD, 24V

NZ Display Extender Board in format suitable for “picture frame” cabinet.

PA0741 PCB ASSY, PFD 16 ALARM LED DISPLAY, 24V

“Picture Frame” format 16 Zone display board (alarm LEDs only).

PA0754 PCB ASSY, PFD 16 ZONE FULL STATUS, 24V

“Picture Frame” format 16 Zone display board (all LEDs fitted).

PA0753 PCB ASSY, PICTURE FRAME DISPLAY, 16 LED MIMIC, 24V

“Picture Frame” cabinet format board for mimicking 16 Fire LEDs from Display

board.

PA0760 PCB ASSY, NZ DISPLAY EXTENDER, PFD MIMIC

“Picture Frame” cabinet format board for mimicking 3 LEDs from Display

Extender Board.

PA0483 PCB, UNPROTECTED TERMINATION BOARD

With a 26 way FRC gives access Display Extender Board inputs and outputs.

PA0772 PCB ASSEMBLY, PFD TERMINATION BOARD

Breaks 26-way display FRC out to multicore cable (12 way).

PA0769 PCB, UNPROTECTED TERMINATION BOARD, C/W RESISTORS

Versions of PA0483 with 3k3 resistor per output for LED current limit.

ME0074 PICTURE FRAME DISPLAY, F/S NZ LOCK, C/W INDEX

Wall mounting “Picture frame” display cabinet.

ME0076 PICTURE FRAME DISPLAY, R/S NZ LOCK, C/W INDEX