Page 1

Worldwide

Contacts

www.tyco-fire.com

Model ESFR-25

Early Suppression, Fast Response Pendent Sprinklers

25.2 K-factor

General

Description

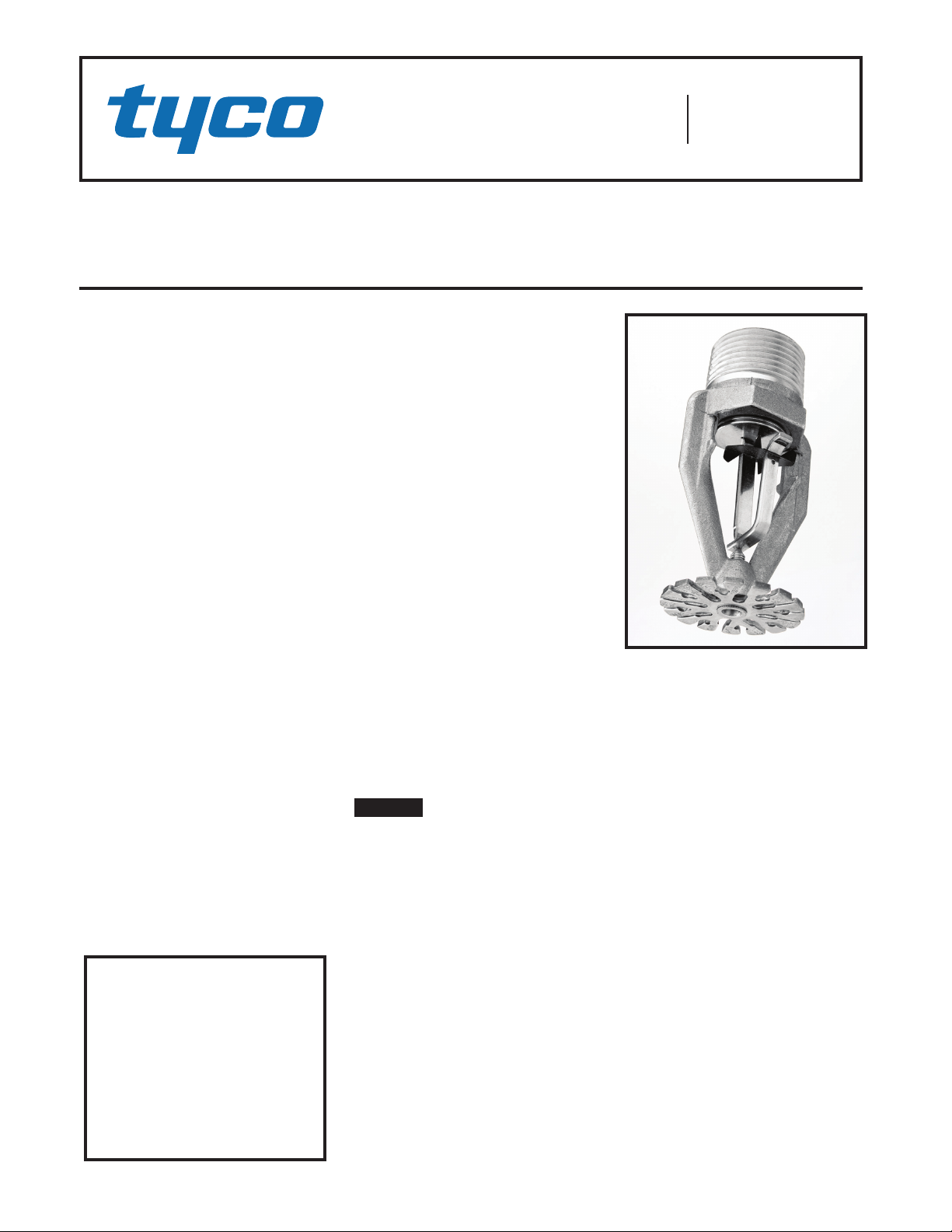

The TYCO Model ESFR-25 Pendent

Sprinklers are Early Suppression, Fast

Response Sprinklers” having a nominal K-factor of 25.2. (Refer to Figure

1.) They are suppression-mode sprinklers that are especially advantageous

as a means of eliminating the use of

in-rack sprinklers when protecting

high-piled storage.

The Model ESFR-25 Sprinklers are

primarily used for ceiling-only sprinkler protection of (but not limited to)

the following storage applications:

• Most encapsulated or non-encapsulated common materials including

cartoned, unexpanded plastics.

• Uncartoned (exposed) expanded

plastics in accordance with NFPA

13 and FM Global standards.

• Some storage arrangements of

rubber tires, roll paper, ammable

liquids, aerosols, and automotive

components.

For more specic criteria, refer to

Table 1 as well as the applicable design standard.

The Model ESFR-25 Pendent

Sprinklers provide the system

designer with hydraulic and sprinkler

placement options not presently

available to the traditional ESFR

sprinklers having nominal K-factors of

14.0 and 16.8. In particular, the Model

ESFR-25 Sprinkler has been designed

to operate at substantially lowerend head pressures, as compared

IMPORTANT

Always refer to Technical Data

Sheet TFP700 for the “INSTALLER

WARNING” that provides cautions with respect to handling

and installation of sprinkler systems and components. Improper handling and installation can

permanently damage a sprinkler system or its components

and cause the sprinkler to fail

to operate in a fire situation or cause

it to operate prematurely.

to ESFR Sprinklers having nominal

K-factors of 14.0 and 16.8. This feature

offers exibility when sizing system

piping, as well as possibly reducing or

eliminating the need for a system re

pump.

Also, Model ESFR-25 Sprinklers permit use of a maximum deector-toceiling distance of 18 inches (460 mm)

versus 14 inches (356 mm). Additionally, a storage arrangement of 40 ft.

(12,2 m) with a ceiling height of 45 ft.

(13,7 m) does not require in-rack sprinklers as do other ESFR Sprinklers having nominal K-factors of 14.0 and 16.8.

The Model ESFR-25 Sprinklers are

listed by Underwriters Laboratories

(UL) for specic applications with a

maximum storage height of 43 ft. (13,1

m) with a maximum ceiling height of

48 ft. (14,6 m) without the requirement

for in-rack sprinklers. Refer to the

Specic Application Listing (UL) for

the design criteria.

Applications for the TYCO ESFR

Sprinklers are expanding beyond currently recognized installation standards. For information on research re

tests (e.g., with ammable liquids and

aerosols) that may be acceptable to an

authority having jurisdiction, contact

the Technical Services department.

NOTICE

The Model ESFR-25 Sprinklers described

herein must be installed and maintained

in compliance with this document, as

well as with the applicable standards of

the National Fire Protection Association,

in addition to the standards of any

authorities having jurisdiction (e.g., FM

Global). Failure to do so may impair the

performance of these devices.

The owner is responsible for maintaining

their fire protection system and devices in

proper operating condition. The installing

contractor or sprinkler manufacturer

should be contacted with any questions.

In all cases, the appropriate NFPA or FM

installation standard, or other applicable

standard, must be referenced to ensure

applicability and to obtain complete

installation guidelines. The general

guidelines in this data sheet are not

intended to provide complete installation

criteria.

Sprinkler

Identification

Number (SIN)

TY9226

TY9226 is a re-designation for C9226,

G8441, and S8010.

Technical

Data

Approvals

UL and C-UL Listed

FM and VdS Approved

LPCB Approved (094b/01 and 07l/01)

NYC under MEA 356-01-E

CE Certied Certicate of Conformity

1725-CPD-H0010

Maximum Working Pressure

175 psi (12,1 bar)

Pipe Thread Connections

1 inch NPT

ISO 7-R1

Discharge Coefficient

K = 25.2 GPM/psi

(362,9 LPM/bar

1/2

1/2

)

Page 1 of 4 NOVEMBER 2012 TFP312

Page 2

TFP312

Page 2 of 4

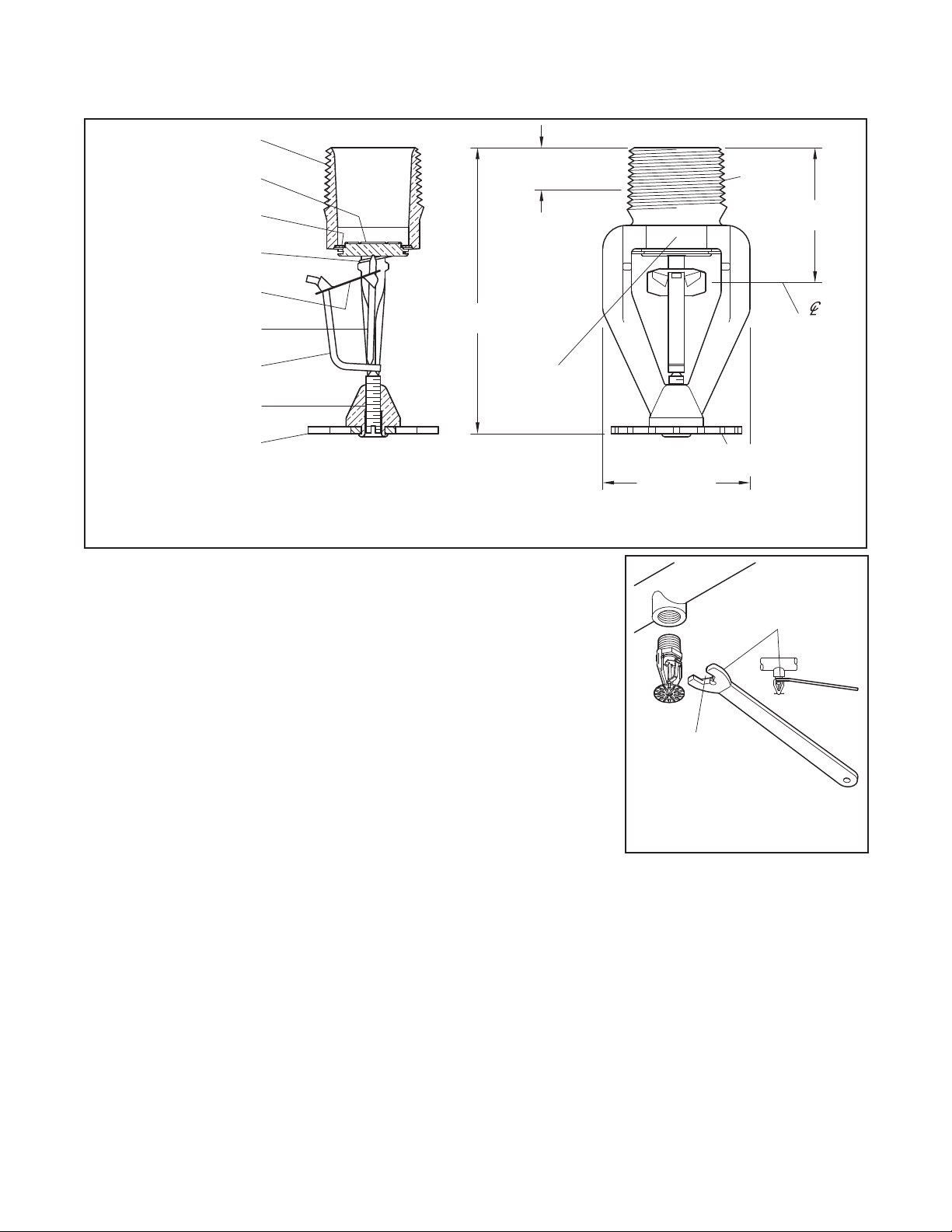

1

7

Components:

-

1

Frame

-

2

Deector

-

3

Compression

Screw

-

Hook4

-

5

Strut

-

6

Link Assembly

-

7

Button

-

8

Sealing

Assembly

-

9

Ejection Spring

8

9

6

5

4

3

2

MODEL ESFR-25, EARLY SUPPRESSION, FAST RESPONSE

Temperature Ratings

165°F (74°C)

214°F (101°C)

Finish

Natural Brass

Physical Characteristics

Frame . . . . . . . . . . . . . . . . . . . . . . . . Brass

Deector. . . . . . . . . . . . . . . . . . . . . Bronze

Compression Screw. . . . . . Stainless Steel

Hook.........................Monel

Strut .........................Monel

Link Assembly . . . . . . . . . . .Solder, Nickel

Button. . . . . . . . . . . . . . . . . . . . . . . . Brass

Sealing Assembly. . . . . . . Beryllium Nickel

Ejection Spring. . . . . . . . . . . . . . . . Inconel

with TEFLON

Design

Criteria

The following general guidelines provided for the TYCO Model ESFR-25

Pendent Sprinklers can be used for a

quick reference.

The National Fire Protection Association (NFPA) and FM Global (FM) provide installation standards that must

be used to properly design an automatic sprinkler system utilizing Early

Suppression, Fast Response (ESFR)

Sprinklers. The guidelines provided

by NFPA and FM may differ. Consequently, the appropriate standard

must be used for a given installation.

In all cases, the appropriate NFPA or

FM installation standard must be referenced to ensure applicability and

9/16"

(14,3 mm)

NOMINAL

MAKE-IN

3-13/16"

(96,8 mm)

WRENCH

FLATS

FIGURE 1

PENDENT SPRINKLER 25.2 K-FACTOR

to obtain complete installation guidelines. The following general guidelines

are not intended to provide complete

installation criteria.

In addition to this data sheet, the following data sheets describe other

TYCO ESFR Sprinklers:

• TFP315 — Model ESFR-17

(TY7226), K=16.8 Pendent Sprinkler

• TFP316 — Model ESFR-17

(TY7126), K=16.8 Upright Sprinkler

• TFP318 — Model ESFR-1

(TY6226), K=14.0 Pendent Sprinkler

Sys t e m Type

Wet pipe system

Roof Construction

Unobstructed or obstructed construction; for example, smooth ceiling,

bar joists, beam and girder, and so

forth. Where the depths of the solid

structural members (e.g., beams and

stem) exceed 12 inches (302 mm), install ESFR Sprinklers in each channel

formed by the structural members.

Ceiling Slope

Maximum 2 inch rise for 12 inch run

(16.7%)

Maximum Coverage Area

100 ft2 (9,3 m2). In some cases, the

installation standards permit a greater

coverage area.

Minimum Coverage Area

64 ft2 (5,8 m2) per NFPA 13/FM 2-0

Maximum Spacing

12 feet (3,7 m) for building heights up

to 30 feet (9,1 m)

1" NPT

1-13/16"

(46,0 mm)

THERMAL

SENSING

ELEMENT

TEMPERATURE

RATING

2" (50,8 mm)

"FITTING SIDE"

TOWARDS SPRINKLER

FITTING

WRENCH

RECESS

FIGURE 2

W-TYPE 1

SPRINKLER WRENCH

10 feet (3,1 m) for building heights

greater than 30 feet (9,1 m). In some

cases, installation standards permit a

greater spacing.

Minimum Spacing

8 feet (2,4 m)

Minimum Clearance to Commodity

36 inches (914 mm)

NFPA 13 Deflector-to-Ceiling

Distance

6 to 18 inches (152 to 457 mm)

FM 2-0

Consult FM and/or FM Guidelines for

allowable deector-to-ceiling distances as well as thermal sensing elementto-ceiling criteria.

Page 3

TFP312

Page 3 of 4

Storage Type NFPA FM

Open Frame (that is, no solid shelves)

Single, Double, Multiple-Row, or Portable Rack Storage

of Class I-IV and Group A or B Plastics

Solid Pile or Palletized Storage of Class I-IV

and Group A or B Plastics

Idle Pallet Storage Refer to NFPA 13, Chapter 12. Refer to FM 2-0, 8-9, and 8-24.

Rubber Tire Storage Refer to NFPA 13, Chapter 18. Refer to FM 2-0 and 8-9.

Rolled Paper Storage (Refer to the standard.) Refer to NFPA 13, Chapter 19. Refer to FM 8-21.

Flammable Liquid Storage (Refer to the standard.) Refer to NFPA 30. N/A

Aerosol Storage (Refer to the standard.) Refer to NFPA 30B. Refer to FM 7-31.

Refer to NFPA 13, Chapters 16 and 17. Refer to FM 2-0 and 8-9.

Refer to NFPA 13, Chapters 14 and 15. Refer to FM 2-0 and 8-9.

Automotive Components in Portable Racks

(Control mode only; refer to the standard.)

N/A = Non-Applicable

COMMODITY SELECTION AND DESIGN CRITERIA OVERVIEW FOR

Specific

Application

Listing (UL)

The TYCO Model ESFR-25 Pendent

Sprinklers are listed by Underwriters

Laboratories for Specic Applications

with a ceiling height greater than 45

ft. (13,7 m) up to and including 48 ft.

(14,6 m), and a storage arrangement

up to and including 43 ft. (13,1 m), the

following guideline are provided for

the TYCO Model ESFR-25 Pendent

Sprinklers:

Sprinkler Position

Pendent, frame arms aligned with

pipe, deectors parallel with ceiling or

roof.

Sys t e m Type

Wet Pipe System only.

Maximum Area of Coverage

100 ft2 (9,3 m2). In some cases, the

installation standards permit a greater

coverage area.

Minimum Area of Coverage

64 ft2 (5,8 m2) according to NFPA 13.

Maximum Slope Ceiling

2 inch rise for 12 inch run (16.7%)

Refer to NFPA 13, Chapter 20. N/A

TABLE 1

MODEL ESFR-25 PENDENT SPRINKLERS

Maximum Spacing

10 ft. (3,1 m). In some cases, the installation standards permit a greater

spacing.

Minimum Spacing

8 ft. (2,4 m)

Temperature Rating

214°F (101°C)

Deflector Distance from Walls

Minimum of 4 inches (102 mm) from

walls but no more than 1/2 the allowable distance permitted between

sprinklers.

Deflector to Top of Storage

Minimum of 36 inches (914 mm).

Deflector to Ceiling Distance

6 to 14 inches (152 to 356 mm).

Maximum Ceiling Height

48 ft. (14,6 m)

Maximum Storage Height

43 ft. (13,1 m)

Storage Arrangement

Palletized, solid piled, open frame;

single row, double row, or multiple row

and portable rack arrangement.

Commodity

Class I-IV

Cartoned, unexpanded plastic

Sprinkler System Design

NFPA 13 for ESFR Sprinklers based

upon 45 psi (3,1 bar) design pressure

169 gpm (640 L/m) with 12 sprinkler

remote area.

Minimum Aisle Width

8 ft (2,4 m)

Operation

The fusible link assembly is comprised

of two link halves that are joined together by a thin layer of solder. When

the rated temperature is reached, the

solder melts and the two link halves

separate, activating the sprinkler and

owing water.

Page 4

TFP312

Page 4 of 4

Installation

The TYCO Model ESFR-25 Pendent

Sprinklers must be installed in accordance with this section.

General Instructions

Damage to the fusible Link Assembly

during installation can be avoided by

handling the sprinkler by the frame

arms only (that is, do not apply pressure to the fusible Link Assembly),

and by using the appropriate sprinkler

wrench. Failure to do so can lead to an

unstable link assembly and premature

activation of the sprinkler. Damaged

sprinklers must be replaced.

A leak-tight 1 inch NPT sprinkler joint

should be obtained by applying a minimum-to-maximum torque of 20 to 30

ft./lbs. (26,8 to 40,2 Nm). Higher levels

of torque can distort the sprinkler inlet

with consequent leakage or impairment of the sprinkler.

Step 1. Install the Model ESFR-25

Pendent Sprinkler in the pendent position (Figure 2).

Step 2. With pipe-thread sealant applied, hand-tighten the sprinkler into

the sprinkler tting. Do not apply pressure to the Link Assembly, and handle

the Model ESFR-25 Pendent Sprinkler

only by the Frame arms.

Step 3. Wrench-tighten the Model

ESFR-25 Pendent Sprinkler using only

the W-Type 1 Sprinkler Wrench (Figure

2) and by fully engaging (seating) the

wrench on the sprinkler wrench ats

(Figure 1).

Step 4. After installation, inspect the

Link Assembly of each Model ESFR25 Pendent Sprinkler for damage. In

particular, verify that the Link Assembly and Hook are positioned as illustrated in Figure 1, and that the Link

Assembly is not bent, creased, or

forced out of normal position in any

way. Replace damaged sprinklers.

Care and

Maintenance

The TYCO Model ESFR-25 Pendent

Sprinklers must be maintained and

serviced in accordance with this

section.

Before closing a re protection system

main control valve for maintenance

work on the re protection system that

it controls, permission to shut down

the affected re protection system

must be obtained from the proper authorities and notify all personnel who

may be affected by this action.

Sprinklers which are found to be leaking or exhibiting visible signs of corrosion must be replaced.

Automatic sprinklers must never be

painted, plated, coated, or otherwise altered after leaving the factory.

Modied sprinklers must be replaced.

Sprinklers that have been exposed to

corrosive products of combustion, but

have not operated, should be replaced

if they cannot be completely cleaned

by wiping the sprinkler with a cloth or

by brushing it with a soft bristle brush.

Care must be exercised to avoid damage to the sprinklers - before, during,

and after installation. Sprinklers damaged by dropping, striking, wrench

twist/slippage, or the like, must be

replaced. Also, replace any sprinkler

that has a cracked bulb or that has

lost liquid from its bulb. (Ref. Installation Section.)

The owner is responsible for the inspection, testing, and maintenance of

their re protection system and devices in compliance with this document,

as well as with the applicable standards of the National Fire Protection

Association (e.g., NFPA 25), in addition to the standards of any authorities

having jurisdiction. Contact the installing contractor or sprinkler manufacturer regarding any questions.

Automatic sprinkler systems are

recommended to be inspected,

tested, and maintained by a qualied

Inspection Service in accordance with

local requirements and/or national

codes.

Ordering

Procedure

Contact your local distributor for availability. When placing an order, indicate the full product name and Part

Number (P/N).

Sprinkler Assemblies

Specify: Model ESFR-25 (TY9226),

K=25.2, Early Suppression, Fast Response Pendent Sprinkler with (specify) temperature rating, natural brass,

P/N (spec ify).

165°F (74°C) ...............P/N 5 8-4 41-1 -165

214°F (101°C) ..............P/N 58 -441-1-214

Special-Order Sprinkler

Assemblies with ISO 7/1 Thread

Connections

Specify: Model ESFR-25 (TY9226),

K=25.2, Early Suppression, Fast Response Pendent Sprinkler with ISO

7/1 thread connection, (specify) temperature rating, natural brass, P/N

(specify).

165°F (74°C) .............. P/N 58 - 442-1-16 5

214°F (101°C) ............. P/N 58-442-1-214

Sprinkler Wrench

Specify: W-Type 1 Sprinkler Wrench,

P/N 56-87 2-1- 0 25.

GLOBAL HEADQUARTERS | 1400 Pennbrook Parkway, Lansdale, PA 19446 | Telephone +1-215-362-0700

Copyright © 2012 Tyco Fire Products, LP. All rights reserved.

TEFLON is trademark of The DuPont Corporation.

Loading...

Loading...